#Bobbin Winding Machine

Explore tagged Tumblr posts

Text

Emerging Materials in Coil Winding: How They Are Shaping Equipment Design and Performance

The coil winding industry is experiencing a transformative phase, thanks to emerging materials that enhance the design and performance of coil winding equipment. As the demand for smaller, more efficient, and high-performance electrical components grows, manufacturers are pushing the boundaries of material science to meet industry requirements. In this blog, we delve into how these innovative materials are reshaping coil winding machines, their applications, and the impact on industry stakeholders.

Revolutionizing Coil Winding Machines with Advanced Materials

1. The Role of Advanced Materials in Modern Coil Winding

Emerging materials are addressing challenges such as thermal management, durability, and weight reduction in coil winding machines. These advancements have led to:

Improved Thermal Conductivity: Materials like polyimide films and advanced ceramics dissipate heat effectively, ensuring longer operational lifespans.

Enhanced Magnetic Properties: New ferromagnetic alloys reduce energy loss, boosting the efficiency of electrical devices.

Lightweight Designs: Carbon fiber composites are replacing traditional metals, allowing for lighter yet robust coil winders.

2. Key Materials Driving Innovation

Several materials have emerged as game-changers in the coil winding industry:

High-Performance Polymers: These materials offer excellent insulation and thermal resistance, making them ideal for high-frequency applications.

Nanomaterials: Carbon nanotubes and graphene are being integrated into conductors, offering superior conductivity and strength.

Amorphous Metals: Their unique properties reduce core losses, which is particularly beneficial for high-efficiency transformers.

Practical Applications in Winding Equipment

1. Enhanced Coil Winders

Modern coil winders now incorporate materials that minimize wear and tear, reducing maintenance costs. For example:

Composite Bearings: These provide smooth operation and withstand high rotational speeds.

Heat-Resistant Insulation: Essential for manufacturing coils used in high-temperature environments such as aerospace and automotive industries.

2. Specialized Applications

Emerging materials are also influencing niche applications:

Miniature Coils: Used in medical devices and sensors, where precision and reliability are critical.

High-Power Coils: For renewable energy projects, such as wind turbines and electric vehicle motors, requiring enhanced durability and efficiency.

Impact on Equipment Design and Manufacturing

1. Efficiency and Cost-Effectiveness

By adopting advanced materials, manufacturers can produce equipment that delivers higher efficiency while minimizing costs. Innovations like self-lubricating materials reduce the need for manual interventions, streamlining operations.

2. Sustainability

Sustainable materials are gaining traction as environmental regulations tighten. Recyclable composites and biodegradable insulation materials align with green manufacturing goals, offering a dual benefit of performance and eco-friendliness.

Spotlight on Industry Leaders

Companies like ACME Electronics, a renowned Coil Winding Machine Manufacturer Supplier, are at the forefront of adopting these materials. Their focus on integrating cutting-edge materials into their equipment has set benchmarks for performance and innovation.

Challenges and Future Trends

While the potential of emerging materials is undeniable, challenges such as cost, scalability, and compatibility with existing manufacturing processes remain. Looking ahead, the industry can expect:

Increased Use of AI and IoT: To optimize material usage and enhance machine performance.

Further Miniaturization: Driving demand for materials with superior properties in compact designs.

Collaborative Innovations: Partnerships between material scientists and equipment manufacturers to accelerate breakthroughs.

Conclusion

Emerging materials are not just enhancing the capabilities of coil winding machines; they are redefining the industry’s future. By improving efficiency, sustainability, and performance, these materials promise to address evolving demands across diverse sectors. As manufacturers and engineers explore these advancements, what new frontiers will material science unlock for winding equipment design?

#coil winding machine#winding machine#coil winder#programmable winding machine#cnc winding machine#winding equipment#transformer winding machine#bobbinwindingmachine#bobbin winding machine

0 notes

Text

Understanding Linear Winding Machines: The Key to Efficient Coil Production

In the world of coil winding, precision and efficiency are paramount. Linear winding machines have emerged as essential tools for manufacturers seeking to optimize their production processes. With their ability to create coils with consistent quality and minimal waste, these machines are transforming the landscape of industries ranging from electronics to automotive. In this article, we will explore the features and benefits of linear winding machines, spotlighting ACME Electronics as a leading manufacturer and supplier in this domain.

What is a Linear Winding Machine?

A linear winding machine is designed to produce coils by winding wire around a core in a straight, linear manner. Unlike traditional winding machines that may use circular or complex movements, linear winding machines employ a straightforward approach that maximizes efficiency. This type of machine is particularly suited for applications where precision is critical, such as in the production of transformers, inductors, and various electronic components.

Key Features of Linear Winding Machines

Precision Control: Linear winding machines come equipped with advanced control systems that ensure accurate winding. Users can set specific parameters for tension, speed, and layer count, which leads to improved product consistency.

Automation Capabilities: Many modern linear winding machines feature automation technology that reduces the need for manual intervention. This not only speeds up the production process but also minimizes the likelihood of human error.

Versatility: These machines can accommodate various wire sizes and types, making them suitable for a wide range of applications. Whether it’s small, intricate coils or larger industrial applications, linear winding machines can adapt to meet specific needs.

Space Efficiency: The linear design of these machines often requires less floor space compared to traditional winding setups. This makes them an ideal choice for manufacturers looking to optimize their workspace.

Benefits of Using Linear Winding Machines

Enhanced Production Speed: The automation and precision of linear winding machines significantly increase production speeds, allowing manufacturers to meet higher demand without compromising quality.

Cost Efficiency: By minimizing material waste and reducing labor costs through automation, businesses can achieve greater cost efficiency. This is especially important in competitive markets where margins are tight.

Improved Product Quality: Consistency in coil production translates to better quality products. Linear winding machines reduce the variability often associated with manual winding processes, leading to higher customer satisfaction.

ACME Electronics: A Leader in Linear Winding Solutions

As a renowned manufacturer and supplier of linear winding machines, ACME Electronics stands out for its commitment to innovation and quality. With a focus on providing cutting-edge technology, ACME’s winding machines are designed to meet the evolving needs of the industry. Their extensive range of products caters to various applications, ensuring that customers receive tailored solutions for their winding requirements.

Conclusion

In summary, linear winding machines are revolutionizing coil production with their precision, efficiency, and versatility. As industries continue to demand higher quality and faster production times, these machines offer a viable solution. With ACME Electronics leading the charge as a trusted manufacturer and supplier, businesses can confidently invest in technology that will enhance their production capabilities. Are you ready to elevate your coil production with the latest in linear winding technology?

#coil winding machine#coil winding equipment#coil winder#coil winding machinery#winding machine#automatic winding machine#motor coil winding machine#bobbin winding machine

0 notes

Text

0 notes

Text

Nah cause the parts in newer machines are prolly made in factories.

Then they put them together in factories elsewhere.

I doubt any one person is present for the entire assembly of sewing machines now.

Kinda like clocks.

Really quite sad.

Bringing it down.

But the classics are always more fuckable.

Look at them curves.

Look at that crank.

Made of dreams and by rough hands and mechanical tools.

Newer ones are made of greed and by assembly lines and robotic machines.

Which is only sexy if you're into transhumanism and sin.

Which...come to think of it...well...

Anyway.

Do you think the people who design modern sewing machines in plastic cases ever feel insignificant because of it? knowing that they're making machines with the lifespan of a dog when they could (if they'd been born a few generations earlier) be making machines with the lifespan of a Galapagos tortoise?

#Don't have sex with sewing machines though#Did I lose the thread? Only if it was sexy#Sewing machines are pricks all of them#Clocks are way more geared toward smexiness#Clocks really wind me up#Sewing machines only leave me bobbin and theadbare#Gimme an 8 day Gilbert any day.#Unseamly post

29K notes

·

View notes

Text

oh my god there is such a learning curve on new sewing machines. i did not know it mattered how the thread was wound on the spool

#some of them are zigzag-y and some arent???#trying to wind bobbins and Struggling because this is my first time using a horizontal spool pin lmao#magpiemending#i got a new sewing machine and im very excited but also Oh My God#4 tries at winding the bobbin. and i still havent got the colour i wanted wound#got a different one at least though

1 note

·

View note

Text

I feel like an engineer or smth

#singesewing#had to use pliers to remove the machine hand crank bc it was too tight it took five ever#then tested it to lock and unlock the needle so ill be able to wind the bobbin#listen to me its like ik what stuff means and things do 💅 <- doesnt#i am running out of time to make this blouse lmao

1 note

·

View note

Text

youtube

#Youtube#how to wind a bobbin#sewing machine#sewing#sewing instruction#how to#sew#cute#handmade#sewing machine tutorial

1 note

·

View note

Text

i half-made 2 gloves, i think that counts

can i sew a glove in half an hour. lets find out

#break for t shot & then we'll see. i may just need to go to bed. alas#also i did steam a shirt during part of the 30 mins. so im doing pretty good here#finishing them is going to take at least half an hour more tho b/c i have to get the sewing machine out#AND wind a bobbin r.i.p#personal#also: i think pattern weights is a great use for old awards and participation trophies#if theyre heavy enough and will sit nicely#not necessarily true of all of them#but i got some at a rummage sale for 25 cents each that ive been using & theyre great

4 notes

·

View notes

Text

My grandma's kenmore sewing machine from 1971 performs better than my new babylock in every way but at least the babylock has... *checks notes* a drop-in bobbin that jams up half of the time and an automatic thread cutter that works properly only when the winds are blowing eastward 🙄

#sewing machines are kinda like cars if there's more fiddly little bullshit that can break it will it's just a matter of time#yes i do clean my babylock it's just overpriced unreliable plastic trash and a lot of these newer machines are#if you're planning on buying a sewing machine go vintage; the metal ones made in the 70's and before are absolute tanks#thank you for coming to my vent post

131 notes

·

View notes

Text

The sewing machine advice post.

Here's an introduction to sewing machines, from someone who has gone from "making costumes with a busted old machine I bought at a thrift store" to "Teaching how to care for your sewing machine as a living."

Read the manual. Can't find it? Don't have it? There are lots of PDFs online. The manual is going to tell you important things like which way to insert the bobbin and how to thread the machine. It will also tell you what kind of bobbin to use.

Get some more bobbins. The machine needs a bobbin that is wound with the same thread you plan to sew with. There are situations where you can use two different threads, but while you're learning, use the same kind of thread above and below. Follow the manual's instructions to properly wind a bobbin, and only wind one thread at a time on each bobbin.

Change the needle. I have a whole other helpful post about what kind.

When you put thread on the machine, follow each step and make sure the Presser Foot is in the "up" position before you start.

Right before you thread the needle, pull the thread to make sure it moves freely and isn't caught anywhere. Then, lower the presser foot, and pull again. It should be very tight. (If it is not tight with the foot down, raise the foot and re-thread the machine from the beginning.)

Find and get to know the Take-Up Lever. It goes up and down faster than the needle, and kinda looks like a dinosaur head. The thread has to be settled in the eye of the take up lever or your machine won't make a good stitch. It will go "stitch stitch stitch clunk bang stop." If the thread isn't in the take up lever, re-thread the machine.

You're going to spend a lot of time re-threading your machine. Gird your loins, and be prepared to do this.

Make sure you insert the bobbin correctly. Follow the manual. Once it is set in the bobbin case, the thread should pull tightly, not freely.

Your control of the fabric happens before the needle goes into it; your hands should be in front of the needle, not behind it. Don't pull the fabric from the back. Just guide the fabric from the front; don't push it or overdrive. Try using one finger on each hand to just keep the fabric straight while the machine feeds the fabric through.

If the fabric won't feed through properly, take the metal needle plate (AKA Throat plate) off and clean between the pointy bits that stick up through the needle plate. Those are the feed dogs and lint collects between them under the plate. Keep that area clear of lint and dust.

If the machine still won't feed properly, take it to a service technician. There may be a feed timing problem.

THE HAT TRICK: If you have a problem with the machine, do these three things:

Remove the bobbin, check it over. If the thread isn't wound on it properly, or if it's cracked or bent or rusty, it might be bad. Replace it if necessary.

Change the needle. Make sure the needle is inserted in the correct direction and that it is indeed inserted completely. (Choose the correct needle, too.)

Re-Thread the machine from the beginning. Make sure to hit each step, make sure the presser foot is up, and make sure to lower the presser foot at the end to check the tension.

This is really a beginner's list. There's a lot more, but I wanted to start simply. Please feel free to share it around, or add your opinions.

**My credentials: I've been teaching sewing, serving, and machine embroidery professionally for 20+ years. Been sewing for over 40 years. I'm also a trained sewing machine technician.

26 notes

·

View notes

Text

i borrowed my mother's machine to sew a nice piece of silk and that thing threads its own needle? winds its own bobbins? auto-lock stitch AND it cuts the thread for you?? why are we talking about ai

12 notes

·

View notes

Text

Coil Winding Machines for Small Businesses: Are They Worth the Investment?

For small businesses and startups in industries such as electronics, automotive, and energy, investing in manufacturing equipment like a coil winding machine can be a game-changer. However, for companies with limited capital, such an investment can also seem daunting. In this article, we will explore whether coil winding machines are a smart investment for smaller companies, analyzing the benefits, potential return on investment (ROI), and key considerations.

As small businesses look to scale up their operations, the decision to invest in equipment becomes critical. The winding machine plays a central role in industries requiring precision-manufactured coils for products such as transformers, electric motors, and sensors. But are these machines worth the expense for a small business? Will the benefits justify the initial cost? To answer these questions, we need to analyze the advantages of owning a coil winding machine, the potential for cost savings, and the overall impact on business efficiency.

1. Key Benefits of Coil Winding Machines for Small Businesses

Coil winding machines bring several immediate and long-term benefits to small businesses, from increased production control to enhanced product quality.

A. Enhanced Production Control and Flexibility

Outsourcing coil winding can limit flexibility and slow down production, especially when working with external suppliers. By investing in a winding machine, small businesses can take control of their manufacturing process, allowing them to adjust specifications quickly, meet customer demands faster, and implement custom designs.

Example: A small electronics startup specializing in custom transformers can rapidly adapt production to meet new orders with an in-house coil winding machine, avoiding lead times typically associated with outsourcing.

B. Improved Product Quality

A coil winding machine ensures a higher level of precision and consistency, crucial for maintaining product quality. For smaller businesses looking to establish a strong reputation in competitive industries, producing high-quality coils is non-negotiable.

Example: Companies that manufacture high-performance inductors or solenoids for medical devices can ensure tight tolerances and error-free windings with their own machine, reducing the risk of defects and product failures.

C. Cost Savings Over Time

While the initial investment in a coil winding machine might seem substantial, it can lead to significant long-term savings. By eliminating the need for third-party suppliers and minimizing transportation costs, businesses can reduce operating expenses. Additionally, in-house winding offers the ability to cut costs on small-scale or custom projects, where outsourcing may be more expensive.

Example: A small electric vehicle (EV) startup that produces its own motor windings in-house avoids costly outsourcing fees, particularly for low-volume production runs.

2. Analyzing ROI: How Long Until You See Returns?

When considering whether to invest in a coil winding machine, ROI is one of the most critical factors. The decision-making process involves analyzing how long it will take for the savings and benefits to outweigh the initial investment cost.

A. Initial Costs vs. Ongoing Savings

The cost of a coil winding machine can vary greatly depending on the complexity, type (manual, semi-automatic, or fully automatic), and the production requirements. For a small business, a high-quality semi-automatic machine may offer the best balance between cost and functionality. While initial costs may be high, the savings on outsourced winding services and the added efficiency of in-house production often lead to a favorable ROI over time.

Example: A small electronics manufacturer purchases a semi-automatic winding machine for $25,000. If they were previously outsourcing production for $2 per coil and producing 20,000 coils annually, the cost savings would amount to $40,000 per year. With this calculation, the business would see a return on its investment within the first year.

B. Long-Term Profitability

Apart from cost savings, the ability to meet deadlines more effectively, respond to custom orders, and enhance product quality can have a positive effect on profitability. In industries where quality and precision are valued, owning a coil winding machine can differentiate a small business from its competitors.

Example: A custom electronics business that can offer faster lead times and higher precision windings compared to competitors can gain an edge in securing new contracts, boosting revenue.

3. Key Considerations Before Investing

Before making the decision to invest in a winding machine, small businesses need to consider a range of factors to ensure the machine fits their specific needs and capabilities.

A. Production Volume and Frequency

The most important factor to consider is whether the production volume justifies the purchase. For businesses with low-volume requirements, outsourcing may still be more cost-effective. However, for those with consistent or growing demand, in-house production becomes more attractive.

Tip: If your production volume fluctuates, consider machines that offer flexibility in handling different coil sizes and specifications.

B. Technical Expertise and Training

Operating a coil winding machine requires technical expertise, particularly for semi-automatic or fully automatic systems. Small businesses may need to invest in training their employees to operate and maintain the machine effectively.

Tip: Ensure you have the right training resources or service contracts in place to avoid operational delays due to machine downtime or technical issues.

C. Future Growth and Scalability

If your business plans to expand its operations or diversify its product line, investing in a versatile coil winding machine that can grow with your business is essential. Machines with modular features or upgradability options can save costs in the long term by allowing for scalability without requiring additional investment in new equipment.

Tip: Look for machines that offer software upgrades or modular components to future-proof your investment.

Conclusion: Is a Coil Winding Machine Right for Your Business?

For small businesses looking to gain greater control over their production processes, improve product quality, and realize long-term savings, investing in a coil winding machine can be a smart move. However, the decision hinges on factors like production volume, technical expertise, and future scalability. While the initial investment may seem steep, the potential for increased efficiency and higher profitability makes it an attractive option for many small businesses.

The question is: Does your business have the volume, growth potential, and expertise to make the most of this investment?

#coil winding machine#winding machine#coil winder#programmable winding machine#cnc winding machine#winding equipment#toroidal winding machine#transformer winding machine#bobbin winding machine#bobbinwindingmachine#Business

1 note

·

View note

Text

Automatic Winding Machines: Revolutionizing Coil Production

In the fast-paced world of manufacturing, efficiency and precision are critical. Automatic winding machines have emerged as vital tools for producing high-quality coils with minimal human intervention. These machines streamline the winding process, ensuring consistent results and reducing production time. In this article, we will explore the functionalities, advantages, and applications of automatic winding machines, highlighting ACME Mechatronics as a leading manufacturer and supplier in this field.

Understanding Automatic Winding Machines

1. What is an Automatic Winding Machine?

An automatic winding machine is a device designed to wind wire around a core or form automatically. These machines are equipped with advanced technology that allows for programmable settings and automated processes, resulting in precise and uniform coils. They are used in various applications, including transformers, inductors, and motors, where consistent coil quality is essential.

2. Key Features of Automatic Winding Machines

Automatic winding machines come with a range of features that enhance their functionality and usability:

Programmable Control Systems: These machines allow operators to input specific winding parameters, including speed, tension, and coil patterns, ensuring accuracy and flexibility.

Automatic Tension Control: Maintaining consistent tension throughout the winding process is crucial. Automatic winding machines are designed to adjust tension dynamically, preventing wire breaks and ensuring uniformity.

Data Monitoring and Feedback: Many automatic winding machines include data logging and monitoring capabilities, providing real-time feedback on production metrics and enabling operators to optimize processes.

3. Benefits of Using Automatic Winding Machines

Investing in automatic winding machines can bring numerous benefits to manufacturers:

Increased Efficiency: Automation significantly speeds up the winding process, allowing for higher production volumes without compromising quality.

Enhanced Precision: With programmable controls and automatic tension management, these machines minimize human error and produce more consistent coils.

Cost Savings: By reducing labor costs and increasing output, manufacturers can achieve better profit margins and reinvest savings into other areas of their operations.

ACME Mechatronics: Your Reliable Manufacturer and Supplier

ACME Mechatronics is a trusted manufacturer and supplier of automatic winding machines, dedicated to providing high-quality solutions that meet the diverse needs of the industry.

Why Choose ACME Mechatronics?

Expertise in Coil Winding Technology: With extensive experience in coil production, ACME Mechatronics understands the intricacies of automatic winding and offers tailored solutions for various applications.

Cutting-Edge Technology: Their automatic winding machines incorporate the latest advancements to enhance performance and reliability.

Comprehensive Support: ACME provides ongoing support and training, ensuring customers maximize the efficiency and longevity of their equipment.

Conclusion

Automatic winding machines are transforming the coil manufacturing landscape, offering unparalleled efficiency and precision. By partnering with ACME Mechatronics, manufacturers can access advanced winding technology and expert support to elevate their production capabilities. Are you ready to embrace automation and enhance your coil production process with an automatic winding machine?

#coil winding machine#coil winding equipment#coil winder#coil winding machinery#winding machine#automatic winding machine#bobbin winding machine#winding machines#motor coil winding machine#toroidal winding machines

0 notes

Text

Galaxy Print Knee Patches

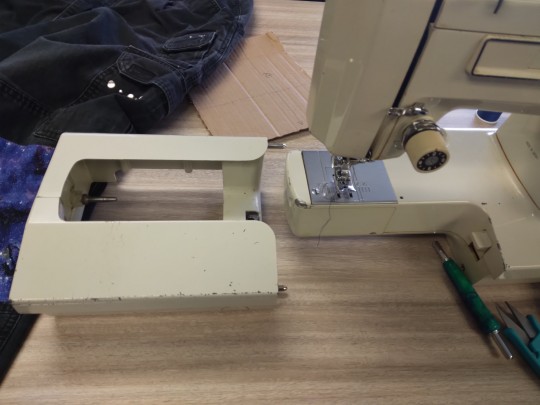

I've just spent two hours locked in mortal combat with my machine, but I emerge victorious with awesomer pants!

Yep, we're working on the same tac pants as always. I have two other pairs of solid black pants, so I can confidently decorate these to match my primarily black-and-blue wardrobe.

Step one was cutting two 9-by-9 patches. (I thought about doing cool hexagons for about 30 seconds and then couldn't decide which way to orient them, so no.) I did my usual trick of putting cardboard in the leg of the pants. Then I folded the edges under slightly and pinned down all around. (Retrospect: Since I didn't iron those folds, I should've used more pins. They kept trying to unfold as I sewed.)

Step two was finding this bobbin of variegated purple thread from my grandma. Rather than hand-winding it onto a spool, I just put it on the machine. Seemed to work!

Step three was realizing this was gonna be difficult. The knee parts of the pants are already two layers thick, and I'm adding another folded layer on top of them. Plus, wrestling the heavy pants under the machine. Eliza has a lovely feature where the bottom comes apart to help you get into sleeves and such, but cramming this fabric in was still a pain.

The above photos are called "Why I'm not a quilter." Also, they show how much trouble Eliza was having with the fabric. The stitch lengths are uneven, I kept hitting pins, and every time I stopped and started, she pulled to one side or the other. On the very first seam, in the first photo, I tried to turn around and do a second row of topstitching, but it came up so uneven that I quit immediately and unpicked it.

Also, she's had this worsening problem where, when I finish a seam, I can't pull the fabric away without turning the top tension back to 0, or the thread will just break. This necessitates remembering to put the tension back to 4. Remember that.

Of course, it wouldn't be a proper sewing project if I didn't sew the pant leg shut on the final corner. So I pulled it off the machine, unpicked it, and went back over it again.

And forgot to reset the tension to 4! Just look at that mess on the back.

I clipped the loops and just sewed it all down again in eagerness to be done. It's a tad noticeable, but I don't care. It's done!

And here's the end result!

Would it be neater by hand? Probably! Is Eliza due for a spa day at the repair shop? Yes! And am I thrilled with the end result?

ABSOLUTELY!

#galaxy print#knee patches#patches#solarpunk#diy#sewing#cj sews#beginner sewing#it's not waste until you waste it#use it up wear it out make it do or do without

69 notes

·

View notes

Text

For all of my crafting folks out there.... can we talk about how ridiculous some of these craft stores are with pricing? I went to a new craft store and I looked at thread for my sewing machine because I haven't figured out how my bobbins work yet and the pre-wound bobbins were $6.50 each ($8.50 if you bring your own and let an attendant wind it for you). So I pass that and I look at the fabric because they had a pretty one in the window display. They were each $22 A YARD and you had to have 1 yard minimum to even check out! I asked the lady if they did half yards because I really just wanted something to add length to a few clothes so dropping $22 on just one fabric print would have been silly, but they didnt allow that either unless it was in one of their pre-cut bundles (at that point I was terrified of checking the price) I've never left a store so quickly in my life-

8 notes

·

View notes

Text

Reading aita posts while trying to wake up makes me (once again) yell about how if your partner/spouse/domestic partner/fuck buddy/platonic-roommate-for-life doesn't respect your hobbies, they aren't meant for you. This is very much a gender neutral statement because I've seen it happen in many forms.

Look, they don't need to join in with your hobbies. They don't even need to like them. They're your hobbies, not theirs. But if they try to stop you from doing them, either with arbitrary rules or by destroying things involved with them, get rid of them (not the hobbies obviously, the significant other).

My mom used to sew and crochet. My stepfather hated it and kept making the space he "allowed" her to do it in farther away from "his space". Eventually she was regulated to a tiny corner of the garage and only allowed to do things if he was asleep (even if it involved fixing or hemming his clothes like he asked). Even when the weather was below freezing. And heaven help her if he woke up while she was making things.

Someone my mom knew loved to cosplay. He had spent a year working on an exact replica of a Qui-Gon costume and only needed the boots (to buy them would be about $300 at the time when the movie came out). Both he and his wife made a ton on money and each had very large "fun money" accounts that did not affect household bills or repairs or savings. She told him absolutely not and threatened to burn his costume if he bought them. He never did. She divorced him two years later to move in with her affair partner.

One of teachers my mom worked with, who I used to make enrichments for, bragged about how she threw out all of her husband's star wars toys. Originals still in their packages, prequels figures from midnight releases, special limited exclusives. All in the dump while he was on a business trip. He had then carefully stored on shelves on one side of the garage, out of the way, and came back to nothing. She came crying to me one day while I was helping set up things in the classroom about how he was divorcing her and she might wind up homeless over some stupid toys. I called her a bitch because she was.

My grandpa used to threaten to turn my grandma's sewing machines into jigsaws because he hated that she had something that made her happy. She's why I still hide my bobbins even though my partner loves that I make things (and helps me pick out colors if I'm indecisive).

On a more positive note, someone in a collector's group I'm in has art prints by an artist their spouse hates. They compromised with the prints stay in their home office or at their in person office because their partner didn't want them to get rid of them. That's a good compromise to me.

My partner loves dnd and video games. I like them too, but not to the same degree because they can make my anxiety much worse. But I watching them play while I crochet and will help them if they get stuck on a puzzle (sometimes they'll ask for an outside perspective). I help them set up for in person games and listen and provide feedback when they need to bounce ideas of someone. And I do play with them on better days because it's fun. They love to watch me crochet and call it witchcraft and calculate how many miles of yarn I use in projects.

There's a big difference with rule such as "let's make sure our hobbies are allowing us time to just be together and to talk and enjoy life" and "you can only do this when I approve it". People need to do things that make them happy. That could be writing, that could be a fiber craft, that could be video games, or even cooking random things. If it's not hurting someone, why try to stop it? Everyone needs an outlet. And if your partner or even you really can't stand something that someone does in their free time, maybe it's time to admit that this isn't the person for you.

#birdy has weird thoughts#i know I've talked about this before but reading something this morning triggered the rant again#have respect for your partners but also have respect for yourself#my cats are very mad that i wrote this instead of feeding them lol

10 notes

·

View notes