#and Messung Automation

Explore tagged Tumblr posts

Text

Smarter Surface Protection – PLC Automation in Autophoretic Coating Plants

In modern manufacturing, surface coating is not just cosmetic—it’s essential for durability, corrosion resistance, and performance. Autophoretic coating (also known as A-coating) has emerged as a water-based, eco-friendly alternative to electro-coating. When combined with PLC-based automation, it becomes a powerful, scalable solution for high-quality, uniform metal finishing.

Because let’s face it—metal without proper protection is like a knight without armour. In today’s industrial world, that armour comes in the form of surface coating. And when it comes to smart, sustainable, and scalable coating, autophoretic coating is the unsung hero.

But wait, here’s where it gets exciting. Pair this eco-warrior coating with PLC automation, and what you get is nothing short of magic. At Messung Industrial Automation, we believe that the perfect coat is not just about shine—it's about smarts, speed, and sustainability.Let’s dive into the world where chemistry meets code, and surface protection meets the future.

What is Autophoretic Coating?

Autophoretic coating, also known as A-coating, is a process where metal parts are dipped in a reactive water-based solution. The result? A self-depositing layer forms on the surface, without any electric current. Unlike traditional methods that zap the surface with electricity, A-coating lets chemistry take the wheel.

Why Are Industries Making the Switch?

Industries are coating their bets on it because it avoids the need for heavy electric setups and provides uniform coverage even in complex geometries. Since it is water-based, it is also very environmentally friendly.

Where Is It Being Used?

From under-the-hood car parts to refrigerator frames, autophoretic coating is making waves in:

Automotive parts

Appliance components

Agricultural and construction machinery

General industrial structures

In an age where efficiency, sustainability, and performance go hand in hand, autophoretic coating emerges as a transformative solution. Its simplicity belies its power, ushering in a cleaner, smarter way to protect surfaces without compromising on quality or cost. As industries across the board continue to embrace greener practices, A-coating, powered by automation and intelligence, is painting the future—one seamless coat at a time.

Role of PLC in the Coating Plant

In the realm of autophoretic coating, precision isn't a luxury—it's a necessity, and that precision begins with the silent genius of automation: the Programmable Logic Controller (PLC). Think of the PLC as the central nervous system of your coating plant—connecting, communicating, and commanding every mechanical muscle with machines. Here is how PLCs turn a basic coating line into a harmonious dance of efficiency and intelligence.

Precision Process Automation

A modern autophoretic coating plant runs smoothly like a well-coordinated team, and the PLC (Programmable Logic Controller) is in charge. It doesn’t just control the machines—it helps everything work perfectly together. From:

Tank temperature

Solution pressure & pH levels

Cycle timing for each dip and rise

...every step is monitored and controlled by PLC automation.

Material Handling Magic

Using intelligent material handling controllers, our PLC guides parts through multiple stages:

Degreasing

Surface conditioning

Coating dip

Rinsing & curing

Like a choreographer directing a ballet of metal.

Circulation & Filtration Mastery

Good coating = Consistent flow. Our process controllers and PLC control systems manage:

Fluid circulation

Filtration cycles

Solution replacement timing

Synchronisation with Process Controllers

Through seamless synchronisation with motion control systems, everything moves with precision. No drips, no downtime.

In an industry where milliseconds matter and uniformity is sacred, PLC automation elevates the autophoretic coating plant from functional to phenomenal. It enables not just control, but clarity—ensuring that every part, every dip, and every process flows with intelligent intent.

NX-ERA JET PLC System Architecture

Our flagship—NX-ERA JET PLC—is a robust, real-time, and rugged automation genius. It’s compact, reliable, and battle-tested in industrial heat.

Talk the Talk: MODBUS & TCP/IP

Built-in PLC communication protocols like:

MODBUS TCP/IP

MODBUS RTU

Make it plug-and-play with SCADA and automation systems. Yes, it speaks fluent-machine.

Ethernet-Based Controllers for High-Speed Sync

Using Ethernet-based controllers, data flows like molten metal. Zero lag, maximum productivity.

HMI with PLC Controllers

With user-friendly HMIs with PLC controllers, even a non-techie can operate complex coating sequences. Tap, drag, drop—and coat!

From seamless communication to intuitive control, the NX-ERA JET PLC is more than just a controller—it's the central nervous system of your autophoretic coating plant. With its advanced architecture, lightning-fast data sync, and plug-and-play compatibility, it transforms complexity into clarity. Whether you're scaling up or starting smart, this system offers the flexibility, durability, and intelligence your operations demand.In a world where precision meets pressure, the NX-ERA JET PLC ensures your plant doesn’t just perform—it excels.

Advanced PLC Automation for Smart Manufacturing

In the age of Industry 4.0, surface coating is no longer just about chemistry—it's about intelligence, precision, and adaptability. That’s where advanced PLC automation steps in as the invisible powerhouse behind your plant’s performance. Whether you're scaling up operations or streamlining a compact facility, smart automation is the lever that elevates your process from ordinary to outstanding.

Let’s uncover how Messung’s cutting-edge PLC technology is revolutionising autophoretic coating plants with flexible, responsive, and future-ready control systems.

Modular, Compact & Ready to Go - Whether it’s a big plant or a small-scale setup, our Modular PLC, Compact PLC, and Smart PLC configurations give you tailor-made flexibility.

Motion Control with Millisecond Precision - Our motion control systems enable synchronised movement, avoiding delays or overlaps in the coating sequence.

Material Handling - Our embedded material handling controllers do the heavy lifting—literally—without breaking a sweat.

This isn't just automation. This is smart automation that thinks ahead, moves with purpose, and adapts to demand. With Messung’s PLC-powered intelligence, your coating plant doesn’t just run—it evolves.

Because in the world of advanced manufacturing, it’s not just about staying ahead—it's about setting the pace.

Smart. Sustainable. Secure: The Evolution of PLC Automation in Coating Plants

In the era of Industry 4.0, coating plants need more than just control—they need intelligence, integration, and intention. Here’s how Messung’s PLC automation is redefining autophoretic coating systems:

Built for Harsh Industrial Realities – Our Industrial PLCs endure dust, moisture, heat, and vibration. Conformal-coated PLCs protect against corrosive chemicals in A-coating zones and provide long-lasting performance in extreme environments.

Safety Meets Smarts - PLCs are integrated for emergency stops, controlled shutdowns, and real-time fault alerts with logs, making them smart, secure, and always in control.

Welcome to Industry 4.0-Based Controllers

PLC with IoT for remote monitoring and real-time plant access.

MQTT-based PLCs for cloud-friendly, lightweight data communication.

Full PLC system integration with BMS, SCADA & more—ensuring a harmonious automation ecosystem.

Green Gains: Eco-Friendly A-Coating Automation

Water-based chemistry reduces VOCs and emissions.

Smart PLCs optimize dosing & disposal—minimising waste, maximising results.

Cleaner air, cleaner conscience, smarter coatings.

With Messung’s intelligent PLC, you don’t just automate—you evolve. Sustainable, scalable, and secure—this is the new face of PLC-based automation solutions in A-coating.

Business Benefits of PLC-Based Automation Solutions

In today’s hyper-competitive manufacturing world, success isn’t just about innovation—it’s about consistency, efficiency, and scalability. This is where PLC-based automation doesn’t just support your coating process—it transforms it. Let’s explore how Messung’s smart automation systems turn operational goals into tangible business advantages.

Uniformity Every Time - When every product must meet the same high standard, there’s no room for guesswork. Thanks to PLC control systems, your coating process is even, repeatable, and of high quality.

Never any Downtime - Time is money, and downtime is a thief. With real-time monitoring and intelligent automation controllers, potential issues are detected and resolved before they affect production. Fewer breakdowns. More uptime. Happier bottom line.

Easy to Maintain & Scale - Growth shouldn’t be a gamble. With built-in PLC maintenance alerts, you get proactive notifications that prevent surprises. Want to expand operations? Simply plug and play with modular I/O modules. You’re ready for tomorrow—today.

In essence, PLC automation is not just a control system—it’s a business strategy. It safeguards quality, boosts efficiency, and equips your coating plant with the agility to evolve. Because when your process is smart, your performance is unstoppable.

Conclusion: The Final Coat

A surface is only as strong as the system behind it. In the era of smart manufacturing, Messung’s PLC automation solutions empower autophoretic coating plants with unmatched precision, efficiency, and sustainability. From real-time monitoring and advanced PLC control systems to seamless IoT integration and predictive maintenance, our technology ensures optimal surface protection with minimal waste. Whether it’s modular PLCs, industrial automation controllers, or motion control systems, Messung delivers the complete package. So why let inefficiencies corrode your bottom line? Upgrade your coat. Upgrade your process. Upgrade with Messung PLCs—where intelligent automation meets perfect protection.

FAQs

How does PLC contribute to energy efficiency in coating plants?

By optimizing process timings, reducing idle machine hours, and enabling intelligent power management, PLCs help cut down energy consumption and operational costs.

Can PLC automation reduce coating defects?

Absolutely. With real-time monitoring, precision control, and error alerts, PLC automation ensures consistent quality.

How easy is it to integrate Messung PLCs in existing lines?

Very! Our modular PLC systems and versatile PLC communication protocols like MODBUS and TCP/IP allow seamless integration.

Are conformal-coated PLCs necessary?

Yes, especially in chemically aggressive environments like coating plants. They extend the life and reliability of your Programmable Logic Controller.

What industries benefit most from PLC with IoT?

Automotive, general manufacturing, and any industry embracing Industry 4.0-based controllers and smart factory setups.

#Autophoretic coating#Messung Industrial Automation#PLC automation#Programmable Logic Controller (PLC)#material handling controllers#motion control systems#NX-ERA JET PLC#HMI with PLC Controllers#advanced PLC automation#Modular PLC#Compact PLC#Smart PLC#Industrial PLCs#Smart PLCs#PLC-based automation solutions#PLC control systems#PLC automation solutions#IoT integration#industrial automation controllers#Industry 4.0-based controllers

0 notes

Text

The Messung XMP8-11 BDIO 08/06R Relay is a high-performance industrial relay designed for seamless automation and control. It ensures reliable switching, enhanced safety, and efficient operation in industrial environments. This relay is built for precision, offering 8 digital inputs and 6 relay outputs, making it ideal for automation systems. With robust construction and advanced technology, the Messung XMP8-11 BDIO 08/06R enhances machine performance and minimizes downtime. Whether used in manufacturing, process control, or industrial automation, it delivers optimal efficiency. Get Messung XMP8-11 BDIO 08/06R Relay at Auto2mation for reliable industrial solutions.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#Automation#manufacturing#Messung#xmp8-11 bdio#relay

0 notes

Text

Optimize energy, security & comfort with Messung BACD’s Building Automation & Control Systems. Smart solutions for seamless building management.

0 notes

Text

ZimmWriter bietet KI-gesteuerte SEO-Optimierung durch präzise Keyword-Platzierung und thematische Autorität. Sein Sieben-Keyword-System steigert den organischen Traffic um 157% bei gleichzeitiger Beibehaltung des natürlichen Textflusses. Das Tool erfasst Content-Lücken, verknüpft relevante Themen und überwacht SERP-Rankings automatisch. ZimmWriters Automation hilft Content-Teams, SEO-Ergebnisse effizient zu steigern. Verstehen der Keyword-Optimierungskraft von ZimmWriter Sprechen wir darüber, wie ZimmWriter die Keyword-Optimierung revolutioniert. Anders als einfache SEO-Tools verfolgt ZimmWriter einen verfeinerten Ansatz, indem es sieben strategische Keywords unter jede Zwischenüberschrift platziert. Diese kalkulierte Verteilung schafft die perfekte Balance zwischen Suchsichtbarkeit und natürlicher Lesbarkeit. Stellen Sie sich ZimmWriter als Ihr Präzisionsinstrument für Content-Ausrichtung vor. Anstatt Sie mit endlosen Keyword-Vorschlägen zu überfluten, zeigt es genau auf, wo jeder Begriff hingehört. Die integrierte KI analysiert Ihr Thema und generiert gezielte Keyword-Kombinationen - besonders wirkungsvoll, wenn Sie über spezialisierte Themen schreiben, bei denen traditionelle Keyword-Research-Tools daneben liegen. Sie werden feststellen, dass Sie Inhalte erstellen, die gut ranken und dabei einen natürlichen Fluss beibehalten, frei von den starren Vorgaben alter SEO-Praktiken. SEO-Erfolg durch maßgeschneiderte Prompt-Schichtung ZimmWriters individuelles Prompt-Schichtungssystem wandelt komplexe SEO-Aufgaben in eine strategische Abfolge gezielter Prompts um, die aufeinander aufbauen, um Inhalte zu erstellen, die sowohl bei Suchmaschinen als auch bei Lesern Anklang finden. Durch die Aufteilung der Content-Erstellung in methodische Schritte - von der Keyword-Recherche bis zum internen Linking - stellt die Plattform sicher, dass jedes Element eine dedizierte Optimierung erhält und dabei den natürlichen Fluss und Kontext beibehält. Der Schichtungsansatz steigert nicht nur die Arbeitseffizienz, sondern erzielt auch messbar bessere Ergebnisse, da jede Prompt-Schicht dazu beiträgt, umfassende, suchmaschinenfreundliche Inhalte zu erstellen, die sich in wettbewerbsintensiven Nischen abheben. Geschichtete Prompts für Ranglisten Lassen Sie mich etwas Faszinierendes über Prompt-Layering teilen, das gerade die digitalen Rankings verändert. Stellen Sie sich das wie den Aufbau eines stabilen Gerüsts vor - jede Schicht stärkt das Fundament Ihres Contents und verbessert die Suchleistung. Kluge Content-Ersteller nutzen geschichtete Prompts ähnlich wie geschickte Architekten Gebäude entwerfen. Die Technik leitet KI-Systeme an, Inhalte zu generieren, die sich natürlich an den Suchanfragen der Nutzer orientieren, untermauert durch Daten, die verbesserte Engagement-Raten über alle wichtigen Suchmaschinen hinweg zeigen. Diese strategischen Schichten arbeiten zusammen: - Präzisions-entwickelte Prompts, die spezifische Keyword-Cluster ansprechen - Content-Frameworks, die thematische Autorität Schritt für Schritt aufbauen - Systematische Ansätze zur Qualitätssicherung im großen Maßstab - Vernetzte Prompt-Strukturen zur Kontextwahrung - Leistungsverfolgungssysteme zur Messung der Ranking-Auswirkungen Die wahre Stärke liegt in der kohäsiven Verbindung dieser Elemente. Wenn Sie Prompts strategisch strukturieren, verstärkt jeder Content-Baustein die anderen und schafft einen Netzwerkeffekt, der die Domain-Autorität stärkt. Untersuchungen zeigen, dass Websites mit geschichteten Prompt-Techniken konstant bessere Suchsichtbarkeit erreichen im Vergleich zu traditionellen Ansätzen. Die Schönheit liegt in der Skalierbarkeit - Sie erschaffen im Wesentlichen ein wiederholbares System, das die Qualität beibehält, während sich Ihr digitaler Fußabdruck erweitert. Jedes neue Teil fügt sich perfekt in Ihr bestehendes Content-Ökosystem ein und treibt sowohl unmittelbares Engagement als auch langfristige Ranking-Verbesserungen voran. Die Beherrschung der Prompt-Implementierung Lassen Sie mich zeigen, was die Prompt-Implementierung zu einem echten Game-Changer für die Verbesserung der SEO-Performance durch KI-gestützte Content-Erstellung macht. Die Aufteilung komplexer SEO-Aufgaben in klare, verbundene Schritte hilft Ihnen, beeindruckende Ergebnisse zu erzielen und dabei Ihre Inhalte punktgenau und relevant zu halten. Betrachten Sie die Prompt-Erstellung wie Bausteine - jeder sorgfältig entwickelt, um KI-Modelle durch spezifische Content-Phasen zu führen. Wenn Sie mit der Keyword-Recherche beginnen und systematisch zur Content-Struktur übergehen, werden Sie erkennen, wie gezielte Prompts einen natürlichen Fluss erzeugen. Studien zeigen, dass kürzere, fokussierte Prompt-Ketten bessere Ergebnisse erzielen als große, komplizierte, indem sie die thematische Autorität bewahren und Keywords nahtlos einbinden. Ihr Erfolg basiert darauf, Ihren Ansatz zu messen und anzupassen. Beobachten Sie Ihre Metriken, verfeinern Sie Ihre Prompts und sehen Sie, wie jede Komponente Ihre gesamte SEO-Strategie stärkt. Studien belegen, dass diese methodische Verfeinerung zu deutlichen Verbesserungen in den Suchrankings und der Sichtbarkeit führt. Durch das Tracking dieser Ergebnisse entwickeln Sie ein evidenzbasiertes Framework, das konstant messbare SEO-Erfolge liefert. Aufbau von thematischer Autorität durch KI-gestützte Inhalte Vertiefen wir uns in etwas, das die SEO-Landschaft verändert - der Aufbau von thematischer Autorität mit KI-Tools. Die Stärke der Expertise Ihrer Website ist heute wichtiger denn je, und KI macht es einfacher, diese Autorität aufzubauen und zu erhalten. Betrachten Sie KI-Content-Tools als Ihren digitalen Recherche-Assistenten, der Themenlandschaften kartiert und versteckte Möglichkeiten aufdeckt. Diese Tools analysieren riesige Datenmengen, um Ihnen genau zu zeigen, wo Ihr Content wachsen muss: - KI scannt Ihr Content-Ökosystem, um Lücken in Ihrer Expertise zu identifizieren - Intelligente Clustering-Technologie gruppiert verwandte Themen für maximale Wirkung - Natürliche Verlinkungsmuster stärken die Autoritätssignale Ihrer Website - Echtzeit-Updates halten Ihre Inhalte frisch und relevant - KI-gestützte Recherche-Tools verbinden Sie mit glaubwürdigen Quellen Die Zahlen belegen dies - Websites, die KI-gestützte Content-Strategien nutzen, verzeichnen deutliche Verbesserungen in den Suchrankings. Untersuchungen von Semrush zeigen, dass umfassende Themenabdeckung den organischen Traffic um bis zu 47% steigern kann. Der Einsatz von KI-Tools bedeutet nicht, dass Sie Qualität opfern müssen - es bedeutet, Ihre Expertise effizient zu skalieren. Während maschinelle Lernalgorithmen Millionen von Datenpunkten verarbeiten, können Sie sich darauf konzentrieren, wertvollen Content zu erstellen, der sowohl bei Suchmaschinen als auch bei Lesern ankommt. Diese strategische Kombination aus menschlicher Einsicht und KI-Fähigkeiten schafft eine starke Grundlage für nachhaltigen SEO-Erfolg. Maximale Sichtbarkeit von Inhalten durch intelligente Videointegration Die strategische Videointegration hat sich als bahnbrechendes Element im modernen SEO erwiesen, wobei Studien zeigen, dass sie bei richtiger Implementierung den organischen Traffic um beeindruckende 157% steigern kann. Die KI-gestützte Plattform von ZimmWriter hilft Content-Erstellern dabei, Videoelemente nahtlos einzubinden, die mit Suchalgorithmen übereinstimmen und gleichzeitig ansprechende Multimedia-Narrativen schaffen, die die Aufmerksamkeit des Publikums fesseln. Durch die Nutzung der starken Suchmaschinenposition von YouTube und des viralen Potenzials sozialer Medien können Content-Ersteller ihre Sichtbarkeit über mehrere Kanäle hinweg deutlich erhöhen und gleichzeitig durch dynamische Videoinhalte dauerhafte Publikumsverbindungen aufbauen. Video-Ranking-Optimierung Tipps Lassen Sie mich Ihnen etwas Beeindruckendes über Videoinhalte zeigen - Suchergebnisse mit Videos generieren 157% mehr organischen Traffic im Vergleich zu reinem Text. Deshalb kann die Beherrschung von Video-SEO Ihre digitale Präsenz transformieren und Ihnen helfen, sich mit Zielgruppen über verschiedene Plattformen hinweg zu verbinden. Möchten Sie in den Rankings aufsteigen? Konzentrieren Sie sich auf diese bewährten Strategien: - Gestalten Sie auffällige Thumbnails, die zum Klicken animieren (höhere CTR = bessere Sichtbarkeit) - Erstellen Sie Inhalte, die auf natürliche Weise Gespräche und Teilen anregen - Füllen Sie jedes Metadaten-Feld mit sorgfältig ausgewählten Schlüsselwörtern - Halten Sie Zuschauer länger mit überzeugender Storytelling - Teilen Sie Ihre Videos strategisch über mehrere Plattformen, um Autorität aufzubauen Die Zahlen lügen nicht - YouTube ist zur zweitgrößten Suchmaschine der Welt geworden. Durch die durchdachte Implementierung dieser Techniken erschließen Sie eine unglaubliche Chance für organisches Wachstum und erweiterte Reichweite. Denken Sie daran: Jeder Optimierungsschritt baut auf den anderen auf und erzeugt einen Multiplikatoreffekt, der die Performance Ihres Videos deutlich steigern kann. Betrachten Sie Video-SEO als ein Puzzle, bei dem jedes Teil zählt. Wenn Sie all diese Elemente zusammen zum Laufen bringen, verbessern Sie nicht nur Rankings - Sie schaffen Inhalte, die sowohl bei Suchalgorithmen als auch bei echten Zuschauern ankommen. SEO-Taktiken für ansprechendes Multimedia Lassen Sie mich etwas teilen, das das digitale Marketing gerade verändert - Multimedia SEO ist nicht mehr optional. Echte Zahlen erzählen die Geschichte: Wenn Sie interaktive Videos und Multimedia-Storytelling in Ihre Inhalte einbinden, werden Sie 157% mehr organischen Traffic und 52,6% mehr Engagement sehen. Strategie Auswirkung Umsetzung Video-Content 41% höhere CTR YouTube-Integration Interaktive Elemente 52,6% mehr Engagement Nutzergesteuerte Funktionen Gemischte Medien Erhöhte Verweildauer Text + Video-Kombination Plattformübergreifend Größere Reichweite Multi-Kanal-Distribution Sie fragen sich wahrscheinlich, wie Sie dieses Wissen in die Tat umsetzen können. Betrachten Sie Ihre Content-Strategie wie eine Symphonie - jedes Element spielt seine Rolle. Durch die Kombination von Video mit traditionellen Content-Formaten schaffen Sie ein Erlebnis, das bei Ihrem Publikum Anklang findet. Die Beweise sind eindeutig: Videos erscheinen jetzt in 26% der Google-Suchergebnisse und machen 82% des gesamten Internet-Traffics aus. Um diese höheren Rankings zu erreichen, müssen Sie die Kunst der Multimedia-Integration beherrschen. Lassen Sie uns das gemeinsam aufschlüsseln: Beginnen Sie mit einem Video, fügen Sie einige interaktive Elemente hinzu und beobachten Sie, wie Ihre Engagement-Metriken steigen. Jeder von Ihnen erstellte Content wird zu einer Gelegenheit, über mehrere Kanäle Verbindungen aufzubauen, zu engagieren und zu konvertieren. Ausbrechen aus KI-generierten Content-Mustern Schauen wir uns an, was authentische Inhalte von KI-generierten Arbeiten unterscheidet. Denken Sie darüber nach - Ihre einzigartige Stimme entsteht, wenn Sie aus gelebter Erfahrung schreiben, nicht durch das Kopieren von Mustern. Autoren, die sich mit ihren Lesern verbinden, teilen echte Geschichten, authentische Erkenntnisse und hart erarbeitete Weisheit. Sie haben wahrscheinlich bemerkt, dass KI dazu neigt, vorhersehbaren Formeln zu folgen. Großartige menschliche Texte durchbrechen diese Formen auf natürliche Weise. Mischen Sie kurze, prägnante Sätze mit längeren, fließenden. Teilen Sie die Momente, in denen Sie wichtige Lektionen gelernt haben, oder beschreiben Sie genau, wie Sie ein kniffliges Problem gelöst haben. Diese Details spiegeln Ihre Expertise wider und schaffen Vertrauen. Berücksichtigen Sie diese bewährten Techniken, um authentischere Inhalte zu erstellen: - Bauen Sie persönliche Geschichten ein, die Ihr direktes Wissen zeigen - Entwickeln Sie unterschiedliche Satzrhythmen, die natürliche Sprachmuster widerspiegeln - Zeichnen Sie lebendige Bilder mit spezifischen Beispielen aus Ihrem Fachgebiet - Nutzen Sie emotionale Intelligenz, die durch echte Interaktionen gewonnen wurde - Bewahren Sie Ihre charakteristische Schreibstimme und lassen Sie natürliche Variationen zu Die Daten zeigen, dass Leser am besten auf Inhalte reagieren, die authentisch wirken. Untersuchungen von Content-Analyse-Firmen bestätigen, dass Artikel mit persönlichen Einblicken und konkreten Beispielen 47% mehr Engagement erzielen als generische, KI-ähnliche Texte. Ihre Erfahrungen sind wichtig - lassen Sie sie Ihre Worte leiten und Ihre Inhalte herausstechen. Skalierung Ihrer SEO-Strategie mit automatisierter Content-Erstellung Lassen Sie mich zeigen, was derzeit im SEO funktioniert - intelligente Unternehmen revolutionieren ihre Content-Strategien durch KI-Automatisierung, und die Ergebnisse sind beeindruckend. Teams verzeichnen 40% Produktivitätssteigerungen und behalten dabei ihre einzigartige Markenstimme bei. Es geht nicht nur darum, schneller zu arbeiten - sondern intelligenter. Die Zahlen erzählen eine überzeugende Geschichte: Unternehmen, die Content-Automatisierung einsetzen, steigern ihren Umsatz um 25% und beobachten, wie ihre Engagement-Metriken steigen. Besonders bemerkenswert ist, dass 93% der Unternehmen eine strenge Qualitätskontrolle beibehalten und KI-generierte Inhalte sorgfältig prüfen, um ihren Standards gerecht zu werden. Es geht nicht darum, menschliche Kreativität zu ersetzen - sondern Teams zu befähigen, automatisierte Effizienz mit strategischem Denken zu verbinden. Indem man KI sich um repetitive Aufgaben kümmern lässt, können sich Content-Ersteller darauf konzentrieren, tiefere Einblicke und Verbindungen mit ihrer Zielgruppe zu entwickeln. Das Endergebnis? Eine Content-Strategie, die effektiv skaliert und dabei die authentischen menschlichen Elemente bewahrt, mit denen sich Leser verbunden fühlen. SEO-Wirkung messen mit Zimmwriter Tools Tauchen wir ein in die wahre Kraft hinter Ihrem SEO-Erfolg. Die Messwerkzeuge von ZimmWriter verwandeln Rohdaten in umsetzbare Erkenntnisse und geben Ihnen einen klaren Überblick darüber, was funktioniert und was angepasst werden muss. Betrachten Sie ZimmWriter als Ihren digitalen Kompass, der Sie zu aussagekräftigen Kennzahlen führt, die Ihre Online-Präsenz prägen. Die Plattform kombiniert hochentwickelte Verkehrsanalyse mit Inhaltsrelevanz-Indikatoren und zeigt Ihnen genau, wo Sie in der digitalen Landschaft stehen. Sie werden diese wichtigen Tracking-Funktionen beherrschen: - Echtzeit-SERP-Positionsverfolgung lässt Sie Ranking-Änderungen sofort erkennen - Engagement-Metriken zeigen, wie Nutzer durch Klicks und Shares mit Ihren Inhalten interagieren - Detaillierte Konversionsanalyse zeigt, welche Inhalte tatsächliche Ergebnisse liefern - Content-Relevanz-Bewertungen helfen Ihnen, echte thematische Autorität aufzubauen - Technische SEO-Überprüfungen stellen sicher, dass Ihre Website auf allen Geräten einwandfrei funktioniert Jedes Messwerkzeug integriert sich nahtlos mit den anderen und schafft ein vollständiges Bild Ihrer SEO-Leistung. Durch die Konzentration auf diese Schlüsselmetriken treffen Sie datengesteuerte Entscheidungen, die Ihre digitale Strategie stärken und Ihre Sichtbarkeit in Suchmaschinen erhöhen. Die Analysetools von ZimmWriter stellen Ihnen professionelle Werkzeuge zur Verfügung und machen komplexe SEO-Daten zugänglich und umsetzbar. Dieser gemessene Ansatz hilft Ihnen, Ihre Content-Strategie zu optimieren und dabei den Fokus auf das zu behalten, was Ihre Rankings wirklich beeinflusst. Read the full article

0 notes

Text

Programmable Logic Controllers (PLC) for Industrial Automation | Messung IAC

Enhance industrial automation with advanced Programmable Logic Controllers (PLC) from Messung IAC. Our high-performance PLC solutions offer precision control, real-time monitoring, and seamless integration for improved efficiency, reduced downtime, and optimized production. Designed for various industries, our PLCs ensure reliability, flexibility, and cost-effective automation. Upgrade to smart industrial control with Messung IAC’s cutting-edge PLC technology.

0 notes

Text

Experience Unparalleled Convenience and Customization

Welcome to the Ourican View App by Messung Ourican, the ultimate solution for seamless smart automation control. Designed to integrate effortlessly with the MES-IP-SERVER, this cutting-edge application empowers users to manage their KNX ecosystem across homes, commercial spaces, and even hospitality industry, directly from their smartphones or tablets.

0 notes

Text

For best performance, install Messung KNX-based automation systems

Messung Automation is dedicated to staying abreast of new developments in technology. And for all settings, home and office automation is the way of the future. Messung Home Automation offers a lot of benefits. Internet and KNX technology are used in home automation to give users access and control.

0 notes

Text

#ibms#ems#iot services#messung bacd#industrial automation#artificial intelligence#technology#business

0 notes

Link

With decades of industry experience and our expertise in new technology, we develop advanced manufacturing process automation and control solutions to meet the varied demands of the Paper & Pulp industries.

0 notes

Text

MESSUNG IS DISTRIBUTOR IN INDIA FOR FUJI ELECTRIC’S VFD DRIVES

WHAT IS A VFD?

VFD full form is a variable frequency drive. So the obvious questions then are: what is VFD drive? Why do we use VFD? Advantages of VFD?

According to Wikipedia, "a variable-frequency drive (VFD) or adjustable-frequency drive (AFD), variable-voltage/variable-frequency (VVVF) drive, variable speed drive (VSD), AC drive, a microdrive or inverter drive is a type of motor drive used in electro-mechanical drive systems to control AC motor speed and torque by varying motor input frequency and voltage."

This blog aims to explain VFD and introduce you to its basic features and functions.

WORKING OF VFDs

A variable frequency drive controls the speed of an AC motor by varying the frequency supplied to the motor. The drive also regulates the output voltage in proportion to the output frequency to provide a relatively constant ratio of voltage to frequency (V/Hz), as required by the characteristics of the AC motor to produce adequate torque.

To understand the VFD drive working principle or VVVF drive working principle, let’s study the four main VFD drive parts: rectifier, intermediate DC link, inverter, and controlling circuit.

Rectifier: It converts AC power fed from mains to DC power. This section can be unidirectional or bidirectional based on the application used like the four-quadrant operation of the motor. It utilizes diodes, SCR’s, transistors, and other electronic switching devices.

DC bus: This section consists of capacitors and inductors to smooth against ripples and store the DC power. The main function of the DC link is to receive, store and deliver DC power fed from the rectifier section.

Inverter: This section comprises of electronic switches like transistors, thyristors, IGBT, etc. It receives DC power from the DC bus and converts it into AC which is delivered to the motor.

Control circuit: This consists of a microprocessor unit and performs various functions like controlling, configuring drive settings, fault conditions, and interfacing communication protocols. It receives a feedback signal from the motor as a current speed reference and accordingly regulates the ratio of voltage to frequency to control motor speed.

VFD BLOCK DIAGRAM

VFD SPEED CONTROL METHODS

Wondering can a VFD increase motor speed?The answer is yes and there are four VFD speed control methods. These methods have a substantial impact on an application’s performance, efficiency and even the cost of operation. Engineers and operators need to understand the benefits and limitations of each method and choose the best method for their application. The methods are:

V/f Control: a simple, plug-and-play method used when the drive needs very little data from the motor for control and encoders are not required. Less wiring means lower costs. It allows multiple motors run from a single VFD.

VFD applications with this method include machine tools, spindle, fan and pump applications.

V/f with Encoder: When applications require more precise speed regulation and the ability to run at a higher reference frequency, this method is preferred. Voltage and frequency are pre-set, allowing for high-speed control without high dynamic responses.

Open-Loop Vector (OLV) Control: OLV is the method of control where motor speed and torque can be controlled independently. It is used when operators require much more dynamic control over their applications. Because of a higher starting torque at lower speeds, and the availability of four-quadrant torque limits, OLV is very useful for a wide variety of applications.

Closed-Loop Vector Control: This method is similar to OLV in that it employs an algorithm to determine output voltage, but it requires an encoder to operate. It is best suited for applications that hold loads without moving (cranes, elevators, etc.).

ADVANTAGES OF USING VARIABLE FREQUENCY DRIVES

Energy-saving: When an application does not need to be run at full speed, you can cut down energy costs by controlling the motor with a VFD, which allows you to match the speed of the motor-driven equipment to the load requirements. Especially in pumps, fans, compressors, VFDs enable substantial energy saving.

Energy cost savings becomes more pronounced in variable-torque ID fan and pump applications, where the load’s torque and power are directly proportional to the square and cube of the speed respectively.

Controlled acceleration: a VFD starts at zero speed and accelerates smoothly unlike an AC motor which triggers higher mechanical shock loads both for the motor and the mechanically connected load.

This shock, over time, increases wear and tear of the equipment. For example, conveyors in applications that include easy-to-tip products, such as bottling lines, greatly benefit from a soft start and slow ramp-up in power rather than an abrupt jerk to full power.

Adjustable speed and torque limit: Control is always a big benefit for production processes. A VFD allows for remote adjustment of speed by programmable controller or process controller. Torque being applied too can be set and controlled accurately, so it protects the machinery from damage.

High power factor: The power factor is the ratio of kW/KVA (active power/apparent power). Typical AC motors may have a full load power factor ranging from 0.7 to 0.8. As the motor load is reduced, the power factor becomes low. The advantage of using VFDs is that it includes capacitors in the DC Bus itself which maintains a high power factor on the line side of the Variable Frequency Drive. This eliminates the need for additional expensive capacitor banks.

Extend equipment life: Starting a load with a VFD protects the motor or load from starting 'shocks' and issues such as electro thermal overloads, phase protection, under voltage, overvoltage, etc. This reduces wear and tear, helps equipment to last longer and minimizes downtime due to maintenance.

Messung, pioneer and leading provider of industrial automation solutions has tied up with Fuji Electric, Japan, for a wide range of simple and high-performance Variable Frequency Drives (VFDs).

The VFD Drive range includes standard and specialized models that can maximize performance for each application. These VFDs have an environmentally friendly long-life design (10 years), are compliant with RoHS directives, and can be used in most types of applications - from fans and pumps to specialized machinery.

For precision control with VFDs to optimize performance, contact Messung.

#VFD full form#variable frequency drive#what is VFD drive#messung#Why do we use VFD#variable-frequency drive (VFD)#explain VFD#VFD drive parts#VFD drive working principleVVVF drive working principle#VFD speed control methods#VFD applications#industrial automation solutions#VFD Drive range

0 notes

Text

SAVE ENERGY AND COSTS WITH MESSUNG'S ENGERGY MANAGEMENT SOLUTIONS

#energy management system (EMS) monitors#Smart Energy Monitoring solutions#power quality analyser#energy measurement device#energy management software#PLC automation#IoT-based energy management systems#smart energy management systems#energy management solutions#messung electrial engineering

0 notes

Text

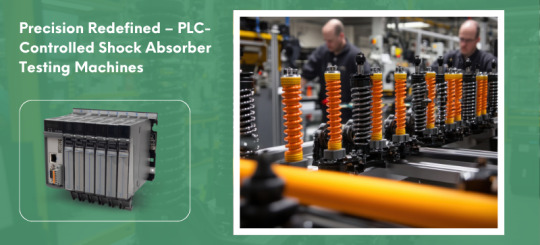

Precision Redefined – PLC-Controlled Shock Absorber Testing Machines

Precision – a word that keeps on getting thrown around often in the world of engineering. However, when it comes to shock absorber testing, precision isn’t a luxury—it’s survival. Every curve, every jolt, every rebound of a shock absorber must be captured, tested, and analysed to microscopic exactness. Gone are the days when manual testing could keep up.

The role of shock absorbers in today’s high-speed automotive innovation and precision engineering is to provide safety, comfort, and performance protection. But how can we make sure that these absorbers meet the high standards required by modern vehicles? This is where PLC automation becomes a useful tool.

The old-fashioned testing methods, which were cumbersome, unreliable, and laborious, have been replaced by PLC-based automation systems. Imagine a testing line with the capacity to think, adapt and respond in real time. The precision of Programmable Logic Controllers (PLCs) is not solely a promise, but rather adherence to standardised protocols.

How PLCs Enhance Shock Absorber Testing

There has been an evolution in the science of testing shock absorbers. Let’s understand how smart and compact PLCs can automate and optimise critical testing stages by providing consistency, control, and clarity.

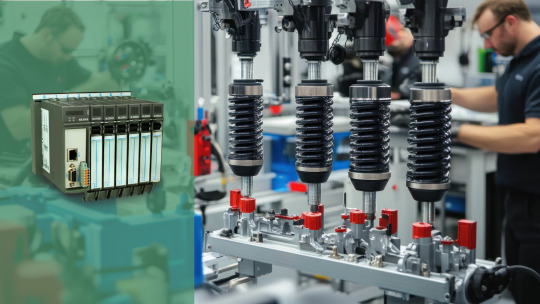

Centralised Control with High Reliability

A robust industrial PLC is the foundation of our testing machines. The real-time control systems embedded in our automation design enable seamless functioning of all sensor, actuator, and motorised components.

Multiple sensors? Check.

Complex test sequences? Seamlessly handled.

From servo motion controllers managing high-speed vertical displacements to compact PLCs managing individual test stations, the formation is digital, deliberate, and dependable.

Real-Time Data Acquisition & Analysis

Here's where things get exciting. Tests on shock absorbers are more than just passing or failing. It's about quantifiable performance with our automation controllers:

Damping force curves

Displacement maps

Velocity and resistance profiles.

The data is gathered by high-resolution sensors and then processed through HMI with PLC controllers. The integration of this with databases is achieved through integrated PLC-based software, resulting in predictive maintenance and long-term performance insights

Feedback Loops for Adaptive Control

Ever wondered what would happen if the test differs? What would be the outcome? Well, with the use of real-time PLC communication protocols (like MODBUS and Ethernet/IP) and closed-loop control enable our systems to identify anomalies mid-test while enabling automatic correction.

Additionally, dynamic adjustment of actuator velocity in a system is possible when the response rate of the unit is slower than the tolerance. Or if temperatures spike? After a system shutdown, it sends an alert via the web server PLC and logs the fault. This requires more than just testing -- intelligent testing.

NX-ERA JET PLC System Architecture

Now let’s explore the engine room that fuels our innovation. The NX-ERA JET PLC, the foundation of our automated testing platform, undergoes a thorough architecture and connectivity analysis.

Core Hardware Components

With its compact size, modular design, and future scalability, the NX-ERA JET PLC is a formidable beast. It houses:

Simple servo systems designed for precise motion control

Energy-efficient motors can be powered by Variable Frequency Drives (VFDs)

HMI interfaces that enable the creation of visual dashboards and manual overrides

I/O modules for interfacing with third-party equipment.

Its modular design makes it suitable for both high-volume testing environments and small-batch production lines that use Micro PLCs or Mini PLCs

Communication & Connectivity

Connectivity should be a fundamental aspect of the entire setup, not an extra one.

Modbus PLC Interface is responsible for ensuring device-to-device communication

High-speed data relays are made possible with Ethernet-based controller systems

PLC with TCP/IP can be used for remote data logging and system control, as well as firmware updates

IoT-ready PLCs enable the integration of the testing machine with ERP, MES, and SCADA

Key Benefits of PLC-Controlled Testing Machines

Indeed, inefficient processes are not easily exploited in the fast-paced manufacturing industry. Your requirements include testing devices that don't blink even when pressured, systems that guarantee high quality, and technology that evolves as your business grows. Our PLC-based automation solutions are precisely in tune with that.

They offer:

Repeatability and Precision - One unit can be tested with ease and accuracy. But what about testing thousands with zero deviation? Our automation solutions that utilize PLCs accomplish this objective. You get:

Identical test cycles

Calibrated control parameters

Automated calibration routines

It implies improved quality control and enhanced audit accessibility.

High Throughput with Reliability - Traditional systems often require individuals to choose between speed and accuracy. Not here. The configurations of our NX-ERA JET PLC enable:

Sub-second test cycles

Parallel station control

Integrated logic and safety layers

All without compromising test integrity.

Reduced Manual Intervention - By utilizing HMI integration, and adaptive PLC programming, operators can not only monitor and but control:

Reduced human error

Faster changeovers

Safer work environment

Safety and Compliance – Safety is crucial for any industrial setup. With our smart PLCs, you can easily:

Emergency stop circuits

Real-time fault diagnostics

Layered safety logic

PLCs are designed to provide timely and effective alerts and shutdowns, complying with international standards such as ISO and CE.

Adaptable and Future-Ready - Different testing may be required for tomorrow's shock absorber. Good news: you won’t need a new machine.

Reprogram testing logic

Add new motion profiles

Update firmware via PLC with IoT

That’s the power of modular PLCs.

Whether you're chasing precision, throughput, or transformation, our PLC-controlled shock absorber testing machines deliver across the board. These benefits aren’t just technical specs—they’re business advantages, engineered to give you control, confidence, and a competitive edge.

Why Choose Messung’s Programmable Logic Controllers for Automation Solutions

Your choice of controller can determine your plant's success in a world propelled by data-driven decision-making, agility, and accuracy. We offer complete PLC-based automation solutions meant to grow with your demands rather than just supply PLCs. Our PLCs are not only intelligent but also necessary for the following reasons:

Smart and Connected PLCs - Our smart PLCs dynamically optimise by adjusting to handle changes. Embedded intelligence enables them to learn from repeated tests, predict component failures, and optimize actuator profiles automatically. Moreover, our edge-computing enabled PLCs help for quicker decisions by lowering cloud dependence.

HMI Integration for Better User Control - No more enigmatic command-line interfaces. With our smart PLCs, you get touchscreen HMIs, customised dashboards and real-time analytics displays.

Compact and Versatile PLC (Programmable Logic Controller) Options - Squeezed on space? You can get the complete power of a typical controller, without worrying about the size, with our compact PLC, micro PLC, and mini PLC range.

From intelligence that anticipates, to interfaces that simplify, to form factors that adapt—Messung’s PLC Programming range is designed not just to meet your automation goals, but to exceed them. Because when you choose Messung, you don’t just adopt automation; you embrace transformation.

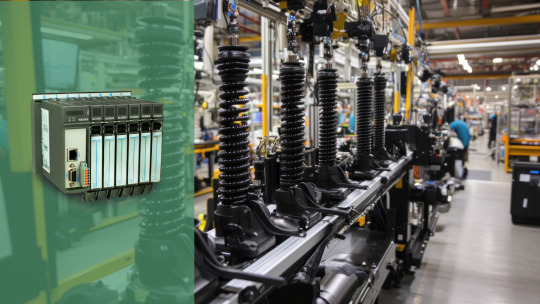

Applications Beyond Shock Absorbers

Although shock absorber testing is where our PLC automation solutions show their power, that's just one section in our automation playbook. Beyond the same technology, fine-tuned for real-time control, precision, and adaptability, extends far. Messung's intelligent PLC solutions provide flexibility and value across a range of sectors, whether you are forming metal or transporting materials.

Let's explore how our PLC Control Systems have a range much outside the damping zone:

Motion Control Systems - Conveyor automation and actuator-driven systems all fall under our motion control solutions. Through synced servo motion controllers, we guarantee millisecond-level accuracy.

Machine Tool Controllers - Integrated with smart CNC tools, our machine tool controllers use feedback to adjust cutting speeds, minimise tool wear and even optimise material usage.

Advanced Automation – Through this end-to-end automation, sending raw material to finished parts, fully automated quality checks and centralized command via connected PLCs can easily become possible.

One shouldn't limit automation to just one purpose. Whether it is in high-speed assembly lines or precise machining at Messung, our PLC automation systems are flexible enough to meet the demands of many industries. Beyond shock absorbers, our solutions usher in intelligent manufacturing possibilities one motion at a time.

Conclusion

Accuracy is a standard, not only a specification. If you are still using obsolete testing configurations, it's time to change course. Designed to bring not just performance but also purpose to your production floor, Messung's PLC-controlled shock absorber testing equipment helps you to achieve this.

Testing has to be quick, adaptable, and flawless, whether you are creating luxury cars or robust trucks. That is precisely what Messung's PLC control systems promise—and deliver.

We do not just automate; we elevate, from servo-tight control to smart data acquisition, from seamless integration to Industry 4.0-based controllers.

At Messung, accuracy is not just redefined. It has changed everything. Hence, go for it. Redefine accuracy. One test at a time!

FAQs

What makes Messung’s PLC Control Systems ideal for shock absorber testing?

Messung’s PLCs (Programmable Logic Controller) offer centralised control, real-time data capture, adaptive feedback loops, and ensure peak accuracy and speed.

Can Messung’s PLC Programming integrate with existing equipment?

Yes. With protocols like MODBUS, TCP/IP, and Ethernet-based controllers, our PLCs are designed for easy retrofitting and compatibility.

How do PLC Control Systems improve the testing process?

PLCs provide real-time emergency stop functionality, error detection, and ensure the equipment runs within safe operational parameters.

Do you offer remote access features?

Absolutely. With web server PLC (Programmable Logic Controller) capabilities and HMI with PLC controllers, you can monitor and manage testing remotely.

Is your PLC solution scalable?

Yes. With modular PLCs and IoT-ready systems, you can scale your setup to match your growth.

#PLC control systems#Programmable Logic Controllers (PLC).#Messung Industrial Automation#PLC automation systems#Smart PLC control#PLC-based AHU control system#modular PLC#Energy management systems#IEC 61131 based PLCs#compact PLC#IEC 61131-3 standard PLC Control Systems#MODBUS RTU#Modbus TCP#NX-ERA JET#PLC for energy systems#IEC 61131-3 compliant PLCs#modular PLCs#HMI with PLC controller#smart automation systems#programmable logic controller#smart PLCs#Modular PLCs

0 notes

Text

Messung - Industrial Automation Control Solutions |Auto2Mation

Industrial Automation and Control Solutions. Count on Auto2mation to provide the best Messung products for efficient industrial and control solutions.

#industrial automation#marine spare parts#marine automation#industrial equipment#industrialpower supply#industrial automation equipment#industrial spare parts#auto2mation

0 notes

Text

Automation Building Systems in Healthcare - Messung BACD

Healthcare, being a strictly safety-regulated, hygiene-oriented, and efficiency-conscious service operation, requires highly specific control of the environment to achieve these standards. It demands an effective automation building system (ABS) to integrate HVAC, lighting, and access control into one central Building Automation and Control System (BACS).

Messung specializes in delivering tailored ABS solutions for healthcare facilities, ensuring compliance with strict healthcare norms such as ASHRAE 170 (Ventilation of Health Care Facilities). Beyond energy efficiency, Messung's systems provide optimal IAQ, temperature, and humidity, creating a controlled and safe environment. Their advanced solutions ensure comfort and peace of mind for patients and staff, setting a new standard in healthcare automation.

What is an Automation Building System?

An automation building system is a centralized framework that combines hardware, software, and communications protocols to run buildings automatically and optimally. It is engineered to manage critical systems, including HVAC (heating, ventilation, and air conditioning), lighting, security, and energy management systems.

How Do Automation Building Systems Work in Healthcare?

These ABS systems offer a structured method for controlling and handling the critical environmental parameters of the healthcare premises. Therefore, it involves three stages.

Environmental Data Acquisition

Sensors continuously monitor parameters such as airflow, temperature, humidity, pressure and occupancy. In sensitive zones such as operating rooms or isolation wards, high-precision sensors ensure that real-time data acquisition occurs to make critical decisions.

Centralized Processing

It analyzes the sensor data, using complex algorithms in real-time, to assess the conditions. The systems also ensure compliance with other parameters such as air exchange rates, pressure differential, and thermal comfort that are required in healthcare environments.

Automated Adjustments

The actuators comprise dampers, valves, and AHUs that BACS controls in changing HVAC settings, lighting, or filtration systems. Closed-loop processes are the best for optimal performance, high health standards, and enhanced energy efficiency.

ABS ensures seamless communication between components via open communication protocols like BACnet, Modbus, and KNX, providing flexibility for future upgrades and integration.

Key Benefits of Automation Building Systems in Healthcare

The technical and operational benefits of implementing an ABS in healthcare institutions are as follows:

Energy Management

HVAC systems account for a large percentage of energy consumption in healthcare settings. ABS optimizes ventilation rates, thereby saving energy but not compromising performance.

Automated scheduling and adaptive controls reduce wastage by automatically adjusting HVAC operations during non-peak hours. The integration with renewable energy systems further improves energy efficiency and sustainability.

Accurate Environmental Control

The most critical zones, such as operating theaters, isolation wards, and ICUs, need controlled temperature, humidity, and air quality. ABS ensures compliance with ASHRAE and CDC guidelines by having precise control over its environment.

Besides, adaptive algorithms adjust the conditions depending on the occupancy and activity.

Operational Efficiency

Automated diagnostics and system monitoring reduce the need for manual interventions, allowing maintenance teams to focus on high-priority tasks.

Also, real-time alerts and predictive maintenance features reduce equipment downtime, thereby raising overall reliability.

The Role of Automation Building Systems in Infection Control

Infection control is the cornerstone of operations in healthcare, and automation building systems play a critical role in minimizing the spread of pathogens in healthcare facilities.

Air Flow and Pressure Control Zones

ABS maintains positive pressure in areas such as operation rooms and maintains negative pressure in isolation wards to limit the flow of pathogens. Advanced air handling systems ensure directional airflow as established by healthcare standards.

Humidity Control

30-60% optimal humidity can be maintained with minimum microbial growth and static discharge, which could influence highly sensitive medical equipment.

Air Filtration and Exchange

ABS can integrate HEPA filtration systems, making sure that there are ACHs in the needed areas. Automated ventilation ensures that fresh air circulates, reducing contaminant buildup.

Automatic Alerts and Notifications

Sensors monitor critical parameters continuously, detecting deviations that cause alarms. Facility managers can respond quickly to restore compliant conditions, ensuring uninterrupted patient care.

Messung’s ABS Solutions for Healthcare: Key Features

Messung offers end-to-end solutions for building automation, specializing in project management and customized services tailored to the healthcare industry. So, here's how Messung supports healthcare organizations:

Comprehensive Project Management

Messung oversees every aspect of building automation projects, from initial consultation and planning to design, execution, and commissioning through the network of highly trained SI Partners.

Tailored Solutions

Messung provides customized automation solutions based on the unique needs of healthcare facilities. Their solutions include integrating HVAC, lighting, access control, and environmental monitoring systems into a unified Building Automation and Control System (BACS).

State-of-the-Art Technologies

Messung employs advanced technologies such as IoT, SCADA, and data analytics to enhance system functionality, enabling better decision-making, energy efficiency, and compliance with healthcare standards.

Maintenance and Support

Messung offers robust after-sales services, including preventive maintenance, upgrades, and troubleshooting.

Regulatory Expertise

Messung’s ABS solutions are fully compliant with stringent healthcare regulations like ASHRAE 170, CDC guidelines, and LEED standards.

Conclusion

Automation building systems (ABS) are the backbone of modern healthcare infrastructure, seamlessly integrating sophisticated technology with precise control to achieve optimal building operations. From infection control and energy efficiency to improved patient outcomes and enhanced staff productivity, ABS systems manage it all with unparalleled efficiency.

With a proven track record and focus on innovation, Messung ensures that its clients receive high-quality ABS solutions to build smarter, more efficient healthcare infrastructures.

0 notes

Text

Explore industrial automation in industry with Messung IAC and revolutionize your operations with cutting-edge technology. Our advanced automation solutions enhance productivity, reduce operational costs, and improve overall efficiency by integrating smart control systems, sensors, and IoT-enabled technologies. With real-time monitoring, precision control, and seamless process automation, industries can achieve higher output quality, minimal downtime, and optimized resource utilization. Messung IAC’s industrial automation solutions cater to various sectors, ensuring reliability, safety, and long-term sustainability. Upgrade your manufacturing and production processes with intelligent automation and experience a smarter, more efficient future with Messung IAC.

0 notes

Text

Experience Unparalleled Convenience and Customization

Welcome to the Ourican View App by Messung Ourican, the ultimate solution for seamless smart automation control. Designed to integrate effortlessly with the MES-IP-SERVER, this cutting-edge application empowers users to manage their KNX ecosystem across homes, commercial spaces, and even hospitality industry, directly from their smartphones or tablets.

0 notes