#Advanced CNC programming

Explore tagged Tumblr posts

Text

Are you ready to dive into the world of CNC Programming & Operations? As industries across India increasingly rely on CNC machines for productivity and precision, this course offers an exciting opportunity to become a skilled professional in this dynamic field. From the automotive sector to precision component manufacturing and aerospace industries, CNC machines play a pivotal role, driving the demand for proficient CNC programming and operation experts.

0 notes

Text

femme4femme, girls who stink good, hairy pits, body worship, chest fondling, in public, being watched, embarrassment, soft cnc, consensual, just two shy women smelling each other in the middle of a store, alternate timeline universe for aesthetic and nostalgic reasons, pwp... pits. 🩷

time travel to a busy mall where an event is taking place in the main area downstairs, leaving the rest of the building relatively uncrowded. the familiar sound of the escalator as the ascent to the next floor further drowns out the noise of excitement elsewhere. an exploration to find some meaning in another place, so far and yet so close to home. the calming music lulling me into a shop that nearly appears empty...

a kind woman, young and older than she seems, looks up from her magazine. eyes sparkling over like a reflection of some ethereal being had caught her attention. she fixes her posture and carefully stows away the glimpse of visible nerves, quickly replaced by a warm smile and inviting voice...

"can i help you with anything? there's a decent sale going on if you're interested in a new parfum... maybe you'd like to try our skincare? i just graduated last week from the local beauty salon's program. not that it's a big deal - i guess, i'm still celebrating my success there. it's an advanced level program, so if you were interested in a makeover, it wouldn't be some rookie, amateur experiment... not that you need a makeover or anything, it's just nice to try a change of scenery from time to time."

i take in the view of the shop as she speaks... the glistening metal accents and glass cases, home to beautiful bottles and palettes of all kinds, like a labyrinth of promises and unnecessary remedies. maybe a new scent would be nice... i decide to make my way over to her and have a seat in the provided chair. she begins by selecting a few options and test strips to spray the parfum on.

"try this one first, and we'll see where that leads us, okay?" ... i find the scent too generic, not quite to my liking. we talk about some of the notes in the scent profile, and she selects another option for me. "how about... this one? it fits the description without being overly saturated, but not too subtle, either."

something about it evokes a sense of nostalgia i thought i'd never feel again... an optimistic, sort of resolute, kind of hope in a new future... i close my eyes and share my thoughts aloud, describing the feeling as best i can. she tinkers around with the bottles and assures me the third choice ought to be exactly what i was searching for. my nose instinctively leans into the scent, and suddenly, i feel a totally new sensation wash over my entire body...

with my eyes still closed, i feel the hair on me rise up in little goosebumps, then a dull aching settles in the lowest pit of my tummy - just between my legs, actually. as she was reaching over the counter, the scent of her body and underarms had enveloped and enticed me as though i'd become enchanted... i ask how she knew, unaware of the quiet groan escaping my lips. i tell her how good she is, how smart and amazing she is... for finding such a wonderful parfum!

i lean forward, slightly, and unintentionally make contact with the unusually quiet woman in front of me. opening my eyes, the lush haze blurring my vision begins to refocus, and soon i become embarrassingly aware of what smell had captured me so ardently. her natural, musky, furry underarms... centered in front of my face. i move back, awkwardly silent, and begin to collect myself and my belongings...

i turn in the chair and begin to leave when her hand crosses over me, holding onto the arm rest. she looks worried, or maybe afraid...? "wait, please, don't go... i - i underst- it's ok, look!" she quickly kneels down, gently grabs my arm to hold at an angle, and presses her face into my own hairy pit. "see...!? there's nothing to be ashamed of..." she holds my astonished gaze with the utmost sincerity before her eyes drift half-closed with pleasure.

and then she glances at what's now in front of her face and reaches with her free hand to move my flimsy low cut top over and caress my exposed tit while still holding my other arm up and sniffing my pit like smelling deep and then doing the same on the other side so my chest is totally exposed and she's straddling me and some other woman is not hiding well behind a rack of clothes while she watches us and jerks off as quietly as she can (very obvious) 💕😳

#femme nsft#sapphic nsft#mtf nsft#transfem nsft#older women <3#musk k!nk#scent kink#smell kink#girl who stinks good#hypnok1nk#hypnotized#bd/sm mommy#domme mommy#dom bottom#sub top

12 notes

·

View notes

Text

CNC Press Brake Machine in India: Shaping the Future of Metal Bending

In the dynamic world of metal fabrication, CNC Press Brake Machines have become indispensable. These machines are critical in industries that demand precision bending and forming of sheet metal components. In India, the rising focus on infrastructure development, automotive manufacturing, and localized production has driven the adoption of CNC press brake technology across various sectors.

From small workshops to large-scale factories, CNC press brakes are revolutionizing how Indian manufacturers handle metal forming—efficiently, accurately, and consistently.

What is a CNC Press Brake Machine?

A CNC (Computer Numerical Control) Press Brake Machine is used to bend and shape metal sheets with precision. It uses a punch and die to perform various bends, guided by a CNC system that ensures exact specifications for angle, length, and repetition.

Modern CNC press brakes are far more advanced than traditional mechanical or hydraulic versions. They come with programmable controls, automated back gauges, and advanced sensors to deliver high-speed and high-precision bending.

Why CNC Press Brakes are Gaining Popularity in India

1. Precision and Consistency

In sectors like automotive, aerospace, and electronics, even minor deviations in part dimensions can lead to quality issues. CNC press brakes eliminate human error and ensure consistent output across batches.

2. Growing Industrialization

India’s expanding industrial base, especially in Tier 2 and Tier 3 cities, is fueling demand for reliable fabrication equipment. CNC press brakes allow businesses to scale up production without compromising on accuracy.

3. Labour Efficiency

With a skilled labor shortage and rising wages, automation is becoming more attractive. CNC press brakes require minimal human intervention, reducing labor costs and dependency on manual operators.

4. Government Incentives

Government initiatives like Make in India and Production Linked Incentive (PLI) Schemes are encouraging manufacturers to invest in advanced machinery, including CNC press brakes, for higher productivity.

Key Features of CNC Press Brake Machines in the Indian Market

High-Tonnage Capability: Machines ranging from 30 to 1000+ tons to suit various applications.

CNC Control Systems: Brands like Delem, ESA, and Cybelec offer intuitive interfaces for programming and automation.

Servo-Electric or Hydraulic Drive Systems: Depending on precision, energy efficiency, and speed requirements.

Multi-Axis Back Gauge: Enables complex bends and reduces setup time.

Automatic Tool Changers (ATC): For higher production environments.

Leading Indian and International Brands

India has a strong presence of both domestic and international CNC press brake manufacturers. Some notable names include:

Hindustan Hydraulics

Electropneumatics

Energy Mission

LVD India

Amada (Japan)

Durma (Turkey)

Yawei (China)

These companies offer machines tailored to the needs and budget of Indian manufacturers.

Applications in India

Automobile Body & Chassis Manufacturing

Kitchen Equipment Fabrication

Electrical Enclosures & Cabinets

Elevator and Escalator Components

Construction and Infrastructure Products

Railways and Defence Equipment

Challenges for Indian Buyers

High Initial Investment: CNC press brakes can be capital intensive, though the ROI is excellent over time.

Skill Development: Operators need training to use CNC systems effectively.

After-Sales Service: Choosing a vendor with reliable local support is crucial for maintenance and uptime.

The Road Ahead: Smart Factories & Industry 4.0

India is steadily moving towards smart manufacturing. CNC press brakes are now integrating with IoT, ERP systems, and robotic automation, enabling real-time monitoring, predictive maintenance, and remote troubleshooting. This evolution is making Indian factories more agile and globally competitive.

Conclusion

The CNC Press Brake Machine is no longer a luxury—it's a necessity in modern Indian manufacturing. With its unmatched accuracy, efficiency, and automation capabilities, it empowers businesses to meet rising customer expectations while optimizing operational costs.

As India continues to climb the global manufacturing ladder, CNC press brake machines will play a pivotal role in shaping the future—quite literally.

2 notes

·

View notes

Text

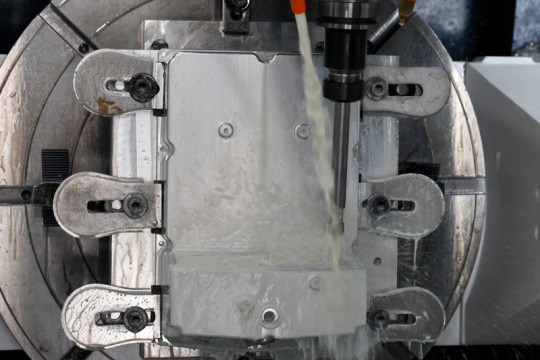

Summary Analysis of CNC Milling Process

In modern manufacturing, CNC milling technology is widely used for its high precision and flexibility. Whether it's a mechanical part, an automotive component, or a component for a medical device, CNC milling provides excellent machining results.

What is CNC Milling?

CNC milling is a computer-controlled machining process that utilises a rotating tool to cut a workpiece. CNC milling allows for greater accuracy and consistency than traditional manual milling. It is often combined with other machining methods (e.g. turning, drilling) to meet different and diverse manufacturing needs.

Workflow of CNC Milling

Design stage In the initial stages of CNC milling, designers use Computer-Aided Design (CAD) software to create a model of the product. Commonly used software includes SolidWorks and Autodesk, which are tools that help designers accurately draw the shape and dimensions of the desired part.

Programming stage Once the design is complete, the CAD file needs to be converted to G-code, a language that CNC machines can understand. With Computer-Aided Manufacturing (CAM) software, the design files are converted into machine-executable instructions that enable automated machining.

Machine setting During the machine set-up phase, the workpiece needs to be fixed to the table and a suitable tool selected. At the same time, the operator needs to set the initial co-ordinates to ensure accurate positioning during machining.

Advantages of CNC Milling

High precision and dimensional stability CNC milling allows for micron-level machining accuracy, ensuring consistency from part to part.

Complex shapes can be processed Whether it's a simple flat surface or a complex three-dimensional structure, CNC milling can handle it with ease.

Efficient production capacity Due to its high degree of automation, CNC milling can significantly increase productivity and shorten lead times.

Applications of CNC Milling

CNC milling technology is used in a wide range of industries, including:

Mechanical parts: Used in the manufacture of key components in a variety of mechanical equipment.

Automotive parts: High-precision parts for the automotive industry, such as engine components.

Medical device parts: Ensure the reliability and safety of medical devices.

Optical product parts: For the production of optical instruments and related products.

Frequently Asked Questions

What materials can be CNC milling machined? CNC milling is suitable for a wide range of materials, including metals (e.g. aluminium, steel), plastics, wood, and more. However, for some materials, such as ceramics or certain composites, the machining is more difficult and requires special handling.

What are the limitations of CNC milling? Despite its advanced technology, CNC milling has some limitations. For example, machining may be limited for internal vertical angles or very complex small structures.In addition, high hardness materials may lead to faster tool wear, which can affect productivity.

Comparison of CNC milling with other manufacturing technologies The advantages and disadvantages of each can be seen when comparing CNC milling with other manufacturing techniques such as 3D printing. CNC milling is generally superior to 3D printing in terms of accuracy and surface finish, but 3D printing has advantages in rapid prototyping and complex geometries. In terms of cost-effectiveness, the choice of technology depends on specific project needs and budget.

Summary

In summary, CNC milling is an indispensable manufacturing technology that plays an important role in several industries with its efficiency, precision and flexibility.

#prototyping#prototype#rapid prototyping#prototype machining#precision machining#cnc machining#cnc milling#machining parts#cnc milling 5 axis#cnc milling machining#cnc milling turning#precision cnc milling#cnc milling parts

2 notes

·

View notes

Text

Rotary CNC Router Machine

At GK Laser Enterprises, we pride ourselves on delivering cutting-edge solutions to meet the evolving needs of the manufacturing and fabrication industries. One such innovation that has gained popularity for its versatility and precision is the Rotary CNC Router Machine. As a leader in CNC technologies, we offer a range of advanced CNC machines, and today we dive deep into how a rotary CNC router machine can revolutionize your operations.

What is a Rotary CNC Router Machine? A Rotary CNC Router Machine is a computer-controlled cutting machine that uses rotary tools to carve, cut, or engrave materials in three dimensions. The term “rotary” refers to its ability to rotate the material around an axis while it works, providing access to all sides of the material. This capability enables intricate detailing, sculpting, and shaping of cylindrical or irregularly shaped materials.

Unlike traditional CNC routers that work on flat surfaces, rotary CNC routers can handle 3D shapes, making them ideal for creating complex, multi-faceted designs.

How Does a Rotary CNC Router Machine Work? The Rotary CNC Router works by rotating the material, typically using a rotary axis attachment, while the cutting tool precisely follows the programmed paths. Here’s a breakdown of the process:

Material Preparation: A workpiece, such as wood, metal, or plastic, is mounted on the rotary axis, which allows it to rotate. Programming: A computer-aided design (CAD) program creates a digital blueprint of the desired outcome. This is then converted into machine-readable code using computer-aided manufacturing (CAM) software. Cutting Process: The router uses its rotary axis to rotate the material while the cutting tool moves along the X, Y, and Z axes to carve, cut, or engrave the material into the desired shape. Finishing: Once the operation is complete, the workpiece is inspected and may require minimal finishing, thanks to the machine’s precision.

Key Features of a Rotary CNC Router Machine High Precision and Accuracy: Rotary CNC routers are known for their precision in handling complex designs, offering high accuracy even in detailed cuts and engravings. Versatility: Whether you’re working with wood, metal, plastic, or composites, the rotary CNC router can handle a wide range of materials. This versatility makes it invaluable for industries such as furniture design, sculpture, and sign-making. 3D Carving and Engraving: With the ability to rotate the material, rotary CNC routers are ideal for creating 3D objects like sculptures, chair legs, moldings, and even complex cylindrical designs. Automation and Efficiency: The CNC aspect automates the cutting process, ensuring uniformity in production and reducing the need for manual labor. This enhances efficiency and speeds up production time.

Why Choose a Rotary CNC Router Machine for Your Business? If your business requires precision, complexity, and scalability, a rotary CNC router is a wise investment. At GK Laser Enterprises, we emphasize the value it can bring to industries like:

Furniture Manufacturing: Intricate 3D carvings and details for chair legs, columns, and sculptures can be easily achieved using rotary CNC routers. Sign Making and Woodworking: From large signs to ornate wood designs, rotary CNC routers deliver exceptional precision that elevates your craftsmanship. Sculpture and Artwork Creation: Artists and designers benefit from the ability to craft complex shapes and details, providing unmatched creativity. Metal and Plastic Fabrication: Industrial manufacturers who work with metals and plastics can create custom parts, components, and molds with great precision.

Benefits of Using a Rotary CNC Router Machine Enhanced Productivity: With automated processes, your business can take on more projects with faster turnaround times, maximizing profitability. Cost Efficiency: Despite the upfront investment, the long-term savings on labor, material waste, and improved product quality make it a highly cost-effective solution. Precision and Consistency: The automation ensures that each piece you produce is identical in quality and detail, improving overall consistency. Flexibility: Whether you’re producing one-of-a-kind custom pieces or bulk products, the rotary CNC router offers the flexibility to handle both with ease. Lower Material Waste: Precision machining ensures that there is minimal waste, reducing the cost of raw materials and promoting sustainable practices.

Why Buy From GK Laser Enterprises? At GK Laser Enterprises, we provide high-quality rotary CNC router machines tailored to meet the unique needs of businesses across industries. With our deep industry expertise, we ensure that you get the most suitable machine for your applications, ensuring optimal performance and cost-efficiency.

We also offer:

Comprehensive Training and Support: Our team will provide full training on how to operate and maintain your CNC router machine. Maintenance Services: Regular servicing to keep your machine running smoothly, ensuring minimal downtime and maximum output. Custom Solutions: We understand that every business has different requirements, so we provide customized solutions that best fit your needs.

Conclusion The Rotary CNC Router Machine offers unparalleled precision and flexibility, making it an essential tool for businesses involved in woodworking, metalworking, and creative design. At GK Laser Enterprises, we’re committed to providing top-tier CNC solutions that enhance productivity and reduce costs. By investing in a rotary CNC router, your business can stay ahead of the competition while delivering superior quality products. Contact us today to learn more about our CNC machines and how they can benefit your operations!

2 notes

·

View notes

Text

The Importance of High-tech Rapid Prototyping

In the industrial industry, precision is not only desirable—it is essential. Consider a situation in which parts of a jet engine are even marginally machined incorrectly or misaligned. The repercussions can be disastrous and might cause the engine to fail in midair. Precision becomes the key to success in sectors like aerospace, automotive, and medical where safety and dependability are non-negotiable. Put simply, it's the capacity to manufacture parts or components that precisely conform to given dimensions, tolerances, and quality requirements. It takes state-of-the-art equipment, painstaking attention to detail, and highly competent operators to achieve this degree of accuracy. This is the sweet spot for Precision CNC Machining.

So how precisely can CNC machining accomplish such high precision levels?

Computerized Control: Advanced computer software is the brains of CNC machining, translating digital design requirements into exact motions and orders for the milling tools. This removes the possibility of human error and guarantees the highest level of precision in each cut, drill, and mill.

Superior Quality Equipment: Modern spindles, tools, and cutting implements that are designed to provide exact results are standard on CNC machines. These devices may operate at extremely tight tolerances, which are sometimes expressed in microns, guaranteeing an accurate reproduction of even the minutest features.

Consistency: The ability of CNC machining and High-tech Rapid Prototyping to manufacture similar components with little variance is one of its main advantages. A machine program that has been developed and tuned may be repeated endlessly with reliable outcomes. In fields where stability and dependability are critical, this degree of constancy is priceless.

Advanced Techniques: Multi-axis milling, turning, EDM (Electrical Discharge Machining), laser cutting, and other state-of-the-art methods are all included in CNC machining. With unmatched accuracy and efficiency, manufacturers can handle complicated geometries and materials thanks to these procedures.

Quality Assurance: CNC systems frequently include integrated quality control mechanisms including automated inspections, feedback loops, and real-time monitoring in addition to accurate machining. This reduces waste and rework by guaranteeing that any deviations from the intended standards are quickly identified and fixed. It is impossible to exaggerate the value of accuracy in production. Precision by Precision CNC Machining Manufacturer plays a crucial role in today's competitive economy, as it ensures everything from satisfying regulatory requirements and consumer expectations to assuring product performance and dependability.

Follow our Facebook and Twitter for more information about our product

#High-tech Rapid Prototyping#Precision CNC Machining#Precision CNC Machining Manufacturer#CNC Machining Manufacturer Company

2 notes

·

View notes

Text

Revolutionizing CAM: High-Speed Machining with Autodesk PowerMill

Unlocking Precision and Speed: The Future of CAM with PowerMill

In the rapidly evolving landscape of manufacturing, staying ahead requires leveraging cutting-edge technology that enhances both efficiency and precision. Autodesk PowerMill stands out as the definitive choice for professionals seeking to elevate their CNC machining processes. Designed for high-speed, high-efficiency manufacturing, PowerMill empowers engineers and machinists to produce complex parts with unmatched accuracy and reduced cycle times.

One of the core advantages of PowerMill is its sophisticated 5-axis CAM programming capabilities. This feature allows for intricate tool paths that can access difficult-to-reach areas, ensuring high-quality finishes and minimizing manual interventions. Whether you're working on aerospace components, automotive parts, or intricate molds, PowerMill offers the flexibility and power needed for complex geometries.

Speed is essential in today’s competitive market. PowerMill’s advanced algorithms optimize tool paths to reduce machining time significantly. By intelligently managing material removal and tool engagement, it ensures maximum productivity without compromising on quality. This not only accelerates project timelines but also reduces operational costs, making it an invaluable asset for manufacturing enterprises aiming for lean production.

Moreover, the software’s user-friendly interface combined with robust simulation features allows for comprehensive testing before actual machining. This reduces errors, tool breakage, and material wastage, further enhancing efficiency. PowerMill’s ability to simulate and verify complex operations ensures that every project is executed flawlessly, saving time and resources.

For businesses looking to expand their capabilities, acquiring a license for PowerMill is a strategic investment. You can find affordable options and even purchase a autodesk powermill ultimate price that fits your budget. This access opens doors to a suite of powerful features that can transform your manufacturing process and help you stay competitive in a global marketplace.

In conclusion, Autodesk PowerMill is more than just a CAM tool; it’s a comprehensive solution that combines speed, precision, and ease of use. Its role in high-speed machining and complex part manufacturing makes it the expert’s choice for those serious about quality and efficiency. Embrace the future of manufacturing with PowerMill and see your productivity soar.

0 notes

Text

Enhancing Metal Fabrication: A Deep Dive into V Grooving Automation

In the world of sheet metal fabrication, precision and efficiency are paramount. Among the arsenal of cutting-edge tools transforming the industry, the Automatic V Grooving Machine has emerged as a game-changer—delivering sharp accuracy, reducing material deformation, and enhancing aesthetic appeal across architectural and industrial applications.Get more news about Automatic V Grooving Machine,you can vist our website!

What Is an Automatic V Grooving Machine?

An Automatic V Grooving Machine is a highly specialized piece of equipment designed to create narrow, precise V-shaped grooves on sheet metal or composite panels. These grooves allow for clean, sharp bends without distorting the surface—an essential requirement in high-end fabrication, particularly for elevator panels, cabinet doors, decorative finishes, and signage.

Unlike manual grooving, which can be inconsistent and labor-intensive, automatic systems ensure uniform depth, angle, and spacing. The technology typically features CNC (Computer Numerical Control) integration, enabling operators to input exact specifications and produce flawless results in a fraction of the time.

Key Features and Benefits

High Precision: Automatic V groovers offer micrometer-level accuracy, which translates to cleaner angles and better alignment when parts are bent or folded.

Reduced Material Stress: By pre-grooving the metal, the machine minimizes internal stress during bending, preserving the material’s surface and integrity.

Increased Efficiency: Automation dramatically reduces setup times and manual labor, improving overall throughput.

Customization and Flexibility: Advanced models allow programming of multiple groove patterns, depths, and panel dimensions, catering to diverse design requirements.

Cleaner Aesthetics: The resulting folds are crisp and professional, elevating the visual quality of the final product.

Applications Across Industries

The versatility of V grooving makes it indispensable across various sectors. In architecture, it’s used to fabricate decorative claddings, column covers, and wall panels with elegant seams. In the elevator industry, grooved panels provide seamless transitions and modern aesthetics. Furniture manufacturers utilize it for sleek cabinetry and fixture components, while signage companies rely on it for precise lettering and sleek edges.

Additionally, with the increasing demand for metal furniture and minimalistic interiors, V grooving supports thin, lightweight designs without compromising structural integrity.

Technological Advancements and Trends

Modern V grooving machines continue to evolve alongside digital manufacturing trends. Integration with CAD/CAM software enables seamless workflow from design to production. Real-time diagnostics, touch-screen controls, and remote monitoring are becoming standard features, increasing accessibility and reducing operator errors.

Environmental impact is also being considered: some machines are built with noise-reduction chambers and energy-efficient drives, aligning with green manufacturing principles.

Conclusion

The Automatic V Grooving Machine is more than just a fabrication tool—it’s a symbol of precision engineering and aesthetic craftsmanship. In an era where customization and speed are everything, its ability to elevate both function and form makes it an invaluable asset across industries. As manufacturing leans further into digital automation, machines like these will define the future of design and fabrication—where art meets industry in every flawless fold.

0 notes

Text

3D Printing Stainless Steel Market Overview: Trends, Drivers, and Emerging Opportunities

The 3D Printing Stainless Steel Market has emerged as a transformative force across multiple industries, enabling unprecedented flexibility, efficiency, and innovation in manufacturing processes. As industries shift toward digital and on-demand production, stainless steel 3D printing is gaining traction due to its strength, durability, corrosion resistance, and adaptability. This article explores the key trends, growth drivers, and emerging opportunities shaping this dynamic market.

Current Market Landscape

3D printing, also known as additive manufacturing, has transitioned from a prototyping tool to a viable production method for end-use components. Stainless steel is one of the most widely used metals in this space, prized for its high tensile strength, temperature resistance, and biocompatibility. Sectors such as aerospace, automotive, healthcare, and industrial machinery are increasingly leveraging stainless steel 3D printing to streamline operations and produce high-performance components.

In recent years, the market has witnessed a growing number of manufacturers integrating metal 3D printing capabilities into their production lines. From powder-based techniques like Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS) to newer filament-based technologies, the range of printing methods has expanded, allowing for broader applications.

Key Market Trends

Shift Toward Mass Customization One of the standout trends in the 3D Printing Stainless Steel Market is the ability to create highly customized products at scale. This shift is revolutionizing sectors such as healthcare (custom implants), automotive (engine components), and consumer goods (designer accessories).

Integration with Digital Twins and Simulation Digital twins are being used to simulate and optimize the performance of 3D-printed components before actual manufacturing. This reduces error rates, saves material costs, and accelerates product development cycles.

Hybrid Manufacturing Approaches Companies are increasingly combining traditional subtractive manufacturing (e.g., CNC machining) with additive processes to enhance surface finishes and mechanical properties. This hybrid model helps achieve better functional performance and lowers production time.

Advancements in Stainless Steel Powders The development of advanced stainless steel powders with improved flowability and particle distribution has made 3D printing more reliable and consistent. These improvements are critical in aerospace and medical applications where component quality is non-negotiable.

Market Drivers

Rising Demand for Lightweight and Strong Components Aerospace and automotive industries are driving demand for lightweight yet durable materials. Stainless steel’s strength-to-weight ratio makes it ideal for these applications, pushing its adoption in 3D printing.

Faster Time-to-Market The ability to produce parts on-demand directly from digital designs significantly shortens product development timelines. Companies can bring innovations to market faster, responding swiftly to customer needs and market changes.

Growing Focus on Sustainability Additive manufacturing generates less material waste compared to traditional methods. As environmental concerns intensify, this eco-efficiency is becoming a compelling driver for adoption.

Government and Institutional Support Many countries are investing heavily in Industry 4.0 technologies, including metal 3D printing. Supportive policies, funding for research and development, and training programs are accelerating market growth.

Emerging Opportunities

Medical Applications: As regulatory standards for 3D-printed medical devices become clearer, opportunities in orthopedics, dental, and surgical tools are expanding rapidly.

Energy Sector: The oil & gas and renewable energy sectors are exploring stainless steel 3D printing for critical components like turbine blades, valves, and pump housings.

Construction Industry: While still in its infancy, the use of 3D-printed stainless steel in architectural structures and reinforcement components is gaining interest due to design flexibility.

Education and Research: Institutions are investing in 3D printing labs to train the next generation of engineers and develop novel alloys and applications.

Challenges Ahead

Despite its promising outlook, the 3D Printing Stainless Steel Market faces several hurdles:

High Initial Investment: Industrial metal 3D printers and high-quality stainless steel powders are expensive, limiting access for small and medium enterprises.

Technical Barriers: Issues such as residual stress, anisotropy, and post-processing requirements can impact the mechanical properties and reliability of printed parts.

Material Standards and Certification: Lack of standardization in material quality and testing methods can hinder regulatory approvals, especially in aerospace and medical fields.

Conclusion

The 3D Printing Stainless Steel Market is entering a period of significant growth, driven by advances in technology, materials science, and demand for customization. While challenges remain, the benefits in terms of speed, precision, and sustainability are too compelling to ignore. As industries continue to explore the full potential of additive manufacturing, stainless steel will play a central role in unlocking new possibilities across the global manufacturing landscape.

0 notes

Text

CNC Machining Services in Bangalore: Driving Innovation and Precision

Summary

CNC machining services in Bangalore offer precision, efficiency, and scalability for industries like aerospace and automotive. Supported by skilled talent and advanced equipment, it's a top choice for modern manufacturing needs.

Introduction

Bangalore, widely recognized as India’s technological and industrial epicenter, is also home to a growing network of precision engineering and manufacturing units. In recent years, the rise of CNC (Computer Numerical Control) machining has revolutionized how businesses in this region produce high-accuracy components across diverse industries.

For manufacturers seeking efficiency, consistency, and precision, the availability of reliable CNC machining services in Bangalore offers a significant competitive edge. This article explores the city's CNC capabilities, the role of machine manufacturers, and how businesses can find the right partners without relying on brand names.

The Role of CNC Machining in Modern Industry

CNC machining enables automated control of machining tools using pre-programmed software. It is vital for industries such as aerospace, automotive, healthcare, and electronics due to its ability to deliver:

Exceptional accuracy with minimal error margins

Uniformity across large production volumes

Speed and efficiency in manufacturing processes

Flexibility in handling multiple materials, from metals to plastics

By reducing manual labor and improving consistency, CNC technology forms the backbone of advanced manufacturing. This is especially evident in Bangalore, where technology and manufacturing intersect to deliver world-class solutions.

Why Bangalore Stands Out for CNC Services

1. Established Manufacturing Clusters

Industrial zones such as those in Peenya, Bommasandra, and surrounding areas host a vast concentration of workshops and factories offering advanced machining services. The region’s infrastructure supports a variety of CNC operations, including:

Milling (3-axis and 5-axis)

Turning and boring

Wire EDM

Grinding and surface finishing

These capabilities allow CNC machining services in Bangalore to meet requirements from prototyping to large-scale production.

2. Skilled Technical Workforce

Bangalore’s strong educational ecosystem ensures a steady supply of CNC programmers, operators, and mechanical engineers. This talent pool plays a key role in upholding the quality and innovation standards expected from CNC-driven projects.

3. Integration of Smart Technologies

Manufacturers in the city are adopting cutting-edge tools like CAD/CAM software, IoT-enabled machines, and digital inspection systems. This tech-forward mindset results in smoother operations and better precision control throughout the production cycle.

Versatile CNC Services in Bangalore

A wide range of businesses turn to CNC company in Bangalore providers for various services, including:

a. Prototype Development

Startups and design teams frequently use CNC for quick-turn prototypes. It allows for fast iteration and testing without the need for expensive tooling.

b. Batch and Mass Production

When consistency and volume are critical, CNC is the preferred option. Bangalore’s machining providers can handle small runs to thousands of units with reliable accuracy.

c. Complex and Custom Parts

For components with intricate geometries, internal features, or specific surface finishes, multi-axis CNC machines provide the flexibility needed to create high-quality, complex parts.

d. Material Flexibility

Whether it’s aluminum, stainless steel, titanium, brass, or engineering-grade plastics, machining providers in Bangalore are equipped to handle a broad spectrum of materials, giving manufacturers full control over performance and cost.

CNC Machine Manufacturers in Bangalore: Supporting Production from the Ground Up

Behind the growth of the machining sector is a strong base of CNC machine manufacturers in Bangalore. These manufacturers design and produce the machinery that powers precision workshops across the region.

Available machines include:

Vertical and horizontal machining centers

CNC lathes and turning machines

CNC routers and engravers

Laser and plasma cutters

Wire EDM equipment

The proximity of machine builders to end users ensures faster maintenance support, easier access to spare parts, and the ability to customize machines according to project needs. Many of these manufacturers also offer automation features, like tool changers and robotic interfaces, allowing for improved throughput and efficiency.

Sectors That Rely on CNC in Bangalore

The application of CNC machining spans many industries in Bangalore, such as:

Aerospace & Defense: High-precision parts requiring tight tolerances

Automotive: Engine and transmission components, custom brackets, and bushings

Medical: Surgical tools, prosthetics, and orthopedic parts

Consumer Electronics: Precision housings, connectors, and circuit fixtures

Industrial Equipment: Gears, shafts, and custom machine parts

This wide usage reflects how critical the CNC company in Bangalore ecosystem is to the overall manufacturing economy.

How to Choose a CNC Machining Partner in Bangalore

Selecting the right service provider is essential to achieving quality results. Here’s what to consider:

1. Assess Capabilities

Make sure the provider can meet your technical requirements—tolerance levels, materials, and part complexity. Ask if they use 3-axis, 5-axis, or turning centers as needed for your components.

2. Verify Certifications

Look for recognized quality standards like ISO 9001, AS9100 (aerospace), or medical-grade certifications. These ensure process consistency and regulatory compliance.

3. Request Trial Jobs

Consider asking for sample components or test runs to evaluate the quality before committing to a larger batch.

4. Review Turnaround and Delivery

Timely delivery is critical. Evaluate the provider’s lead times and ability to handle urgent or bulk orders.

5. Check Post-Machining Services

Many companies offer additional services such as anodizing, powder coating, heat treatment, and assembly. Opting for full-service solutions reduces coordination efforts.

Advantages of CNC Machining Services in Bangalore

Choosing CNC service providers in Bangalore comes with several advantages:

Affordable and efficient solutions

Access to a well-trained engineering workforce

Latest software and machining technologies

Reliable support and fast turnaround

Proximity to major industrial and logistics hubs

These strengths make CNC machining services in Bangalore a smart choice for companies seeking quality and scalability.

Conclusion

CNC machining has become a vital part of manufacturing, and Bangalore is well-positioned to meet the growing demand. With a rich ecosystem of talent, machinery, and infrastructure, the city offers unmatched value for companies needing everything from rapid prototyping to large-scale production.Whether you're working on high-precision aerospace parts or consumer product enclosures, collaborating with a skilled CNC company in Bangalore ensures a smoother path to success. Combined with the support of innovative CNC machine manufacturers in Bangalore, the city continues to evolve as a national hub for precision engineering.

FAQ

1. What types of CNC machining services are available in Bangalore?

Bangalore offers a wide range of CNC services including turning, milling (3-axis and 5-axis), drilling, grinding, and wire EDM. Whether you need rapid prototyping or high-volume production, CNC machining services in Bangalore can accommodate diverse project requirements across various materials and industries.

2. Why choose CNC machining services in Bangalore over other cities?

Bangalore stands out due to its strong industrial ecosystem, skilled technical workforce, and access to advanced CNC technology. In addition, service providers here offer competitive pricing, fast turnaround, and compliance with global quality standards—all making Bangalore a preferred destination for precision manufacturing.

3. Are there certified CNC companies in Bangalore?

Yes. Many CNC companies in Bangalore follow international standards like ISO 9001 and AS9100, ensuring quality assurance and process reliability. Certifications demonstrate a company's commitment to meeting regulatory and industry-specific requirements.

4. Can CNC machining services in Bangalore handle custom and complex parts?

Absolutely. CNC providers in Bangalore are equipped with advanced multi-axis machines and trained personnel to handle intricate designs, tight tolerances, and complex geometries. They support both one-off custom jobs and large-scale production runs.

5. Who are the CNC machine manufacturers in Bangalore and what do they offer?

While we’re not naming specific brands, Bangalore is home to several CNC machine manufacturers that design and supply a variety of machines including turning centers, milling machines, routers, and laser cutters. These manufacturers also offer automation options and local support for businesses investing in new equipment.

6. How do I select the right CNC company in Bangalore for my project?

To choose the right CNC company in Bangalore, assess their technical capabilities, machinery, certifications, and track record. Also, consider lead time, quality control systems, and whether they offer additional services like coating, assembly, or inspection.

7. What industries benefit the most from CNC machining in Bangalore?

A wide range of industries rely on CNC machining in Bangalore, including aerospace, automotive, medical devices, electronics, and industrial equipment manufacturing. The versatility of CNC technology allows it to serve both high-precision and high-volume production needs efficiently.

0 notes

Text

The Mechatronic Design Engineer: Powering Automation with CODESYS

Mechatronic design engineering is a multidisciplinary field that blends mechanical engineering, electronics, control systems, and software development to create intelligent, automated systems. Mechatronic design engineers are at the forefront of innovation, designing solutions for industries like robotics, automotive, aerospace, and manufacturing. CODESYS, an IEC 61131-3-compliant development platform, is a critical tool for these engineers, enabling them to program and integrate control systems for complex mechatronic applications. This article explores the role of a mechatronic design engineer, how CODESYS supports their work, key responsibilities, required skills, and real-world applications, highlighting the impact of this profession on modern automation.

The Essence of Mechatronic Design Engineering

Mechatronic design engineering focuses on creating systems that integrate mechanical components, electronic circuits, sensors, actuators, and software to achieve precise, reliable performance. These systems, such as robotic arms, autonomous vehicles, or CNC machines, require seamless coordination between hardware and software. Mechatronic design engineers ensure that these components work together to meet performance, safety, and efficiency goals, making them essential in industries embracing Industry 4.0 and smart automation.

CODESYS is a cornerstone for mechatronic design engineers, offering a versatile, hardware-independent platform for programming embedded control systems. Its compliance with IEC 61131-3, support for multiple programming languages, and robust tools for simulation and debugging make it ideal for developing sophisticated mechatronic systems.

Responsibilities of a Mechatronic Design Engineer

Mechatronic design engineers undertake a variety of tasks to bring complex systems to life:

System Design and Integration: Designing integrated systems that combine mechanical structures, electronics, and control software to meet specific functional requirements.

Control System Programming: Developing control algorithms to manage sensors, actuators, and motion systems, ensuring precise operation.

Simulation and Testing: Using simulation tools to validate system performance before deployment, minimizing errors and risks.

Prototyping and Commissioning: Building prototypes, integrating components, and deploying systems in real-world environments.

Optimization and Troubleshooting: Analyzing system performance, debugging issues, and optimizing designs for efficiency and reliability.

Collaboration: Working with mechanical, electrical, and software teams to ensure cohesive system development.

How CODESYS Empowers Mechatronic Design Engineers

CODESYS provides a comprehensive environment tailored to the needs of mechatronic design engineers:

IEC 61131-3 Programming Languages: CODESYS supports Ladder Diagram (LD), Function Block Diagram (FBD), Structured Text (ST), Instruction List (IL), and Sequential Function Chart (SFC). These languages enable engineers to develop control logic for diverse applications, from simple discrete controls to advanced motion systems.

Hardware Flexibility: Compatible with PLCs and embedded controllers from vendors like Beckhoff, WAGO, and Siemens, CODESYS allows engineers to choose hardware that suits project budgets and requirements.

Motion Control Libraries: CODESYS offers libraries for motion control, supporting tasks like servo motor control, trajectory planning, and multi-axis coordination, critical for mechatronic systems like robotics.

Simulation and Debugging Tools: The built-in simulation mode enables testing without physical hardware, while debugging features like breakpoints and real-time monitoring help identify and resolve issues quickly.

HMI Development: CODESYS provides tools to create Human-Machine Interfaces (HMIs) for operator interaction, including graphical displays and web-based visualizations.

Communication Protocols: Support for EtherCAT, CANopen, Modbus, and OPC UA ensures seamless integration with sensors, actuators, and other devices in mechatronic systems.

Safety Standards: For safety-critical applications, CODESYS supports IEC 61508 (SIL 2/3), enabling engineers to design systems for industries like automotive and aerospace.

Example: Robotic Arm Control Program

Below is a sample Structured Text (ST) program for controlling a robotic arm’s position in a mechatronic system:

RoboticArmControl.st

plain

Show inline

This program implements a proportional control loop to adjust a robotic arm’s joint angle, ensuring precise positioning in a mechatronic application.

Essential Skills for Mechatronic Design Engineers

To succeed, mechatronic design engineers need a diverse skill set:

Multidisciplinary Knowledge: Proficiency in mechanical design, electronics, and control systems programming, including CODESYS and IEC 61131-3 languages.

Control Theory: Understanding of control algorithms, such as PID control, for precise system management.

Software Development: Experience with embedded systems programming and real-time operating systems (RTOS).

Problem-Solving: Analytical skills to troubleshoot and optimize complex systems.

Teamwork: Collaboration with cross-functional teams to integrate hardware and software components.

Adaptability: Staying updated with emerging technologies like IoT, AI, and cybersecurity.

Benefits of Using CODESYS

Streamlined Development: The integrated IDE and simulation tools reduce development time and errors.

Cost Efficiency: Hardware independence and code reusability lower project costs.

Scalability: CODESYS supports projects from small prototypes to large-scale industrial systems.

Flexibility: Multiple programming languages and protocols cater to diverse project needs.

Community Support: A global user base and resources like the CODESYS Store provide access to libraries and tutorials.

Applications in Industry

Mechatronic design engineers leverage CODESYS in various sectors:

Robotics: Developing control systems for industrial and collaborative robots.

Automotive: Designing ECUs for engine management, braking, and autonomous driving.

Manufacturing: Automating production lines, CNC machines, and material handling systems.

Aerospace: Controlling actuators and sensors in aircraft and spacecraft.

Medical Devices: Creating precise control systems for surgical robots and diagnostics.

Challenges in Mechatronic Design Engineering

Interdisciplinary Complexity: Integrating mechanical, electrical, and software components requires broad expertise.

Learning Curve: Mastering CODESYS and IEC 61131-3 languages can be time-intensive for beginners.

Resource Constraints: Embedded systems often have limited processing power, necessitating optimized code.

Safety Requirements: Meeting standards like IEC 61508 for safety-critical applications adds complexity.

Getting Started with CODESYS

To begin as a mechatronic design engineer using CODESYS:

Install CODESYS: Download the free IDE from the official website.

Learn Programming: Study IEC 61131-3 languages through tutorials and documentation.

Select Hardware: Choose a compatible PLC or embedded controller.

Develop and Simulate: Write control logic, test in simulation mode, and debug.

Deploy: Compile and deploy code to the target hardware.

Future Trends

As industries embrace digital transformation, mechatronic design engineers will increasingly use CODESYS for IoT-enabled systems, cloud-based monitoring, and AI-driven control. Support for protocols like OPC UA and MQTT positions CODESYS for smart manufacturing, while advancements in cybersecurity ensure its relevance in safety-critical applications.

Conclusion

Mechatronic design engineers by Servotechinc are key to creating the intelligent systems that drive modern automation, from robotics to autonomous vehicles. CODESYS empowers these professionals with a flexible, IEC 61131-3-compliant platform for programming, testing, and deploying control systems. Its robust features, hardware independence, and support for motion control and communication protocols make it indispensable for mechatronic applications. As technology advances, CODESYS and mechatronic design engineers will continue to shape the future of automation, delivering innovative, efficient, and reliable solutions.

0 notes

Text

Affordable Cobot Solutions: Safe, Smart, and Efficient Automation for Your Business

In today's competitive industrial landscape, businesses of all sizes are seeking smarter and more cost-effective ways to improve productivity and streamline operations. One of the most transformative innovations in recent years is the collaborative robot, or cobot. Designed to work safely alongside humans, cobots offer the benefits of industrial automation without the need for expensive safety barriers or complex programming. For businesses looking to enhance their workflows without breaking the bank, an affordable cobot is the ideal solution.

What Is a Cobot?

A cobot, short for collaborative robot, is a type of robot specifically engineered to interact directly and safely with humans in a shared workspace. Unlike traditional industrial robots that require isolation due to safety concerns, cobots are equipped with advanced sensors, force limitations, and user-friendly interfaces. These features make them ideal for applications in manufacturing, logistics, packaging, inspection, and even healthcare.

Cobots are not only safer but also more flexible and easier to deploy than traditional robots. Whether it's repetitive assembly tasks, material handling, or precision testing, cobots offer intelligent automation with minimal setup time.

Why Choose an Affordable Cobot?

The term affordable cobot is becoming increasingly relevant as businesses search for practical automation solutions without the high costs typically associated with robotic systems. In the past, automation was considered a luxury, accessible only to large manufacturers with deep pockets. Today, however, advancements in technology and increased market competition have driven down costs, making high-quality cobots more accessible than ever.

Here are some key reasons to choose an affordable cobot:

Lower Upfront Investment Compared to traditional robotic systems, cobots require less initial capital. Many affordable cobot models are designed with small to medium-sized businesses in mind, providing excellent ROI (return on investment) even with limited budgets.

Ease of Use Most cobots come with intuitive programming interfaces, including drag-and-drop features or hand-guided teaching. This allows non-technical staff to set up and operate cobots without needing advanced engineering skills.

Rapid Deployment Unlike conventional robots that may take weeks to install and configure, cobots can be set up and integrated into your production line in just a few hours. This minimizes downtime and ensures you start seeing productivity gains quickly.

Flexibility Across Tasks A single cobot can perform multiple tasks. With quick tool changes and easy reprogramming, your team can adapt a cobot for different functions, maximizing its value and utilization.

Enhanced Safety Cobots are built with built-in safety protocols that allow them to detect collisions and reduce force upon impact. This means they can safely work side-by-side with human operators without compromising workplace safety.

Top Applications of Affordable Cobots

Affordable cobots can be deployed across a variety of industries and applications, including:

Assembly: Speed up repetitive assembly processes while maintaining precision and consistency.

Pick and Place: Reduce labor costs in material handling and packaging operations.

Machine Tending: Automate the loading and unloading of CNC machines, reducing human fatigue and improving productivity.

Quality Inspection: Use vision systems to automate inspection processes and ensure product quality.

Lab Automation: Perform repetitive lab tasks like pipetting and sample handling in pharmaceutical or research environments.

How to Select the Right Affordable Cobot

Choosing the right cobot for your business starts with understanding your specific needs. Consider these factors:

Payload and Reach: Match the cobot's payload and reach with your application requirements.

Precision and Speed: Depending on your task, select a cobot that delivers the right balance of speed and accuracy.

Compatibility: Ensure the cobot integrates well with your existing systems and machinery.

Support and Training: Opt for a vendor that offers reliable customer support, training, and resources to help your team succeed.

Where to Find the Best Deals on Affordable Cobots

As the demand for collaborative robots increases, more vendors are offering competitive pricing, financing options, and bundled packages that include software, end-effectors, and support. When exploring your options, look for providers that offer:

Transparent pricing with no hidden fees

Comprehensive warranties and service plans

Online configurators to tailor cobot packages to your needs

Real customer reviews and case studies

At [Your Website Name], we specialize in connecting businesses with top-rated affordable cobots from leading manufacturers. Our curated selection ensures safety, reliability, and performance at unbeatable prices. Whether you're automating a single workstation or upgrading your entire production line, our team is here to help you choose the best cobot solution for your business.

Final Thoughts

affordable cobot are revolutionizing the way businesses approach automation. No longer confined to large corporations, cobots are now accessible, practical, and safe for small and mid-sized enterprises. With the right cobot, you can enhance operational efficiency, reduce costs, and improve product quality — all while keeping your team safe and engaged.

If you're ready to explore the possibilities of smart automation, start by browsing our collection of affordable cobots today. Experience the future of work — collaborative, efficient, and within your reach.

0 notes

Text

CNC Milling: The Core of High-Precision Manufacturing

Introduction

The CNC milling process is a fundamental technique in precision machining, enabling manufacturers to create high-quality components with minimal human intervention. By utilizing computer numerical control (CNC) technology, milling machines shape materials such as metal, plastic, and wood into intricate designs with exceptional accuracy. In this blog, we explore the fundamentals of CNC milling, its advantages, and key applications across industries.

What is CNC Milling?

CNC milling is a subtractive manufacturing process that removes material from a solid workpiece using rotating cutting tools. Unlike manual milling, CNC milling is automated, following pre-programmed G-code instructions to achieve precise dimensions and complex geometries.

Key Features of CNC Milling

Multi-Axis Control – Operates on 3-axis, 4-axis, or 5-axis configurations for intricate designs.

High Precision – Achieves tolerances as tight as ±0.001 inches.

Versatile Material Compatibility – Works with metals, plastics, composites, and wood.

Automated Efficiency – Reduces human error and speeds up production.

Advantages of CNC Milling

1. Exceptional Accuracy and Consistency

CNC milling ensures repeatable precision, making it ideal for industries requiring tight tolerances:

Aerospace Components – High-precision parts for aircraft and spacecraft.

Medical Devices – Surgical instruments and prosthetics with intricate details.

Automotive Parts – Engine components and custom vehicle parts.

2. Increased Production Efficiency

Automated CNC milling enhances manufacturing speed:

Rapid Prototyping – Quickly produces prototypes for testing.

Mass Production – Scales up production with minimal waste.

Reduced Labor Costs – Minimizes manual intervention.

3. Complex Geometries and Customization

CNC milling allows for intricate designs that manual machining cannot achieve:

3D Contouring – Smooth curves and detailed engravings.

Multi-Surface Machining – Works on multiple angles and depths.

Custom Tooling – Adapts to unique project requirements.

Applications of CNC Milling

1. Aerospace and Automotive Industries

CNC milling is essential for high-performance components:

Aircraft Frames and Engine Parts – Lightweight, durable materials.

Automotive Prototypes – Custom designs for testing and production.

2. Medical and Electronics Manufacturing

Precision machining supports advanced medical and electronic devices:

Implants and Prosthetics – Biocompatible materials for healthcare.

Circuit Boards and Casings – High-precision parts for electronics.

3. Industrial and Consumer Goods

CNC milling is widely used in custom manufacturing:

Machinery Components – Gears, brackets, and housings.

Furniture and Decorative Items – Wood and metal engravings.

How to Optimize CNC Milling for Your Project

1. Choose the Right Material

Select materials based on strength, durability, and machinability:

Aluminum and Titanium – Lightweight and corrosion-resistant.

Plastics and Composites – Ideal for electronics and medical applications.

2. Optimize Tooling and Cutting Parameters

Enhance efficiency with proper tool selection:

End Mills and Face Mills – Different tools for varied surface finishes.

Cutting Speed and Feed Rate – Adjust settings for precision and efficiency.

3. Utilize Advanced CNC Software

Improve accuracy with CAD/CAM integration:

3D Modeling and Simulation – Ensures design feasibility.

Automated Toolpath Generation – Reduces programming time.

Conclusion

The CNC milling process is a powerful, precise, and efficient manufacturing method used across industries. Whether producing aerospace components, medical devices, or industrial machinery, CNC milling offers high-quality results with minimal waste. Investing in advanced CNC technology ensures cost-effective production, superior accuracy, and limitless customization.

0 notes

Text

Tube Sheet Drilling: Precision Engineering for Heat Exchanger Efficiency

Introduction to Tube Sheet Drilling

Tube sheet drilling is a highly specialized machining process used to create accurate and aligned holes in tube sheets—critical components in heat exchangers, boilers, pressure vessels, and condenser systems. These precision-drilled holes allow for the insertion and secure mounting of heat exchange tubes, ensuring optimal thermal transfer efficiency and mechanical stability.

With increasing demands in petrochemical, oil & gas, power generation, and chemical industries, high-precision tube sheet drilling has become more essential than ever for leak-proof, high-pressure, and high-temperature applications.

What is a Tube Sheet?

A tube sheet is a thick metal plate, typically made from carbon steel, stainless steel, copper alloys, or nickel-based alloys, that holds tubes in position within a heat exchanger or similar device. These plates are drilled with hundreds or even thousands of holes, each of which must be precisely located and dimensioned to ensure proper tube alignment and flow dynamics.

Tube sheets may be:

Flat or flanged

Cladded or solid

Fixed or floating

The integrity of tube sheet drilling directly influences the operational efficiency and lifespan of the entire equipment.

Key Features of Tube Sheet Drilling

1. Ultra-Precision Hole Placement

Hole pitch accuracy within ±0.02 mm

Accurate alignment for seamless tube-to-sheet welding or expansion

Support for complex configurations like square, triangular, or staggered pitch patterns

2. Custom Hole Diameters

Hole diameters typically range from 10 mm to 50 mm

Precision tools for countersinking, reaming, and chamfering as per design requirements

3. CNC and Multi-Spindle Drilling Options

CNC drilling offers repeatability, speed, and automation

Multi-spindle heads reduce cycle time by drilling multiple holes simultaneously

Option to program tool paths, feed rates, and depths

4. Compatibility with Multiple Materials

High-speed steel and carbide-tipped drill bits for superior performance

Capability to drill cladded tube sheets (e.g., stainless steel + carbon steel)

Coolant-fed tools and optimized cutting conditions to handle exotic alloys

Applications of Tube Sheet Drilling

1. Heat Exchangers

Critical for U-tube heat exchangers, shell & tube designs, and double-pipe configurations

Precise drilling ensures efficient thermal conductivity and mechanical locking

2. Boilers and Pressure Vessels

Supports high-pressure operations

Helps in achieving zero-leakage expansion joints

3. Oil Refineries and Chemical Plants

Used in corrosive environments where precision and metallurgy are key

Hole alignment ensures uninterrupted flow of process fluids

4. Power Generation and Nuclear Plants

Used in superheaters, economizers, and condenser systems

Requires radiographic inspection compliance for nuclear-grade tube sheets

Tube Sheet Drilling Process: Step-by-Step

1. Design and Layout Preparation

3D CAD models or 2D technical drawings created for hole mapping

Pitch, margin, and hole count are finalized

2. Material Preparation

Tube sheets undergo annealing, cleaning, and marking

Plate thickness checked (often ranges from 20 mm to 200 mm)

3. CNC Drilling Operation

CNC-controlled drill head moves in X-Y coordinates

Drilling depth, diameter, and tolerance pre-set for each hole

Coolant system active to prevent heat build-up and tool wear

4. Finishing

Chamfering or reaming if needed

Deburring for smooth hole edges

Non-destructive testing (NDT) to check hole accuracy and spacing

Advanced Technologies in Tube Sheet Drilling

1. Deep Hole Drilling Machines

Capable of handling thick tube sheets over 150 mm

Specialized gun drilling or BTA (Boring & Trepanning Association) methods used

2. Laser Drilling (For Special Alloys)

Non-contact, heat-concentrated drilling

Used where traditional tooling may not work (e.g., titanium, Inconel)

3. Robotic Drilling Systems

Fully automated arms integrated with CAD/CAM

Ideal for custom tube sheets or small production batches

Quality Control and Inspection

1. Dimensional Inspection

Coordinate Measuring Machines (CMM) used for verifying hole positions

Ensures compliance with ASME, TEMA, and ISO standards

2. Surface Integrity Checks

Inspection for burrs, cracks, or work hardening

Use of penetrant testing (PT) and ultrasonic testing (UT)

3. Fit-Up Verification

Tube insertion test to validate hole alignment and tightness

Simulates real working conditions under thermal and hydraulic stress

Choosing the Right Tube Sheet Drilling Partner

When selecting a supplier for tube sheet drilling, consider the following:

Experience in large-diameter tube sheets

Capability for high-volume or prototype jobs

Access to modern CNC drilling machines

Compliance with international QA/QC standards

In-house NDT and post-drilling inspection systems

Conclusion

Tube sheet drilling is more than just a machining task—it is an engineering-critical operation that demands micron-level accuracy, repeatability, and material adaptability. As industries continue to evolve towards energy efficiency and system reliability, precision-drilled tube sheets form the backbone of high-performance heat exchange systems. Investing in advanced tube sheet drilling solutions means investing in long-term operational safety, energy conservation, and system longevity.

1 note

·

View note

Text

The Applications of 5 axis machining Across Industries

The keys to success in the field of advanced manufacturing are accuracy and effectiveness. 5 axis machining services are a ground-breaking strategy that has expanded the potential for producing complicated and sophisticated components. In this article, we explore the realm of 5-axis machining, examining its advantages, uses, and the radical changes it has brought about across several sectors.

5-axis Machining: Beyond Traditional Boundaries

To obtain the required form, traditional machining techniques frequently entail moving the workpiece along many axes. However, these techniques have drawbacks when it comes to creating intricate geometries. This is where 5-axis machining comes into play, expanding the realm of what is feasible.

5-axis machining adds two rotating axes (usually A and B), in contrast to 3-axis machining, which moves the workpiece along three linear axes (X, Y, and Z). This gives the tool an unmatched degree of flexibility in its movement, allowing it to approach the workpiece from several angles and orientations. A capacity for producing complex designs, speeding up production, and requiring fewer setups overall is the outcome.

5-axis Machining Shining Applications

· Aerospace: The aircraft sector requires complex, lightweight, yet robust components. In materials like titanium and aluminum, 5 axis machining enables the production of complicated geometries that are essential for airplane and spacecraft parts.

· Medical: The medical industry benefits from the accuracy of 5-axis machining in generating patient-specific components and sophisticated designs that support greater biocompatibility. This includes orthopedic implants and medical gadgets.

· Automobile: Precision 5-axis machining is utilized to create molds, prototypes, and crucial engine components in the highly competitive automobile industry, improving performance and reducing weight.

· Even in the creative sectors, such as art and design, 5-axis machining has a role. By using technology, designers, and artists can bring their imaginative ideas to life by producing elaborate sculptures, molds, and architectural models.

The Challenges and Innovations Ahead

5-axis machining is a constantly evolving field, much like any cutting-edge technology. Its capabilities are being further improved by advancements in automation, real-time monitoring, and adaptive toolpaths, which are turning it into a crucial resource in the industrial environment. Nevertheless, there are still issues like programming complexity and greater startup costs. To fully utilize the potential of 5-axis machining services at the 5 axis CNC machining center, it is imperative to understand the complexities of programming and engage in training.

Follow our Facebook and Twitter for more information about our product.

#5 axis machining#5 axis machining services#5 Axis CNC Machining Center#Custom 5 Axis Machining services#5 Axis CNC Machine Shop#5 Axis Machining Center

3 notes

·

View notes

Text

Explore how manufacturing, electronics, and robotics have transformed mankind—from early automata and industrial machinery in the 1950s to today's smart factories, AI-powered robots, and space exploration. Learn how innovations like CNC machines, pick-and-place electronics robots, surgical bots, and Mars rovers increased productivity, safety, and scientific discovery, playing a pivotal role in human progress and future advancements.

#Manufacturing programs#Manufacturing Electronics History#The role of robots in human evolution#Industrial automation impact#CNC and robotics evolution#pick-and-place electronics robots#Smart factories IoT#Surgical robots' benefits#Mars rover robotics#Electronics and human progress

0 notes