#Vacuum coating

Link

1 note

·

View note

Text

Overview of Vacuum Coating Materials And Technologies

Vacuum coating technology mainly involves the use of different vacuum coating equipment and process methods to generate coated materials on the surface of specific substrates in order to prepare a variety of thin film materials with specific functions. Application areas for vacuum coating technology include flat-panel displays, semiconductors, solar cells, magnetic and optical recording medias, optical components, energy saving glass, LEDs, tool modifications, high-end decorative items, etc. Thin film materials grow on top of substrate materials (such as screen glass, optical glass, etc.) and are generally formed by metal, non-metal, alloy or compound materials (collectively referred to as coating materials) after coating, and have the functions of increased transmission, absorption, cut-off, spectroscopy, reflection, light filtering, interference, protection, water and dirt repellency, anti-static, electrical conductivity, magnetic conductivity, insulation, abrasion resistance, high temperature resistance, corrosion resistance, oxidation resistance, radiation protection, decoration and composite and other functions. Thin film materials can improve product quality, environmental protection, energy saving, extend the life of the product and improve the original performance, etc. As the thin film material is formed after the transfer of the coating material to the substrate, the quality of the film is directly related to the quality of the coating material. Currently, thin film material preparation technologies mainly include: physical vapour deposition (PVD) and chemical vapour deposition (CVD) technologies. Among them, physical vapour deposition (PVD) technology mainly includes vacuum sputtering coating, vacuum evaporation coating and vacuum ion coating.

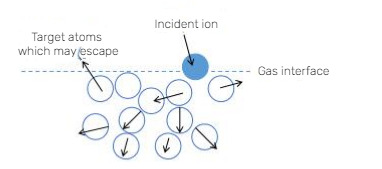

Vacuum sputter coating. It refers to the technique of using ions generated by an ion source, which are accelerated and gathered in a vacuum to form a high ion beams, to bombard the surface of the target (coating material), where kinetic energy is exchanged between the ions and the atoms on the surface of the target, causing the atoms on the surface of the target to leave and be deposited on the surface of the substrate material. The object bombarded with ions is the raw material for the deposition of thin film materials by the vacuum sputtering method and is called a sputtering target.

Principle of vacuum sputtering coating

Generally speaking, sputtering targets are mainly composed of target blanks, back plates (or back tubes) and other parts, of which, target blanks are the target material bombarded by high-speed ion beams, belonging to the core part of sputtering targets. In the sputtering coating process, target blanks are hit by ions and its surface atoms are sputtered out and deposited on the substrate, making thin film materials. As the sputtering target needs to be installed in special equipment to complete the sputtering process, the equipment has a high voltage, high vacuum inner working environment and most of the target blank material is soft or highly brittle, not suitable for direct installation in the equipment, therefore, it need to be bound with the back plate (or back tube) which mainly plays a role as the fixator of sputtering target and has good electrical and thermal conductivity.

Characteristics of vacuum sputtered films:

Good controllability and repeatability of film thickness. The thickness of the film is controlled at a predetermined value, known as controllability of film thickness. The required film thickness can occur repeatedly, called film thickness repeatability. In vacuum sputter coating, the film thickness can be controlled by controlling the target current.

Strong adhesion of the film to the substrate. The energy of the sputtered atoms is 1-2 orders of magnitude higher than the energy of the evaporated atoms, and the energy conversion of the high-energy sputtered atoms deposited on the substrate is much higher than that of the evaporated atoms, generating higher energy and enhancing the adhesion of the sputtered atoms to the substrate.

In the preparation of alloy and compound films, the components of the target material are very close to that of the film material deposited onto the substrate, avoiding variation and inconsistency in the components and structure of the coating material as it is transferred to produce the film material.

New material films can also be prepared which are different from the target material. If a reactive gas is passed through the sputtering so that it reacts chemically with the target, a new material film which is completely different from the target can be obtained.

High purity of the film layer. The purity of the film is high. The sputtering method does not have the crucible component of the evaporation method, so the sputtering coating does not mix with the crucible heater material and has a higher purity. The disadvantages of the sputtering method are that the film formation speed is lower than that of evaporation, the substrate temperature is higher, it is more susceptible to impurity gases and the device structure is more complex.

Vacuum sputtering has become one of the mainstream technologies for the preparation of thin film materials due to the reproducibility and controllable thickness of the sputtering process, the ability to obtain uniform thickness films on large areas of substrate materials, the high purity of the films prepared, the good density and the strong bonding with the substrate materials. Various types of sputtering targets have been widely used, so the demand for sputtering targets, a functional material with high added value, is increasing at a high rate year by year, and sputtering targets have become the largest market application of PVD coating materials.

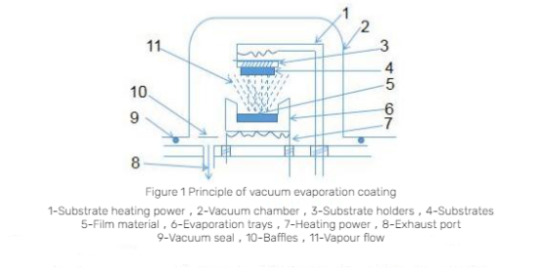

Vacuum evaporation coating. It is a deposition technique that uses the thermal energy of a film heating device (called an evaporation source) under vacuum conditions to deposit a substance on the surface of a substrate material by heating it to evaporate. When the mean free path of the evaporated molecules is larger than the dimension line between the evaporation source and the substrate, the evaporated particles escape from the surface of the evaporation source and are rarely hindered by the collision of other particles (mainly residual gas molecules) in the process of flying towards the surface of the substrate, and arrive directly at the surface of the substrate, condensing and producing a thin film. The evaporated material is the raw material for the deposition of thin film materials by vacuum evaporation coating and is called vapour deposition material.

Vacuum evaporation coating system generally consists of three components: the vacuum chamber, the evaporation source or evaporation heating unit, and the device for placing and heating the substrate. In order to evaporate the material to be deposited in a vacuum, a vessel is required to support or contain the evaporate and to provide evaporation heat to bring the evaporate to a high enough temperature to generate the required vapour pressure.

Principle of vacuum evaporation coating

Features of vacuum evaporation coating technology: simple equipment, easy operation, high purity and quality of the film made, accurate controllability of the thickness, fast filming rate , high efficiency, relatively simple growth mechanism of the film, etc.; the disadvantage are that it is not easy to obtain the film with crystalline structure; the adhesion of the film formed on the substrate is small; the repeatability of the process is not good enough, etc.

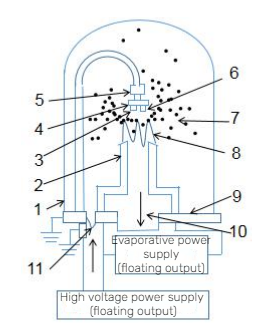

Vacuum ion coating. This refers to a process in which the film is evaporated or sputtered in a vacuum atmosphere, using an evaporation source or sputtering target, and part of the evaporated or sputtered particles are ionized into metal ions in the gas discharge space, and these particles are deposited onto the substrate under the action of an electric field to produce a thin film. The principle is shown in followed Figure. Firstly, the pressure of the coating chamber is evacuated to below 10-3pa, then the working gas is passed in to increase the pressure to 10^0~10^-1pa and the high pressure is accessed. As the cathode of the evaporation source grounded, the substrate is connected to the adjustable negative bias voltage, then the power supply can establish a low temperature plasma area with low pressure gas discharge between the evaporation source and the substrate, after the evaporation source of resistance heating type is energised and heats the film material, part of the neutral atoms escape from the surface of the film material and ionise into positive ions due to collision with electrons when passing through the plasma in the process of migration to the substrate; another part of the neutral atoms ions can also be generated by colliding with ions in the working gas and exchanging charges. These ions are then accelerated by the electric field and shot towards the substrate where they are connected to the negative potential, resulting in a thin film.

Principle of Vacuum Ion Coating

Characteristics of vacuum ion coating:

film/substrate adhesion is strong and the film layer is not easy to fall off;

ion plating has good diffraction, thus improving the coverage of the film layer;

high quality of the coating;

high deposition rate, film speed. 30 micron thick film can be prepared;

coating can be applied to a wide range of substrate materials and film materials.

Chemical Vapour Deposition (CVD). It is a filming technique that uses heating, plasma enhancement and light assist to make a solid film on the surface of a substrate by chemical reaction of gaseous substances under atmospheric or low pressure conditions.

Chemical vapour deposition CVD technology has the following characteristics:

the process and operation of the equipment is relatively simple and flexible, enabling the preparation of single or composite film layers and co-layers in various ratios;

the chemical vapour deposition CVD method is widely applicable;

the deposition rate can be as high as a few microns to hundreds of microns per minute, resulting in high production efficiency;

compared to the PVD method (vapour deposition, sputtering), it has good diffraction properties and is suitable for coating substrates with complex shapes;

good denseness of coating;

low damage after exposure to radiation and integration with the MOS integrated circuit (an integrated circuit consisting of metal-oxide-semiconductor field-effect transistors as the main components) process.

Summary: Vacuum coating technology mainly includes physical vapour deposition (PVD) technology and chemical vapour deposition (CVD) technology. The above mentioned vapour deposition, sputtering and ion deposition are all physical vapour deposition PVD, the basic principle of which can be summarised as follows: vapourisation of the plating material → migration of the atoms, molecules or ions in plating materials → deposition of atoms, molecules or ions in the plating materials on the substrate to recreate a thin film. Chemical vapour deposition CVD can be summarised as: formation of volatile substances → transfer of the substances to the deposition area → chemical reaction on the solid and production of a solid film substance.

0 notes

Text

i think im going to need a moment of not opening messages right now. im going to read stormbringer instead.

#sigh#my friend keeps sending me video after video about how her floors are covered in fur bc if my dog#(who is staying with her for now)#but like. yes. i understand. i get it.#my dog has incredibly thick fur and is shedding her fucking winter coat. i dont know what the fuck you want me to do???????#i get it?? so sorry?? ill come vacuum your house like ?????#i get it that its annoying having her fur all over bc she has black fur in your light beige carpet#what i DON'T get is WHY YOU KEEP SENDING ME VIDEOS OR PHOTOS. MULTIPLE TIMES A DAY.#WHY. JUST WHY.#IM SORRY LITERALLY I CANT DO ANYTHING ABOUT IT SHES A DOG SHE SHEDS LIKE.#shes going to my other sisters house soon and then she wont be shedding all over your floor and you KNOW THAT#so WHY.#im just. tired#i wanted to say 'i cant do this anymore' but that is unfortunately the doorway in which the suicidal thoughts will squirm through.#so. instead i will set my phone to the side and read my book.#it is much thicker than i expected it to be.#i cant turn my phone off bc my mom is going to be sending messages later that i need to look at but#im just going to try not to open any messages anyway and not touch my phone or anything#shh ac

13 notes

·

View notes

Text

i'm so so fucking tired

#today i vacuumed a Bunch of fixtures & replaced ALL the upstairs lightbulbs with warm LEDs instead of harsh white ones#and uninstalled the weird insufficient peg rack in the bathroom & spackled all the holes#and installed two new (normal) towel rods#and did a bunch of online shopping for more house things like coated steel clotheslines for the pulley system i'm setting up#and put away one of the three giant piles of clothes on my floor#and showered#i'm just so weary#first time using spackle & damn that shit is magical#$5 putty knife and it goes on So smooth#i am gonna get a LOT of practice bc the previous owners put nails for art EVERYWHERE#personal#my house in the middle of my street

7 notes

·

View notes

Text

It's not even cold tonight but I have spent HOURS trapped under TWO cats insisting It is Lap Time. I kicked them off to go do human activities for a bit and the MINUTE I sat down again it was once again Lap Time. They don't even like each other. They're making a concentrated effort to not so much as graze one another. But it is Lap Time, so they'll consider a temporary truce until the next time I desperately shift around so as not to completely lose feeling in my legs.

I am. So warm.

#winter always means Link NEEDS cuddles despite having the thickest winter coat of all the creatures#he also seeks me out more when his mouth hell is acting up#so it's once again reached a point where i feel weird if there isn't an inky goblin leech on top of me#and Lillian has always been my cuddlebug#but my goodness guys#the sound my hip made when i stood up#enforced cuddle time is hard on the joints#at least Lillian is perma-kitten size and they're both bony because roommate's orange cats are living vacuums

11 notes

·

View notes

Note

Please tell me about your theories for the ecological niches of the upside down. I could not be invested quicker.

You have now unlocked my special interest.

So! There's only 4 known creatures within the Upside-down: the Mind Flayer, the Demogorgon (with bonus pupa stage), the Demobats, and the vines. Of those 4, 3 have actively attacked people, though it's unclear whether the vines began as omnivores or developed into it over time, and it's unclear exactly how the Mind Flayer sustains itself. However, there is an inherent and glaring flaw to their ecological system: with mostly predators, the world of the Upside-down is completely fucked and will consume itself until everything dies.

Which is, in terms of habitats, not ideal. The brief glimpses of the world we get before 1 began shaping it to his will are a completely barren wasteland, and even with his powers to copy the other side (not touching how that was possible with a 10 foot pole), even with these new additions to the environment it's completely unsustainable, which is why 1 began to propagate the Demogorgons in our world, with far more resources. Even with full grown Demogorgons being able to pass onto our world via portals and hunt, such activity in high enough numbers to sustain the population of the dying world.

Dying? Yes, I think that before Henry stumbled into it, the Upside-down had been decaying for many years. On top of the predatory nature of the only creatures there, they also act much like scavengers, especially with the vines that create almost a net like a spider to grab prey (Though that's subjective, as you could say that the vines are being controlled in all the moments we see, we don't really know how they work. So I'll say that with the lack of water and generally any type of nutrients to grow, this particular plant adapted to also scavenge for water and nutrients within living/dead things).

We also have no idea how the Mind Flayer sustains itself. It absorbs flesh to create constructs, but that could again be Henry manipulating it through whatever dumb construction powers he got. What we do know is that it's an incredibly powerful lifeform, can communicate telepathically or at least mess with the minds of others, and can shift through worlds easily once a portal has been opened. Perhaps it's like a flock of micro-organisms that function like a fusion of starlings and nanobots. I digress.

In short, I think a catastrophic apocalyptic event happened within the Upside-down. Perhaps it was a natural disaster, like the asteroid that started a mass-extinction. Perhaps it was a bloody and terrible war of elevated creatures similar to or even beyond the Mind Flayer that doomed their world. Either way, I think the glimpses we see are Henry pulling together the last stragglers of another world.

#of course they'll never explain this in the show#and I didnt even touch on the spore-like dust that coats the world#perhaps that dust is how the Mind Flayer eats?? Like a giant whale vacuuming up the tiny spores#or maybe its from the plant?? that thing had spore dust too#Idk Im just a random person on the internet

5 notes

·

View notes

Text

me, holding a spray bottle filled with vinegar like it’s the light of elendil in one hand and my vacuum cleaner in the other: and that’s why I’m the apex predator and you’re not

#i have weapons and tools and the internet that’s why#shelob has been defeated! my bathroom is free of evil!#there is literal spider juice coating the inside of my vacuum#on one hand having a clear plastic reservoir means i have proof it’s dead on the other… yikes#calyss vs the mountain spiders

7 notes

·

View notes

Text

forgot i’m trying to move out by June (hopefully. our budget and savings have been good for the first time since like. 2020) and my place is just soooo hit. it’s so bad. i’ve been here for like fiiive? years now? we have so much shit. why do i have two coffee tables and five end tables. why do i have a non-functioning sewing machine just taking up space. no less than seven laptops in this place and only one works. we suffer both from Well Maybe We’ll Need This Later Or Can Get It Fixed Later syndrome.

#good thing i love cleaning and organizing and moving#well i don’t love moving. i love unpacking and setting a place up#there’s just no hood in the kitchen for some reason?! so everything is coated ina. fine layer of grease and cat hair#no matter how diligent i am. which is not as diligent as i should be god help me#we both have ADHD ok. i clean a room put something in another room start cleaning there#everything is 75% clean always#would rather die than clean the kitchen. bathroom sucks too#reaaaally i just need money for cleaning supplies. it’s hard to remember pantry and fridge and cleaning#when i shop :/#if we’re good in two areas we’re down bad in another#foods great rn! need wood polish and soap and a mop and a vacuum that doesn’t just. spew dust out the back#ANYWAY. gorgeous today. opening the windows putting my plants back to soak up sun#:) love you guys

9 notes

·

View notes

Text

a moment of joy in days of tired darkness!!!

#i complain way too much here so sharing my triumphs <3#(taking a page from songbird because i want to be more like her)#getting home from work today i was able to get ALL of my chores done!!!#i loooved having my friend stay with me for a week i truly needed the break and she’s such a blessing <3#(we bought ‘soul sisters’ matching bracelets - hers gold and mine silver - and the statement couldn’t be more true 🥹)#but in that i let my room get VERY messy#and i was busing working yesterday and didn’t have time (literally cried on my way home because of how tired i was)#so i made it a goal to do everything tonight so tomorrow (my one day off) i may relax!#so i was able to clean my room; do two loads of laundry; wash my bedding; vacuum; water my plants; and tidy my bathroom!!#it may not sound like much but it was a MESS#also i did my nails cause they broke :(#so now they are VERY short (had to cut them) and i painted a few coats of clear nail polish so hopefully they won’t break#i have to get gas and get my oil changed and exchange some icecream tomorrow morning#but then i’m just gonna relax!!!#would like to change my themes but we shall see. i want to watch tv and read mostly#also i’m gonna stop in and book a hair appointment for next week!!#that’s right i’m gonna chop off my hair#it’s been years and i didn’t get it trimmed as it was growing out so i have lots of split and dead ends#and if i have to get it cut i may as well just go all the way yknow#i love having short hair and i’m lowkey excited#and i work 6 days after that but thankfully i booked myself for opening shifts which leaves my evenings free to myself which i really love

2 notes

·

View notes

Text

hate anxiety hate anxiety hate anxiety

#my previous apartment is trying to charge me $500 to paint one bedroom.#i’m trying to dispute it right now because what the fu k#i left that place in much better circumstances than i found it#i swept and mopped and vacuumed and cleaned#one crusty coat of paint isn’t gonna cost $500 fucking dollars

6 notes

·

View notes

Text

Every time I open my bedroom door, I can hear my dog’s collar start jingling from across the house as he gets up and trots over to come lie down by my bed, which is sweet, but also unfortunate because I’m reacting to his dander.

#ghost posts#Percy is fine but Leo has awful dander#and it makes my eyes itchy and my chest tightish#but I feel bad kicking him out 🥺#…so I don’t and just suffer#I keep vacuuming and I feel better when I do so I KNOW it’s him#his previous owners did not manage his coat it’s been 3months and we still haven’t gotten it all fixed yet#daily brushing and combing but it’s still so thick

4 notes

·

View notes

Text

Sprocket is shedding very badly rn and most of it is coming out of her pants and I cannot believe the fur she's keeping in there, like girl why do you need all that there

#barkin up some trees#is ur bum cold??#also she has more coat than all her littermates#looking at the baby photos the breeder posted she has the fluffiest coat#the rest of them arent as floofy#so i bet i have the worst shedder lol#i am vacuuming every day and its absolutely insane how much fur there is every day#im so over it#like please stop#please be done shedding#shes worse than all my other 4 combined#and that says a lot because lucky is BAD

9 notes

·

View notes

Text

did the gardening and then cleaned the kitchen a bit (and then made a mess again) but then gave up and dozed and read in bed bc it was too hot to do anything else.

look I really want a nice clean apartment but I need one fucking weekend where it's cool and cloudy in order to do that!!!

#also i made a huge mess in the living room packing up gardening supplies#i did get a full bin of soil to save for next year but at the coat of dust and dirt aaaalllll over everything OTL#i will try and vacuum at least that this evening so i don't track dirt all over the apt#we're supposed to get a thunderstorm this evening so hopefully that actually happens for once and it cools down tonight

1 note

·

View note

Text

Global Top 5 Companies Accounted for 73% of total Vacuum Coating Machines market (QYResearch, 2021)

The report mainly focuses on PVD coating machine. Physical Vapor Deposition - also known as PVD Coating - refers to a variety of thin film deposition techniques where solid metal is vaporized in a high vacuum environment and deposited on electrically conductive materials as a pure metal or alloy coating.

The global Vacuum Coating Machines market was valued at US$ 4075.26 million in 2021 and will reach US$ 5754.88 million by the end of 2028, growing at a CAGR of 5.40% during 2022-2028.

The data for 2022 is an estimate, based on the historical data and the integrated view of industrial experts, manufacturers, distributors, and end users, etc.

Top-down and bottom-up approaches are used to validate the global Vacuum Coating Machines market size and to estimate the market size for company, regional division, product type and application (end users). In the complete market engineering process, both top-down and bottom-up approaches along with several data triangulation methods have been extensively utilized to perform market estimation and market forecast for the overall market division and subdivision listed in this report. Extensive qualitative and further quantitative analysis has also been done from all the numbers arrived at in the complete market engineering process to list key information throughout the report.

According to the new market research report “Global Vacuum Coating Machines Market Report 2023-2029”, published by QYResearch, the global Vacuum Coating Machines market size is projected to reach USD 6 billion by 2029, at a CAGR of 4.6% during the forecast period.

Figure. Global Vacuum Coating Machines Market Size (US$ Million), 2018-2029

Figure. Global Vacuum Coating Machines Top 5 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

The global key manufacturers of Vacuum Coating Machines include Applied Materials, ULVAC, Optorun, Buhler Leybold Optics, Von Ardenne, Shincron, Evatec, Veeco Instruments, HCVAC, Satisloh, etc. In 2021, the global top five players had a share approximately 73.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

For more information, please contact the following e-mail address:

Email: [email protected]

Website: https://www.qyresearch.com

0 notes

Text

vacuuming your mattress is important but also. deeply disturbing

#ime it pulls up huges amounts of fine white dust and... that came from me :( shannon dust :(#and the dust just COATS the vacuum canister and it's so gross

0 notes