#Meat Processing

Explore tagged Tumblr posts

Text

Steak Dinner 🥩

#steak dinner#steak#taste#food#street food#foodporn#flavor#foodlover#gourmet food#foodpics#food tumblr#food photography#foodie#foodgasm#meat processing#meatwad#potatoes#fast food#sweet and savory#sweets#good taste#liking posts#meat lovers

742 notes

·

View notes

Text

#mine#photography#minnesota#sign#meat market#brick#vintage advertising#small town america#small town aesthetic#small town gothic#rural gothic#farmcore#the church of splatter day saints#meat processing#slaughtering#sausage

12 notes

·

View notes

Note

But what if I want to eat the doves, dove frico

I would highly advise against it, even in an emergency! (Non-graphic discussion of parasites and eating birds under the cut, for anyone who wants to look away!)

- In general, don't eat animals that died of sickness - Because they were sick, their body condition is very poor. They won't have much meat anyway - What little meat the adult birds have will be extremely stringy because they're old birds - They're feral pigeons, not production breeds, so even in optimal conditions, they'd still not be great meat producers - They definitely have encysted tapeworms So like. You can. But it will be very bad and I hope you cook them real well, or you're gonna wind up with hitchhikers in your intestines...

#Anon Answers#animal death#parasite#meat processing#Ik this was a silly funny ask. The joke is that I have an interest in animal domestication#and squab has fallen out of favour in a lot of places. But they were and are raised for meat. Esp historically!

19 notes

·

View notes

Text

Swift’s Meats for Babies.

#vintage illustration#vintage advertising#beef#meat#baby food#swift foods#swift’s#it’s full of meaty goodness#meaty goodness#canned meat#canned foods#swift & company#swift meats#meat processing#meat packing#meat packers#package design#vintage packaging#vintage labels#label design

12 notes

·

View notes

Text

Big companies love merging

#Big companies love merging#companies#merging#class war#extortion#exploitation#exploitative#eat the rich#eat the fucking rich#airlines#carriers#meat processing#gst#tax#us taxes#property taxes#death and taxes#indirect taxes#taxes#ausgov#politas#auspol#tasgov#taspol#australia#fuck neoliberals#neoliberal capitalism#anthony albanese#albanese government#eat the 1%

6 notes

·

View notes

Text

Small Talk, Ecocide & Genocide

The societal obsession with civility, small talk, decorum & “being nice” is slowly killing the planet & allowing a merciless genocide to continue unabated for nearly a year.

Its not “polite” to engage in small talk about climate change or the fact that the fucking planet is literally dying and there is an impending ecocide that over a hundred studies predict could happen by 2100.

Literally in less than one human being's lifespan from today, the earth is predicted to be uninhabitable.

But thats not “nice” to say and its not “polite small talk”.

Last year, on my birthday three days before Halloween, for the first time in my life — 42 years — it was 80 fucking degrees on fucking Halloween weekend!

I even wrote a tumblr blog post about it because I was so fucking gagged by the weather.

Still, societally, you are only allowed to acknowledge that its “kind of warm for October” or “its going to be a hot Halloween”.

Banal small talk to cover up extreme unprecedented weather never before seen instead of calling it for what it is — the literal destruction of planet earth.

The sky is actually falling but still anyone wants to do is discuss unprecedented weather as it pertains to their Labor Day weekend, beach, travel, party and dinner plans.

Never about climate change, never about fossil fuels, never about forever chemicals, never about landfills, never about deforestation, never about excessive central air conditioning and heat usage, never about replacing air conditioning with open windows and a ceiling or box fan, never about maximalism, hypercapitalism, industrial pollution, industrial runoff, oceanic & air pollution, logging industry, big pharma, big ag, 9 billions tons of single use plastic, oil, coal, meat packaging, airplanes, cruise ships, automobiles, not owning a personal vehicle, the toxic forever chemicals produced by the batteries in electric vehicles, cobalt, mining, factory farms, sweatshops, war pollutants. . .

Ive lived in NJ my whole life for 42 years and for the first time in my life there was an earthquake earlier this summer.

Still, its just a dinner party topic, an icebreaker, something to discuss with a coworker.

Similarly, earlier this year, for the first time in 42 years of being a NJ resident, there was a tornado.

Still, no actual climate change legislation is ever enacted that would produce results that would actually save the fucking planet.

Elon Musk is already planning to colonize Mars.

Once Earth has been humped, pumped and dumped, they will repeat the pattern again with Mars.

Rapists.

It is the beginning of September. Labor Day was yesterday.

I do get that its Fall and that Summer is over.

However, a TWENTY SIX DEGREE DIFFERENCE IN WEATHER IN ONE FUCKING DAY IS THE VERY FURTHEST thing from normal.

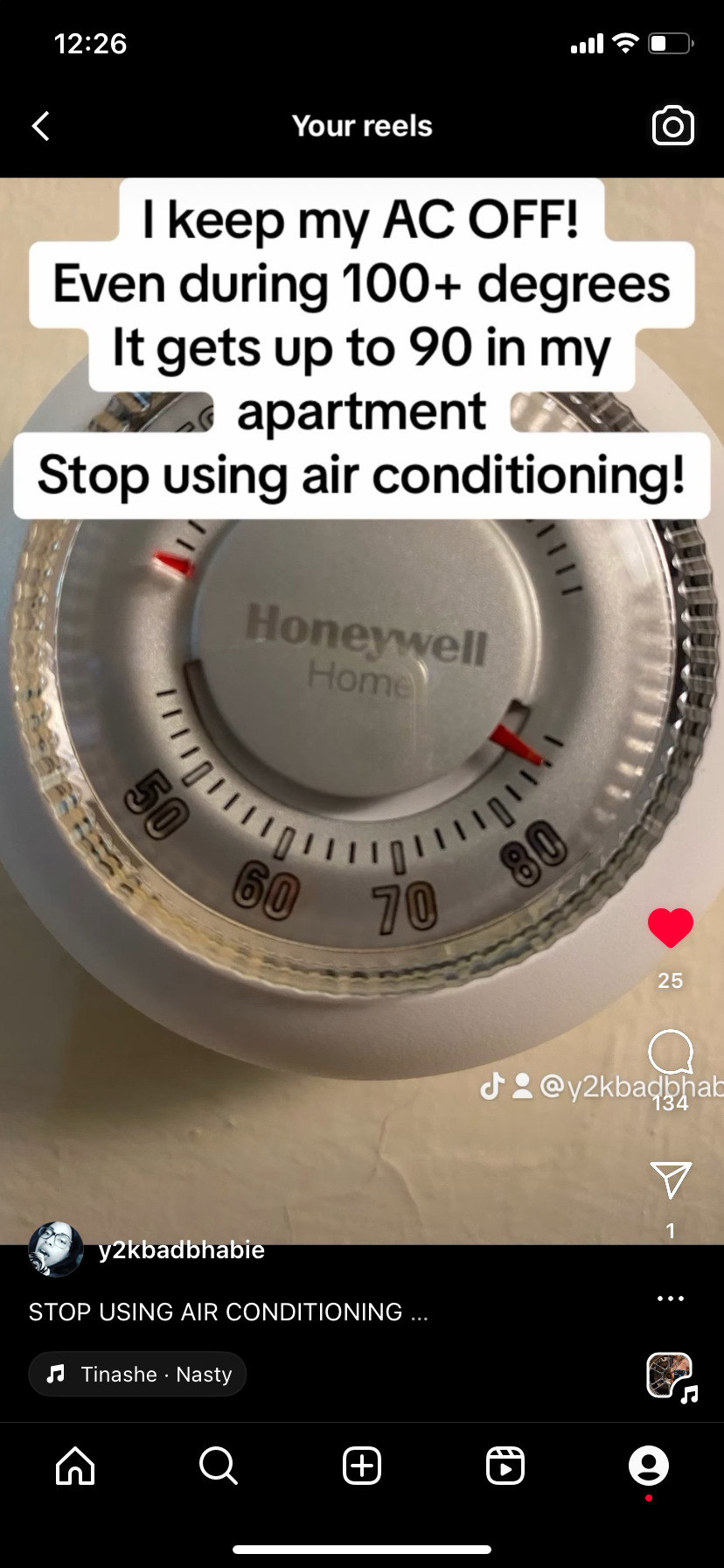

I live in a one bedroom apartment and do not utilize air conditioning.

I live in NJ and we do have heat waves that get up to 100+ degrees which happened several times this summer. My apartment has gotten as hot as 90 degrees.

I still did not turn my air conditioning on.

I opened the windows and turned on a ceiling fan.

I wear light, minimal clothing and stay hydrated and drink water.

92% of American homes utilize air conditioning — 92%!

The EPA states via a survey that Americans keep their thermostats at a disgustingly wasteful and fucking ridiculous 68 degrees to 72 degrees and the vast majority (76%) dont even bother to fucking adjust the thermostat up when they arent home.

So fucking disgustingly wasteful.

Air conditioning utilizes the most energy in a home outside of heating and refrigerators.

It emits the equivalent of millions of carbon units a year.

Americans use more air conditioning than the rest of the world COMBINED.

Most homes in the UK, France and Germany dont have air conditioning.

Many public buildings and residential homes in Japan dont have air conditioning.

In certain Scandinavian countries, it is illegal for offices to utilize air conditioning.

The EPA suggests in their guidelines that Americans keep their AC thermostats at 80 degrees.

I suggest Americans do what I do and just turn their air conditioning off and open the windows and turn on a ceiling or a box fan.

My grandparents in rural Georgia where it got very hot did not have air conditioning when I would visit them for a month every summer as a kid.

Air conditioning was only invented in 1906 — it isnt a NECESSITY, it is a LUXURY and Americans pretend otherwise even though in my own lifetime, there were plenty of homes and buildings without air conditioning!

Air conditioning is completely ubiquitous in America to the level of brainwashing — you can literally go an entire summer in America and never once encounter an internal environment or building without artificially cooled air!

That is brainwashing!

My windows have been open every single day all summer — June through August.

I came out to my living room this morning and it was fucking frigid.

56 degrees outside.

But I wont bother closing the windows because due to climate change, the high today is an unbelievable 76 degrees and the low is 50 fucking degrees.

Still, noone just says, you know it was never the norm for a twenty six fucking degree change in weather in one fucking day.

I have an oversized sweater, leggings and socks on inside my apartment with the windows open and my fingertips are legitimately numb.

And the average American on a day like today just shuts their air conditioning off mindlessly in the morning then just as mindlessly blasts it in the afternoon when the temperature is going to jump twenty fucking degrees to a high of 76 then just as mindlessly shuts their air conditioning off at night as the low is a fucking disgusting 50 degrees tonight.

Never with one single solitary fucking thought.

I left corporate in 2019 and have been a work from home freelance podcaster since 2021.

But I worked in corporate for 15 years — six years in customer service, five years as a recruiter and then I owned my own career coaching and resume writing business for 3 years.

I know for a fact if I was still in a W-2 job that the weather today instead of being correctly and honestly flagged as one of the most fucking egregious and disgusting examples of climate change I have ever witnessed — along with the earthquake and tornado both for the first time fucking ever earlier this summer and the 80 degree weather Halloween weekend last fucking October — it would have just been another inane topic of small talk.

And if I had dared to bring up climate change, I would have been accused of “politicizing” things.

For telling the fucking truth.

So then, instead, someone tells a “joke” about how Starbucks brought the Pumpkin Spice Latte back “early”. Then someone says Dairy Queen also brought their Fall menu out early. Then someone chimes in that Ritas Italian Ice did the same.

Cue laugh track.

Instead of telling the fucking truth — that these extreme weather patterns, these extremely humid and hot heat waves, earthquakes and tornados in fucking NJ, 80 degree weather Halloween weekend in NJ, a TWENTY SIX DEGREE CHANGE IN THE WEATHER IN ONE FUCKING DAY has been proven in study after study to be a sign of our impending planetary doom and incoming ecocide and death of our planet if we dont change our hypercapitalist, maximalist, overconsumptive, consumerist, materialistic, wasteful, single use plastic, throwaway culture, fast food eating, Doordashing, fast fashion obsessed, toilet paper obsessed, air conditioning addicted, automobile addicted, vacation addicted, airplane flying, cruise shipping, retail shopping addicted, Amazon delivery addicted, Starbucks coffee addicted, Runs on Dunkin addicted, trash generating, food wasting, Amazon landfilling ways. . .

But no, instead of that truth, which we can all evidently see and feel — climate change and the extreme weather, heat waves, natural disasters, 30+ degree weather changes in ONE fucking day, 80 degree weather in October that should have been a wake up call to change our ways and save our planet — it just becomes yet another inane small talk topic of discussion.

Add it to Paris Olympics, Met Gala, NFL, Oscars, Kamala, Biden, Trump, Vance, Walz and all the other bullshit.

Anything to avoid discussing a genocide that every American adult that earned more than $400 as a freelancer, all entrepreneurs that generated income and all W-2 earners are funding that has murdered over 198k Palestinian civilians despite it being livestreamed to us in real time every single day on social media in the palms of our hands on our phones.

We're seeing elderly men handcuffed being run over by armored Israeli tanks.

Were seeing children be stepped on, bombed, cut to pieces, exploded, injured, dying, crying, screaming, running, evacuating, mourning murdered family members.

Were seeing executions, war crimes, atrocities, crimes against humanity, torture, rapes, mass graves with hundreds of civilian bodies and bombings of refugee camps, open air street markets, residential areas, hospitals, schools and homes by the IOF — Israeli OCCUPATION Force — a genocide is not defense — with total impunity as the IOF is calmly documenting their own war crimes and uploading them to social media.

Still, the ICC and ICJ do nothing.

Ten months of this!

Still, Netanyahu and Gallant arent arrested.

Still, the US continues to send Israel billions — $17 billion this year alone by the Biden/Kamala administration but all anyone cares about is that Kamala is half Black??

Still, the US continues to supply the IOF with 500 lb bombs by Boeing meant to be used on fortified military bunkers being dropped on tents in refugee camps instantly incinerating the civilians within.

Still, the world stands by in silent complicity and streams it live like an updated reality TV show. Every day, more images of death, destruction and despair as you stream peoples deaths live on your couch.

Survivor: Genocide Style!

Who will be voted off the Gaza Strip next?

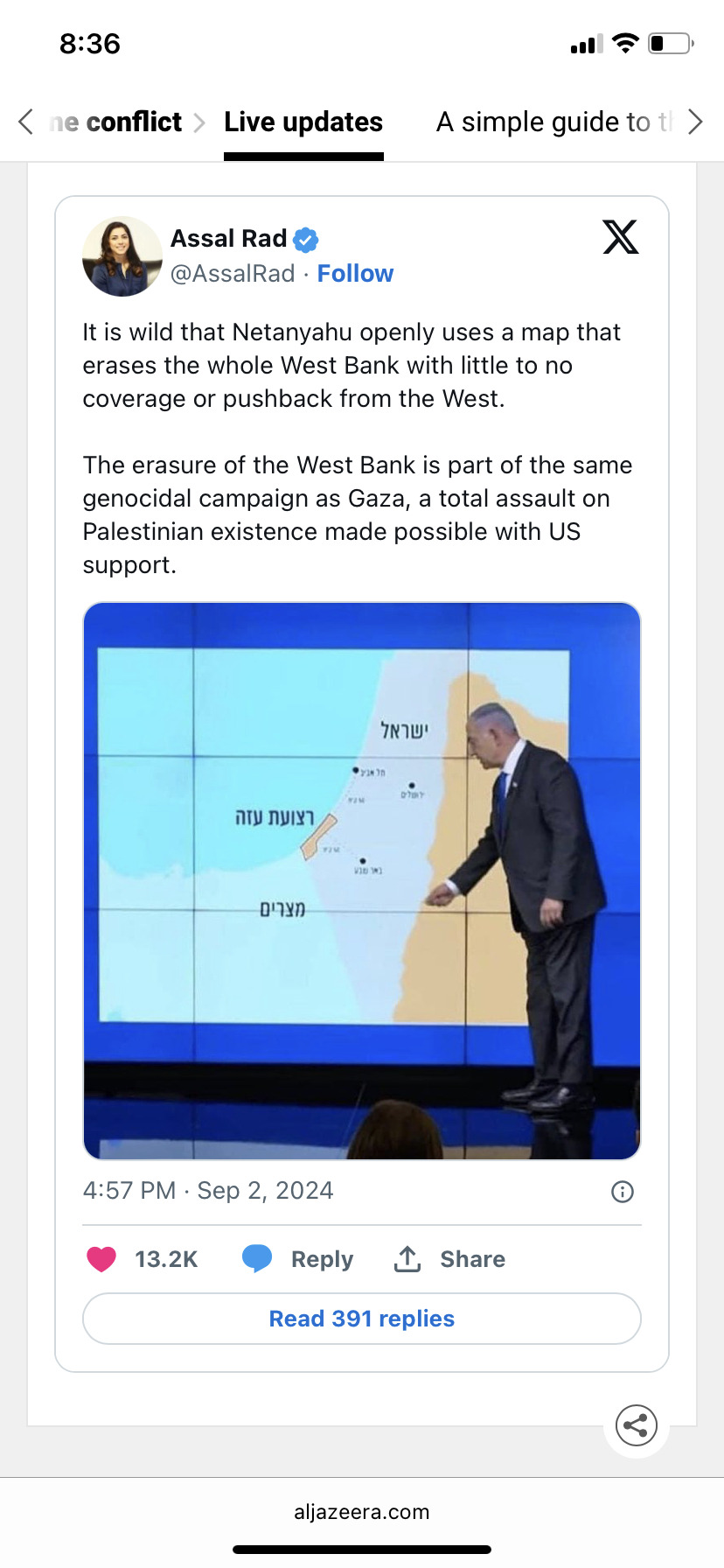

Netanyahu demands the Phillipi corridor in any ceasefire agreement and in the map during his genocidal press conference he has the absolute fucking unmitigated gall to claim West Bank as part of Israel.

Still, mainstream western media stays complicit referring to this genocide, the mass slaughter of Palestinians, tens of thousands buried unidentified under rubble, tens of thousands blown up bombed and incinerated into pieces unidentified — 198k dead Palestinian civilians & 4k dead Israeli civilians and you have the motherfucking audacity in the mainstream Western media complex to call that a “war”, a “conflict” and “complicated”?

Israel was created in 1948. The Nakba happened in 1948 displacing and murdering hundreds of thousands of Palestinians.

There is nothing “complicated” about that.

The state of Palestine was first recorded in history thousands of years ago.

Israel is a false creation by the US & UK.

This is readily admitted to.

Biden stated while addressing Congress in 1986 that if Israel didnt exist, “we” would have had to create her.

Ask yourself who “we” is.

But even an ongoing streamed in real time live on your nearest cell phone in gory 4K clarity realness genocide isn't enough to slow down the small talk dick sucking for clout social climbers that use even a genocide as social currency and capital.

Just another blip on the small talk radar.

And if you dare to tell the truth that polio reappeared for the first time in decades for the first time in Palestine because of Israel destroying Palestines infrastructure which has caused open sewage, mountains of trash, bacteria, insects, infections and now polio and even scabies. . .

So, Israel caused the reappearance of polio in Palestine — how can anyone not question the IOFs intentions this weekend temporarily pausing their butchering and murdering (“pausing hostilities”) to distribute a fucking vaccine for a goddamned disease that they are responsible for reintroducing to Palestine?????

The same genocidal fucks that have murdered at least 15k children (probably double or triple that if you count the bodies buried under rubble and cut up into unidentifiable pieces) now all of a sudden care about these same exact children getting polio when they have been indiscriminately murdering them for the past ten fucking months which we have seen endless literal videos for????

If Israel was so “concerned” about a polio outbreak in Palestine spreading to Israel, dont you think that Israel would be vaccinating THEIR OWN POPULATION and NOT vaccinating Palestinians?

Its not a vaccine, you dumb fucks.

The US has done this before — it is the exact same playbook.

The US gave blankets to Native Americans as a “gift” which they actually infected with diseases that they knew the Native Americans had no immunological defense for killing thousands.

Some gift.

The US medically experimented on Black Tuskegee airmen trying to develop vaccines for STIs.

The US has forcibly sterilized women in Puerto Rico without their consent against their will.

Why do you think Israel isnt sterilizing Palestinians and lying and claiming its some vaccine?

The US has done this exact same thing in the very recent past.

You'll notice noone in the IOF is injecting themselves with this “polio vaccine” — why do you think that is?

If Israel is so worried about the polio outbreak in Palestine — wouldnt they be vaccinating their genocidal troops with the same vaccine Israel is administering to Palestinians?

I post videos about this and TikTok and Youtube immediately removed them.

“Medical misinformation”?????????????

Wake the FUCK up at some point!!!!!!!

#small talk#ecocide#genocide#gaza genocide#palestine genocide#free palestine#palestine will be free#arrest netanyahu#climate change#landfill#deforestation#big oil#fossil fuels#big ag#meat processing#fast food#amazon#fast fashion#walmart inc#extreme weather#civility#industrial revolution#auto industry#travel industry#cruise ship#holiday#mindless#fuck elon musk#air conditioning#carbon footprint

4 notes

·

View notes

Text

Cure (recipe at bottom)

100g of cure #1: 6.25g (6 250mg) sodium nitrite; 93.75g salt (sodium chloride).

10g cure 1: 0.625g (625mg) NaNO2; 9.375g salt.

1g: 0.0625g (62.5mg); 0.9375g.

Alright. If my recipe calls for 3g cure for every 1kg of meat, I am getting (62.5x3=)187.5mg nitrite/kg. If I am curing 4kg then it is (187.5x4=)750mg. If I am curing 500g then it is (187.5x0.5=)93.75mg nitrite.

100g of cure #2: 5.67g (5 670mg) sodium nitrite; 3.63g (3 630mg) sodium nitrate; 9.3 (9 300mg) both; 90.07g salt.

10g cure 2: 0.567g (567mg) nitrite; 0.363g (363mg) NaNO3; 0.93g (930mg) both; 9.07g salt.

1g: 0.0567 (56.7mg) ite; 0.0363g (36.3mg) ate; 0.093g (93mg) both

If my recipe calls for 3g of cure for every 1kg of meat, I am getting 170.1mg nitrite/kg & 0.1089g nitrate/kg, or 279mg both/kg.

EU regulation says 150mg. Good thing I'm in Canada.

Alright so, celery leaf.

"Cold-smoked sausages containing 2.58% of freeze-dried celery (corresponding to 150 mg/kg of nitrate) or 150 mg/kg nitrite or 150 mg/kg nitrate were manufactured with S. xylosus or with S. xylosus and P. pentosaceus mixture."

This seems to imply that they cured meat with normal 150mg nitrate, then they cured meat with 150mg nitrate in the form of celery, & they cured meat with 150m nitrite. To get 150mg nitrate in the form of celery, they needed 25.8g of freeze dried celery powder.

According to my assumptions, there are 150mg of nitrate in 25.8g celery powder.

Celery Total Nitrate Content (mg kg−1[which means ppm or mg/kg]): 1103, 1544, 1495, according to different sources

That is for fresh celery & not dried celery leaves. How much weight does celery lose when dried? If I wanted to do the math, I would find a conversion for something like parsley leaves weight fresh vs dry & celery fresh vs freeze dried. Either that or multiply away the water weight from celery.

"The five different sausage formulations were: Control negative (CN) no nitrate added; Control positive (CP) 150 mg/kg potassium nitrate; Group with celery powder (GSe) 3 g/kg celery powder. Based on Sindelar et al. (2006), a mild effect on the colour of the meat was expected from celery and spinach, and beet powder was added in two lots."

So here it seems like they are treating 3g of celery as equivalent to 150mg nitrate.

This is a far cry from 26g of celery equivalent to 150mg.

Celery is 95% water. According to my brother, dry celery has 14 000mg (14g) of nitrate in one kilo.

If I need 279mg of nitrates/ites for one kilogram of meat, how many grams of dried celery powder do I need?

279 is basically 280mg. I need 20grams of dried celery.

So without further ado, here is my recipe:

For every kilogram of meat you want to cure, you need the following:

Salt: 25g (& an extra 3g from cure 2)

Cure 2: 3g (280mg nitrate/ite, 2.7g salt); ALTERNATIVELY - Dried celery leaf powder: 20g

Dry sage: 0.9g

Rosemary: 0.6g

Fennel seed: 1g

Ground fennel: 1g

White pepper: 0.3g

Garlic powder: 0.5g

Chianti (italian/tuscan red wine from sangiovese grape)

Mixing vessel, something with which to open the chianti, gram scale, fridge/cooler, plastic bag/vacuum seal bag, probably a tray or smth to do this on.

Keep all the parts apart until you are ready to mix. You'd be surprised how often you forget that you already did a part of it. Phone rings? Oh now where was I. Did I already get the salt? Hmm...

Weigh the meat you want to cure. Multiply each number by how many kilos of meat you have. Measure the ingredients all apart.

Wet with wine until it is like sand at the beach. Pack on all the salt mix. Do not waste any because this is already measured for this amount of meat. Put it into the bag & seal.

Store in the fridge for a few weeks up to a few months.

When ready, I would suggest using a thermocirculator to low-temperature pasteurize it, & then it is safe to store for another few months.

(Here is what my teacher said: Yes, once we cured the whole muscle, we store it under refrigeration to cure through. Depending on the cut and temp, that's usually about 3-4 weeks for the Coppa and 2-3 for the lomo, as reference. You can keep it vac sealed with the curing ingredients for months. Max I've done personally is 5 months. After the curing phase, I cooked them sous vide. And it's neat because once it's been cooked sous vide, the shelf life in the fridge is then also months.)

#cured meats#cured meat#culinary school#culinary#meat processing#lomo#coppa#capicola#food preservation#fermentation process#recipe#recipes#meat recipe#whole muscle cure#whole muscle recipe

3 notes

·

View notes

Text

Don't miss this: hormones in beef and chicken washed in acid are already legal in the U.S. That's Trump policy AND RFK Jr. policy.

Yes, it is.

After all, if these policies only reflect the will of past Administrations, why haven't Trump and Kennedy struck these policies down?

0 notes

Text

Himalayan Salt Wall + Dry Ager + Superb Quality Beef = A match made in HEAVEN!!!

Happy Thursday

everyone....................

for more info visit us at:

https://buildsaltwall.com

1 note

·

View note

Text

Fermentation in Meat and Fish Processing: 5 Traditional Preservation Methods (2025)

>>> Fermentation in Meat and Fish Processing: 5 Traditional Preservation Methods (2025) #Fermentation, #FishProcessing, #FoodPreservation, #MeatProcessing, #TraditionalMethods #Articles https://equipment7.com/articles/fermentation-meat-fish-processing-5-traditional-preservation-methods-2025/

0 notes

Text

The Role of Meat Processing Companies in South Africa

Meat processing companies in South Africa play a key role in the agricultural sector, contributing significantly to the economy and food security. These businesses oversee converting raw beef into a variety of products for both domestic and foreign markets. Understanding the relevance of meat processing companies in South Africa can shed light on their impact on food security, employment, and industry standards. Economic Contribution Meat processing companies in South Africa contribute significantly to the economy by producing jobs and earning cash. These enterprises employ thousands of people in a variety of industries, including farming, processing, and distribution. This employment not only benefits local families, but also boosts regional economies. As consumer demand for meat products rises, meat processing companies in South Africa are well-positioned for expansion, boosting their economic influence even more. Food Security Food security is a grave concern and meat processing companies in South Africa are essential for guaranteeing a consistent supply of protein-rich meals. By processing and packing meat products, these businesses contribute to meeting the population's dietary demands. They provide a varied selection of items, including fresh cuts, processed meats, and ready-to-eat meals. This variety ensures that customers have access to nutritious options that appeal to a wide range of tastes and preferences, emphasising the critical role that meat processing companies in South Africa play in food security. Quality Standards Meat processing companies in South Africa must adhere to tight rules and quality standards to maintain food safety. These standards address everything from animal welfare to cleanliness measures in processing facilities. By adhering to these criteria, meat processing companies in South Africa ensure that their goods are of high quality and reliable for consumers. This commitment to quality not only protects public health but also improves the reputation of South African beef products both locally and globally. Innovation & Technology Meat processing companies in South Africa is constantly evolving, with companies adopting novel technologies to improve productivity and product quality. Advances in processing processes, packaging solutions, and preservation procedures allow these businesses to offer safer and more appealing products. meat processing companies in South Africa can better satisfy market expectations by investing in technology, reducing waste and increasing sustainability. Export Opportunities South Africa is known for its high-quality meat products, making it a competitive player in the global market. These businesses can export their products to a variety of nations, boosting foreign exchange revenues. Meat processing companies in South Africa can enter profitable markets by fulfilling international standards, demonstrating the unique quality of South African meats on a worldwide scale.

Supporting Local Farmers Meat processing companies in South Africa frequently work closely with local farmers to get raw materials. This relationship benefits the agriculture industry by providing farmers with a consistent market for their cattle. These alliances allow meat processing companies in South Africa to maintain a consistent supply of high-quality meat while also encouraging sustainable farming techniques. Conclusion Finally, meat processing companies in South Africa contribute significantly to the country's economy and food security. Their contributions go beyond simply providing meat; they also create jobs, maintain quality standards, promote innovation, and support local agriculture. As the demand for meat products rises, these businesses will become increasingly vital in addressing consumer needs while also benefiting the economy.

0 notes

Text

#Pork Products#Premium Pork#Pork Offals#Pork Chops#Pork Belly#Pork Shoulder#Food Safety#Meat Processing#Culinary Uses#Comercial Maxagro S.A

0 notes

Text

This Date In Manka Bros. History - July 25, 1990:

Manka Bros. closes its Manka Meats division for being ‘non-strategic.’

#parody#satire#funny#hollywood#movies#bulgaria#beef#meat processing#des moines#hollywood history#today in history#hollywood studios

1 note

·

View note

Text

Chef WK, lead charcuterie specialist in Alberta Canada

Table of contents

1. Control Program Requirements for Fermented Meat Products

2. Facility and Equipment Requirements

3. Starter Culture

4. Chemical Acidification

5. Water Activity Critical Limits

6. Time and Temperature for Fermented Products

7. Fermentation Done at a Constant Temperature

8. Examples of Degree-hours at constant room temperatures

9. Fermentation Done at Different Temperatures

10. Fermentation done at Different temperatures

11. What happens if fermentation fails to hit critical limit?

12. E. coli and Salmonella Control in Fermented Sausages

13. Options for E. coli validation

14. Option1; Heating

15. Option 2; pH, heating, holding, diameter

16. Safety and consistency

Control Program Requirements for Fermented Meat Products

The producer must have a program in place to assess the incoming product. This program should outline specifications for the incoming ingredients. This may include criteria including receiving temperature, farm/ supplier, lot code or packed on date, species/cut etc.

2. Facility and Equipment Requirements

Equipment used in the fermentation process must be included in the operator's prerequisite control programs. These must include the following elements:

Temperature in the fermentation, drying and smoking chambers must be uniform and controlled to prevent any fluctuation that could impact on the safety of the final product.

Fermentation, drying and smoking chambers must be equipped with a shatter resistant indicating thermometer, (or equivalent), with graduations of 1°C or less. If mercury thermometers are used, their mercury columns must be free from separations. All thermometers must be located such that they can be easily read.

Fermentation and smoking chambers must be equipped with a recording thermometer for determining degree-hours calculations in a reliable manner. Recording thermometers are also preferable in drying and aging rooms but, in these rooms, it may be sufficient to read and record the temperatures 2 times a day.

Drying and aging rooms must be equipped with humidity recorders in order to prevent uncontrolled fluctuations of the relative humidity. The only alternative to an automatic humidity recorder in these rooms would be for the company to manually monitor and record ambient humidity twice a day (morning and afternoon) every day with a properly calibrated portable humidity recorder.

For routine monitoring, accurate measurement electronic pH meters (± 0.05 units) should be employed. It is important that the manufacturer's instructions for use, maintenance and calibration of the instrument as well as recommended sample preparation and testing be followed.

When the aw of a product is a critical limit set out in the HACCP plan for a meat product, accurate measurement devices must be employed. It is important that the manufacturer's instructions for use, maintenance and calibration of the instrument be followed.

3. Starter Culture

The operator must use a CFIA approved starter culture. This includes Freeze-dried commercially available culture as well as back-slopping (use of previously successful fermented meat used to inoculate a new batch). When performing back-slopping, the operator must have a control program in place to prevent the transmission of pathogens from when using the inoculum from a previous batch to initiate the fermentation process of a new batch. These must include:

The storage temperature must be maintained at 4°C or less and a pH of 5.3 or less.

Samples for microbiological analysis must be taken to ensure that the process is in line with the specifications.

The frequency of sampling is to be adjusted according to compliance to specifications.

Any batch of inoculum which has a pH greater than 5.3 must be analysed to detect at least Staphylococcus aureus. Only upon satisfactory results will this inoculum be permitted for use in back slopping.

This can be an expensive and a time exhaustive process and is generally avoided due to food safety concerns. AHS does not allow back-slopping.

[Chef WK was in communication with the U of A to get his method, a starter mix, studied.]

4. Chemical Acidification

If product is chemically acidified by addition of citric acid, glucono-delta-lactone or another chemical agent approved for this purpose, controls must be in place and records kept to ensure that a pH of 5.3 or lower is achieved by the end of the fermentation process. These acids are encapsulated in different coatings that melt at specific temperatures, which then release the powdered acids into the meat batter and directly chemically acidulate the protein.

Summer sausage is a very common chemically acidified product. The flavor profile tends to be monotone and lacking depth.

5. Water Activity Critical Limits

The aw may be reduced by adding solutes (salt, sugar) or removing moisture.

Approximate minimum levels of aw (if considered alone) for the growth of:

molds: 0.61 to 0.96

yeasts: 0.62 to 0.90

bacteria: 0.86 to 0.97

Clostridium botulinum: 0.95 to 0.97

Clostridium perfringens: 0.95

Enterobacteriaceae: 0.94 to 0.97

Pseudomonas fluorescens: 0.97

Salmonella: 0.92 - 0.95

Staphylococcus aureus: 0.86

parasites: Trichinella spiralis will survive at an aw of 0.93 but is destroyed at an aw of 0.85 or less.

The above levels are based on the absence of other inhibitory effects such as nitrite, competitive growth, sub-optimum temperatures, etc., which may be present in meat products. In normal conditions, Staphylococcus aureus enterotoxins are not produced below aw 0.86, although in vacuum packed products this is unlikely below aw 0.89.

6. Time and Temperature for Fermented Products

Certain strains of the bacteria Staphylococcus aureus are capable of producing a highly heat stable toxin that causes illness in humans. Above a critical temperature of 15.6°C, Staphylococcus aureus multiplication and toxin production can take place. Once a pH of 5.3 is reached, Staphylococcus aureus multiplication and toxin production are stopped.

Degree-hours are the product of time as measured in hours at a particular temperature multiplied by the "degrees" measured in excess of 15.6°C (the critical temperature for growth of Staphylococcus aureus). Degree-hours are calculated for each temperature used in the process. The limitation of the number of degree-hours depends upon the highest temperature in the fermentation process prior to the time that a pH of 5.3 or less is attained.

The operator is encouraged to measure temperatures at the surface of the product. Where this is not possible, the operator should utilize fermentation room temperatures. The degree hour calculations are based on fermentation room temperatures. Temperature and humidity should be uniform throughout the fermentation room.

A process can be judged as acceptable provided the product consistently reaches a pH of 5.3 using:

fewer than 665 degree-hours when the highest fermentation temperature is less than 33°C;

fewer than 555 degree-hours when the highest fermentation temperature is between 33° and 37°C; and

fewer than 500 degree-hours when the highest fermentation temperature is greater than 37°C.

This means that as the temperature increases, the amount of time that you have available to reach 5.3 or under is shorter. The warmer the temperature, the sharper the log growth phase of bacteria, which equates to more overshoot in lactic acid production, faster.

8. Examples of Degree-hours at constant room temperatures

Example 1:

Fermentation room temperature is a constant 26°C. It takes 55 hours for the pH to reach 5.3.

Degrees above 15.6°C: 26°C - 15.6°C = 10.4°C Hours to reach pH of 5.3: 55 Degree-hours calculation: (10.4°C) x (55) = 572 degree-hours

The corresponding degree-hours limit (less than 33°C) is 665 degree-hours.

Conclusion: Example 1 meets the guideline because its degree-hours are less than the limit.

Example 2:

Fermentation room temperature is a constant 35°C. It takes 40 hours for the pH to reach 5.3.

Degrees above 15.6°C: 35°C - 15.6°C = 19.4°C Hours to reach pH of 5.3: 40 Degree-hours calculation: (19.4°C) x (40) = 776 degree-hours

The corresponding degree-hours limit (between 33 and 37°C) is 555 degree-hours.

Conclusion: Example 2 does not meet the guideline because its degree-hours exceed the limit

9. Fermentation Done at Different Temperatures

When the fermentation takes place at various temperatures, each temperature step in the process is analyzed for the number of degree-hours it contributes. The degree-hours limit for the entire fermentation process is based on the highest temperature reached during fermentation.

Example 1:

It takes 35 hours for product to reach a pH of 5.3 or less. Fermentation room temperature is 24°C for the first 10 hours, 30°C for second 10 hours and 35°C for the final 15 hours.

Step 1

Degrees above 15.6°C: 24°C - 15.6°C = 8.4°C Hours to reach pH of 5.3: 10 Degree-hours calculation: (8.4°C) x (10) = 84 degree-hours

Step 2

Degrees above 15.6°C: 30°C - 15.6°C = 14.4°C Hours to reach pH of 5.3: 10 Degree-hours calculation: (14.4°C) x (10) = 144 degree-hours

Step 3

Degrees above 15.6°C: 35°C - 15.6°C = 19.4°C Hours to reach pH of 5.3: 15 Degree-hours calculation: (19.4°C) x (15) = 291 degree-hours

Degree-hours calculation for the entire fermentation process = 84 + 144 + 291 = 519

The highest temperature reached = 35°C

The corresponding degree-hour limit = 555 (between 33°C and 37°C)Conclusion: Example 1 meets the guideline because its degree-hours are less than the limit.

10. Fermentation done at Different temperatures

Example 2:

It takes 38 hours for product to reach a pH of 5.3 or less. Fermentation room temperature is 24°C for the first 10 hours, 30°C for the second 10 hours and 37°C for the final 18 hours.

Step 1

Degrees above 15.6°C: 24°C - 15.6°C = 8.4°C Hours to reach pH of 5.3: 10 Degree-hours calculation: (8.4°C) x (10) = 84 degree-hours

Step 2

Degrees above 15.6°C: 30°C - 15.6°C = 14.4°C Hours to reach pH of 5.3: 10 Degree-hours calculation: (14.4°C) x (10) = 144 degree-hours

Step 3

Degrees above 15.6°C: 37°C - 15.6°C = 21.4°C Hours to reach pH of 5.3: 18 Degree-hours calculation: (21.4°C) x (18) = 385.2 degree-hours

Degree-hours calculation for the entire fermentation process = 84 + 144 + 385.2 = 613.2

The highest temperature reached = 37°C

The corresponding degree-hour limit = 555 (between 33°C and 37°C)

Conclusion: Example 2 does not meet the guidelines because its degree-hours exceed the limit.

11. What happens if fermentation fails to hit critical limit?

What happens if the batch takes longer than degree-hours allows? For restaurant level production, it's always safer to discard the product. The toxin that Staph. Aureus produces is heat stable and cannot be cooked to deactivate. In large facilities that produce substantial batches, the operator must notify the CFIA of each case where degree-hours limits have been exceeded. Such lots must be held and samples of product submitted for microbiological laboratory examination after the drying period has been completed. Analyses should be done for Staphylococcus aureus and its enterotoxin, and for principal pathogens, such as E. coli O157:H7, Salmonella, and Clostridium botulinum and Listeria monocytogenes.

If the bacteriological evaluation proves that there are fewer than 104 Staphylococcus aureus per gram and that no enterotoxin or other pathogens are detected, then the product may be sold provided that it is labelled as requiring refrigeration.

In the case of a Staphylococcus aureus level higher than 104 per gram with no enterotoxin present the product may be used in the production of a cooked product but only if the heating process achieves full lethality applicable to the meat product.

In the case where Staphylococcus aureus enterotoxin is detected in the product the product must be destroyed.

12. E. coli and Salmonella Control in Fermented Sausages

Business' that manufacture fermented sausages are required to control for verotoxinogenic E. coli including E. coli O157:H7 and Salmonella when they make this type of product. This includes:

establishments which use beef as an ingredient in a dry or semi-dry fermented meat sausage;

establishments which store or handle uncooked beef on site;

Establishments which do not use beef and do not obtain meat ingredients from establishments which handle beef are not currently required to use one of the five options for the control of E. coli O157:H7 in dry/semi-dry fermented sausages.

Any processed RTE product containing beef or processed in a facility that also processed beef, must be subjected to a heat treatment step to control E. coli O157:H7. Heating to an internal temperature of 71°C for 15 seconds or other treatment to achieve a 5D reduction is necessary. This is a CFIA requirement and is not negotiable.

Uncooked air dried products produced as RTE, must meet shelf stable requirements as detailed for Fermented-Dry products.

13. Options for E. coli validation

Without lab testing, the two main methods of validation are with heat treating by either low temp and a long duration, or various hotter processing temperatures for a shorter timeframe.

A challenge study to validate a process can take 1 year and over $100,000!

14. Option1; Heating

15. Option 2; pH, heating, holding, diameter

16. Safety and consistency

The aw and pH values are critical in the control of pathogens as well as to ensure shelf-stability in all semi-dry and dry fermented meat products. Each batch must be tested for aw and/or pH in order to verify that the critical limits are met.

Although aw measurement is mandatory only for shelf stable products, it is strongly recommended that the producer determine the aw values achieved for each product type they manufacture and for each product. Once this has been established, frequent regular checks should be made to ensure consistency. In the U.S., they rely on moisture to protein ratio and have set targets. This lab-tested value is a direct correlation of the % water to % meat protein and not aw. This gives more consistency to common names. For example, to legally call a product "jerky" it must have a MPR of 0.75:1 or lower. Remember your ABCs:

Always be compliant.

-AND-

Documentation or it didn't happen.

(tags)

Charcuterie,Fermented Meat,Food Safety,Starter Culture,Chemical Acidification,Water Activity,Fermentation Process,Degree-Hours Method,Foodborne Pathogens,Meat Processing Guidelines,Chef WK Alberta Canada,Food Industry Standards,pH Critical Limits,Thermal Processing,Food Preservation,Food Microbiology,Sausage Fermentation,Charcuterie Expertise,Fermented Meats ,Food Safety Standards,Food Processing Guidelines,Starter Cultures,Chemical Acidification,Water Activity (a_w),Critical Limits,Degree-Hours Method,Foodborne Pathogens,Meat Processing Equipment,Processing Facility Requirements,Hazard Analysis and Critical Control Points (HACCP),Food Preservation Techniques,Temperature Control,Pathogen Reduction,Food Industry Compliance,Documentation Practices,Heat Treatment,pH Control,Food Stability,Consistency in Production,Microbial Testing,Real-time Monitoring,Process Validation,Regulatory Requirements,Verotoxigenic E. coli,Lethality Standards,Product Labelling,Spoilage Prevention,Enterotoxin Detection,Shelf-Stable Products,Moisture to Protein Ratio (MPR)

#Charcuterie#Fermented Meat#Food Safety#Starter Culture#Chemical Acidification#Water Activity#Fermentation Process#Degree-Hours#Meat Processing Guidelines#Thermal Processing#Food Preservation#Food Microbiology#Sausage Fermentation#Starter Cultures#Critical Limits#Meat Processing#Food Preservation Techniques#Temperature Control#Pathogen Reduction#Food Industry#Heat Treatment#pH Control#Food Stability#Microbial Testing#Real-time Monitoring#Process Validation#Spoilage Prevention#Enterotoxin Detection#Shelf-Stable Products#Moisture to Protein Ratio (MPR)

3 notes

·

View notes

Text

Preserve your meat naturally with Himalayan Salt Brick Walls and Rooms!

The perfect solution for long-lasting freshness and flavor.

for more info Please visit us at:

1 note

·

View note

Text

My two cents on how much of Mind!Varric is Rook’s mind trying to fill the blank space and how much is Solas actively talking through a convenient blood magic paper doll of the mind: I think it's a mix of both, a truly collaborative psychosocial horrorshow if you would, but waaaay more towards the second. It feels too directed and tactical at times to be anything else. Rook's mind is willing to go along with the denial phase as far as it can fucking carry them to not have to face the grief and regret and does its part in papering over details that don’t make any sense, the way brains will strive to create coherent meaning even out of deeply confusing input, but to my understanding it's a collaborateur in how that plays out, not the instigator or control center. Solas is using it as a path to agency and to gather insight into Rook as a person unguarded as he can't count on in his own guise. (That stoic option that leads to him being like 'oh I see you're cautiously denying me access to your inner life. well. at least you still have Varric to talk to. y'know as an outlet :)'. You absolute BITCH Solas! That alone convinced me that he HAS to have an active hand in it on some level.)

My guess is that it takes considerable effort on Solas’ part to make Mind!Varric do anything more involved or complicated than seeming to sit up in bed and give casual commentary, and that’s why he keeps having eerie five minute shallow pep talks with you before he announces he conveniently needs a nap aaanyway good luck kid you got this haha. When he’s just spouting NPC lines from his bedrest, I’m ready to believe that could be Rook’s mind being allowed to improv lines for him more freely because it’s less about Solas trying to get something out of them or working an angle and more ‘Still here! Still totally alive and fine and the mentor figure you know and love and trust :) don’t even worry about it! Thankfully there is no war in Ba Sing Sei, as we all know’ upkeep work lol. Rook’s mind is allowed to set the tone of Varric, the outlines, but not always the content.

AND, on a (beautifully fucked up) character psychology level, I feel like Solas is indulging in actually getting to be the good supportive mentor figure to Rook with one hand to assuage the guilt he feels about what he's done -- and what he's going to do -- to them with the other. Same internal logic as he uses in Trespasser about the Qun. ‘Almost everyone is going to die from the course of action I’m doggedly pursuing eventually. But at least I can make their last years happier and freer and kinder than they would have been otherwise. and that kind of makes up for it right. a little bit. doesn't it. doesn't that make it better at least. I need that to make it better)'. Did I really take your beloved mentor and friend from you if you don’t know yet that I did? Some philosophers would argue not really! So it’s probably almost ok actually. Isn’t it even a little noble that I’m taking all this grief and guilt on myself and shielding you for now. With undertones that I’m not sure he would realize himself (and might be mortified by if he did) that he is so incredibly lonely, and even a dishonest and indirect emotional connection is more than nothing when you’re that desperate. In this setup he gets idk. Both the control he craves so incredibly badly in relationships and over himself, and the scraps, the fading afterimages, of intimacy and warmth and companionship, even second hand. The one thing Solas and Rook agree on deep deep down is that they really wish Varric weren't gone. They're handshake memeing this in the saddest and most creepy way possible.

I think an important element too is that Solas needs Rook and their team to *succeed* — up to a certain point. He needs someone to hold the two other elven mean girls off until he can get out of here. Ideally, in a perfect world, even do all the hard work of killing them so he can swoop in at the end and do his thing when both sides are exhausted and out of resources to stop him, and then Bob’s your uncle! Same logic as he was using with Corypheus, and after that worked out so well, too! King of choosing to never learn from a single solitary mistake he’s ever made even though i fully believe he could have the capacity to Fen’Harel <3 The underlying idea isn’t flawed, you see, it was just unforeseen circumstances getting in the way. This time for sure it’ll all work out the way I cleverly imagined it in my head beforehand. Cue By Talos this can’t be happening etc. in the form of a statue almost crushing him like a bug.

So he's providing guidance and forging Rook into a leader from two angles: one Rook might not trust, and one they probably will. Shaping them into what he needs slowly and carefully. He’s helping you hone your team into their most effective state, as he might have done with his own agents back in the day, setting up his chess pieces even if he has to squint through two glimpsed realities to do it haha. Pincer maneuver of an insidious stealth mentor you never asked for. Also… at one point mind Varric gives you a whole little monologue about how Solas' problem is that he’s always seen his interpersonal connections as flaws and see where it’s landed him, all alone and the worst part? it hasn’t even worked. it’s all been for nothing he’s back where he began with nothing to show for it but his mistakes. Like...that has such strong 'uh okay happy to play your therapist from two rooms away here what the fuck kind of traumadump is this' energy to me, I’m not sure Rook like. Thinks that much about Solas as a private person. So much of Solas' self-loathing and futile insights into his own flaws seem to shine through in Mind!Varric's dialogue all the time — I just can't believe that there's no guiding hand behind it as it were.

Most of all. I feel like people underestimate the degree to which Solas is incredibly funny. As in, he has a very consistent and recognizable sense of humour. It’s one of my very favourite things about him. We must remember — it is crucial that we always keep in mind — Orlesian accent and wig Solas from May The Dread Wolf Take You (my beloved, the explanation for why I love this dude even with the. All of the everything else. No one does it quite like him). He is not at all above doing things or adding little flourishes for his own obscure amusement, in fact that seems to me to be one of his most consistent traits. The Randy Dowager Quarterly comment Varric has? The ‘Maybe this is the Dread Wolf’s revenge. Forcing us to house sit for him’ thing? To Me this is 100% Solas amusing himself in his boring Fade jail surrounded by the screaming hellscape of all his regrets. Source: it came to me as divine revelation through pure vibes trust me bro

If nothing else I find it much more narratively interesting personally if the connection between Rook and Solas really is that defenselessly intimate and entwined (and so unbalanced!), and the sense of violation and invasion and betrayal afterwards consequently all the more nauseatingly intense. Even if you kept him at arm’s length in the open, he’s been under your skin the whole time, looking around, gathering what he needs to destroy you, wearing the face of a friend. Regretfully, probably, but choosing to do it every step of the way anyway. (Sound familiar, Inquisitor? Solas doesn’t have that many tricks when you actually look at it, he keeps returning to old tried and true ones like a dog with a bone haha.) Maybe he even genuinely meant some of it as mercy, which only makes it so much worse. It makes his sin against his own core principles of autonomy and the freedom of all beings in mind, spirit and body so much more juicily grave if it’s something he pursues actively and consistently, rather than it half-falling into his lap as a happy accident mainly orchestrated by Rook’s own subconscious. Solas, too, is at his very lowest point, the closest to giving in and becoming his own antithesis fully that he’s ever been, and it makes the choice of whether you still reach out your hand to him one last time or not all the more impactful and difficult.

#dragon age#dragon age: the veilguard#dragon age: the veilguard spoilers#dragon age spoilers#dragon age meta#solas#varric tethras#rook#I love what weeekes has managed to do with solas in this game honestly. both kinder and harsher reads on him?#completely supported by the text and completely valid. it really does come down to how you feel individually at the end of it all#there are good arguments to be made in every direction. sing o muse about a complicated man.#and also a motherfucker (affectionate *and* derogatory)#forgiveness isn't about him it's about you ultimately. do you find it in yourself or are there things that shouldn't be forgiven? up to you#he deserves both compassion and to be slam dunked straight into hell often with equal intensity. and i think that's beautiful#face in my hands. it keeps happening to me. I black out and I've written a whole thing and feel like I've been through a meat grinder#clearly my brain needs to Process things very badly but god I wish I could maybe control a bit more when and how intensely it does it lol#obligatory disclaimer that this is only my personal opinion and read on the game and characters involved etc. YMMV

767 notes

·

View notes