#Electronic Automatic Temperature Controls

Explore tagged Tumblr posts

Text

Vehicle Recall: Ford Transit Vans:

#crash hazard#Display Screen#Electronic Automatic Temperature Controls#Electronics#Ford Transit#Recalls Direct RIN: 19637-2025#SYNC 4#TC Identification number: RA-72163#Transport Canada#Transport Canada ID: 2022596#Transports Canada#Ventilation Control System ("HVAC")

0 notes

Text

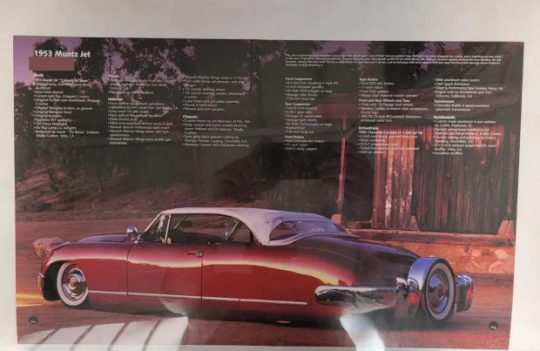

Custom 1953 Muntz Jet Convertible

This 1953 Muntz Jet convertible underwent a three-year custom build under previous ownership, and it was purchased by the seller in 2021. The car is powered by a fuel-injected 5.7-liter LT1 V8 engine paired with a four-speed automatic transmission and a Ford 9″ rear end, and it is finished in Apple Pearl with a white Carson-style removable top over gray snakeskin-style Naugahyde upholstery. Features include custom bodywork, an Art Morrison frame, power-assisted steering, four-wheel disc brakes, airbag suspension, Painless Performance wiring, and more modified and fabricated details. This custom-built Muntz is now offered with a copy of Rodder’s Journal magazine featuring a story on the build and a clean California title in the name of the seller’s business.

Custom 1953 Muntz Jet Convertible

The steel, aluminum, and fiberglass body is mounted on an Art Morrison ladder frame that was boxed and finished in semi-gloss black, and the floor was raised 3″. The exterior was repainted in a Sherwin Williams two-stage Apple Pearl mixed by the late Stan Betz. Features include a chopped Duvall-style windshield, 1950 Chevrolet headlights, dual Appleton spotlights, 1951 Ford Victoria side windows, and a white removable Carson-style top fabricated to match the height of the chopped windshield. Additional equipment includes color-matched rear fender skirts and chrome bumpers. Wear from fitting the top is noted on the rear deck.

Custom 1953 Muntz Jet Convertible

Steel wheels sourced from a 1976 Dodge measure 15″ and are mounted with Cadillac Sombrero-style covers and whitewall tires. A matching spare fitted with a BFGoodrich Silvertown tire is mounted within a rear-mounted Continental-style chrome carrier. A Mustang II front end accommodates power rack-and-pinion steering , and the car rides on an electronically-adjustable Air Ride Technologies airbag suspension system along with 2” lowered front spindles, Strange Engineering tube shocks, a rear Panhard bar, and front and rear sway bars. The seller reports that the front control arm bushings were recently replaced.

Custom 1953 Muntz Jet Convertible

Custom 1953 Muntz Jet Convertible

Braking is handled by GM G-body-sourced calipers matched with Ford Granada discs up front and Ford SVO-specification calipers and discs at the rear.

Custom 1953 Muntz Jet Convertible

The cabin was customized by Jim’s Auto Trim of San Diego, California, and features Glide bucket seats and a rear bench trimmed in gray snakeskin-style Naugahyde upholstery, along with matching treatments for the dash trim, headliner, and door panels. Additional equipment includes a 1952 Lincoln steering wheel mounted to a shortened Lincoln steering column, gray cut-pile carpet, and a Pioneer stereo housed within a custom center cubby.

The engine-turned “Hollywood” instrument cluster houses Stewart Warner gauges consisting of an 8k-rpm tachometer, a 160-mph speedometer, and auxiliary readings for fuel level, battery charge, oil pressure, and water temperature. The five-digit odometer displays 25k miles, though total chassis mileage is unknown. A Lokar pedal assembly was fitted during the build.

Custom 1953 Muntz Jet Convertible

The Corvette-sourced 5.7-liter LT1 V8 features a polished fuel intake manifold along with billet aluminum valve covers, and additional features include an Opti-Spark distributor, a Griffin aluminum radiator, and a wiring loom sourced from Painless Performance Wiring. A set of long-tube headers are connected to a 2.5″ exhaust system equipped with dual Dynaflow mufflers. The seller reports that the oil was recently changed.

Custom 1953 Muntz Jet Convertible

Power is routed to the rear wheels via a four-speed 4L60E automatic transmission and a Ford 9″ rear end with with 3.55:1 gears and Strange Engineering 31-spline axles. Additional photos of the underside, drivetrain, and suspension components are presented in the gallery below.

Custom 1953 Muntz Jet Convertible

The car was featured in issue #36 of Rodders Journal magazine

#Custom 1953 Muntz Jet Convertible#Custom 1953 Muntz Jet#Muntz Jet Convertible#Custom Muntz Jet Convertible#Muntz Jet#Convertible#car#cars#muscle car#american muscle

111 notes

·

View notes

Text

CNC development history and processing principles

CNC machine tools are also called Computerized Numerical Control (CNC for short). They are mechatronics products that use digital information to control machine tools. They record the relative position between the tool and the workpiece, the start and stop of the machine tool, the spindle speed change, the workpiece loosening and clamping, the tool selection, the start and stop of the cooling pump and other operations and sequence actions on the control medium with digital codes, and then send the digital information to the CNC device or computer, which will decode and calculate, issue instructions to control the machine tool servo system or other actuators, so that the machine tool can process the required workpiece.

1. The evolution of CNC technology: from mechanical gears to digital codes

The Beginning of Mechanical Control (late 19th century - 1940s)

The prototype of CNC technology can be traced back to the invention of mechanical automatic machine tools in the 19th century. In 1887, the cam-controlled lathe invented by American engineer Herman realized "programmed" processing for the first time by rotating cams to drive tool movement. Although this mechanical programming method is inefficient, it provides a key idea for subsequent CNC technology. During World War II, the surge in demand for military equipment accelerated the innovation of processing technology, but the processing capacity of traditional machine tools for complex parts had reached a bottleneck.

The electronic revolution (1950s-1970s)

After World War II, manufacturing industries mostly relied on manual operations. After workers understood the drawings, they manually operated machine tools to process parts. This way of producing products was costly, inefficient, and the quality was not guaranteed. In 1952, John Parsons' team at the Massachusetts Institute of Technology (MIT) developed the world's first CNC milling machine, which input instructions through punched paper tape, marking the official birth of CNC technology. The core breakthrough of this stage was "digital signals replacing mechanical transmission" - servo motors replaced gears and connecting rods, and code instructions replaced manual adjustments. In the 1960s, the popularity of integrated circuits reduced the size and cost of CNC systems. Japanese companies such as Fanuc launched commercial CNC equipment, and the automotive and aviation industries took the lead in introducing CNC production lines.

Integration of computer technology (1980s-2000s)

With the maturity of microprocessor and graphical interface technology, CNC entered the PC control era. In 1982, Siemens of Germany launched the first microprocessor-based CNC system Sinumerik 800, whose programming efficiency was 100 times higher than that of paper tape. The integration of CAD (computer-aided design) and CAM (computer-aided manufacturing) software allows engineers to directly convert 3D models into machining codes, and the machining accuracy of complex surfaces reaches the micron level. During this period, equipment such as five-axis linkage machining centers came into being, promoting the rapid development of mold manufacturing and medical device industries.

Intelligence and networking (21st century to present)

The Internet of Things and artificial intelligence technologies have given CNC machine tools new vitality. Modern CNC systems use sensors to monitor parameters such as cutting force and temperature in real time, and use machine learning to optimize processing paths. For example, the iSMART Factory solution of Japan's Mazak Company achieves intelligent scheduling of hundreds of machine tools through cloud collaboration. In 2023, the global CNC machine tool market size has exceeded US$80 billion, and China has become the largest manufacturing country with a production share of 31%.

2. CNC machining principles: How code drives steel

The essence of CNC technology is to convert the physical machining process into a control closed loop of digital signals. Its operation logic can be divided into three stages:

Geometric Modeling and Programming

After building a 3D model using CAD software such as UG and SolidWorks, CAM software “deconstructs” the model: automatically calculating parameters such as tool path, feed rate, spindle speed, and generating G code (such as G01 X100 Y200 F500 for linear interpolation to coordinates (100,200) and feed rate 500mm/min). Modern software can even simulate the material removal process and predict machining errors.

Numerical control system analysis and implementation

The "brain" of CNC machine tools - the numerical control system (such as Fanuc 30i, Siemens 840D) converts G codes into electrical pulse signals. Taking a three-axis milling machine as an example, the servo motors of the X/Y/Z axes receive pulse commands and convert rotary motion into linear displacement through ball screws, with a positioning accuracy of up to ±0.002mm. The closed-loop control system uses a grating ruler to feedback position errors in real time, forming a dynamic correction mechanism.

Multi-physics collaborative control

During the machining process, the machine tool needs to coordinate multiple parameters synchronously: the spindle motor drives the tool to rotate at a high speed of 20,000 rpm, the cooling system sprays atomized cutting fluid to reduce the temperature, and the tool changing robot completes the tool change within 0.5 seconds. For example, when machining titanium alloy blades, the system needs to dynamically adjust the cutting depth according to the hardness of the material to avoid tool chipping.

3. The future of CNC technology: cross-dimensional breakthroughs and industrial transformation

Currently, CNC technology is facing three major trends:

Combined: Turning and milling machine tools can complete turning, milling, grinding and other processes on one device, reducing clamping time by 90%;

Additive-subtractive integration: Germany's DMG MORI's LASERTEC series machine tools combine 3D printing and CNC finishing to directly manufacture aerospace engine combustion chambers;

Digital Twin: By using a virtual machine tool to simulate the actual machining process, China's Shenyang Machine Tool's i5 system has increased debugging efficiency by 70%.

From the meshing of mechanical gears to the flow of digital signals, CNC technology has rewritten the underlying logic of the manufacturing industry in 70 years. It is not only an upgrade of machine tools, but also a leap in the ability of humans to transform abstract thinking into physical entities. In the new track of intelligent manufacturing, CNC technology will continue to break through the limits of materials, precision and efficiency, and write a new chapter for industrial civilization.

#prototype machining#cnc machining#precision machining#prototyping#rapid prototyping#machining parts

2 notes

·

View notes

Text

Chef WK, lead charcuterie specialist in Alberta Canada

Table of contents

1. Control Program Requirements for Fermented Meat Products

2. Facility and Equipment Requirements

3. Starter Culture

4. Chemical Acidification

5. Water Activity Critical Limits

6. Time and Temperature for Fermented Products

7. Fermentation Done at a Constant Temperature

8. Examples of Degree-hours at constant room temperatures

9. Fermentation Done at Different Temperatures

10. Fermentation done at Different temperatures

11. What happens if fermentation fails to hit critical limit?

12. E. coli and Salmonella Control in Fermented Sausages

13. Options for E. coli validation

14. Option1; Heating

15. Option 2; pH, heating, holding, diameter

16. Safety and consistency

Control Program Requirements for Fermented Meat Products

The producer must have a program in place to assess the incoming product. This program should outline specifications for the incoming ingredients. This may include criteria including receiving temperature, farm/ supplier, lot code or packed on date, species/cut etc.

2. Facility and Equipment Requirements

Equipment used in the fermentation process must be included in the operator's prerequisite control programs. These must include the following elements:

Temperature in the fermentation, drying and smoking chambers must be uniform and controlled to prevent any fluctuation that could impact on the safety of the final product.

Fermentation, drying and smoking chambers must be equipped with a shatter resistant indicating thermometer, (or equivalent), with graduations of 1°C or less. If mercury thermometers are used, their mercury columns must be free from separations. All thermometers must be located such that they can be easily read.

Fermentation and smoking chambers must be equipped with a recording thermometer for determining degree-hours calculations in a reliable manner. Recording thermometers are also preferable in drying and aging rooms but, in these rooms, it may be sufficient to read and record the temperatures 2 times a day.

Drying and aging rooms must be equipped with humidity recorders in order to prevent uncontrolled fluctuations of the relative humidity. The only alternative to an automatic humidity recorder in these rooms would be for the company to manually monitor and record ambient humidity twice a day (morning and afternoon) every day with a properly calibrated portable humidity recorder.

For routine monitoring, accurate measurement electronic pH meters (± 0.05 units) should be employed. It is important that the manufacturer's instructions for use, maintenance and calibration of the instrument as well as recommended sample preparation and testing be followed.

When the aw of a product is a critical limit set out in the HACCP plan for a meat product, accurate measurement devices must be employed. It is important that the manufacturer's instructions for use, maintenance and calibration of the instrument be followed.

3. Starter Culture

The operator must use a CFIA approved starter culture. This includes Freeze-dried commercially available culture as well as back-slopping (use of previously successful fermented meat used to inoculate a new batch). When performing back-slopping, the operator must have a control program in place to prevent the transmission of pathogens from when using the inoculum from a previous batch to initiate the fermentation process of a new batch. These must include:

The storage temperature must be maintained at 4°C or less and a pH of 5.3 or less.

Samples for microbiological analysis must be taken to ensure that the process is in line with the specifications.

The frequency of sampling is to be adjusted according to compliance to specifications.

Any batch of inoculum which has a pH greater than 5.3 must be analysed to detect at least Staphylococcus aureus. Only upon satisfactory results will this inoculum be permitted for use in back slopping.

This can be an expensive and a time exhaustive process and is generally avoided due to food safety concerns. AHS does not allow back-slopping.

[Chef WK was in communication with the U of A to get his method, a starter mix, studied.]

4. Chemical Acidification

If product is chemically acidified by addition of citric acid, glucono-delta-lactone or another chemical agent approved for this purpose, controls must be in place and records kept to ensure that a pH of 5.3 or lower is achieved by the end of the fermentation process. These acids are encapsulated in different coatings that melt at specific temperatures, which then release the powdered acids into the meat batter and directly chemically acidulate the protein.

Summer sausage is a very common chemically acidified product. The flavor profile tends to be monotone and lacking depth.

5. Water Activity Critical Limits

The aw may be reduced by adding solutes (salt, sugar) or removing moisture.

Approximate minimum levels of aw (if considered alone) for the growth of:

molds: 0.61 to 0.96

yeasts: 0.62 to 0.90

bacteria: 0.86 to 0.97

Clostridium botulinum: 0.95 to 0.97

Clostridium perfringens: 0.95

Enterobacteriaceae: 0.94 to 0.97

Pseudomonas fluorescens: 0.97

Salmonella: 0.92 - 0.95

Staphylococcus aureus: 0.86

parasites: Trichinella spiralis will survive at an aw of 0.93 but is destroyed at an aw of 0.85 or less.

The above levels are based on the absence of other inhibitory effects such as nitrite, competitive growth, sub-optimum temperatures, etc., which may be present in meat products. In normal conditions, Staphylococcus aureus enterotoxins are not produced below aw 0.86, although in vacuum packed products this is unlikely below aw 0.89.

6. Time and Temperature for Fermented Products

Certain strains of the bacteria Staphylococcus aureus are capable of producing a highly heat stable toxin that causes illness in humans. Above a critical temperature of 15.6°C, Staphylococcus aureus multiplication and toxin production can take place. Once a pH of 5.3 is reached, Staphylococcus aureus multiplication and toxin production are stopped.

Degree-hours are the product of time as measured in hours at a particular temperature multiplied by the "degrees" measured in excess of 15.6°C (the critical temperature for growth of Staphylococcus aureus). Degree-hours are calculated for each temperature used in the process. The limitation of the number of degree-hours depends upon the highest temperature in the fermentation process prior to the time that a pH of 5.3 or less is attained.

The operator is encouraged to measure temperatures at the surface of the product. Where this is not possible, the operator should utilize fermentation room temperatures. The degree hour calculations are based on fermentation room temperatures. Temperature and humidity should be uniform throughout the fermentation room.

A process can be judged as acceptable provided the product consistently reaches a pH of 5.3 using:

fewer than 665 degree-hours when the highest fermentation temperature is less than 33°C;

fewer than 555 degree-hours when the highest fermentation temperature is between 33° and 37°C; and

fewer than 500 degree-hours when the highest fermentation temperature is greater than 37°C.

This means that as the temperature increases, the amount of time that you have available to reach 5.3 or under is shorter. The warmer the temperature, the sharper the log growth phase of bacteria, which equates to more overshoot in lactic acid production, faster.

8. Examples of Degree-hours at constant room temperatures

Example 1:

Fermentation room temperature is a constant 26°C. It takes 55 hours for the pH to reach 5.3.

Degrees above 15.6°C: 26°C - 15.6°C = 10.4°C Hours to reach pH of 5.3: 55 Degree-hours calculation: (10.4°C) x (55) = 572 degree-hours

The corresponding degree-hours limit (less than 33°C) is 665 degree-hours.

Conclusion: Example 1 meets the guideline because its degree-hours are less than the limit.

Example 2:

Fermentation room temperature is a constant 35°C. It takes 40 hours for the pH to reach 5.3.

Degrees above 15.6°C: 35°C - 15.6°C = 19.4°C Hours to reach pH of 5.3: 40 Degree-hours calculation: (19.4°C) x (40) = 776 degree-hours

The corresponding degree-hours limit (between 33 and 37°C) is 555 degree-hours.

Conclusion: Example 2 does not meet the guideline because its degree-hours exceed the limit

9. Fermentation Done at Different Temperatures

When the fermentation takes place at various temperatures, each temperature step in the process is analyzed for the number of degree-hours it contributes. The degree-hours limit for the entire fermentation process is based on the highest temperature reached during fermentation.

Example 1:

It takes 35 hours for product to reach a pH of 5.3 or less. Fermentation room temperature is 24°C for the first 10 hours, 30°C for second 10 hours and 35°C for the final 15 hours.

Step 1

Degrees above 15.6°C: 24°C - 15.6°C = 8.4°C Hours to reach pH of 5.3: 10 Degree-hours calculation: (8.4°C) x (10) = 84 degree-hours

Step 2

Degrees above 15.6°C: 30°C - 15.6°C = 14.4°C Hours to reach pH of 5.3: 10 Degree-hours calculation: (14.4°C) x (10) = 144 degree-hours

Step 3

Degrees above 15.6°C: 35°C - 15.6°C = 19.4°C Hours to reach pH of 5.3: 15 Degree-hours calculation: (19.4°C) x (15) = 291 degree-hours

Degree-hours calculation for the entire fermentation process = 84 + 144 + 291 = 519

The highest temperature reached = 35°C

The corresponding degree-hour limit = 555 (between 33°C and 37°C)Conclusion: Example 1 meets the guideline because its degree-hours are less than the limit.

10. Fermentation done at Different temperatures

Example 2:

It takes 38 hours for product to reach a pH of 5.3 or less. Fermentation room temperature is 24°C for the first 10 hours, 30°C for the second 10 hours and 37°C for the final 18 hours.

Step 1

Degrees above 15.6°C: 24°C - 15.6°C = 8.4°C Hours to reach pH of 5.3: 10 Degree-hours calculation: (8.4°C) x (10) = 84 degree-hours

Step 2

Degrees above 15.6°C: 30°C - 15.6°C = 14.4°C Hours to reach pH of 5.3: 10 Degree-hours calculation: (14.4°C) x (10) = 144 degree-hours

Step 3

Degrees above 15.6°C: 37°C - 15.6°C = 21.4°C Hours to reach pH of 5.3: 18 Degree-hours calculation: (21.4°C) x (18) = 385.2 degree-hours

Degree-hours calculation for the entire fermentation process = 84 + 144 + 385.2 = 613.2

The highest temperature reached = 37°C

The corresponding degree-hour limit = 555 (between 33°C and 37°C)

Conclusion: Example 2 does not meet the guidelines because its degree-hours exceed the limit.

11. What happens if fermentation fails to hit critical limit?

What happens if the batch takes longer than degree-hours allows? For restaurant level production, it's always safer to discard the product. The toxin that Staph. Aureus produces is heat stable and cannot be cooked to deactivate. In large facilities that produce substantial batches, the operator must notify the CFIA of each case where degree-hours limits have been exceeded. Such lots must be held and samples of product submitted for microbiological laboratory examination after the drying period has been completed. Analyses should be done for Staphylococcus aureus and its enterotoxin, and for principal pathogens, such as E. coli O157:H7, Salmonella, and Clostridium botulinum and Listeria monocytogenes.

If the bacteriological evaluation proves that there are fewer than 104 Staphylococcus aureus per gram and that no enterotoxin or other pathogens are detected, then the product may be sold provided that it is labelled as requiring refrigeration.

In the case of a Staphylococcus aureus level higher than 104 per gram with no enterotoxin present the product may be used in the production of a cooked product but only if the heating process achieves full lethality applicable to the meat product.

In the case where Staphylococcus aureus enterotoxin is detected in the product the product must be destroyed.

12. E. coli and Salmonella Control in Fermented Sausages

Business' that manufacture fermented sausages are required to control for verotoxinogenic E. coli including E. coli O157:H7 and Salmonella when they make this type of product. This includes:

establishments which use beef as an ingredient in a dry or semi-dry fermented meat sausage;

establishments which store or handle uncooked beef on site;

Establishments which do not use beef and do not obtain meat ingredients from establishments which handle beef are not currently required to use one of the five options for the control of E. coli O157:H7 in dry/semi-dry fermented sausages.

Any processed RTE product containing beef or processed in a facility that also processed beef, must be subjected to a heat treatment step to control E. coli O157:H7. Heating to an internal temperature of 71°C for 15 seconds or other treatment to achieve a 5D reduction is necessary. This is a CFIA requirement and is not negotiable.

Uncooked air dried products produced as RTE, must meet shelf stable requirements as detailed for Fermented-Dry products.

13. Options for E. coli validation

Without lab testing, the two main methods of validation are with heat treating by either low temp and a long duration, or various hotter processing temperatures for a shorter timeframe.

A challenge study to validate a process can take 1 year and over $100,000!

14. Option1; Heating

15. Option 2; pH, heating, holding, diameter

16. Safety and consistency

The aw and pH values are critical in the control of pathogens as well as to ensure shelf-stability in all semi-dry and dry fermented meat products. Each batch must be tested for aw and/or pH in order to verify that the critical limits are met.

Although aw measurement is mandatory only for shelf stable products, it is strongly recommended that the producer determine the aw values achieved for each product type they manufacture and for each product. Once this has been established, frequent regular checks should be made to ensure consistency. In the U.S., they rely on moisture to protein ratio and have set targets. This lab-tested value is a direct correlation of the % water to % meat protein and not aw. This gives more consistency to common names. For example, to legally call a product "jerky" it must have a MPR of 0.75:1 or lower. Remember your ABCs:

Always be compliant.

-AND-

Documentation or it didn't happen.

(tags)

Charcuterie,Fermented Meat,Food Safety,Starter Culture,Chemical Acidification,Water Activity,Fermentation Process,Degree-Hours Method,Foodborne Pathogens,Meat Processing Guidelines,Chef WK Alberta Canada,Food Industry Standards,pH Critical Limits,Thermal Processing,Food Preservation,Food Microbiology,Sausage Fermentation,Charcuterie Expertise,Fermented Meats ,Food Safety Standards,Food Processing Guidelines,Starter Cultures,Chemical Acidification,Water Activity (a_w),Critical Limits,Degree-Hours Method,Foodborne Pathogens,Meat Processing Equipment,Processing Facility Requirements,Hazard Analysis and Critical Control Points (HACCP),Food Preservation Techniques,Temperature Control,Pathogen Reduction,Food Industry Compliance,Documentation Practices,Heat Treatment,pH Control,Food Stability,Consistency in Production,Microbial Testing,Real-time Monitoring,Process Validation,Regulatory Requirements,Verotoxigenic E. coli,Lethality Standards,Product Labelling,Spoilage Prevention,Enterotoxin Detection,Shelf-Stable Products,Moisture to Protein Ratio (MPR)

#Charcuterie#Fermented Meat#Food Safety#Starter Culture#Chemical Acidification#Water Activity#Fermentation Process#Degree-Hours#Meat Processing Guidelines#Thermal Processing#Food Preservation#Food Microbiology#Sausage Fermentation#Starter Cultures#Critical Limits#Meat Processing#Food Preservation Techniques#Temperature Control#Pathogen Reduction#Food Industry#Heat Treatment#pH Control#Food Stability#Microbial Testing#Real-time Monitoring#Process Validation#Spoilage Prevention#Enterotoxin Detection#Shelf-Stable Products#Moisture to Protein Ratio (MPR)

3 notes

·

View notes

Text

THE FUTURE OF KITCHEN APPLIANCES DUBAI PRECEDES

THE FUTURE OF KITCHEN APPLIANCES DUBAI PRECEDES

Manually handling an entire kitchen is not what you need for your 2024. Electronic home appliances have been around since the 20th century, being stuck washing dishes or cleaning bigger appliances with no versatile options, after so many decades, is just outdated.

So here’s what you need to learn about the future of kitchen appliances Dubai has to offer.

Freestanding Cookers

Traditional dishes sometimes need traditional gas cookers but if you want to save energy, space and time Tesla Freestanding cookers are a must-try!

They consist of a smooth surfaced black enamelled cavity which is easy-to-clean. Glass panel over at the bottom with removable door plate, minimum energy consumption with Tesla’s Energy Class ovens.

Fast cooking and auto-cut off to ensure your safety, with turbo grill oven and simple ignition.

Induction Cookers

Tesla Induction cookers feature touch sensors for everyday convenience while cooking.

Bringing safety and sophisticated dark design together with Black Crystal glass and safety features such as auto shut-down after a minute and overheating protection system.

Efficient cooking with 8 different power levels easily adjustable for all kinds of cooking needs.

Citrus Juicers

Health comes first, and nothing is healthier than a fresh glass of homemade juice. Here’s a juicer that makes it easy, fast and convenient to make your own vitamin drinks.

Featuring dust protection, just plug in and choose your citrus fruit, and two-direction twist is automatically activated once pressure is applied, no need for buttons.

Make your immune system stronger with various sizes of drinks, two different sized cones to squeeze all kinds of citruses.

Electric Kettles

Tesla kettles with a capacity of 1.7 L make warm drinks, boiling water for tea, instant coffee or other beverages fast, safe, energy saving and clean.

With 2200W of power with easy-to-open and handle devices that helps keep track of the water quantity is super simple yet highly useful.

Auto Cut-off when the temperature reaches 100 °C, with Strix kettle control manufactured to exceed 12.000 cycles of normal operation as well as comply with all international standards.

Air Fryers

The air fryer uses 360° hot air circulation to cook healthier fried food as compared to the alternative of conventional frying. Easy to control temperature levels (60 – 200°C) and cooking time with 12 preset programs, or customization.

It is fast, with crispy and delicious results, and can manage a good quantity at once due to the large basket, enough food for a whole family. And the basket and baking tray are dishwasher-safe.

Automatic turn off, preheat, periodic notification for food “turn-over”, easy to clean, with non-stick coating and other quality of life features. It has overheating protection, and will also automatically shut down if the pot is removed.

And now you know how to remodel your kitchen with one of the most innovative and trendy kitchen appliances Dubai offers and never stress over time management or physical labour with Tesla electronic home appliances.

2 notes

·

View notes

Text

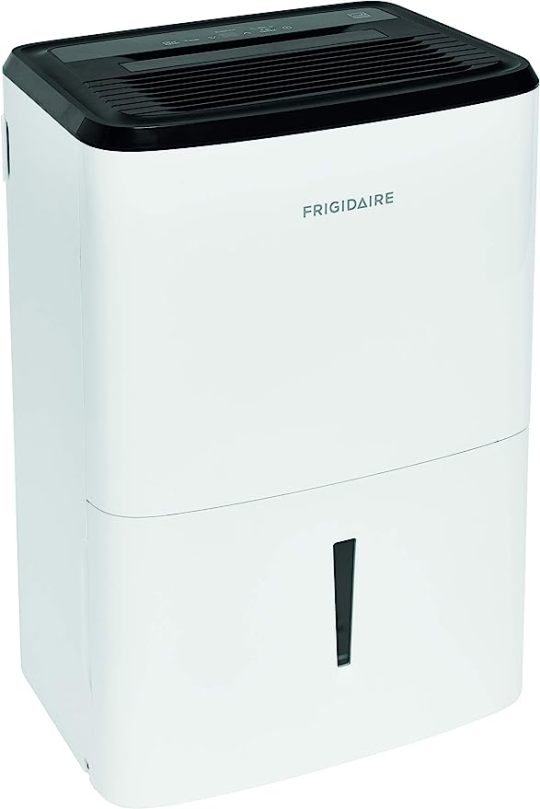

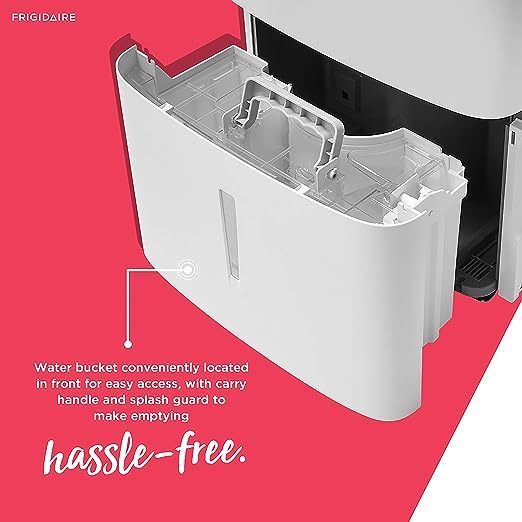

Frigidaire 50 Pint Dehumidifier, White

A 50-pint dehumidifier is an essential appliance designed to regulate indoor humidity levels in spaces that are prone to excessive moisture. This type of dehumidifier is capable of removing up to 50 pints of moisture from the air within a 24-hour period, making it suitable for medium-sized rooms or areas such as basements, living rooms, bedrooms, and even small offices.

Excessive humidity can lead to various problems such as mold growth, musty odors, damage to furniture and electronics, and discomfort for occupants. A 50-pint dehumidifier effectively addresses these issues by extracting excess moisture from the air, thus creating a more comfortable and healthier living environment.

Key features of a typical 50-pint dehumidifier include:

Capacity: As the name suggests, the dehumidifier can remove up to 50 pints of moisture from the air within a day. This capacity is well-suited for rooms or spaces ranging from 1,000 to 2,500 square feet.

Automatic Controls: Most 50-pint dehumidifiers come equipped with built-in humidistats, allowing the appliance to maintain a specific target humidity level. Once the desired level is reached, the dehumidifier automatically turns on and off to maintain the set humidity.

Drainage Options: These dehumidifiers usually offer multiple drainage options. They can collect extracted moisture in an integrated collection tank that needs to be emptied periodically. Alternatively, they might offer a continuous drainage option that allows you to connect a hose for the water to drain directly into a sink or a drain.

Built-in Filters: Many models come with washable and reusable filters that help improve air quality by capturing dust, pet dander, and other airborne particles. This not only reduces moisture but also promotes cleaner air circulation.

Portability: 50-pint dehumidifiers often feature built-in casters or wheels for easy mobility, enabling you to move the unit around your space as needed.

Energy Efficiency: Modern dehumidifiers are designed to be energy-efficient, which helps you save on electricity bills while effectively maintaining optimal humidity levels.

User-Friendly Controls: These dehumidifiers typically have user-friendly digital controls that allow you to set the desired humidity level, adjust fan speed, set timers, and more.

When selecting a 50-pint dehumidifier, it's important to consider factors such as the size of the area you want to dehumidify, the specific features that suit your needs, and any additional considerations such as noise levels.

In summary, a 50-pint dehumidifier is a valuable appliance for maintaining healthy humidity levels in medium-sized spaces. Its ability to remove excess moisture from the air can help prevent mold growth, protect your belongings, and create a more comfortable living environment.

Product Details:

Brand

Frigidaire

Color

White

Special Feature

Manual

Capacity

50 Pints

Tank Volume

2.11 Gallons

Product Dimensions

12.19"D x 15.97"W x 24.25"H

Price: $210.45

About this item

Easy-to-Clean Washable Filter: Capture dust from the air and keep your dehumidifier working efficiently with our easy-to-clean washable filter.Low Temperature Operation: This unit is designed to operate at low temperatures down to 41 degrees F.Voltage Rating : 115 V. Installation : Power Cord Length. Motor RPM (Low) :880 RPM, Motor RPM (Med) : 980 RPM, Motor RPM (High) : 1160 RPM.

Custom Humidity Control: Maximize your comfort with customized control over the amount of humidity in your room

Continuous Drain Option: Skip emptying the water bucket -- this unit continuously drains your dehumidifier so that you don’t have to lift a finger

Automatic Shut Off: Unit shuts off automatically when the water bucket is full

Front Loading Bucket with Carrying Handle and Splash Guard: A water bucket is conveniently located in the front of the unit for easy access, while the carry handle and splash guard make emptying your bucket hassle-free

link:https://t.co/cLg0HVNs6N

4 notes

·

View notes

Note

IDW starbee

Okay, let's get started

Starscream and bumblebee never said what they were but you could tell they were very close, and that generated a lot of comments.Bumblebee, affected by stress + expectations + desire to please, ends up breaking up with starscream and it was an ugly ending.

Star disappears after that and bee, filled with guilt and the realization that he fucked up, decided to "confess" during an interview. Obviously it's a scandal and there's dialogues like this:

Windblade: Y-you lied to us!

Bumblebee:No, I chose you and that was the most cowardly thing I could have done! I cared so much about being the leader you wanted that I made the worst choices possible! You guys never asked about what really happened because you automatically assumed I was the right one!

A few days later (still at the height of the collective scandal) everyone is surprised by ice and extreme temperatures around the leaders' buildings The building and surrounding street were completely frozen and riddled with spikes of almost black ice, the electronics were a lost cause and some areas were frozen to the point of being very breakable.

There are survivors, but many are trapped in the ice and in need of assistance. Cromia lost an optic and some of the surrounding metal was destroyed, w Windblade had one of his legs completely destroyed, Wheeljack lost the lower part of his jaw and Bumblebee almost dies with ice crystals on his neck.

Someone manages to find a working camera... and they see a dark blue seeker with yellow details that looks like a mixture of Star and bee (with the characteristics of star prevailing). Cybertron (smart enough to connect the dots) sits on what can only be defined as "a burning ship" and, despite heavy investigations, the "bastard of the two leaders" (as dubbed by the media and paparazzi) is not found.

(As the growth of sparklings is not something concrete, I'm going with the idea that they grow quickly to the standards of long-lived species.)

God, the idea of the entire building being encased in frightening black ice is so good. I love that imagery. It's so sinister and scary looking, but Starscream is as trapped inside as everyone else is trapped outside.

I like to imagine every seekerling born to the royal line of Vos is given some sort of special ability courtesy of Alchemist Prime (Vos's creator god)

I....... am seriously struggling to read this big body of text rn, but I don't think this mentions how old the twins are. I like to imagine they're very small and are struggling to control their powers; lashing out because they can sense their carrier's ire and pain and Jetstorm's ability has decided to try and shield them from everyone. I love this

4 notes

·

View notes

Text

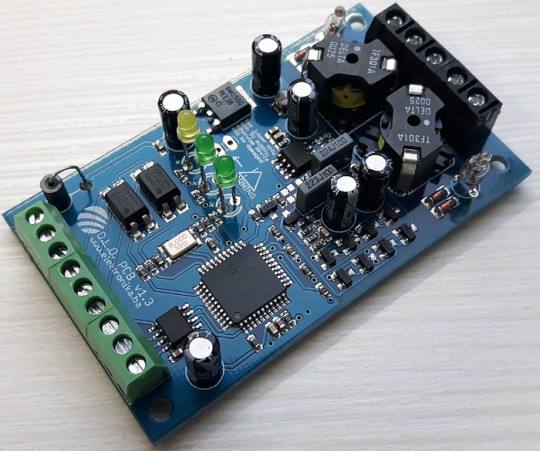

EXPLORING THE 5 COOL PARTNER SELLER ELECTRONICS PRODUCTS-Part1

Exploring the 5 Cool Partner Seller Electronics Products

Prologue

Are you an electronics enthusiast looking to expand your electronics project repertoire? Want to take your skills to the next level by exploring new and exciting products? Look no further than our list of five cool electronics products from partner sellers!

Whether you’re interested in building your own smart home devices, experimenting with sensors, or creating your own robot, these products are sure to inspire you. They cover a lot of application areas, from loop detectors used to monitor vehicle count in parking garages to Arduino CNC shields used in CNC machines, from simple pulse sensors used to detect cardiovascular pulse signals from fingertip to RGB LED panel light used in smart home, these products are unique, compact, and functional. Not only are these products fun to build and use but they’re also designed to help you learn new skills and techniques along the way.

What’s more, these products all come from trusted partner sellers who are committed to developing high-quality products. They’re happy to provide technical support for customers who have questions, so you can be sure you’re getting the best in electronics.

So get ready to dive into the world of electronics and explore these five cool partner seller products. You’re sure to find something that piques your interest and takes your own electronics projects to the next level.

Inductive Loop Vehicle Detector by Elektronika-ba

Whether you need to monitor occupancy and count vehicles in parking garages, control vehicle access at door and barrier controls, or facilitate traffic light installations and traffic controllers, the inductive loop detector is the perfect solution. It can even detect the direction and speed of vehicle traffic, making it an invaluable tool for a variety of traffic-related applications. In addition, this device can function as a stand-alone speed trap and can be easily interfaced with Arduino.

We can also provide a pre-programmed PIC chip to meet your project requirements.

Specifications

Number of operating modes: 4

Tuning: Automatic

Detection type: Presence/Pulse

Presence time: Adjustable in 3 steps

Pulse duration: 250 ms / 500 ms

Signal filtering: Adjustable in 2 steps (NORMAL, HIGH)

Loop inductance: 20 uH — 1000 uH

Frequency range: 20 kHz — 145 kHz

Frequency selection: 2 combinations (LOW, HIGH)

Sensitivity: Maximum 0.0025% Δf/f, adjustable in 8 steps

Detection speed: 10 ms by default, adjustable

Start-up time: ~ 1 second per channel (or longer if the frequency is not stable)

Temperature range: -35°C — 120°C

Sensor protection: Galvanic isolation + gas discharge tube for lightning protection

Don’t settle for less — click here to learn more about the Inductive Loop Vehicle Detector and experience the compact, yet cool detector!

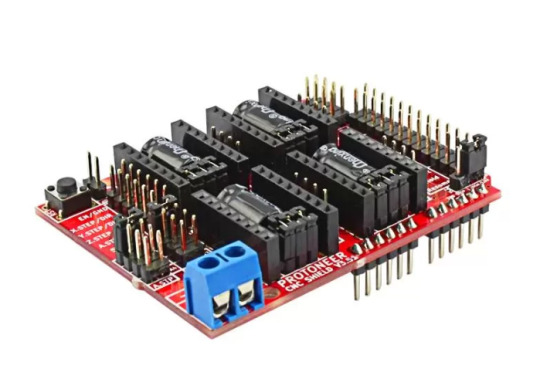

Arduino CNC Shield V3.51 by Protoneer

Designed by Protoneer, this kit is packed with features to ensure high precision control of your stepper motors, you can use it to easily build small CNC routers, DIY laser cutters, 3D printers, or any project that requires precise stepper motor control.

Our latest version 3.51 includes several enhancements to make assembly and installation even easier. We’ve added end-stop and probe signal filtering circuitry to eliminate false triggers and allow the use of unshielded cables for end-stops and probes. We’ve also increased the size of the solder pads for easier assembly and updated the probe pin labels to make installation a breeze.

With the Arduino CNC Shield Kit, you’ll have everything you need to build your own CNC router or mill with ease.

Features

Includes Noise Filers on all end stops and the probing pin. (New in V3.51)

GRBL 0.9 compatible. (Open source firmware that runs on an Arduino UNO that turns G-code commands into stepper signals https://github.com/grbl/grbl)

4-Axis support (X, Y, Z, A-Can duplicate X, Y, Z or do a full 4th axis with custom firmware using pins A4 and A3)

2 x End stops for each axis (6 in total)

Coolant enable

Uses removable Pololu A4988 compatible stepper drivers. (A4988, DRV8825 and others)(Not Included)

Jumpers to set the Micro-Stepping for the stepper drivers. (Some drivers like the DRV8825 can do up to 1/32 micro-stepping )

Compact design.

Stepper Motors can be connected with 4-pin molex connectors or soldered in place.

Runs on 12–36V DC. (At the moment only the Pololu DRV8825 drivers can handle up to 36V so please consider the operation voltage when powering the board.)

Don’t wait — click here to see more about the Arduino CNC Shield V3.51 and start your next project today!

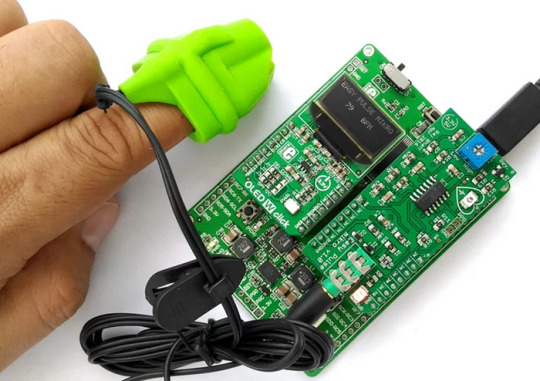

Easy Pulse Mikro by Embedded Lab

What’s more, the Easy Pulse Mikro is designed in the convenient Mikro bus form factor, making it easy to integrate with a wide range of mikroElektronika’s development boards. With all necessary instrumentation and amplification built right in, this powerful sensor provides a clean and precise analog PPG waveform output that’s routed to the AN pin of the mikroBus connector.

Whether you’re a hobbyist, student, or professional developer, the Easy Pulse mikro is the perfect tool for monitoring heart rate and other vital signs.

Click here to see more about the Easy Pulse mikro.

Features

Compatible with mikroBus socket.

Filtered and amplified analog PPG signal output

On-board potentiometer for adjusting amplifier gain, if needed (rotate clock-wise for increasing gain)

Onboard LED for indicating heartbeat. It flashes synchronously with the heartbeat on detecting the pulse from the fingertip.

2 notes

·

View notes

Text

Importance of Using a Licensed Electrician in Jupiter Island and Wellington, FL

Using licensed electricians' services is vital for residents and business owners within an area. While the control panel, wiring, devices, and outlets need to function efficiently with 24/7 power being ensured, power outages tend to make such homes and business entities malfunction, disrupting several tasks and inconveniencing the users substantially. It is thus essential to consider an alternative to continued power supply. Going for a Kohler generator installation in Jupiter Island Palm Beach, FL, can be an ideal solution, with the brand being endorsed and appreciated by almost all consumers. Undoubtedly, there are many other brands of generators that are equally good, but choosing the Kohler generator comes explicitly with many pluses, including the following:

Automatic Operation—The generators automatically detect power failures/outages and turn on instantly, making the transition smooth and hassle-free.

Loads—The power requirement is not identical for all consumers. Fortunately, the end user can choose to power the entire home or workplace or simply have a few essential appliances or devices function without any break. Many home residents prefer to have their lights, water pumps, refrigerators, or HVAC systems up and running during a power outage.

Extended Run Time—A natural disaster such as a hurricane, thunderstorm, or earthquake may leave a specific region out of power for days at a stretch. While the authorities do their best to restore power, the end users feel the need to use a quality generator to continue with their lives. The Kohler generator is capable of functioning for days and weeks at a stretch, depending on its fuel capacity.

Installation - The generators may be installed outside the home, eliminating the need for storage, setup, and refueling during the power outage. Having the generator installed permanently can be the best possible solution to power outages.

Transfer Switch—The generator includes an automatic transfer switch that monitors the power supply 24/7. It transfers power to the generator once a disruption of power is noted. The user does not have to physically turn on the switch to ensure a power supply immediately, either.

Protection of Appliances/ Electronics- The smooth transition from the main power supply to the generator does not disrupt power. This helps to protect sensitive appliances and electronic gadgets, thus saving the user from huge expenses for repairs/replacements.

Weather Preparedness- The Kohler generator can also run the HVAC system effectively, thus ensuring temperature optimization. Even during inclement weather, the consumer does not have to be discomfited or suffer from heat or freezing conditions indoors.

Low Sound—The generators of yesteryear were notorious for noisy operations that shatter the peace of the entire neighborhood. Thankfully, branded generators such as Kohler generators are not loud in the least. Instead, they have been appreciated for their low noise and almost soundless operations.

A home is a sacrosanct space for residents, who need to contact a licensed electrician in Jupiter Island and Wellington, FL, to ensure repairs and upgrades as needed.

#Kohler generator installation in Jupiter Island Palm Beach#FL#electrician in Jupiter Island and Wellington

0 notes

Text

Sizzle Up Your Snacks with Trendy Sandwich Makers at Poorvika!

In today’s fast-paced lifestyle, a quick, delicious, and wholesome meal is a blessing. Enter the sandwich maker — your kitchen’s best buddy for lip-smacking sandwiches, toasties, and grilled delights. At Poorvika, India's favorite tech and home appliance destination, you’ll discover a variety of trendy sandwich makers that are stylish, compact, efficient, and packed with features to make every bite a gourmet experience.

Why Choose a Sandwich Maker?

Gone are the days when making a sandwich meant just two slices of bread and a spread. Today, it’s all about perfect grills, crispy exteriors, and melty, cheesy interiors—made with ease. Here’s why a sandwich maker from Poorvika is a must-have:

Fast & Fuss-Free Cooking

Get perfectly toasted sandwiches in minutes without dirtying multiple utensils.

Multi-functional Magic

Grill sandwiches, make paninis, cook eggs, heat rotis, or even whip up crispy dosas!

Healthier Meals

Non-stick plates reduce oil usage, making your meals lighter and guilt-free.

Compact & Stylish

Modern sandwich makers are sleek and space-saving — ideal for any kitchen counter.

Top Features to Look for at Poorvika

Poorvika’s sandwich maker collection is curated with smart features that elevate your cooking:

Non-Stick Grill Plates

No mess, no stick, and super easy to clean.

Cool Touch Handle

Safety meets style with heat-resistant handles for worry-free cooking.

Automatic Temperature Control

Say goodbye to burnt edges — get even browning every time.

Indicator Lights

Know exactly when it’s hot enough and ready to cook.

Vertical Storage & Cord Winder

Keep your kitchen clutter-free and organized.

Popular Sandwich Makers at Poorvika

From entry-level models to premium brands, Poorvika offers sandwich makers that suit all budgets and needs.

Prestige Sandwich Maker

Simple, efficient, and trusted by Indian households for generations. Prestige models come with sturdy handles, non-stick plates, and compact designs — perfect for quick breakfasts.

Philips Daily Collection Sandwich Maker

Sleek and modern, Philips sandwich makers are known for their build quality, fast heating, and uniform grilling. Great for those who like their sandwiches just right.

Morphy Richards Grill & Toast

If you're someone who likes café-style paninis, this one’s for you. Morphy Richards sandwich makers offer deeper grill plates, stylish exteriors, and powerful performance.

Why Buy from Poorvika?

Poorvika isn’t just another retail store — it’s your trusted neighborhood electronics and appliance expert. Here’s why customers across India love shopping for sandwich makers here:

Huge Selection

Choose from top brands like Philips, Prestige, Morphy Richards, Havells, Bajaj, and more.

Best Prices

Enjoy exclusive deals, combo offers, and instant discounts both online and in-store.

Home Delivery

Get your sandwich maker delivered right to your doorstep with fast and safe delivery options.

Customer Support

Facing an issue? Poorvika’s friendly service team is always ready to help.

Easy EMIs

Don’t worry about the cost — No Cost EMI options make your purchase budget-friendly.

Sandwich Makers Make the Best Gifts Too!

Looking for a smart and useful gift for a wedding, housewarming, or festive occasion? A sandwich maker is practical, thoughtful, and always appreciated. Wrap it with love, and you’ve got a winner!

Available Online & Offline

Whether you’re browsing from home or visiting a Poorvika store near you, the sandwich maker collection is available everywhere you are. You can:

Visit Poorvika.com to check live stock, deals, and product details

Use the mobile app for seamless shopping on the go

Walk into your nearest Poorvika store and see the products in action!

Final Toast

If you’re dreaming of golden-brown sandwiches, quick snacks, and convenient cooking — it’s time to bring home a sandwich maker from Poorvika. It’s affordable, stylish, and makes every meal a treat.

Buy the latest Sandwich Makers at the best Prices in Poorvika!

Click here: https://www.poorvika.com/sandwich-makers

0 notes

Text

Turnstile Cooling Fans: Reliable Thermal Solutions for Continuous Operation

Ensuring 24/7 Performance in High-Traffic Areas

In busy environments such as transportation hubs, commercial buildings, and public facilities, turnstiles must operate continuously without failure. Constant operation leads to internal heat buildup, which can cause electronic components to age prematurely, system lag, or even sudden shutdowns—disrupting traffic flow and degrading user experience. The solution? A high-performance turnstile cooling fan designed to maintain stable, efficient heat dissipation.

Cooltron: Your Trusted Thermal Management Partner

With 26 years of expertise in thermal solutions, Cooltron offers custom-designed cooling modules tailored for a variety of turnstile systems. Powered by our proprietary turbo-boost air duct technology, our cooling fans feature aerospace-grade aluminum alloy frames and dual ball bearing construction for unmatched durability and performance.

Key Advantages of Cooltron Turnstile Cooling Fans:

High-Efficiency Cooling: Airflow speed up to 5.2 m/s, delivering 40% greater heat dissipation compared to conventional solutions.

Ultra-Quiet Operation: Low-noise design (<25dB) ensures minimal disturbance in public areas such as subways and office buildings.

Exceptional Durability: IP55-rated for dust and water resistance, with a certified lifespan exceeding 100,000 hours; capable of operating in extreme temperatures from -30°C to 80°C.

Proven Reliability Across Multiple Applications

Metro Stations at Peak Hours: Cooltron fans prevent motherboard overheating in turnstiles, ensuring smooth, delay-free operation even during heavy passenger flow.

Outdoor Tourist Attractions: Advanced design balances internal and external air pressure, blocking rainwater intrusion while accelerating air circulation under direct sunlight.

Smart Office Buildings: Seamlessly integrated with access control terminals, our silent cooling systems provide reliable thermal management to enhance the modern workplace experience.

Why Choose Cooltron Turnstile Cooling Fans?

Trusted by over 300 global transportation projects, Cooltron’s modular design allows for quick, tool-free installation or replacement within 5 minutes. The built-in intelligent temperature control chip monitors real-time device temperatures, automatically adjusting fan speed to balance cooling efficiency with power consumption—helping clients reduce operating and maintenance costs by 30%.

Get Started Today!

Visit www.cooltron.com to download the full product catalog or contact [email protected] for a customized thermal solution tailored to your turnstile systems.

0 notes

Text

Smart Fire Protection in Singapore: Innovative Technologies & Excellence in Best Practices

In Singapore, a technologically driven country, fire protection is witnessing revolutionary changes. Alarms and sprinklers are no longer adequate to safeguard buildings today, especially when building and usage patterns get more advanced. Welcome to the era of smart fire protection systems—a connected, high-tech system combining automation, analytics, and connectivity.

Today, structures are adopting a multi-dimensional fire suppression system in singapore that not just reacts but foresees and prevents fire threats. A data center, high-rise office building, or restaurant with heavy crowds does not matter; smart integration and innovation are the way forward for Singapore's fire protection.

Why Smart Fire Protection Is Needed in Singapore

Singapore's closely constructed city and stringent building regulations demand safety systems to do more with less space, less time, and fewer people. Smart fire technology delivers real-time intelligence, faster detection, and choreographed response—in capacity to meet the demanding conditions of commercial and residential areas alike.

And for businesses that have combustible materials or dangerous processes—such as factory kitchens—a smarter fire suppression system in Singapore may be the difference between a minor inconvenience and a disastrous loss.

What Does "Smart" in a Fire Protection System

A smart fire suppression system in Singapore usually includes:

IoT-enabled detectors: Real-time monitoring sensors for temperature, smoke, and air quality

Automated warning and response: Direct communication with central control systems and emergency services

Predictive analytics and AI: These are systems using historical as well as current data for forecasting as well as evasion of likely fire breaks out

Remote monitoring: The facility managers can remotely view and manage the system through a mobile app or a control room

All these factors combine for the construction of an active, as opposed to a passive, approach to dealing with fire safety.

Singapore's Contemporary Fire Suppression Systems

There are various fire suppression system in Singapore depending on the surroundings and the intensity of the hazards. Some of the most common ones include:

.Advanced water-based systems integrate converging nozzles, pressure control, and zoning automation to reduce water wastage and property damage—best suited for residential apartments and commercial offices drako fire.

Gas-Based Systems

Effective in areas where water may be employed to destroy equipment (like computer data centers), these systems release clean agents such as FM-200 or Novec 1230 to extinguish fires without harming electronics.

Foam Suppression

Used in application that entails flammable liquids, such systems quickly smother fires to deprive them of oxygen.

Kitchen Fire Suppression System Singapore

Among the most important types, the oil and grease fire suppression system in singapore eateries have is dedicated to oil and grease fires. These types of systems automatically sense flare-ups and deploy wet chemicals to put out the fires and cool surfaces.

For food and beverage businesses, choosing the best fire suppression system in Singapore—especially for use in the kitchen—is not just a matter of compliance, but a matter of safety.

Smartest Fire Protection Practices

Only smart systems can function when installed and maintained smartly. Practice these best practices:

. Conduct a Fire Risk Assessment

Before installing a fire suppression system in Singapore, analyze the property-level fire hazards. This will allow you to select a system that's relevant, scalable, and compliant with local fire regulations.

Engage Certified Experts

Installation and maintenance should be carried out by qualified professionals who are familiar with both traditional and intelligent systems.

Systematic Testing and Maintenance

Smart system or otherwise, periodic testing needs to be carried out in order to remain in compliance and operating. Most of the fire suppression system in singapore service providers offer annual servicing packages.

Train Your Employees

Train staff members on how the system operates, drill evacuation during emergencies, and fault reporting. Human intuition remains crucial even with automation.

Catch Up with Technology

Fire protection technology keeps changing day by day. Periodically check if the current system is at industry level or not and whether an intelligent upgrade is required or not.

Singapore Future Trends of Fire Suppression System

Singapore is already moving towards AI-based fire detection and suppression. For example, some intelligent systems employ thermal imaging to detect overheating in electric panels prior to detecting smoke.

The second encouraging field is integrating fire suppression system Singapore with building control systems throughout the entire building—upholding a smart response strategy with lighting, ventilation, elevators, and communication equipment.

The integrated approach is extremely effective in environments like commercial kitchens, where an extinguishing kitchen fire suppression system Singapore restaurants depend on must be coordinated with exhaust systems, cooking ranges, and protective equipment.

Conclusion

Singapore fire protection is quicker, smarter, and more efficient than ever. But intelligent systems are not just about glossy technology—but about pre-emptive protection, compliance, and reassurance.

Whether you own a high-rise office complex or a fast-paced restaurant, it's no longer an option to invest in a quality fire protection system in Singapore. However, it's now mandatory. Protect yourself, protect your compliance, and face the future of fire protection—smart, networked, and engineered for evolving needs in Singapore.

0 notes

Text

1969 Holden Hurricane Concept

1969 Holden Hurricane Concept

1969 Holden Hurricane Concept

1969 Holden Hurricane Concept

1969 Holden Hurricane Concept

Holden has gone back to the future, restoring its very first concept car - the 1969 Holden Hurricane Concept.

The futuristic research vehicle described as an experiment "to study design trend, propulsion systems and other long range developments" has been restored to its former glory as a labour of love by a dedicated group of Holden designers and engineers.

Code named RD 001; the Holden Hurricane is a mid-engined, rear-wheel drive, two-seater sports car which incorporates a remarkable array of innovative features and technology, much of it way ahead of its time.

Features such as electronic digital instrument displays, station-seeking radio, automatic temperature control air conditioning, rear vision camera and an automated route finder were all showcased in this ground-breaking vehicle 42 years ago. Many of these technologies have only recently made their way into mass production, demonstrating Holden's remarkable foresight into both design and engineering technology.

The Holden Hurricane stole headlines and dropped jaws nationwide when it debuted at the 1969 Melbourne Motor Show.

Michael Simcoe, Executive Director GMIO Design, said it was fantastic to see such a significant vehicle restored.

"At Holden we have always prided ourselves on our ability to look into the future through our concept cars," Mr Simcoe said.

"It's amazing to think that the features we take for granted today were born out of creative minds over 40 years ago."

As its code name suggests, the RD 001 was the first product of the GMH Research and Development organisation, staffed by a small squad of engineers working in conjunction with the Advance Styling Group at the Fishermans Bend Technical Centre in the 1960s.

The team that designed and built the original Holden Hurricane employed some advanced technologies and techniques when it came to the powertrain. Powered by an experimental 4.2-litre (253 cubic inch) V8, this engine was a precursor to the Holden V8 engine program which entered production in late 1969.

The Holden Hurricane's V8 engine featured many advanced design components such as the four-barrel carburettor - a feature which wouldn't be seen on a production 253ci Holden V8 until the late 1970s. The end result was approximately 262hp (193kW), a towering power output in 1969 and one that ensured the Holden Hurricane had the go to match its show.

But perhaps the two most innovative features were the "Pathfinder" route guidance system and the rear-view camera.

The "Pathfinder", essentially a pre-GPS navigation system, relied on a system of magnets embedded at intersections along the road network to guide the driver along the desired route. A dash-mounted panel informed the driver of which turn to take by illuminating different arrows, as well as sounding a warning buzzer.

The rear-view camera was also a ground-breaking innovation.

Engineers using a Closed Circuit Television (CCTV) system with a camera mounted in the rear bumper feeding vision to a small black-and-white TV mounted in the centre console.

Former Holden Chief Studio Engineer Rick Martin led the modern-day Hurricane team in researching the vehicle's components, systems and history in order to restore it.

"There are some genuinely remarkable ideas and technology in the Hurricane," said Mr Martin.

"From the automatic air-conditioning and magnet-based guidance system, to the inertia-reel seat belts and metallic paint, this was a car that was genuinely ahead of its time.

"The hand-picked team of engineers and designers who built the original Holden Hurricane worked in strict secrecy and began Holden's now proud tradition of ground-breaking concept cars."

RD 001 stands just 990mm high and has no doors in the conventional sense. A hydraulically-powered canopy opens upwards and forward over the front wheels, combined with twin "astronaut type" power-elevating seats which rise up and pivot forward, along with the steering column for ease of access. Occupants are then lowered to a semi-reclining position before the roof closes over them.

The wind tunnel-tested fibreglass body consists of three segments; the canopy, the engine hood and body shell and was finished in an experimental aluminium flake-based metallic orange paint.

Safety innovations included a foam-lined fuel tank, integrated roll-over bar, digital instrument readouts, ignition safety locks, interior padding and a fire warning system.

The project to restore RD 001 began in 2006 and has been a genuine labour of love for some very dedicated Holden employees. The entire restoration process has been driven primarily by volunteer labour from Holden designers and engineers in their spare time.

But the Hurricane first entered Holden Design in less than immaculate condition. RD 001 had a residency in a trade school where apprentices practised their welding on the priceless concept.

After being returned to Holden in 2006, the Hurricane restoration project has taken many thousands of painstaking man hours to lovingly restore RD 001 to concourse condition.

Holden's Manager for Creative Hard Modelling, Paul Clarke, has been largely responsible for managing the restoration of RD 001. He ensured as many of the original parts as possible have been used or remade using modern techniques to 1969 specification, in order to preserve the authenticity of this hugely important Holden.

"The entire team has done a fantastic job in bringing this beautiful concept back to life," Mr Clarke said.

"The talent we have within the Holden organisation is simply outstanding. Every time we take on a project I'm constantly amazed by the passion and talent in this company, making it a genuine pleasure to work on these projects.

"The Hurricane plays a crucial role in Holden's story and the company has such a great sense of history and heritage that it was very important to bring RD 001 back to life. It's been a challenging but incredibly rewarding process."

Since the debut of the Holden Hurricane Concept in 1969, Holden has continued to build a global reputation for envisioning and executing world-class concept vehicles. Holden is recognised globally within General Motors as a centre of excellence for concept vehicle and show car development and is one of only three GM design studios that is capable to design and build concept cars.

Michael Simcoe added that the Hurricane holds a particularly special place in Holden's history as it kick-started Holden's long love affair with concepts that has since seen the likes of the iconic GTR-X, Torana TT36, Coupe 60, the GMC Denali XT (which was requested specifically by GM for the North American market) and the award-winning Efijy.

Holden Hurricane Concept (1969)

58 notes

·

View notes

Text