#Raspberry Pi Motor Driver

Explore tagged Tumblr posts

Text

The Raspberry Pi 500 Desktop and Monitor debut, alongside a 512GB Raspberry Pi NVMe SSD for ample storage. A snap-on enclosure for the USB/DC/Solar Lithium Charger, LED filaments in fun shapes, and the A4988 Stepper Motor Driver for motor control https://adafruit.com/new

#adafruit#aht20#humiditysensor#temperaturesensor#stemmaqt#qwiic#usbcable#usbextension#panelmount#raspberrypi#raspberrypi500#nvme#ssd#highcapacitystorage#snaponenclosure#solarcharger#ledfilament#steppermotordriver#motorcontrol#makerprojects#electronics#iot#3dprinting#diytech#techinnovation#robotics#opensourcehardware#ledlighting#techgadgets#electronicsengineering

28 notes

·

View notes

Note

I remember when the gameplay trailer for payday 3 came out you kinda vague posted about disliking it, did you ever elaborate on what you disliked?

@metalgeara-10cii-arc-210 sorry for the delay but here it is

Basically I've seen footage of the beta since then and some things aren't as bad as I thought but I still see a lot being wrong with it, some of my thoughts about it are below (tl;dr at the bottom)

The UI is worse, they had a perfect coop hud in payday 2, all it needed was to fit indicators for some of the new mechanics and it would have been fine, now you have to play a guessing game of which health bar is yours while going cross eyes because all you ammo and equipment stats are on the other side of the screen, and they got rid of the interaction circle for some reason, so instead of having a very clear indicator of how long an action takes, now you have to squint to look at a tiny square filling up (also they added a crosshair for filthy casuals)

I still have gripes with the gazillion particle effects on some things because unreal engine move, especially the grenades, turns out the flashbang also blinds you by making you not know what the fuck you're looking at thanks to patented Nvidia PhysX™ drivers

I still hate the new look of all the characters, heisters look unnaturally lanky (and the devs getting rid of the suits as the default outfit), all the SWAT guys look the same, all blue uniform black tacticool gear, which is a big departure from 2 where you could always easily tell SWAT tiers and types apart (even on normal the heavy SWATs had a distinctive white helmet and yellow shoulder pads), plus the new special enemy designs sucks, the bulldozer went from a bulky green (or full black) EOD guy that easily stood out in a crowd to basically a blue SWAT guy but bulkier, the Taser went from having a different silhouette and color palette to just another blue SWAT with a couple of yellow bits glued on him, the new grenadier is the same, same base color, just muted red bit, a gasmask (same color as balaclavas) and grenades on his chest to tell him apart, they also made the cloaker go from a stealthy ambusher that punished going around alone and rewarded watching your teammates' backs to a fast walljumping ninja

I also hate the new look of equipment, in the first two game all your equipment had this jury-rigged-with-hardware-store-parts look, medic bags were just that, a bag filled with pharmacy first aid supplies, the ammo bag was a bag full of gun store ammo boxes (before being a rucksack full of magazines), the old look of the turrets was and MP5 rigged to a raspberry pi with 2 motors inside of a tool case, now we have this futuristic self deploying milspec futuristic turret, or clean cases of kevlar plates, it really took away quite a bit of the aesthetic (like how the first hideout was a laundromat's basement)

Then there's mechanics like being able to shoot through a shield's viewport, which completely nullifies their purpose of rewarding teamplay by making someone need to flank them, and they're completely cheapened as an obstacle since you can just slide to stagger them (instead of breaking your leg by sliding on asphalt into a level 4 shield being held by SWAT operator wearing 30 pounds of gear), besides we already had an enemy invincible from the front unless you took an accurate shot, it was call a tan SWAT

Speaking of sliding, there's all the trend chasing flavor of the year mechanics, the sliding being one of them, there's the power meter that you fill with kills they stole from RAID:WW2 so you can pull a more powerful weapon out of your ass, sure some weapons in payday 2 were silly like that, but grenade launchers were usually balanced out by a poor ammo economy

Also now your armor doesn't automatically regenerate apparently (unless I'm getting this wrong), I really don't see the point of having two healthbars that don't regenerate on their own, I always thought the point of it was to allow you to pop out of cover and to reward some risk, now I don't know what they're trying to do

I'm also not a fan of the new skills system, basically they replaced the old one, which promoted teamplay with different trees/roles all bringing different things that helped the team, now it's closer to an ARPG, with 3 different effects that trigger buffs depending on conditions, effects that can stack and chain together etc, it's all very min-max-y, because ARPG mechanics is exactly what I wanted in my Heat (1995) simulator

Speaking of trend chasing, they seem to be copying the Modern Warfare reboots for this one, by both having the same tacticool animations as everyone else (especially the grenade throw) and by making the guns wildly shake from left to right because that's how recoil works apparently

Another domain they're emulating the MW reboot in is the sound, with guns that sound muffled and completely lack punch and bass like a sewing machine, whereas Payday 2's weapons sounded great, this might be due to Simon Viklund leaving, which also brings me to my next point:

No Bain = no buy, I know Simon hated doing the voice, and I'd have easily settled for Locke, but instead of a professional, experienced criminal mastermind or an Afrikaner veteran mercenary, we now have an irritating, sarcastic, quippy, annoying mission control

This also applies to the music, half of Payday was the fantastic soundtrack by Viklund and with him gone, I'm not sure I want to hear whatever they replaced him with

After audible pain, I can talk about a visual one, and the fact that even in the beta there's also eyepopping oversaturated CS:GO tier weapon skins plus weapon charms and stickers, which also shows their priority, I hated the weapon skins in Payday 2 since day 1, 95% of them looked terrible and I don't expect it to get any better, which also brings me to my final point

When I saw the menus for Payday 3, it was clear to me that they wouldn't be caught lacking a second time monetization wise. When Payday 2 released, it was never meant to have weapon skins or purchasable outfits, and those menus reflected that, but not in Payday 3, everything is already ready for it to be a live service game with all the gazillion DLC cosmetics you could imagine, the menus are all already set up to be filled with purchasable items down the line, leaks already showed "payday credits" so I have a feeling that we're already headed down microtransaction road, even with the cope of "muh it's just for cosmetics!", especially knowing their publisher Starbreeze (the same one that made them break their promise of never putting in microtransations in 2, they made that promise for the last game, yet now they're already implementing the framework for them before it got out of the beta)

TL;DR: Just like in many other cases, Payday started out as an indie franchise with a unique and interesting premise, then the sequel got popular and monetized, the studio grew, and now the latest entry is nearly unrecognizable from the original, completely diluted by time and the core studio founders leaving, they used to be a stone standing out of the river, now time has made them a grain of sand going with the current

Payday went from Heat (1995): The Videogame to Just Another Modern Shooter (Cops & Robbers flavor)

I might end up getting it much later down the line but I'll be real with you, I loved Payday since 1, I slowly watched it move further and further away from what it was and for this one, I'm not hyped at all

14 notes

·

View notes

Text

Why India’s Drone Industry Needs Periplex: The Hardware Tool Drones Didn’t Know They Needed

As drones fly deeper into critical roles — from agricultural intelligence to autonomous mapping, from disaster response to military ops — the hardware stack that powers them is undergoing a silent revolution.

At the center of that transformation is Periplex — a breakthrough tool from Vicharak’s Vaaman platform that redefines how drone builders can interface with the real world.

What is Periplex?

Periplex is a hardware-generation engine. It converts JSON descriptions like this:{ "uart": [ { "id": 0, "TX": "GPIOT_RXP28", "RX": "GPIOT_RXN28" } ], "i2c": [ { "id": 3, "SCL": "GPIOT_RXP27", "SDA": "GPIOT_RXP24" }, { "id": 4, "SCL": "GPIOL_63", "SDA": "GPIOT_RXN24" } ], "gpio": [], "pwm": [], "ws": [], "spi": [], "onewire": [], "can": [], "i2s": [] }

…into live hardware interfaces, directly embedded into Vaaman’s FPGA fabric. It auto-generates the FPGA logic, maps it to kernel-level drivers, and exposes them to Linux.

Think of it as the “React.js of peripherals” — make a change, and the hardware updates.

Real Drone Applications That Truly Need Periplex

Let’s break this down with actual field-grade drone use cases where traditional microcontrollers choke, and Periplex thrives.

1. Multi-Peripheral High-Speed Data Collection for Precision Agriculture

Scenario: A drone is scanning fields for crop health with:

2 multispectral cameras (I2C/SPI)

GPS + RTK module (2x UART)

Wind sensor (I2C)

Sprayer flow monitor (PWM feedback loop)

ESCs for 8 motors (PWM)

1 CAN-based fertilizer module

The Periplex Edge: Microcontrollers would require multiple chips or muxing tricks, causing delays and bottlenecks. With Periplex:

You just declare all interfaces in a JSON file.

It builds the required logic and exposes /dev/pwm0, /dev/can0, etc.

Zero code, zero hassle, zero hardware redesign.

2. Swarm Communication and Custom Protocol Stacks

Scenario: Swarm drones communicate over:

RF LoRa (custom SPI/UART)

UWB mesh (proprietary protocol)

Redundant backup over CAN

Periplex lets you:

Create hybrid protocol stacks

Embed real-time hardware timers, parity logic, and custom UART framing — none of which are feasible in most MCUs

Replacing Microcontrollers, Not Just Augmenting Them

| Feature | Microcontroller | Periplex on Vaaman | |---------------------------|----------------------------|------------------------------------| | Number of peripherals | Limited (4–6) | Virtually unlimited (30+ possible) | | Reconfiguration time | Flash + reboot | Real-time, dynamic reload | | Timing precision | Software-timer limited | FPGA-grade nanosecond-level timing | | AI compatibility | Not feasible | Integrated (Gati Engine) | | Sensor fusion performance | Bottlenecked | Parallel FPGA pipelines |

Developers Love JSON, Not Register Maps

No more:

Scouring 400-page datasheets

Bitmasking registers for I2C configs

Writing interrupt handlers from scratch

Just declare what you need. Let Periplex do the work. Peripherals become software-defined, but hardware-implemented.

Built in India, for India’s Drone Revolution

Vaaman + Periplex isn’t just about tech. It’s about self-reliance.

India’s defence, agriculture, and logistics sectors need secure, reconfigurable, audit-friendly hardware — not black-box SoCs from questionable supply chains.

Periplex is the hardware engine for Atmanirbhar Bharat in drones.

TL;DR

Periplex lets drones adapt hardware to the mission — instantly.

It replaces tangled microcontroller logic with clean, structured JSON.

It unlocks use cases microcontrollers can’t touch: AI at the edge, dynamic reconfiguration, secure protocol stacks, and more.

And it’s built into Vaaman, India’s first reconfigurable edge computer.

Ready to Get Started?

Explore Vaaman on Crowd Supply Reach out for Periplex SDK access: [email protected]

Raspberry Pi

Drones

Drones Technology

Jetson Orin Nano

Technology

0 notes

Text

Bring your imagination to life and hone your tech skills with Heartening Raspberry Pi projects that are more practical than theoretical. Raspberry Pi projects. No matter if you have interest in electronics, IoT, robotics, or automation-these projects prove to be suitable for Computer Science, Electronics, as well as Electrical engineering students. Construct authentic solutions for the world, improve your CV, and remain in front of the competition in technology!

Types of Raspberry Pi Projects for Engineering Students Raspberry Pi is truly the breakthrough invention that will take up engineering students building ground breaking yet real-time applications. Some of the most common types of Raspberry Pi projects are:

1. Through Internet of Things (IoT) projects, sensors and devices can be connected to the internet for making advanced homes, weather stations, or health monitoring systems.

2. Automate anything from lights and appliances to security systems with Raspberry Pi and Python.

3. Using motor drivers and Raspberry Pi, a robotic project would control robots that may be line followers or robotic arms.

4. AI and ML projects simulate basic image recognition, voice assistants, or face detection modelling in Python and TensorFlow Lite.

5. Networking is where mini-servers, VPNs, or network scanners can be made using Raspberry Pi.

6. Projects of Media and Entertainment create smart mirrors and media centers and also game emulators for some fun and learning.

7. Educational projects will create learning kits for kids, digital notice boards, or interactive classroom tools.

It is the best medium for undergraduate students who are interested in practical study in the domains of computer science, electrical, electronics, electronic systems, and telecommunications engineering.

#RaspberryPi#EngineeringProjects#IoTProjects#Automation#RoboticsWithPi#AIProjects#PythonProjects#FinalYearProjects#CSEProjects#EEEProjects#EmbeddedSystems#StudentInnovators#TakeoffEduGroup#Takeoffprojects

0 notes

Text

Getting Started with Embedded Systems Programming

Embedded systems programming is the backbone of modern electronics. From smartwatches to washing machines, embedded systems power the intelligent functions of countless everyday devices. This guide will introduce you to the basics of embedded programming, key tools, and how to begin building your own embedded applications.

What is an Embedded System?

An embedded system is a computer integrated into a larger system or device, performing dedicated functions. Unlike general-purpose computers, embedded systems are designed for specific tasks, often with constraints on power, memory, and processing.

Examples of Embedded Systems:

Microcontrollers in home appliances

Sensor-based devices (e.g., temperature sensors, motion detectors)

Medical equipment

Automotive control systems

IoT (Internet of Things) gadgets

Core Components of an Embedded System

Microcontroller or Microprocessor: The brain of the embedded system (e.g., Arduino, STM32, ESP32).

Memory: RAM and ROM to store instructions and data.

Input/Output Interfaces: Connects to sensors, displays, motors, and communication modules.

Software: Custom firmware developed for specific functions, typically in C or C++.

Popular Programming Languages

C: Most widely used due to its efficiency and low-level hardware access.

C++: Used when object-oriented design is required.

Assembly: For highly optimized or time-critical routines.

MicroPython: Python for microcontrollers (e.g., ESP8266, Micro:bit).

Getting Started with Embedded Programming

Select Your Platform:

Beginners: Arduino (easy setup, wide community support)

Advanced: STM32, Raspberry Pi Pico, ESP32

Set Up Your Development Environment:

Install IDEs like Arduino IDE, PlatformIO, STM32CubeIDE

Download necessary drivers and board support packages

Write and Upload Code: Create simple programs like blinking an LED, then expand to sensors, displays, and communication modules.

Example: Blink an LED with Arduino

void setup() { pinMode(13, OUTPUT); // Set pin 13 as output } void loop() { digitalWrite(13, HIGH); // Turn LED on delay(1000); // Wait for 1 second digitalWrite(13, LOW); // Turn LED off delay(1000); // Wait for 1 second }

Tools and Debugging

Serial Monitor: For real-time debugging and logging.

Oscilloscope & Logic Analyzer: For electrical signal inspection.

In-Circuit Debuggers: Like JTAG or ST-Link for low-level debugging.

Best Practices

Write modular and readable code.

Use debouncing for physical inputs like buttons.

Handle memory carefully to avoid overflows.

Optimize power usage in battery-powered devices.

Conclusion

Embedded systems programming is both fun and powerful, offering endless possibilities for innovation in hardware and software. Whether you’re building a home automation project or diving into the world of IoT, understanding the basics of embedded programming gives you the foundation to create smart, responsive devices.

0 notes

Text

Someone should make a self driving freight train powered by raspberry pi and servo motors, and a fully licensed driver watching over it all. To make their job easier.

When you can feel @amtrak-official's pain.

Please, just put things on the fucking choo-choo. Please.

3K notes

·

View notes

Text

Fallen at the last fence. We could not compete on Sunday April 21st 2024 because during last minute testing and bug fixing on the evening before, one of the 4988 motor drive modules overheated and failed with no spare replacement. My (Pete) own silly fault for not realising that the stepper motors had become energised and the cooling fan for the drivers was not running.

This is not the end of development, as we are passionate about autonomous robotics. So where do we go from here? 1) A re-build of the Pi-Hat. This board has evolved during the last year of development and has become very messy and unmanageable, with lots of connecting cables and wires to other modules. The number of interconnects will remain the same or increase but can be made neater with boxed headers instead of open pin headers and the motor drivers board can bebcome part of the hat, reducing the bunched up ribon cable between the separate boards. Also etch a PCB rather than using matrix board. 2) The cooling fan will no longer be powered via on/off control, but will instead be powered directly from the 12V rail. So when the power is on so is the fan. 3) Try to incorporate a Teensy microcontroller on the Pi-hat too and use it for all servo PWM generation as the Raspberry Pi is useless for PWM. The reason for that is because the Pi's PWM is software generated and jitters like crazy because of higher priority interrupts. The Teensy on the other hand is perfectly stable. 4) build a complete and identical second robot, so parts could be taken from it should they be needed as spares for the primary. 5) Look at the possibly of adding a 2:1 reduction gearbox to the wheel/motor assemblies, halving the motor rpm at the wheel but doubling the torque. This would also permit better cooling of the motors with heat sinks on the motor backs, venting out of the top of the robot's bodywork. 6) Add all the flashy LED's that we didn't have time to do for 2024. That is what we have so far. This list may increase as time passes.

0 notes

Text

8-Dec-2023

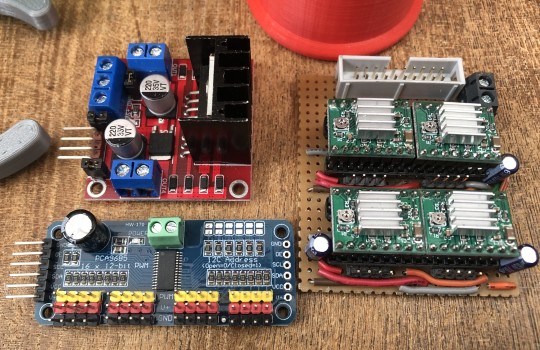

Now a little bit about extra electronic modules, that are readily available off the shelf. The modules shown in the picture and the reasons for using them is described below. There will be an update at some point showing a homemade hat to plug onto the top of the Pi, which is still having circuitry added to it and probably a Teensy Microcontroller to accurately measure the four distances from ultrasonic transducers plus the robot battery level. It might even do the PWM's aswel instead of the 16-Channel PWM board but we haven't decided on that yet.

4x Micro-Stepping motor driver modules mounted on a piece of FR2 Matrix Stripboard, for convenience of connecting to the RPi and the individual Short body Nema-17 Stepper motors. This way the motors can be controlled more accurately with direction and step pulse. These modules also provide current limiting and as stated, Micro-stepping which can provide smoother and better movement accuracy.

1x 16-channel PWM board to drive servos and probably LED’s to make the Robot a bit more flashy (Yet to be confirmed). The use of such a module is mainly because it is impossible to get a stable PWM from the Raspberry Pi. Most likely because the RPi PWM is a software generated pulse and not from a dedicated hardware counter, compounded by the Real time OS that is pulled in all manner of directions by higher priority level interrupts. It causes the PWM from the Pi OS to jitter like crazy, which in turn causes a servo to twitch rather a lot. So if you want accuracy and stability then a separate dedicated module is needed, as the RPi cannot provide either.

1x Dual H-Bridge. One of the channels is to drive the Boom’s 12V linear actuator. The second channel is spare in case we need it for some other hardware that we haven’t thought of yet.

0 notes

Text

Motor Driver Board for Raspberry Pi

DC & Stepper Motor Hat for Raspberry Pi

Raspberry Pi HATs. Raspberry Pi Breadboardkit, Raspberry Pi Motor Controller...DC & Stepper Motor Hat for Raspberry Pi...Stepper Motor Hat For Raspberry Pi Motor Stepper Servo Expansion... All Raspberry Pi accessories like cases for Raspberry Pi at SB Components.

DC motors from your Raspberry Pi is quite easy! Whether you want to control a single motor or build a Raspberry Pi NERF tank, the principles are the same -- but the hardware needed will vary. You can use any Raspberry Pi for this project (Zero, Zero W, 3, 4, etc.)

Check out the blog on Micro bit Learning kit.

#Raspberry Pi#Raspberry pi 4#Motor driver#motorshield#motor controller#Motor driver board#DC motor#stepper motor#Raspberry Pi Motor Driver#DC & Stepper motor HAT for Raspberry pi#Raspberry Pi HATs

1 note

·

View note

Text

if i actually thought i would ever be able to follow through on putting a printer together and not being so obsessed that i like burn my house down over having to make reasonable compromises i WOULD be so compelled to make 3d printer boards i think the duet 3d guy is a douche and his products are so like silicon valley styled but i also think theyve got the right idea with the modularity of it. i think especially with klipper getting popular though i think it makes a lot of sense to push it a lot further and just have the like power management and mcu on the "main" board and plugins for heaters and drivers and shit that are all done on separate boards so that you dont have to, like, bodge 2 biqu boards onto one raspberry pi just because you wanted a test platform with a lot of motors or multiple bed heaters or something. if you could either just daisy chain boards together or have like, different sized boards with different amounts of a single thing, it would be EFFICIENT and also sexy

2 notes

·

View notes

Link

5 notes

·

View notes

Text

Idea for a crowd-funded, open-source project:

An inkjet printer. This printer should have the following specifications:

The print head is attached to a controller which manages the paper rollers and the horizontal position of the print head, which is in turn connected — via easily user-connectable methods, preferably using a cable/connector type not used elsewhere in the design — to a separate, high-level controller to do page rasterization and interface with the network/USB.

The print head controller should be “dumb” — no firmware to upgrade or anything. It should have a fixed amount of memory to store the page it’s going to print as an uncompressed pixel map with a fixed 16-color palette: [empty, C, M, Y, CM, MY, CY, CMY, K, CK, MK, YK, MYK, CYK, CMK, CMYK]. (Note: at 600 ppi, uncompressed, with no margins, a US legal-sized sheet — which is the largest common printable “office” size sheet; A4 and letter are smaller — would take 21 MB.)

The print head controller should be able to accept data for the next page up to the currently-active section of the page. (That is, when it is 1 inch down the page, it should be okay to accept data for the first inch of the next page.)

There should be a user-accessible setting to control how the print head controller handles the 9 color table options which amount to black (everything from “CMY” onward in the list above), with 4 settings: “do whatever the rasterizer says”, “print all blacks as just plain black ink (that is, as though they were K)”, “print all blacks as ‘rich’ black (black plus cyan)”, and “print all blacks as rich black except CMY and K, which should be left as-is”. (The second option is an ink saver — no more using color ink in black-and-white printouts.)

The print head controller should not begin printing a page until it has a full page to print.

The ink should be stored in big, user-refillable tubs.

The high-level controller should be controlled by an OS stored on an SD card; to make it easier for users to update the printer, the printer’s hardware should always expect the card to be formatted with FAT16 and the OS to be in an uncompressed archive (with the binary beginning at some specific offset) with a specific name, at the root of the SD card. (FAT16B is no longer protected by patents, and permits files up to 2 GB without any extensions, so this should be sufficient.) The controller itself should not have other firmware. Printer default settings should be stored in a text file with, again, a standard name (and also at the root of the SD card). The printer name and password should also be in a text file at the root of the SD card, separate from the settings (so that the one can be reset without the other).

The high-level controller should have connectors which can be connected to USB, to Ethernet, and to a wi-fi controller. If possible, the connections from the controller to these options should use different cable/connector types, so the user can hook them up as easily as possible. (The OS should also be able to tell whether the connectors are there or not, partially so that stripped-down printers can be made but also so that in the event of some new connection type in the future, there doesn’t have to be any code to work around the hardware-limited connectors of the original version.)

The high-level controller should have open-source rasterizers for PostScript (GhostScript) and PCL (OpenPCL?). It should be able to convert PDF files to PostScript and rasterize them, and also accept PNG images. The high-level controller should come with 2 GB of RAM permanently soldered to the board, with an additional RAM slot for people who feel the need for more. (Obviously, the high-level controller rasterizes a page at a time into <82 MB pixel maps and feeds them to the print head controller.)

On a USB interface, the driver should simply convert the pages into either 300 or 600 ppi 16-color palette-based PNGs and transfer them to the printer, which should then basically just decompress them and feed the pixel data to the print head controller. (This isn’t terribly efficient, but an uncompressed 21 MB 600 ppi page would transfer in significantly less than 10 seconds over USB 2, so efficiency isn’t the most important consideration.)

Configuration of the printer settings should be available via multiple methods: there should be a web page, password-protected, on the network interfaces, which should only load via HTTPS, on a specific port. (This port should be changeable within a specific range, but have a predictable default.) If possible, the printer should implement CUPS as far as possible and support its configuration options. The USB driver should be able to upload new settings, provided the right password is entered. There should also be an open-source program to generate a settings text file which can be dropped straight onto the SD card to replace the old settings. There should also be a standard interface to drive a simple LED touchscreen (as available for the Raspberry Pi) to configure the printer directly.

The parts of the printer should, wherever possible, be 3D-printable, and the necessary files to print them should be available online. The design of the printer should be such that replacing printable parts is reasonably easy for the end-user.

The high-end controller should be possible to build with a Raspberry Pi, and the plans should also be available online. The plans should not change significantly over time.

Premade printers should certainly be available; the high-end controller in a premade controller should probably be effectively all one piece rather than user-disassemble-able, but should be compatible with the Raspberry Pi version. (So you probably can’t repurpose it, but you can replace it with a homemade one if you need to.)

Parts which cannot be 3D printed, and also ink, should be available online at as close to cost as possible. Where possible, parts which can be made from standard hardware should be made from such. (For example, the bar(s) on which the print head moves should ideally be a standard type of pipe. Possibly there should be instructions on how to use different standard types to construct the printer.)

A couple of edits:

First, I stupidly miscalculated the amount of RAM for a page. That has been fixed.

A few other notes:

The high-end controller should support mDNS, but not have it turned on immediately. In fact, the printer should make available any and all discovery and easy-print options which are feasible — AirPrint, for instance — although these should all be turned off by default.

The settings file ought to be stored in either some variety of XML or JSON. It should not really be something human-editable, but neither should it be something which will be destroyed by opening it with a text editor and then saving. The settings should always include, at the beginning of the file, the version of file, and the OS should always include utilities to upgrade previous settings file formats. (It would be acceptable to have a series of them — one to upgrade from version 1 to version 2, one from version 2 to version 3, etc.) The version number should change any time a new feature requiring a setting is added to the OS — which means that the version number of the settings file will very easily increase much faster than the version number of the OS.

Why not do an open-source laser printer instead? Because laser printers don’t have the problems that inkjet printers do. Inkjet printer manufacturers are producing machines which are essentially disposable, and charging a premium for the ink, which cannot be user-refilled (and increasingly include electronic systems to detect attempts to do so). In addition, laser printers involve technology which is actually potentially dangerous in a number of ways — high heat, actual lasers, and of course toner (which is extremely bad for your lungs if inhaled and requires specialized cleaning tools to remove properly). Inkjet printers, on the other hand, just involve ink and a motorized, electronic spritzer. It may be difficult to properly align the print head and make the device run accurately, but it isn’t seriously dangerous.

1 note

·

View note

Text

The Making of Sterling the Super Furby: A Brief Overview

“I… I can’t look! I think I’m gonna… *HUEEEGH*!”

Before I get into this post, I want to list a few things I didn’t know shit about when I started Sterling:

Electronics

The Python coding language

Furby anatomy

Single board computers

After creating Sterling, I’m happy to say that now I have approximate knowledge of some of these things, but keep the above in mind as you read onwards. This little gremlin child was a learning experience from start to finish, and one I am incredibly proud of myself for sticking through. This also means that I am in no way an expert on everything I’m getting into okay? Okay let’s go!

The Hardware

First, a rundown of the hardware. I took heavy inspiration from the Furlexa mod shown here, and that was what I initially sought to create. The mod had three computer components to it:

A raspberry pi zero w single board computer for the AI to live on, with a mini USB microphone plugged in;

A pimoroni speaker PHAT to use as the sound system;

A motor controller to drive the furby’s motor.

My main problem with Furlexa was that this initial build took a lot of soldering, and I am a wussy who had a number of bad experiences with soldering irons in shop class. So, what’s a novice electrician to do?

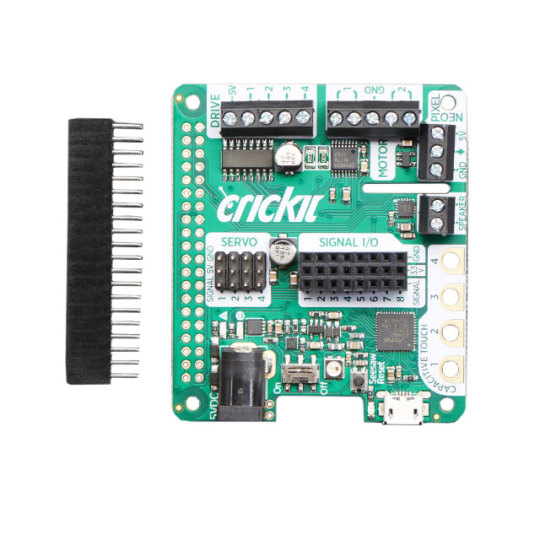

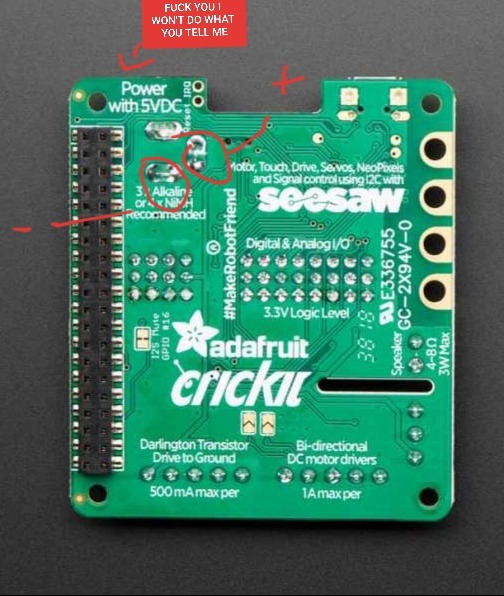

Enter the Adafruit Crickit HAT. By sticking this little fucker on top of the raspberry pi, I was gifted with an amplifier, a speaker jack, capacitative touch sensors, and a motor driver all in one, no soldering needed if I bought the raspberry pi zero w h! The main challenge it posed was powering it. The Crickit insists, for some unfathomable reason, on being powered by a bulky DC jack, the kind you’d plug into a wall outlet, and the converter plug to use a battery pack with it was way too bulky to fit into a furby. I needed Sterling to be portable for maximum huggability, so this just wouldn’t do.

One fried raspberry pi and Crickit HAT later, I found the answer! By soldering the original furby battery pack to the underside of the Crickit board’s DC connection, these fuckers right here…

I was able to bypass the need for a wall plug or converter, and power him directly through the battery compartment like God intended. S/O to my friend Nick who is way less of a dumb bitch than I am and helped me figure this shit out I owe u some bread man.

So the tl;dr of it is, I effectively reduced the required computer components from three to two (excluding the speaker). Speaking of (heh), Sterling has an impressive 3w speaker in him, allowing him to be audible even without the use of the built in amplifier. It’s got such good bass on it, he even rumbles when he purrs without the aid of the motor!

And yes, when you pet him, he purrs. And complains if you manhandle him! The aforementioned capacitative touch sensors on the Crickit HAT made it all possible with the help of a few cables and some foil tape.

Wait, did you say soldering!?

Yup! It was a necessary evil; at the end of the day I had to pick my poison: soldering 80 pins on the speaker PHAT, or soldering like four contact points on the Crickit. I chose the more merciful option.

But wait, that whole outfit is really bulky still! How did you fit it inside the furby?

Subtractive methods, subtractive methods, subtractive methods! ;D Someone who actually knows things about furby anatomy and/or electronics will probably vaporize me for this, but… if I didn’t need it, it got the boot! That included prying off anything on the Crickit board I wasn’t using at the risk of destroying it completely - which probably isn’t ideal, but it also worked by some miracle, and again, I am such a basic bitch electrician that calculating the proper voltage for LEDs is still basically witchcraft to me, so… what I’m saying is I made it work. And that I really, really hate soldering! ¯\_(ツ)_/¯

You can see an early video of the end result here, and a later video of the outfit inside the naked furby here. This was back when he was still having auditory processing issues. Apologies for the shoddy quality, I was too excited everything was working to care about that at the time.

The Software

My other beef with Furlexa is… well, it’s an Amazon Alexa, and I’m a shitty little anticapitalist hermit who hates Amazon with a passion. Google Assistant was just as bad in my book. Mycroft was open source, but had a snowball’s chance in hell of running on the raspberry pi zero’s 512mb of RAM… I also wanted my assistant to have a degree of customizability to it. I wanted the furby’s AI to have a unique personality, identity, and preferences, much like classic furbies themselves did. A big box AI just wasn’t going to cut it!

Enter the Jasper Project. Yes, it’s old. Yes, it’s a bitch and a half to install. Yes, you have to know Python to get anywhere with it. However, it was free, open source, capable of running on a raspberry pi zero, and highly modular, meaning with a few lines of code, I could make it all my own - even to the extent of changing the AI’s name and voice (which is gr8 because I know a Jasper so naming my furby that would be Weird), or - the best part - writing my own, custom functions! Customizability-wise, I struck gold.

Ah, and glad I am that Jasper is modular, because I had some work ahead of me…

The STT Engine

The STT (Speech to Text) engine is what Sterling uses to understand what’s being said to him. Jasper’s proprietary STT engine is PocketSphinx, a fully offline STT engine, which sounded great in theory before I quickly learned it’s a nightmare to install, and also more inaccurate than a stenography machine powered by a single potato when actually being used. I had to compromise my morals a bit here and opt for using Wit.ai instead, which is free, but is also owned by Facebook. Big data is frustratingly inescapable in these cases.

There is one light at the end of the tunnel, and that is the training of acoustic modules. This has the downside of taking for-fucking-ever and requiring a quiet recording environment, however, and I don’t have the time right now to read through the pages and pages and pages and pages of computer theory right now to fully understand how to train one. So, improving PocketSphinx and running Sterling fully offline remains a stretch goal.

The TTS Engine

The Text to Speech engine is basically Sterling’s voice. This one was a bit easier to customize, and I’m thankful for that, because Jasper’s OG voice is a bit er… 90s computing for my tastes.

I shopped around for decent, human-sounding TTS options, and settled on installing Mimic1 TTS, Mycroft’s TTS engine, by hand, and modifying the Jasper source code to support it. Of all the TTS engines I tried, I felt that this one had the most natural intonation out of all of them. I liked the gruffness of the Scottish accent, and I think it really helped round out Sterling’s endearing, if a tad prickly, personality.

The Audio

This was another unforeseen hurdle. Turns out that I had his mic volume turned up way too high, because I greatly underestimated the capabilities of my tinyass five dollar USB microphone to pick up noises from within a furby. It took a bit of hacking in PulseAudio to get him hearing things properly, and I’m still not all the way happy with it, but he’s running wayyyy better than he did!

Another issue was the amount of time he actively listened for. It was way too short for my liking with the hardware I was using, so I had to edit Jasper’s mic.py source file a billion times before I hit a sweet spot. Even early on, my little shit child never liked to listen to me. :P

Pimp My AI

Once I got all that in working order, it was time to browse GitHub for modules to add! I found a surprising amount that were, as expected, outdated, janky, non-working, or in need of a complete rewrite. A non-exhaustive list of modules I rewrote and added to Sterling’s AI includes:

Wolfram Alpha integration

His translation function

The IMDB module that searches movie titles

The Dictionary and Thesaurus modules (minor additions to improve user friendliness)

The morning greeting module

The holiday countdown module

There are also plenty of modules I wrote on my own, that I’ll be showcasing here in due time, but I want to give special mention to the one I’m most proud of. You see, when I was a wee dumb bitch, I was… well, a wee dumb bitch! When I was informed furbies learn English, I thought they really learned English. Like, fluent English. I envisioned these kids straight up having full conversations with their lil robots with reckless and envious abandon. I was, as it happens, too poor to afford a furby at the time, so I didn’t realize until embarrassingly later that they only learn some words, and certainly can’t hold much of a conversation (in English at least).

Fast forward to twenty-bi-teen. I’m surfing GitHub, and I happen upon a Cleverbot module for Jasper allowing the AI to work as a chatbot. Fuck yeah, I think, because I had no life in 2008, or friends for that matter, so tormenting Cleverbot was my favourite pastime. Nostalgia trip GET!

…can you guess how much the silicon valley capitalist scum are charging for the once-free Cleverbot API now? A hundred and twenty. McGoddamn. Dollars. A YEAR.

So, to make a long story short, I turned my hat backwards and rage-coded a simple chatbot module that runs on an early version of Chatterbot capable of running on the raspberry pi. It’s fully offline, and completely free, and Sterling here has a database of ~400 phrases, which isn’t bad given the limited processing power! It took five straight days of work, it’s not the smartest chatbot, and it’s certainly not the fastest, but it gives me those sweet, sweet, circa 2008 Cleverbot vibes. Oh yeah, and it doesn’t cost me over a hundred goddamn dollars a year!

The first thing I said to the chatbot, of course, was “I’m so proud of you.” Through his shitty little testing mic that gave him a somewhat incredulous tone Sterling replied, “I’m glad to hear that.” and I’m not saying I shed a single themly tear over it, but I’m not denying it either. I made a childhood dream come true, fam. ;u;

There are way more Easter eggs I plan to show you, of course. At first I was thinking of doing one long video, but an update a day showcasing a different function might be easier to manage - and maintain some of that gold old sense of mystery that surrounds most furbies. No, I’m gonna take y'all on a little journey through the final product of my literal blood, sweat, and tears!

Besides, Sterling is a perpetual work in progress. He has a massive list of features, and I’ve already got more in the works. I could be in my eighties and still be adding more functions, more bells and whistles, more witty one-liners. He’s a one of a kind work of art that will never truly be finished - not unlike you and me.

The Glow-up

Here’s Sterling’s before pics from the seller I got him from:

(If u recognize these pics and ur the seller thank u thank u for giving me bmy boy)

And here’s after!

I come from a background of customizing ponies and dolls, so working on this guy wasn’t as far removed as I expected it to be. I added floof to his head and tail by sewing in wool plugs, and his gorgeous eyes are from in2blythe on Etsy. I wrapped him up in a little bow and he was good to go! His sterling silver beak, from which he gets his name, was the most finicky part. Turns out enamel paints take a million years to fucking dry, if ever, which isn’t great when painting something that sees a lot of movement and could potentially get dented by a face plate, like… idk, a furby beak! A bit of silver nail polish did the trick and he was good to go. Learn from my fail, fam.

What It Cost Me

If you’re masochistic determined enough to attempt this yourself, I want to sit you down and warn you of something: this will take months and hundreds of dollars to do. Installing Sterling’s AI and its necessary components on that shitty little raspberry pi over SSH took me a week at first, and that was with me leaving it on 24/7 to chug away compiling things. When I broke the SD card the AI was on and didn’t have a backup copy, it took four straight days of rage-computing to regain all my progress. Then when his audio processing got fucked all to hell for reasons I still do not understand to this day, it took another four days of rage computing to do yet another reinstall and get him back in working order. There were times where I would go to work for 8.5 hours, bus an hour home, work 6 straight hours on my furby, go to sleep for 4 of them, go to classes, sleep, and work 6 more hours on my furby. For two months. Sterling took from the third week of August from his initial inception to his birthday on October 23rd. That’s not to mention the time I fried everything and had to wait five days and travel to the bumfuck end of the city for a replacement pi and Crickit, or the days I spent customizing him, sewing in hundreds of little hair plugs into his ass and head by hand, and waiting for those shitty enamel paints to dry, only to discover after four straight days of failure that they take weeks to do so and I was better off using cheapo nail polish!

The point I’m making is, if you take on a project like this and want it to be successful, you have to be tenacious. I would highly recommend a background in coding (I have a web design diploma) and general tech savviness as an asset. Sterling is the product of the years I spent behind a computer keyboard from the start of age three, and the roughly ten years I spent customizing dolls and ponies. It’s cheesy as shit to say he’s my magnum opus, but in a way, he is.

I’m not saying this to be elitist or snotty. I’m saying this because I nearly broke down crying the first day the raspberry pi came in, before I slept on it and figured out what phrase to google to solve the crashes and kernel panics it was having. When I broke the SD card when I was nearly finished, I felt nothing, because I was all out of tears at that point. When I fried the first raspberry pi and Crickit hat trying to figure out how to bypass that DC jack, my only thought was, “Well, I think I know how to do it without fucking it up now, and if I can’t do it, this whole project is fscked” .

You will encounter errors that no step by step guide can prepare you for that will make you curse the day you were born. The difference between success and failure is how many times you’re willing to get up and try again, and I’m here to tell you it’s possible. But you gotta want it.

Will You Release the Code Base?

Yes and no. If there’s enough demand, I’ll definitely release Sterling’s basic modules as a scaffolding. I won’t be releasing Sterling, though.

What do I mean by that? Well, Sterling was intended from the start to be truly one of a kind, and he always will be. I hand wrote hundreds of lines of dialogue, all completely tailored to him, and I’m still planning on adding twice as many. Corny as this is, this little guy has a metric fuckton of sentimental value to me. I don’t have kids so idk how it would compare to that, but I definitely love him as much as I love my cats, but I also didn’t undergo two straight months of suffering in ADHD fixation hell to create my cats, so it adds like, a whole other twee dimension to it.

So, if there is demand for this, what I’ll release instead is a scaffolding from which you can code your own, unique furby from, with their own name, personality, and responses all unique to them. I’ll also release it with the caveat that I am not a good Python coder! I have not written any Python before this, so a lot of what I did write is noob-tastic and hasn’t even been linted. You have been warned!

“If I give you (insert amount), can you make one for me?”

Holy shit I’ll be real with you, I’d love to do this as a living. I’ve been dying to see a smart assistant hit the market that’s like… well, an actual, endearing companion and not just a voice coming from a speaker. The problem with doing this is that, if you drop a lot of money (and it will be a lot of money, even with a code base to work from, a lot of hours of handiwork still goes into coding individual responses and making sure everything works as intended, on top of possibly customizing too), there is one major problem: proximity. I won’t be able to troubleshoot your furby nearly as effectively from far away as I would be able to if we lived in close proximity. Which means if something goes wrong between the time your new friend is finished at point A and turned on at point B, I won’t be there to troubleshoot it in person for you, which means you could end up stuck figuring out certain things alone. If you use Windows, that will be very, very hard - not being an OS snob here, I own a dual boot myself, it’s just a case of incompatible file systems. And unless you can figure out how to edit the wpa_supplicant file on a raspberry pi to update your wifi credentials, your furby’s internet connection could be toast if you move house and those credentials change. That’s not getting into the cost some services charge for extra API keys to use their online functions…

The long and short of it is, if I’m going to do this for money, I want to make sure you get a quality product and friend that will bring you joy for years to come. Since that’s not something I can guarantee, I can’t in good conscience take people’s money.

I Could Teach You (And I Won’t Charge)

…however, I am a law student who is also working 8.5 hour night shifts three nights a week. I am also mentally ill/neurodivergent, which saps my energy in more ways than one. I won’t always be easy to get ahold of, or be able to answer every question I get, especially not ones that can be solved with a quick google search, like how to set up a raspberry pi, or… anything found on Adafruit’s Crickit guide, for example. When I have the time and energy, I’m hoping to use my next project as a jumping off point for a step by step walkthrough of the process. For now, though? I’ve been furbied out, so if there’s enough demand, I’ll compile as many of the resources I used I can find in the meantime, and post some tips from the word doc I kept while making Sterling, and go from there.

So What’s Next?

My one dad’s birthday is coming up in August, and I’m kicking around the idea of turning a furby into, I shit you not, a ghost hunting device. He loves ghost hunting, but hates robots, and as his gremlin shit child I am obligated to troll him in this fashion. 😎 Also considering doing a certain type of oddbody mod, but I want to get permission from the person who first thought of the concept before I dive head first into it.

And that about covers it! Thanks for reading, and if there’s anything you’d like to see from Sterling and I, don’t hesitate to drop us an ask!

#furby#allfurby#furblr#botblr#custom furby#how tos#the doctor speaks#long post#science isn't about why... it's about why not

25 notes

·

View notes

Text

Wifi HaLoW Devices Market - Forecast (2022 - 2027)

WI-FIHaLow Devices market size was valued at 5.6 million units in 2020 and it is estimated to grow at a CAGR of 12.6% during 2021-2026. The growth can be attributed to the adoption of Wi-Fi HaLow devices across various industries due to its ability to offer long range connectivity at low cost, low power consumption, and avail high data speed as compared to others. Furthermore, its ability to provide network in dead zones, better battery life, higher scalability, simple installation process are the main market drivers. Wi-fi HaLow technology’s ability to penetrate through walls, buildings or other barriers is also considered as an important factor contributing to the market growth. This technology supports a carrier-sense multiple access with collision avoidance (CSMA/CA) which acts to prevent collision before it occurs. This in turn, increases the adoption rate of this technology. In addition, it also supports machine to machine communication, various types of adaptive coding and modulation (ACM) schemes that are progressively being used to increase the network capacity or downlink data rates. This is a major contributing factor to the market growth.

Report Coverage

The report: “Wi-Fi HaLow Devices Market Forecast (2021-2026)”, by IndustryARC, covers an in-depth analysis of the following segments of the Wi-Fi HaLow Devices Market.

By device type: Transceiver, Chipsets, Modules, and others.

By application: Industrial sensor network systems, smart security surveillance, building automation, smart agriculture, connected vehicles, home automation, digital healthcare system, industrial automation and others.

By end user industry : power, oil & gas, automotive, healthcare, mining, agriculture, waste water & treatment, transportation & logistics, electronics & semiconductors, metal processing, general manufacturing, paper & pulp, Construction and others.

By geography: North America (US, Canada, Mexico),Europe (Germany, France, UK, Italy, Spain, Rest of Europe), APAC (Japan, China, India, Australia, South Korea, rest of APAC), South America (Brazil, Argentina, rest of South America), and RoW (Africa, Middle East)

Request Sample

Key Takeaways

Agriculture sector is analyzed to grow with a significant pace during the forecast period, owing to increasing demand for IoT, connected devices and digital platforms in agricultural sector.

By device type, chipsets market is estimated to witness the fastest growth, owing to the rising investments and collaboration among the organizations.

North America dominated the Wi-Fi HaLow Devices market in terms of value in 2020 owing to its technological advancement and having the ideal operating ISM band.

The market's ability to provide network coverage to dead zones works as a growth driver.

Wi-Fi HaLow industry outlook is consolidated with the top market players including NEWRACOM Inc., AdvanWISE, Morse Micro Pty. Ltd., Methods2Busines B.V., Silex Technology and many others.

By device type, this market is segmented into Transceiver, Chipsets, Modules, and others. Wi-Fi HaLow chipsets market is analyzed to grow with the fastest CAGR of 15.5%

during the forecast period. Organizations are collaborating and investing heavily for the development of this market. In June 2019, NEWRACOM had collaborated with Fortune tech system in order to provide world’s first miniaturized HaLow solution built on Raspberry Pi 3. This product is highly integral and equipped with NEWRACOM’S 802.11ah WI-FI-SoC. This solution can be used in various IoT applications such as smart home, smart office, smart industry, smart city, healthcare sectors, smart grid, security systems, smart controllers, smart motors and others. In March 2021, LitePoint collaborated with Morse Micro to accelerate the connectivity of Wi-Fi HaLow. LitePoint IQxel-MWTM also validates the performance of the Morse Micro System-on-Chip family. These types of collaborations will drive the WiFi HaLow module market in the forecast period 2021-2026.

Inquiry Before Buying

WI-FI HaLow Devices Market Segment Analysis- By Device Type

By device type, this market is segmented into Transceiver, Chipsets, Modules, and others. Wi-Fi HaLow chipsets market is analyzed to grow with the fastest CAGR of 15.5% during the forecast period. Organizations are collaborating and investing heavily for the development of this market. In June 2019, NEWRACOM had collaborated with Fortune tech system in order to provide world’s first miniaturized HaLow solution built on Raspberry Pi 3. This product is highly integral and equipped with NEWRACOM’S 802.11ah WI-FI-SoC. This solution can be used in various IoT applications such as smart home, smart office, smart industry, smart city, healthcare sectors, smart grid, security systems, smart controllers, smart motors and others. In March 2021, LitePoint collaborated with Morse Micro to accelerate the connectivity of Wi-Fi HaLow. LitePoint IQxel-MWTM also validates the performance of the Morse Micro System-on-Chip family. These types of collaborations will drive the WiFi HaLow module market in the forecast period 2021-2026.

WI-FI HaLow Devices Market Segment Analysis- By End-User Industry

The WI-FI HaLow market is segmented into power, oil & gas, automotive, healthcare, mining, agriculture, waste water & treatment, transportation & logistics, electronics & semiconductors, metal processing, general manufacturing, paper & pulp, Construction and others, based on the end-used industry. Healthcare WI-FI HaLow device Market is estimated to witness a highest growth CAGR 18.1% during forecast period 2021-2026 owing to its ability to provide real time information about a patient’s health condition and their location. The demand for reliable communication system and a quick access to patient’s medical record facilitates the adoption of IoT in this sector. Thereby, increases the demand for WI-FI HaLow. These features make HaLow devices ideal for healthcare sector in which getting real time information is a pertinent feature. The current Covid-19 pandemic has accelerated the growth in demand for digital health care services such as smart monitoring, tele-health services, tele-medicine services, personal fitness wearable devices, elderly monitoring and others, which in-fact created various new growth avenues for Wi-Fi HaLow based devices. The above mentioned factors will play a major role in the market growth.

WI-FI HaLow Devices Market Segment Analysis- By Geography

North America dominated the Wi-Fi HaLow Devices market in 2020 with a share close to 38%, and is estimated that the market of this region is also going to witness highest growth during the forecast period. WI-FI HaLow has different radio spectrum allocation for different countries. The band ranges for different countries are 902-928MHz in U.S., 863-868 MHz in Europe, 717-723 MHz in Korea, 755-787 MHz in China and many countries do not even have an operating frequency spectrum. The only operating ISM band for HaLow product is 900 MHz, which makes HaLow a U.S. centric product which drives the North American market.

Schedule a Call

WI-FI HaLow Devices Market Drivers

Network Connectivity:

Wi-Fi HaLow builds on spectral efficient orthogonal frequency-division multiplexing (OFDM) foundations and operates in frequency bands below one gigahertz due to which, it can offer a prolonged use, as it consumes less power and connectivity to Wi-Fi products. These features make HaLow devices ideal for short and burst data which is particularly used for IoT applications. Apart from this, it can provide network connectivity even to those places where the cellular networks or the traditional Wi-Fi connectivity can’t reach such as dead zones, subways, hilly areas, typical rural areas, deep inside the buildings and others which makes HaLow ideal for smart home, digital health care services, connected cars, smart city as well as industrial application. It also uses direct-sequence spread spectrum (DSSS), that effectively helps this technology to avoid intentional interference such as jamming and performs better than FHSS in the presence of noise that makes it perfectly suitable for security related applications.

Increasing Investment and Development in WI-FI HaLoW:

The investment in WI-FI HaLow is anticipated to grow rapidly due to the tremendous level of development and innovation scope for this technology. In November 2020, Australia based company, Morse Micro had secured additional $13 million fund to accelerate WIFI HaLow development. In November 2020, Scenestek came up with the first skyline technology based Wi-Fi HaLow security camera with 1000 foot range. It can easily penetrate through walls, buildings and the installation process is super easy. It is said that the world wide shipping will start from April or May 2021. Recent developments and increasing investment in Wi-Fi HaLow are working as growth drivers for this market.

Buy Now

Wi-FiHaLow Devices Market Challenges

Availability of beneficial alternatives:

The launch of the 802.11ax alongside the launch of Wi-Fi HaLow had a distinct adverse effect on the market of Wi-Fi HaLow. 802.11ax solutions that were more in demand than 802.11ah or HaLow solutions because unlike HaLow, it had a standard frequency spectrum which makes them cost effective. Similarly, there has been a perceptible increase in the demand and the investment for 5g and LTE IoT products, leaving almost no resources for HaLow market to grow which is a major market challenge for WI-FI HaLow.

WI-FI HaLow Devices Market Landscape

Technology launches, Acquisitions, Collaboration, and R&D activities are key strategies adopted by players in the Wi-FiHaLow Devicesmarket. Top Wi-Fi HaLow Devices companies include NEWRACOM Inc., AdvanWISE, Morse Micro Pty. Ltd., Methods2Busines B.V., Silex Technology, Palma CeiaSemiDesign, Inc., Scenestek technology, Adapt-IP and others.

Acquisitions/Technology Launches

In February 2020, Silex technology collaborated with Newracom and launched industries first WIFI HaLow module, SX-NEWAH. Powered by NEWRACOM's NRC7292 system on a chip, SX-NEWAH operates in the Sub 1 GHz licensed band and enables 1 km+ long connectivity range while maintaining the low power requirement.

In August 2019, Adapt-IP had announced the availability of their newly developed platform for WI-FI HaLow Development. This is available for the integrators and developers of IoT market. This platform supports the IEEE 802.11ah standards and offers a hardware and software environment for development.

For more Electronics related reports, please click here

#WI-FI#WI-FI HaLow Devices Market#WI-FI HaLow Devices Market share#WI-FI HaLow Devices Market trends#WI-FI HaLow Devices Market size#WI-FI HaLow Devices Market analysis

1 note

·

View note

Text

Small servo motor arduino

Small servo motor arduino driver#

In fact, you can even stack multiple Motor HATs, up to 32 of them, for controlling up to 64 stepper motors or 128 DC motors (or a mix of the two) - just remember to purchase and solder in a stacking header instead of the one we include. Only two pins (SDA & SCL) are required to drive the multiple motors, and since it's I2C you can also connect any other I2C devices or HATs to the same pins. This chip handles all the motor and speed controls over I2C.

Small servo motor arduino driver#

Since the Raspberry Pi does not have a lot of PWM pins, we use a fully-dedicated PWM driver chip onboard to both control motor direction and speed. Raspberry Pi and motors are not included. This Raspberry Pi add-on is perfect for any motion project as it can drive up to 4 DC or 2 Stepper motors with full PWM speed control. Let your robotic dreams come true with the new DC Stepper Motor HAT from Adafruit. How to control a ULN2003 stepper motor with Raspberry Pi Suitable for microcontroller developmentĭimensions: 1.38 in x 1.18 in x 0.39 in (3.5 cm x 3.0 cm x 1.0 cm) High quality stepper motor with ULN2003 driver The board also comes with an ON/OFF jumper to isolate power to the stepper Motor. They provide a nice visual when stepping. The board has four LEDs that show activity on the four control input lines (to indicate stepping state). Four out of seven pairs are used on this board. The ULN2003 is one of the most common motor driver ICs, consisting of an array of 7 Darlington transistor pairs, each pair is capable of driving loads of up to 500mA and 50V. The power consumption of the motor is around 240mA. In addition, the motor has a 1/64 reduction gear set. That means there are 32 steps per revolution (360°/11.25° = 32). The 28BYJ-48 motor runs in full step mode, each step corresponds to a rotation of 11.25°. The maximum speed for a 28byj-48 stepper motor is roughly 10-15 rpm at 5 V.

0 notes

Text

I see the light tangled on keyboard

I see the light tangled on keyboard driver#

I see the light tangled on keyboard portable#

I see the light tangled on keyboard android#

In truth, it’s hard to see it as anything but a gaming PC. It’s got water cooling, RGB LED lighting, and an ATX power supply, all of which happen to be mounted inside a flashy computer case complete with a clear window. Posted in Arduino Hacks, Robots Hacks Tagged 3d printed, python, robot arm, robotics, scara, stepper motorĪt first glance, you might think the piece of hardware pictured here is a modern gaming computer. This looks like something that you could reasonably assemble and program over a weekend or two, and then put to work in your ad-hoc PPE factory. We’ve seen some impressive 3D printed robotic arms over the years, but the simplicity of the PyBot is particularly compelling. As the name implies, the PyBot is controlled by Python tools running on the computer, so it should be relatively easy to get this capable arm to do your bidding. But if you wanted to build your own version from the parts bin, you could certainly wire up all the principle components manually. In the base of the arm is a custom control board that combines an Arduino M0, an ESP8266, and a trio of stepper motor drivers. By default it features a simple gripper, but that can easily be changed out for whatever tool or gadget you have in mind. But while that robot was designed to carry an extruder and act as a 3D printer, intends for the PyBot to be more of a general purpose platform. Those who’ve researched similar projects might notice that the design of this arm has clearly been influenced by the Mostly Printed SCARA (MPSCARA). A custom control board keeps the wiring tight. Smooth rods, linear bearings, lead screws, and NEMA 17 motors are all exceptionally cheap these days thanks to the innumerable 3D printer kits that make use of them. One could argue that this is a project made entirely possible by desktop 3D printing as not only are most of the structural components printed, but most of the mechanical elements are common 3D printer parts. The PyBot designed by is an open source robotic arm that should be well within the means of the average hardware hacker. Unless of course, you’re willing to build it yourself. Unfortunately, while the prices for things like 3D printers and oscilloscopes have dropped lower than what many would have believed possible a decade ago, high-performance robotics are still too pricey for the home player. We’ve all seen videos of blisteringly fast SCARA arms working on assembly lines, and more than a few of us have fantasied about having that same kind of technology for the home shop.

I see the light tangled on keyboard portable#

Posted in Raspberry Pi Tagged portable computer, rugged raspberry pi, ruggedized It could also be a nice compartment to keep your RTL-SDR for some mobile radio work.įor those that don’t mind spending name-brand money and have access to a 3D printer, the Raspberry Pi Quick Kit by is another great way to get yourself a rough and tumble Pi without reinventing the wheel. We especially like the large open area that he’s kept around the Raspberry Pi’s ports that allow you to easily hook up to the network or plug in a flash drive.

I see the light tangled on keyboard android#

Rounding out the build, found a cheap Android phone case that included a tiny USB keyboard which plugs right into the Pi and he’s looking to add a BlackBerry trackball to the setup down the line. As for the display, the nine inch LCD is perfectly sized to press fit into the lid. Of course if you have access to the appropriate tools, you could certainly cut the plate out of something stouter. The “carbon fiber” sticker he put on the PVC sheet won’t do much for the structural integrity of the build, but it sure looks nice.

I see the light tangled on keyboard driver#

Most of the effort involves cutting the PVC foam sheet that holds the Raspberry Pi, battery pack, and the driver board for the LCD in the bottom of the $15 USD case managed to track down on AliExpress. Short of just buying one of these rigs pre-built from somebody, it’s hard to imagine it could get much easier than this. You could even do it without soldering anything, if you really wanted to. You don’t need a CNC to cut out any face plates or a 3D printer to create an internal framework for all your components. Inspired by these builds but looking to make it even easier and cheaper to roll your own version, recently took the wraps off of what he calls the Militarish Pi. Especially if you can avoid popping any holes in the side. It’s not hard to see why whether you spring for the Pelican case or get a cheaper alternative, these water-tight cases are far stronger than anything you’re going to 3D print or otherwise cobble together in the home shop. Over the last year we’ve seen a wave of portable computer builds that center around the Raspberry Pi taking up residence inside a commercial heavy-duty storage case.

0 notes