#Testing and Measuring Instruments Company

Explore tagged Tumblr posts

Text

#Whiteness Meter Manufacturers in India#Whiteness Meter Manufacturers#Testing and Measuring Instruments Company

0 notes

Text

NASA Aims to Fly First Quantum Sensor for Gravity Measurements

This mission will pave the way for groundbreaking observations of everything from petroleum reserves to global supplies of fresh water.

Researchers from NASA’s Jet Propulsion Laboratory in Southern California, private companies, and academic institutions are developing the first space-based quantum sensor for measuring gravity. Supported by NASA’s Earth Science Technology Office (ESTO), this mission will mark a first for quantum sensing and will pave the way for groundbreaking observations of everything from petroleum reserves to global supplies of fresh water.

Earth’s gravitational field is dynamic, changing each day as geologic processes redistribute mass across our planet’s surface. The greater the mass, the greater the gravity.

You wouldn’t notice these subtle changes in gravity as you go about your day, but with sensitive tools called gravity gradiometers, scientists can map the nuances of Earth’s gravitational field and correlate them to subterranean features like aquifers and mineral deposits. These gravity maps are essential for navigation, resource management, and national security.

“We could determine the mass of the Himalayas using atoms,” said Jason Hyon, chief technologist for Earth Science at JPL and director of JPL’s Quantum Space Innovation Center. Hyon and colleagues laid out the concepts behind their Quantum Gravity Gradiometer Pathfinder (QGGPf) instrument in a recent paper in EPJ Quantum Technology.

Gravity gradiometers track how fast an object in one location falls compared to an object falling just a short distance away. The difference in acceleration between these two free-falling objects, also known as test masses, corresponds to differences in gravitational strength. Test masses fall faster where gravity is stronger.

Cooled to a temperature near absolute zero, the particles in these clouds behave like waves. The quantum gravity gradiometer will measure the difference in acceleration between these matter waves to locate gravitational anomalies.

Using clouds of ultra-cold atoms as test masses is ideal for ensuring that space-based gravity measurements remain accurate over long periods of time, explained Sheng-wey Chiow, an experimental physicist at JPL. “With atoms, I can guarantee that every measurement will be the same. We are less sensitive to environmental effects.”

Using atoms as test masses also makes it possible to measure gravity with a compact instrument aboard a single spacecraft. QGGPf will be around 0.3 cubic yards (0.25 cubic meters) in volume and weigh only about 275 pounds (125 kilograms), smaller and lighter than traditional space-based gravity instruments.

Quantum sensors also have the potential for increased sensitivity. By some estimates, a science-grade quantum gravity gradiometer instrument could be as much as 10 times more sensitive at measuring gravity than classical sensors.

The main purpose of this technology validation mission, scheduled to launch near the end of the decade, will be to test a collection of novel technologies for manipulating interactions between light and matter at the atomic scale.

“No one has tried to fly one of these instruments yet,” said Ben Stray, a postdoctoral researcher at JPL. “We need to fly it so that we can figure out how well it will operate, and that will allow us to not only advance the quantum gravity gradiometer, but also quantum technology in general.”

This technology development project involves significant collaborations between NASA and small businesses. The team at JPL is working with AOSense and Infleqtion to advance the sensor head technology, while NASA’s Goddard Space Flight Center in Greenbelt, Maryland is working with Vector Atomic to advance the laser optical system.

Ultimately, the innovations achieved during this pathfinder mission could enhance our ability to study Earth, and our ability to understand distant planets and the role gravity plays in shaping the cosmos. “The QGGPf instrument will lead to planetary science applications and fundamental physics applications," said Hyon.

IMAGE: A map of Earth’s gravity. Red indicates areas of the world that exert greater gravitational pull, while blue indicates areas that exert less. A science-grade quantum gravity gradiometer could one day make maps like this with unprecedented accuracy. Credit: NASA

7 notes

·

View notes

Note

With all the talks about Kar'niss as a bard, I was wondering if you could write something with Tav and Kar'niss dancing together? (though I guess given how tall Kar'niss is, it might be difficult)

The air was thick with the aroma of burning wood from the nearby campfire. A blanket of stars spanned across the sky, twinkling from a far off distance. Tav had broken away from the group for some quiet time, wandering toward a nearby stream so they could bask in the crisp night air. Once they settled on the shore near the forest line they pulled out their violin from it’s case. They took time to tune the instrument, desiring a moment to play a pleasant tune for their pleasure. Tav sensed eyes on him from the nearby treeline, their head turning to see the familiar silhouette of a drider lingering between two trees.

“You’re welcome to join me if you’d like. I’m not opposed to the company,” Tav said.

Kar’niss froze once he realized he had been spotted, his hands clasped together to rub them in a nervous fashion. He emerged from the underbrush and wandered over to where Tav was seated, maintaining a small measure of distance.

“What are they doing?” Kar’niss asked, peering over their shoulder at the violin.

“Taking a moment while we have it. I haven’t had the chance to play for a bit, now seemed like a good time. Do you play any instruments?”

Kar’niss’ brows knit, mulling the question over. “We...used to. Don’t anymore.”

“Oh?” Tav perked up, interest piqued. “What instrument?”

“Violin, flute at times. Long time ago, doesn’t matter now.” Kar’niss waved a hand dismissively, turning his face away from Tav.

“Well, would you like to with me? A duet sounds fun. We have an extra violin in camp.”

Kar’niss scoffed and reared his head back as if insulted. “We cannot play anymore. We would ruin your music with our screeching.” Tav chuckled while pushing themselves up to stand. “I doubt that. Just give it a try. If you hate it then you aren’t obligated to continue. Please?” Tav leaned forward and boldly bat their eyelashes at the hesitant drider.

His cheeks puffed out with indignation. “Are they mocking us?”

“No, not at all. I’d just like to try something with you, that’s all.”

He growled under his breath, tapping a single leg against the ground while considering the proposal. “...Fine. One song only. If the instrument breaks it is not my problem.”

“Wonderful! I’d not worry much about the violin honestly. I think Astarion stole it from some merchant or another, won’t be much of a loss if it snaps. I’ll be back!”

Kar’niss watched Tav scurry back to camp to retrieve the item. He crossed his arms tight against his chest, his pedipalps trembled in place, betraying his anxiety for the performance soon to come. He’d not have to wait long. Tav had been swift in their retrieval of the instrument, they ran up to Kar’niss and held it up for him to take.

“Phew, there you go,” Tav panted, wiping a bit of sweat from their brow.

He lifted the violin and bowstring into his clawed hands, looking over each piece as if he’d been reunited with an old friend. It felt strange in his grasp and the jagged nature of his fingertips made either item a challenge to grip. Tav stood back and let him become adjusted to them, watching as he plucked a few strings to test their muted chords in succession. His nose wrinkled with some concern.

“What is it you wish to play?” Kar’niss asked.

“Have you heard of the waltz of the feywilds? It’s a bit complicated but it is one of my favorite songs.”

Kar’niss squinted and mulled over the request, his tongue darting out to swipe over his lips. “We are not certain. The title sounds familiar, it has been too long since I have played it.”

“Tell you what. I’ll start playing solo and if you catch the rhythm feel free to jump in as you wish. How does that sound?”

He hummed and nodded. “Very well.”

[Music]

Tav tucked the butt of the violin under their chin and rested the bow over the strings, straightening their posture. Kar’niss mirrored this, relearning the proper stance. It was a bit awkward as his chin now had an extra layer molded over top via the hardened chitin but he managed to adjust well enough. Tav positioned their fingers over the proper strings on the violin neck and began to play, a gentle melody rising from the instrument into the night air.

Kar’niss closed his eyes as Tav began to play, opting to focus with his pointed ears rather than his sight. He listened to the first notes of the song and honed in on it, digging deep into the recesses of his memory in search of something he’s heard before. It took him a moment but he soon willed himself to play the first note, sliding into Tav’s solo to turn it into a duet. At first he struggled, his fingers larger than he was accustomed to which made hitting the right strings a struggle. He’d strike off key or hold a note for longer than it was meant to be but Tav didn’t seem to mind.

“You’re doing great, keep going,” Tav insisted.

He exhaled his nerves and stuck with it even if he felt the urge to drop the violin and walk away. Steadily, he became accustomed to the added bulk of his chin and fingers, shifting the instrument in such a way that it worked for him rather than against. Once he did so the notes flowed smoother, in line with Tav’s own contribution. This made Tav smile, their body bobbing up and down on their knees once the music started to hit their core.

Their playing continued, gradually picking up pace into an uplifting harmony. Even for as stiff as Kar’niss could be he felt the draw of the music seep into his skin, pulling him back to a different time in his life. As his comfort levels grew his confidence in manipulating the instrument to his will increased, playing with a bit more passion than at the start. Despite his best efforts he found himself swaying from side to side in time with the beat, his long legs curled while rocking his large body like a pendulum. Tav took notice, unable to wipe the growing grin from their face. They chose to join him by shuffling their feet on the grass below, stepping from side to side to match Kar’niss’ rhythm.

He tipped his head to the side slightly at the sight of the display, deciding to up the ante a notch. He lowered his front half toward the ground, extending his pedipalps to drum against the dirt when he felt added percussion was needed for the melody. Tav unleashed joyful laughter due to Kar’niss’ improvised antics, finding them clever. They stepped forward and began to dance around the drider while he tapped at the ground, spinning and skipping around his impressive abdomen, soon returning to his front. All the while the two continued to play, their song growing in intensity as they progressed.

Kar’niss had become lost in the duet, the faintest of smiles threatening to stretch his mouth. The ballad increased in pace and came to a high pitched mid point, the pair putting their all into assaulting the strings with determined ferocity. Kar’niss closed all of his eyes and tipped his head back, matching Tav tit for tat. Once the mid point had passed they would side step to and fro while facing one another, Tav spinning around in place and Kar’niss following suit. Albeit his turn was slower thanks to his extra girth, but he still managed to do so with grace. Tav stepped toward their partner and Kar’niss stepped in to meet them before both walked back to restore distance between them. His legs stamped at the ground in sync with the anthem, his torso bending into the violin as he leaned into the more fast paced tone. His rounded abdomen swayed and rocked concurrently with his legs, putting his entire body in motion.

Both continued to prance from one side to the next in unison with one another, turning around in place at proper intervals, lowering their bodies into a crouch then springing upright. The smile Kar’niss had fought came out victorious, fully visible on his expression. It was a toothy grin that was both endearing and haunting at the same time. Despite his impressive size Tav wasn’t intimidated with his dance partner, rather savoring his enjoyment knowing how rare such a treat was for him.

The pair were reaching the crescendo of their song, the very apex building in urgency between the pair of them. As the final elongated note was shared between them, Kar’niss lifted his body upward while he held the high pitched sound, pushing until he was balancing on his back four feet. The other four extended outward alongside his pedipalps, opening wide as if he were in a defensive stance and yet that was far from the case. He tipped his torso back until his hair fell from his shoulders and dangled freely in the air, Tav watching the display in awe of his beauty in that moment.

The lengthy note was dropped, the final chords played afterward in rapid succession to end off the song with a flourish. Both Tav and Kar’niss played the final refrain in a quick strike and once finished they dropped into a low bow in front of one another. Their arms extended outward, bow string and violin clutched in either hand jutting from their grasp. They held the lowered position for a moment to catch their breath, Tav the first to lift their head to find they were eye level with Kar’niss; A rare thing indeed. Their gazes met, the drider offering the smallest of smiles in Tav’s direction, his hair a mess across his face.

“You did it,” Tav whispered.

Before Kar’niss could respond the pair heard the sound of clapping nearby. Tav stood with a jolt, looking behind them to see others at camp had gathered around. Wyll in particular seemed enthused by the performance.

“Well done, well done!” Wyll called out.

“Got an encore in you??” Karlach shouted.

Tav smiled sheepishly at the pair and shook their head. “I doubt it, but glad you enjoyed it.”

Kar’niss made a face at the unexpected audience. He dropped the bow and violin, backing away as he felt a tingle in his cheeks.

“Kar’niss, are you alright?” Tav asked.

The drider growled ever so slightly and then turned, quickly scuttling away from Tav and the others. He fled back into the underbrush of the forest and disappeared from sight, having none of it.

“Ah shit, did we scare him off?” Karlach asked.

“We’re sorry Tav, we didn’t think it’d be a bother.” Wyll added.

Tav exhaled and wandered over to retrieve the discarded instrument, looking it over with some fondness.

“No, nothing to be sorry for. I think he is a bit more shy than he lets on. Give him time, he’ll return when he’s ready.”

Kar’niss wandered back into the forest and climbed into the tree he picked to call home for the night, complete with scattered webbing throughout the area. He’d settle on a thick branch, his arms crossed as he worked through his temporary embarrassment. Part of him was still in disbelief that he’d done that at all, that he still could. The feeling of an instrument in his hands felt better than he dared admit aloud. Once he started to calm down he turned his gaze to the stars, a sight he often favored while alone. The tips of his pedipalps began to gently tap at the branch below, one, two, one, two. He bobbed his head from side to side and before he knew it he was humming the song they had just played. He continued to do so while training his eyes on the sky, his wobbled smile making a return.

For now at least.

#baldur's gate 3#kar'niss#drider#bg3#karniss#baldurs gate 3#answered#my writing#bard#music#violin#kar'niss fanfic#bg3 fanfic#kar'niss x tav#gender-neutral tav#This was a challenge but fun to write#Kar'niss is 80% legs

90 notes

·

View notes

Text

Rapid Screening-Differential Scanning Calorimeter for Antibody Drug Development

TA Instruments is the world leader in manufacturing industry-leading systems for thermal analysis, rheology, microcalorimetry and mechanical analysis. We offer innovative and reliable instruments that help scientists in top laboratories test the physical properties of their materials. Our instruments contribute to leading discoveries in medicine, materials science, electronics and other areas of science devoted to improving our world.

Waters Corporation is the world’s leading specialty measurement company focused on improving human health and well-being through the application of high-value analytical technologies and industry-leading scientific expertise.

#PharmaNews#PharmaUpdate#PharmaInnovation#RapidScreening#DifferentialScanningCalorimeter#AntibodyDrugDevelopment#PharmaceuticalIndustry#BiotechNews#DrugDiscovery#PharmaTech

2 notes

·

View notes

Text

My heart leaps as I feel his breath there.

One Piece AU | Tralfagar Law x Luffy

“Your enchantments last long after your song fades.

Trafalgar Law is a successful young marine biologist who, together with his research unit, sails the seas in a yellow submarine. After a malfunction, the submarine needs to be repaired in a small harbour where the myths of mermaids remain strong and deep.

In the middle of his investigation along the "Grand Line" measuring the salinity of the water and collecting small samples, a magical encounter arises between him and what he always thought was a fantasy.

A curious young merman with a huge smile, red scales and a straw hat tied to his neck, found him in the sunset among the rock formations of the bay collecting samples.

This merman will follow him while his research is halted due to repairs on his submarine that mysteriously do not progress while the singing in the black water lulls the young tattooed doctor into lucid dreams of a naked black-haired boy with a scar under his left eye.

Between these dreams of the boy and his encounter with the dweller of the Deep, the Captain of the "Polar Tang" has stopped his voyage without revealing anything to his crew but hoping to unravel or at least resolve the longings of the past that have sunk into his chest.

The siren does not speak, but smiles at him, plays and makes a dolphin-like sound while they seeks to get closer to the men while his tail still touching the water. At night the boy in his dreams asks him about the things he found during the day and of which he had a record in his logbook. The mysterious boy seems to know more than he does about what dwells on the seabed. He snoops through his papers, sees his drawings, and in some cases gives him precise details of which only he and his "unwanted" company know, as he has started to narrate to the mermaid his discoverings In search of feeling less lonely on their "walks” along the beach.

Somehow Law has the feeling that the boy of his dreams and the mermaid are the same person who against all odds or inclemency has chosen him as his home and the sunset on the beach likewise the company at night are the only ways they can "live together" until he figures out how to make this son of the ocean break the chains that bind him to the salty waters.

At first he thought of using it as an object of study, a revolutionary discovery for his already successful and rising career in the field of marine research. But slowly, the newt's innocence and warm gentleness made him soften and want to protect his evenings sharing the golden hour on the sandy beach.

As the weeks go by, the crew of the "Polar Tang" begin to worry about the lack of interest in their captain returning the submarine to the seabed. Seeing it immersed in his "research" as it does not comment on anything, the hours he spends outside are longer and longer, carrying with him more than two portions of lunch and snacks instead of his instruments or diving equipment. This arouses the suspicions of all the crew, for when they return, night has fallen, and Captain Law is up to his waist in seawater and wants to bathe and sleep without complaints or comments on how the submarine keeps failing safety tests to set sail again.

19 notes

·

View notes

Note

[MIC CHECK] - It's hard work to make sure all the equipment is good working order! Help the sound team out by singing in a few notes with a partner.

SQKREEEEEEE - !!!

The microphone would not stop screaming at him - no matter the distance of his fingers to its base, it protested shrilly to his presence in a way that had begun to appear most distressing to not merely the sound team, but passers-by.

Kevin grimaced - or rather, his lips ticked slightly downward in contemplation of the predicament. He was not the sort of man to leave a task unfinished, once he had pledged himself to it, but if this was the way that it kept behaving...

Eyes slid to the side, seeking out someone - anyone, in truth, who might have taken to the stage better than he - and finding his mark in a man whose smile seemed to wear him, rather than the other way around.

"...Perhaps you might be better suited to help with this. Would you come, lend your talents?"

Static buzzing, crackling with feedback, Kevin handed the microphone off to the young man, gaze simultaneously curious and pleading.

THE TINNY SCREECH OF MISBEHAVING TECH, the din of a hosted event venue in its preparation stages——sometime in the years since shedding rags and the ubiquitous roughness of sand for his newly-minted image, he'd gotten used to things like this.

aventurine is just passing by when the notes of shrill whining reaches its peak, every head in the room turning to glare at the unfortunate perpetrator. the young man standing on the stage looks no better off for it, nervously cognizant of the unwanted attention yet seemingly at a loss to fix it. where were the sound technicians? he can't imagine they'd left someone who had no idea what he was doing to set up the equipment.

as luck would have it, those nervous eyes scanning the room land on his, and decide to stick there. he sighs ; the meaning's clear enough. who'd he be to let this man stand up there and continue to flounder?

"i'm here today to meet with the producer about details regarding expenditures, not as an extra hand for the sound crew." measured steps bring him up abreast of the other on the stage, dimming the microphone's grating screech with a sharp tip of the instrument down toward the floor. though his words alone seem couched in admonishment——even threat——his tone is gentle and pleasant, lulling between the hypnotic serenade of honeyed tongue and auroral eyes. "i'm just letting you know: the company may end up owing for this."

he's no expert, but enough times on a variety of stage, set, radio, and otherwise, and anyone might pick up a trick or two from watching. the problem has to be with the speaker towers set up not a far distance away. but just as he positions to lift the microphone stand with both hands and move it, the instrument's shrieking suddenly stops completely. caught by surprise, he gingerly releases it. still nothing, even though it hadn't shifted an inch.

"hm. . . " he tilts the microphone back up. "testing, testing." the avgin's velvet caresses the air of the auditorium just fine, so he steps back and gestures for the other to try his luck again——but almost immediately, the stand begins to whine again as though sentient.

mm, i see how this is.

with a chuckle, he returns to his previous place ; the impending screech quiets once more to obedience as he looks to the other with something part apology, part admittance. "looks like something's gotten into this one. i'd be careful about sourcing anything from penacony if you're not accustomed to handling it. best to just find a new mic for now."

#◟〈 ♠ 〉 kevin ━━ 🇨🇭🇦🇷🇦🇨🇹��🇷﹒#jxrmngxndr#GHOverture2024#the way i know nothing about hi3 jNKALNSKDGJ#ty tches!! much appreciated

2 notes

·

View notes

Text

The Global Impact of High-Quality Current Transformer Bases

In the ever-evolving landscape of energy distribution and management, current transformers play a pivotal role in ensuring accurate measurement and monitoring of electrical currents in power systems. A critical component within these transformers is the current transformer base, which serves as the foundation for the safe and efficient operation of transformers. As global demand for energy continues to surge, the significance of high-quality current transformer bases in modern power infrastructures cannot be overstated.

Current transformer bases are instrumental in energy distribution networks, helping to measure current accurately and protect electrical systems from faults and overloading. This blog will delve into the global impact of high-quality current transformer bases and highlight the importance of reliable manufacturers and exporters in India, the growing role of air-insulated switchgear companies, and the increasing need for advanced power monitoring systems.

The Role of Current Transformer Bases in Power Systems

Current transformers (CTs) are essential in the measurement and control of electrical currents in various applications, from power generation and transmission to industrial automation and energy metering. The current transformer base acts as the structural platform on which the transformer operates, ensuring the stability and insulation of the CT during operation.

High-quality current transformer bases provide enhanced accuracy in current measurement, which is critical for maintaining the efficiency and safety of power systems. These bases also ensure proper insulation and protection of the transformer, preventing short circuits, arcing, and other potential hazards.

For industries where power quality and reliability are paramount, such as manufacturing, utilities, and data centers, the performance of the current transformer base directly impacts the effectiveness of power monitoring and control systems.

India: A Global Hub for Current Transformer Base Manufacturing

India has emerged as a key player in the global energy sector, and its manufacturers are becoming increasingly prominent in the production of critical power components. As a leading current transformer base manufacturer and exporter in India, Radiant Enterprises and other companies have made significant strides in meeting global demand for high-quality products. Indian manufacturers are known for their technical expertise, innovative solutions, and adherence to international standards, making them a trusted source for current transformer bases.

The rise of India as a global manufacturing hub has been driven by several factors:

Cost-Effective Production: Indian manufacturers offer competitive pricing without compromising on quality, making their products attractive to global markets.

Skilled Workforce: India boasts a highly skilled workforce with expertise in the design, production, and testing of electrical components, including current transformer bases.

Adherence to International Standards: Indian manufacturers comply with global quality standards such as ISO, IEC, and other industry certifications, ensuring that their products meet the stringent requirements of international clients.

Growing Export Market: India’s export market for electrical components has seen steady growth, with manufacturers catering to the needs of clients across Europe, North America, Africa, and Asia.

As the global demand for energy continues to rise, the role of Indian manufacturers and exporters in meeting the need for high-quality current transformer bases becomes even more significant.

Impact on Power Monitoring Systems

Power monitoring systems are essential tools in modern electrical infrastructure, providing real-time data on the performance of power distribution networks. These systems help monitor energy usage, detect faults, and optimize the efficiency of electrical systems, thereby ensuring the reliability and safety of power networks.

The accuracy of power monitoring systems depends heavily on the precision of current transformers and, by extension, the quality of the current transformer bases. High-quality current transformer bases ensure that the transformers can operate effectively, delivering accurate data to power monitoring systems.

Some of the key benefits of power monitoring systems include:

Real-Time Data: Power monitoring systems provide instant data on power usage, current levels, and potential faults, allowing for immediate corrective action.

Improved Energy Efficiency: By analyzing data from power monitoring systems, businesses can optimize their energy usage, reduce waste, and lower operational costs.

Enhanced Safety: Power monitoring systems can detect anomalies in current flow, such as overloads or short circuits, and alert operators to potential safety hazards before they escalate.

Preventive Maintenance: With accurate data on system performance, companies can implement preventive maintenance strategies, reducing downtime and preventing costly repairs.

Given the growing emphasis on energy efficiency and sustainability, the demand for high-quality power monitoring systems continues to rise globally. In turn, the importance of reliable current transformer bases in supporting these systems cannot be overstated.

The Role of Air Insulated Switchgear Companies in India

Switchgear is a vital component of power distribution systems, used to control, protect, and isolate electrical equipment. Air-insulated switchgear (AIS) is one of the most widely used types of switchgear in medium- and high-voltage power distribution applications. These systems use air as the primary insulating medium and are designed to protect electrical circuits from faults while ensuring the continuity of power supply.

Air-insulated switchgear companies in India are playing a key role in modernizing electrical infrastructure across the country and globally. India has become a prominent player in manufacturing air-insulated switchgear due to its expertise in power distribution equipment, favorable production costs, and adherence to international quality standards.

Air-insulated switchgear companies in India contribute to the global power industry in several ways:

Innovative Solutions: Indian manufacturers are continually developing advanced air-insulated switchgear solutions to meet the evolving demands of modern power systems. These innovations include more compact designs, improved insulation technologies, and enhanced safety features.

Cost Efficiency: Indian air-insulated switchgear companies offer competitive pricing compared to manufacturers in other parts of the world, making them a cost-effective solution for global clients.

Environmental Considerations: As the world shifts toward greener energy solutions, air-insulated switchgear offers an environmentally friendly alternative to gas-insulated switchgear, which uses greenhouse gases such as SF6 for insulation.

The Global Impact of High-Quality Electrical Components

The global energy landscape is undergoing a profound transformation driven by the increasing demand for electricity, the transition to renewable energy sources, and the need for improved energy efficiency. As a result, the demand for high-quality electrical components, including current transformer bases and air-insulated switchgear, is growing at an unprecedented rate.

High-quality current transformer bases are crucial for ensuring the accuracy and reliability of electrical measurements, which in turn supports the effective operation of power monitoring systems. These systems are essential for optimizing energy usage, improving safety, and ensuring the reliability of electrical infrastructure.

The growing role of current transformer base manufacturers and exporters in India in meeting global demand highlights the country's importance in the global energy sector. Indian manufacturers are supplying high-quality products that meet international standards, helping to improve power distribution networks around the world.

Similarly, air-insulated switchgear companies in India are contributing to the modernization of electrical infrastructure, both domestically and internationally. Their innovations are helping to improve the efficiency and reliability of power systems, while also offering environmentally friendly solutions.

Conclusion: Powering the Future with Quality

As the world moves toward a more connected and energy-efficient future, the importance of high-quality electrical components, such as current transformer bases, air-insulated switchgear, and advanced power monitoring systems, will continue to grow. These components are critical to ensuring the safe, reliable, and efficient operation of power distribution networks, which are essential to the global economy.

Manufacturers and exporters in India, including current transformer base manufacturers, are playing a vital role in meeting global demand for high-quality electrical products. Their commitment to innovation, quality, and sustainability is helping to shape the future of the global energy landscape, ensuring that power systems are equipped to handle the challenges of tomorrow.

With the rise of renewable energy, the expansion of smart grids, and the increasing focus on energy efficiency, the demand for reliable and accurate electrical components will only continue to grow. By investing in high-quality current transformer bases and partnering with reputable air-insulated switchgear companies in India, businesses can ensure that they are prepared for the future of energy.

#Power monitoring system#Current transformer base manufacturer and exporter in India#Air insulated switchgear companies in India

4 notes

·

View notes

Text

Chef WK, lead charcuterie specialist in Alberta Canada

Table of contents

1. Control Program Requirements for Fermented Meat Products

2. Facility and Equipment Requirements

3. Starter Culture

4. Chemical Acidification

5. Water Activity Critical Limits

6. Time and Temperature for Fermented Products

7. Fermentation Done at a Constant Temperature

8. Examples of Degree-hours at constant room temperatures

9. Fermentation Done at Different Temperatures

10. Fermentation done at Different temperatures

11. What happens if fermentation fails to hit critical limit?

12. E. coli and Salmonella Control in Fermented Sausages

13. Options for E. coli validation

14. Option1; Heating

15. Option 2; pH, heating, holding, diameter

16. Safety and consistency

Control Program Requirements for Fermented Meat Products

The producer must have a program in place to assess the incoming product. This program should outline specifications for the incoming ingredients. This may include criteria including receiving temperature, farm/ supplier, lot code or packed on date, species/cut etc.

2. Facility and Equipment Requirements

Equipment used in the fermentation process must be included in the operator's prerequisite control programs. These must include the following elements:

Temperature in the fermentation, drying and smoking chambers must be uniform and controlled to prevent any fluctuation that could impact on the safety of the final product.

Fermentation, drying and smoking chambers must be equipped with a shatter resistant indicating thermometer, (or equivalent), with graduations of 1°C or less. If mercury thermometers are used, their mercury columns must be free from separations. All thermometers must be located such that they can be easily read.

Fermentation and smoking chambers must be equipped with a recording thermometer for determining degree-hours calculations in a reliable manner. Recording thermometers are also preferable in drying and aging rooms but, in these rooms, it may be sufficient to read and record the temperatures 2 times a day.

Drying and aging rooms must be equipped with humidity recorders in order to prevent uncontrolled fluctuations of the relative humidity. The only alternative to an automatic humidity recorder in these rooms would be for the company to manually monitor and record ambient humidity twice a day (morning and afternoon) every day with a properly calibrated portable humidity recorder.

For routine monitoring, accurate measurement electronic pH meters (± 0.05 units) should be employed. It is important that the manufacturer's instructions for use, maintenance and calibration of the instrument as well as recommended sample preparation and testing be followed.

When the aw of a product is a critical limit set out in the HACCP plan for a meat product, accurate measurement devices must be employed. It is important that the manufacturer's instructions for use, maintenance and calibration of the instrument be followed.

3. Starter Culture

The operator must use a CFIA approved starter culture. This includes Freeze-dried commercially available culture as well as back-slopping (use of previously successful fermented meat used to inoculate a new batch). When performing back-slopping, the operator must have a control program in place to prevent the transmission of pathogens from when using the inoculum from a previous batch to initiate the fermentation process of a new batch. These must include:

The storage temperature must be maintained at 4°C or less and a pH of 5.3 or less.

Samples for microbiological analysis must be taken to ensure that the process is in line with the specifications.

The frequency of sampling is to be adjusted according to compliance to specifications.

Any batch of inoculum which has a pH greater than 5.3 must be analysed to detect at least Staphylococcus aureus. Only upon satisfactory results will this inoculum be permitted for use in back slopping.

This can be an expensive and a time exhaustive process and is generally avoided due to food safety concerns. AHS does not allow back-slopping.

[Chef WK was in communication with the U of A to get his method, a starter mix, studied.]

4. Chemical Acidification

If product is chemically acidified by addition of citric acid, glucono-delta-lactone or another chemical agent approved for this purpose, controls must be in place and records kept to ensure that a pH of 5.3 or lower is achieved by the end of the fermentation process. These acids are encapsulated in different coatings that melt at specific temperatures, which then release the powdered acids into the meat batter and directly chemically acidulate the protein.

Summer sausage is a very common chemically acidified product. The flavor profile tends to be monotone and lacking depth.

5. Water Activity Critical Limits

The aw may be reduced by adding solutes (salt, sugar) or removing moisture.

Approximate minimum levels of aw (if considered alone) for the growth of:

molds: 0.61 to 0.96

yeasts: 0.62 to 0.90

bacteria: 0.86 to 0.97

Clostridium botulinum: 0.95 to 0.97

Clostridium perfringens: 0.95

Enterobacteriaceae: 0.94 to 0.97

Pseudomonas fluorescens: 0.97

Salmonella: 0.92 - 0.95

Staphylococcus aureus: 0.86

parasites: Trichinella spiralis will survive at an aw of 0.93 but is destroyed at an aw of 0.85 or less.

The above levels are based on the absence of other inhibitory effects such as nitrite, competitive growth, sub-optimum temperatures, etc., which may be present in meat products. In normal conditions, Staphylococcus aureus enterotoxins are not produced below aw 0.86, although in vacuum packed products this is unlikely below aw 0.89.

6. Time and Temperature for Fermented Products

Certain strains of the bacteria Staphylococcus aureus are capable of producing a highly heat stable toxin that causes illness in humans. Above a critical temperature of 15.6°C, Staphylococcus aureus multiplication and toxin production can take place. Once a pH of 5.3 is reached, Staphylococcus aureus multiplication and toxin production are stopped.

Degree-hours are the product of time as measured in hours at a particular temperature multiplied by the "degrees" measured in excess of 15.6°C (the critical temperature for growth of Staphylococcus aureus). Degree-hours are calculated for each temperature used in the process. The limitation of the number of degree-hours depends upon the highest temperature in the fermentation process prior to the time that a pH of 5.3 or less is attained.

The operator is encouraged to measure temperatures at the surface of the product. Where this is not possible, the operator should utilize fermentation room temperatures. The degree hour calculations are based on fermentation room temperatures. Temperature and humidity should be uniform throughout the fermentation room.

A process can be judged as acceptable provided the product consistently reaches a pH of 5.3 using:

fewer than 665 degree-hours when the highest fermentation temperature is less than 33°C;

fewer than 555 degree-hours when the highest fermentation temperature is between 33° and 37°C; and

fewer than 500 degree-hours when the highest fermentation temperature is greater than 37°C.

This means that as the temperature increases, the amount of time that you have available to reach 5.3 or under is shorter. The warmer the temperature, the sharper the log growth phase of bacteria, which equates to more overshoot in lactic acid production, faster.

8. Examples of Degree-hours at constant room temperatures

Example 1:

Fermentation room temperature is a constant 26°C. It takes 55 hours for the pH to reach 5.3.

Degrees above 15.6°C: 26°C - 15.6°C = 10.4°C Hours to reach pH of 5.3: 55 Degree-hours calculation: (10.4°C) x (55) = 572 degree-hours

The corresponding degree-hours limit (less than 33°C) is 665 degree-hours.

Conclusion: Example 1 meets the guideline because its degree-hours are less than the limit.

Example 2:

Fermentation room temperature is a constant 35°C. It takes 40 hours for the pH to reach 5.3.

Degrees above 15.6°C: 35°C - 15.6°C = 19.4°C Hours to reach pH of 5.3: 40 Degree-hours calculation: (19.4°C) x (40) = 776 degree-hours

The corresponding degree-hours limit (between 33 and 37°C) is 555 degree-hours.

Conclusion: Example 2 does not meet the guideline because its degree-hours exceed the limit

9. Fermentation Done at Different Temperatures

When the fermentation takes place at various temperatures, each temperature step in the process is analyzed for the number of degree-hours it contributes. The degree-hours limit for the entire fermentation process is based on the highest temperature reached during fermentation.

Example 1:

It takes 35 hours for product to reach a pH of 5.3 or less. Fermentation room temperature is 24°C for the first 10 hours, 30°C for second 10 hours and 35°C for the final 15 hours.

Step 1

Degrees above 15.6°C: 24°C - 15.6°C = 8.4°C Hours to reach pH of 5.3: 10 Degree-hours calculation: (8.4°C) x (10) = 84 degree-hours

Step 2

Degrees above 15.6°C: 30°C - 15.6°C = 14.4°C Hours to reach pH of 5.3: 10 Degree-hours calculation: (14.4°C) x (10) = 144 degree-hours

Step 3

Degrees above 15.6°C: 35°C - 15.6°C = 19.4°C Hours to reach pH of 5.3: 15 Degree-hours calculation: (19.4°C) x (15) = 291 degree-hours

Degree-hours calculation for the entire fermentation process = 84 + 144 + 291 = 519

The highest temperature reached = 35°C

The corresponding degree-hour limit = 555 (between 33°C and 37°C)Conclusion: Example 1 meets the guideline because its degree-hours are less than the limit.

10. Fermentation done at Different temperatures

Example 2:

It takes 38 hours for product to reach a pH of 5.3 or less. Fermentation room temperature is 24°C for the first 10 hours, 30°C for the second 10 hours and 37°C for the final 18 hours.

Step 1

Degrees above 15.6°C: 24°C - 15.6°C = 8.4°C Hours to reach pH of 5.3: 10 Degree-hours calculation: (8.4°C) x (10) = 84 degree-hours

Step 2

Degrees above 15.6°C: 30°C - 15.6°C = 14.4°C Hours to reach pH of 5.3: 10 Degree-hours calculation: (14.4°C) x (10) = 144 degree-hours

Step 3

Degrees above 15.6°C: 37°C - 15.6°C = 21.4°C Hours to reach pH of 5.3: 18 Degree-hours calculation: (21.4°C) x (18) = 385.2 degree-hours

Degree-hours calculation for the entire fermentation process = 84 + 144 + 385.2 = 613.2

The highest temperature reached = 37°C

The corresponding degree-hour limit = 555 (between 33°C and 37°C)

Conclusion: Example 2 does not meet the guidelines because its degree-hours exceed the limit.

11. What happens if fermentation fails to hit critical limit?

What happens if the batch takes longer than degree-hours allows? For restaurant level production, it's always safer to discard the product. The toxin that Staph. Aureus produces is heat stable and cannot be cooked to deactivate. In large facilities that produce substantial batches, the operator must notify the CFIA of each case where degree-hours limits have been exceeded. Such lots must be held and samples of product submitted for microbiological laboratory examination after the drying period has been completed. Analyses should be done for Staphylococcus aureus and its enterotoxin, and for principal pathogens, such as E. coli O157:H7, Salmonella, and Clostridium botulinum and Listeria monocytogenes.

If the bacteriological evaluation proves that there are fewer than 104 Staphylococcus aureus per gram and that no enterotoxin or other pathogens are detected, then the product may be sold provided that it is labelled as requiring refrigeration.

In the case of a Staphylococcus aureus level higher than 104 per gram with no enterotoxin present the product may be used in the production of a cooked product but only if the heating process achieves full lethality applicable to the meat product.

In the case where Staphylococcus aureus enterotoxin is detected in the product the product must be destroyed.

12. E. coli and Salmonella Control in Fermented Sausages

Business' that manufacture fermented sausages are required to control for verotoxinogenic E. coli including E. coli O157:H7 and Salmonella when they make this type of product. This includes:

establishments which use beef as an ingredient in a dry or semi-dry fermented meat sausage;

establishments which store or handle uncooked beef on site;

Establishments which do not use beef and do not obtain meat ingredients from establishments which handle beef are not currently required to use one of the five options for the control of E. coli O157:H7 in dry/semi-dry fermented sausages.

Any processed RTE product containing beef or processed in a facility that also processed beef, must be subjected to a heat treatment step to control E. coli O157:H7. Heating to an internal temperature of 71°C for 15 seconds or other treatment to achieve a 5D reduction is necessary. This is a CFIA requirement and is not negotiable.

Uncooked air dried products produced as RTE, must meet shelf stable requirements as detailed for Fermented-Dry products.

13. Options for E. coli validation

Without lab testing, the two main methods of validation are with heat treating by either low temp and a long duration, or various hotter processing temperatures for a shorter timeframe.

A challenge study to validate a process can take 1 year and over $100,000!

14. Option1; Heating

15. Option 2; pH, heating, holding, diameter

16. Safety and consistency

The aw and pH values are critical in the control of pathogens as well as to ensure shelf-stability in all semi-dry and dry fermented meat products. Each batch must be tested for aw and/or pH in order to verify that the critical limits are met.

Although aw measurement is mandatory only for shelf stable products, it is strongly recommended that the producer determine the aw values achieved for each product type they manufacture and for each product. Once this has been established, frequent regular checks should be made to ensure consistency. In the U.S., they rely on moisture to protein ratio and have set targets. This lab-tested value is a direct correlation of the % water to % meat protein and not aw. This gives more consistency to common names. For example, to legally call a product "jerky" it must have a MPR of 0.75:1 or lower. Remember your ABCs:

Always be compliant.

-AND-

Documentation or it didn't happen.

(tags)

Charcuterie,Fermented Meat,Food Safety,Starter Culture,Chemical Acidification,Water Activity,Fermentation Process,Degree-Hours Method,Foodborne Pathogens,Meat Processing Guidelines,Chef WK Alberta Canada,Food Industry Standards,pH Critical Limits,Thermal Processing,Food Preservation,Food Microbiology,Sausage Fermentation,Charcuterie Expertise,Fermented Meats ,Food Safety Standards,Food Processing Guidelines,Starter Cultures,Chemical Acidification,Water Activity (a_w),Critical Limits,Degree-Hours Method,Foodborne Pathogens,Meat Processing Equipment,Processing Facility Requirements,Hazard Analysis and Critical Control Points (HACCP),Food Preservation Techniques,Temperature Control,Pathogen Reduction,Food Industry Compliance,Documentation Practices,Heat Treatment,pH Control,Food Stability,Consistency in Production,Microbial Testing,Real-time Monitoring,Process Validation,Regulatory Requirements,Verotoxigenic E. coli,Lethality Standards,Product Labelling,Spoilage Prevention,Enterotoxin Detection,Shelf-Stable Products,Moisture to Protein Ratio (MPR)

#Charcuterie#Fermented Meat#Food Safety#Starter Culture#Chemical Acidification#Water Activity#Fermentation Process#Degree-Hours#Meat Processing Guidelines#Thermal Processing#Food Preservation#Food Microbiology#Sausage Fermentation#Starter Cultures#Critical Limits#Meat Processing#Food Preservation Techniques#Temperature Control#Pathogen Reduction#Food Industry#Heat Treatment#pH Control#Food Stability#Microbial Testing#Real-time Monitoring#Process Validation#Spoilage Prevention#Enterotoxin Detection#Shelf-Stable Products#Moisture to Protein Ratio (MPR)

3 notes

·

View notes

Link

A SpaceX Falcon 9 rocket carrying Intuitive Machines’ Nova-C lunar lander lifts off from Launch Pad 39A at NASA’s Kennedy Space Center in Florida at 1:05 a.m. EST on Feb. 15, 2024. As part of NASA’s CLPS (Commercial Lunar Payload Services) initiative and Artemis campaign, Intuitive Machines’ first lunar mission will carry NASA science and commercial payloads to the Moon to study plume-surface interactions, space weather/lunar surface interactions, radio astronomy, precision landing technologies, and a communication and navigation node for future autonomous navigation technologies. A suite of NASA science instruments and technology demonstrations is on the way to our nearest celestial neighbor for the benefit of humanity. Through this flight to the Moon, they will provide insights into the lunar surface environment and test technologies for future landers and Artemis astronauts. At 1:05 a.m. EST on Thursday, Intuitive Machines’ Nova-C lander launched on a SpaceX Falcon 9 rocket from Launch Complex 39A at the agency’s Kennedy Space Center in Florida. At approximately 1:53 a.m., the lander deployed from the Falcon 9 second stage. Teams confirmed it made communications contact with the company’s mission operations center in Houston. The spacecraft is stable and receiving solar power. These deliveries are part of NASA’s CLPS (Commercial Lunar Payload Services) initiative and Artemis campaign, which includes new solar system science to better understand planetary processes and evolution, search for evidence of water and other resources, and support long-term human exploration. “NASA scientific instruments are on their way to the Moon – a giant leap for humanity as we prepare to return to the lunar surface for the first time in more than half a century,” said NASA Administrator Bill Nelson. “These daring Moon deliveries will not only conduct new science at the Moon, but they are supporting a growing commercial space economy while showing the strength of American technology and innovation. We have so much to learn through CLPS flights that will help us shape the future of human exploration for the Artemis Generation.” While enroute to the Moon, NASA instruments will measure the quantity of cryogenic engine fuel as it is used, and during descent toward the lunar surface, they will collect data on plume-surface interactions and test precision landing technologies. Once on the Moon, NASA instruments will focus on investigating space weather/lunar surface interactions and radio astronomy. The Nova-C lander also will carry retroreflectors contributing to a network of location markers on the Moon for communication and navigation for future autonomous navigation technologies. NASA science aboard the lander includes: Lunar Node 1 Navigation Demonstrator: A small, CubeSat-sized experiment that will demonstrate autonomous navigation that could be used by future landers, surface infrastructure, and astronauts, digitally confirming their positions on the Moon relative to other spacecraft, ground stations, or rovers on the move. Laser Retroreflector Array: A collection of eight retroreflectors that enable precision laser ranging, which is a measurement of the distance between the orbiting or landing spacecraft to the reflector on the lander. The array is a passive optical instrument and will function as a permanent location marker on the Moon for decades to come. Navigation Doppler Lidar for Precise Velocity and Range Sensing: A Lidar-based (Light Detection and Ranging) guidance system for descent and landing. This instrument operates on the same principles of radar but uses pulses from a laser emitted through three optical telescopes. It will measure speed, direction, and altitude with high precision during descent and touchdown. Radio Frequency Mass Gauge: A technology demonstration that measures the amount of propellant in spacecraft tanks in a low-gravity space environment. Using sensor technology, the gauge will measure the amount of cryogenic propellant in Nova-C’s fuel and oxidizer tanks, providing data that could help predict fuel usage on future missions. Radio-wave Observations at the Lunar Surface of the Photoelectron Sheath: The instrument will observe the Moon’s surface environment in radio frequencies, to determine how natural and human-generated activity near the surface interacts with and could interfere with science conducted there. Stereo Cameras for Lunar Plume-Surface Studies: A suite of four tiny cameras to capture imagery showing how the Moon’s surface changes from interactions with the spacecraft’s engine plume during and after descent. Intuitive Machines’ Nova-C-class lunar lander, named Odysseus, is scheduled to land on the Moon’s South Pole region near the lunar feature known as Malapert A on Thursday, Feb. 22. This relatively flat and safe region is within the otherwise heavily cratered southern highlands on the side of the Moon visible from Earth. Landing near Malapert A will also help mission planners understand how to communicate and send data back to Earth from a location where Earth is low on the lunar horizon. The NASA science aboard will spend approximately seven days gathering valuable scientific data about Earth’s nearest neighbor, helping pave the way for the first woman and first person of color to explore the Moon under Artemis. Learn more about NASA’s CLPS initiative at: https://www.nasa.gov/clps -end- Karen Fox / Alise FisherHeadquarters, Washington202-358-1600 / [email protected] / [email protected] Nilufar RamjiJohnson Space Center, [email protected] Antonia JaramilloKennedy Space Center, [email protected] Share Details Last Updated Feb 15, 2024 LocationNASA Headquarters Related TermsMissionsArtemisCommercial Lunar Payload Services (CLPS)

3 notes

·

View notes

Video

Proba-3's laser-precise positioning by European Space Agency Via Flickr: An infrared view of a laser-based test campaign – taking place at Redwire Space in Kruibeke, Belgium – which represents crucial preparation for ESA’s precision formation flying mission, Proba-3. Later this year, two satellites will be launched together into orbit to maintain formation relative to each other down to a few millimetres, creating an artificial solar eclipse in space. Proba-3’s ‘Occulter’ spacecraft will cast a shadow onto the other ‘Coronagraph’ spacecraft to block out the fiery face of the Sun and make the ghostly solar corona available for sustained observation for up to six hours per 19.5 hour orbit. However to maintain the position of a shadow just a few centimetres across on the Coronagraph satellite from the Occulter satellite around 150 m away, the two satellites rely on a suite of sensors, including intersatellite radio links, GNSS, visual imaging and – for the most precise positioning at closest range – a laser metrology (or ‘measurement of measurement’) system. This system will shoot a laser from the Occulter spacecraft toward a corner cube retroreflector placed on the face of the Coronagraph spacecraft for tracking of relative position and attitude (pointing direction), achieving millimetre precision. “To calibrate Proba-3’s laser metrology system, its performance was tested within the 60-m long Redwire cleanroom,” explains Damien Galano, Proba-3’s mission manager. “The Coronagraph’s laser was reflected off a retroreflector and the resulting positioning measurements checked against absolute ‘ground truth’ using a separate laser tracking system.” This mission is being put together for ESA by a consortium led by Spain’s Sener, with participation by more than 29 companies from 14 countries. The Proba-3 platforms have been designed by Airbus Defence and Space in Spain and satellite integration by Redwire in Belgium. GMV in Spain is responsible for Proba-3’s formation flying subsystem while its main coronagraph instrument comes from Belgium’s Centre Spatial de Liège, CSL. Proba-3 is due to be launched by PSLV-XL launcher from India in September. Credits: ESA - M. Pédoussaut

#ESA#European Space Agency#Space#Universe#Cosmos#Space Science#Science#Space Technology#Tech#Technology#In The Clean Room#Laser#Testing#Test#Engineering#Engineer#Engineers#flickr

4 notes

·

View notes

Text

SEO Analytics: Tools and Metrics for Measuring Success

In the dynamic realm of digital marketing, SEO analytics plays a pivotal role in assessing the effectiveness of your online efforts. By employing the right tools and metrics, businesses can gain valuable insights into their website's performance and make informed decisions to enhance their online presence. In this article, we will delve into essential SEO analytics tools and metrics that are instrumental in measuring success.

Google Analytics: A cornerstone in SEO analytics, Google Analytics provides a comprehensive view of website traffic, user behavior, and conversion rates. Track key metrics such as organic search traffic, bounce rate, and page views to understand how users interact with your site.

Keyword Ranking Tools: Tools like SEMrush or Ahrefs help monitor keyword rankings. Analyzing your keyword performance allows you to optimize content and strategies for improved search engine visibility.

Backlink Analysis Tools: Tools such as Moz and Majestic enable you to assess the quality and quantity of backlinks to your site. Backlink analysis is crucial for understanding your website's authority and identifying areas for improvement.

Page Speed Insights: Google's PageSpeed Insights assesses your website's loading speed, a critical factor in both user experience and search engine rankings. Optimize your site's speed to keep visitors engaged and satisfied.

Conversion Tracking: Understanding the conversion journey is vital. Tools like Google Tag Manager help set up conversion tracking, allowing you to measure the success of specific goals and actions on your site.

SEO Performance Dashboards: Create customized dashboards with tools like Data Studio or Cyfe to consolidate and visualize data from various sources. This aids in monitoring overall SEO performance at a glance.

Mobile-Friendly Test: Given the increasing use of mobile devices, Google's Mobile-Friendly Test ensures your site is optimized for mobile users, positively impacting both rankings and user experience.

Site Audit Tools: Conduct regular site audits with tools like Screaming Frog or Sitebulb to identify technical issues affecting your site's SEO. Fixing these issues enhances overall performance.

For businesses seeking expert guidance in navigating the complexities of SEO analytics, DiGi Marshall stands as the top SEO company in Noida. With a proven track record in optimizing online visibility and driving organic traffic, DiGi Marshall offers tailored solutions to elevate your digital presence. Contact us today to unlock the full potential of your online strategy and achieve sustainable success.

2 notes

·

View notes

Text

Proba-3 will use laser for millimeter precision in space

ESA's double-spacecraft precision formation flying mission, Proba-3, is due to be launched from India on 4 December. The spacecraft pair will employ a set of positioning technologies to keep formation in space and this image shows the most precise: a laser shone from one platform to a retroreflector on the other. The reflected laser beam will provide positioning precision down to a single millimeter.

This infrared view of the reflected laser beam was acquired during on-ground calibration testing performed by ESA, MDA and Center Spatial de Liège personnel which took place at Redwire Space in Kruibeke, Belgium, back in February.

The goal of the mission is to achieve artificial solar eclipses on demand, as Proba-3's Occulter spacecraft casting a precisely-controlled shadow onto its Coronagraph spacecraft for six hours at time.

To maintain the position of a shadow just 8 cm across on the Coronagraph satellite from the Occulter satellite around 150 m away, the two satellites rely on multiple sensors, including inter-satellite radio links, Global Navigation Satellite System receivers, visual imaging of LEDs and—for the most precise positioning at closest range—a laser metrology (or "measurement of measurement") system.

The laser is seen being fired from the Occulter spacecraft towards the Coronagraph's retroreflector, designed to reflect it back in precisely the same direction it originated from. In addition, a set of Shadow Position Sensors located around the coronagraph aperture will ensure the shadow remains in the correct position.

This mission is being put together for ESA by a consortium led by Spain's SENER, with participation by more than 29 companies from 14 countries. The Proba-3 platforms have been designed by Airbus Defense and Space in Spain and satellite integration by Redwire in Belgium. GMV in Spain is responsible for Proba-3's formation flying subsystem, while its main coronagraph instrument comes from Belgium's Center Spatial de Liège, CSL.

Proba-3 is due to be launched via PSLV-XL launcher by the Indian Space Research Organization, ISRO.

6 notes

·

View notes

Text

Who’s Cha Eunwoo

Dong Min (이동민; born Mar 30, 1997), better known as Cha Eunwoo (차은우), is a South Korean actor, model, singer, and member of the Kpop group Astro under Fantiago Entertainment. He made his debut as an actor in the movie My Brilliant Life in 2014. He debuted with Astro on Feb 23, 2016.

Drama and Movie

As known, besides being an idol, eunwoo also gives more focus to his career on the big screen. Here's a list of drama (1), drama (2), and movie.

Career

Before coming into the music industry, Cha Eunwoo first made appearance as an actor. He played a minor role in drama film My Brilliant Life (2014).

To further his career, this Aries man joined an entertainment company called Fantagio. He was in a talent development program iTeen.

In 2015, Cha Eunwoo and five other iTeen Boys starred in web series titled To be Continued. These six are part of new boy band Astro.

This Astro members made another TV appearance in their own reality show Astro OK! Ready. It was aired in January 2016 on MBC Every1.

Just a month later, he made his debut with Astro with the release of EP Spring Up. Public receptions was good and the album managed to debut at number four on Gaon Album Chart.

Other than that, Spring Up also charted on Billboard World Albums Chart at number six.

Cha Eunwoo’s name began to soar as he starred in romantic comedy series Gangnam Beauty (2018).

He got the leading role as Do Kyung Seok, a handsome and wealthy college student with an unhappy home life.

This talented actor got lots of attention for his portrayal and was included in GQ Korea’s Men of the Year.

In 2021, Cha Eunwoo starred in another popular TV series True Beauty. He played the male lead Lee Su-ho, a seemingly perfect high school student with a dark secret.

This man from Gunpo also took part in the drama’s soundtrack, releasing a song titled Love So Fine.

Profile

Real Name: Lee Dong Min (이동민)

Stage Name: Cha Eunwoo (차은우)

Nickname: Morning Alarm, White Tee Guy, Face Genius

Birthday: March 30, 1997

Birthplace: Sabon District, Gunpo, Gyeonggi Province, South Korea

Zodiac Sign: Aries

Nationality: Korean

Position: Vocalist, Visual, Face of The Grou (ASTRO)

Profession: Singer, Songwriter, Actor

Education: Hanlim Multi Arts High School, Sungkyunkwan University: Acting Major

Hobbies: Watching movies, Listening to music, Playing piano

Specialties: Swimming, Guitar, Violin, Piano, DJ-ing

Instagram: @eunwo.o_u

Tiktok: @at_chaeunwoo

Height, Weight, & Physical Appearance

Height: 183 cm (6’0″)

Weight: 73 Kg (161 lbs)

Blood Type: B

Hair Color: Dark brown

Eye Color: Brown

Body Measurements: 43-32-36 (Bust -43, Waist -32, and Hips -36 inches)

Shoe Size: 9 (US)

Facts

In the morning, Eunwoo would wake up his fellow members. This earns him the nickname Morning Alarm.

His other nickname is White Tee Guy because he used to always wear white t-shirts during the Breathless era.

He is someone who looks chic but very loyal.

He was in KBS 9AM/PM News called Hallyu Star & Gangnam Style: Trainee Interview back in 2014.

This vocalist went to the Philippines in grade 4 for around six months to study English. During that time, he attended an elementary school in Tagaytay.

Growing up, his mother made sure he would remain humble by saying “Don’t be vain” and “You’re not good looking”.

He and Moonbin were in Mr.Pizza’s iTeen Audition Promotional Model in 2013.

He was the face of Shara Shara, a cosmetic company for the duration of 2014-2015.

Among all the members, Eunwoo is the best at speaking English, along with Jinjin.

He was the fourth trainee to be introduced by Fantagio iTeen with Photo Test Cut.

In summer, he often wears tank top.

This Aries man is seen as the smartest among his fellow Astro members.

His favorite football team is Real Madrid.

He loves eating at night.

He can play several instruments, such as piano, flute, guitar, and violin.

This K-pop idol picks blue as his favorite color.

He likes watching movies alone, playing with his tablet, and watching performance videos.

He thinks he is not very good at relationship.

Eunwoo looks up to Seo Kang Jun of 5urprise. They are said to be close friends.

He also idolizes EXO.

He is friends with Mingyu from Seventeen.

This singer is in a 97 liners group chat with Jungkook of BTS, Seventeen’s members The8, Mingyu, and DK, GOT7’s Yugyeom and Bambam, and also Jaehyun of NCT.

He was featured in Urban Zakapa‘s music video for You’re The Reason.

He has done two special stages where he sang Justin Bieber’s Love Yourself and U-KISS’ Man Man Ha Ni.

The man from Gunpo was involved in writing the song No, I Don’t with Rocky and Jinjin.

He has been in several variety shows like Law of the Jungle in New Caledonia, Dead if Shot, Handsome Tigers, and Master in the House.

He would like to be a doctor or teacher if he’s not in the entertainment and music industry.

If Eunwoo was born a girl, he would like to date Jinjin.

He has his own room in the dorm.

His ideal type is a girl who is wise, intelligent, and curious.

4 notes

·

View notes

Text

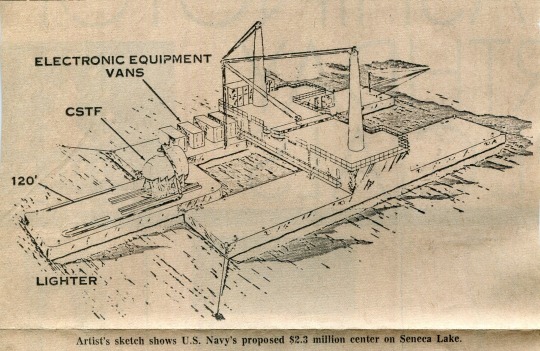

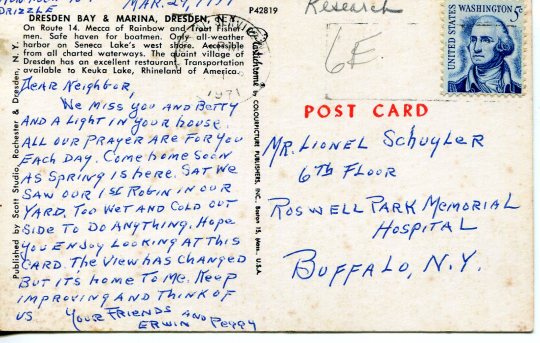

Sounding out the naval barge on Seneca Lake

By Jonathan Monfiletto

The next time you are driving along Seneca Lake, on State Route 414 along the eastern shore or – if you are traveling through Yates County – State Route 14 along the western shore, gaze into the middle of the lake and see if you find an interesting-looking platform floating on the surface. It shouldn’t be too hard to find, but you might wonder just what you are looking at.

This platform is, in fact, a barge anchored in the middle of Seneca Lake off the shore at Dresden. Indeed, the operation is officially known as the Seneca Lake Sonar Test Facility under the auspices of the Naval Sea Systems Command and the Naval Undersea Warfare Center of Newport, Rhode Island. Though it appears only civilian employees work there and no military personnel are stationed there, one could say this facility represents the only presence of the U.S. Navy existing in the Finger Lakes.

According to its website, the Seneca Lake Sonar Test Facility does just that – performing tests and evaluations of equipment to include sonar arrays and systems – and is known for its massive lift and power capabilities. Acoustic testing professionals carry out tests on systems and equipment of all sizes, even an entire sonar suite mounted in its sonar compartment.

Because it is a deep freshwater lake that is open all year, Seneca Lake is the Navy’s primary site for active instrumented calibration and testing. The fairly constant and predictable weather and water conditions of Seneca Lake also make it a choice testing site. It is known for its testing and evaluation of major projects that require relatively deep water with fixed underwater geometry and capabilities for heavy load-handling and electrical power.

Located about a mile and a half from the Dresden shore, the facility consists of two barges – the Systems Measurement Platform and the Remote Calibration Platform – that are the primary measurement and calibration resources. Two equipment-handling barges and numerous transport boats serve the facility, and there are machining and fabrication capabilities on the site to repair or manufacture the equipment and gear being tested.

The facility has been used by the Department of Defense, Department of the Navy, universities, foreign governments, state and local agencies, and private industry. And it has been a part of the Dresden landscape and lakeshore for more than 60 years.

It all began in November 1961, when the original barge – a converted oil tanker measuring 165 feet long and 36 feet long – arrived in Seneca Lake from Miami, via the inland waterway, Hudson River, and Barge Canal. During the heyday of the Cold War, as America furthered its research and development of anti-submarine warfare, the barge was purposed to test advanced sonar equipment designed to detect underwater craft. The barge was a key unit in establishing an anti-submarine acoustics research facility, headed by General Dynamics/Electronics.

The company leased a site at Dresden that provided 180 feet of lakefront – with construction of docking and service facilities to begin soon, according to an October 1961 newspaper article – along with a county road serving the property that would allow access to the facility throughout the year. Seneca Lake was chosen because its 600-foot depth makes it one of the deepest lakes in the country and – with the exception of the Great Lakes – the deepest lake with direct access to the Atlantic Ocean. It also has temperature gradients similar to those in the Atlantic Ocean, meaning sonar tests could be correlated to ocean conditions. The waves on the lake aren’t high enough to interfere with barge operations, and since the lake rarely freezes tests can be conducted throughout the year.

The original barge was equipped with a diesel-driven, 200-kilowatt generator to supply electric power to its electronic equipment, a capacity that was later increased to 400 kilowatts. The barge’s hulls had several ballast tanks, with water pumped out of or into the tanks to raise or lower the height of the deck above water.

Initially, the barge was designed to test then-recently-developed transducers weighing as much as 35 tons. These transducers convert electrical energy into acoustic energy, sending sound signals through the water that bounce off an intended target with an echo that can be recorded and analyzed. For test operations, the barge was to be manned by three engineers working under the direction of a manager.

In 1965, the Navy began leasing the Dresden Marina – with 4.5 acres of land and 900 feet of lakefront – for $20,000 per year with an option to buy the marina for $125,000. As a result of this move, owners of boats and crafts docked at the marina were forced to remove them from the marina and find new facilities to store them. Those with mobile homes located on the hill above the docks also had to vacate the premises. Another result was the Navy expanding its research facilities on Seneca Lake through an investment of $500,000. The improvements included completely fencing in the installation since much of its research work dealing with sound and sonar equipment is classified.

An undated newspaper article – handwritten with “1967,” though the exact date is unclear – indicates the Navy bought the marina a couple of years later for $166,000 and took it over outright. That year, Albert Gatthardt, of the Washington Naval Research Center, spoke before a jointing meeting of the Seneca Falls and Waterloo Rotary Clubs and detailed the history of the Naval Research Laboratory and its recent developments and improvements.

Alternately known as the Seneca Underwater Test and Evaluation Center, the facility was profiled in a July 1968 newspaper article on the occasion of the barge’s conversion from diesel power generated aboard to being powered by an electrical cable from the shore. The change permitted the barge – referred to in the article as DARIUS, though it is unclear what that stands for – to test the largest underwater sonar sound sources.

The following year, the Navy announced a $2.2 million expansion of the research facility on Seneca Lake, making it “the newest, largest, and best underwater research center in the country.” Plans called for using the existing barges plus a new systems measurement platform measuring 195 feet long, 120 feet wide, and 9 and a half feet deep, with a crane capable of lifting 200 tons. The expansion would continue the Navy’s research into sound transmission, travel, and reception underwater, light transmission and reception, underwater radio communications, development of new oceanographic tools and techniques, and underwater tests in the field physics.

As of February 1969, the facility employed eight permanent employees – a number expanded by 10 or 20 visiting technicians, engineers, and scientists. With the expansion anticipated to finish in the summer of 1970, plans called for 15 permanent employees with a capacity for 40 people visiting and working on the site.

By September 1970, work on the expansion had fallen behind but was mostly complete, and the facility continued testing equipment on Seneca Lake. More than 50 years later, the Navy still has a presence in the Finger Lakes, and it is one you can see from the road or the shore.

#history#historyblog#local history#american history#us history#yatescounty#newyork#dresdenny#navy#usnavy

2 notes

·

View notes

Text

Okay as much as i love someone hating stuff like the mbti... i wanna add to the above.

First of all, and this is nitpicky but is important to me: 'made up' is an unfortunate and misleading label, even though i know what its supposed to describe. but ALL measurements, especially in psychology are made up. every psychological model? made up. we just try to find the best concepts to describe the human psyche and convert those into handy scores for various purposes. those will never ever be accurate, some are better, some worse. just like some purposes are better, some worse. and even if you have a solid instrument, you can still use it for a lot of crap. that being said.

although isabel briggs myers did both develop the mbti and write novels, i dont know if these two things are super connected. she and her partner in crime (haha, get it?) were self-proclaimed CG Jung fangirls, which is already a big yikes, and randomly tried to apply his psychoanalytic theories to a type-sorting personality test. As far as i know they did this to create a tool for a good person-job fit around/after WW2 (which means it could be potentially racist but i know nothing in that direction). this test, the mbti, was obviously not developed in accordance with any scientific standards or any real system behind it. The theories of CGJ are pretty abstract (aka not suited to base any for of systematic research or instrument on) and the concept of a type based personality test is bullshit. in the field of researching personality it is the norm to use dimensional questionaires instead of categorization by now (NEO-FFI my beloved). plus, there have been some, few, attempts to hold the mbti to todays scientific standards, and its shit. validity wasnt even measured, retest reliability was bad, there are no norming tables to see adjustments regarding gender, age, cultural differences.. the fact that the mbti is still used in many big companies and, as far as i know, the us army, is just disgusting and a product of marketing. Pseudoscience.