#Codex Alimentarius

Explore tagged Tumblr posts

Text

Repost from #fnorduniversity on #instagram

3 notes

·

View notes

Text

O artigo analisa a revisão da regulamentação sobre rotulagem de alimentos alergênicos proposta pela ANVISA para 2025, destacando as principais atualizações baseadas no Codex Alimentarius e os aperfeiçoamentos previstos para proteção dos consumidores.

#alergias alimentares#alimentos alergênicos#ANVISA#Codex Alimentarius#halal#legislação sanitária#proteção ao consumidor#RDC 727/2022#rotulagem#Segurança de Alimentos

0 notes

Text

Pesticida a raudales en melones procedentes de Marruecos

Tras la polémica suscitada por el hecho de que las frutas y hortalizas importadas de Marruecos no reflejen si se trata de productos procedentes del Sahara Occidental, territorio que Marruecos ocupa ilegalmente, y de que una abogada general del Tribunal de Justicia de la Unión Europea haya solicitado que la etiqueta de estos productos refleje si su procedencia es de esta región y no de Marruecos,…

View On WordPress

0 notes

Text

Food adulteration threatens health and fair competition. International bodies like Codex Alimentarius set standards. Mexico's CIAD lab deploys advanced techniques—chromatography, spectroscopy, DNA analysis—to detect and combat adulteration.

#Food adulteration#fair competition#Codex Alimentarius#chromatography#spectroscopy#DNA analysis#combat adulteration#adulteration

0 notes

Text

Codex Alimentarius published a report on threshold levels for non-priority allergens

Codex Alimentarius recently published another useful report on the review of scientific data to establish threshold levels for non-priority allergens (not considered in the previous reports), namely: – specific tree nuts (Brazil nut, macadamia/Queensland nut, pine nut)– soy– celery– lupin– mustard– buckwheat– oats For any inquiry, please contact me or Bert Popping at Food Orbit…

View On WordPress

#allergens#Bert Popping#celery#Codex Alimentarius#Food#food orbit#lupin#mustard#PAL#soy#threshold#tree nuts

0 notes

Text

India Advocates for Global Food Standards at Codex Alimentarius Commission

India played a crucial role in supporting the establishment of global standards for spices and vegetable oils during the 86th session of the Executive Committee (CCEXEC) of the Codex Alimentarius Commission (CAC). Held at the Food and Agriculture Organization (FAO) headquarters in Rome from July 1-5, the session focused on reviewing proposals for new standards and monitoring the development of existing ones. The CAC, a joint initiative by the FAO and the World Health Organization (WHO), aims to ensure consumer health protection and fairness in food trade.

Represented by G. Kamala Vardhana Rao, CEO of the Food Safety and Standards Authority of India (FSSAI), India emphasized the importance of advancing standards for spices such as small cardamom, turmeric, and vanilla. As a major producer and exporter of these spices, India's initiative is aimed at facilitating smoother international trade and ensuring high-quality standards. Rao highlighted that these efforts are particularly significant for India's economy and its position in the global spice market.

Read More: (https://luminarytimes.com/india-advocates-for-global-food-standards-at-codex-alimentarius-commission/)

#Codex Alimentarius Commission#Global Food#World Health Organization#leadership#leadership magazine#luminary times#technology#the best publication in the world#world news#world’s leader magazine#news

0 notes

Note

Related to your interest in food safety, would you ever consider international work e.g. with the Codex Alimentarius Commission?

First time im hearing of this! Very interesting. I very much appreciate being thought of because I Am interested in food safety but I will say. It’s not something I’ve done a ton of research on I just keep seeing US outbreaks and US budgets and getting mad. Im kind of in the fuck around phase of my life rn in that I have a job I’m contracted with for another year and then after that. I have to decide if I. 1) want to stay in lab science forever (no I don’t think so) 2) go to grad school (yes I think so) 2a) go to grad school to continue studying biology (yes) which would translate to a continued 40 hr in person work week (not as hot on this) 2b) go to grad school for something Else to pivot careers into fake work from home bullshit. But I have flirted with the idea of moving in a direction that leads to FDA or CDC. who hasn’t

5 notes

·

View notes

Text

Round 1

Propaganda:

Huntsman Cheese

This actually looks sick - if cheese looked like cake!

Mutant hybrid cheese - double gloucester and stilton

Classic cheese board moment

Havarti

Another cheese with controversy! Whoever thought that the cheese lobby is a mess

A member of the Codex Alimentarius - no clue what this is but it sounds mysterious

Havarti's deadname is Danish Tilsiter

#tumblr cheesy man#cheese tournament#cheese#cheese-tournament#cheese poll#tumblr polls#cheddar cheese#food poll#polls#tournament poll#tumblr tourney#politics#huntsman#united kingdom#Havarti#denmark

4 notes

·

View notes

Text

How UAE Microbiological Testing Labs Help Exporters Meet International Standards? | +971 554747210

In today’s global marketplace, meeting international standards is not just a preference—it’s a necessity. Whether you're exporting food, pharmaceuticals, cosmetics, or water-based products, regulatory bodies across Europe, North America, Asia, and other regions demand strict adherence to safety and quality benchmarks. This is where the role of a Microbiological Testing Lab becomes crucial.

For exporters based in the UAE, leveraging the services of a certified Microbiological Testing Lab helps ensure compliance with stringent global regulations. These laboratories provide scientific assurance that your products are free from harmful microorganisms and meet the safety and hygiene expectations of importing countries. This article explores how UAE-based microbiological testing labs support exporters in achieving international market access and consumer trust.

What Is a Microbiological Testing Lab?

A Microbiological Testing Lab is a specialized facility that detects and analyzes microorganisms in various products, such as bacteria, yeast, mold, and viruses. These labs ensure that goods are microbiologically safe and meet the required health and safety regulations. Industries such as food and beverage, pharmaceuticals, cosmetics, and personal care products rely on these labs to verify product integrity and prevent contamination.

In the UAE, these labs play a strategic role in helping local manufacturers and exporters comply with both national and international safety requirements.

Importance of Microbiological Testing for Exporters

When exporting goods, microbial contamination is one of the primary concerns that can lead to:

Rejected shipments at customs

Hefty fines or product recalls

Loss of credibility with overseas clients

Legal liabilities

Health hazards for consumers

To mitigate these risks, exporters must demonstrate that their products meet international microbiological standards such as those set by:

Codex Alimentarius (FAO/WHO)

European Food Safety Authority (EFSA)

U.S. Food and Drug Administration (FDA)

ISO (International Organization for Standardization)

Health Canada and other regulatory bodies

Using a Microbiological Testing Lab in the UAE ensures your products are thoroughly tested before export, reducing delays and increasing acceptance in foreign markets.

Key Ways UAE Microbiological Testing Labs Support Exporters

1. Adherence to Global Testing Standards

Top-tier microbiological testing labs in the UAE adhere to internationally recognized standards such as:

ISO 17025 (General requirements for the competence of testing laboratories)

ISO 21149 (Microbiology of cosmetics)

ISO 6579 (Detection of Salmonella)

USP <61> and <62> (Microbiological examination of pharmaceutical products)

These certifications ensure that your test results are globally accepted, which is critical for exporters aiming to access international markets.

2. Pathogen Detection and Quality Assurance

Labs in the UAE are equipped to test for a broad range of microorganisms that are considered harmful or unacceptable in international markets, including:

Salmonella

Listeria monocytogenes

Escherichia coli (E. coli)

Staphylococcus aureus

Pseudomonas aeruginosa

Total Plate Count (TPC)

Yeasts and molds

This comprehensive testing ensures your products meet microbial limits and do not pose any health risks to consumers abroad.

3. Customized Testing for Industry-Specific Requirements

Different countries and industries impose unique testing requirements. A Microbiological Testing Lab in the UAE can tailor test parameters based on your target market and product type. For example:

Food & Beverage: Detection of pathogens like Salmonella and Listeria, shelf-life studies, water activity testing.

Cosmetics: Preservative efficacy testing, microbial limit tests for creams and lotions.

Pharmaceuticals: Sterility testing, endotoxin testing, bioburden analysis for sterile and non-sterile drugs.

By aligning testing with specific export standards, UAE labs help ensure smooth customs clearance and regulatory approval overseas.

4. Rapid Turnaround and Pre-Shipment Clearance

Time is a critical factor in international logistics. UAE-based microbiological labs offer:

Fast turnaround (24–72 hours for many tests)

Emergency testing services for urgent consignments

Pre-shipment clearance testing

Certificates of Analysis (CoA) accepted by global regulatory bodies

This speed and reliability help prevent shipment delays and build trust with foreign buyers.

5. Accredited Reports and Documentation Support

Exporters often need to submit testing documentation along with their shipments. UAE microbiological labs provide:

Official test reports with ISO/IEC 17025 accreditation

CoAs with full traceability

Batch-level testing documentation

Electronic and hard copy formats

These documents support the importer’s due diligence and regulatory filings, minimizing the chance of shipment rejections.

6. Regulatory Guidance and Export Consulting

Many leading Microbiological Testing Labs in the UAE offer added value through export consulting services. These may include:

Guidance on country-specific microbiological limits

Advice on sampling techniques

Pre-audit preparation for regulatory inspections

Regulatory updates and compliance tips

This makes the lab not just a service provider, but a strategic partner in your export journey.

7. Support for Halal and Hygiene Certifications

In addition to microbial testing, many UAE labs support halal certification, HACCP compliance, and GMP inspections—all of which are essential for global exports, especially to Muslim-majority countries.

Microbiological testing is often a key step in:

Halal product certification

ISO 22000 food safety management certification

GHP/GMP audits for cosmetics and pharmaceuticals

By integrating these services, microbiological labs streamline your path to multi-market compliance.

8. Digital Integration and Real-Time Access

Modern UAE labs offer digital platforms where exporters can:

Track sample progress in real time

View historical test reports

Schedule pickups and consultations

Download compliance certificates

This level of automation simplifies logistics and ensures transparency throughout the testing cycle.

Top Cities in the UAE Offering Microbiological Testing for Exporters

Exporters in the UAE have access to microbiological labs in major business hubs, including:

Dubai: Strategically located near Jebel Ali Port and Dubai International Airport

Abu Dhabi: Serving government and industrial sectors with high-end testing services

Sharjah & Ajman: Popular with SME exporters and food producers

Ras Al Khaimah & Fujairah: Supporting industrial free zones and logistics corridors

No matter where your business operates, reliable microbiological testing facilities are within reach.

Conclusion

For UAE exporters, microbiological safety is non-negotiable. It protects consumer health, preserves brand integrity, and most importantly, opens doors to international markets. A certified Microbiological Testing Lab in the UAE ensures that your products comply with international standards, preventing costly delays and legal issues.

By partnering with a lab that offers accredited testing, tailored services, and export guidance, you position your business for global success. In a world where safety and quality are paramount, microbiological testing is not just a requirement—it’s a competitive advantage.

#Microbiological Testing Lab#Microbiological Testing#Microbiological Testing Lab UAE#Testing Lab near me#Testing Lab UAE

0 notes

Text

Certification of ISO 22000 in Kuwait

Certification of ISO 22000 in Kuwait

The International Organization for Standardization (ISO) developed the outcome-focused ISO 22000 food safety management system, which lays out specifications for any food industry organization with the aim of enhancing overall food safety performance. The goal of these guidelines is to guarantee food safety across the world's supply chain. In addition to focusing on traceability in the feed and food chain, the standards cover the general rules for managing food safety.

A food safety management system's (FSMS) standards are outlined in the international standard ISO 22000 in Kuwait . It is intended to guarantee that companies in the food chain can reliably deliver services and goods that are safe. The standard incorporates the application procedures created by the Codex Alimentarius Commission as well as the Hazard Analysis and Critical Control Point (HACCP) system's concepts. It incorporates widely accepted essential components, such as interactive communication, system management, and preparatory programming, to guarantee food safety across the food chain.

ISO 22000: Why is it important?

For both consumers and businesses, ISO 22000 is essential in Kuwait because it allows organizations to take a methodical approach to improving their overall performance in terms of food safety. From farm to fork, it assists in identifying, preventing, and controlling food safety problems at every point in the food chain. All businesses that produce food, supplies, and materials that come into contact with food, as well as those that work in retail, catering, and other associated industries, are subject to this standard, regardless of their size or level of sophistication.

The prerequisites for ISO 22000 in Kuwait

Organizations must set up precondition programs that try to lower the risk of contamination when attempting to comply with ISO 22000. ISO does not specify the particular criteria of each program, but it does identify some areas and programs that enterprises should take into account. Rather, each institution will create its own programs according to its own need.

It's important to understand that ISO/TS 22002-1 only applies to food manufacturers and not to other entities throughout the food chain. When creating their precondition programs, enterprises should take into account the following areas, according to ISO 22000:

Control of pests

Bioterrorism, biovigilance, and food defense

Building design and construction

Avoiding cross-contamination

Equipment appropriateness, upkeep, and cleaning

Facilities for employees and personal hygiene

Administration of acquired materials The design of the workspace and the building

Methods for cleaning and sanitizing

Details about the product Energy, water, and air utilities

Storage

Disposal of waste

Protocols for product recalls

How can one obtain ISO 22000 certification in Kuwait?

You can write to us at [email protected] or fill out the contact form with the required information and submit it if you want your company to be certified ISO 22000 in Kuwait. One of our certification experts will get in touch with you to better understand your needs and offer the best solution on the market.

ISO 22000 Services in Kuwait

1 note

·

View note

Text

The Impact of Food Testing Laboratories in Ajman on the UAE’s Food Safety Regulations | +971 554747210

Food safety is a critical concern in every nation, especially in countries with diverse food imports and a growing domestic food production sector. In the UAE, food safety regulations are essential to protect public health, ensure food quality, and maintain consumer trust. One key player in ensuring these standards are met is the food testing laboratory, which plays an integral role in enforcing and supporting the UAE's food safety regulations.

Ajman, one of the emirates in the UAE, has emerged as a hub for food testing laboratories, which contribute significantly to the country's food safety ecosystem. This blog will explore the profound impact of food testing laboratories in Ajman on the UAE’s food safety regulations, examining how they help maintain public health, facilitate regulatory compliance, and support the local food industry.

1. Role of Food Testing Laboratories in Upholding Food Safety Standards

The UAE's food safety regulations are designed to ensure that all food products available in the market are safe for human consumption. These regulations cover every stage of the food supply chain, from production to packaging and transportation. However, ensuring compliance with these stringent standards requires rigorous testing, which is where food testing laboratories in Ajman come into play.

Food testing laboratories are responsible for performing a variety of tests to detect contaminants, such as microorganisms, chemicals, heavy metals, and pesticide residues in food products. They also carry out nutritional analysis to ensure food products are accurately labeled and meet the nutritional content stated on packaging.

By conducting these tests, food testing laboratories help ensure that food producers and suppliers comply with the regulations set by UAE authorities, including the UAE Ministry of Climate Change and Environment (MOCCAE) and the Dubai Municipality Food Control Department. This ensures that food products sold in the UAE market are safe for consumers.

2. Ensuring Regulatory Compliance with Local and International Standards

The food industry in the UAE is highly regulated, with strict guidelines designed to protect consumer health and maintain the integrity of the food supply. These regulations are enforced by local authorities, but their effectiveness depends on the ability of food producers to meet established standards. Food testing laboratories in Ajman are crucial for ensuring that food producers comply with both local regulations and international standards.

Local Regulations:

The UAE has a set of food safety standards and regulations enforced by various government bodies. These regulations govern everything from food labeling, ingredient sourcing, and packaging to the permissible levels of contaminants in food. Food testing laboratories play an essential role in monitoring food products to ensure they meet the GSO 2233-2012, the UAE Food Code, and other relevant national standards.

International Standards:

With the UAE being a major trading hub for food imports and exports, it is essential for food products to meet international food safety standards. Key regulations include the Codex Alimentarius, European Food Safety Authority (EFSA) standards, and FDA requirements for food exports to countries like the US and Europe.

Ajman-based food testing laboratories are equipped to carry out a wide range of testing that adheres to both local and international standards, making them indispensable for businesses that need to meet global compliance for export. This ability helps local food producers and importers maintain credibility in the global market and prevents costly regulatory violations.

3. Promoting Public Health by Detecting Contaminants

Foodborne illnesses can have severe consequences, including hospitalizations and deaths, and are often caused by harmful microorganisms or toxic substances in food. Ajman’s food testing laboratories are instrumental in identifying and preventing food contamination, which is crucial for public health.

Microbiological Testing: Microbiological contamination, such as bacteria like Salmonella, E. coli, and Listeria, is one of the most common causes of foodborne illnesses. Food testing laboratories in Ajman routinely carry out microbiological testing to detect these pathogens in food products, particularly in high-risk foods such as meat, dairy, and fresh produce. By identifying contamination early, these laboratories prevent unsafe products from reaching consumers.

Chemical Contaminant Testing: Food testing laboratories in Ajman also test for various chemical contaminants that can pose significant health risks. For example, pesticide residues in fruits and vegetables or the presence of heavy metals like lead, mercury, and cadmium in seafood can be dangerous. These substances can accumulate in the human body over time, leading to long-term health issues such as cancer and organ damage.

By performing comprehensive tests, food testing laboratories help ensure that food products meet permissible levels of contaminants and prevent hazardous substances from entering the food chain.

4. Facilitating Compliance with Halal Standards

Halal certification is an important aspect of food safety in the UAE, as the majority of the population follows Islamic dietary laws. Halal certification ensures that food products meet the dietary requirements as prescribed by Islamic law, prohibiting ingredients such as pork and alcohol and ensuring that slaughtering processes are carried out in accordance with Halal guidelines.

Ajman’s food testing laboratories play a key role in Halal testing. These laboratories are accredited to perform comprehensive checks on food products to ensure that they meet Halal standards. Testing includes verifying that ingredients are free from haram (forbidden) substances, such as pork, and ensuring that no cross-contamination occurs during the food production process.

Halal testing not only ensures food safety and quality but also boosts consumer confidence in locally produced food. For businesses, Halal certification is vital for accessing Muslim markets both locally and internationally.

5. Supporting the Export of Food Products

Ajman’s food testing laboratories also help local food producers meet the necessary export requirements for international markets. The UAE is a major food exporter, particularly to other GCC countries, Africa, and Asia, and it is critical that food products comply with the regulations of the importing countries.

Many countries require food products to undergo rigorous testing to ensure that they meet the destination country's food safety standards. Food testing laboratories in Ajman are well-equipped to handle testing requirements for various international markets, including countries with stringent import regulations like the EU, the US, and Saudi Arabia.

By providing accurate and comprehensive testing services, food testing laboratories in Ajman help food producers access new markets and increase their export potential. This is especially important in today’s globalized economy, where food safety and quality are paramount for maintaining international trade relationships.

6. Maintaining Transparency and Consumer Confidence

Transparency in the food supply chain is critical for maintaining consumer trust. Food testing laboratories in Ajman help ensure that food producers maintain transparency by providing accurate testing results and certification. These results can be used to verify that food products comply with health and safety regulations, offering consumers the confidence that the food they are purchasing is safe.

For businesses, partnering with accredited food testing laboratories not only ensures compliance with food safety regulations but also helps build a positive reputation. By having testing results readily available for inspection and certification, businesses show their commitment to consumer health and safety, which enhances their credibility in the marketplace.

Conclusion

Food testing laboratories in Ajman play a critical role in shaping the UAE’s food safety regulations and supporting the food industry’s growth and sustainability. From ensuring compliance with local and international standards to detecting contaminants and promoting consumer health, these laboratories are indispensable in maintaining the integrity of the UAE’s food supply.

Their impact is felt at every stage of the food production and supply chain, from importers to producers and exporters, and they help businesses navigate the complex regulatory landscape. As the UAE continues to be a global food trading hub, the role of Ajman-based food testing laboratories in upholding food safety standards will only continue to grow in importance.

#food testing lab#food testing#food testing laboratory#food testing services#testing lab near me#testing lab uae

0 notes

Text

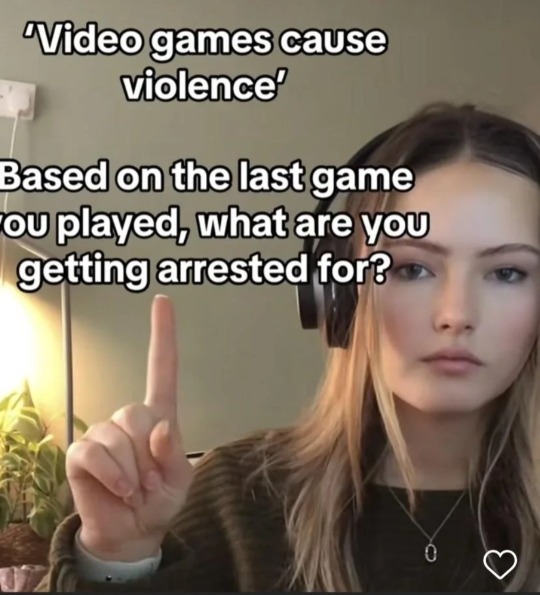

Violating the codex alimentarius vis~a~vis cookie production- so manslaughter on a mass scale.

duality of man

82K notes

·

View notes

Text

How Microbiological Testing Labs Detect Spoilage Organisms in Food?

When it comes to food safety and shelf-life, detecting spoilage organisms is just as important as testing for harmful pathogens. Spoilage organisms may not always make food unsafe, but they can significantly affect the taste, smell, appearance, and quality of food products. That’s where a Microbiological Testing Lab plays a vital role.

These labs use advanced scientific methods to identify, monitor, and control the growth of microorganisms that cause food to deteriorate. Whether it’s mold in bread, souring in dairy, or off-odors in meats, microbiological testing ensures that food producers deliver high-quality, stable products to market.

In this blog, we’ll explore how a Microbiological Testing Lab detects spoilage organisms in food, what methods are used, and why it’s essential for food manufacturers, exporters, and retailers.

What Are Spoilage Organisms?

Spoilage organisms are microorganisms such as bacteria, yeasts, and molds that cause food to deteriorate. Unlike foodborne pathogens, which pose health risks, spoilage microbes affect sensory properties like:

Texture

Flavor

Odor

Color

Common spoilage organisms include:

Pseudomonas spp. (meat, seafood, dairy)

Lactic acid bacteria (dairy, pickles)

Yeasts (fruit juices, sauces)

Molds (bread, cheese)

Enterobacteriaceae (various processed foods)

Controlling these organisms helps extend shelf-life and maintain product quality, which is critical for both local consumption and international exports.

Why Is Spoilage Detection Important in Food?

Spoilage leads to consumer dissatisfaction, product recalls, and economic losses. It can damage a food brand's reputation and reduce buyer confidence. Food manufacturers must meet national and international quality standards such as:

Codex Alimentarius

ISO 22000

HACCP

GSO standards (in GCC countries)

By working with a certified Microbiological Testing Lab, food businesses can regularly monitor microbial levels and act early to prevent spoilage and waste.

How Microbiological Testing Labs Detect Spoilage Organisms

A Microbiological Testing Lab follows a comprehensive approach to detect spoilage organisms in food products. Let’s break down the process:

1. Sample Collection and Preparation

Testing begins with properly collected samples. This might include:

Raw materials

In-process food

Finished products

Packaging materials

Swabs from equipment or environment

Samples are transported under controlled conditions to preserve microbial integrity.

2. Culture-Based Testing

This is one of the most traditional yet effective methods. It involves growing microorganisms on specific agar media under controlled temperature and pH conditions.

Common Media Used:

Plate Count Agar (PCA): Total viable count

MacConkey Agar: Detects coliforms

Rose Bengal Agar: Molds and yeasts

Lactic Acid Bacteria Agar: Detects lactic bacteria

After incubation (24–72 hours depending on the organism), colonies are observed, counted, and identified.

3. Enumeration Techniques

Spoilage organism populations are measured using:

Colony Forming Units (CFU/g or CFU/ml)

Most Probable Number (MPN) method for low levels

Spread plate and pour plate techniques

These counts help determine if microbial levels are within acceptable limits or if the product is at risk of spoilage.

4. Biochemical Identification

Once colonies are isolated, labs use biochemical tests to identify the type of microbe. These may include:

Catalase and oxidase tests

Sugar fermentation tests

Enzyme activity profiles

This helps pinpoint specific spoilage organisms (SSOs) that are known to affect certain food types.

5. Molecular Testing (PCR and DNA Sequencing)

Advanced Microbiological Testing Labs often use molecular techniques like:

Polymerase Chain Reaction (PCR)

Real-time PCR

DNA barcoding

These tests detect microbial DNA or RNA with high accuracy, especially for fastidious organisms that may not grow easily on culture media.

6. Metabolic and Sensory Analysis

Some labs assess metabolites produced by spoilage microbes—like lactic acid, alcohol, or sulfur compounds. These can indicate fermentation, souring, or off-odors.

Sensory panels and chemical testing (e.g., pH, Brix, TVBN) often complement microbiological data for holistic quality control.

Benefits of Working with a Microbiological Testing Lab

✅ Ensure Product Freshness

Regular testing helps confirm the microbial stability of food products and prevent premature spoilage during distribution or storage.

✅ Extend Shelf-Life

By identifying which spoilage organisms are active in your food product, you can adjust formulations, packaging, or processing conditions to extend shelf life.

✅ Reduce Waste and Recalls

Early detection minimizes product losses and helps companies take corrective action before spoilage becomes widespread.

✅ Meet Regulatory and Export Standards

Many countries require microbiological testing certificates for imported food. Partnering with a reliable lab helps meet these compliance needs smoothly.

✅ Strengthen Brand Trust

Consistent product quality leads to customer satisfaction, repeat purchases, and strong market presence—especially for premium food brands.

Choosing the Right Microbiological Testing Lab

When selecting a testing partner, consider the following:

Accreditation (ISO/IEC 17025, GAC, EIAC)

Experience with your product type

Capability in rapid testing and molecular diagnostics

Turnaround time and reporting formats

Expertise in shelf-life studies

Labs that offer customized testing plans and consultation on results add more value to your food safety strategy.

Final Thoughts

Food spoilage isn’t just about unpleasant taste or appearance—it can mean lost revenue, damaged reputations, and even health hazards. That’s why working with a Microbiological Testing Lab is essential for every food producer, processor, or exporter.

By detecting spoilage organisms early and accurately, these labs help maintain product quality, ensure regulatory compliance, and deliver safe, long-lasting food to the consumer.

Whether you're manufacturing dairy, seafood, ready-to-eat meals, or beverages, partnering with a certified Microbiological Testing Lab ensures that your brand delivers on its promise of freshness and safety every time.

0 notes

Text

Validation of Commercial Baking as an Effective Step to Control/Inactivate Salmonella in Baked Products Major findings, analysis and conclusions Description of the baking industry and baking emphasis in the United States. Purpose and structure of importance Description of the problem being addressed and its importance to the practice of applied food safety Process of Consultation Outline how the client (ABA) will be engaged and carefully define the problem Identification of key stakeholders Overview and feedback of findings and results Recommended actions and dissemination of these recommendations Plans for implementation and measurement Major findings. The U.S. had approximately 167,600 baker positions available in 2012 and around 6% of these were self-employed (Bakery business, 2016). Although industry analysts project sustained growth in the U.S. baking industry, this growth will not be on par with other industries (Bakery business, 2016). Currently, the U.S. baking industry is a nearly $310 billion industry that has enjoyed a remarkably safe record for the production of shelf stable processed foods over the years (Channaih, 2015). Despite this impressive safety record, pathogens such as Salmonella spp. are still capable of being introduced into bakery products through a wide array of constituent ingredients, including milk products, eggs, flour, milk chocolate, coconut, peanut butter, fruit, spices and yeast flavorings (Channaih, 2015). Mitigating the Salmonella threat is a fundamental responsibility of all food manufacturers and effective strategies are required in order to prevent associated illnesses and deaths (Channaih, 2015). Moreover, a number of U.S. regulatory agencies have implemented zero tolerance guidelines for Salmonella for all ready-to-eat food products (Channaih, 2015). Since the Salmonella pathogens can survive and even thrive in low-water activity foods and processing environments, identifying and implementing Salmonella control processes represent an important responsibility for food manufacturers today (Channaih, 2015). In addition, the introduction of Salmonella spp. into bakery products holds the potential for causing a threat to public health if products are not properly baked (Channaih, 2015). There are some proven methods for controlling the threat of Salmonella, though, including most especially kill-step validation procedures that have demonstrated efficacy in destroying the bacteria. Although the kill-step validation procedures recommended by the FDA are time-consuming, the procedures are fairly straightforward and can be accomplished by experienced microbiologists and statisticians who have access to containment and laboratory facilities as well as commonly used data analysis applications such as Excel. Moreover, the FDA also publishes good-specific kill-step validation guidelines for different types of common baked goods. Definitions of the key terms used in this study are provided below. Validation: According to the Codex Alimentarius Commission (Codex), validation is defined as "obtaining evidence that a control measure or combination of control measures, if properly implemented, it is capable of controlling the hazard to a specified outcome. In other words, validation attempts to answer the questions: Are process parameters the right ones? Will they work? Validation is clearly distinct but often confused with verification which is also a major requirement of the Food Safety Modernization Act of 2011" (cited in Microbiological safety validation of food processes, 2013, p. 2). Verification: The Codex defines this term as "the application of methods, procedures, tests, and other evaluations, in addition to monitoring, to determine whether a control measure is or has been operating as intended" (cited in Microbiological safety validation of food processes, 2013, p. 2). Monitoring: The Codex defines this term as "the act of conducting a planned sequence of observations and/or measurements of control parameters to assess whether a control measure is under control" (cited in Microbiological safety validation of food processes, 2013, p. 2). Analysis. The analysis of the U.S. baking industry that follows below included the number of commercial bakeries, their economic impact including both wages and taxes paid at the state level as well as national totals. In addition, current working conditions, wage levels and industry forecasts are also included in the analysis. Beyond the foregoing issues, this study also analyzed the paths by which Salmonella can be introduced into commercial bakery products in order to identify opportunities for improvement in storage, production and cooking methods. Finally, an analysis of the recommended steps to be used in kill-step validation for commercial bakeries is followed by a summary of these issues in the study's conclusion which are discussed below. Conclusions. The research was consistent in underscoring the major impact of the baking industry on local, state and national economies and the ubiquity of baked goods in Americans' diets. Given the enormity of these activities, identifying opportunities to improve the safety of commercial baked goods represents a timely and valuable enterprise. Although the majority of food products that are used today are required to be subjected to a kill-step at the production points, there remains a lack of scientific evidence to confirm their efficacy. Consequently, there is a compelling need for an industry-wide scientific-validation procedure that can help ensure food safety (Channaih, 2015). Introduction Today, the American baking industry generates more than $102 billion in economic activity each year and employs more than 706,000 workers who are highly skilled (Baking industry economic impact study, 2016). This economic impact is just the tip of the commercial bakery iceberg, though, because the production generated by these commercial bakeries uses constituent ingredients that are purchased from other vendors, creating a multiplier effect that further increases this economic impact (Baking industry economic impact study, 2016). According to the American Bakers Association, "Thus, economic activity started by the baking industry generates output (and jobs) in hundreds of other industries, often in sectors and states far removed from the original economic activity" (Baking industry economic impact study, 2016, p. 2). At present, this aggregated economic impact is estimated at nearly $310 billion a year (Baking industry economic impact study, 2016). This study provides a review of the relevant literature concerning the American baking industry to include an analysis of this economic impact as well as the potential for the introduction of Salmonella into commercial bakery products to disrupt this industry. Although the U.S. baking industry has experienced an enviable safety record with respect to Salmonella, outbreaks of Salmonellosis have occurred in the past and continue to adversely affect bakery operations in the U.S. and abroad. In response, government agencies including the U.S. Food and Drug Administration, have developed standardized, step-by-step protocols for handling and monitoring commercial bakery products that ensure the destruction of any Salmonella contamination that might slip through quality assurance protections. Moreover, specific step-by-step protocols for kill-step validation have been formulated for the most commonly manufactured commercial bakery goods that provide a valuable framework in which to ensure the food safety of these products. To gain some new insights concerning the importance of these kill-step validation procedures to the contemporary multi-billion dollar baking industry, a brief description of the baking industry in the United States is provided below. Description of the baking industry in United States The baking industry in the United States is older than the country itself, and a number of flour mills in the American colonies operated bakeries (Albion & Williamson, 1944). Many of the baked goods that were produced by these early bakeries, though, especially bread products, bore little resemblance to their modern, enriched counterparts. For instance, Albion and Williamson (1944) report that, "A considerable part of their exports being bread, probably mainly a 'hardtack' that would not deteriorate on long sea voyages" (p. 447). Over time, the American baking industry became more specialized, with one sector focusing on the production of pastries, cakes, pies and breads while a second sector produced biscuits and crackers (Albion & Williamson, 1944). The biscuits and cracker sector of the American baking industry was the first to introduce large-scale factory production, due in large part to the fact that its products were not as perishable as pastries and breads and were able to be distributed over larger geographic regions (Albion & Williamson, 1944). At the fin de siecle, American bakeries competing in the biscuits and crackers sector began to form strategic alliances and large corporations became commonplace (Albion & Williamson, 1944). For instance, Albion and Williamson note that, "In 1898 the National Biscuit Company was formed by the merger of four large companies. The new company, it was claimed, would control the cracker and biscuit trade from the Atlantic to the Rockies, operating 139 plants and about 90% of the total capacity of the industry" (p. 447). Indeed, NBC was good for its word and by applying improved packaging methods and innovative marketing strategies, the company grew its market share throughout the country rapidly to the point where by 1900, it was using more than two million barrels of flour each year and had plans to make its production even more efficient by milling its own flour (Albion & Williamson, 1944). As noted above, the other baking industry sector that emerged during this period in early American history specialized in more perishable baked goods such as breads, pies, cakes and pastries (Albion & Williamson, 1944). Additional improvements in manufacturing and processing that were implemented during World War I helped this sector to develop commercial bakery products, most especially breads with preservatives that enjoyed widespread popularity (Albion & Williamson, 1944). By 1940, though, the U.S. federal government was faced with a world war looming on the horizons and became concerned over the malnourishment that adversely affected the American population during the Great Depression (Wonder Bread, 2012). In fact, this concern was well warranted and even represented a national security threat because at least 13% of the initial million men assessed by draft boards in 1940 were refused active duty service due to malnourishment and associated symptoms (Wonder Bread, 2012). According to the editors of The Wilson Quarterly, "It dawned on the government to spike the most ubiquitous items in American pantries with vitamins. Thiamin, niacin, iron, and eventually riboflavin became banner ingredients of enriched bread" (Wonder Bread, 2012, p. 66). In an effort to ensure that the American public would be receptive to this enriched bread product, the U.S. Department of Agriculture partnered with researchers in the baking industry to launch was has been termed the "Manhattan Project of bread" in 1952 (Wonder Bread, 2012, p. 66). The goals of this collaborative public-private partnership were two-fold: (a) to identify American consumers preferences for white bread taste, texture and appearance, and (b) to develop manufacturing processes that could produce large quantities of bread rapidly (Wonder Bread, 2012). The findings that emerged from this research were based on exhaustive testing of 600 American families living in Rockford, Illinois (Wonder Bread, 2012). The majority of these consumers were found to prefer "extremely fluffy bread," most likely since this quality was widely regarded as a sign of freshness (Wonder Bread, 2012). In addition, this research found that American consumers preferred bread that was two-and-a-half times sweeter than the typical product of the day (Wonder Bread, 2012). With respect to manufacturing, researchers identified a new method for discretely fermenting yeast that significantly reduced the amount of time commercial bakeries were required to wait for bread products to respond by rising (Wonder Bread, 2012). Other innovations that facilitated the production process of bread during this period in American history included new methods for strengthening gluten strands that could withstand the more rigorous automatic production methods that were being introduced (Wonder Bread, 2012). As the editors of The Wilson Quarterly conclude, "Four years and almost one hundred thousand slices of bread later, the prototypical loaf of enriched white bread was born" (Wonder Bread, 2012, p. 66). The "Manhattan Project of bread" succeeded beyond anyone's expectations, and average American consumers were eating one-and-a-half pounds of the newly enriched bread product each week by 1962 which provided between 25% and 30% of their requisite caloric intake for the period (Wonder Bread, 2012). While the average consumption level has declined somewhat from this 1962 peak year, the editors of The Wilson Quarterly conclude that, "Bread remains a fundamental conduit of governmentally mandated nutrients -- and]a staple of American diets" (Wonder Bread, 2012, p. 66). Today, companies competing in the American baking industry produce an enormous array of products, including fresh and frozen bread as well as cakes, pies, and doughnuts (Bakery business, 2016). In the United States, major competitors in the baking industry include Flowers Foods and Mckee Foods (Bakery business, 2016). At present, bakery products in the U.S. are produced by approximately 2,800 commercial bakeries that account for a combined annual revenue of approximately $36 billion together with around 6,000 retail bakeries that generate combined annual revenue of approximately $3.8 billion (Bakery business, 2016). The early research by the U.S. government concerning consumer preferences for baked goods has been greatly expanded in the intervening years, and the U.S. baking industry continues to evaluate optimal recipes to satisfy changing consumer tastes (Bakery business, 2016). Demand for bakery goods is also affected by the extent to which bakeries are operated by grocery stores rather than purchasing from commercial bakeries (Bakery business, 2016). According to the U.S. Small Business Development Centers (SBDC), "Profitability for individual companies is determined by efficiency of operations. Large companies have scale advantages in procurement, production, and distribution" (Bakery business, 2016, p. 2). By contrast, smaller baking industry companies seek to gain and sustain a competitive advantage through optimal distribution processes or by providing specialty baked goods (Bakery business, 2016). The SBDC adds that, "In the United States, the commercial side of the industry is concentrated: the 50 largest companies generate 75% of revenue. The retail side of the industry is highly fragmented: the 50 largest companies generate about 15% of revenue, and the typical company operates just one facility" (Bakery business, 2016). Although companies competing in the baking industry range from micro to major conglomerates, the general product line produced by this industry includes fresh and frozen bread and baked goods (this category includes muffins, cakes, and croissants but not cookies and crackers) (Bakery business, 2016). Besides marketing these baked good products to grocery stores and other food service companies, many commercial bakeries also market their products to the public directly (Bakery business, 2016). Given that bread remains the "staff of life" for most American consumers, demand for these products is projected to increase at a yearly rate of approximately 0.6% over the next 5 years, reaching a total of nearly $40 billion (Bakery business, 2016). The SBDC also reports that, "Consumers are expected to continue to trend toward health eating and increase demand for items like fortified breads, gluten-free loaves and sprouted and organic sweets" (Bakery business, 2016, p. 3). As a result, the profitability of the baking industry in the United States is also projected to increase over the next 5 years due to the stabilization of constituent ingredient prices and the enhanced ability of commercial bakeries to adjust their pricing levels as prices for ingredients shift (Bakery business, 2016). There are also expectations that continued strategic alliances between major players in the industry will further enhance productivity and profitability during the next 5-year period (Bakery business, 2016). External competition has increased over the past five years and imports will continue to grow at an annualized rate of 7.1%. However, growing demand for this product outside of the country will increase exports by 9.8% per year over the next five years. (Bakery business, 2016) A categorical breakdown of projected sales for individual bakery good products is provided in Table 1 below. Table 1 Projected sales for individual bakery good product categories Category Description Cakes and Cupcakes The largest households, which are those with children, are the best customers for cakes and cupcakes. Six in ten married couples with children spend more than the average household on cakes and cupcakes, with that rate increasing to almost three in four for people with school-aged children. Hispanics spend about 17% more than average on this product and Asians spend an even greater amount at 25% more. The average household spending on this product fell by more than one fifth between 2000 and 2006. The cake and cupcake sector of the baking industry then stabilized between 2006 and 2009. Cookies The largest portion of revenue from cookies is derived from households with children. A household with a married couple and children will spend 54% more than the average household on this product within the baking industry. If the children are school-aged, the household will spend 73% more than average. Spending on cookies fell by over two tenths between 2000 and 2006, but has held steady since then. Prepared Desserts The oldest consumers as well as married couples with school-aged children or older children at home are the best customers for the prepared desserts segment of the baking industry. Couples with school-aged children spend over a fourth more and those with adult children spend more than 54% more than the average household on this product. People aged 65 years or older spend 12 to 17% more than the average household on prepared desserts. An increase in consumer preference for the convenience of prepared desserts has led to an 18% increase in household spending from 2000 to 2009. (Bakery business, 2016) Pies, Tarts and Turnovers Households with children are the best customers of pies, tarts and turnovers. Those households spend 47 to 71% more than the average, while single parents spend just above the average on this product. People aged 35 to 54 spend around two fifths more than the average household and take up 47% of the market. Sweetrolls Coffee Cakes and Doughnuts: Households with children are the best customers for sweetrolls, coffee cakes and doughnuts and spend about 52 to 69% more than the average household on this segment of the baking industry. Household spending on sweetrolls, coffee cakes and doughnuts fells 23% between 2000 and 2009, and will continue to decline as the baby-boomer generation exits the best customer life stage. Source: Adapted from Bakery business, 2016 In 2012, there were approximately 167,600 baker jobs in the United States and about 6% of these bakers were self-employed (Bakery business, 2016). Read the full article

0 notes

Video

youtube

NCF Dr Rima Laibow Codex Alimentarius and the Nazi Agenda 21 depoulatio...

0 notes