#Sputtering

Explore tagged Tumblr posts

Text

New material shows promise for next-generation memory technology

Phase change memory is a type of nonvolatile memory that harnesses a phase change material's (PCM) ability to shift from an amorphous state, i.e., where atoms are disorganized, to a crystalline state, i.e., where atoms are tightly packed close together. This change produces a reversible electrical property which can be engineered to store and retrieve data. While this field is in its infancy, phase change memory could potentially revolutionize data storage because of its high storage density, and faster read and write capabilities. But still, the complex switching mechanism and intricate fabrication methods associated with these materials have posed challenges for mass production. In recent years, two-dimensional (2D) Van Der Waals (vdW) transition metal di-chalcogenides have emerged as a promising PCM for usage in phase change memory.

Read more.

#Materials Science#Science#Data storage#Phase transitions#Phases#2D materials#van der Waals#Transition metal dichalcogenides#Sputtering#Tohoku University

8 notes

·

View notes

Text

MAVEN Reveals How Mars Lost Its Atmosphere and Became a Barren World

Introduction NASA’s MAVEN spacecraft has made a groundbreaking discovery that explains why Mars transformed from a once wet and potentially habitable planet into the cold, dry, airless world we see today Mars lost its atmosphere. The key process? A phenomenon known as atmospheric sputtering. This direct observation has provided critical evidence confirming how solar wind stripped away the…

#argon mapping#atmosphere loss#climate change Mars#Mars#MAVEN spacecraft#NASA#Red Planet#solar wind#space science#sputtering

0 notes

Text

Understanding the Basics of Nano Research Elements

Nano Research Elements is set up by a group of expert Nanotechnologists to concentrate on giving an answer for each mind-boggling complex issue with the assistance of Nanotechnology products and applications. In the most recent decade, improvements in nanotechnology have been fuelled by noteworthy advances in nanomaterials synthesis and in addition, promising application information for the biomedical, electronics, and energy fields.

To know more visit below-mentioned links:

The Vital Role of Metal Nanoparticles in Environmental Remediation

Source: https://nanoresearchelements.blogspot.com/.../the-vital...

Silicon Wafers: Heart of Semiconductor Industry

Source: https://www.knockinglive.com/silicon-wafers-heart-of.../

How Sputtering Targets Are Revolutionizing Solar Cell Technology?

Source: https://empireadda.com/sputtering-targets/

#sputtering#Sputteringtarget#Semiconductor#SiliconWafers#MetalNanoparticles#nanotechnology#nanoparticles

0 notes

Text

Benedict turned the key again as the engine sputtered.

"The Hungry Moon" - Ramsey Campbell

0 notes

Link

Welcome to Astronomy Daily, your go-to podcast for the latest news and discoveries in space and astronomy. I'm your host, Anna. Today we have some exciting stories lined up for you. We'll dive into new research on our moon's atmosphere, revealing the powerful effects of meteorite impacts. Next, we'll explore why detecting signs of advanced extraterrestrial civilizations, known as technosignatures, is more challenging than we might think. Finally, we'll uncover recent findings about potential dark matter objects in space discovered using pulsars. So sit back, relax, and let's embark on this cosmic journey together. - NASA astronauts from the Apollo missions uncovered a fascinating aspect of the moon that was previously unknown. It has an atmosphere, although it's incredibly thin, so much so that it's technically classified as an exosphere. But what drives this tenuous lunar atmosphere? - NASA scientists have been delving into the intriguing question of why we might not be able to detect advanced extraterrestrial civilizations, also known as technosignatures. One prevailing theory suggests that these civilizations may have relatively modest energy requirements, which means they wouldn't necessarily need to construct vast, detectable stellar energy structures, like enormous solar panel arrays that cover their planet's surface, or giant orbiting megastructures, to harvest energy from their star. - Recent research has brought exciting news in our quest to understand dark matter, something that has intrigued astronomers for decades. The study involves pulsars, which are neutron stars known for emitting regular beams of radio waves. - If you enjoyed today's show, be sure to visit our website at astronomydaily.io. Until next time, keep looking up. www.bitesz.com

#astronomy#atmosphere#civilizations#dark#extraterrestrial#impacts#lunar#mass#matter#meteorite#moon#nasa#news#pulsars#regolith#research#solar#sputtering#technosignatures#wind

0 notes

Text

Customer in the store this morning tells me that in one of our sister-stores, the book dept was shelved BY SPINE COLOUR.

Absolutely atrocious. You've turned your merchandise into decor. Nobody's gonna wanna read every single title like that.

I'm so appalled I don't even have WORDS FOR THIS

0 notes

Text

30-something year old government woman

#sfr draws#alice dyer#star draws tmp#don't let her look at you#you will turn into a flustered sputtering mess

1K notes

·

View notes

Text

A sputtering offense, a stubborn coach and a $76 million buyout: Inside Jimbo Fisher's Texas A&M downfall

Dave Wilson, ESPN Staff WriterNov 16, 2023, 02:30 PM ET Close Dave Wilson is an editor for ESPN.com since 2010. He previously worked at The Dallas Morning News, San Diego Union-Tribune and Las Vegas Sun. SHORTLY AFTER TEXAS A&M athletic director Ross Bjork fired Jimbo Fisher, he described what the Aggies are seeking in a replacement. They’re looking for a coach who’s open to change, adaptable,…

View On WordPress

0 notes

Text

Overview of Vacuum Coating Materials And Technologies

Vacuum coating technology mainly involves the use of different vacuum coating equipment and process methods to generate coated materials on the surface of specific substrates in order to prepare a variety of thin film materials with specific functions. Application areas for vacuum coating technology include flat-panel displays, semiconductors, solar cells, magnetic and optical recording medias, optical components, energy saving glass, LEDs, tool modifications, high-end decorative items, etc. Thin film materials grow on top of substrate materials (such as screen glass, optical glass, etc.) and are generally formed by metal, non-metal, alloy or compound materials (collectively referred to as coating materials) after coating, and have the functions of increased transmission, absorption, cut-off, spectroscopy, reflection, light filtering, interference, protection, water and dirt repellency, anti-static, electrical conductivity, magnetic conductivity, insulation, abrasion resistance, high temperature resistance, corrosion resistance, oxidation resistance, radiation protection, decoration and composite and other functions. Thin film materials can improve product quality, environmental protection, energy saving, extend the life of the product and improve the original performance, etc. As the thin film material is formed after the transfer of the coating material to the substrate, the quality of the film is directly related to the quality of the coating material. Currently, thin film material preparation technologies mainly include: physical vapour deposition (PVD) and chemical vapour deposition (CVD) technologies. Among them, physical vapour deposition (PVD) technology mainly includes vacuum sputtering coating, vacuum evaporation coating and vacuum ion coating.

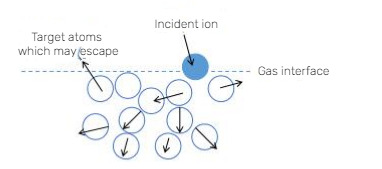

Vacuum sputter coating. It refers to the technique of using ions generated by an ion source, which are accelerated and gathered in a vacuum to form a high ion beams, to bombard the surface of the target (coating material), where kinetic energy is exchanged between the ions and the atoms on the surface of the target, causing the atoms on the surface of the target to leave and be deposited on the surface of the substrate material. The object bombarded with ions is the raw material for the deposition of thin film materials by the vacuum sputtering method and is called a sputtering target.

Principle of vacuum sputtering coating

Generally speaking, sputtering targets are mainly composed of target blanks, back plates (or back tubes) and other parts, of which, target blanks are the target material bombarded by high-speed ion beams, belonging to the core part of sputtering targets. In the sputtering coating process, target blanks are hit by ions and its surface atoms are sputtered out and deposited on the substrate, making thin film materials. As the sputtering target needs to be installed in special equipment to complete the sputtering process, the equipment has a high voltage, high vacuum inner working environment and most of the target blank material is soft or highly brittle, not suitable for direct installation in the equipment, therefore, it need to be bound with the back plate (or back tube) which mainly plays a role as the fixator of sputtering target and has good electrical and thermal conductivity.

Characteristics of vacuum sputtered films:

Good controllability and repeatability of film thickness. The thickness of the film is controlled at a predetermined value, known as controllability of film thickness. The required film thickness can occur repeatedly, called film thickness repeatability. In vacuum sputter coating, the film thickness can be controlled by controlling the target current.

Strong adhesion of the film to the substrate. The energy of the sputtered atoms is 1-2 orders of magnitude higher than the energy of the evaporated atoms, and the energy conversion of the high-energy sputtered atoms deposited on the substrate is much higher than that of the evaporated atoms, generating higher energy and enhancing the adhesion of the sputtered atoms to the substrate.

In the preparation of alloy and compound films, the components of the target material are very close to that of the film material deposited onto the substrate, avoiding variation and inconsistency in the components and structure of the coating material as it is transferred to produce the film material.

New material films can also be prepared which are different from the target material. If a reactive gas is passed through the sputtering so that it reacts chemically with the target, a new material film which is completely different from the target can be obtained.

High purity of the film layer. The purity of the film is high. The sputtering method does not have the crucible component of the evaporation method, so the sputtering coating does not mix with the crucible heater material and has a higher purity. The disadvantages of the sputtering method are that the film formation speed is lower than that of evaporation, the substrate temperature is higher, it is more susceptible to impurity gases and the device structure is more complex.

Vacuum sputtering has become one of the mainstream technologies for the preparation of thin film materials due to the reproducibility and controllable thickness of the sputtering process, the ability to obtain uniform thickness films on large areas of substrate materials, the high purity of the films prepared, the good density and the strong bonding with the substrate materials. Various types of sputtering targets have been widely used, so the demand for sputtering targets, a functional material with high added value, is increasing at a high rate year by year, and sputtering targets have become the largest market application of PVD coating materials.

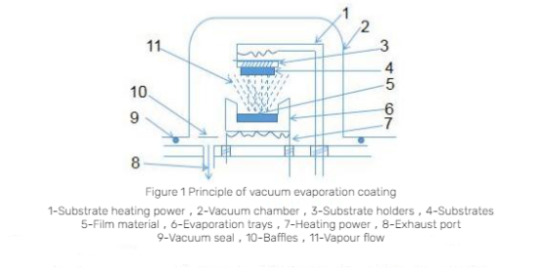

Vacuum evaporation coating. It is a deposition technique that uses the thermal energy of a film heating device (called an evaporation source) under vacuum conditions to deposit a substance on the surface of a substrate material by heating it to evaporate. When the mean free path of the evaporated molecules is larger than the dimension line between the evaporation source and the substrate, the evaporated particles escape from the surface of the evaporation source and are rarely hindered by the collision of other particles (mainly residual gas molecules) in the process of flying towards the surface of the substrate, and arrive directly at the surface of the substrate, condensing and producing a thin film. The evaporated material is the raw material for the deposition of thin film materials by vacuum evaporation coating and is called vapour deposition material.

Vacuum evaporation coating system generally consists of three components: the vacuum chamber, the evaporation source or evaporation heating unit, and the device for placing and heating the substrate. In order to evaporate the material to be deposited in a vacuum, a vessel is required to support or contain the evaporate and to provide evaporation heat to bring the evaporate to a high enough temperature to generate the required vapour pressure.

Principle of vacuum evaporation coating

Features of vacuum evaporation coating technology: simple equipment, easy operation, high purity and quality of the film made, accurate controllability of the thickness, fast filming rate , high efficiency, relatively simple growth mechanism of the film, etc.; the disadvantage are that it is not easy to obtain the film with crystalline structure; the adhesion of the film formed on the substrate is small; the repeatability of the process is not good enough, etc.

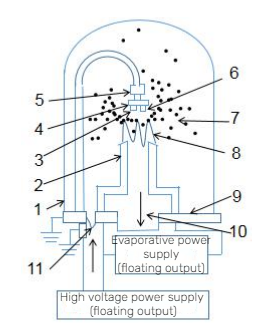

Vacuum ion coating. This refers to a process in which the film is evaporated or sputtered in a vacuum atmosphere, using an evaporation source or sputtering target, and part of the evaporated or sputtered particles are ionized into metal ions in the gas discharge space, and these particles are deposited onto the substrate under the action of an electric field to produce a thin film. The principle is shown in followed Figure. Firstly, the pressure of the coating chamber is evacuated to below 10-3pa, then the working gas is passed in to increase the pressure to 10^0~10^-1pa and the high pressure is accessed. As the cathode of the evaporation source grounded, the substrate is connected to the adjustable negative bias voltage, then the power supply can establish a low temperature plasma area with low pressure gas discharge between the evaporation source and the substrate, after the evaporation source of resistance heating type is energised and heats the film material, part of the neutral atoms escape from the surface of the film material and ionise into positive ions due to collision with electrons when passing through the plasma in the process of migration to the substrate; another part of the neutral atoms ions can also be generated by colliding with ions in the working gas and exchanging charges. These ions are then accelerated by the electric field and shot towards the substrate where they are connected to the negative potential, resulting in a thin film.

Principle of Vacuum Ion Coating

Characteristics of vacuum ion coating:

film/substrate adhesion is strong and the film layer is not easy to fall off;

ion plating has good diffraction, thus improving the coverage of the film layer;

high quality of the coating;

high deposition rate, film speed. 30 micron thick film can be prepared;

coating can be applied to a wide range of substrate materials and film materials.

Chemical Vapour Deposition (CVD). It is a filming technique that uses heating, plasma enhancement and light assist to make a solid film on the surface of a substrate by chemical reaction of gaseous substances under atmospheric or low pressure conditions.

Chemical vapour deposition CVD technology has the following characteristics:

the process and operation of the equipment is relatively simple and flexible, enabling the preparation of single or composite film layers and co-layers in various ratios;

the chemical vapour deposition CVD method is widely applicable;

the deposition rate can be as high as a few microns to hundreds of microns per minute, resulting in high production efficiency;

compared to the PVD method (vapour deposition, sputtering), it has good diffraction properties and is suitable for coating substrates with complex shapes;

good denseness of coating;

low damage after exposure to radiation and integration with the MOS integrated circuit (an integrated circuit consisting of metal-oxide-semiconductor field-effect transistors as the main components) process.

Summary: Vacuum coating technology mainly includes physical vapour deposition (PVD) technology and chemical vapour deposition (CVD) technology. The above mentioned vapour deposition, sputtering and ion deposition are all physical vapour deposition PVD, the basic principle of which can be summarised as follows: vapourisation of the plating material → migration of the atoms, molecules or ions in plating materials → deposition of atoms, molecules or ions in the plating materials on the substrate to recreate a thin film. Chemical vapour deposition CVD can be summarised as: formation of volatile substances → transfer of the substances to the deposition area → chemical reaction on the solid and production of a solid film substance.

0 notes

Text

ITO Target

ITO target is made up of a combination of indium oxide and tin oxide and serves as a crucial component in the production of ITO film. This film holds a significant position in the electronic information area and is used in a range of applications such as liquid crystal displays, organic light emitting diodes, touch screens and thin-film solar cells.

Operating Principle of ITO Target

An ITO target is a combination of indium oxide and tin oxide and serves as a crucial raw material in the field of electronic information, specifically in the production of ITO film. Due to its superior electrical conductivity, optical transparency, and high stability, ITO film is employed in different applications such as liquid crystal displays, organic light emitting diodes, touch screens, and thin-film solar cells.

Japan and South Korea have enjoyed a monopoly in the ITO target market for some time now, particularly in high-end TFT applications. However, our company has achieved independent innovation by acquiring core technology for mass-producing high-end ITO target, with multiple intellectual property rights and patent achievements. Presently, our production capacity for ITO targets is approximately 300 tons per year and we provide a steady supply to all TFT production lines ranging from G2.5 to G10.5. The quality of our targets ranks top in China, reaching world-class standards. Our growing market share is a testament to the satisfaction of our clients in the industry.

1 note

·

View note

Text

Wof sona as todays warm up

#Ice Sandwing mix cuz I'm mixed (most logical thought they've ever sputtered out)#art#my art#doodle#wof#wings of fire#sona#wof sona

1K notes

·

View notes

Text

hopping on the cleo & the machine album art trend @myrathefarmer started with dance fever 🕺

#yes yes i got around 70% of the way through rendering and my will to carry on sputtered and died like a car engine#but i did deeply enjoy listening to the album while drawing this ^_^ and cleo art is always happy to me#zombiecleo fanart#zombiecleo#florence and the machine#mcyt fanart#mcyt#thellos art corner

691 notes

·

View notes

Text

Round 3 - Reptilia - Passeriformes

(Sources - 1, 2, 3, 4)

Our last, and largest, order of birds are the Passeriformes, collectively known as “passerines” or “perching birds.” This huge, diverse order contains more than half of all bird species. It includes the families… *deeeep breath*…

Acanthisittidae (“New Zealand wrens”), Philepittidae (“asities”), Eurylaimidae (“typical broadbills”), Calyptomenidae (“African and green broadbills”), Sapayoidae (“Sapayoa”), Pittidae (“pittas”), Melanopareiidae (“crescentchests”), Conopophagidae (“gnateaters”), Thamnophilidae (“antbirds”), Grallariidae (“antpittas”), Rhinocryptidae (“tapaculos”), Formicariidae (“antthrushes”), Furnariidae (“ovenbirds”), Pipridae (“manakins”), Cotingidae (“cotingas”), Tityridae (“tityras”), Oxyruncidae (“Sharpbill”), Onychorhynchidae (“royal flycatchers” and “myiobiuses”), Tyrannidae (“tyrant flycatchers”), Atrichornithidae (“scrubbirds”), Menuridae (“lyrebirds”), Climacteridae (“Australasian treecreepers”), Ptilonorhynchidae (“bowerbirds”), Pomatostomidae (“Australo-Papuan babblers”), Orthonychidae (“logrunners”), Acanthizidae (“Australian warblers”), Meliphagidae (“honeyeaters”), Maluridae (“Australasian wrens”), Dasyornithidae (“bristlebirds”), Pardalotidae (“pardalotes”), Cinclosomatidae (“quail-thrushes” and “jewel-babblers”), Campephagidae (“cuckooshrikes” and “trillers”), Mohouidae (“whiteheads”), Neosittidae (“sittellas”), Psophodidae (“whipbirds” and “wedgebills”), Eulacestomatidae (“Wattled Ploughbill”), Falcunculidae (“shriketits”), Oreoicidae (“Australo-Papuan bellbirds”), Paramythiidae (“painted berrypeckers”), Vireonidae (“vireos”), Pachycephalidae (“whistlers”), Oriolidae (“Old World orioles”), Machaerirhynchidae (“boatbills”), Artamidae (“butcherbirds” and “woodswallows”), Rhagologidae (“Mottled Berryhunter”), Malaconotidae (“bushshrikes”), Pityriasidae (“Bornean Bristlehead”), Aegithinidae (“ioras”), Platysteiridae (“wattle-eyes”, “batises”, and “shrike-flycatchers”), Vangidae (“vangas”), Rhipiduridae (“fantails”), Dicruridae (“drongos”), Monarchidae (“monarch flycatchers”), Ifritidae (“Blue-capped Ifrit”), Paradisaeidae (“birds-of-paradise”), Corcoracidae (“White-winged Chough” and “Apostlebird”), Melampittidae (“melampittas”), Laniidae (“shrikes”), Platylophidae (“Crested Jayshrike”), Corvidae (“corvids”), Cnemophilidae (“satinbirds”), Melanocharitidae (“berrypeckers” and “longbills”), Callaeidae (“New Zealand wattlebirds”), Notiomystidae (“Stitchbird”), Petroicidae (“Australasian robins”), Eupetidae (“Rail-babbler”), Picathartidae (“rockfowl”), Chaetopidae (“rockjumpers”), Hyliotidae (“hyliotas”), Stenostiridae (“fairy flycatchers”), Paridae (“tits”), Remizidae (“penduline tits”), Panuridae (“Bearded Reedling”), Alaudidae (“larks”), Nicatoridae (“nicators”), Macrosphenidae (“African warblers”), Cisticolidae (“cisticola warblers”), Acrocephalidae (“reed warblers”), Locustellidae (“grass warblers”), Donacobiidae (“Black-capped Donacobius”), Bernieridae (“Malagasy warblers”), Pnoepygidae (“wren-babblers”), Hirundinidae (“swallows”), Pycnonotidae (“bulbuls”), Sylviidae (“sylviid warblers”), Paradoxornithidae (“parrotbills”), Zosteropidae (“white-eyes”), Timaliidae (“Old World babblers”), Leiothrichidae (“laughingthrushes”), Alcippeidae (“Alcippe fulvettas”), Pellorneidae (“ground babblers”), Phylloscopidae (“leaf warblers”), Hyliidae (“hylias”), Aegithalidae (“bushtits”), Scotocercidae (“Streaked Scrub Warbler”), Cettiidae (“cettiid warblers”), Erythrocercidae (“yellow flycatchers”), Dulidae (“Palmchat”), Bombycillidae (“waxwings”), Ptiliogonatidae (“silky-flycatchers”), Hylocitreidae (“Hylocitrea”), Hypocoliidae (“Grey Hypocolius”), Elachuridae (“Spotted Elachura”), Cinclidae (“dippers”), Muscicapidae (“Old World flycatchers”), Turdidae (“thrushes”), Buphagidae (“oxpeckers”), Sturnidae (“starlings”), Mimidae (“mockingbirds” and “thrashers”), Regulidae (“kinglets”), Tichodromidae (“Wallcreeper”), Sittidae (“nuthatches”), Certhiidae (“treecreepers”), Salpornithidae (“spotted creepers”), Polioptilidae (“gnatcatchers”), Troglodytidae (“wrens”), Promeropidae (“sugarbirds”), Modulatricidae (“dapplethroats”),

Nectariniidae (“sunbirds”), Dicaeidae (“flowerpeckers”), Chloropseidae (“leafbirds”), Irenidae (“fairy-bluebirds”), Peucedramidae (“Olive Warbler”), Urocynchramidae (“Przevalski's Finch”), Ploceidae (“weavers”), Viduidae (“indigobirds”, “whydahs”, and “Cuckoo-finch”), Estrildidae (“estrildid finches”), Prunellidae (“accentors”), Passeridae (“Old World sparrows”), Motacillidae (“wagtails”, “longclaws”, and “pipits”), Fringillidae (“true finches”), Rhodinocichlidae (“Rosy Thrush-tanager”), Calcariidae (“longspurs” and “snow buntings”), Emberizidae (“buntings”), Cardinalidae (“cardinals” and “grosbeaks”), Mitrospingidae (“mitrospingid tanagers”), Thraupidae (“tanagers”), Passerellidae (“New World sparrows”), Parulidae (“New World warblers”), Icteriidae (“Yellow-breasted Chat”), Icteridae (“New World blackbirds”), Calyptophilidae (“chat-tanagers”), Zeledoniidae (“wrenthrush”), Teretistridae (“Cuban warblers”), Nesospingidae (“Puerto Rican Tanager”), Spindalidae (“spindalises”), and Phaenicophilidae (“Hispaniolan tanagers”).

As this is such a large, diverse order (whose list of families have already taken up way too much room), it would be hard for me to summarize them. They are defined by the anisodactyl arrangement of their toes (three pointing forward and one back), which facilitates perching.

In the Cretaceous, the most dominant clade of birds were the Enantiornithes. After the K-Pg extinction, all Enantiornithes went extinct, leaving large swaths of empty niches behind. By the Eocene, around 52.5 million years ago, Passeriformes began to diverge and fill all those empty niches, leading to the large wealth of bird diversity today.

Propaganda under the cut:

Aside from the parrots, Passeriformes contains most of the birds capable of mimicry, including lyrebirds, mockingbirds, starlings, and corvids. Starlings and corvids are even known to mimic human words and sentences.

The largest passerine is the Thick-billed Raven (Corvus crassirostris), which ranges from 60 - 70 cm (2 - 2.3 ft) in length and weighs approximately 1.15 kg (2.5 lb) in females and 1.5 kg (3.3 lb) in males. The pheasant-sized Superb Lyrebird (Menura novaehollandiae) is sometimes called the largest passerine, but the Thick-billed Raven is around 25% heavier on average!

The smallest passerine is the Short-tailed Pygmy Tyrant (Myiornis ecaudatus), at 6.5 cm (2.6 in) long and weighing 4.2 g (0.15 oz).

There’s too many of these to talk about; I’m overwhelmed. Just know that if you like birds, you probably have a favorite in this order!

#sputtering coughing out of breath#I hit Tumblr’s text box limit rofl#I love them and want them to move to the next Round but I’m also dreading covering every family ALONG WITH every rodent and squamate family#🥲#animal polls#round 3#reptilia#Passeriformes

332 notes

·

View notes

Text

Geto is a tummy grabber I fear. It’s such a mindless activity for him: he could be hugging you from behind and, there we are, tummy grab. Driving? Hand on tummy. It isn’t just a resting hand either. He’s gripping the fupa. Geto gets such big heart eyes when he does, a part of him melts feeling the plush weight in his hands. He loves when you wear tight clothing that outlines the puffy part of your stomach; he’s practically salivating waiting to get his hands all over your soft tummy. God knows how bad he just want to see his pale dick dragging against your soft midsection. he aches to cover it all in his cum and lap it up like a dog. His cock jumps just thinking about you riding him, stomach bouncing from all of the motion. The way he’d run his fingers through your stretch marks and then plant his hands on your love handles and squeeze. The curse user is pretty much purring when you let him cuddle your tummy,he relishes the smell of the sacred skin. He doesn’t care what he has to do as long as he can touch your tummy. Geto absolutely needs it

#jjk#jjk x reader#thirst post#gn reader#geto suguru#suguru geto x gnc reader#geto x chubby reader#i wrote this for ME#geto x reader#geto suguru x reader#geto smut#god he’s obbessed#he saw a fupa in a pencil skirt and got so hard he started coughing and sputtering#i do not apologize

1K notes

·

View notes

Text

Thinking about the new episode of cr and about Dorian and Orym but I’ve seen a lot of people making jokes about Dorian’s dad seeing everyone intrusive themselves and is like ‘wtf is that my son’ and so true so valid but consider.

You are the father of the Wyvernwinds, a family who essentially serves as royalty in their culture. Several years ago your youngest left, likely against your wishes, and just a short period of time ago your oldest dies, and now all of the worlds leaders are gathering to develop a plan to deal with a potential Calamity level event. You spot someone who looks similar to your only living son. He is then a part of the group of, frankly, hooligans who are fucked in the head brave and are gonna be the main task force against this event and summons your goddamn wyvern dragon horse, while wearing the sluttiest outfit you’ve ever seen, as well as a sending stone that matches with the halfling who approached you after who very clearly is fond of your son. Not to mention he doesn’t go by his birth name and title but is wearing gold to symbolize the death of his older brother. What would you do then

#I’d like to think that Dorian’s dad is gonna talk to him and be like ‘so how long have you been courting the halfling’#and Dorian will sputter some half truth about caring about the whole group and not just Orym in particular#I am delusional I can admit but please just let me have this#also I haven’t actually seen the whole episode cause I only caught the very beginning and the last quarter of the episode when it aired#waiting for Monday for it to be posted on YouTube#critical role#critical role spoilers#cr spoilers#bells hells#dorym#Dorian storm#orym of the air ashari

440 notes

·

View notes