#CAD automation

Explore tagged Tumblr posts

Text

🚀 Unlock the Future of Design with ProtoTech's CAD Automation Tools! 🛠️

🚀 Discover the Future of CAD with ProtoTech! 🚀

Struggling with repetitive design tasks? ProtoTech's 𝐂𝐀𝐃 𝐀𝐮𝐭𝐨𝐦𝐚𝐭𝐢𝐨𝐧 𝐓𝐨𝐨𝐥𝐬 are here to revolutionize your workflow! Discover how our innovative solutions can streamline your design process, enhance productivity, and elevate your projects to new heights. 💡

✨ Key Features:

𝐀𝐮𝐭𝐨𝐦𝐚𝐭𝐞𝐝 𝐂𝐀𝐃 𝐂𝐮𝐬𝐭𝐨𝐦𝐢𝐳𝐚𝐭𝐢𝐨𝐧: Tailor your designs effortlessly with our advanced automation capabilities.

𝐒𝐞��𝐦𝐥𝐞𝐬𝐬 𝐈𝐧𝐭𝐞𝐠𝐫𝐚𝐭𝐢𝐨𝐧: Easily integrate with popular CAD software for a smooth, efficient workflow.

𝐀𝐝𝐯𝐚𝐧𝐜𝐞𝐝 𝐒𝐜𝐫𝐢𝐩𝐭𝐢𝐧𝐠: Utilize powerful scripting tools to automate complex tasks.

𝐀𝐮𝐭𝐨𝐦𝐚𝐭𝐞𝐝 𝐏𝐫𝐨𝐜𝐞𝐬𝐬𝐞𝐬: Save time with automated repetitive tasks, allowing you to focus on creativity.

𝐄𝐫𝐫𝐨𝐫 𝐑𝐞𝐝𝐮𝐜𝐭𝐢𝐨𝐧: Minimize manual errors and ensure design accuracy.

🔍 Dive into our latest blog post to learn more about how ProtoTech is transforming the CAD landscape with cutting-edge technology.

🔗 Read the full article here: https://prototechsolutions.com/blog/key-features-and-capabilities-of-prototechs-cad-automation-tools/

#Automation#CAD#CAD Design#Design Automation#CAD Workflow#Design Innovation#CAD Automation#ProtoTech Tools#Efficiency In Design#Engineering#ProtoTech Solutions

0 notes

Text

HOW CAD AUTOMATION TOOLS STREAMLINE WORKFLOW & BOOSTS PRODUCTIVITY

Discover the transformative impact of CAD Automation in simplifying intricate design tasks and enhancing the overall quality of your final product.

Read our latest article to explore how CAD Automation tools are revolutionizing workflows, reducing errors, and optimizing productivity.

0 notes

Text

@kodedgeekthings eyo you mentioned wanting a dpxdc prompt for Howard, Batman’s mechanic!

Harold misses fixing toys for kids and in his off hours has taken up the habit of answering questions on forums about machining, electrical, engineering, mechanics, and mechanical design that are often frequented by students.

One day, he comes across a request by a college student who is trying to assemble his own car out of scrap he bought from a local wrecking yard.

Ghostly_Boy states that he has previous experience in machining and can make replacements for broken or too-damaged parts if need be, but he doesn’t know where to start and what specific requirements he needs to reach to ensure it’s street legal.

Harold willing to help, he answers a few of Ghostly Boy’s clarifying questions:

- Great questions!

It’s good to note that if you’re not careful, fixing or making your own car from parts can be a moneysink and can cost you more than a brand new vehicle. - That being said, your first major step to ensuring you can drive the car is to get the title of the body/frame of the car you plan to build. It’ll have the VIN on a plate welded to the frame usually near the lower edge of the windshield wipers on the drivers side. It’s how the DMV identifies vehicles for licensing.

- Generally, you’ll at first get a “wreck out” title that shows the vehicle is listed as a total loss, but if you can assemble the parts for the car with that frame, the DMV can check if it’s properly running and road worthy & license for you to use it on public roads if you’ve done the proper paperwork.

- Once that is done, it’s largely a case of getting the right parts and assembling them. Depending on how much you have to repair, you could be taking on a task that could give a challenge to even a seasoned mechanic. There may be additional paperwork depending on what exactly you need to repair, like the breaks, lights, steering, etc.

- If you want to build the car entirely from scratch, chassis and all, that’s an entirely different story with a much more complicated list of requirements to make it street legal, so getting a frame from a junkyard is a great first step!

- Make sure to keep all bills of sale, junkyard receipts, invoices and manufacturers’ certificates on any major parts you used in building the vehicle to prove its road worthy to the DMV when it’s complete!

Harold doesn’t always answer first but over time he’s found the adventures of this kid amusing and keeps up with it.

Ghostly_Boy keeps the forum updated with his progress:

The kid spontaneously deciding to scrap the wiring system and make his own in a span of 3 days, leaving experienced mechanics on the forum practically screaming at the kid for his updates showing him using random wires he salvaged and pigtailing them together to get the length of wire he needed.

Mixing not only multiple types of wires but ones that didn’t have the protection needed for auto use. DIY-ing his own relay and fuses he didn’t have and connecting the wrong grounds and switches. And planning on leaving the wires unwrapped and loose.

Leaving Ghost to promptly redo the wiring, correctly this time, within 78 hours.

Making a repair of a massive rusted hole on the passenger side by the bumper and the front tire via cutting 1/2in past the rust, grinding it pretty and clean, tac & seam welding the vintage aluminum housing material of a toaster to cover the hole to the response of Harold and many others in the forum just going “… I guess that would work?”

Harold and many others telling the kid that this “ectoplasm” material wasn’t cleared through the EPA’s Clear Air Act and could be illegal to drive with it as it’s fuel source unless he got the emissions tested & the center of gravity of the car adjusted to have the center of gravity a gas car has, it wouldn’t pass Federal Motor Vehicle Safety Standards. Nor would the previously untested on material make it easy or quick to get an Emissions testing certificate. Best to just stick with gas.

Removing what he thought was a “skid plate” that turned out to be another rusted out section on the frame on the bottom of his car and repairing it with steel he salvaged from an old medical table he had laying around. (To the multiple slightly confused commenters asking how Ghost had a spare medical table, he replied, “eh, my folks visit every so often and they’ve been giving me things they’re clearing out of the house so they can move closer to my older sister. I just so happened to get the ye olde medical table. They’re an odd couple of folks but that’s why I love them.”)

People just crying at the kid to go to rockauto.com and just buy the damn parts he needs for his car. (A good resource btw)

The kid kept cutting corners to save cash but through the badgering of Harold and many others that he actually would have to spend money to make this car be safe to drive in, he finally got it completed.

Ghost’s post of him leaving DMV waving the updated title to the car in its envelope in the air, titled, “THE DMV FINALLY SAID IT WASN’T A FIRE HAZARD! ONLY TOOK 2 YEARS! THANKS EVERYONE!” Got the most amount of responses he’d ever had with congratulations from lurkers and previous commenters.

Over the course of those two years, Danny learned how to draw his own wiring diagrams, properly solder and weld, and learning to actually plan out his projects so he got it right at least the fifth time instead of the 20th. Not bad for a kid that went straight from graduating high school with a 1.5GPA to construction jobs.

But after finally getting the car approved, Ghostly_Boy returns to the forum with a new problem. Lamenting that his parents keep coming over and “modifying” his car to no longer make it street legal.

At this point, about half of the answers to the submission think it’s either a joke project taken very, very seriously with a good chunk of money behind it, or a kid with parents that have narrowly avoided falling completely down the mad scientist rogue rabbit hole.

After all, what sort of parent would think that the DMV would approve to “anti-ghost missiles” being attached to the outer body of the car? Either way, the submissions always had video attached showing a demonstration, proving that Ghost wasn’t just completely yanking their chain. And a good amount of money would have to be sunken in to not only pay for the fines Ghostly continued to get from the additions to his car, but to actually manufacture and make a unique working product for each plea for help request.

Harold is not only taking notes on some of these defense measures but also decides to bring up the boy to Alfred. Intrigued, they together keep an eye on Ghostly_Boy. Bruce may be their employer, but they can handle a case or two on their own.

- I wanted Danny to try to make smth for himself now that he doesn’t have access to his parent’s lab anymore but he also doesn’t have access to ectoplasm so he’s fairly unfamiliar how to wire things Not for ectoplasmic standards.

Also I wanted to make a prompt where Danny had a good relationship with his parents & went into a fairly realistic job after high school with his fairly bad GPA so he’s saving up for a technical school via construction jobs as he doesn’t like the idea of working fast food for understandable reasons.

#dpxdc#bones writes#i have about 3 dozen ideas for dpxdc ideas to do with Howard#I’m going to be a manufacturing engineer.#i got so many ideas for this dude teaching one of the batkids or a visitor to the batcave about how cad programs work#& why he’s using x material for its purpose#instead of y material#like this dude could just be any of my automation profs

341 notes

·

View notes

Text

Key Features of Dispensing automation solution

High Precision : Accurate, repeatable dispensing with precise control over material flow and placement.

Versatility : Suitable for a wide range of materials, including adhesives, sealants, lubricants, coatings, and more.

Increased Efficiency : Reduced cycle time and material waste, ensuring cost-effective production.

Customization : Tailored solutions designed to meet the unique needs of your production environment and application.

#3dcad#3dcadindia#dispensing automation#dispensing#Key Features of Dispensing automation solution#3d cad modeling

0 notes

Text

nCircle Tech is transforming CAD design automation in India.

It is more important than ever to find effective and creative design solutions in the quickly changing field of technology. nCircle Tech, a trailblazing Indian business at the forefront of CAD design automation, is spearheading this change. nCircle Tech is revolutionizing the design process by utilizing state-of-the-art technology and a thorough understanding of the industry to make design processes faster, more precise, and highly efficient.

In fields like engineering, manufacturing, and architecture, computer-aided design, or CAD, has long been a mainstay. It enables experts to produce intricate 2D and 3D models of their projects. But the conventional method of CAD design can be laborious and prone to human error, particularly for intricate projects that demand painstaking attention to detail. In this situation, nCircle Tech can help by providing cutting-edge CAD automation solutions that greatly expedite the design process.

With the automation tools from nCircle Tech, designers may spend more time on creativity and innovation and less time on tedious activities. Project completion is accelerated and accuracy is improved with nCircle Tech's automation of repetitive tasks including draughting, modeling, and rendering. This shortens the product's time to market and improves the design's overall quality.

Furthermore, nCircle Tech's solutions are very adaptable and can be tailored to meet the unique requirements of various sectors. nCircle Tech offers specialized solutions that are customized to meet the particular needs of each project, whether it is automating the design of intricate mechanical components or optimizing architectural draughting.

Businesses like nCircle Tech are essential in propelling India's continued rise to prominence as a global leader in innovation and technology. nCircle Tech is revolutionizing CAD design automation to help organizations remain competitive in an increasingly digital environment while establishing new benchmarks for productivity and design quality.

0 notes

Text

Our professional design experts streamline your resources more effectively with shifting workloads, thus improving, and optimizing results. As a trusted design extension for global businesses in various industries, you can count on us offshore for all your CAD needs.

Get in touch with us, for more information Visit: https://www.designautomations.com/ or Call us on 📞 +91 9574 024 279

1 note

·

View note

Text

Revolutionizing Manufacturing: Discovering the Game-Changing Advantages of CAD Automation for Companies

Introduction

In the dynamic landscape of modern manufacturing, the integration of advanced technologies is reshaping the way companies operate. One such transformative technology is Computer-Aided Design (CAD) automation. CAD automation refers to the use of computer software and algorithms to streamline and optimize the design and drafting processes in manufacturing. In this blog post, we will delve into the myriad benefits that CAD automation brings to manufacturing companies, from enhanced productivity to improved product quality.

1. Increased Efficiency in Design Iterations

Traditionally, manual drafting processes in design can be time-consuming and prone to errors. CAD automation revolutionizes this aspect by providing a platform for rapid prototyping and design iterations. Engineers and designers can make quick changes to a digital model, test variations, and explore multiple design options effortlessly. This iterative process not only accelerates the design phase but also allows for the exploration of more innovative and efficient solutions.

2. Time and Cost Savings

Time is money, and CAD automation is a potent tool for saving both. The efficiency gained through automated design processes significantly reduces the time required to bring a product from conception to production. Moreover, as design iterations become quicker and more accurate, the overall development cycle is shortened. This time compression results in substantial cost savings, making manufacturing processes more cost-effective and competitive.

3. Precision and Accuracy

Manual drafting is inherently susceptible to human errors, which can lead to costly mistakes during the manufacturing phase. CAD automation, on the other hand, ensures a high level of precision and accuracy in design. Measurements and specifications are consistently maintained, minimizing the risk of errors in the final product. This not only improves product quality but also reduces the likelihood of defects and the need for rework.

4. Seamless Collaboration and Communication

CAD automation facilitates seamless collaboration among multidisciplinary teams involved in the product development process. Designers, engineers, and other stakeholders can work on the same digital model in real time, fostering effective communication and coordination. This level of collaboration ensures that everyone is on the same page throughout the design process, reducing misunderstandings and enhancing overall project efficiency.

5. Enhanced Product Lifecycle Management (PLM)

CAD automation integrates seamlessly with Product Lifecycle Management (PLM) systems, providing a comprehensive solution for managing the entire lifecycle of a product. From initial design and prototyping to manufacturing, distribution, and maintenance, CAD automation ensures that all aspects of the product's lifecycle are interconnected and efficiently managed. This holistic approach improves traceability, reduces time-to-market, and optimizes resource utilization.

6. Adaptability to Customization

In today's manufacturing landscape, customization is becoming increasingly important to meet diverse customer demands. CAD automation empowers manufacturing companies to easily customize products without significant disruptions to the production process. Whether it's adapting a design for a specific client requirement or making quick adjustments to respond to market trends, CAD automation enables manufacturers to be agile and responsive.

Conclusion

The benefits of CAD automation for manufacturing companies are profound and multifaceted. From accelerated design iterations and significant time and cost savings to enhanced precision and adaptability, the integration of CAD automation technology is a game-changer. As manufacturing continues to evolve, companies that embrace these advancements position themselves at the forefront of innovation, setting the stage for a more efficient, competitive, and sustainable future.

#CAD Automation#Manufacturing Design#Machine Design#Manufacturing Companies#CAD Services#CAD Design Automation#CAD Design

0 notes

Text

6 BEST PRACTICES OF CAD AUTOMATION GIVEN BY INDUSTRY EXPERTS

Discover top CAD automation tips from industry experts.

Optimize workflows with these 6 best practices for efficient and precise design processes.

0 notes

Text

Benefits of Metal Industry Automation

Increased Production Speed: Automated systems allow you to run production lines continuously with minimal downtime, helping you meet tight production schedules.

High Precision and Consistency: Automation ensures that each part is produced to the highest standards of quality, reducing defects and variations.

Cost Reduction: By automating labor-intensive processes, reducing waste, and optimizing resource use, automation helps to lower production costs.

Improved Safety: Automation allows for easy scaling and adjustments to production lines, enabling quick adaptation to changing market demands or new product variations.

Sustainability: Automated systems help ensure production meets regulatory standards and provides traceability for safety, quality control, and reporting.

#3dcad#3dcadindia#general industries#3d cad modeling#metal industry#automation in metal industry#benefits of metal industry automation

0 notes

Text

Designing and manufacturing custom doors is a complex task due to the bespoke design needs of customers. Technological advancements, such as design automation using visual CAD configurators, have accelerated design development time for custom doors. These configurators simplify door design customization and generate accurate manufacturing drawings faster. Read the full article.

0 notes

Text

Randee Butrus, the Mechanical Designer & CAD Specialist

Randee Butrus is a highly skilled mechanical designer and CAD expert, with years of experience in the field. With a keen eye for detail and a passion for innovative solutions, she has built a reputation as one of the top designers in the industry. Randee's expertise extends across a wide range of projects, from small-scale components to complex industrial machinery, and she is known for her ability to work closely with clients to bring their ideas to life.

0 notes

Text

HP SitePrint Launches in Australia to Boost Construction Industry Productivity

Today HP Inc announced the availability of HP SitePrint in Australia, following a successful general availability in five regions with a proven track record across North America and Europe. HP SitePrint is a robotic solution that prints the most complex construction site layouts with pinpoint accuracy, empowering construction pros with up to ten times the productivity of traditional chalk-line…

View On WordPress

#advanced robotics#Australia launch#autonomous robots#building layout#CAD integration#cloud tools#construction accuracy#construction challenges#construction efficiency#construction growth#construction innovation#construction management#construction sector#construction sites#construction software#construction solutions#construction technology#digital construction#digital layout tools#erasable inks#global availability#global construction#high productivity#HP Inc#HP robotics#HP SitePrint#interchangeable inks#layout automation#layout precision#obstacle avoidance

1 note

·

View note

Text

nCircle Tech: Revolutionizing CAD Design Automation for Efficiency

Efficiency is critical in the fast-paced fields of engineering and design. The speed and accuracy with which CAD models may be created, edited, and managed has a big impact on project schedules and overall productivity. Now enter nCircle Tech, a leader in CAD design automation, providing cutting-edge solutions that are revolutionizing the workflow of designers and engineers.

CAD Design Automation's Necessity

Draughting, detailing, and updating models are examples of repetitive operations that are frequently involved in traditional CAD design processes. These manual procedures may take a long time and are prone to mistakes, which can cause delays and higher expenses. It is not only convenient, but also essential to automate these processes in a competitive business where speed and accuracy are critical.

nCircle Tech: Setting the Standard

By streamlining these tedious operations, nCircle Tech's sophisticated CAD design automation technologies free up engineers and designers to work on more intricate and imaginative project components. nCircle Tech's solutions automate normal procedures to minimize errors, improve accuracy, and save a substantial amount of time compared to manual tasks.

The seamless integration of nCircle Tech's CAD design automation with pre-existing CAD software is one of its most notable advantages. Whether you use SolidWorks, AutoCAD, or another well-known platform, nCircle Tech's solutions are made to improve your workflow without necessitating a whole rebuild of your present setup.

CAD Design Automation's advantages

There are many advantages to using nCircle Tech's CAD design automation. Projects can be finished more quickly, for less money, and with fewer mistakes. Increased productivity from efficiency improvements enables businesses to take on more projects and raise their bottom line.

Conclusion

For maximum productivity, nCircle Tech is automating CAD design in a field where every second matters. nCircle Tech enables engineers and designers to work smarter, not harder, by automating repetitive activities and improving accuracy. With nCircle Tech, you may experience the CAD design of the future and advance your projects.

0 notes

Text

How I ditched streaming services and learned to love Linux: A step-by-step guide to building your very own personal media streaming server (V2.0: REVISED AND EXPANDED EDITION)

This is a revised, corrected and expanded version of my tutorial on setting up a personal media server that previously appeared on my old blog (donjuan-auxenfers). I expect that that post is still making the rounds (hopefully with my addendum on modifying group share permissions in Ubuntu to circumvent 0x8007003B "Unexpected Network Error" messages in Windows 10/11 when transferring files) but I have no way of checking. Anyway this new revised version of the tutorial corrects one or two small errors I discovered when rereading what I wrote, adds links to all products mentioned and is just more polished generally. I also expanded it a bit, pointing more adventurous users toward programs such as Sonarr/Radarr/Lidarr and Overseerr which can be used for automating user requests and media collection.

So then, what is this tutorial? This is a tutorial on how to build and set up your own personal media server using Ubuntu as an operating system and Plex (or Jellyfin) to not only manage your media, but to also stream that media to your devices both at home and abroad anywhere in the world where you have an internet connection. Its intent is to show you how building a personal media server and stuffing it full of films, TV, and music that you acquired through indiscriminate and voracious media piracy various legal methods will free you to completely ditch paid streaming services. No more will you have to pay for Disney+, Netflix, HBOMAX, Hulu, Amazon Prime, Peacock, CBS All Access, Paramount+, Crave or any other streaming service that is not named Criterion Channel. Instead whenever you want to watch your favourite films and television shows, you’ll have your own personal service that only features things that you want to see, with files that you have control over. And for music fans out there, both Jellyfin and Plex support music streaming, meaning you can even ditch music streaming services. Goodbye Spotify, Youtube Music, Tidal and Apple Music, welcome back unreasonably large MP3 (or FLAC) collections.

On the hardware front, I’m going to offer a few options catered towards different budgets and media library sizes. The cost of getting a media server up and running using this guide will cost you anywhere from $450 CAD/$325 USD at the low end to $1500 CAD/$1100 USD at the high end (it could go higher). My server was priced closer to the higher figure, but I went and got a lot more storage than most people need. If that seems like a little much, consider for a moment, do you have a roommate, a close friend, or a family member who would be willing to chip in a few bucks towards your little project provided they get access? Well that's how I funded my server. It might also be worth thinking about the cost over time, i.e. how much you spend yearly on subscriptions vs. a one time cost of setting up a server. Additionally there's just the joy of being able to scream "fuck you" at all those show cancelling, library deleting, hedge fund vampire CEOs who run the studios through denying them your money. Drive a stake through David Zaslav's heart.

On the software side I will walk you step-by-step through installing Ubuntu as your server's operating system, configuring your storage as a RAIDz array with ZFS, sharing your zpool to Windows with Samba, running a remote connection between your server and your Windows PC, and then a little about started with Plex/Jellyfin. Every terminal command you will need to input will be provided, and I even share a custom #bash script that will make used vs. available drive space on your server display correctly in Windows.

If you have a different preferred flavour of Linux (Arch, Manjaro, Redhat, Fedora, Mint, OpenSUSE, CentOS, Slackware etc. et. al.) and are aching to tell me off for being basic and using Ubuntu, this tutorial is not for you. The sort of person with a preferred Linux distro is the sort of person who can do this sort of thing in their sleep. Also I don't care. This tutorial is intended for the average home computer user. This is also why we’re not using a more exotic home server solution like running everything through Docker Containers and managing it through a dashboard like Homarr or Heimdall. While such solutions are fantastic and can be very easy to maintain once you have it all set up, wrapping your brain around Docker is a whole thing in and of itself. If you do follow this tutorial and had fun putting everything together, then I would encourage you to return in a year’s time, do your research and set up everything with Docker Containers.

Lastly, this is a tutorial aimed at Windows users. Although I was a daily user of OS X for many years (roughly 2008-2023) and I've dabbled quite a bit with various Linux distributions (mostly Ubuntu and Manjaro), my primary OS these days is Windows 11. Many things in this tutorial will still be applicable to Mac users, but others (e.g. setting up shares) you will have to look up for yourself. I doubt it would be difficult to do so.

Nothing in this tutorial will require feats of computing expertise. All you will need is a basic computer literacy (i.e. an understanding of what a filesystem and directory are, and a degree of comfort in the settings menu) and a willingness to learn a thing or two. While this guide may look overwhelming at first glance, it is only because I want to be as thorough as possible. I want you to understand exactly what it is you're doing, I don't want you to just blindly follow steps. If you half-way know what you’re doing, you will be much better prepared if you ever need to troubleshoot.

Honestly, once you have all the hardware ready it shouldn't take more than an afternoon or two to get everything up and running.

(This tutorial is just shy of seven thousand words long so the rest is under the cut.)

Step One: Choosing Your Hardware

Linux is a light weight operating system, depending on the distribution there's close to no bloat. There are recent distributions available at this very moment that will run perfectly fine on a fourteen year old i3 with 4GB of RAM. Moreover, running Plex or Jellyfin isn’t resource intensive in 90% of use cases. All this is to say, we don’t require an expensive or powerful computer. This means that there are several options available: 1) use an old computer you already have sitting around but aren't using 2) buy a used workstation from eBay, or what I believe to be the best option, 3) order an N100 Mini-PC from AliExpress or Amazon.

Note: If you already have an old PC sitting around that you’ve decided to use, fantastic, move on to the next step.

When weighing your options, keep a few things in mind: the number of people you expect to be streaming simultaneously at any one time, the resolution and bitrate of your media library (4k video takes a lot more processing power than 1080p) and most importantly, how many of those clients are going to be transcoding at any one time. Transcoding is what happens when the playback device does not natively support direct playback of the source file. This can happen for a number of reasons, such as the playback device's native resolution being lower than the file's internal resolution, or because the source file was encoded in a video codec unsupported by the playback device.

Ideally we want any transcoding to be performed by hardware. This means we should be looking for a computer with an Intel processor with Quick Sync. Quick Sync is a dedicated core on the CPU die designed specifically for video encoding and decoding. This specialized hardware makes for highly efficient transcoding both in terms of processing overhead and power draw. Without these Quick Sync cores, transcoding must be brute forced through software. This takes up much more of a CPU’s processing power and requires much more energy. But not all Quick Sync cores are created equal and you need to keep this in mind if you've decided either to use an old computer or to shop for a used workstation on eBay

Any Intel processor from second generation Core (Sandy Bridge circa 2011) onward has Quick Sync cores. It's not until 6th gen (Skylake), however, that the cores support the H.265 HEVC codec. Intel’s 10th gen (Comet Lake) processors introduce support for 10bit HEVC and HDR tone mapping. And the recent 12th gen (Alder Lake) processors brought with them hardware AV1 decoding. As an example, while an 8th gen (Kaby Lake) i5-8500 will be able to hardware transcode a H.265 encoded file, it will fall back to software transcoding if given a 10bit H.265 file. If you’ve decided to use that old PC or to look on eBay for an old Dell Optiplex keep this in mind.

Note 1: The price of old workstations varies wildly and fluctuates frequently. If you get lucky and go shopping shortly after a workplace has liquidated a large number of their workstations you can find deals for as low as $100 on a barebones system, but generally an i5-8500 workstation with 16gb RAM will cost you somewhere in the area of $260 CAD/$200 USD.

Note 2: The AMD equivalent to Quick Sync is called Video Core Next, and while it's fine, it's not as efficient and not as mature a technology. It was only introduced with the first generation Ryzen CPUs and it only got decent with their newest CPUs, we want something cheap.

Alternatively you could forgo having to keep track of what generation of CPU is equipped with Quick Sync cores that feature support for which codecs, and just buy an N100 mini-PC. For around the same price or less of a used workstation you can pick up a mini-PC with an Intel N100 processor. The N100 is a four-core processor based on the 12th gen Alder Lake architecture and comes equipped with the latest revision of the Quick Sync cores. These little processors offer astounding hardware transcoding capabilities for their size and power draw. Otherwise they perform equivalent to an i5-6500, which isn't a terrible CPU. A friend of mine uses an N100 machine as a dedicated retro emulation gaming system and it does everything up to 6th generation consoles just fine. The N100 is also a remarkably efficient chip, it sips power. In fact, the difference between running one of these and an old workstation could work out to hundreds of dollars a year in energy bills depending on where you live.

You can find these Mini-PCs all over Amazon or for a little cheaper on AliExpress. They range in price from $170 CAD/$125 USD for a no name N100 with 8GB RAM to $280 CAD/$200 USD for a Beelink S12 Pro with 16GB RAM. The brand doesn't really matter, they're all coming from the same three factories in Shenzen, go for whichever one fits your budget or has features you want. 8GB RAM should be enough, Linux is lightweight and Plex only calls for 2GB RAM. 16GB RAM might result in a slightly snappier experience, especially with ZFS. A 256GB SSD is more than enough for what we need as a boot drive, but going for a bigger drive might allow you to get away with things like creating preview thumbnails for Plex, but it’s up to you and your budget.

The Mini-PC I wound up buying was a Firebat AK2 Plus with 8GB RAM and a 256GB SSD. It looks like this:

Note: Be forewarned that if you decide to order a Mini-PC from AliExpress, note the type of power adapter it ships with. The mini-PC I bought came with an EU power adapter and I had to supply my own North American power supply. Thankfully this is a minor issue as barrel plug 30W/12V/2.5A power adapters are easy to find and can be had for $10.

Step Two: Choosing Your Storage

Storage is the most important part of our build. It is also the most expensive. Thankfully it’s also the most easily upgrade-able down the line.

For people with a smaller media collection (4TB to 8TB), a more limited budget, or who will only ever have two simultaneous streams running, I would say that the most economical course of action would be to buy a USB 3.0 8TB external HDD. Something like this one from Western Digital or this one from Seagate. One of these external drives will cost you in the area of $200 CAD/$140 USD. Down the line you could add a second external drive or replace it with a multi-drive RAIDz set up such as detailed below.

If a single external drive the path for you, move on to step three.

For people with larger media libraries (12TB+), who prefer media in 4k, or care who about data redundancy, the answer is a RAID array featuring multiple HDDs in an enclosure.

Note: If you are using an old PC or used workstatiom as your server and have the room for at least three 3.5" drives, and as many open SATA ports on your mother board you won't need an enclosure, just install the drives into the case. If your old computer is a laptop or doesn’t have room for more internal drives, then I would suggest an enclosure.

The minimum number of drives needed to run a RAIDz array is three, and seeing as RAIDz is what we will be using, you should be looking for an enclosure with three to five bays. I think that four disks makes for a good compromise for a home server. Regardless of whether you go for a three, four, or five bay enclosure, do be aware that in a RAIDz array the space equivalent of one of the drives will be dedicated to parity at a ratio expressed by the equation 1 − 1/n i.e. in a four bay enclosure equipped with four 12TB drives, if we configured our drives in a RAIDz1 array we would be left with a total of 36TB of usable space (48TB raw size). The reason for why we might sacrifice storage space in such a manner will be explained in the next section.

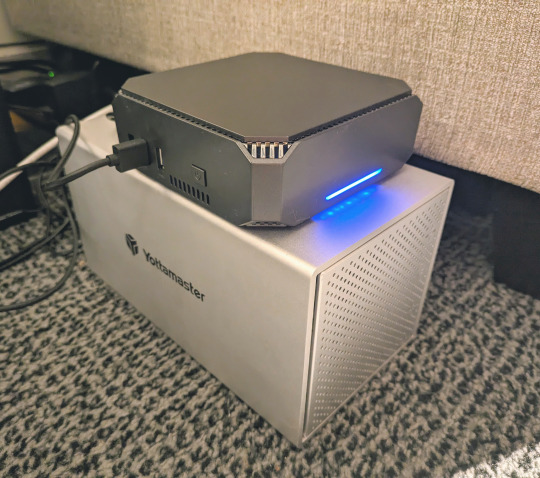

A four bay enclosure will cost somewhere in the area of $200 CDN/$140 USD. You don't need anything fancy, we don't need anything with hardware RAID controls (RAIDz is done entirely in software) or even USB-C. An enclosure with USB 3.0 will perform perfectly fine. Don’t worry too much about USB speed bottlenecks. A mechanical HDD will be limited by the speed of its mechanism long before before it will be limited by the speed of a USB connection. I've seen decent looking enclosures from TerraMaster, Yottamaster, Mediasonic and Sabrent.

When it comes to selecting the drives, as of this writing, the best value (dollar per gigabyte) are those in the range of 12TB to 20TB. I settled on 12TB drives myself. If 12TB to 20TB drives are out of your budget, go with what you can afford, or look into refurbished drives. I'm not sold on the idea of refurbished drives but many people swear by them.

When shopping for harddrives, search for drives designed specifically for NAS use. Drives designed for NAS use typically have better vibration dampening and are designed to be active 24/7. They will also often make use of CMR (conventional magnetic recording) as opposed to SMR (shingled magnetic recording). This nets them a sizable read/write performance bump over typical desktop drives. Seagate Ironwolf and Toshiba NAS are both well regarded brands when it comes to NAS drives. I would avoid Western Digital Red drives at this time. WD Reds were a go to recommendation up until earlier this year when it was revealed that they feature firmware that will throw up false SMART warnings telling you to replace the drive at the three year mark quite often when there is nothing at all wrong with that drive. It will likely even be good for another six, seven, or more years.

Step Three: Installing Linux

For this step you will need a USB thumbdrive of at least 6GB in capacity, an .ISO of Ubuntu, and a way to make that thumbdrive bootable media.

First download a copy of Ubuntu desktop (for best performance we could download the Server release, but for new Linux users I would recommend against the server release. The server release is strictly command line interface only, and having a GUI is very helpful for most people. Not many people are wholly comfortable doing everything through the command line, I'm certainly not one of them, and I grew up with DOS 6.0. 22.04.3 Jammy Jellyfish is the current Long Term Service release, this is the one to get.

Download the .ISO and then download and install balenaEtcher on your Windows PC. BalenaEtcher is an easy to use program for creating bootable media, you simply insert your thumbdrive, select the .ISO you just downloaded, and it will create a bootable installation media for you.

Once you've made a bootable media and you've got your Mini-PC (or you old PC/used workstation) in front of you, hook it directly into your router with an ethernet cable, and then plug in the HDD enclosure, a monitor, a mouse and a keyboard. Now turn that sucker on and hit whatever key gets you into the BIOS (typically ESC, DEL or F2). If you’re using a Mini-PC check to make sure that the P1 and P2 power limits are set correctly, my N100's P1 limit was set at 10W, a full 20W under the chip's power limit. Also make sure that the RAM is running at the advertised speed. My Mini-PC’s RAM was set at 2333Mhz out of the box when it should have been 3200Mhz. Once you’ve done that, key over to the boot order and place the USB drive first in the boot order. Then save the BIOS settings and restart.

After you restart you’ll be greeted by Ubuntu's installation screen. Installing Ubuntu is really straight forward, select the "minimal" installation option, as we won't need anything on this computer except for a browser (Ubuntu comes preinstalled with Firefox) and Plex Media Server/Jellyfin Media Server. Also remember to delete and reformat that Windows partition! We don't need it.

Step Four: Installing ZFS and Setting Up the RAIDz Array

Note: If you opted for just a single external HDD skip this step and move onto setting up a Samba share.

Once Ubuntu is installed it's time to configure our storage by installing ZFS to build our RAIDz array. ZFS is a "next-gen" file system that is both massively flexible and massively complex. It's capable of snapshot backup, self healing error correction, ZFS pools can be configured with drives operating in a supplemental manner alongside the storage vdev (e.g. fast cache, dedicated secondary intent log, hot swap spares etc.). It's also a file system very amenable to fine tuning. Block and sector size are adjustable to use case and you're afforded the option of different methods of inline compression. If you'd like a very detailed overview and explanation of its various features and tips on tuning a ZFS array check out these articles from Ars Technica. For now we're going to ignore all these features and keep it simple, we're going to pull our drives together into a single vdev running in RAIDz which will be the entirety of our zpool, no fancy cache drive or SLOG.

Open up the terminal and type the following commands:

sudo apt update

then

sudo apt install zfsutils-linux

This will install the ZFS utility. Verify that it's installed with the following command:

zfs --version

Now, it's time to check that the HDDs we have in the enclosure are healthy, running, and recognized. We also want to find out their device IDs and take note of them:

sudo fdisk -1

Note: You might be wondering why some of these commands require "sudo" in front of them while others don't. "Sudo" is short for "super user do”. When and where "sudo" is used has to do with the way permissions are set up in Linux. Only the "root" user has the access level to perform certain tasks in Linux. As a matter of security and safety regular user accounts are kept separate from the "root" user. It's not advised (or even possible) to boot into Linux as "root" with most modern distributions. Instead by using "sudo" our regular user account is temporarily given the power to do otherwise forbidden things. Don't worry about it too much at this stage, but if you want to know more check out this introduction.

If everything is working you should get a list of the various drives detected along with their device IDs which will look like this: /dev/sdc. You can also check the device IDs of the drives by opening the disk utility app. Jot these IDs down as we'll need them for our next step, creating our RAIDz array.

RAIDz is similar to RAID-5 in that instead of striping your data over multiple disks, exchanging redundancy for speed and available space (RAID-0), or mirroring your data writing by two copies of every piece (RAID-1), it instead writes parity blocks across the disks in addition to striping, this provides a balance of speed, redundancy and available space. If a single drive fails, the parity blocks on the working drives can be used to reconstruct the entire array as soon as a replacement drive is added.

Additionally, RAIDz improves over some of the common RAID-5 flaws. It's more resilient and capable of self healing, as it is capable of automatically checking for errors against a checksum. It's more forgiving in this way, and it's likely that you'll be able to detect when a drive is dying well before it fails. A RAIDz array can survive the loss of any one drive.

Note: While RAIDz is indeed resilient, if a second drive fails during the rebuild, you're fucked. Always keep backups of things you can't afford to lose. This tutorial, however, is not about proper data safety.

To create the pool, use the following command:

sudo zpool create "zpoolnamehere" raidz "device IDs of drives we're putting in the pool"

For example, let's creatively name our zpool "mypool". This poil will consist of four drives which have the device IDs: sdb, sdc, sdd, and sde. The resulting command will look like this:

sudo zpool create mypool raidz /dev/sdb /dev/sdc /dev/sdd /dev/sde

If as an example you bought five HDDs and decided you wanted more redundancy dedicating two drive to this purpose, we would modify the command to "raidz2" and the command would look something like the following:

sudo zpool create mypool raidz2 /dev/sdb /dev/sdc /dev/sdd /dev/sde /dev/sdf

An array configured like this is known as RAIDz2 and is able to survive two disk failures.

Once the zpool has been created, we can check its status with the command:

zpool status

Or more concisely with:

zpool list

The nice thing about ZFS as a file system is that a pool is ready to go immediately after creation. If we were to set up a traditional RAID-5 array using mbam, we'd have to sit through a potentially hours long process of reformatting and partitioning the drives. Instead we're ready to go right out the gates.

The zpool should be automatically mounted to the filesystem after creation, check on that with the following:

df -hT | grep zfs

Note: If your computer ever loses power suddenly, say in event of a power outage, you may have to re-import your pool. In most cases, ZFS will automatically import and mount your pool, but if it doesn’t and you can't see your array, simply open the terminal and type sudo zpool import -a.

By default a zpool is mounted at /"zpoolname". The pool should be under our ownership but let's make sure with the following command:

sudo chown -R "yourlinuxusername" /"zpoolname"

Note: Changing file and folder ownership with "chown" and file and folder permissions with "chmod" are essential commands for much of the admin work in Linux, but we won't be dealing with them extensively in this guide. If you'd like a deeper tutorial and explanation you can check out these two guides: chown and chmod.

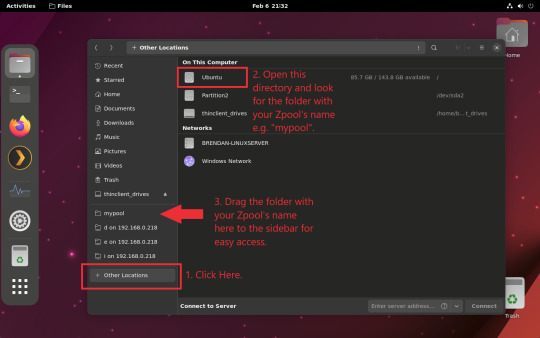

You can access the zpool file system through the GUI by opening the file manager (the Ubuntu default file manager is called Nautilus) and clicking on "Other Locations" on the sidebar, then entering the Ubuntu file system and looking for a folder with your pool's name. Bookmark the folder on the sidebar for easy access.

Your storage pool is now ready to go. Assuming that we already have some files on our Windows PC we want to copy to over, we're going to need to install and configure Samba to make the pool accessible in Windows.

Step Five: Setting Up Samba/Sharing

Samba is what's going to let us share the zpool with Windows and allow us to write to it from our Windows machine. First let's install Samba with the following commands:

sudo apt-get update

then

sudo apt-get install samba

Next create a password for Samba.

sudo smbpswd -a "yourlinuxusername"

It will then prompt you to create a password. Just reuse your Ubuntu user password for simplicity's sake.

Note: if you're using just a single external drive replace the zpool location in the following commands with wherever it is your external drive is mounted, for more information see this guide on mounting an external drive in Ubuntu.

After you've created a password we're going to create a shareable folder in our pool with this command

mkdir /"zpoolname"/"foldername"

Now we're going to open the smb.conf file and make that folder shareable. Enter the following command.

sudo nano /etc/samba/smb.conf

This will open the .conf file in nano, the terminal text editor program. Now at the end of smb.conf add the following entry:

["foldername"]

path = /"zpoolname"/"foldername"

available = yes

valid users = "yourlinuxusername"

read only = no

writable = yes

browseable = yes

guest ok = no

Ensure that there are no line breaks between the lines and that there's a space on both sides of the equals sign. Our next step is to allow Samba traffic through the firewall:

sudo ufw allow samba

Finally restart the Samba service:

sudo systemctl restart smbd

At this point we'll be able to access to the pool, browse its contents, and read and write to it from Windows. But there's one more thing left to do, Windows doesn't natively support the ZFS file systems and will read the used/available/total space in the pool incorrectly. Windows will read available space as total drive space, and all used space as null. This leads to Windows only displaying a dwindling amount of "available" space as the drives are filled. We can fix this! Functionally this doesn't actually matter, we can still write and read to and from the disk, it just makes it difficult to tell at a glance the proportion of used/available space, so this is an optional step but one I recommend (this step is also unnecessary if you're just using a single external drive). What we're going to do is write a little shell script in #bash. Open nano with the terminal with the command:

nano

Now insert the following code:

#!/bin/bash CUR_PATH=`pwd` ZFS_CHECK_OUTPUT=$(zfs get type $CUR_PATH 2>&1 > /dev/null) > /dev/null if [[ $ZFS_CHECK_OUTPUT == *not\ a\ ZFS* ]] then IS_ZFS=false else IS_ZFS=true fi if [[ $IS_ZFS = false ]] then df $CUR_PATH | tail -1 | awk '{print $2" "$4}' else USED=$((`zfs get -o value -Hp used $CUR_PATH` / 1024)) > /dev/null AVAIL=$((`zfs get -o value -Hp available $CUR_PATH` / 1024)) > /dev/null TOTAL=$(($USED+$AVAIL)) > /dev/null echo $TOTAL $AVAIL fi

Save the script as "dfree.sh" to /home/"yourlinuxusername" then change the ownership of the file to make it executable with this command:

sudo chmod 774 dfree.sh

Now open smb.conf with sudo again:

sudo nano /etc/samba/smb.conf

Now add this entry to the top of the configuration file to direct Samba to use the results of our script when Windows asks for a reading on the pool's used/available/total drive space:

[global]

dfree command = /home/"yourlinuxusername"/dfree.sh

Save the changes to smb.conf and then restart Samba again with the terminal:

sudo systemctl restart smbd

Now there’s one more thing we need to do to fully set up the Samba share, and that’s to modify a hidden group permission. In the terminal window type the following command:

usermod -a -G sambashare “yourlinuxusername”

Then restart samba again:

sudo systemctl restart smbd

If we don’t do this last step, everything will appear to work fine, and you will even be able to see and map the drive from Windows and even begin transferring files, but you'd soon run into a lot of frustration. As every ten minutes or so a file would fail to transfer and you would get a window announcing “0x8007003B Unexpected Network Error”. This window would require your manual input to continue the transfer with the file next in the queue. And at the end it would reattempt to transfer whichever files failed the first time around. 99% of the time they’ll go through that second try, but this is still all a major pain in the ass. Especially if you’ve got a lot of data to transfer or you want to step away from the computer for a while.

It turns out samba can act a little weirdly with the higher read/write speeds of RAIDz arrays and transfers from Windows, and will intermittently crash and restart itself if this group option isn’t changed. Inputting the above command will prevent you from ever seeing that window.

The last thing we're going to do before switching over to our Windows PC is grab the IP address of our Linux machine. Enter the following command:

hostname -I

This will spit out this computer's IP address on the local network (it will look something like 192.168.0.x), write it down. It might be a good idea once you're done here to go into your router settings and reserving that IP for your Linux system in the DHCP settings. Check the manual for your specific model router on how to access its settings, typically it can be accessed by opening a browser and typing http:\\192.168.0.1 in the address bar, but your router may be different.

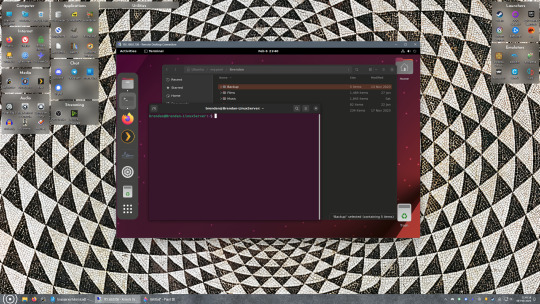

Okay we’re done with our Linux computer for now. Get on over to your Windows PC, open File Explorer, right click on Network and click "Map network drive". Select Z: as the drive letter (you don't want to map the network drive to a letter you could conceivably be using for other purposes) and enter the IP of your Linux machine and location of the share like so: \\"LINUXCOMPUTERLOCALIPADDRESSGOESHERE"\"zpoolnamegoeshere"\. Windows will then ask you for your username and password, enter the ones you set earlier in Samba and you're good. If you've done everything right it should look something like this:

You can now start moving media over from Windows to the share folder. It's a good idea to have a hard line running to all machines. Moving files over Wi-Fi is going to be tortuously slow, the only thing that’s going to make the transfer time tolerable (hours instead of days) is a solid wired connection between both machines and your router.

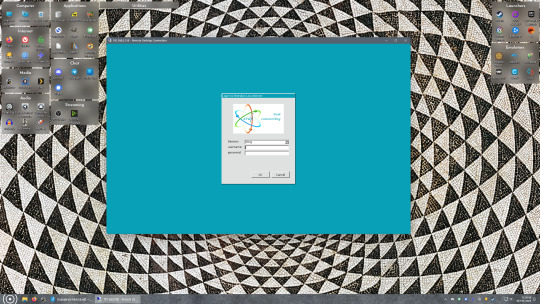

Step Six: Setting Up Remote Desktop Access to Your Server

After the server is up and going, you’ll want to be able to access it remotely from Windows. Barring serious maintenance/updates, this is how you'll access it most of the time. On your Linux system open the terminal and enter:

sudo apt install xrdp

Then:

sudo systemctl enable xrdp

Once it's finished installing, open “Settings” on the sidebar and turn off "automatic login" in the User category. Then log out of your account. Attempting to remotely connect to your Linux computer while you’re logged in will result in a black screen!

Now get back on your Windows PC, open search and look for "RDP". A program called "Remote Desktop Connection" should pop up, open this program as an administrator by right-clicking and selecting “run as an administrator”. You’ll be greeted with a window. In the field marked “Computer” type in the IP address of your Linux computer. Press connect and you'll be greeted with a new window and prompt asking for your username and password. Enter your Ubuntu username and password here.

If everything went right, you’ll be logged into your Linux computer. If the performance is sluggish, adjust the display options. Lowering the resolution and colour depth do a lot to make the interface feel snappier.

Remote access is how we're going to be using our Linux system from now, barring edge cases like needing to get into the BIOS or upgrading to a new version of Ubuntu. Everything else from performing maintenance like a monthly zpool scrub to checking zpool status and updating software can all be done remotely.

This is how my server lives its life now, happily humming and chirping away on the floor next to the couch in a corner of the living room.

Step Seven: Plex Media Server/Jellyfin

Okay we’ve got all the ground work finished and our server is almost up and running. We’ve got Ubuntu up and running, our storage array is primed, we’ve set up remote connections and sharing, and maybe we’ve moved over some of favourite movies and TV shows.

Now we need to decide on the media server software to use which will stream our media to us and organize our library. For most people I’d recommend Plex. It just works 99% of the time. That said, Jellyfin has a lot to recommend it by too, even if it is rougher around the edges. Some people run both simultaneously, it’s not that big of an extra strain. I do recommend doing a little bit of your own research into the features each platform offers, but as a quick run down, consider some of the following points:

Plex is closed source and is funded through PlexPass purchases while Jellyfin is open source and entirely user driven. This means a number of things: for one, Plex requires you to purchase a “PlexPass” (purchased as a one time lifetime fee $159.99 CDN/$120 USD or paid for on a monthly or yearly subscription basis) in order to access to certain features, like hardware transcoding (and we want hardware transcoding) or automated intro/credits detection and skipping, Jellyfin offers some of these features for free through plugins. Plex supports a lot more devices than Jellyfin and updates more frequently. That said, Jellyfin's Android and iOS apps are completely free, while the Plex Android and iOS apps must be activated for a one time cost of $6 CDN/$5 USD. But that $6 fee gets you a mobile app that is much more functional and features a unified UI across platforms, the Plex mobile apps are simply a more polished experience. The Jellyfin apps are a bit of a mess and the iOS and Android versions are very different from each other.

Jellyfin’s actual media player is more fully featured than Plex's, but on the other hand Jellyfin's UI, library customization and automatic media tagging really pale in comparison to Plex. Streaming your music library is free through both Jellyfin and Plex, but Plex offers the PlexAmp app for dedicated music streaming which boasts a number of fantastic features, unfortunately some of those fantastic features require a PlexPass. If your internet is down, Jellyfin can still do local streaming, while Plex can fail to play files unless you've got it set up a certain way. Jellyfin has a slew of neat niche features like support for Comic Book libraries with the .cbz/.cbt file types, but then Plex offers some free ad-supported TV and films, they even have a free channel that plays nothing but Classic Doctor Who.

Ultimately it's up to you, I settled on Plex because although some features are pay-walled, it just works. It's more reliable and easier to use, and a one-time fee is much easier to swallow than a subscription. I had a pretty easy time getting my boomer parents and tech illiterate brother introduced to and using Plex and I don't know if I would've had as easy a time doing that with Jellyfin. I do also need to mention that Jellyfin does take a little extra bit of tinkering to get going in Ubuntu, you’ll have to set up process permissions, so if you're more tolerant to tinkering, Jellyfin might be up your alley and I’ll trust that you can follow their installation and configuration guide. For everyone else, I recommend Plex.

So pick your poison: Plex or Jellyfin.

Note: The easiest way to download and install either of these packages in Ubuntu is through Snap Store.

After you've installed one (or both), opening either app will launch a browser window into the browser version of the app allowing you to set all the options server side.

The process of adding creating media libraries is essentially the same in both Plex and Jellyfin. You create a separate libraries for Television, Movies, and Music and add the folders which contain the respective types of media to their respective libraries. The only difficult or time consuming aspect is ensuring that your files and folders follow the appropriate naming conventions:

Plex naming guide for Movies

Plex naming guide for Television

Jellyfin follows the same naming rules but I find their media scanner to be a lot less accurate and forgiving than Plex. Once you've selected the folders to be scanned the service will scan your files, tagging everything and adding metadata. Although I find do find Plex more accurate, it can still erroneously tag some things and you might have to manually clean up some tags in a large library. (When I initially created my library it tagged the 1963-1989 Doctor Who as some Korean soap opera and I needed to manually select the correct match after which everything was tagged normally.) It can also be a bit testy with anime (especially OVAs) be sure to check TVDB to ensure that you have your files and folders structured and named correctly. If something is not showing up at all, double check the name.

Once that's done, organizing and customizing your library is easy. You can set up collections, grouping items together to fit a theme or collect together all the entries in a franchise. You can make playlists, and add custom artwork to entries. It's fun setting up collections with posters to match, there are even several websites dedicated to help you do this like PosterDB. As an example, below are two collections in my library, one collecting all the entries in a franchise, the other follows a theme.

My Star Trek collection, featuring all eleven television series, and thirteen films.

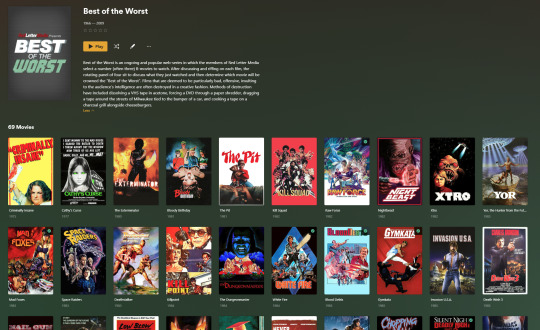

My Best of the Worst collection, featuring sixty-nine films previously showcased on RedLetterMedia’s Best of the Worst. They’re all absolutely terrible and I love them.

As for settings, ensure you've got Remote Access going, it should work automatically and be sure to set your upload speed after running a speed test. In the library settings set the database cache to 2000MB to ensure a snappier and more responsive browsing experience, and then check that playback quality is set to original/maximum. If you’re severely bandwidth limited on your upload and have remote users, you might want to limit the remote stream bitrate to something more reasonable, just as a note of comparison Netflix’s 1080p bitrate is approximately 5Mbps, although almost anyone watching through a chromium based browser is streaming at 720p and 3mbps. Other than that you should be good to go. For actually playing your files, there's a Plex app for just about every platform imaginable. I mostly watch television and films on my laptop using the Windows Plex app, but I also use the Android app which can broadcast to the chromecast connected to the TV in the office and the Android TV app for our smart TV. Both are fully functional and easy to navigate, and I can also attest to the OS X version being equally functional.

Part Eight: Finding Media

Now, this is not really a piracy tutorial, there are plenty of those out there. But if you’re unaware, BitTorrent is free and pretty easy to use, just pick a client (qBittorrent is the best) and go find some public trackers to peruse. Just know now that all the best trackers are private and invite only, and that they can be exceptionally difficult to get into. I’m already on a few, and even then, some of the best ones are wholly out of my reach.

If you decide to take the left hand path and turn to Usenet you’ll have to pay. First you’ll need to sign up with a provider like Newshosting or EasyNews for access to Usenet itself, and then to actually find anything you’re going to need to sign up with an indexer like NZBGeek or NZBFinder. There are dozens of indexers, and many people cross post between them, but for more obscure media it’s worth checking multiple. You’ll also need a binary downloader like SABnzbd. That caveat aside, Usenet is faster, bigger, older, less traceable than BitTorrent, and altogether slicker. I honestly prefer it, and I'm kicking myself for taking this long to start using it because I was scared off by the price. I’ve found so many things on Usenet that I had sought in vain elsewhere for years, like a 2010 Italian film about a massacre perpetrated by the SS that played the festival circuit but never received a home media release; some absolute hero uploaded a rip of a festival screener DVD to Usenet. Anyway, figure out the rest of this shit on your own and remember to use protection, get yourself behind a VPN, use a SOCKS5 proxy with your BitTorrent client, etc.

On the legal side of things, if you’re around my age, you (or your family) probably have a big pile of DVDs and Blu-Rays sitting around unwatched and half forgotten. Why not do a bit of amateur media preservation, rip them and upload them to your server for easier access? (Your tools for this are going to be Handbrake to do the ripping and AnyDVD to break any encryption.) I went to the trouble of ripping all my SCTV DVDs (five box sets worth) because none of it is on streaming nor could it be found on any pirate source I tried. I’m glad I did, forty years on it’s still one of the funniest shows to ever be on TV.

Part Nine/Epilogue: Sonarr/Radarr/Lidarr and Overseerr

There are a lot of ways to automate your server for better functionality or to add features you and other users might find useful. Sonarr, Radarr, and Lidarr are a part of a suite of “Servarr” services (there’s also Readarr for books and Whisparr for adult content) that allow you to automate the collection of new episodes of TV shows (Sonarr), new movie releases (Radarr) and music releases (Lidarr). They hook in to your BitTorrent client or Usenet binary newsgroup downloader and crawl your preferred Torrent trackers and Usenet indexers, alerting you to new releases and automatically grabbing them. You can also use these services to manually search for new media, and even replace/upgrade your existing media with better quality uploads. They’re really a little tricky to set up on a bare metal Ubuntu install (ideally you should be running them in Docker Containers), and I won’t be providing a step by step on installing and running them, I’m simply making you aware of their existence.

The other bit of kit I want to make you aware of is Overseerr which is a program that scans your Plex media library and will serve recommendations based on what you like. It also allows you and your users to request specific media. It can even be integrated with Sonarr/Radarr/Lidarr so that fulfilling those requests is fully automated.

And you're done. It really wasn't all that hard. Enjoy your media. Enjoy the control you have over that media. And be safe in the knowledge that no hedgefund CEO motherfucker who hates the movies but who is somehow in control of a major studio will be able to disappear anything in your library as a tax write-off.

1K notes

·

View notes

Text

CAD Automation: Redefining the Design Landscape for Success

In the world of modern engineering and design, Computer-Aided Design (CAD) has revolutionized the way products are conceived, developed, and manufactured. As technology continues to advance, CAD automation emerges as a key player in enhancing design efficiency and fostering innovation. This blog post delves into the realm of CAD automation, exploring its significance, benefits, challenges, and potential future trends.

Understanding CAD Automation

CAD automation refers to the process of utilizing software tools and scripts to streamline various aspects of the design process. It involves automating repetitive tasks, generating complex designs, and facilitating seamless collaboration between designers and engineers. The goal of CAD automation is to reduce manual effort, minimize errors, improve consistency, and accelerate the overall design cycle.

Significance of CAD Automation

1. Efficiency Enhancement:

Automating routine and time-consuming tasks, such as dimensioning, detailing, and generating drawings, allows designers and engineers to allocate more time to creative and high-value tasks. This not only accelerates the design process but also increases productivity and reduces the risk of human errors.

2. Design Iteration and Optimization:

Automation tools enable rapid design iteration. Designers can easily generate variations of a concept, test different parameters, and evaluate multiple scenarios. This iterative process aids in identifying the most optimal design solution and fosters innovation.

3. Consistency and Standardization:

CAD automation enforces design standards and guidelines consistently across projects. This ensures that designs adhere to industry best practices and regulatory requirements, reducing the chances of errors caused by deviations from standards.

4. Complex Geometry and Customization:

Automated scripts and parametric modeling techniques enable the creation of intricate and complex geometries that might be challenging to achieve manually. Additionally, automation allows for easy customization of designs to meet specific customer requirements.

5. Collaboration and Communication:

CAD automation tools facilitate seamless collaboration between cross-functional teams. Design modifications, updates, and feedback can be efficiently communicated and integrated into the design process, enhancing teamwork and reducing communication gaps.

Benefits of CAD Automation

1. Time Savings:

Automating repetitive tasks drastically reduces the time required for design and drafting. This leads to faster project completion and quicker time-to-market for products.

2. Error Reduction:

Human errors are inevitable in manual tasks, but automation significantly reduces the risk. Consistent and standardized designs generated by automation tools mitigate the chances of costly mistakes.

3. Innovation Encouragement:

By handling routine tasks, designers can focus on exploring innovative design concepts and pushing boundaries. This results in more creative and inventive solutions.

4. Cost Efficiency:

Efficient design processes translate to cost savings. Reduced design time, fewer errors, and optimized designs contribute to lower production costs.

5. Enhanced Quality:

Automation tools ensure that designs adhere to defined standards, leading to higher-quality outputs that meet or exceed customer expectations.

Challenges of CAD Automation

While CAD automation offers numerous benefits, it's important to acknowledge the challenges that come with its implementation:

1. Initial Setup Complexity:

Developing and implementing automation scripts requires specialized skills and time. Setting up an automation workflow can be complex and resource-intensive.

2. Maintenance and Updates:

Automation workflows need continuous monitoring and updates to remain effective. Changes in design requirements or software updates may necessitate adjustments to the automation process.

3. Skill Requirements:

CAD automation demands a certain level of programming and scripting skills. Not all design professionals possess these skills, which might lead to a skill gap within the team.

4. Balancing Automation and Creativity:

While automation improves efficiency, there's a concern that excessive automation might stifle creativity. Striking the right balance is crucial to ensure that designers still have the freedom to innovate.

Future Trends in CAD Automation

The future of CAD automation holds exciting possibilities:

1. AI-Powered Design Generation:

Artificial Intelligence (AI) could play a significant role in generating design concepts based on user inputs and requirements. This could lead to the rapid creation of diverse design options.

2. Cloud-Based Collaboration:

Collaboration tools and CAD software are likely to move towards the cloud, enabling real-time collaboration between team members regardless of their geographical location.

3. Integration with Simulation and Analysis:

Automation could seamlessly integrate design with simulation and analysis tools, allowing for quicker evaluation of design performance and optimization.

4. Generative Design Evolution:

Generative design algorithms, driven by AI, could become more advanced, producing complex designs that consider multiple variables and constraints.

Conclusion

CAD automation is transforming the design landscape by freeing designers from repetitive tasks, empowering them to innovate, and enhancing design efficiency. While challenges exist, the benefits of CAD automation outweigh the drawbacks, and the continuous evolution of technology promises even greater possibilities in the future. Embracing CAD automation can position design teams at the forefront of innovation and efficiency in the rapidly evolving engineering and manufacturing industries.

ProtoTech Solutions' journey into the realm of CAD automation is a testament to the transformative power of technology. Their commitment to streamlining design processes, fostering innovation, and embracing the future sets an inspiring example for the entire design and engineering community. As ProtoTech Solutions continues to pioneer advancements in CAD automation, the design landscape stands poised for a future of unprecedented efficiency, creativity, and collaboration.

#CAD Automation#Design Efficiency#Design Workflow#Engineering Automation#Automation Solutions#Design Technology#AI-driven Design#Design Optimization#CAD Integration#Design Standards#CAD Software#CAD Customization

0 notes

Text

Immersiv Technologies | Best 3D Design and Automation Company

Leveraging 3D animation, CAD automation, and design automation services can significantly enhance your projects. Incorporating these technologies not only improves project visualization but also streamlines workflows, reducing costs and saving time.

With 3D animation, you can create compelling presentations that enhance communication and pitch portfolios effectively. CAD automation ensures precision in design processes, minimizing errors and optimizing efficiency.

Design automation services further contribute to project success by automating repetitive tasks. This integrated approach not only refines project quality but also increases return on investment (ROI) through enhanced efficiency, reduced costs, and a more competitive pitch portfolio.

1 note

·

View note