#CAD Design Automation

Explore tagged Tumblr posts

Text

nCircle Tech is transforming CAD design automation in India.

It is more important than ever to find effective and creative design solutions in the quickly changing field of technology. nCircle Tech, a trailblazing Indian business at the forefront of CAD design automation, is spearheading this change. nCircle Tech is revolutionizing the design process by utilizing state-of-the-art technology and a thorough understanding of the industry to make design processes faster, more precise, and highly efficient.

In fields like engineering, manufacturing, and architecture, computer-aided design, or CAD, has long been a mainstay. It enables experts to produce intricate 2D and 3D models of their projects. But the conventional method of CAD design can be laborious and prone to human error, particularly for intricate projects that demand painstaking attention to detail. In this situation, nCircle Tech can help by providing cutting-edge CAD automation solutions that greatly expedite the design process.

With the automation tools from nCircle Tech, designers may spend more time on creativity and innovation and less time on tedious activities. Project completion is accelerated and accuracy is improved with nCircle Tech's automation of repetitive tasks including draughting, modeling, and rendering. This shortens the product's time to market and improves the design's overall quality.

Furthermore, nCircle Tech's solutions are very adaptable and can be tailored to meet the unique requirements of various sectors. nCircle Tech offers specialized solutions that are customized to meet the particular needs of each project, whether it is automating the design of intricate mechanical components or optimizing architectural draughting.

Businesses like nCircle Tech are essential in propelling India's continued rise to prominence as a global leader in innovation and technology. nCircle Tech is revolutionizing CAD design automation to help organizations remain competitive in an increasingly digital environment while establishing new benchmarks for productivity and design quality.

0 notes

Text

Revolutionizing Manufacturing: Discovering the Game-Changing Advantages of CAD Automation for Companies

Introduction

In the dynamic landscape of modern manufacturing, the integration of advanced technologies is reshaping the way companies operate. One such transformative technology is Computer-Aided Design (CAD) automation. CAD automation refers to the use of computer software and algorithms to streamline and optimize the design and drafting processes in manufacturing. In this blog post, we will delve into the myriad benefits that CAD automation brings to manufacturing companies, from enhanced productivity to improved product quality.

1. Increased Efficiency in Design Iterations

Traditionally, manual drafting processes in design can be time-consuming and prone to errors. CAD automation revolutionizes this aspect by providing a platform for rapid prototyping and design iterations. Engineers and designers can make quick changes to a digital model, test variations, and explore multiple design options effortlessly. This iterative process not only accelerates the design phase but also allows for the exploration of more innovative and efficient solutions.

2. Time and Cost Savings

Time is money, and CAD automation is a potent tool for saving both. The efficiency gained through automated design processes significantly reduces the time required to bring a product from conception to production. Moreover, as design iterations become quicker and more accurate, the overall development cycle is shortened. This time compression results in substantial cost savings, making manufacturing processes more cost-effective and competitive.

3. Precision and Accuracy

Manual drafting is inherently susceptible to human errors, which can lead to costly mistakes during the manufacturing phase. CAD automation, on the other hand, ensures a high level of precision and accuracy in design. Measurements and specifications are consistently maintained, minimizing the risk of errors in the final product. This not only improves product quality but also reduces the likelihood of defects and the need for rework.

4. Seamless Collaboration and Communication

CAD automation facilitates seamless collaboration among multidisciplinary teams involved in the product development process. Designers, engineers, and other stakeholders can work on the same digital model in real time, fostering effective communication and coordination. This level of collaboration ensures that everyone is on the same page throughout the design process, reducing misunderstandings and enhancing overall project efficiency.

5. Enhanced Product Lifecycle Management (PLM)

CAD automation integrates seamlessly with Product Lifecycle Management (PLM) systems, providing a comprehensive solution for managing the entire lifecycle of a product. From initial design and prototyping to manufacturing, distribution, and maintenance, CAD automation ensures that all aspects of the product's lifecycle are interconnected and efficiently managed. This holistic approach improves traceability, reduces time-to-market, and optimizes resource utilization.

6. Adaptability to Customization

In today's manufacturing landscape, customization is becoming increasingly important to meet diverse customer demands. CAD automation empowers manufacturing companies to easily customize products without significant disruptions to the production process. Whether it's adapting a design for a specific client requirement or making quick adjustments to respond to market trends, CAD automation enables manufacturers to be agile and responsive.

Conclusion

The benefits of CAD automation for manufacturing companies are profound and multifaceted. From accelerated design iterations and significant time and cost savings to enhanced precision and adaptability, the integration of CAD automation technology is a game-changer. As manufacturing continues to evolve, companies that embrace these advancements position themselves at the forefront of innovation, setting the stage for a more efficient, competitive, and sustainable future.

#CAD Automation#Manufacturing Design#Machine Design#Manufacturing Companies#CAD Services#CAD Design Automation#CAD Design

0 notes

Text

HOW CAD AUTOMATION TOOLS STREAMLINE WORKFLOW & BOOSTS PRODUCTIVITY

Discover the transformative impact of CAD Automation in simplifying intricate design tasks and enhancing the overall quality of your final product.

Read our latest article to explore how CAD Automation tools are revolutionizing workflows, reducing errors, and optimizing productivity.

0 notes

Text

Our professional design experts streamline your resources more effectively with shifting workloads, thus improving, and optimizing results. As a trusted design extension for global businesses in various industries, you can count on us offshore for all your CAD needs.

Get in touch with us, for more information Visit: https://www.designautomations.com/ or Call us on 📞 +91 9574 024 279

1 note

·

View note

Text

Designing and manufacturing custom doors is a complex task due to the bespoke design needs of customers. Technological advancements, such as design automation using visual CAD configurators, have accelerated design development time for custom doors. These configurators simplify door design customization and generate accurate manufacturing drawings faster. Read the full article.

0 notes

Text

Randee Butrus, the Mechanical Designer & CAD Specialist

Randee Butrus is a highly skilled mechanical designer and CAD expert, with years of experience in the field. With a keen eye for detail and a passion for innovative solutions, she has built a reputation as one of the top designers in the industry. Randee's expertise extends across a wide range of projects, from small-scale components to complex industrial machinery, and she is known for her ability to work closely with clients to bring their ideas to life.

0 notes

Text

This is very interesting: a novel CAD package built on a text based file format that should allow you to check files into version control and automate tasks, plus a geometry engine optimized for GPU compute.

It's also got some noteworthy backers, the appeal of this is obvious to anyone who has ever tried to integrate CAD into a larger workflow, it takes a lot of manual shunting of files and tagging of releases and fighting with export formats, even with all the features SolidWorks and Inventor and SolidEdge have added over the years.

It's not parametric, of course, because that's a totally different approach to modelling that's much harder to automate this way. I'm not sure if that's reasonably possible without just doing SVG bullshit.

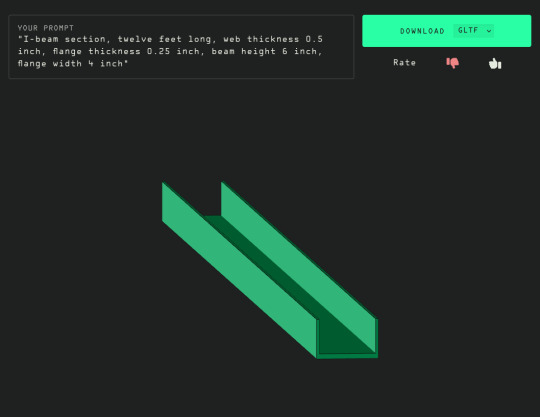

There's an LLM powered Text To CAD thing where you are meant to be able to just describe an object and get back the CAD for it but at least for now it can only do things that are relatively simple, it feels a little like a crutch to deal with how slow generating simple parts through code CAD can be. Defining an I-beam parametrically is the kind of thing you can do basically without thinking. I guess you'd probably want to have a library of parametrically defined common parts to pull from once you've been doing this for five minutes.

Close but no cigar! It does get the flange and web the right way around. Using inches because I assume it's trained in Freedomheit.

They're keeping their geometry solver closed source, but I'd be interested to see if declarative cad like this takes off in industry, it's a slow moving space but hardware design is increasingly available to startups and small businesses who might be willing to throw away a lot of old CAD philosophy.

A lot of industry uses constructive CAD like this, the US military has BRL-CAD. Never could get my head around it.

27 notes

·

View notes

Text

nCircle Tech: Revolutionizing CAD Design Automation for Efficiency

Efficiency is critical in the fast-paced fields of engineering and design. The speed and accuracy with which CAD models may be created, edited, and managed has a big impact on project schedules and overall productivity. Now enter nCircle Tech, a leader in CAD design automation, providing cutting-edge solutions that are revolutionizing the workflow of designers and engineers.

CAD Design Automation's Necessity

Draughting, detailing, and updating models are examples of repetitive operations that are frequently involved in traditional CAD design processes. These manual procedures may take a long time and are prone to mistakes, which can cause delays and higher expenses. It is not only convenient, but also essential to automate these processes in a competitive business where speed and accuracy are critical.

nCircle Tech: Setting the Standard

By streamlining these tedious operations, nCircle Tech's sophisticated CAD design automation technologies free up engineers and designers to work on more intricate and imaginative project components. nCircle Tech's solutions automate normal procedures to minimize errors, improve accuracy, and save a substantial amount of time compared to manual tasks.

The seamless integration of nCircle Tech's CAD design automation with pre-existing CAD software is one of its most notable advantages. Whether you use SolidWorks, AutoCAD, or another well-known platform, nCircle Tech's solutions are made to improve your workflow without necessitating a whole rebuild of your present setup.

CAD Design Automation's advantages

There are many advantages to using nCircle Tech's CAD design automation. Projects can be finished more quickly, for less money, and with fewer mistakes. Increased productivity from efficiency improvements enables businesses to take on more projects and raise their bottom line.

Conclusion

For maximum productivity, nCircle Tech is automating CAD design in a field where every second matters. nCircle Tech enables engineers and designers to work smarter, not harder, by automating repetitive activities and improving accuracy. With nCircle Tech, you may experience the CAD design of the future and advance your projects.

0 notes

Text

What's New in AutoCAD 2026?

What's New in AutoCAD 2026?

Explore the newest features in AutoCAD 2026 — Smart Blocks, powerful automation, and intelligent AI-driven insights that are transforming the way you design.

Smart Blocks, with their advanced capabilities, simplify the creation, management, and use of blocks. By using artificial intelligence algorithms to analyze drawing context and recognize patterns, Smart Blocks offer a suite of intelligent features. These include automatic block placement, smart block replacement suggestions, object detection, and seamless block conversion.

👉 Dive into what’s new: https://blog.prototechsolutions.com/whats-new-in-autocad-2026-smart-blocks-revolutionize-repetitive-tasks/

0 notes

Text

How ERP Software for Engineering Companies Improves Operational Efficiency

In today's competitive market, engineering companies are under immense pressure to deliver innovative solutions, maintain cost-efficiency, and meet tight deadlines—all while ensuring the highest standards of quality. As the engineering industry becomes more complex and digitally driven, operational efficiency has become a key metric for success. One of the most transformative tools driving this change is ERP (Enterprise Resource Planning) software.

For companies seeking to streamline their operations, ERP software for engineering companies provides a centralized platform that integrates every function—ranging from procurement, design, production, finance, HR, and project management. In India, especially in industrial hubs like Delhi, the demand for such software is growing rapidly. Let us explore how ERP systems significantly enhance operational efficiency and why choosing the right ERP software company in India is vital for engineering enterprises.

Centralized Data Management: The Foundation of Efficiency

One of the major challenges engineering companies face is managing vast amounts of data across departments. Manual entries and siloed systems often lead to redundancies, errors, and miscommunication. With ERP software for engineering companies in India, organizations gain access to a unified database that connects all operational areas.

Real-time data availability ensures that everyone, from the design team to procurement and finance, is working with the latest information. This reduces rework, improves collaboration, and speeds up decision-making, thereby increasing efficiency.

Streamlined Project Management

Engineering projects involve numerous stages—from planning and design to execution and maintenance. Tracking timelines, resources, costs, and deliverables manually or via disparate systems often results in delays and budget overruns.

Modern engineering ERP software companies in Delhi provide robust project management modules that allow firms to plan, schedule, and monitor projects in real time. This includes milestone tracking, Gantt charts, resource allocation, and budget forecasting. Managers can gain visibility into bottlenecks early on and reallocate resources efficiently, ensuring timely delivery.

Automation of Core Processes

Automating routine tasks is one of the key advantages of implementing ERP software. From generating purchase orders and invoices to managing payroll and inventory, ERP eliminates the need for repetitive manual work. This not only saves time but also minimizes human error.

The best ERP software provider in India will offer customizable automation workflows tailored to the specific needs of engineering companies. For instance, when a material stock reaches a minimum threshold, the ERP system can automatically generate a requisition and notify the purchasing team. This ensures zero downtime due to material shortages.

Enhanced Resource Planning and Allocation

Resource planning is crucial in engineering projects where labour, materials, and machinery must be utilized efficiently. A good ERP software for engineering companies provides detailed insights into resource availability, utilization rates, and project requirements.

By analysing this data, companies can better allocate resources, avoid overbooking, and reduce idle time. This leads to significant cost savings and ensures optimal productivity across the board.

youtube

Integration with CAD and Design Tools

Many ERP solution providers in Delhi now offer integration with design and CAD software. This is particularly useful for engineering firms where design data is often needed for procurement, costing, and production.

When ERP is integrated with CAD, design changes automatically reflect across related departments. This seamless flow of information eliminates miscommunication and ensures that downstream processes such as procurement and manufacturing are aligned with the latest design specifications.

Real-time Cost and Budget Management

Keeping engineering projects within budget is a continuous challenge. Unexpected costs can arise at any stage, and without proper monitoring, they can spiral out of control. ERP software providers in India equip engineering companies with real-time budget tracking tools.

From initial cost estimation to actual expenditure, companies can monitor every aspect of the financials. Alerts can be configured for budget deviations, helping management take corrective action promptly. This financial control is a cornerstone of operational efficiency and long-term profitability.

Improved Compliance and Documentation

Engineering companies must adhere to various compliance standards, certifications, and audit requirements. Maintaining accurate documentation and audit trails is critical. ERP systems automate compliance tracking and generate necessary documentation on demand.

By partnering with trusted ERP software companies in Delhi, engineering firms can ensure they meet industry standards with minimal administrative overhead. Features like document versioning, digital signatures, and compliance checklists help organizations stay audit-ready at all times.

Scalable and Future-ready Solutions

One of the biggest advantages of working with a reputed engineering ERP software company in Delhi is access to scalable solutions. As engineering businesses grow, their operational complexities increase. Modern ERP systems are modular and scalable, allowing businesses to add new functionalities as needed without disrupting existing operations.

Moreover, cloud-based ERP solutions offer flexibility, remote access, and lower infrastructure costs. These are especially beneficial for engineering companies that operate across multiple locations or work on-site with clients.

Enhanced Customer Satisfaction

Efficient operations lead to improved delivery timelines, better quality products, and faster customer service—all of which directly impact customer satisfaction. With ERP, engineering companies can maintain accurate production schedules, meet delivery deadlines, and respond to customer queries with real-time information.

By choosing the right ERP software for engineering companies in India, firms not only improve internal operations but also build a strong reputation for reliability and professionalism among their clients.

Choosing the Right ERP Partner

With the growing number of ERP solution providers in India, selecting the right partner is crucial. Here are a few factors to consider:

Domain Expertise: Choose a vendor with experience in the engineering sector.

Customization: The software should be tailored to suit your specific workflows.

Scalability: Ensure the ERP solution grows with your business.

Support & Training: Opt for companies that provide ongoing support and employee training.

Integration Capabilities: Check whether the ERP can integrate with your existing systems, including CAD tools, financial software, etc.

Trusted ERP software companies in Delhi like Shantitechnology (STERP) stand out because they offer deep industry knowledge, scalable platforms, and dedicated customer support—making them ideal partners for engineering businesses seeking to transform operations.

youtube

Final Thoughts

In a rapidly evolving business landscape, engineering companies must adopt smart technologies to stay ahead. ERP software is not just an IT solution—it is a strategic tool that can redefine how engineering firms manage their projects, people, and performance.

From streamlining project workflows and automating routine tasks to enhancing collaboration and boosting resource efficiency, ERP solutions deliver measurable gains across the organization. For those looking to make a digital leap, partnering with a top-rated ERP software company in India can be the difference between stagnation and scalable success.

Looking for a reliable ERP partner? Shantitechnology (STERP) is among the leading ERP solution providers in Delhi, offering tailored ERP software for engineering companies to help you boost productivity, reduce costs, and grow sustainably. Contact us today to learn more!

#Engineering ERP software company#ERP software for engineering companies in India#ERP solution providers#ERP software for engineering companies#ERP software companies#ERP software providers in India#Gujarat#Maharashtra#Madhyapradesh#ERP solution providers in India#ERP for manufacturing company#Delhi#Hyderabad#ERP Software#Custom ERP#ERP software company#Manufacturing enterprise resource planning software#Bengaluru#ERP software company in India#Engineering ERP Software Company#Best ERP software provider in India#Manufacturing ERP software company#Manufacturing enterprise resource planning#ERP modules for manufacturing industry#Best ERP for manufacturing industry#India#Youtube

2 notes

·

View notes

Text

The Importance of Cable Management in Electrical Panels

In modern electrical installations, particularly in industrial, commercial, and residential applications, cable management in electrical panels plays a critical role. Poor cable organization can lead to inefficiencies, overheating, safety hazards, and costly downtime. Implementing proper cable management is not just a technical necessity — it’s a long-term investment in the performance, safety, and scalability of your electrical system.

What is Cable Management in Electrical Panels?

Cable management refers to the planning, installation, and maintenance of cables within an electrical panel to ensure neatness, organization, and optimal functionality. It includes the use of accessories such as cable ties, ducts, cable trays, wire markers, and labeling systems.

Common Components Used:

· Cable trays and ducts

· Cable ties and clips

· Wire markers and labels

· Conduits and sleeves

· Cable management panels and grommets

Why is Cable Management Important in Electrical Panels?

1. Enhances Electrical Safety

Proper cable routing reduces the risk of:

· Short circuits

· Arc flashes

· Fire hazards due to overheating or overloading

· Accidental disconnections or loose terminals

Safety is non-negotiable in any electrical system, and disorganized wiring is a known contributor to accidents and failures.

2. Improves System Reliability and Performance

A clean layout ensures stable voltage and current flow by minimizing electrical interference (EMI/RFI). It helps in:

· Preventing signal loss

· Reducing cross-talk in data cables

· Maintaining consistency in power distribution

3. Simplifies Maintenance and Troubleshooting

With labeled and properly routed cables:

· Technicians can quickly identify circuits and connections

· Downtime during maintenance is significantly reduced

· Errors due to wrong connections are minimized

4. Optimizes Space and Panel Layout

Efficient cable arrangement allows:

· Better airflow and heat dissipation

· Accommodation of future upgrades or expansions

· Reduced clutter and stress on terminal blocks

5. Compliance with Standards

Organizations such as IEC, NEC, and IEEE provide guidelines on wiring practices. Adhering to these standards not only ensures safety but also legal compliance during audits and inspections.

Best Practices for Cable Management in Electrical Panels

✅ Plan Before You Install

· Design the cable layout during the panel design phase

· Use CAD software for accurate visualization

✅ Use Quality Cable Management Accessories

· Invest in fire-resistant and durable cable trays and ducts

· Use color-coded wire markers for quick identification

✅ Ensure Proper Bending Radius

· Prevent cable damage by maintaining manufacturer-recommended bend radii

✅ Label Everything Clearly

· Use laser-printed or pre-numbered labels for durability and readability

✅ Separate Power and Signal Cables

· Avoid EMI by isolating high-voltage and low-voltage cables

✅ Secure Cables Firmly

· Use cable ties, clamps, or holders to prevent movement or vibration

✅ Regularly Inspect and Maintain

· Schedule routine inspections to spot frayed, loose, or overloaded cables

Industries Where Cable Management is Critical

· Manufacturing Plants — High-voltage systems and automated machinery

· Data Centers — Dense cable infrastructure and sensitive equipment

· Commercial Buildings — Office automation, security systems

· Healthcare — Life-support systems and diagnostic machines

· Renewable Energy — Solar inverters, battery management panels

Conclusion

Cable management in electrical panels is more than just a matter of aesthetics — it’s a critical component of a safe, reliable, and future-proof electrical system. From enhanced safety to easier maintenance and compliance, the benefits far outweigh the costs. Whether you’re an installer, facility manager, or system designer, investing in organized and well-planned cable management is a smart, long-term decision.

#electrical#electrical equipment#electrical supplies#switchgear#911 abc#oman#arcane#artists on tumblr#batman#cats of tumblr

3 notes

·

View notes

Text

6 BEST PRACTICES OF CAD AUTOMATION GIVEN BY INDUSTRY EXPERTS

Discover top CAD automation tips from industry experts.

Optimize workflows with these 6 best practices for efficient and precise design processes.

0 notes

Text

Summary Analysis of CNC Milling Process

In modern manufacturing, CNC milling technology is widely used for its high precision and flexibility. Whether it's a mechanical part, an automotive component, or a component for a medical device, CNC milling provides excellent machining results.

What is CNC Milling?

CNC milling is a computer-controlled machining process that utilises a rotating tool to cut a workpiece. CNC milling allows for greater accuracy and consistency than traditional manual milling. It is often combined with other machining methods (e.g. turning, drilling) to meet different and diverse manufacturing needs.

Workflow of CNC Milling

Design stage In the initial stages of CNC milling, designers use Computer-Aided Design (CAD) software to create a model of the product. Commonly used software includes SolidWorks and Autodesk, which are tools that help designers accurately draw the shape and dimensions of the desired part.

Programming stage Once the design is complete, the CAD file needs to be converted to G-code, a language that CNC machines can understand. With Computer-Aided Manufacturing (CAM) software, the design files are converted into machine-executable instructions that enable automated machining.

Machine setting During the machine set-up phase, the workpiece needs to be fixed to the table and a suitable tool selected. At the same time, the operator needs to set the initial co-ordinates to ensure accurate positioning during machining.

Advantages of CNC Milling

High precision and dimensional stability CNC milling allows for micron-level machining accuracy, ensuring consistency from part to part.

Complex shapes can be processed Whether it's a simple flat surface or a complex three-dimensional structure, CNC milling can handle it with ease.

Efficient production capacity Due to its high degree of automation, CNC milling can significantly increase productivity and shorten lead times.

Applications of CNC Milling

CNC milling technology is used in a wide range of industries, including:

Mechanical parts: Used in the manufacture of key components in a variety of mechanical equipment.

Automotive parts: High-precision parts for the automotive industry, such as engine components.

Medical device parts: Ensure the reliability and safety of medical devices.

Optical product parts: For the production of optical instruments and related products.

Frequently Asked Questions

What materials can be CNC milling machined? CNC milling is suitable for a wide range of materials, including metals (e.g. aluminium, steel), plastics, wood, and more. However, for some materials, such as ceramics or certain composites, the machining is more difficult and requires special handling.

What are the limitations of CNC milling? Despite its advanced technology, CNC milling has some limitations. For example, machining may be limited for internal vertical angles or very complex small structures.In addition, high hardness materials may lead to faster tool wear, which can affect productivity.

Comparison of CNC milling with other manufacturing technologies The advantages and disadvantages of each can be seen when comparing CNC milling with other manufacturing techniques such as 3D printing. CNC milling is generally superior to 3D printing in terms of accuracy and surface finish, but 3D printing has advantages in rapid prototyping and complex geometries. In terms of cost-effectiveness, the choice of technology depends on specific project needs and budget.

Summary

In summary, CNC milling is an indispensable manufacturing technology that plays an important role in several industries with its efficiency, precision and flexibility.

#prototyping#prototype#rapid prototyping#prototype machining#precision machining#cnc machining#cnc milling#machining parts#cnc milling 5 axis#cnc milling machining#cnc milling turning#precision cnc milling#cnc milling parts

2 notes

·

View notes

Text

Mastering Woodworking with a CNC Router Machine: Unlocking Precision and Efficiency

The CNC router machine for wood has emerged as an indispensable tool for modern woodworking. Whether crafting intricate designs or scaling up production, this advanced technology brings precision, speed, and creativity to the forefront. Among its many variations, the 5x10 CNC router stands out for its large working area and robust functionality. This article delves into the transformative impact of CNC router machines on woodworking and why they are a must-have in today’s workshops.

What is a CNC Router Machine for Wood?

A CNC (Computer Numerical Control) router machine for wood is a sophisticated device that automates cutting, engraving, and carving processes. By using computer-aided designs (CAD), it translates digital plans into precise physical creations. This machine eliminates the challenges of manual craftsmanship, ensuring flawless results even for the most complex patterns.

Key Benefits:

Unmatched Accuracy: Create intricate details with pinpoint precision.

Time-Saving: Reduce production times significantly without compromising quality.

Versatility: Handle diverse projects, from furniture making to decorative carvings.

Consistency: Deliver identical results across multiple pieces, perfect for bulk production.

Exploring the 5x10 CNC Router

The 5x10 CNC router is a preferred choice for professionals who handle large-scale projects or work with oversized wooden sheets. Its generous 5-foot by 10-foot workspace allows for seamless execution of expansive designs, such as furniture panels, doors, and signage.

Features of the 5x10 CNC Router:

Ample Work Area: Ideal for cutting and engraving large materials without the need for piecing.

Precision Mechanics: Designed to maintain accuracy over extended working hours.

Tool Flexibility: Compatible with various attachments for added functionality, such as automated tool changers or multiple spindles.

This model is particularly useful in industries where size and detail matter, such as interior design and furniture manufacturing.

Applications of CNC Router Machines in Woodworking

CNC router machines have diverse applications across various woodworking domains, including:

Furniture Production: Create tables, chairs, cabinets, and other custom pieces with intricate designs.

Interior Décor: Produce unique wooden wall panels, decorative moldings, and ceiling details.

Architectural Designs: Craft custom doors, frames, and staircases with precision.

Artisanal Creations: Design engraved artwork, personalized gifts, and one-of-a-kind decorative items.

Sign Making: Build durable and aesthetically pleasing wooden signs with precision engravings.

Why Choose a CNC Router Machine for Wood?

Ease of Use: With user-friendly software and automated processes, CNC routers make complex projects manageable.

Material Optimization: Reduce waste with precise cutting and carving.

Scalable Production: Adaptable for one-off creations or large-scale manufacturing.

Cost Efficiency: While an initial investment is required, long-term savings are achieved through reduced material waste and increased productivity.

Conclusion

The CNC router machine for wood is a technological marvel that combines precision, versatility, and efficiency to revolutionize woodworking. Its ability to automate complex tasks while maintaining artistic integrity makes it an invaluable asset for both seasoned professionals and hobbyists. The 5x10 CNC router, with its expansive workspace, is especially suited for tackling large and detailed projects. Whether you aim to craft fine furniture or intricate designs, investing in a CNC router ensures that your woodworking ventures achieve excellence with every cut and carve.

2 notes

·

View notes

Text

IEEE Project Center in Tirunelveli

AB Technologies: The Leading IEEE Project Center in Tirunelveli

Engineering students across Tamil Nadu often seek out the best resources for their final year projects, and AB Technologies has become the top choice for students in Tirunelveli. Known for its exceptional quality, innovation, and focus on practical learning, AB Technologies is recognized as the leading IEEE project center in Tirunelveli. Specializing in IEEE-certified projects, the center has carved a niche for itself by providing students with the tools, mentorship, and technical support they need to excel.

The Importance of IEEE Projects

IEEE (Institute of Electrical and Electronics Engineers) projects hold significant value for engineering students. These projects are based on international standards, representing the latest technological advancements and innovations across various fields of engineering. An IEEE-certified project not only strengthens a student’s academic performance but also boosts their resume, providing a strong competitive advantage in the job market. With industries increasingly focusing on cutting-edge technology and innovation, completing an IEEE-certified project from a reputable center like AB Technologies opens up greater career opportunities for students.

Diverse Project Offerings

AB Technologies offers a comprehensive range of project options across several branches of engineering, ensuring that every student can find a project that aligns with their interests and academic requirements. Some of the most popular project domains offered include:

Electronics and Communication Engineering (ECE): AB Technologies provides a variety of IEEE-certified projects in areas like embedded systems, digital communication, IoT (Internet of Things), and VLSI design. Students have the opportunity to work with advanced technologies and tools, preparing them for real-world challenges.

Electrical and Electronics Engineering (EEE): From power systems and electrical machines to renewable energy solutions, AB Technologies offers projects that focus on sustainable and emerging technologies. These projects help students gain a deeper understanding of modern power systems and electrical circuits.

Computer Science and Information Technology: In a field where technological advancements are rapid, AB Technologies offers projects in trending areas like artificial intelligence (AI), machine learning, cybersecurity, web development, and data science. These projects are designed to provide students with hands-on experience in the technologies shaping the future of the industry.

Mechanical Engineering: Mechanical engineering students can explore projects involving robotics, automation, CAD/CAM, and industrial design, gaining practical exposure to cutting-edge mechanical systems and technologies.

Expert Guidance and Mentorship

What sets AB Technologies apart from other project centers is its dedication to providing personalized mentorship. Each student receives one-on-one guidance from experienced professionals and academic experts who ensure that the project is not only completed successfully but also understood in-depth by the student. This mentorship covers every phase of the project, from initial concept and design to development, testing, and final presentation.

Focus on Hands-On Learning

At AB Technologies, students aren’t just completing projects for the sake of academic requirements; they’re getting hands-on, practical experience. The center is equipped with state-of-the-art tools, software, and hardware, allowing students to work on real-world applications of their projects. This practical exposure is invaluable in helping students understand the complexities of modern engineering solutions and preparing them for the challenges they will face in their professional careers.

Building a Reputation of Trust and Excellence

Over the years, AB Technologies has earned a strong reputation for its quality and commitment to excellence. The center has become a trusted partner for engineering students and educational institutions in Tirunelveli, thanks to its consistent track record of delivering successful IEEE projects. Many students have benefited from the expert guidance and innovative project solutions provided by AB Technologies, allowing them to stand out in their academic and professional journeys.

Conclusion

For engineering students in Tirunelveli looking to undertake IEEE-certified projects, AB Technologies is the clear choice. With its wide range of project offerings, expert mentorship, and hands-on learning opportunities, the center ensures that students not only meet their academic goals but also acquire valuable skills that will set them apart in the job market. As the leading IEEE project center in Tirunelveli, AB Technologies continues to empower students to succeed in their engineering careers.

Best IEEE expert engineering project center, Nagercoil | Tirunelveli | Chennai (abtechnologies.in)

#IEEE Project Center in Tirunelveli

#IEEE#Project#Center#in#Tirunelveli

##IEEEProjectCenterinTirunelveli

2 notes

·

View notes

Text

Optimizing Group Projects with SolidWorks PDM: The Ultimate Collaboration Tool

Group assignments can be challenging, especially in engineering, where collaboration and accuracy are crucial. SolidWorks Product Data Management (PDM) is a powerful tool that streamlines collaborative efforts, making group assignments more efficient and manageable. In this blog, we'll explore how SolidWorks PDM facilitates collaboration, enhances productivity, and ensures project success. We'll also highlight the benefits of seeking the Best Solidworks Assignment Help Online and solidworks Assignment Help to maximize your academic performance.

What is SolidWorks PDM?

SolidWorks PDM is a data management solution that centralizes the storage, organization, and control of project data. It allows multiple users to work on the same project simultaneously while ensuring that everyone has access to the latest information. This system is particularly beneficial for group assignments, where collaboration and version control are essential.

Key Features of SolidWorks PDM

Centralized Data Storage

SolidWorks PDM provides a secure, centralized repository for all project files. This ensures that team members can easily access and share data, reducing the risk of lost or misplaced files.

Version Control

With SolidWorks PDM, every modification is tracked, and previous versions are saved. This feature allows team members to revert to earlier versions if needed and ensures that everyone is working with the most up-to-date information.

Workflow Automation

The workflow automation feature streamlines the approval process. Tasks are automatically assigned, and notifications are sent to the relevant team members, ensuring that projects move forward without unnecessary delays.

Access Control

SolidWorks PDM allows administrators to set permissions for different users, ensuring that only authorized personnel can access sensitive information. This feature helps maintain data security and integrity.

Integration with CAD Software

SolidWorks PDM seamlessly integrates with SolidWorks CAD software, providing a cohesive environment for design and data management. This integration enhances productivity and reduces the likelihood of errors.

Benefits of Using SolidWorks PDM for Group Assignments

1. Enhanced Collaboration

SolidWorks PDM facilitates real-time collaboration among team members. By centralizing data storage and providing version control, it ensures that everyone is working on the same page. Team members can easily share updates and feedback, leading to more efficient project completion.

2. Improved Productivity

The workflow automation feature of SolidWorks PDM streamlines the approval process, reducing bottlenecks and ensuring that projects stay on track. By automating routine tasks, team members can focus on more critical aspects of the project, enhancing overall productivity.

3. Reduced Errors

Version control and access control features of SolidWorks PDM significantly reduce the likelihood of errors. Team members can always access the latest version of a file, and unauthorized changes are prevented. This ensures that the final output is accurate and meets the required standards.

4. Time Savings

With SolidWorks PDM, team members can quickly locate and access the necessary files, reducing the time spent searching for information. Workflow automation further saves time by eliminating manual approval processes. These time savings translate into more efficient project completion and better use of resources.

5. Better Project Management

SolidWorks PDM provides tools for tracking project progress and managing tasks. Team leaders can monitor the status of assignments, identify potential issues, and allocate resources effectively. This leads to better project management and successful completion of group assignments.

Seeking the Best Solidworks Assignment Help Online

While SolidWorks PDM offers numerous benefits for collaborative engineering projects, seeking professional assistance can further enhance your academic performance. The Best Solidworks Assignment Help Online provides expert guidance and support for your group assignments. Here are some reasons to consider seeking solidworks Assignment Help:

Expert Guidance

Professional assignment help services employ experts with extensive knowledge and experience in SolidWorks and PDM. They can provide valuable insights and guidance, helping you understand complex concepts and complete your assignments effectively.

Customized Solutions

Assignment help services offer customized solutions tailored to your specific requirements. Whether you need assistance with a particular aspect of the project or comprehensive support, they can provide the help you need.

Time Management

Balancing multiple assignments and responsibilities can be challenging. Seeking solidworks Assignment Help allows you to manage your time more effectively, ensuring that you can focus on other important tasks without compromising the quality of your work.

Quality Assurance

Professional assignment help services ensure that your assignments are of the highest quality. They provide thorough reviews and edits, ensuring that your final output meets academic standards and is free of errors.

Plagiarism-Free Work

Reputable assignment help services guarantee original, plagiarism-free work. This ensures that your assignments are unique and adhere to academic integrity guidelines.

Conclusion

Collaborative engineering projects can be complex and challenging, but SolidWorks PDM provides the tools necessary to streamline group assignments and enhance productivity. By centralizing data storage, providing version control, automating workflows, and ensuring data security, SolidWorks PDM facilitates efficient collaboration and successful project completion.

In addition to utilizing SolidWorks PDM, seeking the Best Solidworks Assignment Help Online can further enhance your academic performance. Expert guidance, customized solutions, and quality assurance ensure that your assignments meet the highest standards. By combining the benefits of SolidWorks PDM with professional assignment help, you can achieve success in your engineering studies and group projects.

For those looking to maximize their efficiency and productivity in group assignments, integrating SolidWorks PDM and leveraging solidworks Assignment Help is the way to go. This combination provides a comprehensive approach to collaborative engineering, ensuring that you and your team can achieve your academic and project goals with ease.

reference:

#solidworks#assignmenthelp#solidworks assignment help#solidworksassignmenthelp#studentassistance#education#school#academicsuccess

3 notes

·

View notes