#Sorting machine

Explore tagged Tumblr posts

Text

Pi Day

In honor of Pi Day, let us remember the New Pi developed by Bloody Stupid Johnson.

Wait, you don't know who that is?

Well, in the Terry Pratchett book Going Postal, the Discworld's most infamous inventor "Bloody Stupid" Johnson built the Ankh-Morpork Post Office a mail-sorting machine, whose parts included a wheel with the circumference of pi. Pi, as we know, is "three and a bit", but Johnson thought that was messy, so he built a wheel where pi equaled exactly 3. According to some wizards, the machine twists the universe a tiny bit where the wheel is, so pi equals three, with the extra digits being sent into oblivion. The side effect of this time-spacial twistery is that letters that weren't written yet would come out. The Post Office's management at the time tried to take advantage of this so they could deliver letters mere seconds after they were sent to the post office, but, as with all things where you try to cheat with magic, it went horribly wrong. The Sorting Engine began to churn out thousands of letters, some that weren't supposed to have been written, or those that could have been written, and so on and so forth. And the bloody thing couldn't be turned off, as the wizards feared doing so would destroy the universe. Pretty soon the Post Office was swamped with letters they couldn't deliver. Eventually, Chief Postal Inspector Rumbelow began to hit the Sorter with a crowbar until the machine finally broke down. While he saved the Post Office from further overload, the inspector was brought before the Postmaster Cowerby and asked to explain why he thought to nearly end the universe in one go. He replied,

"Firstly, sir, I reasoned that if I destroyed the universe all in one go, no one would know; secondly, when I walloped the thing the first time, the wizards ran away, so I surmised that unless they has another universe to run to they weren't really certain; and lastly, sir, the bloody thing was getting on my nerves. Never could stand machinery, sir."

#Pi Day#terry pratchett#Going Postal#Bloody Stupid Johnson#Book#post office#mail#sorting machine#sorting engine#wizards#magic#end of the universe#a classic case of “How did you know?” “I didn't”

7 notes

·

View notes

Photo

Siemens DBCS 5 Delivery Bar Code Sorter located inside the Minneapolis Main Post Office in Downtown Minneapolis.

1 note

·

View note

Text

What is Battery Cell Sorting, Why Is It Required, and How Do We Do It?

In the fast-growing battery industry, ensuring the quality and efficiency of lithium-ion battery packs is crucial. One of the most essential steps in battery pack manufacturing is battery cell sorting—a process that directly impacts the final battery pack's performance, lifespan, and safety.

What is Battery Cell Sorting?

Battery cell sorting is the process of categorizing battery cells based on their voltage, capacity, internal resistance, and other electrical characteristics. Since no two battery cells are exactly the same due to manufacturing tolerances, sorting ensures that only cells with similar performance characteristics are used together in a battery pack. This improves overall efficiency and prevents issues such as imbalanced charging and discharging.

Why is Battery Cell Sorting Required?

Cell sorting is necessary because of the inherent variability in battery manufacturing. Even with stringent quality control, individual cells can exhibit slight differences in their characteristics.

Performance Consistency – Mixing cells with varying capacities can lead to an imbalanced battery pack, reducing efficiency and reliability.

Enhanced Safety – Properly sorted cells reduce the risk of overheating, overcharging, and thermal runaway.

Longer Battery Life – Matching cells with similar characteristics minimizes degradation and extends the battery pack’s lifespan.

Optimized Energy Output – Well-matched cells deliver consistent energy, ensuring stable performance in EVs, energy storage systems, and other applications.

How to Perform Battery Cell Sorting?

Battery cell sorting is typically done using automated testing and sorting machines. The process of cell sorting involves several key steps:

Cell Receiving and Inspection: Incoming cells are inspected for physical defects and initial quality checks.

Electrical Testing: Cells undergo rigorous electrical testing to measure OCV, IR, and capacity.

Data Acquisition and Analysis: The measured data is collected and analyzed to determine cell characteristics.

Sorting and Binning: Based on the analysis, cells are sorted into different bins according to predefined criteria.

Traceability: Data is recorded to provide traceability for each cell. Semco Infratech’s Advanced Battery Cell Sorting Machines

At Semco Infratech, we offer state-of-the-art battery cell sorting machinesdesigned for precision, speed, and scalability. Our machines ensure accurate measurement of key parameters like voltage, capacity, and resistance, allowing manufacturers to build reliable battery packs with optimal performance. Features include:

High-speed automatic sorting with multi-channel testing.

Advanced algorithms for precise classification.

Customizable sorting bins to match manufacturing requirements.

User-friendly interface for seamless operation and monitoring.

As battery technology advances, ensuring high-quality manufacturing processes is critical. With Semco Infratech’s cell-sorting solutions, manufacturers can enhance efficiency, safety, and performance in lithium-ion battery production.

#battery cell sorting#battery cell sorting machine#lithium ion battery cell sorting machine#lithium ion battery sorting machine#sorting machine

0 notes

Text

Ensuring Perfection: How 100% Sorting Machines Revolutionize Manufacturing

In today's highly competitive manufacturing landscape, ensuring product quality is paramount. Consumers expect flawless products, and even minor defects can lead to significant reputational damage and financial loss. Enter the 100% Sorting Machine—a technological marvel that has revolutionized quality control in manufacturing. By inspecting every single product on the production line, these machines ensure that only those meeting the highest standards reach the market. This article delves into the transformative impact of 100% Sorting Machines, exploring their benefits, applications across various industries, and essential considerations for manufacturers contemplating their adoption.

Key Takeaways

Enhanced Quality Control: 100% Sorting Machines automate the inspection process, ensuring consistent and accurate detection of defects, leading to superior product quality.

Increased Efficiency: By rapidly sorting products, these machines boost production speeds, reduce bottlenecks, and optimize operational workflows.

Cost Reduction: Automated sorting minimizes the need for manual inspections, reduces labor costs, and decreases the likelihood of costly recalls due to defective products reaching consumers.

Industry Versatility: From automotive to pharmaceuticals, various sectors benefit from the precision and reliability of 100% Sorting Machines.

How 100% Sorting Machines Enhance Quality Control

What Are 100% Sorting Machines?

100% Sorting Machines are advanced automated systems designed to inspect and sort every individual product on a production line. Utilizing technologies such as high-resolution cameras, lasers, and sensors, these machines detect defects based on criteria like color, size, shape, and structural integrity. Unlike traditional sampling methods, which inspect only a fraction of products, 100% Sorting Machines ensure that each item undergoes thorough evaluation, guaranteeing uniform quality.

The Importance of Accuracy in Manufacturing

Precision is the cornerstone of manufacturing excellence. Inaccurate or inconsistent products can lead to:

Customer Dissatisfaction: Defective products can erode trust and lead to loss of clientele.

Financial Losses: Recalls and returns due to product defects can be costly and harm a company's bottom line.

Regulatory Non-compliance: Substandard products may fail to meet industry regulations, resulting in legal penalties.

Implementing 100% Sorting Machines addresses these challenges by ensuring that every product aligns with the desired quality standards.

Key Benefits of Using 100% Sorting Machines

Enhanced Precision and Accuracy

Automated Detection: Advanced sensors and imaging technologies identify even the minutest defects that might escape human inspectors.

Consistency: Machines operate without fatigue, ensuring uniform inspection standards throughout the production process.

Improved Production Speed

High Throughput: Capable of inspecting thousands of items per hour, these machines keep pace with high-speed production lines.

Reduced Downtime: Continuous operation minimizes delays associated with manual inspections, ensuring a smoother workflow.

Minimized Product Waste

Early Detection: Identifying defects early prevents defective products from advancing through the production line, reducing material waste.

Selective Sorting: Machines can categorize products based on defect types, allowing for targeted rework or recycling.

Cost-Effective Quality Control

Labor Savings: Automation reduces reliance on manual inspectors, leading to significant labor cost savings.

Recall Prevention: Ensuring only high-quality products reach consumers minimizes the risk of expensive recalls and associated brand damage.

Industries That Benefit from 100% Sorting Machines

Automotive Industry

Component Integrity: Ensures that engine parts, bolts, and other critical components are free from defects, enhancing vehicle safety and performance.

Regulatory Compliance: Meets stringent industry standards, reducing the risk of non-compliance penalties.

Electronics Manufacturing

Microcomponent Inspection: Detects flaws in microchips, circuit boards, and connectors, ensuring the reliability of electronic devices.

Consumer Satisfaction: Delivers defect-free gadgets, enhancing brand reputation and customer loyalty.

Food and Beverage Industry

Foreign Object Detection: Identifies and removes contaminants, ensuring food safety and compliance with health standards.

Quality Assurance: Sorts products based on size, color, and ripeness, maintaining consistent product quality.

Pharmaceutical Sector

Dosage Accuracy: Ensures tablets and capsules meet precise weight and size specifications, crucial for patient safety.

Contaminant Removal: Detects foreign particles, preventing contamination and ensuring compliance with stringent health regulations.

Choosing the Right 100% Sorting Machine for Your Manufacturing Needs

Key Features to Consider

Detection Capabilities: Ensure the machine can identify defects relevant to your products, such as color variations, size discrepancies, or structural flaws.

Speed and Throughput: Align the machine's inspection speed with your production rate to avoid bottlenecks.

Flexibility: Opt for machines that can handle various product types and sizes, offering adaptability to different production lines.

Understanding Throughput Capacity

Match Production Demands: Select a machine that can handle your peak production volumes without compromising inspection accuracy.

Scalability: Consider machines that allow for future expansion or upgrades as your production needs grow.

Software and Data Analytics Integration

Real-Time Monitoring: Advanced software enables continuous monitoring of inspection results, facilitating immediate corrective actions.

Data-Driven Decisions: Analytics provide insights into defect patterns, helping to identify root causes and improve overall manufacturing processes.

Steps to Implement a 100% Sorting Machine in Your Production Line

Step 1: Assess Your Quality Control Needs

Identify Critical Control Points: Determine stages in your production where defects are most likely to occur.

Define Defect Criteria: Establish clear parameters for what constitutes an acceptable product.

Evaluate Production Speed: Ensure the selected sorting machine can keep pace with your production line requirements.

Step 2: Select the Right Sorting Machine

Consult with Experts: Seek guidance from equipment suppliers to choose a machine tailored to your product's characteristics.

Consider Machine Flexibility: Opt for a system capable of adapting to various product shapes, sizes, and materials.

Review Maintenance Requirements: Choose machines with accessible parts and straightforward cleaning procedures to minimize downtime.

Step 3: Train Your Staff for Effective Use

Comprehensive Training: Provide hands-on training to operators to ensure they understand machine controls, software, and troubleshooting.

Establish Standard Procedures: Develop clear guidelines for monitoring, calibration, and responding to errors.

Step 4: Regular Maintenance and Calibration

Routine Inspections: Schedule periodic checks to ensure sensors, cameras, and moving parts are functioning correctly.

Software Updates: Ensure your sorting machine's software remains updated for improved detection accuracy and performance.

Conclusion

Incorporating a 100% Sorting Machine into your manufacturing process can drastically improve product quality, streamline production, and reduce costs associated with defective goods. By ensuring every item meets stringent quality standards, manufacturers can boost customer satisfaction and maintain a strong brand reputation. Whether you operate in the automotive, electronics, food, or pharmaceutical industry, investing in a reliable sorting machine is a strategic move that offers long-term benefits. With proper implementation, training, and maintenance, a 100% Sorting Machine can become a game-changer for your production line.

FAQs

1. What makes 100% Sorting Machines different from traditional inspection methods?

Unlike traditional methods that inspect random product samples, 100% Sorting Machines evaluate every single item, ensuring no defective product reaches the market.

2. Are 100% Sorting Machines suitable for small-scale manufacturers?

Yes, many modern sorting machines are designed with scalable features, making them adaptable for small to medium-sized production lines.

3. How do I know which 100% Sorting Machine suits my production line?

Assess your quality control needs, production volume, and product characteristics. Consulting with an expert supplier can help you select the right machine.

4. What maintenance is required for a 100% Sorting Machine?

Routine cleaning, sensor checks, calibration, and software updates are essential to maintaining optimal performance.

5. How quickly can a 100% Sorting Machine improve my production quality?

Many manufacturers see immediate improvements in defect detection and product quality, especially when combined with proper training and integration into existing workflows.

1 note

·

View note

Text

Vision Based Assembly Machine in pune | India

Visimaster, another name for Varad Automation and Robotics, is a well-known brand in the Indian market for Vision Based Assembly Machine. This company produces well-known robotics and vision-based assembly machines in the market.

#Optical Inspection#Sorting Machine#Glass Disc Introduction#O Ring Assembly Machine Pune#Manufacturer India#Best Product#Vision Based Sorting Machine Pune#Robotics Machine India#Vision-Based Assembly Machine Pune#Robotics Assembly India

0 notes

Text

Shenanigans ensue

#had this silly idea and then realised it was nearly actually Valentine’s Day#and sort of rushed to try get it out on the day. close enough.#anyway I just think this would be a funny episode idea#with misunderstandings and miscommunication galore#they would build some ultimate matchmaker machine.#Candace would be annoyed because she would say you can’t make a machine to do that you have to do it naturally#Perry goes along with it all because he likes spending time with them#and then at the end it’s a lesson about how some people are gay or whatever#pnf#perry the platypus#human perry#my art

9K notes

·

View notes

Text

This came to me in a vision

#tadc#the amazing digital circus#tadc pomni#tadc caine#caine#pomni#showtime#caine x pomni#pomni x caine#tadc showtime#showtime ship#tadc fanart#tadc comic#Animation takes forever; have this thing in the meantime#Sometimes. I need them to be soft. It heals the soul#Supervised Machine Learning#sort of#long post#my art

12K notes

·

View notes

Text

I think Redson would be a V-neck kinda guy(?), yea... He wont recall a thing when he wakes up the next morning LOL, not until someone reminds him ofc 😴⚒ He knows the inner workings of machineries by heart 💪

Did a Part 2! :DDstac

#lego monkie kid#lmk#lmk fanart#lmk red son#lmk mei#2025#heeheeheee#I NEED MORE OF REDSON BEING A MACHINE/TECH GENIUS#HES BEEN DOING THIS FOR CENTURIES (i believe/assume/hc)#GIMME FANART OF HIM LAYING EXHAUSTED ON THE GROUND#all sorts of drafts and blueprints scattered on the floor#NO#He's buried beneath his pile of drafts argh#Fine#Maybe ill do it myself 😤#stackalayers

892 notes

·

View notes

Text

Take all my blue for you

Marcille Donato & Falin Touden Dungeon Meshi, Ryoko Kui

^ 1: The Milk Train Doesn't Stop Here Anymore, Tennessee Williams / 2: The Lightning Strike, Snow Patrol / 3: Mostly Void, Partially Stars, Joseph Fink / 4: Unknown / 5: A.M. Homes / 6: The Return of the King, J.R.R. Tolkien / 7: You Don't Have to Like Me, Alida Nugent / 8: Was I Made For?, Billie Eilish / 9: Chlaurieform / 10: Snarkiwi / 11: Fanart by Aatom87 / 12: Nobodysflower / 13: Who’s There?: Every Story Is a Ghost Story, Ed Simon / 14: Petrichara / 15: Quote from Her (2013) / 16 & 17: Bluets, Maggie Nelson / 18: A self-portrait in letters, Anne Sexton v 19: Everything Stays, from Adventure Time / 20: Langston Hughes

Everything stays Right where you left it Everything stays But it still changes

#Dungeon meshi#angst#Farcille#falin touden#marcille donato#Grief#the love in letting goooooo#Both platonic and romantic reads of this work/are intended n welcome#Say it in unison guys!! Nostalgia is a deadly virus!#Okay not to boast but i cooked with this one. Feeling my soul being ripped out of my ribcage at 2 am sorting thru pics as god intended#I wanted to live back in the before. Before love possessed me. Before grief.#Spoilers#dungeon meshi manga spoilers#More awake inside of my dreams / Was that really you next to me? / Who am I supposed to please? / Who am I?#I don't know what I want / But I know it's not this#Washing machine heart.......#Delicious in dungeon#There must be somewhere in the cosmos / Bound to a word I couldn't say#Supernova soul devoid of feeling / My heart has left me somewhere far away

321 notes

·

View notes

Text

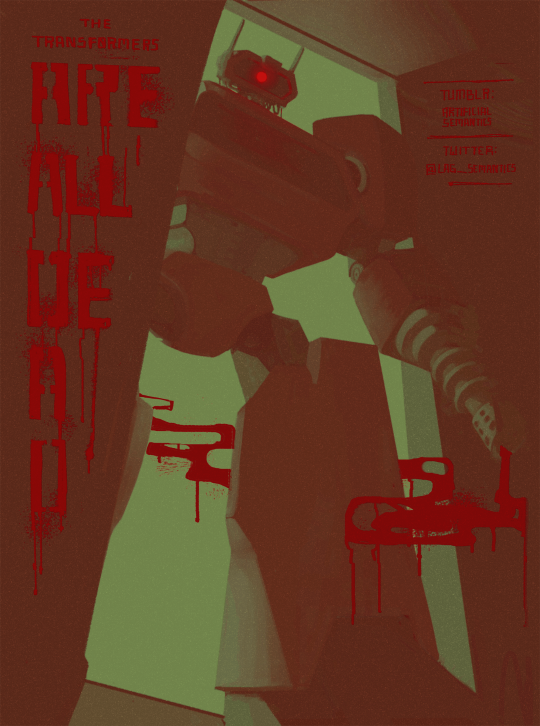

shockwave but its an metaphor for the horrors of war beyond man's comprehension

or alternatively: me at 3AM going into the kitchen in search of shredded cheese (8 found dead, 36 injuried)

based on that one cover by Mark Bright. you know the one.

#oh and also i've been listening a lot to the tank chats by the british tank museum lately#and i sort of wanted to go for a wwi war machine vibe for him#like going for this sort of sense of horror of seeing a tank for the first time#📼 transformers art tag#transformers#shockwave#maccadam#tf g1#original art#artists on tumblr

3K notes

·

View notes

Text

i'll meet you at the newly, everlasting little stint

#chonny jash#cccc#cccc whole#cj whole#cccc soul#cj soul#you know that one part of Time Machine Reprise when the guitar starts up in the background? yeah#hearing that specific part always makes me want to go and punch all of the walls in my house in quick succession#(I like it. it makes me feel some sort of profound emotion still unnamed by humanity)#edit I just realized I forgot to tag this with my art tag??? help#art

276 notes

·

View notes

Text

the inky shadow haunts you.

#xandraws#been a while since i've posted art oopsies#nix im blaming you for this how dare you drag me into the depths#batim#bendy and the ink machine#batdr#bendy and the dark revival#batdr spoilers#sort of. how long has the game been out. do i need to tag that#i will just cuz#bendy#batdr bendy#batdr fanart#batdr ink demon#ink demon

338 notes

·

View notes

Text

Ops I did it again...

funny thing: this edit can be 3 ship (probably more) in 1

[Title: don't stop]

#ineffable husbands#ineffable idiots#aziracrow#illogical husbands#my edit#saddle up sheenie!#dai tennant#welsh seduction machine#soft scottish hipster gigolo#Thank you master of sex#You gave me the perfect pic for this#Don't like it don't watch it#sheenant#sheennant#leave me alone#david tennant and michael sheen#I'm doing this instead of sleeping#photo edit#feel free to reblog#dont care#fanart#sorry not sorry#Aziraphale and Crowley do all sorts of things together#😏

168 notes

·

View notes

Text

How a 100% Product Sorting Machine Ensures Zero Defects in Manufacturing

In today's competitive manufacturing landscape, ensuring product quality is paramount. Achieving zero defects not only enhances customer satisfaction but also bolsters a company's reputation. A pivotal tool in this endeavor is the 100% Product Sorting Machine. These advanced machines meticulously inspect each item on the production line, identifying and removing defective products to ensure that only those meeting strict quality standards proceed. By integrating 100% Product Sorting Machines into their processes, manufacturers can significantly reduce defects, leading to improved efficiency and product reliability.

Key Takeaways

100% Product Sorting Machines enhance manufacturing efficiency by ensuring each product meets quality standards.

They utilize advanced technologies like vision inspection systems and AI to detect defects.

Implementing these machines leads to reduced waste and production costs.

Various industries, including automotive and pharmaceuticals, benefit from zero-defect manufacturing.

Choosing the right machine involves considering factors like speed, accuracy, and integration capabilities.

How 100% Product Sorting Works

100% Product Sorting Machine plays a crucial role in modern manufacturing by automating the inspection process, thereby eliminating human errors and enhancing precision. These machines operate at high speeds, allowing for the rapid inspection of large volumes of products without compromising accuracy. By analyzing each item in real-time, they ensure that only products meeting predefined quality criteria continue down the production line.

Key Technologies in 100% Product Sorting Machines

Vision Inspection Systems: Utilize high-speed cameras to capture detailed images of products, identifying defects such as surface imperfections or dimensional inaccuracies.

AI and Machine Learning: Employ algorithms that learn from data to improve defect detection over time, adapting to new patterns and anomalies.

X-ray and Infrared Scanning: Detect internal defects or contaminants not visible to the naked eye, ensuring comprehensive quality control.

Laser and Optical Sorting: Measure and assess products with high precision, sorting them based on size, shape, and color to ensure uniformity.

Why Zero Defects Matter in Manufacturing

Achieving zero defects is essential for maintaining product quality and safeguarding a brand's reputation. Consistently delivering flawless products fosters customer trust and loyalty, leading to repeat business and positive word-of-mouth. Moreover, adhering to industry regulations and standards is often mandatory, and zero-defect manufacturing ensures compliance, thereby avoiding legal issues and potential fines.

Reducing Waste and Production Costs

Minimizing Material Losses and Rework: By catching defects early, manufacturers can reduce the need for rework and the associated material costs.

Optimizing Manufacturing Efficiency: Streamlining the production process by removing defective items promptly prevents bottlenecks and maintains a steady workflow.

Enhancing Sustainability Efforts: Reducing waste contributes to environmental sustainability, aligning with global initiatives and improving corporate social responsibility profiles.

Industries Benefiting from 100% Product Sorting Machines

Automotive Manufacturing

Ensures that safety-critical components meet stringent quality standards, reducing the risk of malfunctions.

Decreases warranty claims and enhances customer satisfaction by delivering reliable vehicles.

Pharmaceutical and Medical Devices

Complies with strict health and safety regulations by ensuring that each product is free from defects.

Detects microscopic defects that could compromise patient safety, maintaining the integrity of medical products.

Food and Beverage Industry

Removes contaminants and ensures food safety, protecting consumers from potential health hazards.

Maintains uniformity in packaging and labeling, which is crucial for brand consistency and consumer trust.

Electronics and Semiconductor Manufacturing

Prevents faulty components from reaching consumers, reducing returns and enhancing brand reputation.

Enhances precision in microelectronic assembly, ensuring the functionality and longevity of electronic devices.

Choosing the Right 100% Product Sorting Machine for Your Business

Factors to Consider

Speed and Throughput: Ensure the machine can handle your production volume without causing delays.

Detection Accuracy: Look for machines with high precision to minimize the risk of defective products passing through.

Integration Capabilities: The machine should seamlessly integrate with your existing production line and systems.

Cost vs. ROI: Evaluate the initial investment against the long-term benefits, including reduced waste and improved quality.

Top Brands and Technologies to Look For

Leading manufacturers offer advanced sorting solutions equipped with the latest technologies, such as high-resolution cameras and AI-driven software.

Innovations in AI-driven sorting provide future-proof operations, adapting to evolving quality standards and product variations.

Conclusion

Incorporating 100% Product Sorting Machines into manufacturing processes is a strategic move towards achieving zero defects. These machines enhance efficiency, ensure consistent product quality, and reduce waste, leading to increased profitability and a stronger market position. By carefully selecting the right machine and leveraging advanced technologies, businesses can meet the high standards demanded by today's consumers and stay competitive in their respective industries.

FAQs

1. How does a 100% Product Sorting Machine detect defects?

These machines use advanced sensors and cameras to inspect each product in real-time. By analyzing various parameters such as size, shape, color, and internal structure, they identify and remove defective items from the production line.

2. Can small businesses benefit from automated sorting machines?

Yes, small businesses can benefit significantly. Implementing automated sorting enhances product quality, reduces manual labor costs, and minimizes waste, leading to improved profitability even for smaller operations.

3. What industries require zero-defect manufacturing the most?

Industries such as automotive, pharmaceuticals, food and beverage, and electronics heavily rely on zero-defect manufacturing due to the critical nature of their products and the stringent quality standards they must adhere to.

4. Are 100% Product Sorting Machines expensive to implement?

While the initial investment for a 100% Product Sorting Machine may seem high, it is crucial to consider the long-term benefits. These machines significantly reduce waste, minimize rework, and enhance efficiency, leading to cost savings over time. Additionally, many manufacturers offer scalable solutions that cater to businesses of all sizes, allowing for a more cost-effective implementation.

5. How do AI and machine learning improve sorting accuracy?

AI and machine learning allow 100% Product Sorting Machines to continuously improve their defect detection capabilities. By analyzing large sets of data and learning from patterns, AI-powered systems can detect subtle defects that traditional methods might miss. Over time, these machines become more precise, reducing false positives and improving overall sorting accuracy.

6. How do these machines integrate into existing production lines?

Modern 100% Product Sorting Machines are designed with seamless integration in mind. They can be incorporated into existing manufacturing setups with minimal disruption. Many machines offer customizable settings to adapt to specific production requirements, and manufacturers provide software solutions that facilitate data sharing across different systems, ensuring smooth operations.

7. Can these machines handle multiple types of products?

Yes, many advanced 100% Product Sorting Machines are designed to sort various types of products across different industries. They can be adjusted to accommodate different sizes, shapes, and materials, making them versatile solutions for businesses with diverse product lines.

8. What are the key benefits of zero-defect manufacturing?

Enhanced product quality – Ensuring that customers receive only high-quality products.

Stronger brand reputation – Companies known for their reliability gain customer trust and loyalty.

Reduced production waste – Fewer defective products mean lower material costs.

Improved efficiency – Streamlining processes helps manufacturers maintain a competitive edge.

Regulatory compliance – Many industries require strict adherence to quality standards, which zero-defect manufacturing supports.

0 notes

Text

Bolts Inspection Machine Manufacturer in pune | India

Visimaster is the top Indian maker of bolt inspection machines. They have the best tools for inspecting bolts for flaws, scratches, cracks, and other problems. Visimaster is the best Bolts Inspection Machine Manufacturer available in India for bolt inspection equipment.

#Nuts Inspection Machine Manufacturer in Pune#Inspects Hex Nuts#O Ring Inspection Machine Manufacturer Pune#Washer Inspection Machine Pune#Glass Disc Machine India#Optical Inspection#Sorting Machine#Glass Disc Introduction#O Ring Assembly

0 notes

Text

I can't remember all the times I tried to tell myself

to hold on to these moments as they pass

- counting crows, a long december

detail below the cut (and wolverine angsty musings in the tags lol)

#poolverine#the song lyrics are supposed to reflect upon logan's pensive facial expression#I imagine even after he's settled in with wade and feels like that dumpy lil apartment is a sort of home#he would still be waiting for the other shoe to drop#because he's never been able to hold onto happiness for long and he sees no reason this time would be the exception#and when wade is asleep he isnt there to distract him from these thoughts#so he just. drifts off into a melancholic daze#vaguely wondering what will happen to wade#to althea#to puppins#to laura#what bizarre universal machinations are already at play to tear what joy he has been able to scrape together#and quietly ruminates on what he'll do next once it is all inevitably ripped away again#which is why he secretly prefers when wade us awake and Constantly Talking#(though he would never openly admit it)#because then he can just listen and block the weight of knowing deep down it can't last because it never does#I wonder how long it would take him to accept that he couldnt lose wade if he tried#deadpool and wolverine#deadclaws#wolverine#deadpool#logan howlett#old man yaoi#wade wilson#deadpool & wolverine#anyway just always thinking about them on some level#also I'm reading that “psychology of wolverine” book and it just. damn. he never gets to hold on to anything or anyone for very long#especially not worstie

283 notes

·

View notes