#Advanced PCB Technology

Explore tagged Tumblr posts

Text

The Evolution of PCB Manufacturing: From Basics to High-Performance Boards

PCB manufacturing has evolved from single-layer boards to high-performance, multi-layered designs, enabling innovation in automotive, healthcare, telecommunications, and aerospace. Learn how cutting-edge PCB technologies support modern electronics and drive UK industries forward. Explore advanced PCB solutions for your business today.

#PCB manufacturing evolution#high-performance PCBs#multi-layer PCB design#PCB for 5G networks#advanced PCB technology#UK PCB industry#flexible PCBs#PCB signal integrity#automotive PCB solutions#medical device PCBs#aerospace PCB manufacturing#PCB miniaturisation#HDI PCBs#thermal management in PCBs#next-gen PCB solutions#A-Gas Electronic Materials

0 notes

Text

Advanced PCB Manufacturing Cost Effective Solutions Partnership

Introducing a one-stop solution for all your advanced PCB manufacturing needs such as rigid-flex pcb. We're not just a provider; we're your partner in innovation, serving customers globally with top-notch fabrication, solutions, and services. Join our Advanced PCB Manufacturing cost effective solutions for USA, EU, Germany, Switzerland.

#Advanced pcb#pcb manufacturer#usa#europe#germany#switzerland#technology#printed circuit board#affiliate program#partnership#electronic

1 note

·

View note

Text

"As the world grows “smarter” through the adoption of smartphones, smart fridges, and entire smart houses, the carbon cost of that technology grows, too.

In the last decade, electronic waste has become one of the fastest-growing waste streams in the world.

According to The World Counts, the globe generates about 50 million tons of e-waste every year. That’s the equivalent of 1,000 laptops being trashed every second.

After they’re shipped off to landfills and incinerated, the trash releases toxic chemicals including lead, cadmium, arsenic, mercury, and so much more, which can cause disastrous health effects on the populations that live near those trash sites.

Fortunately, Franziska Kerber — a university student at FH Joanneum in Graz, Austria — has dreamed up a solution that helps carve away at that behemoth problem: electronics made out of recyclable, dissolvable paper.

On September 11, Kerber’s invention “Pape” — or Paper Electronics — earned global recognition when it was named a national winner of the 2024 James Dyson Awards.

When she entered the scientific competition, Kerber demonstrated her invention with the creation of several small electronics made out of paper materials, including a fully-functional WiFi router and smoke detector.

“Small electronic devices are especially prone to ending up in household waste due to unclear disposal systems and their small size, so there is significant potential to develop a more user-friendly end-of-life system,” Kerber wrote on the James Dyson Award website.

“With this in mind, I aimed to move beyond a simple recycling solution to a circular one, ensuring long-term sustainability.”

Kerber’s invention hinges on crafting a dissolvable and recyclable PCB board out of compressed “paper pulp.”

A printed circuit board (PCB) is a board that can be found in nearly all modern electronic devices, like phones, tablets, and smartwatches.

But even companies that have started incorporating a “dissolution” step into the end life of their products require deconstruction to break down and recover the PCB board before it can be recycled.

With Kerber’s PAPE products, users don’t need to take the device apart to recycle it.

“By implementing a user-friendly return option, manufacturers can efficiently dissolve all returned items, potentially reusing electronic components,” Kerber explained.

“Rapidly advancing technology, which forms the core of many devices, becomes obsolete much faster than the structural elements, which are often made from plastics that can last thousands of years,” Kerber poses.

PAPE, Kerber says, has a “designed end-of-life system” which anticipates obsolescence.

“Does anyone want to use a thousand-year-old computer?” Kerber asks. “Of course not. … This ensures a sustainable and reliable system without hindering technological advancement.”"

-via GoodGoodGood, September 13, 2024

#ewaste#e waste#e waste recycling#e waste management#e waste solutions#paper#sustainability#green tech#tech news#sustainable technology#recycling#good news#hope

586 notes

·

View notes

Note

great ragebait. who’s your idea of a smart person?

idolizing anyone as "smart" in the general sense is going to inevitably lead to embarrassment when they do or say something stupid. building up an expertise in any one field to the extent that you serve as an inspiration for others in that field will result in shortcomings and blind spots elsewhere. great authors are going to have dogshit takes on IP laws. great political theorists are going to make dumbass points about technology. one of my coworkers at my old job could practically rework PCBs blindfolded and also regularly forgot to include water when microwaving cup noodles. Herman Cain was a genuinely groundbreaking neurosurgeon who invented novel procedures to separate the brains of cojoined twins and also thought that the Great Pyramids were used as grain silos.

the reason i'm so dismissive of people who ever held a positive opinion of Elon Musk is because the only things he's ever been held up as "smart" about are things that he's very obviously (to anyone with actual expertise in that field) a dumbass about. he's not good at "technology"; all of his press events featured untested and faked demos (like an "autonomous" humanoid robot being puppetted from the next room over or his brain implants killing test subjects) and listening to him talk about potential future advancements belies a complete lack of experience in the field. he's not good at urban planning: every suggestion he makes in that field is transparently motivated by his desire to sell more cars. he's not good at making cars: they blow up, catch fire in special ways that require FULL IMMERSION IN WATER to put out, have their autopilot fail fatally, and are only cheaper than the competition because of government contracts. he's not good at aerospace: his rockets blow up, are worse than what NASA has been doing by every conceivable metric, and all of his "advances" in that field are focused around fulfilling contracts for the US military centered around sending arbitrary payloads anywhere on earth really fast (which they also can't do). you can't even fall back on the "well at least he knows how to run a business" argument because he's been running Tesla into the ground since buying it from the original inventors with stunts like getting rid of OSHA-mandated yellow safety markings because he doesn't like yellow, to the extent that literally any other human being on Earth would have been forced out by the board of directors years ago. even if you narrow your focus to any one field, Elon Musk has never been anything other than a fraud to anyone who cared to investigate

190 notes

·

View notes

Text

Inspired by nature: Leaftronics pave way for biodegradable electronics

A research team headed by Prof. Karl Leo at TUD Dresden University of Technology have developed an innovative, nature-inspired solution that could revolutionize the electronics industry: "Leaftronics." This innovative approach leverages the natural structure of leaves to create biodegradable electronic substrates with enhanced properties and offers a sustainable, efficient, and scalable solution to the global-waste problem. These findings have now been published in the journal Science Advances. Electronic devices, from toys to smartphones, consist of circuits. Specific substrates are used to manufacture these circuits. In commercial electronics, these are printed circuit boards (PCBs) made of glass fiber-reinforced epoxy resin.

Read more.

#Materials Science#Science#Biomaterials#Electronics#Plants#Dresden University of Technology#Biodegradable

14 notes

·

View notes

Text

Excerpt from this story from Anthropocene:

In a new spin on green electronics, researchers have made a biodegradable electronic circuit board from tree leaves. Such leaf-based electronics, or “leaftronics” as the team from Dresden University of Technology (TU Dresden) has dubbed it, could reduce millions of tons of waste that humans produce every year.

Today, the world produces over 50 million metric tons of electronic waste a year. That number that is slated to double by 2050. And printed circuit boards (PCBs) – the flat boards onto which all the circuit chips, wires and other components of an electronic gadget are soldered–-constitute a big share of this e-waste.

PCBs are typically made of fiberglass or a composite plastic. The material is difficult to recycle and is usually either dumped in landfills or burned to separate the valuable metals for reuse.

As detailed in the journal Science Advances, the team used the veiny, webbed skeleton of leaves to create their biodegradable substrates. This fine branched structure is made of the same lignocellulose compounds that give its toughness. Postdoctoral researcher Rakesh Nair and colleagues started by stripping away the cells of a magnolia leaf to leave behind the white veined skeleton. They dipped the scaffold into ethyl cellulose, a tough biodegradable polymer.

The resulting leaftronics substrate is smooth, flexible, transparent, and can handle high temperatures. In that sense it rivals plastic and glass, Nair says, but is biodegradable. The researchers could use a laser to cut the substrate, print circuits on it, as well as solder electronic components on top.

To degrade the substrate, the researchers placed it in an ultrasonic acid bath to remove the metals and circuit components. The boards began to degrade after about a month in compost.

“Up until now, substrates made of biodegradable polymers could not be used for electronic device or circuit fabrication, since they naturally do not handle elevated temperatures well,” Nair says. There are ways to improve the thermal and mechanical properties of biodegradable polymers. But, he says, they “often result in these polymers either no longer being biodegradable or requiring complex, high carbon-footprint, chemical processes,” he says.

Others have also made degradable PCBs using paper, silk, and mushroom skins. But the new method that relies on dipping a leaf scaffold in a biodegradable polymer is much simpler and should allow researchers to make specific biodegradable substrates with superior properties.

6 notes

·

View notes

Text

The Benefits of Ordering Printed Circuit Boards Online: A Guide to Choosing the Right PCB Manufacturer

In today's rapidly advancing technological landscape, printed circuit boards (PCBs) play a crucial role in various electronic devices, from smartphones to industrial machinery. As demand for these essential components grows, businesses and hobbyists alike seek efficient and cost-effective solutions for obtaining high-quality PCBs. One of the most convenient methods is to order printed circuit boards online. In this article, we will explore the advantages of ordering PCBs online and provide insights into selecting a reputable PCB manufacturer.

Why Order Printed Circuit Boards Online?

Ordering printed circuit boards online offers several benefits, making it an attractive option for many businesses and individuals:

Convenience: The ability to order PCBs from the comfort of your home or office eliminates the need for in-person visits to manufacturers or suppliers. This convenience saves time and effort, allowing you to focus on your projects or business operations.

Wide Range of Options: Online PCB manufacturers offer a variety of options in terms of materials, layer counts, finishes, and more. This flexibility allows you to customize your PCBs according to your specific requirements and budget.

Cost-Effectiveness: Many online PCB manufacturers provide competitive pricing, especially for bulk orders. Additionally, you can easily compare prices and services from different providers, ensuring you get the best value for your money.

Quick Turnaround Times: Online ordering often comes with expedited production and shipping options, allowing you to receive your PCBs faster. This is particularly beneficial for projects with tight deadlines or when you need quick prototypes.

Access to Advanced Technologies: Many online PCB manufacturers offer advanced technologies such as high-frequency PCBs, flexible PCBs, and more. This access to cutting-edge technology ensures your designs are compatible with the latest industry standards.

Choosing the Right PCB Manufacturer

Selecting the right PCB manufacturer is crucial to ensuring the quality and reliability of your printed circuit boards. Here are some key factors to consider when choosing a PCB manufacturer:

Experience and Reputation: Look for a manufacturer with a solid track record and positive reviews from previous customers. Experienced manufacturers are more likely to produce high-quality PCBs and provide reliable service.

Quality Assurance: Ensure the manufacturer follows strict quality control measures, such as ISO certification and regular testing. High-quality PCBs are essential for the proper functioning and longevity of your electronic devices.

Customer Support: Good customer support is vital, especially if you encounter issues during the ordering process or with the final product. Choose a manufacturer that offers responsive and helpful customer service.

Manufacturing Capabilities: Check the manufacturer’s capabilities, including the types of PCBs they can produce, their layer count capacity, and the materials they use. Make sure they can meet your specific design requirements.

Lead Times and Shipping: Consider the manufacturer’s production lead times and shipping options. Quick turnaround times are crucial for meeting project deadlines, so choose a manufacturer that can deliver within your required timeframe.

Pricing and Payment Terms: While cost is an important factor, it should not be the sole consideration. Ensure the manufacturer offers transparent pricing and flexible payment terms that suit your budget.

Conclusion

Ordering printed circuit boards online is a convenient and cost-effective way to obtain high-quality PCBs for your projects. By choosing a reputable PCB manufacturer, you can ensure the reliability and performance of your electronic devices. Whether you are a business looking to streamline your supply chain or a hobbyist working on a personal project, ordering PCBs online provides a seamless and efficient solution.

For those ready to place a printed circuit board order online, consider the factors outlined above to select the right PCB manufacturer for your needs. With the right partner, you can bring your electronic designs to life with precision and quality.

#printed circuit board#pcb manufacturer#pcb supplier#printed circuit board order online#pcb design & manufacturing services#pcb circuit manufacturer in ahmedabad#electronic circuit design company

2 notes

·

View notes

Text

PCB Manufacturing in Toronto: Expertise, Services, and Local Industry Insights

Discover PCB manufacturing in Toronto, a hub of innovation and quality in electronic manufacturing services. Learn about the specialized capabilities, technological advancements, and diverse offerings of PCB manufacturers Toronto. Explore how local expertise and cutting-edge facilities contribute to producing high-quality printed circuit boards for various industries and applications worldwide. For more details visit our website www.crimpcircuits.com

#pcb manufacturing toronto#printed circuit board design#metal clad pcb#printed circuits#rigid flex pcb#full turnkey pcb services#turnkey pcb services#pcb parts#eagle software#pcb designing#flexible pcb#pcb assembly#printed circuit board manufacturers#pcb manufacturers in canada#circuit board manufacturers in canada#pcb quote#pcb prototype services in canada

2 notes

·

View notes

Text

Understanding the Functionality of Samsung Refrigerator PCB Main Assembly

Samsung refrigerators have become essential appliances in modern households, offering innovative features and advanced technologies to ensure food preservation and convenience. The (Printed Circuit Board) PCB Main Assembly serves as the brain of the refrigerator, coordinating various functions and ensuring optimal performance.

Components of the Refrigerator PCB Main Assembly

The Refrigerator PCB Main Assembly consists of several essential components, each playing a crucial role in the refrigerator's operation.

Microcontroller: It is the central processing unit (CPU) and the computer performs programmed instructions to coordinate communication between the components.

Sensors: The ambient parameters (temperature, humidity, door status) supply critical information for regulation.

Relays: You control the flow of electricity to the compressor, fan motors, and defrost heater.

Capacitors: It will help you store the electrical energy and help to regulate voltage, and guarantee that the PCB is operating reliably.

Resistors: Protect sensitive components from harm by limiting the flow of electricity across certain circuits.

Diodes: Allow current to flow exclusively in one direction to avoid reverse polarity and safeguard components from damage.

Connectors: Facilitate electrical connections between the PCB and other refrigerator components to ensure seamless integration.

Working Principle PCB Main Assembly

The PCB Main Assembly operates on a set of programmed instructions that determine its behavior depending on sensor input and user command. The micro controller continuously monitors sensor input such as the reading of the temperature from the refrigerator compartment, and freezer. The microcontroller controls the transition of the compressor on, or off or the speed of the fan and also the defrost cycles based on the sensor data as to how to keep the temperature and humidity at the optimal level. In addition to the other refrigerator components, for example, display panel and user interface, the PCB Main Assembly provides feedback and enables users’’ interaction. The PCB Main Assembly incorporates safety features of overload protection and temperature sensors to protect the refrigerator from damage and to protect the user.

Communication Protocols

Data can be communicated to other components through microcontrollers by communication protocols like UART (Universal Asynchronous Receiver Transmitter), SPI (Serial Peripheral Interface), and I2C (Inter Integrated Circuit).

UART is used to transfer real-time data from a microcontroller to external devices like display panels and temperature sensors.

There is a power of communication SPI and I2C for the communication of integrated circuits associated with the PCB Main Assembly for efficient data transfer and synchronization between components.

Troubleshooting and Maintenance

Common issues with the Samsung Refrigerator PCB Main Assembly include sensor failures, relay malfunctions, and power supply issues, which can affect the refrigerator's performance.

To solve PCB Main Assembly problems, we can use diagnostic methods, like running self-tests and checking the error code.

The assembly can stay longer depending on the main, such as cleaning dust and debris from the PCB and securing appropriate ventilation.

The PCB Main Assembly is an important component of the Samsung refrigerator systems since it organizes several functions to contribute to the overall efficiency of the refrigerator and food preservation. Fore-knowledge of the PCB Main Assembly and the way it is constructed can assist users in likely managing problems in their fridges.

2 notes

·

View notes

Text

Explore the transformative impact of Advanced PCB Technology on modern electronics with A-Gas Electronic Materials. Dive into the evolution, significance, and future of PCBs in our latest article. Discover how PCBs are reshaping industries from consumer electronics to healthcare. Join the revolution and partner with A-Gas for cutting-edge electronic solutions. Read more now!

#Advanced PCB Technology#Modern Electronics#A-Gas Electronic Materials#Printed Circuit Boards#Electronic Components#PCB Evolution

0 notes

Text

Metal Surface Finish: Key Techniques for Protection and Aesthetic Enhancement

Introduction

A metal surface finish is essential for enhancing durability, performance, and appearance in metal components. Applied across industries such as aerospace, automotive, electronics, and medical equipment, surface finishing improves resistance against corrosion, wear, and environmental damage while achieving a polished or functional aesthetic.

Types of Metal Surface Finishes

1. Mechanical Finishing

Processes such as grinding, polishing, and sandblasting create a smoother, refined surface texture.

2. Chemical Treatment

Includes anodizing, passivation, and chemical etching, improving corrosion resistance and enhancing metal integrity.

3. Coatings & Plating

Techniques like electroplating, powder coating, and painting provide protective and decorative layers.

4. Thermal Treatments

Processes such as heat treatment and thermal spray coatings reinforce material strength and wear resistance.

5. Conversion Coatings

Chemical treatments such as phosphating and chromate conversion improve adhesion and surface protection.

Benefits of Metal Surface Finishing

Corrosion Resistance: Shields components from oxidation and environmental wear.

Enhanced Durability: Improves hardness and abrasion resistance for industrial applications.

Aesthetic Customization: Achieves polished, matte, or textured finishes for visual appeal.

Improved Electrical Conductivity: Essential for electronics and semiconductor components.

Eco-Friendly Protection: Reduces degradation caused by moisture, chemicals, and extreme temperatures.

Industries Utilizing Metal Surface Finishing

1. Automotive & Aerospace

Applied to vehicle bodies, engine components, aircraft structures, and precision-machined parts.

2. Electronics & Semiconductor Manufacturing

Used for PCB coatings, microchip protection, and conductive layers in circuits.

3. Medical & Healthcare Equipment

Essential for sterilization-resistant instruments, implants, and diagnostic devices.

4. Industrial Machinery & Tools

Enhances mechanical components, manufacturing tools, and high-stress industrial equipment.

Latest Innovations in Metal Surface Finishing

Nano-Coatings providing superior resistance and longer lifespan.

Environmentally-Friendly Finishing Solutions reducing hazardous waste.

Automated Surface Treatment Technologies improving efficiency and consistency.

Conclusion

Selecting the ideal metal surface finish optimizes functionality, durability, and aesthetic value across diverse applications. As finishing technologies evolve, industries continue to benefit from advanced solutions that improve product quality and longevity.

0 notes

Text

High-Quality PCB Assembly Services – Precision & Reliability | ESPCBA

ESPCBA provides quality PCB assembly with accuracy and dependability. Whether you are making prototypes or high-volume production, we provide premium circuit board assembly for many sectors. With cutting-edge technology, rigorous quality checking, and prompt turnaround, you can count on the highest performance for your electronics projects. We partner with you for cost-effective and effective PCB solutions. Obtain a quote now for your special PCB assembly requirement!

Read More : https://espcba.com/boosting-business-efficiency-with-advanced-memory-chips-what-you-need-to-know/

0 notes

Text

Ultrasonic Cleaners in Australia: The Smart Way to Achieve Deep Cleaning

In industries where precision and hygiene are non-negotiable, ultrasonic cleaners have become an essential part of the cleaning process. From healthcare to automotive, jewellery to dental practices, ultrasonic cleaning technology offers a fast, efficient, and non-damaging way to remove contaminants from delicate or hard-to-clean items. In Australia, the demand for ultrasonic cleaners has steadily increased as more professionals and businesses seek reliable, advanced cleaning solutions.

What Are Ultrasonic Cleaners?

Ultrasonic cleaners use high-frequency sound waves (usually between 20–40 kHz) to agitate a cleaning solution. This creates microscopic cavitation bubbles that gently lift dirt, oil, blood, polish residues, and other contaminants from surfaces—even those with tiny crevices and holes.

This method is highly effective for cleaning:

Surgical and dental instruments

Jewellery and watches

Car parts and engine components

Optical equipment and lenses

Electronic parts and circuit boards

Tattoo and piercing tools

Key Benefits of Ultrasonic Cleaning

Thorough Cleaning Ultrasonic waves reach into crevices and intricate areas that manual cleaning often misses, ensuring a more comprehensive clean.

Time Efficiency Most ultrasonic cleaners complete a cleaning cycle in just a few minutes, making them ideal for high-throughput environments.

Non-Damaging The process is gentle on delicate instruments and components, reducing the risk of scratches, warping, or corrosion.

Eco-Friendly Options Many Australian suppliers offer ultrasonic cleaning solutions that are biodegradable and safe for both the user and the environment.

Cost-Effective Over time, ultrasonic cleaners reduce labour costs and the need for repeated cleaning, saving businesses money.

Industries in Australia That Use Ultrasonic Cleaners

Healthcare and Medical: For sterilising surgical tools, dental instruments, and lab equipment.

Jewellery Retail and Repair: For restoring the shine and clarity of fine jewellery.

Automotive and Engineering: For cleaning fuel injectors, carburettors, and machined parts.

Tattoo and Beauty: For sterilising reusable equipment safely.

Electronics and Manufacturing: For cleaning PCBs and micro-components without damage.

0 notes

Text

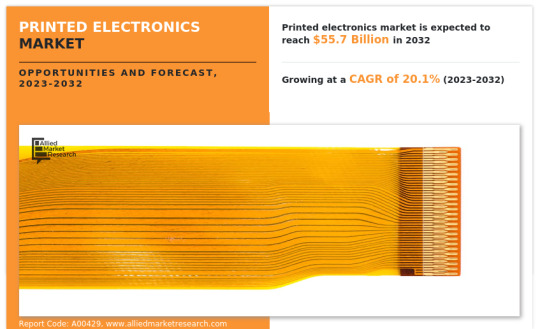

Printed Electronics Market to Witness Exponential Growth by 2032

Allied Market Research, titled, “Printed Electronics Market Size By Technology, Material, and Application" The printed electronics market size was valued at $9.4 billion in 2022, and is estimated to reach $55.7 billion by 2032, growing at a CAGR of 20.1% from 2023 to 2032.

The printed electronics market growth projections is expected to witness substantial growth during the forecast period. This is attributed due to the creation of electrical circuits using additive technologies Traditional electronics production relies on time-consuming and wasteful subtractive techniques such as etching and milling. Printed electronics, on the other hand, take a more environmentally friendly method, depositing electronic inks onto substrates precisely and controllably. This additive manufacturing technology not only reduces material waste, but it also opens new opportunities for building electronics on unusual surfaces. The printed electronics market demand out due to its low cost and scalability. Laser and screen-printing technologies, for instance, may be rapidly adapted for high-volume production, lowering manufacturing costs when compared to older methods.

The increase in demand for flexible electronics and printed circuit boards PCB is a primary driver of printed electronics adoption. Traditional manufacturing procedures are frequently stiff and pricey, whereas printed electronics provide a less expensive and more flexible alternative. Furthermore, rise in interest in Internet of Things (IoT) devices has increased the demand for low-cost, high-volume manufacturing processes, making printed electronics an appealing alternative. In addition, the surge in the demand for the environmental sustainability of printed electronics compared to typical production fuels the market growth as this printing method produces less waste, and the use of organic and biodegradable ingredients corresponds with the worldwide movement toward green technology. As consumers and organizations prioritize sustainability, printed electronics provide a tempting alternative. Furthermore, another significant benefit of printed electronics is its versatility. Printed electronics may be applied on flexible substrates, allowing the development of bendable and stretchy electrical devices. This adaptability offers new avenues for applications in wearable technology, medical devices, and other fields. These factors are anticipated to boost printed electronics market share.

However, despite its tremendous promise, printed electronics confront several limitations that prevent broad implementation. The reduced performance relative to standard silicon-based electronics acts as a barrier to market growth. In addition, the materials employed in printed electronics may not have the same level of conductivity or durability as conventional materials, restricting their usage in high-performance devices. The restricted complexity of circuits that may be created is one of the fundamental limitations of printed electronics. Printing technology may struggle to make elaborate patterns with the precision necessary for modern electrical components now. This constraint limits the usage of printed electronics in several high-tech applications. One noteworthy restriction is that printing procedures are slower and have a lower throughput when compared to traditional production methods. This can be a severe disadvantage for applications that need high-speed, high-volume manufacturing. The materials employed in printed electronics may have limited durability and stability, reducing gadget longevity. Furthermore, reaching the same level of miniaturization as traditional electronics is difficult, limiting use in industries where compact form factors are critical.

On the contrary, the printed electronics technology environment is rapidly changing. Advances in conductive inks, such as graphene and silver nanoparticles, lead to improved printed circuit conductivity and durability. Inkjet, screen printing, and gravure printing technologies are constantly advancing in terms of resolution and speed. Three-dimensional electrical structures are being created using 3D printing techniques. Furthermore, the development of hybrid technologies that combine printed and conventional electronics seeks to capitalize on the advantages of both techniques. These technical advances point to a bright future for printed electronics as researchers and engineers work to overcome present limits and push the boundaries of what is possible. In the future years, research activities are expected to focus on improving the performance and reliability of printed electronic components. This involves creating more efficient conductive inks, increasing the longevity of printed devices, and investigating novel applications in domains such as robotics and artificial intelligence.

The printed electronics market segmentation into material, technology, device and region. On the basis of material, the market is bifurcated into ink and substrate. By technology, the market is classified into inkjet printing, screen printing, gravure printing, and flexography. Depending on device, the market is classified into display, photovoltaic, lighting, RFID and others. Based on region, the market is analyzed across North America, Europe, Asia-Pacific, and Latin America.

The key players profiled in the printed electronics market analysis include Samsung Electronics Co. Ltd, LG Display Co. Ltd, Molex LLC, Agfa-Gevaert Group, Palo Alto Research Center Incorporated (PARC), DuPont de Nemours, Inc, Nissha Co. Ltd, BASF, Nova Centrix, and E Ink Holdings Inc.

The report offers a comprehensive analysis of the global printed electronics market trends by thoroughly studying different aspects of the market such as market segments, market statistics, market dynamics, regional market outlook, investment opportunities, and top players working toward the growth of the market. The report also highlights the current scenario and upcoming trends & developments that are contributing toward the growth of the market. Moreover, restraints and challenges that hold power to obstruct the market growth are also profiled in the report along with the Porter’s five forces analysis of the market to elucidate factors such as competitive landscape, bargaining power of buyers and suppliers, threats of new players, and emergence of substitutes in the market.

Key Findings of the Study

Based on material, the ink sub-segment emerged as the global leader in 2022 and the ink is anticipated to be the fastest growing during the forecast period.

Based on technology, the screen printing sub-segment emerged as the global leader in 2022 and the same segment is predicted to show the fastest growth in the upcoming years.

Based on the device, the display sub-segment emerged as the global leader in 2022 and the same segment is predicted to show the fastest growth in the upcoming years.

Based on region, Asia-Pacific registered the highest market share in 2022 and is projected to maintain its position during the forecast period.

0 notes

Text

Green Electronics Manufacturing Market Consumer Behavior and Industry Shifts to 2033

The global Green Electronics Manufacturing Market is experiencing significant growth, driven by increasing environmental concerns, stringent regulations, and technological advancements. This sector focuses on producing electronic products with minimal environmental impact through sustainable practices, energy-efficient processes, and the use of eco-friendly materials.

Regional Insights:

North America: Led the market in 2023 with a 36% share, driven by consumer demand for eco-friendly products and supportive government initiatives

Asia-Pacific: Emerging as the fastest-growing region, with countries like India, Taiwan, and Vietnam attracting investments in sustainable manufacturing due to lower operational costs and skilled labor

🔧 Key Drivers of Market Growth

Environmental Awareness and Consumer Demand: Growing concerns about climate change and e-waste are prompting consumers to prefer eco-friendly electronics, pushing manufacturers to adopt sustainable practices

Regulatory Pressures: Policies like the EU's RoHS and WEEE directives, along with China's "Green Fence" policy, are compelling manufacturers to reduce hazardous substances and improve recycling efforts

Integration of Renewable Energy: Companies like TSMC are committing to 100% renewable energy sourcing, aligning with global efforts to achieve net-zero emissions

Advancements in Sustainable Technologies: Innovations in biodegradable polymers, paper-based PCBs, and additive manufacturing are reducing energy consumption and material waste in electronics production

Download a Free Sample Report: - https://tinyurl.com/y9cme7em

⚠️ Challenges Facing the Industry

High Initial Investment: Transitioning to green manufacturing involves substantial costs for new equipment, facility upgrades, and employee training

Material Scarcity and Cost: Sustainable materials like bioplastics are often more expensive and less readily available than traditional alternatives

Supply Chain Complexities: Sourcing certified sustainable materials and ensuring compliance with environmental regulations across regions can be challenging

🔮 Future Outlook

The green electronics manufacturing market is poised for continued growth, driven by:

Technological Innovations: Ongoing advancements in sustainable materials and manufacturing processes will enhance efficiency and reduce costs

Policy Support: Government incentives and regulations will continue to promote sustainable practices in electronics manufacturing

Consumer Demand: Increasing consumer preference for eco-friendly products will encourage manufacturers to adopt green practices

📰 Industry Developments

ASML's Refurbishment Center: ASML's initiative to extend the life of older lithography machines exemplifies the circular economy trend in the tech industry

Foxconn's Entry into EV Market: Foxconn's investment in electric vehicle manufacturing reflects the convergence of electronics and automotive industries in sustainable practices

India's E-Waste Policy: India's new e-waste policy aims to formalize the recycling sector, though it has faced opposition from manufacturers due to increased compliance costs

Read Full Report: - https://www.uniprismmarketresearch.com/verticals/semiconductor-electronics/green-electronics-manufacturing

0 notes

Text

The Role of Automation in Transforming Industrial and Marine Operations

Maximizing Efficiency with Industrial Automation Components

In the modern era, industrial automation has revolutionized the way industries operate, particularly in the marine and ship parts sector. Businesses are now empowered to achieve efficiency, precision, and scalability without constant human oversight. Automation components, such as PLC cards, PCB parts, and drives, play a pivotal role in ensuring seamless operations and reducing production errors. Companies like Dropship Automation are at the forefront, delivering high-quality automation solutions that cater to diverse industrial needs.

The Significance of Automation in Industrial Processes

Automation has transformed industries by:

Reducing human error: Streamlining operations for improved accuracy.

Enhancing productivity: Increasing the efficiency of production systems.

Ensuring cost-effectiveness: Minimizing labor costs while maintaining quality.

In sectors like manufacturing and marine engineering, components such as programmable logic controllers (PLCs) and variable-frequency drives (VFDs) are indispensable. Staying updated with the latest automation technologies is crucial for businesses to maintain a competitive edge.

Key Components of Industrial Automation

1. PLC Cards: The Brain of Automated Systems

Programmable Logic Controllers (PLCs) are central to automated operations. They monitor and control industrial processes, ensuring that systems run smoothly. PLC cards allow for:

Customization of processes for specific industrial needs.

Versatility in applications, from manufacturing plants to marine navigation systems.

Industries working with advanced PLC technology can optimize their operations for better performance and reliability.

2. PCB Components: The Backbone of Electronic Systems

Printed Circuit Boards (PCBs) are essential in connecting electronic components within automation systems. In marine and industrial applications, they:

Enable efficient communication between devices.

Provide a compact and reliable framework for electronic systems.

High-quality PCB components ensure durability and operational efficiency, critical for systems in harsh marine environments.

3. Drives: Precision in Motion Control

Variable-Frequency Drives (VFDs) are vital for controlling machinery speed and torque. Their advantages include:

Enhanced energy efficiency.

Reduced wear and tear on equipment.

For companies like Dropship Automation, offering advanced drive solutions is a priority to meet industry standards for precision and sustainability.

Automation in Marine and Ship Parts

In the maritime industry, automation components are indispensable for:

Engine control systems: Ensuring efficient propulsion and energy use.

Navigation and safety systems: Integrating automation for improved performance and security.

By adopting cutting-edge automation technologies, marine operations can achieve enhanced productivity and safety, making businesses more competitive.

Safety Systems in Automation: Fire Alarms and Heat Detectors

Safety is paramount in industrial and marine environments. Automation-enhanced systems like fire alarms and heat detectors offer:

Early detection of potential hazards.

Integration with broader automation systems for rapid response.

Incorporating these systems into operations not only safeguards assets but also protects lives, ensuring compliance with safety regulations.

Human-Machine Interfaces (HMIs): Bridging Operators and Systems

Human-Machine Interfaces (HMIs) are essential for user-friendly interaction with automated systems. They:

Simplify complex operations through intuitive interfaces.

Enhance monitoring and control of industrial processes.

Advanced HMI solutions enable businesses to manage operations effectively, promoting transparency and control.

Why Choose Dropship Automation?

At Dropship Automation, we specialize in delivering top-notch automation components and solutions. From PLC cards to marine automation tools, our expertise ensures:

High-quality, genuine parts from over 1,000 leading brands.

Competitive pricing for cost-effective solutions.

Reliable support for diverse industrial applications.

Partnering with us can transform your operations, whether you’re in manufacturing, marine engineering, or other sectors.

Staying Ahead in Automation

In a rapidly evolving industry, staying updated on automation trends is critical. Here’s how professionals can stay informed:

Attend industry conferences to explore innovations.

Enroll in online courses for in-depth learning.

Join forums and communities for real-world insights.

By leveraging expertise and the latest tools, businesses can achieve unprecedented efficiency and success.

Take Your Operations to the Next Level

Explore the extensive range of automation solutions available at Dropship Automation. From industrial automation parts to marine components, we provide everything you need to simplify processes and boost productivity. Visit our website today and discover how we can help you stay ahead in the automation game.

1 note

·

View note