#NDT Methods

Explore tagged Tumblr posts

Text

Ultrasonic tests play a pivotal role in ensuring the structural integrity of materials without causing harm. Here are a few ultrasonic terminologies. Read More!

#non-destructive testing#ndt techniques#ndt technique#ndt methods#ndt#ndt testing#ultrasonic inspection#ultrasonic testing

6 notes

·

View notes

Text

Magnetic Particle Test: Techniques and Principles Explained

Magnetic Particle Test (MPT) is a widely used non-destructive testing (NDT) method. It detects surface and near-surface discontinuities in ferromagnetic materials, such as iron, nickel, cobalt, and their alloys. This technique is renowned for its speed, cost-effectiveness, and relative ease of application, making it a preferred choice across various industries, including aerospace, automotive,…

#Defect Detection#Engineering Testing#Flaw Detection#Industrial Testing#Infrastructure Testing#Magnetic Field Testing#Magnetic Inspection#Magnetic Particle Inspection#Magnetic Particle Test#Magnetic Particles#Magnetic Testing#Manufacturing Quality#Material Testing#Metal Testing#MPT#MPT Procedure#NDT#NDT Methods#NDT Technology#Non-Destructive Testing#Pipeline Inspection#Quality Inspection#Safety Inspection#Structural Integrity#Subsurface Defects#Surface Defects#Testing Equipment#Weld Inspection#Welding Defects

0 notes

Text

You sit in at contentious scientific meetings. You find university colloquia in which the speaker has hardly gotten thirty seconds into the talk before there are devastating questions and comments from the audience. You examine the conventions in which a written report is submitted to a scientific journal for possible publication, then is conveyed by the editor to anonymous referees whose job it is to ask: did the author do anything stupid? Is there anything in here that is sufficiently interesting to be published? What are the deficiencies of this paper? Have the main results been found by anybody else? Is the argument adequate, or should the paper be resubmitted after the author has actually demonstrated what is here only speculated on? And it's anonymous: the author doesn't know who the critics are. This is the everyday expectation in the scientific community.

Why do we put up with it? Do we like to be criticized? No, no scientist enjoys it. Every scientist feels a proprietary affection for his or her ideas and findings. Even so, you don't reply to critics, wait a minute; this is a really good idea; I'm very fond of it; it's done you no harm; please leave it alone. Instead, the hard but just rule is that if the ideas don't work, you must throw them away. Don't waste neurons on what doesn't work. Devote those neurons to new ideas that better explain the data. The British physicist Michael Faraday warned of the powerful temptation

to seek for such evidence and appearances as are in the favour of our desires, and to disregard those which oppose them . . . We receive as friendly that which agrees with [us], we resist with dislike that which opposes us; whereas the very reverse is required by every dictate of common sense.

Valid criticism does you a favour.

— The Demon-Haunted World: Science as a Candle in the Dark - Carl Sagan (1996)

#giving Neil deGrasse Tyson response to Terrence Howard on Joe Rogan#The Demon Haunted World#Carl Sagan#Ann Druyan#Science As A Candle in the Dark#books#book quotes#quotes#science#nonfiction#philosophy#religion#history#skepticism#atheism#agnostic#psychology#atypicalreads#physics#astrology#papa sagan#popular science#pseudoscience#superstition#scientific method#i did not watch the joe rogan segment and I have no interest in terrence howard or his ego#but i did appreciate NDTs response

1 note

·

View note

Text

Ride 760: Kiji, flying

Pag 1

The MTB Emperor is taking part in the road racing Inter High!!

Pag 2

1: As expected!!

2: The groups from Kyushu, like Fukuoka or Kumamoto are in quiet places close to the course and the main office

3: and close to the water supplies too!!

4: Well, they're from here after all

5: On the other hand, we're towards the end where there's so much noise

6: And above everything, they clearly.... forgot

Pag 3

1: only our tent and they added it in a hurry, fou!!

Pag 4

1: Hmm, that could be

Is it because it's our debut? That's discrimination!!

2: It's handwritten!!

And it's even spelled wrong!!

3: In this kind of situations, you can't do anything even if you get so worked up about it, Ichifuji-kun

Isn't it enough that we have a roof?

Pag 5

2: Should I fix that writing with magic later?

3: Sonomoto-san!!

4: The place is a problem too!!

We're close to where they're holding the bicycles exhibition, so there's a lot of people passing by and they can see us since we have no tent

5: And when we're changing clothes? We use the bath towel like this, that's what they do on elementary schools' pools!! Fou!!

6: During MTB races you either do it in a car or in the wild

It's not like the management just conveniently forgot about us, either

Pag 6

1: But the truth is that we're being treated unequally....?

What about you, Kaida!? What do you think!?

Should we go tho the management tent and say a word to them now? Fou!!

3: I've never got any results in MTB and never participated in the Inter High, so for me it's sufficient enough that I'm able to participate in the road racing Inter High

4: Stuff like the tent aren't important

Ugh.....!! You're kidding, I have zero supporters in this situation!!

Pag 7

1: And isn't it nice to have good ventilation?

2: And also... if you have to say something to the management

Don't you think it would be more persuasive

3: if we first ran in the race

4: and brought results?

Pag 8

1: If we brought results.....!!

2: Fou!! (Yessir)

Now, if you're ready

3: Should we all go for a trial run?

Fou!!

Yeah!!

Yes!!

Pag 9

2: Excuse me! This is a pedestrians crossing!

Pag 10

4: Hello

Are you maybe? A kid from here?

How.....

5: do you stand on the bike like that?

Pag 11

1: Are you interested in bikes?

Even though your feet aren't connected to the ground, you're still in one place

2: Do you want to try?

4: I guess you won't be able to do it right away, but this is the theory

5: Bikes have a center

I'm standing there

6: A center?

7: It's different depending on the model, but a little before the saddle there's the center point of the bike

8: The technique is that you feel for it, find your balance, and then you find your stability if you properly position your body

Pag 12

1: It's called “standing”

Ohhhh...!!

2: Furthermore, if you can put your center of gravity firmly there

4: you can also let go of your hands while standing still, yon

Amazing.....!!

5: Amazing, amazing..!!

6: Yes yes, that's right, Kiji-san is amazing

Why does this guy looks so self-important

7: What's the heaviest thing on a bike?

Pag 13

1: Uh... uhm... the helmet?

3: It's your body

4: When riding a bike, the most important thing is to be conscious of where we put this “body”*, yon

Ah, when you're holding a bucket, if you're holding it with one hand you stagger, right?

(*NdT.: written as “heavy object”)

5: It's the same thing

6: “Weight” is power, yon

Ehh?

Pag 14

1: When you stop thinking “that's obvious”, “I know that”

2: That's when it's over for you

3: Discovery lies in common sense

4: The essential thing when handling a bike.... remember

5: is the “load” and the “unloading” to get ahead of it!!

Pag 15

1: Maybe it's faster if I show you?

2: Ah, that's good

Look at that fence

3: The movement of the “load”, and the “unloading”... and....

Use the same method as when you jump to take a picture at the beach

5: I'll jump over that fence!!

Pag 16

1: No, isn't it better to stop!? Onii-chan!!

2: You'll run into it!!

Just look, boy

3: Hayaaaa

That guy

4: is a guy who jumps over common sense!!

Yaaaaa

Pag 17

2: Don't miss all the multiple techniques he uses in an instant!!

Fou!!

He looks so self-important

3: First, he moves his body back and so he unload the weight from the front wheel

6: “Unloading”!!

Pag 18

1: He's really going to cras-

He's not!!

2: Then, he lowers his body's center of gravity for a moment

3: Then he stretches!!

And pulls the frame!!

5: He's not high enough!!

This is the moment when you jump when taking pictures!!

6: Pull up

7: your knees

The technique of skillfully using your “load” to jump over obstacles

Pag 19

1: is called “bunny hop”!!

Pag 20

1: There are people who have mastered the technique and can do it, but it's at most 30cm.... but Kiji-san

2: can jump 80cm!!

3: Who's that guy!

Did you see that just now

4: He jumped that fence with a road racer

His bike floated!?

The fence!?

5: I've never seen something like that

The jerseys' of the guys who are with him say “Gunma”....!!

6: It was ama.... amazing....

That.... if I practice... will I be able to do it too one day?

Of course

Pag 21

1: If you fall a lot, and skin your knees a lot, and eat a lot....

2: Okay?

3: Well now, since we're participating in the Inter High, come see us!!

4: I'll cheer for you...!!

Thank you!

5: The cyclists will soon gather at the starting line!!

#yowamushi pedal#yowamushi pedal translations#yowapeda#yowapeda manga#yowamushi pedal manga#yowamushi pedal spoilers#ride 760#of course now it would be a chaper about kiji!! watanabe loves him too much to leave him out lmao#and we love to see him as always#ichifuji is so funny and also he's right! go complain to the management!! you shopuldnt be treated unequally!!#btw is their team only made up of four people??? i cant remember if they said it already#kiji showing off to a kid is so him ashdfgshdf there was literally no need but he is a show off always#thats simply what he does to everyone#and now he has a new little fan xD#i love him i love the team and i vant wait to see what theyll do during ih!!!#is it gonna start next chapter???? :eyes emoji:

110 notes

·

View notes

Text

Ensuring Weld Quality: Advanced Ultrasonic Testing Methods

In the world of welding, ensuring the quality and integrity of welds is crucial. One of the most effective ways to inspect welds is through ultrasonic testing, which uses high-frequency sound waves to detect imperfections. This blog explores advanced ultrasonic testing methods for welding inspection, highlighting their benefits and applications in the UK.

Introduction to Ultrasonic Testing

Ultrasonic testing for welding involves high-frequency sound waves to detect flaws in welds. This non-destructive testing (NDT) method effectively identifies internal and surface defects without damaging the material.

Why Ultrasonic Testing for Welding?

Accuracy: Provides precise detection of internal flaws.

Non-Destructive: Does not damage the material being inspected.

Versatility: Suitable for a wide range of materials and thicknesses.

Advanced Ultrasonic Testing Techniques

Advanced ultrasonic testing techniques have revolutionised the NDT industry, providing unprecedented levels of accuracy and efficiency. Below are some of the most advanced testing techniques used in the industry:

1. Phased Array Ultrasonic Testing (PAUT)

PAUT is an advanced technique that uses different ultrasonic elements and electronic time delays to create a sweeping beam. This method provides a detailed image of the weld, allowing for precise identification of defects.

Benefits:

High-resolution and detailed images

Faster inspection times

Improved defect characterisation

2. Time-of-Flight Diffraction (TOFD)

TOFD is another complex ultrasonic testing method that uses the time taken by sound waves to travel and diffract around defects to detect and size flaws accurately.

Benefits:

High accuracy in defect sizing

Effective for detecting both surface and subsurface defects

Reduced operator dependency

3. Automated Ultrasonic Testing (AUT)

AUT involves automated systems that perform ultrasonic inspections. This method enhances the consistency and repeatability of inspections, making it ideal for large-scale projects.

Benefits:

Consistent and repeatable results

Increased inspection speed

Reduced human error

Applications of Ultrasonic Testing in the UK

Ultrasonic testing is widely used in the UK across different industries to provide safety and integrity to critical infrastructure. Here are some key applications of ultrasonic testing in the UK.

1. Oil and Gas Industry

In the UK, the oil and gas industry rely heavily on ultrasonic testing for welding to ensure the integrity of pipelines and other critical infrastructure. PAUT and TOFD are commonly used to inspect welds in pipelines, ensuring they are free from defects that could lead to failures.

2. Aerospace Industry

The aerospace industry requires the highest levels of safety and reliability. Ultrasonic testing methods are used extensively to inspect welds in aircraft components, ensuring they meet strict safety standards.

3. Construction and Infrastructure

Ultrasonic testing plays a crucial role in the construction industry, particularly for inspecting welds in bridges, buildings, and other structures.

Advantages of Advanced Ultrasonic Testing Methods

Check out the advantages of advanced ultrasonic testing methods over traditional approaches.

1. Enhanced Accuracy

Advanced ultrasonic testing methods provide higher accuracy in detecting and sizing defects than traditional methods.

2. Increased Efficiency

Automated and advanced techniques like PAUT and AUT significantly reduce inspection times while maintaining high levels of accuracy.

3. Comprehensive Reporting

These methods offer detailed and comprehensive reporting, providing clear images and data that can be used for further analysis and decision-making.

Conclusion

Adopting advanced ultrasonic testing for welding is essential for industries aiming to maintain high quality and safety standards.

Investing in these advanced techniques enhances inspection reliability and ensures compliance with stringent safety regulations. By leveraging the benefits of advanced ultrasonic testing, industries can achieve greater efficiency, accuracy, and overall project success.

9 notes

·

View notes

Text

The Power of Precision: Exploring the Benefits of PAUT in NDT

In the realm of industrial inspections, the demand for accuracy and efficiency has never been higher. Phased Array Ultrasonic Testing (PAUT) stands out as a revolutionary method that fulfills these requirements, offering unparalleled precision and speed. As an integral part of Non Destructive Testing, PAUT is widely used across various industries to ensure the integrity and reliability of critical components. Here, we delve into the intricacies of PAUT and its benefits.

PAUT is an advanced method of ultrasonic testing that uses multiple elements and electronic time delays to create beams of sound waves. These beams can be steered, focused, and scanned, providing detailed images of internal structures. Unlike conventional ultrasonic testing, which uses a single transducer to send and receive sound waves, PAUT employs an array of transducers. This allows for simultaneous collection of data from multiple angles, resulting in more comprehensive and accurate inspections.

As part of a broader suite of Non Destructive Testing Services, PAUT plays a crucial role in ensuring the safety and reliability of industrial components. Nondestructive testing (NDT) from RVS QUALITY CERTIFICATIONS PVT LTD encompasses various techniques used to evaluate the properties of a material, component, or system without causing damage. PAUT's advanced capabilities enhance the overall effectiveness of NDT services, providing detailed and reliable data that support maintenance and quality assurance programs.

Applications Across Industries

The versatility of PAUT makes it suitable for a wide range of applications. It is commonly used in the aerospace, automotive, and power generation industries for inspecting critical components such as welds, turbine blades, and composite materials. PAUT's ability to detect minute defects and irregularities ensures that even the smallest flaws are identified before they become critical issues. This level of precision is essential for maintaining safety and performance standards in high-stakes environments.

Efficiency and Accuracy Combined

One of the standout features of PAUT is its efficiency. The ability to steer and focus sound waves electronically means that inspections can be performed more quickly compared to traditional methods. This not only reduces downtime but also increases the number of inspections that can be completed within a given timeframe. Additionally, the detailed images produced by PAUT provide a clearer understanding of the inspected material's condition, allowing for more accurate assessments and decision-making.

Enhanced Tube Inspections

A specific area where PAUT excels is in Tube Inspection Services. Tubes, often found in heat exchangers and boilers, are prone to various types of degradation such as corrosion and cracking. PAUT's ability to inspect from multiple angles simultaneously makes it particularly effective for tube inspections. It can detect flaws that may be missed by conventional methods, ensuring that tubes are thoroughly evaluated for any signs of wear or damage. This comprehensive approach helps prevent failures and extends the lifespan of critical equipment.

Advancing with Technology

The continuous evolution of technology has significantly impacted PAUT. Advances in digital signal processing and software have improved the resolution and clarity of the images produced. Portable PAUT equipment from RVS QUALITY CERTIFICATIONS PVT LTD has made it possible to conduct inspections in challenging environments, further expanding its applicability. These technological advancements ensure that PAUT remains at the forefront of nondestructive testing techniques, providing industries with cutting-edge solutions for maintaining safety and quality.

In conclusion, PAUT is a powerful tool that combines precision and efficiency to deliver superior inspection results. Its ability to provide detailed images from multiple angles makes it invaluable for identifying defects and ensuring the integrity of critical components. As a key component of Non Destructive Testing, PAUT supports industries in maintaining high standards of safety and performance. Whether it's for welds, turbine blades, or Tube Inspection Service, PAUT continues to set the standard for advanced nondestructive testing methodologies.

5 notes

·

View notes

Text

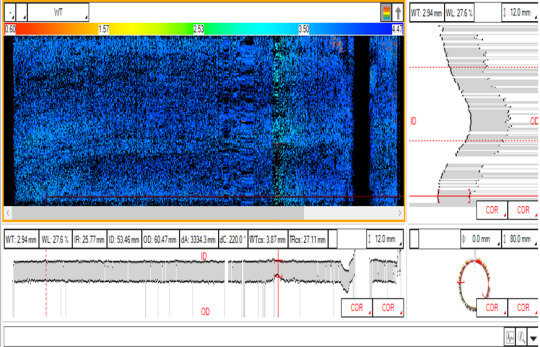

Inspection of Boiler Bank Tubes | Internal Rotary Inspection System (IRIS)

Are you unable to carry out the Inspection of Boiler Bank tubes?

Are you regularly carrying out Capital Investment by purchasing tubes rather than finding only the defective Bank Tubes?

Here is the solution for inspection of Boiler Bank Tubes –

In case of Boiler Bank Tubes, only the Front Column of Tubes are available for Inspection for Thickness Testing externally there is no other way to check the rest of the Tubes. Thus, we have only 5 % of the Tubes available while we miss out on an inspection of the rest of the 95% of the tubes.

RFET was done previously to ascertain the condition of the rest of the 95% of the tubes but due to the limitation of the technique it is also not a right testing method. Then we tried IRIS on these tubes and got amazing results.

HOW IT WORKS –

Because IRIS is an ultrasonic technique, it requires a couplant. In this case, water. Tubes under test must therefore first be flooded to use this technique. IRIS relies on a transducer to generate an ultrasonic pulse parallel to the axis of the tube under test. It also relies on a rotating mirror that directs the ultrasonic wave into the tube wall.

The mirror is driven by a small turbine powered by the pressure of water pumped into the tube. Part of the ultrasonic wave is reflected by the inner diameter (ID) wall, while the rest is reflected by the outer diameter (OD) wall of the tube. Because the ultrasonic velocity of the tube’s material is known, it is possible to assess the thickness of the wall by calculating the difference in times of flight between the two diameters. As the probe is pulled, the spinning motion of the mirror results in a helical scan path.

A critical aspect of IRIS is ensuring that the mirror is at the centre of the tube. An off-centre ultrasonic pulse yields a distorted scan image because of the different ID and OD wall sound paths. That’s why our IRIS kits are equipped with centring devices helping operators keep the system centred.

About IRC Engineering Pvt. Ltd.

IRC is one of the fastest growing Testing and Inspection company in India. We at IRC provide Liquid Penetrant Testing, Non-Destructive Testing, Destructive Testing, Advanced NDT, Third Party Inspection, Condenser Testing, Electrical Testing, Residual Life Assessment of Power Plant, O&M Services, Fitness For Service, Civil Testing and Training services.

Our website - https://ircengg.com/

2 notes

·

View notes

Text

Act VII

Day 31

While the Night Falls,

I Battled For Royalty....

النهاردة يوم Royal بزيادة. خلصت مذاكرة وخلصت جري وخلصت شغل وعملت records في كل دول بشكل جميل.

وانا بجري في ال camp كل الناس كانت نايمة while I battle myself alone... ودا كان امتع احساس. وقبل ما اجري Ms. V قالتلي عاوزه اشوفك وانت بتجري. ثبت الفون وجريت.

النهاردة في وسط الكورس فجاة كدا كان عندي EventListener فجاة كل حاجه دخلت في بعض. لقتني بضغط علي button و action تاني خالص اللي بيحصل. وفي اللحظة دي انا موت ضحك. اللي هو الو.

و هنا سميت الراجل اللي بيديني الكورس اللي اسمه Jonas الراجل الالماني المحترم بتاع كبدة عشان اللي حصل. بس العيب طلع في ال html code و صلحته وكله تمام.

النهاردة ذاكرت 4 ساعات. ودول عملوا ساعة وتلت فيديو. موضوع النهاردة ��ان فيه معلومات كتير وكتبت كتير.

حقيقي بقيت مش متخيل حياتي بدون سعي. حسيت اني لو بطلت هيحصلي حاجة. يمكن ده اكبر كورس اخدته في حياتي. ولسا مخلصش. انا اخدت American License في شهرين ونص وكانت اققل من كدا بس الفكره انها كانت علي 3 امتحانات.

خلصت ال Iso 9001 مع TUV في 5 ايام.

خلصت ال NDT Level II ال 5 Methods في يومين.

خلصت ال ASME Codes ودول كانوا اكبر مراجع ممكن اتخيل اني اخصلها. في 17 يوم.

دا غير حجات كتير مكنتش بتاخد غير يوم معايا.

الكورس ده حتي الان مخلص فيديوهات عاملة 38 ساعة ولسا الطريق لحد 171 ساعة لحد الان وممكن يزيد.

Like A Royal Wolf I'm Going To Keep Fighting For Myself, Till I get To My throne, I will Always Remain Royal,...

Today, Was in The Middle of The Night....

و طبعا كلها 3 ساعات هنامهم دلوقتي وهروح الشغل و هرجع منه اذاكر

To Be Royally Continued

Mr. Act V

6 notes

·

View notes

Text

How Digital Technology Is Transforming Tank Inspection in Malaysia

Digital advancements are revolutionizing tank inspection in Malaysia, making the process faster, safer, and more accurate. Technologies like drones, AI-powered image analysis, and 3D scanning are enhancing NDT inspection methods, reducing the need for manual intervention. These innovations help companies deliver more reliable technical services while minimizing downtime. As digital tools become standard, businesses across Malaysia are benefiting from smarter, more efficient tank inspection practices that meet both safety standards and regulatory compliance. The future of tank inspection in Malaysia is not only digital—it’s data-driven.

0 notes

Text

Ensuring Safe Structures: Structural Stability Test in Bhubaneswar by APS Design Infra

In the fast-developing city of Bhubaneswar, where modern buildings and infrastructure projects are on the rise, ensuring the safety and longevity of structures is more important than ever. Whether it's a residential apartment, commercial complex, or industrial facility, structural integrity is critical to prevent failures and ensure occupant safety. This is where the Structural Stability Test in Bhubaneswarplays a vital role—and APS Design Infra is your trusted partner for professional and certified testing services in Bhubaneswar.

What is a Structural Stability Test?

A Structural Stability Test is an essential evaluation process carried out by qualified engineers to assess the strength, durability, and stability of a building or structure. The goal is to determine whether the structure can safely withstand the loads and environmental factors it is subjected to—such as wind, seismic activity, and usage over time.

The test involves inspecting the foundation, beams, columns, slabs, and overall design layout. It helps identify any signs of wear, fatigue, corrosion, or design flaws that may compromise the building’s safety.

Why Structural Stability Testing is Crucial in Bhubaneswar

Bhubaneswar is undergoing rapid urban expansion with numerous residential and commercial projects underway. However, factors like soil conditions, seismic zone classification, monsoon weather, and increasing population density make it necessary to regularly test buildings for stability.

Some key reasons why Structural Stability Tests are important include:

Legal Compliance: Many municipalities, including Bhubaneswar Municipal Corporation (BMC), mandate periodic structural audits for old and high-rise buildings.

Safety Assurance: Early detection of issues can prevent accidents, collapses, and loss of life.

Longevity of Buildings: Regular testing helps prolong the life of a structure by guiding timely maintenance.

Real Estate Transactions: Structural certificates are often required during property sales, rentals, or renovations.

Why Choose APS Design Infra for Structural Stability Test in Bhubaneswar?

APS Design Infra is one of Bhubaneswar’s most trusted names in structural engineering and consultancy. Here’s why we are the preferred choice for structural stability assessments:

Experienced Team of Structural Engineers

Our team comprises certified and experienced civil and structural engineers with expertise in diverse building types and compliance standards.

Advanced Testing Methods

We use the latest tools and techniques—such as non-destructive testing (NDT), visual inspection, load testing, and material analysis—for accurate results.

Government-Approved Certifications

APS Design Infra provides legally valid structural stability certificates for submission to government bodies, insurance firms, and real estate stakeholders.

Customized Reports & Recommendations

Our detailed reports highlight any structural concerns and offer actionable recommendations to strengthen your structure or carry out repairs.

Book a Structural Stability Test in Bhubaneswar Today

Whether you are a homeowner, builder, property manager, or architect, ensuring the structural soundness of your building is non-negotiable. With APS Design Infra, you get peace of mind backed by professional assessment and transparent reporting.

APS Design Infra—Building Trust. Ensuring Safety. Strengthening Structures.

0 notes

Text

The Science Behind Non-Destructive Gold Testing – How Tarzen Gold Protects Your Precious Metal

Introduction

When it comes to testing gold, many people still imagine old-school methods: scratching jewelry on stone slabs, dropping acids, and possibly damaging what might be a priceless heirloom.

But modern gold testing has entered a new era—one that’s accurate, scientific, and damage-free. At Tarzen Gold, we lead the way with non-destructive gold testing technology, giving you results you can trust without a single scratch.

What Is Non-Destructive Gold Testing?

Non-destructive testing (NDT) refers to any technique used to evaluate the properties of a material without altering or damaging it. In gold testing, this means determining the exact purity of your item without cutting, filing, or using corrosive chemicals.

The most advanced method of NDT used in the gold industry today is X-ray Fluorescence (XRF) testing.

How XRF Technology Works

XRF testing is a scientific process that analyzes the elemental composition of metal using X-rays. Here’s how it works:

A high-energy X-ray beam is directed at the gold item.

The gold atoms absorb the energy and emit secondary (fluorescent) X-rays.

Each element has a unique fluorescence signature, which the machine reads.

In seconds, the system identifies how much gold (Au) and other metals (like silver, copper, or zinc) are present in the item.

The result? Precise purity results (in karats or percentage) displayed instantly—without damaging your jewelry.

Why This Matters to You

Gold is more than just metal. It may carry emotional, financial, or cultural value. Scratching or altering it to check if it’s real is outdated, unnecessary, and risky.

With XRF non-destructive testing at Tarzen Gold, you can:

Get fast, accurate purity reports in seconds

Preserve the condition of antique or delicate items

Make informed decisions about buying, selling, or exchanging

Ensure fair market value based on verified results

What Sets Tarzen Gold Apart

Many local gold buyers still rely on traditional acid tests or estimation methods. These techniques:

May cause permanent damage to your item

Often rely on human judgment

Don’t offer a printed report or verified purity

At Tarzen Gold, we’re redefining trust in the gold trade:

Certified XRF machines for lab-grade analysis

Printed purity reports for your records

Live gold price updates so your valuation is always accurate

Trained experts who explain every step

Our mission? To make purity testing transparent, honest, and scientific—something traditional stores often lack.

Conclusion: Trust the Science. Trust Tarzen Gold.

In an age of digital banking, AI tools, and smart tech, it’s time to treat your gold with the same intelligence. Non-destructive gold testing isn’t just safer—it’s smarter.

Whether you’re verifying an old heirloom, checking a new purchase, or planning to sell, come to Tarzen Gold. We’ll test your gold accurately, instantly, and without a single scratch.

📍Visit your nearest branch or follow us online: Instagram | Facebook Tarzen Gold – Where Science Meets Trust.To stay updated with the latest posts, follow us on social media:

📸 Instagram - https://www.instagram.com/goldtarzen/

📘 Facebook - https://www.facebook.com/profile.php?id=61556562458072

🐦 X - https://www.threads.net/@tarzengold

📌 Pinterest - https://in.pinterest.com/tarzengold/_pins/

🧵 Threads - https://www.threads.net/@tarzengold

❗ Youtube - https://www.youtube.com/@TARZENGOLD

Contact: TarzenGold

+91 9867831193.

Article Published By:

TVM INFO SOLUTIONS PVT LTD

Contact: TVM Info Solutions Pvt. Ltd.

+91-9004590039

Follow us on Social Media

🌐 Website - https://tvminfo.com/

📸 Instagram - https://www.instagram.com/tvm_infosolution/

📘 Facebook - https://www.facebook.com/people/Tvm-Info-Solutions-Pvt-Ltd/61555896761755/

🔗 Linkedin - https://in.linkedin.com/company/tvminfo

▶️ Youtube - https://www.youtube.com/@tvminfosolutions

#GoldPurityTesting#RealGoldCheck#TestYourGold#GoldInvestmentTips#24KGold#XRFTesting#GoldScamAwareness#CertifiedGold#GoldBuyBackIndia#TrustedJewelerIndia#GoldTestingIndia#TarzenGold

0 notes

Text

Ensure safety and reliability with expert non-destructive testing (NDT). Detect flaws without damaging materials using methods like ultrasonic, radiographic, and magnetic particle testing. Ideal for aerospace, construction, and manufacturing industries.

1 note

·

View note

Text

🔧 Looking to start or upgrade your career in Non-Destructive Testing? At Best NDT Inspection Services, our NDT Training Center is the place where real-world skills meet industry standards. Whether you're a fresh graduate or a working professional, our hands-on approach helps you gain the confidence and certification you need to succeed.

🎯 From Ultrasonic Testing to Radiographic Interpretation, our expert trainers guide you through every detail — not just the theory, but the why and how behind each method.

📍Located in a state-of-the-art facility, we focus on practical knowledge, job readiness, and personalized support throughout your training journey.

📞 Ready to step into the NDT industry with the right guidance? Visit: www.bestndtinspection.com and start building your future today.

#NDTTrainingCenter#BestNDTInspection#NDTTraining#NonDestructiveTesting#EngineeringCareers#NDTLevel2#NDTsingapore

0 notes

Text

The Importance of Material Testing Labs for UAE’s Oil and Gas Industry | +971 554747210

The United Arab Emirates (UAE) stands as one of the world’s leading producers and exporters of oil and gas, with the sector playing a critical role in the nation's economy. In such a high-stakes industry, safety, durability, and efficiency are non-negotiable. This is where Material Testing Lab come into the picture — serving as indispensable partners that help maintain the integrity of infrastructure, equipment, and processes in the oil and gas industry.

In this blog, we explore the vital importance of material testing labs for the UAE’s oil and gas sector, highlighting how these facilities ensure quality, safety, and compliance in one of the most challenging industrial environments.

Why Material Testing is Crucial in the Oil and Gas Industry

Oil and gas operations are characterized by extreme conditions — high pressures, corrosive environments, fluctuating temperatures, and mechanical stresses. Components such as pipelines, drilling equipment, storage tanks, and refinery machinery must withstand these challenges to prevent failures, leaks, or catastrophic accidents.

Material testing labs evaluate the properties and performance of raw materials and finished products to ensure they meet rigorous industry standards. This proactive approach prevents costly downtime, environmental hazards, and loss of life.

Key Roles of Material Testing Labs in the UAE Oil and Gas Sector

1. Ensuring Material Quality and Compliance

Material testing labs verify that the materials used — steel, alloys, composites, coatings, and more — conform to industry-specific standards like API (American Petroleum Institute), ASTM, ISO, and BS standards. These standards dictate chemical composition, mechanical strength, corrosion resistance, and durability.

In the UAE, local regulations and international oil companies’ specifications require stringent quality checks. Accredited labs provide unbiased, accurate test results that demonstrate compliance and enable smooth regulatory approvals.

2. Corrosion Testing and Prevention

Corrosion is one of the biggest threats to oil and gas infrastructure, especially in the UAE’s harsh desert and marine environments. Material testing labs conduct specialized corrosion testing, including salt spray tests, electrochemical analysis, and accelerated aging tests.

These tests help identify vulnerable materials or protective coatings, enabling operators to select corrosion-resistant options or schedule preventive maintenance, thereby extending the lifespan of assets.

3. Mechanical and Structural Testing

Oil and gas equipment must withstand intense mechanical loads and stresses. Material testing labs perform mechanical tests such as tensile strength, hardness, impact resistance, and fatigue testing to assess how materials behave under pressure and strain.

Structural components like pipes, valves, and pressure vessels undergo rigorous testing to certify their ability to handle operational demands, avoiding failures that could lead to spills or explosions.

4. Weld Testing and Inspection

Welding is fundamental in constructing pipelines and refinery equipment. Defects in welds can cause leaks or structural failures. Material testing labs carry out non-destructive testing (NDT) methods — including ultrasonic testing, radiography, magnetic particle inspection, and dye penetrant testing — to detect cracks, voids, and inconsistencies in welds.

Reliable weld inspection ensures the safety and longevity of welded joints critical to oil and gas operations.

5. Chemical and Material Composition Analysis

Understanding the exact chemical makeup of materials is essential to predict their behavior under operational conditions. Labs conduct chemical analyses using spectroscopy, chromatography, and other advanced techniques to detect impurities or verify alloy compositions.

This helps avoid material incompatibilities that could lead to corrosion, embrittlement, or other failures in the demanding oil and gas environment.

6. Testing for Safety and Environmental Compliance

With increasing focus on environmental protection and workplace safety, material testing labs assist oil and gas companies in meeting local and international safety regulations. Tests related to fire resistance, toxicity, and environmental impact of materials and coatings help ensure safer operations and reduce the ecological footprint.

In the UAE, adherence to standards set by authorities like the Abu Dhabi Environment Agency and Dubai Municipality is critical, and labs provide the necessary certification.

Benefits of Using Material Testing Labs for the UAE Oil and Gas Industry

1. Risk Mitigation

Material failures in oil and gas projects can lead to accidents, injuries, and costly shutdowns. Regular and rigorous material testing identifies potential issues early, reducing the risk of accidents and enhancing overall safety.

2. Cost Savings

While testing involves upfront costs, it saves money in the long term by preventing equipment failure, extending asset life, and reducing maintenance frequency. Quality assurance through labs also avoids project delays due to non-compliance or substandard materials.

3. Regulatory Compliance

Operating within UAE’s regulatory framework is essential to avoid fines and legal challenges. Material testing labs provide the documentation and certifications required to demonstrate compliance with safety and environmental laws.

4. Enhanced Product and Project Quality

Material testing labs contribute to higher quality projects by verifying that only materials meeting the highest standards are used. This improves operational efficiency, reliability, and client confidence.

5. Supporting Innovation and Sustainable Practices

With the UAE’s push toward sustainable energy and technology, material testing labs assist in evaluating new materials and technologies for enhanced performance and reduced environmental impact, supporting innovation in the oil and gas sector.

Choosing the Right Material Testing Lab for Oil and Gas Projects in the UAE

Given the critical role of material testing labs, selecting the right partner is crucial. Here are important criteria:

Accreditation and Certification: Look for labs accredited by ISO/IEC 17025 and recognized by UAE regulatory bodies.

Industry Experience: Choose labs with proven expertise in oil and gas material testing.

Comprehensive Testing Services: Ensure the lab offers mechanical, chemical, corrosion, NDT, and environmental testing.

State-of-the-Art Equipment: Advanced testing technology is key for reliable results.

Timely Delivery: Fast turnaround times help keep projects on schedule.

Clear Reporting: Detailed, transparent test reports with recommendations support informed decision-making.

Conclusion

The oil and gas industry is the backbone of the UAE’s economy, and ensuring the safety and quality of materials used is paramount. Material Testing Labs play an indispensable role by providing scientific testing, analysis, and certification that safeguard infrastructure and personnel.

By choosing accredited, experienced labs with comprehensive services, oil and gas companies in the UAE can mitigate risks, ensure compliance, reduce costs, and enhance project quality. In an industry where failure is not an option, material testing labs offer the assurance and reliability that modern oil and gas operations demand.

0 notes

Text

Reasons To Choose Magnaflux H-820 And Magnaflux H-810

Different industries use different methods to access materials and perfect their properties. The oil and gas, automotive, and aviation industries often need magnetic particle inspection (MPI) of the ferromagnetic substances used to ensure their operations. Known as a specific type of nondestructive testing (NDT), inspectors are sent to distant industrial sites to carry out such inspections. The technicians must carry the right magnetic particle inspection equipment to serve their purpose. Both the inspector and the consumer need to know and understand the importance of MPI. It suffices to know that the test can identify surface or near-surface flaws in specific ferromagnetic substances such as nickel, iron, and steel. The MPI process involves inducing a magnetic field in the material followed by applying it. The flux leakage areas can be easily identified thereafter.

This test is one of the most used procedures by almost all relevant industries for the following reasons: Flaw Detection—It is normal for the concerned industries to use superior components to ensure their varied operations are perfect. This type of NDT can detect flaws in the chosen ferromagnetic materials. The consumer can identify cracks, laps, seams, and other flaws, such as inclusions, to ensure that the integrity of the components is not compromised.

Versatility- The test is done on multiple ferromagnetic materials. Ferromagnetic materials like nickel, steel, or iron may be tested in the form of weldments, castings, forgings, and diverse machined parts. Moreover, no compulsion exists to test certain size or shape components. The inspectors can go ahead with the test regardless of the shape or size of the item. This is a positive for related industries that need to use tiny or enormous components for their operations.

Speed and Portability—MPI is a quick and effective method that may also be carried out in distant sites. Its portability is advantageous for companies that cannot move the materials from their industrial areas. Another pleasing fact is that, unlike some of the other NDT procedures, the process does not need extensive preparation of the testing surfaces.

Safety- Most consumers are happy with the MPI method as they can easily source the required equipment without any trouble. It is vital to know that the components that are tested will remain usable and intact after they are tested properly.

Outcome—The users prefer to use the MPI because they can get immediate feedback, as each component is tested meticulously. The inspectors can detect flaws and defects within minutes and share the information with the end users as soon as possible. Therefore, there is no impatient waiting period.

Companies that provide diverse services by competent inspectors for NDT source Magnaflux equipment to complete their tasks efficiently. Some of the must-have equipment for NDT testing include the following: -

l Magnetic Yokes l Power Packs l Wet Benches

l Demagnetizers Magnaflux H-820 and H-810 are some of the most popular NDT equipment, ensuring precision, performance, and fantastic durability.

0 notes