#Remote I/O Modul

Explore tagged Tumblr posts

Text

Enhancing Textile Machinery Efficiency with Messung's NX-ERA Xpress PLC

The textile industry, being a part of global manufacturing, has witnessed a massive transformation in recent years due to accelerated technological advancements. From yarn making to dyeing yarns with complex patterns, each process of textile production has been streamlined for higher productivity, accuracy, and efficiency. The need for high-quality products and shorter production cycles has generated fertile ground for automation, especially with the use of Programmable Logic Controllers (PLCs)in textile manufacturing.

This is where we at Messung Industrial Automation come in the picture with our cutting-edge automation solutions. With our strong heritage of delivering strong and scalable automation solutions, we have been the industry leader in industrial automation. Our innovative and compact PLC, NX-ERA Xpress has been crafted to specifically address the specific requirements of industries such as textile manufacturingwith the ideal combination of performance, flexibility, and energy efficiency. In this blog, let’s explore the revolutionary potential of NX-ERA Xpress PLCand its impact on textile machinery, with an emphasis on how it improves operational efficiency, cuts costs, and accelerates the journey towards Industry 4.0.

The Role of PLCs in Modern Textile Manufacturing

Programmable Logic Controllers (PLCs) form the foundation of automation in textile manufacturing, especially in the "cotton to yarn" and "yarn to fabric" segments where their role is most critical. These rugged, industrial-grade controllers ensure precision, speed, and efficiency by managing machinery and processes in real time. From ginning and bale plucking to spinning, carding, drawframe, combing, ring frame machines, and autoconers, PLCs are deeply embedded in every stage of the cotton-to-yarn journey.

In the yarn-to-fabric sector, PLCs continue to play a significant role in the operation of warping machines, twisting machines, and various types of looms such as shuttle, airjet, and rapier looms. They are equally vital in fabric processing lines, managing singeing, bleaching, dyeing, and a wide range of finishing machines designed to enhance textile properties like softness, wrinkle resistance, or water repellency. Printing lines, including rotary and flat bed printing machines, also rely heavily on PLC-controlled automation.

Across these applications, PLCs are integrated with Human Machine Interfaces (HMI), Variable Frequency Drives (VFDs), and in high-speed machines like spinning lines, Servo amplifiers and Servo motors are used for superior speed and torque control.

While the garment sector (fabric to garment) does involve automation, Messung’s core expertise and solutions, including the NX-ERA Xpress PLC and NX-ERA Jet PLC, are primarily focused on the earlier and more automation-intensive stages of textile manufacturing.

Benefits of Implementing PLCs on Textile Machinery

Increased Efficiency: PLCs allow streamline operations by automating processes that were previously manual, significantly reducing downtime and increasing throughput

Improved Accuracy: The high-level precision control afforded by PLCs ensures each activity in the fabric process, whether spinning or weaving, is undertaken with perfection.

Real-Time Monitoring: PLC-based systems make equipment monitoring in real-time a certainty, where defects are flagged off early and avoid costly downtime along with plant operation performance improvements.

As the textile industry advances, compact PLCs are not an indulgence but a must-have. Automation is the key to staying competitive, and industrial automation PLC systems like the NX-ERA Xpress are at the forefront of this revolution.

Learning More About NX-ERA Xpress PLC

The NX-ERA Xpress PLC is our response to the increasing needs of the textile industry. By harnessing the capability of Programmable Logic Control Systems and the flexibility of contemporary communication protocols, the NX-ERA Xpress provides a powerful and scalable solution for numerous industrial automation applications.

Features of NX-ERA Xpress PLC:

High-Density Digital and Analog I/O: The NX-ERA Xpress PLC features a high-density I/O design that is capable of processing vast amounts of data input and output at one time. This is important for the textile industry, where real-time data from many machines need to be processed efficiently in order to optimize performance.

Programming through Codesys® (IEC 61131 Standard): Among the most impressive aspects of the NX-ERA Xpress PLC is its support for Codesys®, an open-source programming platform. This standardization enables seamless integration with industrial equipment across the board, which makes it an attractive option for PLC manufacturing companies.

Integrated Communication Protocols: With inbuilt compatibility for communication protocols such as Ethernet TCP/IP, Modbus, and CANopen, the NX-ERA Xpress PLC facilitates smooth connectivity among various machines and devices on the shop floor. This connectivity is vital for ensuring smooth operation throughout the complete manufacturing process.

Industry 4.0 Readiness: NX-ERA Xpress PLC comes with OPC-UA and MQTT readiness, making it Industry 4.0-ready. These are technologies that support data exchange over different platforms, and they simplify the integration of machines by manufacturers into a smart factory environment.

Integrated HTML Web Server for Remote Monitoring: Remote monitoring has never been simpler. The integrated HTML web server enables operators to monitor and control the PLC remotely, offering flexibility and real-time visibility into machine performance.

The high-performance features and compact PLC design of NX-ERA Xpress PLC make it perfect for the textile industry. Whether you're automating cotton spinning, weaving, or dyeing, the NX-ERA Xpress provides all the power you need to optimize your operations.

Advantages of NX-ERA Xpress in Textile Applications

The textile industry requires solutions that are capable of providing not just high performance but also cost-effectiveness and sustainability. Our NX-ERA Xpress PLC provides a number of benefits for applications in textile machinery, such as:

Energy Efficiency

In the textile industry, energy consumption is a major operational expense. The NX-ERA Xpress PLC is built to maximize control and minimize power consumption, especially in power-hungry processes such as spinning. Through automation processes and optimizing machine efficiency, the PLC ensures textile plants make substantial savings on energy.

High-Speed Processing

Textile production processes often involve rapid and adaptive control systems that are necessary for handling high-speed manufacturing lines. The processing of high speeds facilitated by the NX-ERA Xpress PLC helps data move faster to provide instant adjustment capabilities, ensuring minimum lags in manufacturing processes.

Precision Control

The clothing industry is based on the effective control of variables like thread tension, fabric alignment, and dying processes. NX-ERA Xpress PLC ensures accurate control in order to match every parameter in the manufacturing process to the prescribed specifications. The result is repetitive product quality, and less it is defective.

Scalability

As textile factories develop and expand, scalable automation systems become increasingly relevant. NX-ERA Xpress PLC uses a modular construction that means that automation systems can be expanded as they are required by manufacturers, presenting a great solution for expanding businesses in the textile industry in the long term.

Cost-Effectiveness

Automation must not be expensive. The NX-ERA Xpress PLC is an affordable solution for textile producers that offers high-end features without an exorbitant price tag. It is meant to offer high-performance at an affordable rate, so any textile firm can use it.

Textile Machinery Applications: PLC Precision for a Modern Mill

As textile factories embrace digital transformation, the NX-ERA Xpress PLC emerges as a compact yet powerful solution tailored for automation-ready textile machinery. With its robust control features and Industry 4.0 connectivity, the NX-ERA Xpress brings intelligence and agility to a wide range of textile processes.

Let’s explore key use cases across the textile value chain:

Yarn Steaming Machine:

Steaming is a critical stage in yarn preparation where temperature, pressure, and timing must work in harmony. The NX-ERA Xpress PLC ensures:

Precise control of temperature and steam pressure for consistent yarn conditioning

Regulation of steaming duration to match different yarn types and production speeds

Automation of loading and unloading mechanisms, reducing manual intervention and boosting throughput

With its real-time responsiveness and compact design, the NX-ERA Xpress PLC enhances efficiency, consistency, and reliability in yarn steaming operations.

Heat Setting and Space Dyeing Machine Integration:

In advanced textile finishing, seamless integration between heat setting and dyeing is essential. NX-ERA Xpress PLC brings synchronization and control to:

Temperature management for precise heat setting, improving dimensional stability and dye fixation

Control of dye application in the space dyeing process, enabling unique patterns with consistent results

Coordination of material flow between machines, ensuring smooth transitions and avoiding process bottlenecks

The result is an integrated, high-performance workflow for specialty dyeing applications, digitally governed for optimal output and reduced waste.

Integration with Messung's Automation Ecosystem

One of the major strengths of the NX-ERA Xpress PLC is that it can integrate smoothly with all our other products, like the XM-PRO remote I/O modules. This makes it possible to have a unified automation solution that simplifies the control and monitoring of your entire textile plant.

With a single provider for all automation needs, textile manufacturers can enjoy streamlined operations, reduced complexity, and improved support. The synergy between the NX-ERA Xpress PLC and our other products ensures that your factory is fully equipped to tackle the challenges of modern textile manufacturing.

Conclusion

In summary, our NX-ERA Xpress PLC is a game-changer in the textile sector, providing powerful, scalable, and affordable automation. With its high-performance capabilities, energy efficiency, and accurate control, the NX-ERA Xpress PLC is ideally positioned to address the changing needs of textile producers.

With the NX-ERA Xpress PLC, you can elevate your textile manufacturing process to the next level. Whether you want to optimize spinning, weaving, or dyeing processes, Messung's automation solutions provide the reliability and performance that you require to remain ahead in a competitive market.

So, why wait? Consult Messung today for a customized automation solutionthat suits your textile manufacturing needs. It’s time to embrace the future of textile production with the NX-ERA Xpress PLC - where automation meets innovation

#textile manufacturers#Programmable Logic Controllers (PLCs)#textile manufacturinG#cutting-edge automation solutions#compact PLC#NX-ERA Xpress PLC#textile machinery#Industry 4.0#spinning#carding#drawframe#combing#ring frame machines#autoconers#singeing#bleaching#dyeing#PLC-controlled automation.#NX-ERA Jet PLC#industrial automation#PLC systems#IEC 61131 Standard#Ethernet TCP/IP#Modbus#CANopen#cotton spinning#automation processes#remote I/O modules#automation needs#customized automation solution

0 notes

Text

The industrial landscape is undergoing a metamorphosis, driven by the transformative power of the Internet of Things (IoT) and the dawn of Industry 4.0. At the heart of this revolution lies seamless communication between a myriad of machines and devices that populate the factory floor. This symphony of data exchange hinges on two crucial technologies: Remote Input/Output (I/O) modules and Industrial IoT (IIoT) Gateways. Let's delve into the intricate dance between these technologies and how they unlock the true potential of Industry 4.0.

Demystifying Remote I/O Modules

In today's era of smart work, remote I/O modules serve as extended hands for the factory's control system, enabling signal collection and control from sensors and actuators spread throughout the facility. Connected to a central controller via communication protocols like Modbus or Ethernet, these modules enable real-time monitoring and control, even for distant locations within the factory.

IIoT Gateways: The Vital Link

IIoT Gateways serve as the critical bridge between the bustling industrial world and the ever-evolving information age. IIoT Gateways are devices that serve as intermediaries between sensors, machines, and the cloud in Industrial Internet of Things (IIoT) systems. These gateways collect, process, and transmit data from connected devices to cloud-based platforms for analysis and action. IIoT Gateways play a crucial role in facilitating real-time monitoring, analysis, and control of industrial processes, leading to improved efficiency, productivity, and decision-making in manufacturing environments.

The Power of Integration

Visualise an expansive factory floor adorned with strategically placed sensors and actuators. Remote I/O modules, serving as the backbone, seamlessly collect data from these dispersed devices. The IIoT Gateway assumes the role of the central nervous system, consolidating data from multiple remote I/O modules and perfectly transmitting it to the "brain" – cloud-based analytics and control applications. This harmonious integration heralds a new era of possibilities for Industry 4.0

0 notes

Text

Importance of Using Industry 4.0 Sensors: Check Pros!

Industry 4.0 sensors have become fundamental instruments in many industries, particularly manufacturing, automotive, and logistics. In manufacturing, these technologies provide real-time monitoring of the manufacturing processes, early identify the potential risk of equipment failure, and reduce downtime.

Similarly, logistics companies take advantage of 4.0 sensors and remote I/O modules because these devices permit efficient inventory scheduling, route optimisation, and tracking of items in transit, leading to cost savings and higher customer satisfaction.

In the automobile industry, they enable predictive maintenance, maintain continuous operations and improve vehicle safety.

Pros and Cons of Using Advanced 4.0 Sensors and I/O Modules:

Well-established technical module suppliers deliver top-notch quality advanced human-automation technical solutions to increase productivity, process optimisation, predictive maintenance, proactive decision-making, and performance improvement.

Although, many businesses often think about initial implementation costs, and potential job displacement due to automation, as considered as a few cons of implementing advanced technology like I/O modules or 4.0 sensors.

Despite these difficulties, the overall benefits of employing such technology usually surpass the drawbacks, especially when implemented by lab-tested top-notch quality devices and properly handled by experts.

Well-established suppliers of these advanced human-machine interfaces, provide appropriate training for skill development to operate and optimise the devices along with solving any potential challenges associated with implementing these advanced technologies.

These technologies improve operations, maximise efficiency, and immediate updates on machine health to minimise downtime.

It also enables preventative maintenance processes and simplifies data-driven decision-making.

They allow businesses to respond quickly to changing market demands, increase product quality, and maintain a competitive edge in the industry.

These solutions enable smart businesses to make and carry out quality decisions with minimal human intervention.

They will have a better opportunity to begin integrating 4.0 sensor practices, procedures, and technology than practising traditional technology.

Therefore, businesses should contact only reliable services that can guide them to implement advanced technologies with certification in advanced technical training and control.

How to Find a Trusted Supplier of Advanced Technology Supplier?

It requires thorough research and study to find a reliable supplier of advanced technology like 4.0 sensors or I/O modules.

Identify reliable manufacturers with a demonstrated track record of creating high-quality HMIs.

Consider product reliability, customisation choices, interoperability with existing systems, and after-sales assistance.

Read client testimonials and case studies to determine satisfaction levels. Again, seek guidance from industry counterparts and engage with HMI technology experts.

Contact suppliers to get comprehensive technical support, regular updates, and warranties.

Finally, check and compare overall services, pricing, and customer service, and select the most dependable supplier for your business needs.

Source

0 notes

Text

Interesting Papers for Week 21, 2025

Gustatory cortex neurons perform reliability-dependent integration of multisensory flavor inputs. Allar, I. B., Hua, A., Rowland, B. A., & Maier, J. X. (2025). Current Biology, 35(3), 600-611.e3.

Complex harmonics reveal low-dimensional manifolds of critical brain dynamics. Deco, G., Sanz Perl, Y., & Kringelbach, M. L. (2025). Physical Review E, 111(1), 014410.

Context-dependent decision-making in the primate hippocampal–prefrontal circuit. Elston, T. W., & Wallis, J. D. (2025). Nature Neuroscience, 28(2), 374–382.

Applied Motor Noise Affects Specific Learning Mechanisms during Short-Term Adaptation to Novel Movement Dynamics. Foray, K., Zhou, W., Fitzgerald, J., Gianferrara, P. G., & Joiner, W. M. (2025). eNeuro, 12(1), ENEURO.0100-24.2024.

Touch-evoked traveling waves establish a translaminar spacetime code. Gonzales, D. L., Khan, H. F., Keri, H. V. S., Yadav, S., Steward, C., Muller, L. E., Pluta, S. R., & Jayant, K. (2025). Science Advances, 11(5).

A distinct hypothalamus–habenula circuit governs risk preference. Groos, D., Reuss, A. M., Rupprecht, P., Stachniak, T., Lewis, C., Han, S., Roggenbach, A., Sturman, O., Sych, Y., Wieckhorst, M., Bohacek, J., Karayannis, T., Aguzzi, A., & Helmchen, F. (2025). Nature Neuroscience, 28(2), 361–373.

Sensorimotor environment but not task rule reconfigures population dynamics in rhesus monkey posterior parietal cortex. Guo, H., Kuang, S., & Gail, A. (2025). Nature Communications, 16, 1116.

Dendritic growth and synaptic organization from activity-independent cues and local activity-dependent plasticity. Kirchner, J. H., Euler, L., Fritz, I., Ferreira Castro, A., & Gjorgjieva, J. (2025). eLife, 12, 87527.3.

Prediction of future input explains lateral connectivity in primary visual cortex. Klavinskis-Whiting, S., Fristed, E., Singer, Y., Iacaruso, M. F., King, A. J., & Harper, N. S. (2025). Current Biology, 35(3), 530-541.e5.

Reconstructing a new hippocampal engram for systems reconsolidation and remote memory updating. Lei, B., Kang, B., Hao, Y., Yang, H., Zhong, Z., Zhai, Z., & Zhong, Y. (2025). Neuron, 113(3), 471-485.e6.

Sensorimotor adaptation reveals systematic biases in 3D perception. Lim, C., Vishwanath, D., & Domini, F. (2025). Scientific Reports, 15, 3847.

Enhanced accuracy in first-spike coding using current-based adaptive LIF neuron. Liu, S., & Dragotti, P. L. (2025). Neural Networks, 184, 107043.

Overwriting an instinct: Visual cortex instructs learning to suppress fear responses. Mederos, S., Blakely, P., Vissers, N., Clopath, C., & Hofer, S. B. (2025). Science, 387(6734), 682–688.

Neural mechanisms of relational learning and fast knowledge reassembly in plastic neural networks. Miconi, T., & Kay, K. (2025). Nature Neuroscience, 28(2), 406–414.

Dynamical constraints on neural population activity. Oby, E. R., Degenhart, A. D., Grigsby, E. M., Motiwala, A., McClain, N. T., Marino, P. J., Yu, B. M., & Batista, A. P. (2025). Nature Neuroscience, 28(2), 383–393.

Dendritic excitations govern back-propagation via a spike-rate accelerometer. Park, P., Wong-Campos, J. D., Itkis, D. G., Lee, B. H., Qi, Y., Davis, H. C., Antin, B., Pasarkar, A., Grimm, J. B., Plutkis, S. E., Holland, K. L., Paninski, L., Lavis, L. D., & Cohen, A. E. (2025). Nature Communications, 16, 1333.

The developmental emergence of reliable cortical representations. Trägenap, S., Whitney, D. E., Fitzpatrick, D., & Kaschube, M. (2025). Nature Neuroscience, 28(2), 394–405.

Opposite asymmetry in visual perception of humans and macaques. Tünçok, E., Kiorpes, L., & Carrasco, M. (2025). Current Biology, 35(3), 681-687.e4.

Attention modulates subjective time perception across eye movements. Yan, C., Wang, H., Jiang, X., & Wang, Z. (2025). Vision Research, 227, 108540.

Dissociating the roles of alpha oscillation sub-bands in visual working memory. Zhao, N., & Liu, Q. (2025). NeuroImage, 307, 121028.

#neuroscience#science#research#brain science#scientific publications#cognitive science#neurobiology#cognition#psychophysics#neurons#neural computation#neural networks#computational neuroscience

19 notes

·

View notes

Text

Shortwave Radiogram 403

9356 kHz 2330z reception was bad so I can only bring you text tonight!

@swradiogram

Welcome to program 403 of Shortwave Radiogram.

I'm Kim Andrew Elliott in Arlington, Virginia USA.

Here is the lineup for today's program, in MFSK modes as noted:

1:42 MFSK32: Program preview (now) 2:55 MFSK32: Papua New Guinea to reintroduce shortwave* 5:52 MFSK64: VOA shutdown hits harder in Turkey* 11:01 MFSK64: This week's images* 24:53 MFSK32: Closing announcements

with image(s)

Please send reception reports to [email protected]

And visit http://swradiogram.net

We're on Bluesky now: SWRadiogram.bsky.social

And X/Twitter: @SWRadiogram

tnone0j b . . . . .

From Radio New Zealand

PNG's national broadcaster moves to reintroduce shortwave radio for nationwide coverage by 2030

24 May 2025

Papua New Guinea's National Broadcasting Corporation (NBC) is aiming to reintrivshejtrave radio to achieve the government's goal of 100 percent broadcast coverage by 2030.

This week, the state owned broadcaster hosted a workshop on the reintroduction of shortwave radio transmission, bringing together key government agencies and other stakeholders.

NBC managing director Kora Nou said the proposed reintroduction of shortwave radio can only be achieved through a collaborative effort.

He said it is important because it ensures remote communities have access to timely news and information.

NBC's executive director (engineering) Seloka Lewangu explained the importance of shortwave, while making a comparison with Frequency Modulation [FM], Shortwave, and Mediumwave transmission.

"FM is line of sight. If you see the tower, you receive the signal. If you don't see the tower, you don't receive the signal," he said.

"Medium Wave has a wider coverage compared to FM. Coverage for FM is more for cities and towns.

"When you talk about medium wave, you talk regional now.

"When you talk shortwave, you talk countrywide. That's why we are talking. If shortwave can do it for us, with all our rugged mountains and scattered islands."

This transition is timely and important for wider coverage, as it will enable broader and more reliable broadcast reach across the country's rugged terrain.

NBC also believes this shift will reduce dependency on costly hardware, making maintenance and upgrades easier while ensuring improved emergency communication and public awareness.

https:¹Miaohetfiom/2yga7bv3

tRWenftvb&

Shortwave Radiogram now changes to MFSK64 …

ist| e o

Rf0PCzsi Before RSID: <<2025-05-29T23:35Z MFSK-32 @ 9265000+1500>>

uotnnec R r0

This is Shortwave Radiogram in MFSK64

Please send your reception report to [email protected]

tR tec ud wt . . . . .

From Deutsche Welle …

US public media shutdown hits harder in Turkey iug /¸Ûðzbek May 25, 2025

President Trump's shutdown of Voice eO KP p tx is particularly tough on countries like Turkey, where press freedom is dtc e;r. It was one of the only places to goáanced coverage of Turkish-US relations, users say.

US President Donald Trump's shutdown of US media outlet Voice o@d>Btolaror VOA, has had a particularly strong impact in countries like Turkey where press freedom has long been under threat.

As a result of the Trum yKitration's defunding of the US government-funded internonal news service on March 14, the organization has effec7kee erations. News websites in all languages have not been updated for more than two months. Broadcasts on television and radio have either stopped completely or switched to music-only programming.

B feeepending service, VOA, which was often one of the rare soqoces nqyewkyored news in countries like Turkey, broadcast in 49 languages to a weekly audience estimated at 354 million people worldwide.

Banned in 5ÏoivutFoo6¼ eoµhere approximately 90% of major media outlets are government-controlled, banned access to the Turkish-language website of VOA in 2022, alongside Utanguage versions of Deutsche Welle, or DW. Since then, R eâ6j2n trying to reach its :H cen Turkey via a "mirror" webacte that f tb% uced the content of the original plsioorott1€” until Trump shuttered the broadcaster completely in mid-March.

Media rights group Reporters Without Borders, or RSF, ros Turkey 159th out of 180 countries in it025 World Press Freedom Index, citing ongoing repression of journalists. There are currently 17 jouts in prôon ¯ TurkXöoøYims0 ËT representative Ernm1k » oglu toåyl±ioternatio nal m §b0nizations like VOA, the BBC and DW have emerged as "constructive" role models in recent years, as the country's increasi¿i tged press environment has seen a significant decline in qualitEèCºRoolÔ

The Turkish-language services of international broadcasters gained prominence as independent media in Turkey have diminished. Their newsrooms are basei ¬ road but the language services also employ a small number of reporters within the country.

"VOA has also played an important role in opening the voice of Turkey's civil society movement and journalism community to the outside world and breaking the effects of isolation," Onderoglu said.

VOA Turkish was one of the most important sources for audiences in Turkey, especially regarding developments between Ankara and Washington.

"Whenever there was a development in the US that could put the Erdogan government in a difficult position — for instance, an allegation that could leadr®tctions on Turkey over Iran — the first website I would check was VOA's," one of VOA's Turkish audience told DW.

Journalists at risk

Following Trump's decision to halt federal funding to the parent agency of VOA, most of the Washington-based news service's roughly 1,300 staffers were placed on administrative leave as a first step toward terminatiocoab± A group of VOA employees affected by the March executive order has filed a lawsuit against the Trump administration, accusing the president of executive overreach. A federal appeals court in early May blockedoitwg4ac t the Trump administration to Ýro· employees back to work.

Following the appeal court's decision on World Press Freedom Day, the Trump administration has accelerated efforts to carry out the layoffs.

Nearly 600 contractors, who received termination notices on May 15, were instructed to return their press crjuatials, badges and other VOA property by May 30. Some affected employees are J-1 visa holders and face imminent deportation, with only 3iays to leave the US.

VOA D<Kkxel Abramowitz, also one of the plaintiffs in the court case, said that many of those journalists "have escaped tyranny in their home countries to tell America's story of freedom and democracy."

On Thursday, Abramowitz noted that the May 3 decision remained in effect after the appeals court rejected a request for an en banc review — a full reconsideration by all eleRuouAdges — and warned that the Trumpo3noC oa push for further layoffs.

An unwanted vÉ kM' silenced

Speaking to DW, a Turkey-based VOA employee recalled the day the broadcaster abruptly shut down operations: "Our colleagues in Washington were asked to vacate their offices during working hours. Their badges were seized. They didn't even wait for the end of the day. News operations came to a sudden halt. We couldn't even complete the reports we were Or £ng on."

The journalist, who spoke on conditiof anonymity, said that VOA stood out in a media environment increasingly under pressure from "an authoritarian regime."

"It was percdetF 0srL`oeOo the ruling party, facing both access bans and smear campaigns by pro-government»r u}lì ìrgeting VOA staff. In that sense, it's likelyz HfëPernment welcomed the shutdownXvpCu· they said.

The VOA has also produced broadcasts critical of tbecgigov&nments, theX²iu6eo vple, when experts criticized the US in analyses of Turkish-American relnºnhtakh comments were never x4bWed."

Trump's 'war' on journalism

AntrXhcjrnard, director of advocacy and strategic litigation at RSF, told DW that Trump's attempts to shut down VOA must be Lrstood in the larger context of "his war on the press."

"He has targetvw efb jdf, launched politically motivated investieDtions into media he doesn'Ztike, and b¯noLjournalists from the White House for refusing to use the exact words he wants them to use. Quite simply, he does not tolerate independent media", he said.

RSF recently warned of "an alarming deterioration in press it o in the US under President Trump. The organization highlighted how Trump exacerbated already difficult conditions by cutting off US financial support for state-funded broadcasters ãwMDc s VOA and Radio Free Europe/Radio Liberty (RFE/RL).

Earlier this month, Trump signed yet another executive order seeking to slash funding for the US' Public Broadcasting Service, or PBS and National Public Radio, or NPR. The Trump administration also launched Federal Communi? Iyemify¿on/ deàstigations into major media outlets, including ABC News, CBS News, PBS and NPR.

te ha etnwnr e %äÀviÈpt,. . . .

Thip8xooLeave Radiogram in MFSK64

Please send your reception report to [email protected]

This week's images …

werubh. . . . .

The installation "Err eB;y cing the annual Vivid Sydney festival in Auhtra×M {inyurl.com/25yxnfel …

tR tk9³R tn Sending Pic:201x135C;

2 notes

·

View notes

Text

Was the moon landing fake using CGI? No, this idea is impossible

(picture from the Apollo 11 moon landing Wikipedia Page)

There is an interesting theory that says the moon landing by the crew of Apollo 11 was filmed using Computer-generated imagery or in a studio on Earth.

I am not sure where these people get their ideas from as Computer-generated imagery (CGI) at the time was not that good. In fact, it was rubbish, and not that convincing, you can see examples of this in the picture and the article below, entitled The History of CGI in the Movies.,

Also, movie special effects in the 1960s were mostly done by models, animation, or other practical methods, not computers.

(Picture above from article "8 Bit Sprites to WebGL: How Computer Graphics Have Changed the World" a link to this article can be found in the reference section of this blog post)

They also did not film it in a movie set on Earth, as the lighting and movements of the Astronauts would be all wrong. It could have only been filmed on the moon.

As to the question, some moon landing deniers used in the past to justify their claims, which is

"How did they film the Astronauts coming out of the landing module or LM, as no Astronauts got out at this stage"

This issue can easily be solved by the fact that there was a remote camera mounted to the side of the landing module, or LM, which was moved into position and started filming before the astronauts got out.

(The weird ideas that moon consistency theorists have can be easily researched and easily debunked, probably even by a child moon landing fan as it is that easy and not hard to understand.)

This proves that consistency theory people do not know anything about the subject they are debunking and don't even have a basic understanding of history, science, or photography for, that matter.

Below is an interesting video by the MythBusters as they dismantle ideas, followed by moon landing deniers.

Also, check out photographer Dave McKeegan's video and his YouTube channel below, where he debunks moon landing theory claims, especially the claims that the pictures and videos of the moon landing were faked on Earth.

youtube

Dave McKeegan

References:

Apollo 11 - Wikipedia

Moon landing conspiracy theories - Wikipedia

Moon landing conspiracy theories debunked

The History of CGI in Movies

8-Bit Sprites to WebGL: How Computer Graphics Have Changed the World

Take note, consistency theory, people, maybe the meme below mocking you is correct, and the meme below shows 1980s CGI, not 1960s

Also, check out my history blog version

#moon landing#history#apollo 11#cgi#technology#Youtube#compuer graphics#special effects#space#science#moon

4 notes

·

View notes

Text

Low-Power Design Strategies with Renesas SOM and AMD Ryzen Embedded 8000

In the evolving landscape of embedded systems, low-power design has become a pivotal element, especially in sectors where energy efficiency is crucial. Devices operating in remote locations, battery-operated modules, or environments with strict thermal limitations benefit greatly from components that prioritize low energy consumption without sacrificing performance. The challenge is to maintain computational integrity and feature-richness while adhering to power budgets. With the increasing demand for edge computing and real-time data processing, the importance of efficient power management strategies has grown.

Modern embedded platforms are rising to meet these demands. Companies now offer sophisticated System-on-Modules (SOMs) that are tailored to deliver high performance in compact, energy-efficient packages. Among the industry leaders, Renesas and AMD have produced highly capable platforms that balance performance and power efficiency. Specifically, the Renesas SOM and AMD Ryzen Embedded 8000 family present compelling options for developers who need to address the growing constraints of power, space, and thermal design.

This article explores comprehensive strategies for low-power design using these two platforms. It will delve into hardware-level tactics, software optimizations, and application-level considerations, offering a roadmap for engineers seeking to create efficient and resilient embedded solutions.

The Fundamentals of Low-Power Design

Understanding Power Consumption in Embedded Systems

Power consumption in embedded systems is influenced by a variety of factors, ranging from the silicon architecture and process technology to system software and workload management. In general, total power usage can be broken down into dynamic and static power components. Dynamic power relates to the active switching of transistors, which occurs during computational tasks, while static power is associated with leakage currents when the system is idle.

Key contributors to power consumption include CPU usage, memory access, peripheral activity, and I/O operations. Managing these factors requires a holistic approach, incorporating both hardware selection and software design. Techniques like clock gating, voltage scaling, and power domain management are crucial at the hardware level. Meanwhile, efficient coding practices, power-aware scheduling, and judicious use of peripherals can significantly reduce software-induced power drain.

Designing for low power is not a one-size-fits-all approach. It demands a thorough understanding of the system's operational context. What kind of tasks will the system perform? How frequently will it be active? What are the thermal and energy constraints? Only by answering these questions can designers effectively implement strategies that deliver optimal energy efficiency.

The Role of SOMs in Power Efficiency

System-on-Modules (SOMs) simplify the design of complex embedded systems by integrating processors, memory, and essential interfaces into a single module. This modularity accelerates development and reduces risk, but it also opens opportunities for enhanced power efficiency. SOMs can be engineered with features like dynamic voltage scaling, sleep modes, and modular power domains, all of which contribute to lower energy consumption.

The advantage of using SOMs in low-power applications lies in their configurability. Developers can tailor system performance to match the needs of the application, reducing unnecessary power draw. For instance, a device that performs periodic sensor readings can be designed to spend most of its time in low-power standby mode, waking only when necessary.

Moreover, leading SOM platforms incorporate advanced power management ICs (PMICs) and firmware-level support for power-saving features. These systems are often pre-validated for compliance with low-power standards, enabling developers to focus more on application-specific challenges rather than the intricacies of power management.

Hardware-Level Power Optimization

Efficient Component Selection

Choosing components with inherent power-saving features is a foundational step in low-power design. Processors, memory modules, and peripherals should be evaluated not just on performance but also on their power profiles. Multi-core CPUs with independent power domains, LPDDR memory, and low-leakage I/O controllers can contribute significantly to reducing system power consumption.

Beyond the core components, developers should consider the power characteristics of secondary elements like voltage regulators, clock sources, and sensors. Devices that support dynamic power scaling and offer idle or sleep modes are preferable. It's also important to use components from the same vendor family or ecosystem, as these are more likely to have coordinated power management features.

For embedded systems expected to operate under variable loads, components with wide dynamic performance ranges are especially valuable. These allow the system to scale its power consumption in real-time based on the workload, avoiding the inefficiencies of static, high-power configurations.

Power Domains and Isolation

Power domains refer to independently controlled sections of an integrated circuit or system that can be powered on or off depending on system requirements. Utilizing power domains allows certain parts of the system to be shut down when not in use, thereby conserving energy.

For example, in a multimedia processing unit, the video encoder might only be powered during active video capture, while remaining dormant the rest of the time. Isolating these functions into distinct power domains ensures that energy isn't wasted on unused circuitry. Modern processors, including those used in the Renesas SOM and AMD Ryzen Embedded 8000, support sophisticated power domain architectures.

Effective use of power domains requires coordination between hardware and firmware. Developers must design software routines that can trigger domain transitions without disrupting system stability. Careful planning is required to handle wake-up events, ensure data integrity, and manage timing delays associated with power cycling.

Software Strategies for Power Management

Dynamic Voltage and Frequency Scaling (DVFS)

DVFS is a powerful software-controlled mechanism that adjusts the voltage and frequency of a processor based on workload demands. When high performance is needed, the processor runs at higher frequencies and voltages. During idle or low-load periods, the system scales down to conserve energy.

This technique is widely supported in modern embedded platforms and often integrated into the operating system’s power management framework. Linux, for example, includes governors like "ondemand" and "conservative" that manage DVFS in real time. Custom policies can also be implemented to match specific application profiles.

However, DVFS must be applied judiciously. Frequent transitions between power states can introduce latency and increase wear on components. The key is to balance responsiveness with efficiency, ensuring that the system remains agile without excessive energy costs. Profiling tools and telemetry data can aid developers in fine-tuning DVFS parameters for optimal results.

Efficient Task Scheduling

Task scheduling plays a significant role in power consumption. By organizing computational tasks efficiently, systems can spend more time in low-power states. Techniques such as batching similar operations, aligning wake-up intervals, and prioritizing critical tasks help reduce CPU wake cycles and context switching overhead.

Real-time operating systems (RTOS) and middleware frameworks often provide hooks for power-aware scheduling. These include APIs to manage sleep modes, delay operations, and synchronize peripheral activity. Developers should leverage these capabilities to ensure that tasks are executed only when necessary.

Power-aware task scheduling becomes particularly important in systems with multiple execution contexts or peripherals. For instance, sensor data collection, communication, and UI updates can be coordinated to occur in clusters, allowing the processor to return to sleep mode between activity bursts. This coordinated scheduling is crucial for extending battery life in portable and remote devices.

Peripheral and System-Level Considerations

Smart Peripheral Management

Peripherals can be significant sources of power consumption, especially when left in active states unnecessarily. Smart peripheral management involves configuring devices to enter low-power or idle modes when not in use and waking them only as needed.

This approach often requires a combination of hardware support and software control. Many modern peripherals include built-in support for sleep states, wake-on-interrupt features, and programmable thresholds. Developers must ensure that system firmware is capable of managing these modes without introducing latency or instability.

Moreover, communication interfaces like I2C, SPI, and UART can be optimized for power by adjusting clock rates, using DMA transfers, and disabling unused channels. For systems with wireless connectivity, aggressive management of radio transceivers is essential, as these can rapidly deplete energy reserves.

Thermal and Mechanical Design

Thermal management is closely linked to power efficiency. Excessive heat can not only degrade performance but also lead to higher leakage currents and premature component failure. Designing systems with efficient thermal paths—such as heat sinks, spreaders, and airflow considerations—can reduce the need for active cooling, which consumes additional power.

Mechanical design also plays a role in optimizing power use. Enclosures should be engineered to support passive cooling, minimize dust ingress, and facilitate modular expansion without excessive overhead. Compact designs with integrated shielding can also reduce EMI, improving system stability and reducing the need for error correction processing that adds to the power burden.

Battery and Power Supply Design

For battery-operated systems, choosing the right battery technology and capacity is essential. Lithium-ion, LiFePO4, and other advanced chemistries offer different trade-offs in terms of energy density, discharge rates, and lifespan. The power supply circuitry should be optimized for efficiency, using synchronous regulators, low-dropout converters, and energy-harvesting technologies where applicable.

Accurate battery monitoring, including state-of-charge and health estimation, enables better power budgeting and prevents unexpected shutdowns. These metrics can also feed into the software power management algorithms, allowing dynamic adjustments based on available energy reserves.

Practical Applications and Case Studies

Industrial Automation

In industrial environments, embedded systems often operate in harsh conditions where reliability and power efficiency are critical. Systems may be deployed in locations with limited access to power or require uninterrupted operation during outages. Using platforms like the Renesas SOM allows engineers to design solutions that are both robust and energy-efficient.

For example, programmable logic controllers (PLCs) and remote sensor hubs can benefit from the SOM's low-power sleep modes and fast wake-up capabilities. These features enable real-time data acquisition and processing without maintaining full system activity. Energy savings compound over time, resulting in lower operational costs and improved system longevity.

Smart Surveillance Systems

Modern surveillance systems require high-performance processing for video analytics, yet must operate reliably in various environmental conditions. Here, the AMD Ryzen Embedded 8000 excels by offering a combination of CPU and GPU performance within a manageable power envelope.

These systems can dynamically adjust processing workloads based on motion detection or event triggers. When no motion is detected, the system scales down or enters a low-power state. When activity resumes, the full processing power becomes available to analyze footage and perform recognition tasks. This approach significantly reduces the energy footprint without compromising surveillance capabilities.

Portable Medical Devices

Portable medical devices present stringent requirements for power efficiency, accuracy, and reliability. Whether it's patient monitoring equipment or diagnostic tools, these devices must function for extended periods on battery power. The Renesas SOM offers a practical foundation for such applications.

Its support for advanced power management features, along with its compact form factor, enables the creation of lightweight, energy-efficient devices. Developers can implement task-based scheduling to manage sensors, displays, and communications in a way that prioritizes critical functionality while preserving battery life. In regulated markets, the added reliability of a tested SOM platform also simplifies certification and compliance efforts.

Conclusion

Low-power design is no longer a niche requirement—it is an essential discipline in embedded systems engineering. As devices become more autonomous, connected, and pervasive, the need to manage power consumption grows in tandem. System-on-Modules like the Renesas SOM and AMD Ryzen Embedded 8000 represent the forefront of this evolution, offering the performance developers need alongside the efficiency that modern applications demand.

By combining hardware capabilities with intelligent software design and system-level planning, engineers can create embedded solutions that are both powerful and sustainable. The strategies discussed in this article provide a blueprint for approaching low-power design holistically, ensuring that every component and line of code contributes to energy-conscious innovation.

0 notes

Text

BL335 + Node-Red = The Ultimate Industrial IoT Combo!

BL335: The Industrial-Grade ARM Computer Built for Node-Red - Perfect Balance of Performance and Cost!

In the fields of industrial automation and IoT, Node-Red has become the go-to tool for rapid development of data acquisition, protocol conversion, and edge computing, thanks to its visual programming and low-code features. However, not all hardware is perfectly suited for Node-Red—some are over-spec���d and wasteful, while others lack the necessary resources for smooth operation.

Beilai Technology' s ARMxy BL335 Industrial Computer, with its Node-Red-optimized hardware design, is the ideal choice for industrial users! It delivers smooth performance, rock-solid reliability, and competitive pricing to meet diverse industrial needs.

Why is the BL335 the Best Industrial Computer for Node-Red?

1. Dual-Core A7 Processor – Just the Right Performance

2× ARM Cortex-A7 @1.2GHz, optimized for lightweight applications—Node-Red runs smoothly without lag.

Unlike overpowered quad/octa-core processors, the dual-core A7 design avoids wasted resources, balancing performance and cost efficiency.

2. RAM & ROM Perfectly Matched for Node-Red

512MB/1GB DDR3 RAM, fully meeting Node-Red’s long-term stability requirements (recommended ≥512MB).

4GB/8GB eMMC storage, ensuring ample space for the OS, Node-Red, and data storage without bottlenecks.

3. Pre-Installed Node-Red, Ready Out of the Box

Comes with Ubuntu/Linux + Node-Red pre-installed—power it up and start developing immediately.

Pre-configured system images enable rapid deployment, significantly shortening project timelines.

4. Dedicated Node-Red Technical Support Team

Bairen Technology provides Node-Red application examples, development guides, and customized support to help users get started quickly.

Stuck with protocol conversion or data collection? Our expert team offers real-time remote assistance!

5. Rich Serial & Network Ports for Easy Data Acquisition

Optional 4-8x RS485/RS232 ports, supporting Modbus RTU, DL/T645, and other industrial protocols.

Dual Ethernet (Gigabit + Fast Ethernet), compatible with TCP/IP, MQTT, OPC UA, and more for flexible device integration.

6. Industrial-Grade Stability for 24/7 Reliability

Fully isolated serial ports & independent hardware watchdog prevent crashes, ensuring long-term stable operation.

Wide-temperature design (-40℃~85℃), built to withstand harsh industrial environments.

7. Flexible Expansion for Diverse Needs

Optional DI/DO, CAN, GPIO, AI/AO modules for seamless connectivity with PLCs, sensors, actuators, and more.

4,000+ I/O combinations—customize your setup without overspending.

8. Optimized Hardware, Unbeatable Value

A refined hardware design that perfectly balances performance, stability, and cost.

Priced at just 60%~70% of comparable solutions, making industrial IoT more accessible than ever!

BL335 + Node-Red = The Ultimate Industrial IoT Combo!

✅ Data Acquisition: Easily connect PLCs, meters, and sensors with support for Modbus, CAN, MQTT, and more.

✅ Edge Computing: Local data processing reduces cloud dependency and network costs.

✅ Protocol Conversion: Use BLIoTLink software to quickly integrate with SCADA, Alibaba Cloud, Huawei Cloud, and other platforms.

✅ Remote Maintenance: BLRAT tool enables remote debugging, cutting on-site service costs.

Experience the Power of BL335 for Node-Red Today!

Website: www.BLIIoT.com

Free technical evaluations & industry solutions available!

Let BL335 be your ultimate Node-Red partner—low cost, high efficiency, and the perfect engine for industrial IoT! 🚀

0 notes

Text

Allen-bradley 1771-asb Remote I/O Adapter Module - Auto2mation

The Allen-Bradley 1771-ASB Remote I/O Adapter Module is a reliable solution for connecting I/O chassis to PLC systems. Designed for high-speed data exchange, it supports smooth communication between the processor and remote I/O devices. This module is ideal for industrial automation applications, ensuring accurate and timely data transfer. Easy to install in 1771 I/O chassis, it offers solid performance and durability.Perfect for upgrading or maintaining your control systems, this adapter module helps improve efficiency and reduce downtime in industrial environments. Shop now for fast delivery.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#equipment#automation equipment#industrial automation applications#Manufacturing#Allen-bradley#Adapter#io module

0 notes

Text

Powering the Production Line: Messung’s NX-ERA PLCs in Automotive Material Handling

In automotive manufacturing, precision isn’t a luxury, it’s a necessity. From chassis and engine assembly lines to the press shop and paint line, seamless material handling is critical to keeping production on track. Whether it’s coordinating conveyors, pick-and-place systems, or synchronizing with robotic cells, the need for intelligent control is constant.

Messung’s NX-ERA PLCs deliver this control with unmatched flexibility. With native support for Modbus TCP/IP, Ethernet/IP, EtherCAT, OPC-UA, and IO-Link, they enable high-speed communication across robots, HMIs, VFDs, servo amplifiers, and central SCADA systems. Plus, with remote I/O modules and protocols like CANopen, our PLCs handle large-scale, distributed inputs and outputs effortlessly. Simply put, NX-ERA makes advanced, synchronized automation easy, even in the most demanding environments.

What is Material Handling in the Automotive Industry?

Material handling in the automotive industry involves the movement, positioning, storage, safety, and tracking of components and assemblies throughout the production process—from the arrival of raw materials to the final stages of vehicle assembly. Efficiency here is critical; any delay or misstep can disrupt the entire manufacturing flow.

Key areas such as the chassis and engine assembly lines, along with the press shop and paint line, rely heavily on sophisticated material handling systems, including conveyors, pick-and-place machines, and robotics, to keep production moving seamlessly. These systems must operate in perfect sync, often across large, distributed areas with thousands of I/O points.

The Brain Behind the Brawn: NX-ERA PLCs

Our state-of-the-art NX-ERA PLCs including the NX-ERA Xpress and NX-ERA Jet, are compact PLCs designed for high-speed, reliable control. These programmable logic control systems are the heart of any automated material handling system. By offering real-time control, seamless connectivity, and robust communication protocols like Modbus TCP/IP, Ethernet/IP, EtherCAT, OPC-UA, and IO-Link. They interface effortlessly with robots, HMIs, VFDs, servo amplifiers, and centralized SCADA systems, ensuring reliability and scalability.

Here are some of its most impactful features:

High-Speed Processing Power

The core point of NX-ERA PLCs is that they are capable of real-time processing. These robot systems run as fast as your machinery, and the synchronization is important for the overall efficiency of the system. This compact PLC will guarantee flawless optimization for every aspect of the bottling line, be it controlling the work of conveyors or robotic manipulation.

Modular Design for Flexibility

The greatest feature of the NX-ERA PLC is its modular design. Production plants in the automotive industry often aim for some form of adaptability, and, thus, this feature is very helpful. It allows the installation to expand while the business is developing. The implementation of modularity means that the system can be integrated with any new equipment, production units, or additional features to ensure that there will be no disruption to the system performance.

Integrated I/O Modules for Streamlined Setup

Our smart and compact PLC integration contains integrated I/O modules that reduce installation and wiring times, thus also focusing on the fast-paced phenomenon in the automotive industry. For simplification of the things, input/output capabilities are now directly included in the integrated PLC system, which substantially reduces the external wiring as a result of which the setting up is speedier and less prone to mistakes.

Advanced Web Server Capabilities

It is safe to say that we are far off the days when engineers would have to be on site for them to physically track and diagnose issues on the factory floor. The capability of the built-in web pages of our NX-ERA PLC allows easy remote access for getting the actual real-time state of the diagnostics and monitoring. This feature is incredibly important in an industry that operates around the clock, as it allows maintenance teams to resolve issues remotely, reducing downtime and keeping things running smoothly.

The Role of the NX-ERA PLCs in Material Handling

In the automotive industry, material handling is integral to the success of the production process. From raw materials to semi-finished goods, and finally to finished products, materials need to be handled with precision. Automation is key to achieving this, and Messung’s NX-ERA PLCs are designed to make this process as efficient and effective as possible.

Here is how it is done:

Conveyor Systems Optimization

Conveyor systems, which carry parts between the workstations and at the same time keep the production continuously running, are the most popular form of material handling in the automotive plants. NX-ERA PLCs make sure that the system, no matter what, functions without any breaks by adjusting the speed of the conveyors to fit the pace of production. The real-time processing feature ensures that the system in question becomes flexible almost immediately, providing the assembly line without any interruptions and preventing the end line packing in the last round.

Predictive Maintenance to Maximize Uptime

The predictive maintenance of the system is seen as the golden nugget to maximize uptime. For the maintenance of a plant, having machines down during their run time is quite expensive. In the automotive industry, where the production rates run on a very tight schedule, even a moment's disruption would mean substantial losses. Our PLC Systems use a predictive maintenance system to keep a continuous check on the condition of the equipment. The control system will be equipped with predictive maintenance, which can track the system performance, increasing the change in predicting when maintenance is needed before failure occurs. These stains would reduce chances of equipment going down and also increase whole equipment machines productivity performance.

Power Management for Material Handling Equipment

How NX-ERA PLCs Integrate with SCADA Systems

Industrial automation relies not just on PLCs but also on supervisory control and data acquisition (SCADA) systems to monitor and control large-scale operations. The integration of NX-ERA PLCs with SCADA applications enhances material handling capabilities by providing plant operators with real-time insights into the performance of material handling equipment.

Real-Time Visualization and Data Monitoring

Data gathered from the cluster of service line sensors are then monitored by SCADA systems through real-time visualization and data troubling. By means of the material handling systems' connecting to the SCADA applications, operators are able to visualize every operation stage on a single interface. Our NX-ERA PLC assists the SCADA system in a way that allows real-time data visualization. As for plant automation, this integration enables the operators to redesign the production line and fabricate the survey that they are in full command, including the conveyor speed, robotic movement, and electrical power consumption.

Alarming and Fault Diagnostics

Unexpected malfunctions are a part of any complex system, but SCADA and PLC integration ensures they are dealt with swiftly. The NX-ERA PLC can send alerts to SCADA systems when material handling equipment encounters an issue, whether it’s a malfunction in a conveyor belt, a sensor failure in a robotic arm, or an electrical fault. This proactive approach helps resolve issues before they lead to extended downtime.

Historical data analysis for continuous improvement

Other benefits of integrating the SCADA system with the NX-ERA PLC is to have an ability to analyse historical data. These past data performances can better help the plant managers to see trends, adjust production schedules, and improve the efficiency of the material-handling systems over the long period. In actuality, the PLC saves and disposes of necessary data. This information, then, is fed into the SCADA system and used for analysis and presentation purposes.

The Future of Material Handling with NX-ERA PLCs

As the automotive industry embraces Industry 4.0, NX-ERA PLCs are positioned at the forefront of the shift towards smarter, more connected manufacturing systems. This is brought about by switching to smarter, more connected production systems. Thanks to NX-ERA PLCs, which are able to integrate with SCADA applications, robots, and power supplies, you can now easily build a factory that can quickly adapt to changes in the current demand and the production process.

Benefits Include:

More automation and efficiency with the increasing factories

As factories become more automated, the role of PLCs like the NX-ERA will only grow. The future of material handling will rely on even more precise and automated systems, from fully autonomous robots to smart conveyors that adjust their speed and behavior based on real-time conditions. The NX-ERA PLC is ready to support this evolution with its high-speed processing and robust integration capabilities.

Energy Management and Sustainability

Green manufacturing is a critical concern for the industry today. Automotive manufacturers demand advanced NX-ERA PLCs in a bid to bring down the environmental impact of the production. An essential element that plays a pivotal role in power solutions, predictive maintenance, and derived data for operational efficiency is a way for these to reduce the consumption of energy.

Real-Time Data and IoT Connectivity

With the rise of the Internet of Things (IoT) in manufacturing, NX-ERA PLCs will continue to integrate with a broader network of connected devices. This real-time data flow will empower automotive plants to make more informed decisions and improve their material handling systems.

Conclusion: The Future of Material Handling in the Automotive Industry

In the race for efficiency and innovation, Messung’s NX-ERA PLCs are the pit crew that keeps material handling equipment running at peak performance. Their combination of advanced features, modular design, and seamless integration with SCADA systems positions them as the ideal solution for automotive manufacturers aiming to stay ahead of the competition.

As automotive plants move towards smarter, more automated manufacturing processes, the need for reliable, high-performing PLCs like the NX-ERA will only continue to grow. By embracing the capabilities of Messung’s NX-ERA PLCs, automotive manufacturers can ensure that their material handling systems operate efficiently, sustainably, and with minimal downtime, ultimately contributing to the ongoing success of the industry.

In this fast-paced industry where precision is the name of the game, Messung’s NX-ERA PLCs are the game changers that automotive manufacturers need to optimize their material handling systems and maintain a competitive edge in the global market.

#chassis and engine assembly lines#Modbus TCP/IP#Ethernet/IP#EtherCAT#OPC-UA#remote I/O modules#CANopen#compact PLCs#programmable logic control systems#SCADA systems#automotive industry#PLC system#material handling#PLC Systems#material handling systems#SCADA applications#PLC integration#Automotive manufacturers#Internet of Things (IoT)

0 notes

Text

In today's industrial setup , efficiency reigns supreme. Businesses are constantly seeking ways to streamline processes, boost productivity, and gain a competitive edge. Here’s how Remote I/O modules are changing the perspective. These intelligent devices act as the crucial link between your central control system and the vast network of sensors and actuators spread across your factory floor. But Remote I/Os are no longer just simple data collectors. The latest advancements are revolutionising the way the operations used to be optimised , and let’s take a look at how Instrutel, a frontrunner in industrial automation solutions, is being part of this change.

Remote I/O Modules: The Backbone of Industrial Automation

Remote I/O modules serve as distributed workstations for your central control system. Imagine them as miniature control centres strategically placed near sensors and actuators throughout your facility. These modules collect data from sensors (inputs) like temperature, pressure, or flow rates, and send control signals (outputs) to actuators like motors, valves, and pumps. This eliminates the need for complex, sprawling wiring systems, simplifying plant layout and maintenance.

The Future Technology and Trends in Remote I/Os

The future of Remote I/O modules is brimming with exciting possibilities, driven by advancements in various technological domains. Here's a closer look at some key trends shaping the landscape:

1. Edge Computing and Analytics:

● Traditional Remote I/O modules primarily focus on data collection and transmission. However, the future lies in edge computing. This empowers Remote I/O modules to process and analyse data locally, closer to the source. Imagine modules performing basic anomaly detection or predictive maintenance calculations, enabling faster response times and proactive decision-making.

0 notes

Text

Rockwell Automation 5034 PointMax I/O Modules

youtube

The PointMax I/O architecture provides a wide range of input and output modules to span many applications, such as machine, hybrid, and process control. The architecture uses Producer/Consumer technology that allows input information and output status to be shared among multiple Logix 5000 controllers. PointMax I/O systems are used as remote I/O modules with Logix 5000 controllers. You configure the modules with the Studio 5000 Logix Designer application.

#automation#trending#tumblr trends#viral#bestdeals#trendingnow#viralpost#rockwell automation#allen bradley#plc#5034#pointmax#input module#outputmodule#5000Logix Controller#inputmodule#industry#information technology#technology techpage#software#Youtube

1 note

·

View note

Text

Fire Alarm Systems: Safeguarding Settings Thru Premature Sensors

In any preparing, health and safety may be a goal, together with open fire alert solutions stand up as the necessary part of the fact that health and safety. Those solutions are designed to deliver premature sensors together with rapid word of caution in the case of a good open fire, getting consumers the key point in time should be evacuate together with making it possible for hasty unexpected solution. Irrespective of whether from a your home, office environment, faculty, or simply alternative area, open fire compare home security systems assistance preserve resides together with real estate with the single most threatening together with erratic potential risks.

A good open fire burglar alarm prepares food by finding any appeal for smoke a pipe, heat up, or simply fire, after which you can alerting residents thru excessive may seem, flashing equipment, or simply tone reports. The chief motive is certainly making sure that most people during the setting up is responsive to any chance without delay, including a good reliable together with planned evacuation.

Different kinds of open fire alert solutions can be bought to accomodate many setting up themes together with health and safety necessities. Certain are meant meant for minor settings, whilst others are made meant for great, challenging buildings in the area. What precisely everyone own in common may be a look into monthly interaction together with consistency. Anytime matched utilizing unexpected the amount of light together with straightforward evacuation projects, those solutions end up additional valuable.

Fashionable open fire alert systems has got grown in adding shrewd options together with integration utilizing many other health and safety tools. At this time, countless solutions will get connected to sprinkler solutions, aware unexpected products easily, and be monitored remotely. The volume of automation together with interconnectivity magnifies any acceleration together with efficacy within the complete solution in a open fire unexpected.

Habit test together with care for open fire alert solutions crucial. In time, receptors will get dust particles, battery pack could possibly suffer a loss of ability, together with electrical could possibly decline. Usual bank checks be certain that the system attributes thoroughly when it is the majority important. To blame property holders together with area leaders come up with product care a priority in avoiding wrong compare home security systems together with product outages.

In a good many regions, open fire alert solutions may not be basically recommended—they're within the law demanded. Setting up regulations together with open fire health and safety policies regularly mandate any unit installation together with care of them solutions, mainly in public homes together with multi-residential real estate. Deference would ensure don't just health and safety but will also stays away from opportunity suitable together with money repercussions.

In due course, a good open fire burglar alarm is certainly more than a home gym; it can be a necessary line of shield alongside a good overwhelming party FireClass FC410MIO - Multi I/O Module - 555.800.765. It all creates assurance that will residents together with exhibits an intense obligation that will health and safety. Any appeal associated with a well-performing product often means any main difference somewhere between a good listed car accident in addition to a traumatic events.

Methods, open fire alert solutions would definitely be a building block for fashionable open fire health and safety. Your job during premature sensors, super fast notification, together with coordinated solution is certainly imperative. Anytime thoroughly established together with kept, these deliver mainly because private protectors—ready to act once possibility originates.

0 notes

Text

How to Hire a Linux Kernel Developer: Skills, Experience & Interview Questions

Linux powers everything from web servers to embedded devices, and its core lies at Linux Kernel - a crucial layer that demands deep expertise for modification, maintenance, and optimization. For tech companies that are building high-performance systems, device drivers, or custom operating environments the decision to hire software developers proficient in Linux Kernel can be a strategic move.

But kernel development is a niche skill and to hire the right developer requires you to know what to look for and to ask the right questions. In this article, we will cover how you can do it.

Finding the Right Low-Level Expert for High-Performance Systems

Kernel engineers bridge the gap between user-level apps and hardware by working at the lowest software layer. Frequently, when hiring Linux kernel developers, you often want to:

Patch or modify the kernel to work with particular hardware.

Create or troubleshoot device drivers.

Boost system efficiency or lower delay.

Assure mission-critical systems' security and stability.

This isn't how applications are usually developed. It calls for a solid understanding of memory management, operating systems, and the nuances of C programming.

Key Skills to Look For

Give these crucial areas top priority while vetting applicants:

Proficiency in C: Since C is used for nearly all kernel development, in-depth expertise is non negotiable.

Kernel module experience: Applicants should be able to write, compile, and load kernel modules.

Tools for Debugging and Profiling: It's crucial to be familiar with programs like gdb, perf, and ftrace.

Knowledge of OS Internals: Key ideas include scheduling, memory management, and I/O systems.

Version Control & Patch Submissions: It is highly advantageous to contribute to open-source projects or the mainline Linux kernel.

A candidate's ability to communicate effectively across time zones and accurately document their work is also essential if you're looking to hire remote developers.

Where to Find Talent

Using conventional methods to hire Linux kernel developers isn't always simple. These engineers frequently contribute to specialized communities like Git repositories and kernel mailing groups, or they work on open-source projects.

Some tech companies decide to collaborate with organizations that focus on low-level software development or embedded technologies. Others seek to hire programmers who possess a solid foundation in C and OS, then train them in kernel-specific techniques.

Interview Questions to Ask

After you've found a good applicant, probe further with focused questions:

What distinguishes user space from kernel space?

How would a production system's kernel panic be debugged?

Could you describe the Linux kernel's memory allocation mechanism?

Have you submitted bug fixes or patches to the mainline kernel?

How are dependencies between kernel modules managed?

What function does the Linux kernel's scheduler serve?

Asking them to describe a recent kernel-related project, including its objectives, tools, and methods for testing and validating their work, is another option.

Summing Up

You must know exactly what your system needs and what kernel experience will provide it in order to hire Linux kernel engineers. The correct hire adds dependability, speed, and profound technical understanding to everything from driver creation to system optimization.

These developers are essential to tech companies creating scalable and secure infrastructure. Whether you're looking to hire remote developers or in-house developers, a careful, skills-based strategy can help you find the best fit.

0 notes

Text

How Advanced Components Like the 1769-L24ER-QBFC1B and Industrial Ethernet Switches Are Shaping Smarter Automation

Industrial automation continues to evolve, with modern facilities prioritizing real-time communication, precise control, and seamless device integration. From intelligent controllers to advanced networking gear, the foundation of smart manufacturing relies heavily on dependable hardware. Among the standout tools enabling this transformation are the 1769-L24ER-QBFC1B, the compact yet powerful Allen Bradley controller series, versatile Industrial Ethernet Switches, and legacy-supporting adapters like the 1784-U2DHP.

Why Controllers Like the 1769-L24ER-QBFC1B Matter

Tight control over machine processes starts with the right logic controller. The 1769-L24ER-QBFC1B, part of Allen Bradley's CompactLogix line, is built for integrated motion and control applications. Offering embedded digital, analog, and high-speed counter I/O, this controller is particularly effective in systems where space is limited, but versatility cannot be compromised.

Its dual Ethernet ports support device-level ring topologies, adding fault tolerance and reducing downtime—a critical factor in high-output environments.

The Role of a Modern Allen Bradley Controller in Scalable Systems

Modern automation isn’t just about basic on/off control; it's about data-driven decisions, predictive maintenance, and remote diagnostics. The Allen Bradley controller family—such as the 5069-L320ERMS3—brings high-speed processing, built-in safety, and seamless integration with Studio 5000 software, supporting everything from packaging lines to advanced robotics. These controllers enable synchronized motion, streamlined programming, and scalable deployment.

Reliable Communication Starts with Industrial Ethernet Switches

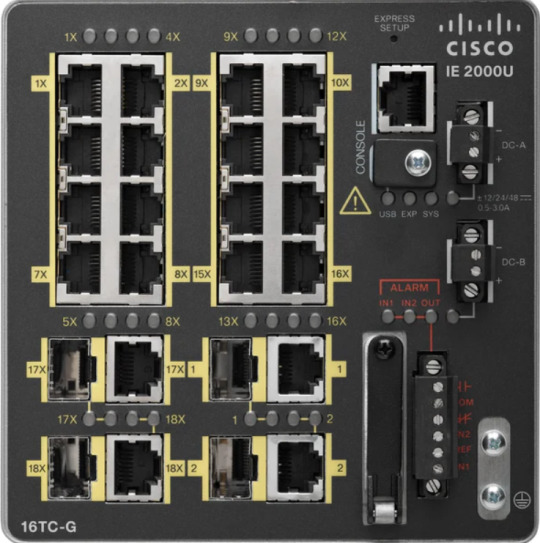

Data flow across industrial networks must be both fast and secure. That’s where an Industrial Ethernet Switch like the Cisco IE-2000-16TC-G-E comes into play. Engineered for harsh environments, this switch features robust build quality and supports advanced switching protocols like QoS and VLANs—ensuring smooth traffic management even in network-heavy setups.

In automation systems where devices like HMIs, PLCs, and I/O modules constantly communicate, an industrial-grade switch ensures that data isn’t just fast—it’s also reliable and isolated from disruptions.

Bridging the Gap with 1784-U2DHP

While modern systems lean on Ethernet-based protocols, many plants still operate legacy systems that use older communication methods like Data Highway Plus (DH+). The 1784-U2DHP adapter serves as a bridge, allowing USB-equipped laptops to interface with DH+ networks. It provides essential diagnostic and programming access to older equipment, extending the lifecycle of valuable assets and supporting a phased modernization strategy.

Final Thoughts

Industrial control systems today demand more than just speed—they need resilience, flexibility, and smart connectivity. From an intuitive Allen Bradley controller like the 1769-L24ER-QBFC1B to rugged Industrial Ethernet Switches and legacy support tools like the 1784-U2DHP, these technologies together form the backbone of intelligent automation systems.

0 notes