#PCBAssemblies

Explore tagged Tumblr posts

Text

Have your PCBs been tested before being shipped? PCBs are ubiquitously present in all equipment in use today. And a malfunctioning PCB can lead to disastrous consequences. Testing of PCB Assemblies is critical. We offer you best-in-class ATEs for Functional Testing of electronic PCBs, capable of testing all functional and performance parameters such as voltage, regulation, and current limits. Equipped with programmable T&M equipment such as DC source, Oscilloscope, DMM, and Waveform generator, our ATEs are customised with a bed of nails fixture for each PCB type, and also provide automated IC programming when required. What’s more, their IPC-based system uses a user-friendly GUI with customised test reports. Please call us for further details or visit: https://zurl.co/uAjNU

0 notes

Text

youtube

Desk of Ladyada - LDACs, Sparkle Motion Mini & Claude 🔧🤖 https://youtu.be/bFcRxufkZjI

Sparkle Motion Mini PCBs are here, featuring a compact 5V-only design. We are also refining small breakout boards like the DAC7578 and working on a TMC2209 driver by refactoring BusIO for versatile interfaces. Lastly, Claude & exploring compact, sensorless BLDC motor drivers via DigiKey.

#ladyada#electronics#makercommunity#adafruit#sparklemotion#pcbdesign#steppermotor#bldcmotors#dac7578#tmc2209#busio#chipdesign#electronicsengineering#hardwarehacking#robotics#iot#microcontrollers#embeddedhardware#diyprojects#opensourcehardware#pcbassembly#sparklemotionmini#claudeai#chatgpt#makersgonnamake#embeddeddevelopment#circuits#diyrobotics#techdesign#hardwaretesting

2 notes

·

View notes

Text

#pcb#pcba#pcbassembly#pcb manufacturer#pcb board#pcb factory#pcb fabrication#aluminum pcb#pcb design#pcb prototype

2 notes

·

View notes

Text

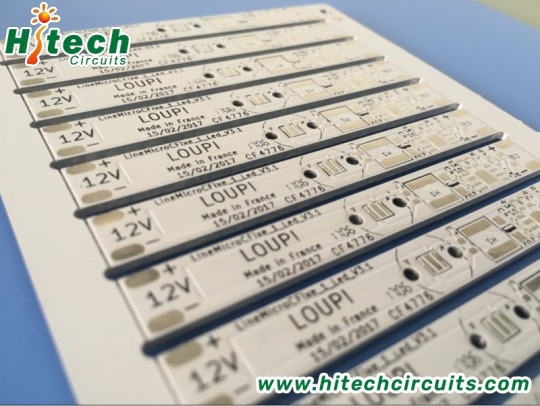

Aluminium PCB

Aluminium PCB are metal-based, copper-clad laminates with a good heat dissipation function. Usually, Aluminium PCB is refer to LED PCB board, which is the most important part of LED display and lighting products, etc.

Hitech Circuits Co., Limited is a professional aluminum pcb board, LED PCB manufacturer in China. Through 10 years of aluminum pcb board designing and manufacturing experience, Hitech are able to provide high quality and cost effective single layer, double layer and multi layer aluminum pcb boards to global customers. For any of your requirements regarding aluminum pcb board, please don’t hesitate to contact [email protected]

#Aluminium PCB#aluminum pcb#pcb assembly#pcb#engineering#technology#pcba#pcb manufacturer#pcbassembly#pcb design#hardware

5 notes

·

View notes

Text

Provide solutions to pcb and pcba problems

2 notes

·

View notes

Text

Devlopment board

#controller#esp32#esp32project#pcb#pcbdesign#pcbassembly#engineer#engineering#electricalengineering#circuits#iot#smarthome#diyelectronics#trending#viral#reels#instagram#instragramreels#followers#boost#explore#explorepage#likeforlikes#electricalengineer#electricalwork#electricalcontractor#electricalhacks#electricallife#electricalsky

4 notes

·

View notes

Text

#hardware design#hardware design services#pcb assembly#pcb design#pcb manufacturer#pcba#pcbassembly#electronics design#automotive electronics

2 notes

·

View notes

Text

We are a 20 years PCB&PCBA factory.

4 notes

·

View notes

Text

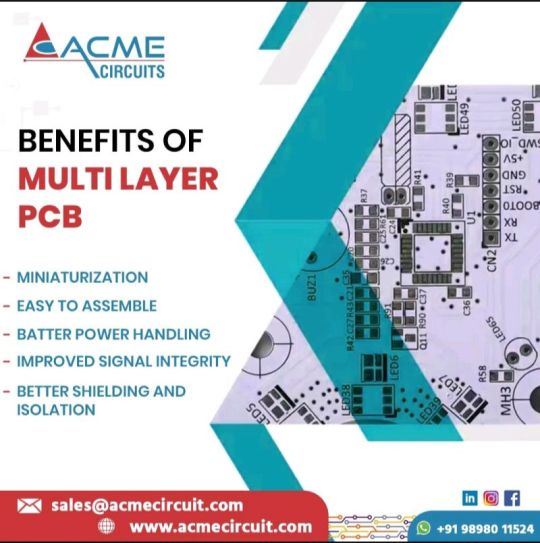

Multilayer PCBs (Printed Circuit Boards) offer numerous advantages over their single-layer or double-layer counterparts. These benefits arise from their enhanced design capabilities, improved performance, and greater flexibility. Here are some key advantages of multilayer PCBs:

#PCB#printed circuit board manufacturers#electronic cable assembly#pcb manufacturing#pcb assembly manufacturer#pcb assembly services#pcb board manufacturer#printed circuit board manufacturer in india#circuit board manufacturing#pcb exporters#pcba#pcb manufacturer#pcb design#pcbassembly#multilayer pcb

2 notes

·

View notes

Text

Quick-turn PCB assembly refers to an assembly service that can manufacture and assemble printed circuit boards in a very short turnaround time, generally taking only 24 to 48 hours to complete. Choosing a reliable quick turn PCB assembler matters, which provides you with high-quality circuit boards within the shortest time. But it’s not easy to make the correct decision as there are many quick-turn PCB assemblers available in the market.

Here are some points to help you choose the best quick turn PCB assembly service.

Experience

Speed

Quality

Equipment

Costs

Know more at: https://aaloktronix.com/what-is-quick-turn-pcb-assembly-know-about-its-fabrication-and-manufacturers/

2 notes

·

View notes

Text

Looking for reliable PCB assembly and electronics manufacturing? inYantra delivers quality, speed, and end-to-end solutions you can trust. 👉 www.inyantra.com

0 notes

Text

The Future of Electronics Starts with the PCB — And It’s Being Built in India

Behind every smartphone, drone, EV, or IoT device, there’s one common core: the Printed Circuit Board (PCB). Often overlooked, yet absolutely essential, PCBs are the unsung heroes of the modern world.

If you're developing a new tech product, here's something you need to know: India is quickly becoming the global hub for PCB fabrication and assembly.

What is PCB Fabrication?

PCB fabrication is the process of manufacturing the actual circuit board — the foundation that holds and connects all electronic components. It involves precise steps such as:

Layering copper and substrate materials

Etching pathways

Drilling and plating vias

Applying solder masks and silkscreens

Electrical testing and inspection

A top-tier PCB fabrication company in India provides quality manufacturing that meets international standards, all while remaining cost-effective and scalable for startups or mass production.

What is PCB Assembly?

Once the board is fabricated, it’s time for PCB assembly — the process of placing and soldering components like resistors, capacitors, and microcontrollers onto the board. Assembly involves:

Surface Mount Technology (SMT)

Through-Hole Technology (THT)

Component placement automation

Reflow soldering and inspection

Functional testing and quality control

A reliable PCB assembly company in India will ensure your product functions flawlessly from the start, and can scale as your demand grows.

Why India is the Smart Choice

Here’s why companies across the globe are turning to India for their PCB needs:

1. Skilled Engineering Talent India has a vast pool of trained professionals with deep expertise in electronics manufacturing and design.

2. State-of-the-Art Facilities Leading PCB companies in India operate world-class cleanrooms and production lines equipped with high-speed SMT machines and automated testing tools.

3. Competitive Costs Get high-quality PCBs at globally competitive prices — without compromising reliability or delivery speed.

4. Fast Prototyping and Mass Production Indian companies support both small-batch prototyping and high-volume orders with quick turnaround times.

5. Compliance and Quality Most Indian manufacturers follow international standards (ISO, IPC, RoHS), ensuring your boards are ready for export or high-performance applications.

Who Needs a PCB Partner in India?

If you're building or scaling a product in any of these industries:

Consumer Electronics

Industrial Automation

Electric Vehicles

Medical Devices

Aerospace and Defense

Telecommunications

IoT and Wearables

Then partnering with a PCB fabrication and assembly company in India could dramatically reduce your time-to-market while keeping production costs under control.

Final Thoughts

The electronics industry is evolving fast. To stay competitive, you need speed, precision, and reliability — right from the circuit board up. By working with a top-tier PCB fabrication or assembly company in India, you're investing in a foundation that’s built for innovation.

India isn't just manufacturing PCBs. It's powering the next generation of technology

#PCB#ElectronicsManufacturing#TechStartup#ProductDesign#PCBIndia#PCBAssembly#HardwareStartup#Innovation#ElectronicsEngineering#PCBFabrication#IndustrialDesign#MadeInIndia

1 note

·

View note

Text

Selective soldering 🔧🔬🔥

Selective soldering involves attaching specific components to printed circuit boards (PCBs) and molded modules, a method particularly useful for items susceptible to heat damage from standard reflow ovens or wave soldering found in conventional surface-mount technology (SMT) or through-hole assembly techniques. Typically, this method is applied after an initial SMT oven reflow phase. The components targeted for selective soldering are often nestled among others already soldered via a surface-mount reflow method. This demands high precision in the selective soldering process to prevent damage to the surrounding elements.

#adafruit#selectivesoldering#pcbassembly#electronicsmanufacturing#surface-mount#throughhole#reflowprocess#precisionengineering#solderingtechnology#circuitboarddesign#manufacturinginnovation#techadvancements

5 notes

·

View notes

Text

#pcb#pcba#pcbassembly#aluminum pcb#pcb design#pcb fabrication#pcb factory#pcb manufacturer#pcb board#pcb prototype

2 notes

·

View notes

Text

Crafting the Future: Aimtron's Mastery in PCB Assembly and Electronics Manufacturing

In today's fast-paced technological landscape, the demand for high-quality PCB Assembly and Electronics Manufacturing is greater than ever. As industries evolve, the need for precision, reliability, and efficiency in electronic components continues to shape the future. Aimtron Electronics has established itself as a leader in PCB Assembly solutions, seamlessly integrating ESDM (Electronic System Design & Manufacturing) expertise to drive innovation.

The Backbone of Electronics Manufacturing: PCB Assembly

At the heart of every electronic device lies a printed circuit board (PCB), the foundation for connectivity and performance. A robust PCB Assembly process ensures seamless operation, longevity, and efficiency. The key stages of PCB Assembly services include:

Component Selection & Sourcing: Procuring premium electronic components for durability.

Surface Mount Technology (SMT): High-precision component placement using automated systems.

Through-Hole Assembly: Strong, reliable connections for demanding applications.

Testing & Quality Control: Rigorous inspections to eliminate defects and ensure peak performance.

With cutting-edge PCB Assembly solutions, manufacturers like Aimtron Electronics empower businesses with reliable and cost-effective technology.

ESDM: Elevating Electronics Manufacturing

Electronic System Design & Manufacturing (ESDM) goes beyond assembling PCBs—it involves designing, prototyping, and producing entire electronic systems. High-quality ESDM solutions optimize:

Efficiency: Streamlined workflows for faster production.

Customization: Tailored designs for industry-specific applications.

Innovation: Advanced engineering for next-generation electronics.

Combining PCB Assembly and ESDM expertise results in high-performance, scalable solutions that meet the demands of modern industries.

Aimtron Electronics: Leading the Charge in PCB Assembly & ESDM

With decades of experience, Aimtron Electronics has set new standards in electronics manufacturing, ensuring quality, reliability, and innovation. Their comprehensive approach includes:

Advanced Manufacturing Facilities: Cutting-edge technology for precision assembly.

Comprehensive Testing Protocols: Stringent quality control for defect-free products.

Custom Solutions: Industry-specific designs for optimized performance.

Sustainability & Efficiency: Eco-friendly production methods for responsible manufacturing.

The Future of Electronics Manufacturing

The fusion of PCB Assembly and ESDM solutions is shaping the future of electronics manufacturing. As industries transition towards smarter, more efficient technologies, Aimtron Electronics continues to drive innovation, crafting the future with mastery in PCB Assembly and ESDM.

Looking for expert PCB Assembly and ESDM solutions? Aimtron Electronics is your trusted partner in delivering cutting-edge electronics manufacturing that stands the test of time.

0 notes

Text

Looking to build smarter, faster, and more reliable electronics? Our high-precision PCB design and manufacturing services are made for innovators in IoT, MedTech, industrial automation, and embedded systems. Whether you're prototyping or scaling, we engineer hardware that performs under pressure.

💡 Explore custom electronic design and manufacturing services at 👉 www.auckam.com

#PCBDesign#IoTProjects#ElectronicsEngineering#SmartDevices#EmbeddedSystems#CustomHardware#PCBAssembly#ProductPrototyping#TechInnovation#IndustrialDesign#MedTechDevices#ManufacturingSolutions

1 note

·

View note