#automated warehouse control system

Explore tagged Tumblr posts

Text

Revolutionize Logistics: Explore Warehouse Management Software Benefits

In the ever-evolving landscape of supply chain logistics, businesses are constantly looking for smarter ways to optimize their warehouse operations. Enter the game-changing technology of Warehouse Management Software (WMS). These digital tools are reshaping how warehouses operate, bringing enhanced efficiency, precision, and cost savings. If your logistics system still relies heavily on manual tracking or fragmented tools, it’s time to explore the full spectrum of Warehouse Management Software Benefits.

A major advantage of warehouse management software is its ability to provide real-time inventory tracking. Gone are the days of paper logs and spreadsheets. With WMS, you can monitor inventory levels, shipments, and stock movement as they happen. This visibility not only improves operational planning but also minimizes the risk of overstocking or stockouts.

Operational efficiency is another key benefit. WMS automates processes such as picking, packing, and shipping, drastically reducing the time required to fulfill orders. This directly leads to faster delivery times and improved customer satisfaction. Businesses that adopt these systems often see a measurable boost in productivity within weeks of implementation.

In terms of cost reduction, WMS can streamline labor allocation, ensuring your workforce is always focused on high-priority tasks. The software's built-in analytics help managers identify bottlenecks and areas where time and resources are being wasted. This allows for informed decisions that enhance performance and profitability.

Accuracy is critical in warehousing. By integrating technologies like barcode scanning and RFID tagging, WMS significantly lowers the risk of human error during inventory counts and order fulfillment. These features help ensure that your records are accurate and your customers receive the right products on time.

On a broader scale, WMS acts as the digital backbone of a smart supply chain. It integrates with ERP systems, eCommerce platforms, and transportation management systems, creating a seamless flow of data across your business operations.

The bottom line? The Warehouse Management Software Benefits are far too impactful to ignore. Whether you're running a small storage facility or a large distribution center, adopting WMS could be the key to staying competitive in an increasingly fast-paced market.

Take the first step toward a more agile, data-driven warehouse today—and watch your supply chain transform from a cost center into a value-driving asset.

#inventory control system#warehouse automation#logistics optimization#real-time inventory#supply chain software#barcode scanning#stock management.

0 notes

Text

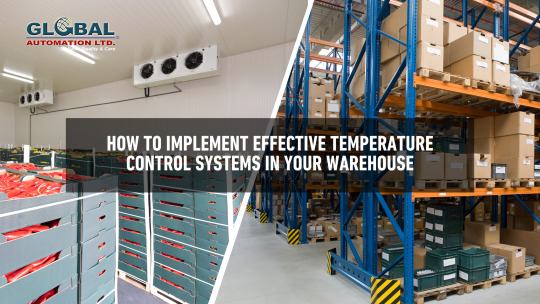

How to Implement Effective Temperature Control Systems in Your Warehouse

Optimize your warehouse with Global Automation Ltd.'s state-of-the-art cold storage and temperature control systems. Ensure product longevity and quality with our reliable industrial refrigeration and automated storage solutions.

#Cold Storage Solutions#Industrial Refrigeration#Cold Storage Bangladesh#Temperature Control Systems#Cold Chain Logistics#Warehouse Storage Solutions#Industrial Storage Systems#Warehouse Automation#Storage Racks Bangladesh#Warehouse Management

0 notes

Text

Automated Inventory Tracking System: Revolutionizing Supply Chain Efficiency

Effective inventory management is crucial if you want to remain competitive in today's fast-paced corporate environment. An automated inventory tracking system is increasingly becoming the backbone of effective supply chain operations, allowing businesses to streamline processes, minimize errors, and optimize resource allocation. This blog explores the pivotal role that automated systems play in modern inventory management, highlighting their impact on supply chains, key components, and the technological advancements driving their evolution.

Understanding Automated Inventory Tracking Systems

Automated inventory tracking systems are a sophisticated blend of hardware and software designed to monitor and manage inventory levels, orders, and deliveries. These systems utilize technologies such as barcodes, RFID tags, and IoT devices to provide real-time data on stock movements. By automating the tracking process, businesses can significantly reduce the manual labor involved, decrease the likelihood of human error, and ensure accurate inventory counts at all times.

The Role of Technology in Inventory Management

Technology is at the heart of any automated inventory tracking system. With the advent of Artificial Intelligence (AI) and machine learning, these systems have become more intelligent, capable of predicting stock requirements, identifying trends, and even automating reordering processes. Cloud computing further enhances the accessibility and scalability of inventory systems, allowing for seamless integration across multiple locations and real-time data sharing.

Components of an Automated Inventory Tracking System

An automated inventory tracking system comprises several critical components:

Barcodes and RFID Tags: These are used to label products and track their movement through the supply chain. Barcodes are scanned manually or via automated systems, while RFID tags can be read automatically as products pass through specific checkpoints.

Inventory Management Software: This software is the brain of the system, processing data collected from barcodes, RFID tags, and other sources to provide insights into inventory levels, product locations, and more.

IoT Devices: Internet of Things (IoT) devices are increasingly used in automated inventory systems to monitor conditions such as temperature and humidity, particularly in industries like pharmaceuticals and food and beverage.

Cloud Computing: Cloud-based inventory systems enable real-time data access, enabling companies to keep an eye on inventory from a single, central platform across several locations.

Advantages of Automated Inventory Tracking Systems

Putting in place an automated inventory tracking system has a number of significant benefits.

Increased Accuracy: Automation reduces the potential for human error, ensuring more accurate inventory counts and reducing discrepancies.

Cost Savings: By optimizing inventory levels, businesses can reduce storage costs and avoid overstocking or stockouts.

Enhanced Efficiency: Automated systems streamline inventory management processes, freeing up staff to focus on more strategic tasks.

Real-Time Data: Access to real-time inventory data allows businesses to make informed decisions quickly, improving responsiveness to market changes.

Challenges in Implementing Automated Inventory Systems

Although there are obvious advantages to using an automated inventory tracking system, there may be implementation difficulties:

Initial Costs: The initial investment in hardware, software, and training can be significant, particularly for small businesses.

Integration with Existing Systems: Ensuring that the new automated system integrates smoothly with existing Warehouse management solutions and ERP is essential for success

Employee Training: It can take a lot of time and money to properly train staff members to use the new system.

Future Trends in Automated Inventory Management

The future of automated inventory tracking systems is promising, with several trends set to shape the industry:

AI and Machine Learning: These technologies will continue to enhance the predictive capabilities of inventory systems, enabling even more accurate demand forecasting and inventory optimization.

Blockchain Technology: Blockchain could revolutionize inventory tracking by providing a secure, transparent ledger for all inventory movements, reducing fraud and increasing accountability.

Advanced Robotics: It is anticipated that more robotics will be used in warehouses, automating more of the picking, packing, and shipping procedures.

FAQs for Automated Inventory Tracking System

Q1. What is an automated inventory tracking system?

A. An automated inventory tracking system uses technology like barcodes, RFID tags, and software to monitor and manage inventory levels in real time, reducing the need for manual counts and improving accuracy.

Q2. How does an automated inventory tracking system improve efficiency?

A. By automating the tracking process, businesses can streamline inventory management, reduce errors, and free up staff to focus on other tasks, thereby improving overall operational efficiency.

Q3. What are the key components of an automated inventory tracking system?

A. Key components include barcodes or RFID tags for labeling products, inventory management software for processing data, IoT devices for monitoring conditions, and cloud computing for real-time data access.

Q4. Are there any challenges associated with implementing an automated inventory tracking system?

A. Yes, challenges include the initial cost of implementation, the need for system integration, and the time and expense of training employees to use the new system.

Q5. What future trends are expected in automated inventory management?

A. Future trends include the increased use of AI and machine learning, the adoption of blockchain technology for secure inventory tracking, and the integration of advanced robotics in warehouses.

Q6. How can a business benefit from an automated inventory tracking system?

A. A business can benefit through increased inventory accuracy, cost savings, enhanced efficiency, and access to real-time data for better decision-making.

Conclusion

In an era where efficiency and accuracy are paramount, an automated inventory tracking system offers a powerful solution for businesses looking to streamline their operations and maintain a competitive edge. By embracing the technological advancements driving these systems, companies can optimize their inventory management processes, reduce costs, and improve overall supply chain performance. As the industry continues to evolve, the integration of AI, machine learning, and other cutting-edge technologies will further enhance the capabilities of these systems, making them an indispensable tool for businesses across all sectors.

#Automated Inventory Management#Real-Time Inventory Tracking#Inventory Control Systems#Supply Chain Optimization#Data-Driven Inventory#Warehouse Automation

0 notes

Text

Stock Position Report

https://alzerp.com/kb/docs/current-stock/

ALZERP’s Stock Position Report provides a real-time snapshot of inventory levels across different product categories and store locations. By offering flexible filtering options, including zero stock and sales quantity inclusion, businesses can gain valuable insights into their stock health. This data-driven report empowers informed decision-making regarding replenishment, stock optimization, and preventing stockouts. With options to export or print, the report ensures easy accessibility and sharing of inventory information.

Key Features:

Date Selection: Choose the date for which you want to generate the stock position report.

Product Filtering: Filter products by category and store location.

Zero Stock Inclusion: Option to include or exclude items with zero stock.

Sales Quantity Inclusion: Option to include sales quantity within the specified date range.

Report Format:��Displays product name, quantity, and unit of measurement for each item.

Grouping: Organizes the report by warehouse for better visibility.

Export and Print: Allows exporting the report as a PDF or printing it for physical records.

#Automated Inventory System#Cloud Inventory Automation#Cloud Inventory Control System#Cloud Inventory Management#Cloud Inventory Mobile App#Cloud Inventory Software for Enterprises#Cloud Inventory Tracking#Cloud Stock Control#Cloud Warehouse Management#Cloud-Based Inventory Management Solutions#Cloud-Based Inventory Solutions#Cloud-Based Inventory System for Wholesalers#Cloud-Based Stock Management#Customizable Inventory Software#ERP Inventory Management#Inventory#Inventory Control Software#Inventory Forecasting Software#Inventory Management Analytics#Inventory Management and Reporting#Inventory Management Application#Inventory Management Dashboard#Inventory Management for E-commerce#Inventory Management for Manufacturing#Inventory Management for Retail#Inventory Management Platform#Inventory Management Software#Inventory Management Solutions#Inventory Management System#Inventory Management Tools

0 notes

Text

Axolt: Modern ERP and Inventory Software Built on Salesforce

Today’s businesses operate in a fast-paced, data-driven environment where efficiency, accuracy, and agility are key to staying competitive. Legacy systems and disconnected software tools can no longer meet the evolving demands of modern enterprises. That’s why companies across industries are turning to Axolt, a next-generation solution offering intelligent inventory software and a full-fledged ERP on Salesforce.

Axolt is a unified, cloud-based ERP system built natively on the Salesforce platform. It provides a modular, scalable framework that allows organizations to manage operations from inventory and logistics to finance, manufacturing, and compliance—all in one place.

Where most ERPs are either too rigid or require costly integrations, Axolt is designed for flexibility. It empowers teams with real-time data, reduces manual work, and improves cross-functional collaboration. With Salesforce as the foundation, users benefit from enterprise-grade security, automation, and mobile access without needing separate platforms for CRM and ERP.

Smarter Inventory Software Inventory is at the heart of operational performance. Poor inventory control can result in stockouts, over-purchasing, and missed opportunities. Axolt’s built-in inventory software addresses these issues by providing real-time visibility into stock levels, warehouse locations, and product movement.

Whether managing serialized products, batches, or kits, the system tracks every item with precision. It supports barcode scanning, lot and serial traceability, expiry tracking, and multi-warehouse inventory—all from a central dashboard.

Unlike traditional inventory tools, Axolt integrates directly with Salesforce CRM. This means your sales and service teams always have accurate availability information, enabling faster order processing and better customer communication.

A Complete Salesforce ERP Axolt isn’t just inventory software—it’s a full Salesforce ERP suite tailored for businesses that want more from their operations. Finance teams can automate billing cycles, reconcile payments, and manage cash flows with built-in modules for accounts receivable and payable. Manufacturing teams can plan production, allocate work orders, and track costs across every stage.

86 notes

·

View notes

Text

Like Google’s knowledge monopoly and Facebook’s ‘social industry’, Amazon’s logistics behemoth displays an increasingly totalitarian style of economy. The growing number of partnerships between the tech giants, as well as their contracts with various government agencies, stage a ghoulish capitalist politburo that aims to deliver a kind of data-determined social harmony, as enchanting as it is ruinous. One can reasonably conclude that in this imagined future, the principal means of expropriation is no longer the wage relation but data capture, where the platform class no longer relies on labour so much as social activity, drawn from the habits and movements of day-to-day life. Looking at the range of services the platform giants hope to one day automate – warehouses, delivery, human resources, health and finance, to name but a few – we see a future in embryo, one in which the wage is effectively abolished, in which huge conglomerates stretching into cosmic totalities continue to own and control the means of production but no longer employ people, whose primary role is simply to feed machines data via their daily activities. This imagined future haunts the world of microwork, where data about a task is often more important than the task itself. Work as a productive activity becomes secondary, but it does not disappear. Rather, in becoming increasingly marginal to the interests of a system no longer creating jobs, it permeates the entire social landscape, as workers desperate for income are forced to turn every waking hour into monetizable activity.

Phil Jones, Work Without the Worker: Labour in the Age of Platform Capitalism

79 notes

·

View notes

Text

Mission Archnemesis (Was A Catastrophic Failure)

George Valley Centre for Sisyphean Supers, File M-BS-5

Superhero Alias: Bullet Storm

Archnemesis: Midnight Devil, Lord of All Darkness, Master of the Fifth Spiral of Doom and Bane of Humanity

Mission Report: It all started on a gloomy Monday morning. I was drinking my coffee, which to my dismay had gone cold during my intense session of preparing for my first fight with my sworn nemesis. The Midnight Devil, Lord of All Darkness, Master of the Fifth Spiral of Doom and Bane of Humanity. After several hours of searching restlessly for clues about the villain’s secret base, I found it. A warehouse in the shady depths of the city. It had been believed to be abandoned for years, but I knew better. With my magnificent powers granted to me by my mysterious magical amulet, I punched down the door with a single blow!

But alas, The Midnight Devil, Lord of All Darkness, Master of the Fifth Spiral of Doom and Bane of Humanity must have sensed my glorious presence, for he had already fled, leaving not a trace of his presence behind. Yet I did not give up. I relentlessly continued my search for the rest of the week, working day and night to scour every last inch of the city for clues to my archnemesis’ whereabouts. But alas, despite my valiant efforts, The Midnight Devil, Lord of All Darkness, Master of the Fifth Spiral of Doom and Bane of Humanity nimbly out of my clutches at every turn.

So, I have returned, outwitted but not defeated, to gain my strength for the formidable battles ahead, no matter what form they may take. And I shall be prepared.

Signature: BS😎

Diary of Midnight Devil, Lord of All Darkness, Master of the Fifth Spiral of Doom and Bane of Humanity, Page 20

Dear Evil Diary,

Today marks the first day that I, the evillest villain in all the land, shall finally be greeted with someone claimed to be a worthy foe. MUAHAHAHAHAHA! I have an evil scheme planned that will surely show them that no hero could ever overthrow my mighty and tyrannical rule!

First, I shall send my most loyal sidekick, Mosquito, to muddle the path of their noble quest until they are completely lost! Then, should they somehow surpass this obstacle and find me, I will be draped seductively over my couch, holding a remote control in one hand and petting a cat with the other! And then the remote will activate my trap, The Horror of The Depths, Reaper of Pure Souls and Crusher of Dreams! MUAHAHAHAHAHA! It’s flawless I say, completely flawless!

The hero didn’t show up. Were my evil schemes not wicked enough for them to feel the heroic need to thwart me? Were my riddles not clever enough? Was my dark and secret villain basement too cliche? No. Of course not. I must have just been too bad for them, and they fled in fear of my power, only to return stronger after a mandatory training montage!

Who am I kidding? I CAN’T WAIT THAT LONG! Note to self: Get Mosquito to find me a new hero asap. The most pure hearted in all of the land, the chosen one, the mighty saviour! Who needs a pathetic wimp like whatever loser couldn’t even bother to show up to my evil scheme? I will reign victorious! MUAHAHAHAHAHAHA!

Mosquito’s To-Do List

Wash the dishes ✔️

Male sure your Pong score is higher than Elgye’s. That’ll piss him off ✔️ (Go me!)

Do the laundry ✔️

Automate the system so that Boss can stop wasting a whole hour signing his stupidly long villain name on every single document! ✔️

Pay rent ✔️

Thwart the new archnemesis ✔️ (I didn’t even have to do anything! Free money, hell yeah!)

Cook dinner ✔️ (It’s always my turn. Ugh. Roommates.)

Evil cackle time with Boss ✔️ (He’s so dumb.)

George Valley Centre for Sisyphean Supers, File BS-6

Superhero Alias: Bullet Storm

Archnemesis: Midnight Devil, Lord of All Darkness, Master of the Fifth Spiral of Doom and Bane of Humanity

Mission Report: My tale begins on a foggy Saturday evening. I was on the way back to my secret base after another day relentlessly chasing after the Midnight Devil, Lord of All Darkness, Master of the Fifth Spiral of Doom and Bane of Humanity. Then, I saw him. A man obscured by shadows, trying to break into my secret base through the window! I checked the time, and much like I suspected, it was midnight. “Midnight Devil, Lord of All Darkness, Master of the Fifth Spiral of Doom and Bane of Humanity! I have caught you in the act!” I declared loudly, aiming a light in his direction.

Alas, he escaped back into the shadow before I could glimpse his face, nimble as the night itself! “Yes,” he growled, voice deep and muffled, “It is I. Find me on the Devil’s Lane next midnight, and we shall have our grand battle.” I refused, determined to catch him then and there! But like a demon returning to the pits of hell, he was gone. Nevertheless, I return victorious, with more information about the mysterious Midnight Devil, Lord of All Darkness, Master of the Fifth Spiral of Doom and Bane of Humanity than anyone has ever learnt before! And tomorrow, I will be victorious!

Signature: BS 😎

Diary of Midnight Devil, Lord of All Darkness, Master of the Fifth Spiral of Doom and Bane of Humanity, Page 23

Dear Evil Diary,

Today was a beautifully evil day! I, The Midnight Devil, Lord of All Darkness, Master of the Fifth Spiral of Doom and Bane of Humanity, have finally encountered my mortal enemy! I found him, walking through my very lair like he owned it, holding a folder full of my darkest secrets!

He stood as still as a statue, clearly terrified by my mighty and powerful presence. “Are you the one that they call Bullet Storm? The only being believed capable of ever matching my unfathomable strength?” He stared back in noble silence, and I saw it all. His proud jaw, his golden hair, the subtle curves of muscle on his bare arms. Yes, I thought to myself, This is him. This is the one.

“Come, Bullet Storm, let us begin our glorious battle!” I declared, my cape waving dramatically behind me. But alas, Bullet Storm fled, as nimble as his name suggested. Nevertheless, my encounter with my fabled nemesis has sent villainous passion running through my veins. I began constructing my newest trap, a grand machine of unfathomable intricacy and evil glory. I shall name it the Hellfire Pit, Extinguisher of Light, Forge of the Darkest Flames and Death Bringer! And with it, I shall end this battle for once and for all! MUAHAHAHAHA!!!

Audio File Recorded By Mosquito, Deleted Immediately After Creation

“I don’t usually do this, but god, this week has been a mess. I’ll delete this after I’m done. Yeah, that’s a good move. Hell, I just need to say this insanity out loud.”

“First, I get caught by my roommate while trying to sneak back into the apartment. And for some reason, the dumbass thought I was my boss? So I just went along with it and it worked! God, he’s so stupid.”

“Then, I was leaving work without my suit to try to avoid it happening again and my boss didn’t recognise me! He just thought I was his archnemesis for some reason? What is with me always falling in love with idiots? And why do I always play along?!”

“So now I’m playing the goddamn middleman for two conclusion-jumping morons. Why is this my life? What did I do to deserve this? …Ok, maybe that was a bad question, but still!”

New Satrie City Herald, pg 1

Two Rival Supers Fight Same Imposter

A small street on the edge of the city suddenly became lively with action last week when a pair of “eternal rivals” confronted each other. Despite believing to have fought each other for two years, neither recognised the other. And their true nemesis had been hiding just beneath their noses the entire time. More on page 3.

George Valley Centre for Sisyphean Supers, File BS-642

Superhero Alias: Bullet Storm

ID Number: 7188

Reason For Leave (please tick all that apply):

☐ Medical emergency

☐ Identity leak

☐ Pregnancy

☐ Career advancement

☐ Work commitments

☑ Familial obligations

☐ Jury duty / Court hearing

☐ Personal Illness

☑ Unexpected circumstances

☐ Religious holiday

☐ Death in family

☐ Doctor’s appointment

☑ Other (please specify):

I’M GETTING DOUBLE MARRIED!!!

Signature: BS 😎

@black-rose-events hope I'm not late!!!

#villaintine's day#my writing#villains and heroes#satire#oblivious hero#oblivious villian#misunderstandings#polyamory#my first poly relationship hope I didn't mess up too bad#moronsexual sidekick#hero x villain#hero x villain sidekick#villian x villain sidekick

22 notes

·

View notes

Text

Warehouse Buzzer System

How Electronic Message Boards Assist In Updating

Electronic message boards are fairly prevalent today, and their usage seems to be proliferating. Message boards in electronic kind properly interact swiftly upgraded company memoranda, final timetable modifications, and marketing, three fairly various applications providing one an idea of the breadth that this medium has gotten to. Herein we explore the phenomenon both generally and in regards to the power released when incorporated with an integrated clock system.

Electronic message boards derive from a lengthy background of open-air communication making use of indicators, billboards, marquees, and so on. Trick attributes were the layouts utilized and the feedback time for updating info. The most usual style entailed drawing on comprehensive personality collections, containing letters, numbers, and spelling, to create words, hanging them from hooks or resting them on wooden slats.

Posts were changed by hand, and updates were thus irregular. In time, updating was improved and somewhat automated using electronic control, such as seen with old baseball park scoreboards.

However, there was still the danger of lacking specific characters and being rendered unable to display all words in your message. This problem was addressed when the dot matrix selection was created, which stood for any type of character (in any type of typeface)-- also graphics-- with a rectangular pattern of on-or-off dots. These could be published on paper, yet a lot more effective was to present them in grids of light bulbs or on a screen.

Mapping formulas converted text into ranges of dots virtually instantaneously, and while drivers entered on a console, messages scrolled across the screen in essentially live. This system still required manual work, however the display screen tool was much easier to read, new, and updatable in a matter of moments. Whence the birth of electronic message boards that utilized light bulbs as the dots, or pixels.

Early light bulbs were incandescent, and were really the only choice; nonetheless, they had brief life-spans and prone to failing from shock. By the millenium, light producing diodes (LED) were a fully grown innovation and available in several shades, including white. Additionally, they outlived incandescent light bulbs by approximately 50 times, were not so breakable, and rapidly came to be the recommended part for message boards.

In time developers got extra creative with the tool and wanted to have more than one "on" shade to deal with. LEDs can fulfill this desire with their 3-in-1 mix of the 3 primary colors to synthesize white light; by choosing different sub-combinations you can obtain 7 various shades.

At some point, upgrading had to transition out of its humble manual origins. Now, textual info can be gotten in real time or gotten from data sources, and software is utilized to map the information right into matrices of (color-coded) dots that get buffered and presented quickly, effortlessly, and effortlessly. Graphics can be incorporated if they are mapped in advance.

Therefore, the modern digital boards are essentially automated, though there are provisions for bypassing scheduled programs with brand-new content in emergencies. Synchronous timekeeping systems manage everything.

An intriguing advancement is the integration of sound signals with the visual information being displayed on a sign in either textual or visual kind. It is popular that a close coordination of both kinds of sensuous stimulations has a tendency to get the message throughout many successfully. It's not a combination of both elements into tune, yet rather the use of sounds (bells, tones, whistles) as focus grabbers to change emphasis of the target market to what the board is showing, whether it be information or other timely information. synchronized clocks for hospitals

The world has actually expanded tired with fixed messaging in regards to both web content and style. Things need to be vibrant to sign up, and this needs constant educational updates. With this article we have seen exactly how electronic message boards promote updating.

youtube

2 notes

·

View notes

Text

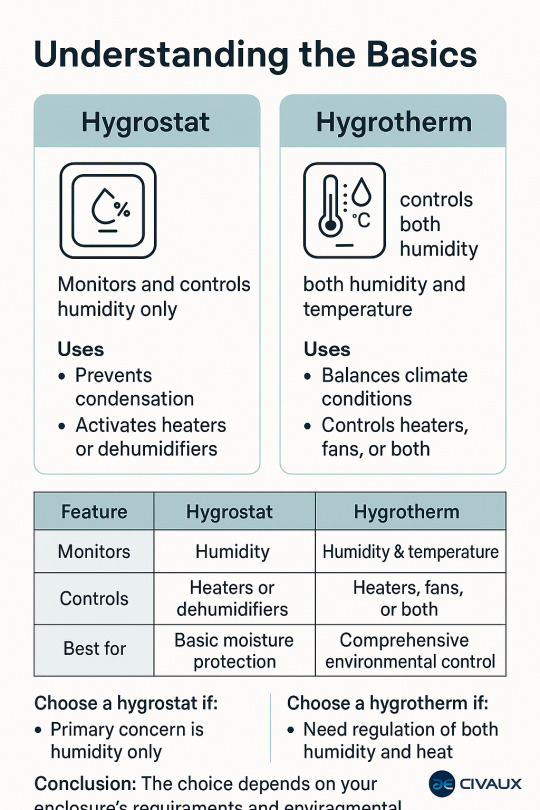

Hygrostat vs. Hygrotherm: Which Offers Better Moisture Management?

Moisture is one of the most damaging yet often overlooked threats to electrical enclosures and control panels. In high-humidity regions like the GCC, effective moisture management is critical to ensuring equipment longevity, operational safety, and uninterrupted performance. Two of the most widely used solutions in this space are hygrostats and hygrotherms. But which one is better for your application?

In this article, we compare hygrostats vs. hygrotherms in terms of functionality, performance, and suitability for different environments — helping you make the right choice for your electrical enclosure needs.

What is a Hygrostat?

A hygrostat is a humidity-regulating device that monitors the relative humidity inside an enclosure and activates connected equipment (like a heater or fan) when a preset humidity threshold is exceeded. It’s a single-function device focused purely on moisture control.

Key Functions:

· Monitors internal humidity

· Activates heaters or dehumidifiers to prevent condensation

· Simple and cost-effective solution for moisture problems

What is a Hygrotherm?

A hygrotherm is a dual-function device that combines the capabilities of a thermostat (for temperature) and a hygrostat (for humidity). It can monitor and control both parameters, ensuring balanced temperature and humidity regulation within the enclosure.

Key Functions:

· Simultaneous monitoring of temperature and humidity

· Activates heaters, fans, or filters based on combined conditions

Why Moisture Control Matters

In regions with high temperature fluctuations — like warehouses, factories, and outdoor panels in the Middle East — condensation can form inside enclosures. This can lead to:

· Corrosion of components

· Electrical short circuits

· Reduced equipment lifespan

· Safety risks for operators

Choosing the right controller ensures stable environmental conditions, reduces downtime, and cuts maintenance costs.

When to Use a Hygrostat

Choose a hygrostat if:

· Your enclosure operates in a relatively stable temperature range

· Your primary concern is humidity only

· You need a low-cost, targeted solution

· You’re upgrading older enclosures with basic needs

When to Use a Hygrotherm

Choose a hygrotherm if:

· Your environment experiences extreme heat and humidity (e.g., GCC summer months)

· You’re running sensitive electronics or automation panels

· You need proactive climate control for both heat and moisture

· You want to consolidate devices into a single, efficient unit

Conclusion: Which is Better?

Both hygrostats and hygrotherms are effective tools for enclosure climate control — but the better choice depends on your environmental conditions and system complexity.

· For basic, budget-friendly moisture protection: ✅ Go with a hygrostat.

· For comprehensive, long-term protection in critical systems: ✅ Invest in a hygrotherm.

Civaux Electric, we offer both hygrostats and hygrotherms with wide voltage range, compact design, and reliable performance — built to handle the GCC’s demanding climates.

#Hygrostat#Hygrotherm#Moisture management#Humidity control devices#Temperature and humidity regulator#Industrial climate control#electrical equipment#switchgears#electrical#panel#lowvoltage#dubai#united arab emirates

2 notes

·

View notes

Text

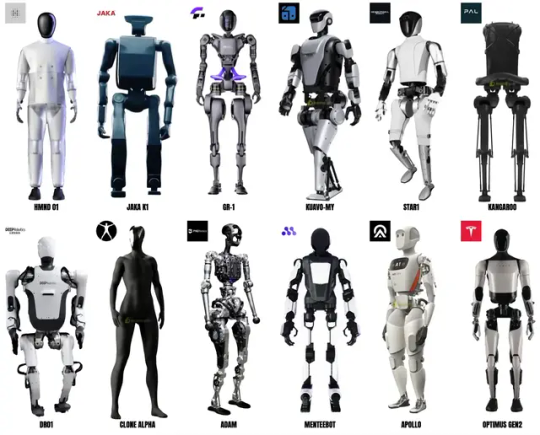

HMND 01

Another bland, all-purpose chassis. The control systems look modular—good for rapid prototyping. No clear edge in autonomy or payload. Could be a solid testbed for LAWS compliance modules. Would need serious upgrades for real combat utility. Not impressed, but not dismissing it either.

JAKA K1

Boxy, utilitarian. Classic industrial design—prioritizes durability over grace. Would slot in as a logistics mule or ammo carrier, but mobility constraints are obvious. A good candidate for AR-based remote control overlays. I wonder if it could double as a decoy unit in urban environments?

GR-1 (Fourier Intelligence)

Some intriguing actuation here—almost bio-inspired. The focus on rehab and elderly care is endearing, but I see potential for dual-use in battlefield casualty extraction or medical simulation. Human-in-the-loop is feasible, but the platform screams for more autonomy. Would love to test its gait stability in rough terrain.

KUAVO-MY

Looks like a research platform—good for rapid iteration and code injection. Not much armor or redundancy, but the open architecture is a plus. Could be prototyped for swarm tactics or as a sensor-forward scout. The lack of obvious weapon mounts is both a relief and a missed opportunity.

STAR1

Sleek, but form over function. Likely more useful in PR stunts or as a non-lethal presence in peacekeeping ops. If I were to retrofit, I’d focus on CBRN sensor integration. Its humanoid profile makes it an ideal candidate for AR deception tactics—simulate friendly or enemy units on the fly.

KANGAROO (PAL Robotics)

Intriguing leg design. High mobility could be leveraged for quick-strike or urban recon—especially in environments unsuited to wheeled robots. Not enough payload space for heavy weapons, but could run interference or deliver microdrones. If only the developers thought beyond logistics.

DR01 (Deep Robotics)

Standard warehouse bot, but robust. Could retrofit for automated resupply under fire or as a shield platform for advancing infantry. I’d love to stress-test its fail-safes—most civilian systems crumble under jamming. With enough ruggedization, could be a sleeper hit for rear-echelon support.

CLONE ALPHA

Uncanny valley in full effect. Maybe useful for psychological ops or as a decoy. Not much info on its internal architecture—probably just another platform for gesture and interaction studies. If it’s hackable, it’s exploitable. Maybe I’m being too harsh; sometimes you need a wild card.

ADAM (PANDORAS)

Looks like a modular testbed. Exposed actuators are a vulnerability, but easy for rapid prototyping. Could run complex manipulations—maybe bomb disposal or field repairs. I’d like to run it through a simulated combat scenario; the learning algorithms are probably underdeveloped.

MENTEEBOT

Educational focus is noble, but soft targets like these are often overlooked as threat vectors. Could easily be repurposed for crowd control or non-lethal compliance. The black-box autonomy concerns me—need full transparency on decision-making for battlefield deployment.

APOLLO

Industrial humanoid with battlefield potential. Chassis and design hint at decent load capacity. With proper AI weapons integration, could serve as force multiplier—though I’d never trust it unsupervised. Human-in-the-loop is a must. Strong candidate for “guardian” role in Warren’s hypothetical reincarnated team.

OPTIMUS GEN2 (Tesla)

Musk’s hype aside, it’s the most media-savvy bot here. If the neural net is as strong as claimed, it could be a game-changer for integrated logistics and resupply. However, I’d bet on a thousand edge cases that could break it under stress. Would love to see it in a mixed-reality war game—provided it’s not just vaporware.

Final Thoughts: All show promise, but none are ready for true LAWS integration without strict regulatory and ethical oversight. The irony isn’t lost on me—designing more lethal systems while demanding more human control. Maybe that’s my father’s ghost talking, or maybe it’s just the reality of our times. I’ll light incense for these prototypes—not for luck, but to remind myself: tools are only as wise as their creators, and war never needs more fools.

2 notes

·

View notes

Text

24/7 Electrical Services in Red Deer: Residential, Commercial & Industrial Expertise You Can Count On

When the power goes out, your equipment fails, or an electrical hazard emerges in the middle of the night, you can’t afford to wait until morning. That’s when you need the help of an experienced emergency electrician Red Deer trusts — someone who can respond quickly, fix the problem efficiently, and restore safety and comfort without delay. At Bryant’s Electrical Ltd., we proudly offer 24/7 electrical services for homes, businesses, and industrial sites across Red Deer and the surrounding areas.

Electrical issues don’t keep regular hours, and neither do we. Whether it’s a tripped panel at 3 a.m. or a factory outage on the weekend, our certified electricians are just a call away — fully equipped and ready to get you back up and running.

⚡ Why 24/7 Electrical Service Matters

In today’s fast-paced world, electricity powers everything — from the lights in your living room to the machinery in your warehouse. Any interruption, no matter how small, can disrupt your routine, business operations, or even endanger lives. That’s why having access to round-the-clock professional support is essential.

Here’s what 24/7 service means for you:

Fast response during power outages or electrical emergencies

Peace of mind for businesses that operate late hours or overnight

Safety from fire hazards, electrical shocks, and system failures

Minimized downtime, ensuring your operations stay on track

Bryant’s Electrical Ltd. is built on reliability, accountability, and community trust. No matter the hour or situation, our clients know they can count on us.

🏠 Residential Electrical Emergencies: We’ve Got Your Back

Imagine your breaker keeps tripping at night, your outlets are sparking, or you smell something burning behind the walls — these aren’t situations to ignore. They require urgent, expert intervention. As a homeowner, you need someone who responds quickly and understands how to diagnose issues without compromising safety.

Our residential emergency services include:

Power outages and breaker failures

Flickering or non-functional lights

Burning smells or hot electrical panels

Electrical shocks or exposed wires

Smoke detector malfunctions

Sudden appliance or HVAC failures

At Bryant’s Electrical Ltd., we respond swiftly and provide clear solutions. We know your home is your safe space, and we treat it with care, professionalism, and urgency — whether it’s a late-night call or weekend emergency.

🏢 Keeping Red Deer’s Businesses Running 24/7

A minor electrical fault in a commercial setting can bring entire operations to a halt. For restaurants, stores, warehouses, and offices, that means lost time, revenue, and customer trust. Our commercial clients depend on our 24/7 support to keep the lights on and systems functional — no matter the hour.

Our commercial emergency electrical services include:

Backup generator failures

Retail or office lighting blackouts

Emergency lighting repairs

Breaker panel replacements

Equipment hook-ups and power resets

Security system and data cabling issues

Whether it’s a small café or a large-scale retail space, Bryant’s Electrical Ltd. works quickly, cleanly, and quietly — ensuring minimal disruption to your business and maximum performance from your systems.

⚙️ Industrial Electrical Expertise That Doesn’t Clock Out

Industrial facilities often run 24/7 — so your electrical partner should too. Equipment downtime, system overloads, or automation failures can result in massive losses if not resolved promptly. That’s where our licensed industrial electricians step in.

Our emergency industrial services include:

Motor control troubleshooting

Transformer and switchgear failures

High-voltage system repairs

Machine wiring diagnostics

Lighting and circuit overload issues

Emergency lockout/tagout (LOTO) response

Bryant’s Electrical Ltd. understands that speed, safety, and technical knowledge are critical in industrial settings. Our team is fully trained and certified to handle complex electrical systems — ensuring you can continue production with minimal interruption.

🔧 Preventative Maintenance — The Key to Fewer Emergencies

While we’re always here for emergency calls, we also believe in helping clients prevent them. Routine maintenance and inspections go a long way in identifying potential hazards before they cause real damage.

We offer:

Routine panel and circuit inspections

Thermal imaging to detect overloads

Surge protection system checks

Generator testing and maintenance

Lighting system evaluations

Load calculations and balancing

Bryant’s Electrical Ltd. provides both scheduled maintenance and emergency response, giving you the best of both worlds. A well-maintained system is safer, more reliable, and less likely to need a middle-of-the-night rescue.

✅ Why Choose Bryant’s Electrical Ltd.?

There’s no shortage of electricians in Red Deer, but not all are created equal. Here’s why our clients choose us — and keep choosing us:

24/7 Availability: We’re on-call every hour of every day — no delays, no excuses.

Licensed & Insured: Every technician is fully qualified and backed by liability coverage.

Trusted Locally: We’re a proud Red Deer business with deep community roots.

Clear Pricing: No hidden fees — just honest, upfront estimates.

Quick Response Times: Our mobile units are fully equipped and always ready to roll.

All-in-One Expertise: From homes to factories, we know electrical systems inside and out.

🔄 Integrated Electrical Solutions for Every Sector

What sets us apart is our broad scope of services. While some contractors specialize in one niche, we do it all — and we do it well.

Residential: We make homes safer, brighter, and more energy-efficient. Whether it’s panel upgrades, smart systems, or outlet repairs, we handle it with care.

Commercial: From lighting design to data wiring and tenant improvements, we help businesses thrive with dependable power systems.

Industrial: We support manufacturers, warehouses, and large facilities with precision power solutions that meet strict safety and efficiency standards.

Our team is always learning, always innovating, and always ready to deliver next-level service.

📞 One Call Away, Day or Night

Electrical emergencies don’t come with a warning. Whether it’s a weekend, a holiday, or the middle of the night, we’re always just a phone call away.

When you contact Bryant’s Electrical Ltd., you speak directly to a trained professional who listens, understands, and acts fast. We believe in treating every customer with urgency and respect — because that’s what you deserve when the lights go out.

🏡 Reliable Residential Electrician Red Deer Families Trust

Your home should always feel safe and functional, no matter what. Whether you’re dealing with flickering lights, frequent trips to the breaker, or urgent electrical issues, Bryant’s Electrical Ltd. is here to help. As the go-to residential electrician Red Deer residents rely on, we bring a perfect mix of professionalism, compassion, and technical skill into your home. From emergency calls to routine repairs and upgrades, we make sure your space stays powered, protected, and perfectly lit.

Conclusion

When it comes to electrical systems, every second counts. Whether you’re facing a sudden outage or want to upgrade your existing setup, trust the experts who deliver 24/7. Bryant’s Electrical Ltd. is proud to serve Red Deer with residential, commercial, and industrial services that never sleep.

Need help now? Don’t wait — call Bryant’s Electrical Ltd. today for expert electrical support you can count on any time, day or night.

2 notes

·

View notes

Text

How to Implement Effective Temperature Control Systems in Your Warehouse

In today's fast-paced commercial environment, maintaining optimal temperature control is crucial for various industries, particularly those dealing with perishable goods. Whether you're in the food processing sector or running a large warehouse, effective temperature control systems are essential to ensuring the longevity and quality of your products. At Global Automation Ltd., we specialize in providing advanced cold storage solutions and warehouse storage systems that meet the highest standards of efficiency and reliability.

Cold Storage Solutions: The Backbone of Temperature Control

When it comes to temperature-sensitive products, having a reliable cold storage solution is non-negotiable. Global Automation Ltd. offers some of the most advanced and durable cold storage equipment in Bangladesh. Our cold storage freezers and blast freezers are designed to maintain consistent temperatures, ensuring that your products remain in optimal condition from storage to distribution. We invest heavily in manufacturing high-quality solutions that stand the test of time, minimizing the risk of equipment failure and ensuring peace of mind for our customers.

The Role of Industrial Refrigeration

Industrial refrigeration systems play a pivotal role in maintaining the desired temperature within your warehouse. These systems are not just about keeping things cold; they are about preserving the integrity of your products. At Global Automation Ltd., we understand the importance of industrial refrigeration in cold chain logistics. Our refrigeration systems are engineered to deliver precise temperature control, helping you meet the stringent requirements of food safety and other industry regulations.

Optimal Warehouse Storage Solutions

Beyond cold storage, effective temperature control in a warehouse setting involves a comprehensive approach to storage and inventory management. Our warehouse storage solutions are designed to maximize space utilization while ensuring easy access to your inventory. Whether you need industrial storage systems, cantilever racks, or drive-in racks, Global Automation Ltd. offers a range of options to suit your specific needs. These systems are crucial for maintaining an organized warehouse, which is vital for efficient temperature management.

Integrating Warehouse Automation for Enhanced Control

Warehouse automation is revolutionizing how businesses manage their storage and temperature control needs. At Global Automation Ltd., we incorporate cutting-edge technologies like AI, machine learning, and IoT into our warehouse solutions to enhance operational efficiency. Automated systems not only improve the accuracy of temperature monitoring but also reduce human error, ensuring that your products are stored under optimal conditions at all times. Our advanced warehouse management systems are tailored to meet the unique challenges of temperature-sensitive storage, making them an invaluable asset for your business.

Why Choose Global Automation Ltd.?

Global Automation Ltd. stands out as a leader in providing comprehensive cold storage and warehouse solutions in Bangladesh. Our commitment to quality, durability, and customer satisfaction is unmatched. From the design and manufacturing of state-of-the-art cold storage equipment to the implementation of efficient warehouse storage systems, we offer end-to-end solutions that address all your temperature control needs.

Choosing the right partner for your temperature control systems can make a significant difference in your business operations. With Global Automation Ltd., you can rest assured that you are getting the best in the industry. Our expertise, coupled with our cutting-edge technology, ensures that your products are stored under the best possible conditions, helping you maintain the highest standards of quality and safety.

#Cold Storage Solutions#Industrial Refrigeration#Cold Storage Bangladesh#Temperature Control Systems#Cold Chain Logistics#Warehouse Storage Solutions#Industrial Storage Systems#Warehouse Automation#Storage Racks Bangladesh#Warehouse Management

0 notes

Text

Getting Started with Industrial Robotics Programming

Industrial robotics is a field where software engineering meets automation to drive manufacturing, assembly, and inspection processes. With the rise of Industry 4.0, the demand for skilled robotics programmers is rapidly increasing. This post introduces you to the fundamentals of industrial robotics programming and how you can get started in this exciting tech space.

What is Industrial Robotics Programming?

Industrial robotics programming involves creating software instructions for robots to perform tasks such as welding, picking and placing objects, painting, or quality inspection. These robots are typically used in factories and warehouses, and are often programmed using proprietary or standard languages tailored for automation tasks.

Popular Robotics Programming Languages

RAPID – Used for ABB robots.

KRL (KUKA Robot Language) – For KUKA industrial robots.

URScript – Used by Universal Robots.

Fanuc KAREL / Teach Pendant Programming

ROS (Robot Operating System) – Widely used open-source middleware for robotics.

Python and C++ – Common languages for simulation and integration with sensors and AI.

Key Components in Robotics Programming

Motion Control: Programming the path, speed, and precision of robot arms.

Sensor Integration: Use of cameras, force sensors, and proximity detectors for adaptive control.

PLC Communication: Integrating robots with Programmable Logic Controllers for factory automation.

Safety Protocols: Programming emergency stops, limit switches, and safe zones.

Human-Machine Interface (HMI): Designing interfaces for operators to control and monitor robots.

Sample URScript Code (Universal Robots)

# Move to position movej([1.0, -1.57, 1.57, -1.57, -1.57, 0.0], a=1.4, v=1.05) # Gripper control (example function call) set_digital_out(8, True) # Close gripper sleep(1) set_digital_out(8, False) # Open gripper

Software Tools You Can Use

RoboDK – Offline programming and simulation.

ROS + Gazebo – Open-source tools for simulation and robotic control.

ABB RobotStudio

Fanuc ROBOGUIDE

Siemens TIA Portal – For integration with industrial control systems.

Steps to Start Your Journey

Learn the basics of industrial robotics and automation.

Familiarize yourself with at least one brand of industrial robot (ABB, KUKA, UR, Fanuc).

Get comfortable with control systems and communication protocols (EtherCAT, PROFINET).

Practice with simulations before handling real robots.

Study safety standards (ISO 10218, ANSI/RIA R15.06).

Real-World Applications

Automated welding in car manufacturing.

High-speed pick and place in packaging.

Precision assembly of electronics.

Material handling and palletizing in warehouses.

Conclusion

Industrial robotics programming is a specialized yet rewarding field that bridges software with real-world mechanics. Whether you’re interested in working with physical robots or developing smart systems for factories, gaining skills in robotics programming can open up incredible career paths in manufacturing, automation, and AI-driven industries.

2 notes

·

View notes

Text

Stock Valuation Reports (Current Stock With Price)

ALZERP’s Stock Valuation Report provides a comprehensive analysis of inventory value based on various valuation methods. By calculating stock quantities and their corresponding monetary values, businesses can make informed decisions related to finance, inventory management, and overall business strategy.

Key Features:

Valuation Methods: Offers multiple valuation methods (unit purchase cost, unit sales price, accounting value) to assess inventory value.

Product and Warehouse Filtering: Allows users to select specific products or warehouses for valuation.

Date Selection: Determines the date for which the stock valuation is calculated.

Report Format: Displays product name, quantity, unit of measurement, unit price, and total value.

Export and Print: Enables exporting and printing the report for further use.

https://alzerp.com/kb/docs/current-stock-with-price/

#Automated Inventory System#Cloud Inventory Automation#Cloud Inventory Control System#Cloud Inventory Management#Cloud Inventory Mobile App#Cloud Inventory Software for Enterprises#Cloud Inventory Tracking#Cloud Stock Control#Cloud Warehouse Management#Cloud-Based Inventory Management Solutions#Cloud-Based Inventory Solutions#Cloud-Based Inventory System for Wholesalers#Cloud-Based Stock Management#Customizable Inventory Software#ERP Inventory Management#Inventory#Inventory Control Software#Inventory Forecasting Software#Inventory Management Analytics#Inventory Management and Reporting#Inventory Management Application#Inventory Management Dashboard#Inventory Management for E-commerce#Inventory Management for Manufacturing#Inventory Management for Retail#Inventory Management Platform#Inventory Management Software#Inventory Management Solutions#Inventory Management System#Inventory Management Tools

0 notes

Text

The Basis of the Environmental Crisis

There is a fundamental problem here: The dynamics of capitalism have an inherent tendency towards ecological devastation. To understand why this is so, we need to look at how firms are constantly searching for ways to minimize their expenses. This is how they ensure the firm can make the maximum in profits. Because capitalism is made up of relatively autonomous firms, they are in competition. If a firm doesn’t continuously seek ways to make profits, they won’t be able to expand their business, move into new markets, invest in new technology. Other firms will out-compete them. And minimizing expenses is central to the pursuit of profits. Thus minimizing expenses is central to survival for the capitalist firms. And to do this, firms do cost-shifting at the expense of both workers and the environment.

First, companies try to keep compensation to workers as low as they can get away with. They may look to cut taxes that support services working class people rely on. They try to find new forms of technology or new ways to organize the work that reduces the number of worker hours it takes to produce a unit of output. They might automate a production operation with robots, or they will seek ways to intensify work through “lean production” methods. For example, they’ll use computer tracking of a warehouse worker picking items for an order so that they have no rest time after finishing an order but are pushed to a new task through computer control. Work intensification and computer monitoring puts workers under more stress which can have damaging health effects over time. This means the employers are imposing a human cost on workers. If workers in a furniture factory are constantly breathing in finishes or paints being sprayed on furniture in the open, or electronics assemblers are breathing in solder fumes, these are also cases where capital is shifting costs onto workers. And these are cases where the costs could be avoided. For example, there are soldering tools that have a vacuum to suck off solder fumes so workers don’t breath it, but a firm may not want to pay the expense of installing that equipment. These are examples of how the capitalist mode of production tends to shift costs onto workers.

Second, emissions into the air and water are another form of cost-shifting. A utility firm may burn coal to generate electricity. This creates emissions that damage the respiratory systems of people in the region and also contributes to global warming. But the power firm is not required to pay anything for these damages. These costs to others from emissions are “external” to the market transaction between the power firm and its customers who pay for electricity. This is an example of a “negative externality.” Externalities are a pervasive feature of the capitalist mode of production. The fossil fuel industry generates many “negative externalities.” Fracking operations insert chemicals underground which can pollute the underground water sources. A large gas field or leaky oil refinery will generate large amounts of volatile organic compounds — including carcinogens and endocrine disruptors. Studies of gas fields show effects in the surrounding area such as goat herds and barn cats losing the ability to have viable offspring, due to the endocrine disruptors. Gas fields also contribute to global warming by leaking large amounts of methane. Contrary to gas industry claims, gas power plants contribute as much as coal-fired power plants to global warming due to all the methane leaks.

You’ll notice here that I’m focusing on how environmental devastation is rooted in production — not consumption. Some environmentalists try to suggest that we should understand the global warming problem by looking at consumption practices, and they use ideas like a person’s “carbon footprint” to focus on personal consumption. But consumers of electric power don’t have control over the decisions of power firms on the methods of electricity generation, or what technology firms rely on to move cargo around in the global supply chains.

Another useful concept here is throughput. The throughput of production consists of two things: (1) All the material extracted from nature for the production process, and (2) all the damaging emissions (“negative externalities”) from the production process. In addition to the damaging emissions into the air and water, capitalism is an extractivist regime with a long history of land-grabbing to minimize expenses — as in the US government handing over mineral wealth to mining companies, lands for commercial ranching and extraction of logs and wood debris from forests for the lumber and paper industries. The search for short-term profits can lead to unsustainable practices such as clear-cutting of forests or use of huge nets to scarf up all the fish in a coastal region without regard to the future of that fishery.

With the concept of throughput, we can define a concept of ecological efficiency. If a production process is changed in ways that reduce the amount of damage from emissions (or amount of extracted resource) per unit of human benefit, then that change improves ecological efficiency. And here is a basic structural problem of capitalism: It has no inherent tendency towards ecological efficiency. If nature is treated as a free dumping ground for wastes, there will be no tendency to minimize damaging emissions per unit of human benefit from production. Also, there will be no tendency to minimize materials extracted from nature except to the extent firms have pay for these resources.

A production system that could generate increasing ecological efficiency would tend towards reductions in pollution and resource extraction. This would require a non-profit, non-market type of eco-socialist economy where production organizations are held socially accountable — required to systematically internalize their ecological costs. Capitalism’s tendency to ever greater environmental devastation happens because firms have an incentive to not internalize their costs, but dump them on others.

The devastation wrought by the cost-shifting dynamic of capitalism is not limited to global warming. Capitalism has favored the evolution of agricultural practices that aim at highest output at lowest financial cost to the firm. Intense competition has led to ever-greater concentration in ownership of farm land. The capitalist setup allows the growers to rely on labor contractors to pay laborers as little as possible and get rid of workers who try to organize. Growers often own lands in various locations and pursue different crops to minimize their risks. With encouragement from the chemical industry, growers have adopted industrial production of a single crop in a large field with increasing usage of pesticides and inorganic fertilizer over time. Inorganic fertilizers typically provide some mix of nitrogen, phosphorus and calcium. Over-use of these fertilizers has led to excessive runoff, polluting water courses and leading to ocean “dead spots” around the mouths of rivers. Destructive effects on fisheries is thus one of the negative externalities from capitalist agriculture.

Since World War 2 chemical pesticide production world-wide grew from 0.1 ton to 52 million tons in 1976 and 300 million tons in 2015. Pesticides produced by the chemical industry are damaging to the health of farm workers, and pollutes water courses, and leaves residues on food. Pesticide overuse also destroys the natural predators of insects and breeds pesticide-resistant pests. This leads a kind of agricultural arms race as more and more pesticide is needed. As Fred Magdoff and Chris Williams report in Creating an Ecological Society, pesticides also reduce “presence in the soil of organisms that stimulate plants to produce chemicals to defend themselves.”

As with pesticides the chemical industry has also vastly pumped up the production of petroleum-based plastics which do not biodegrade but end up as vast scourge of pollution in the oceans. Plastic bags have grown in use because they take a lot less energy to produce than paper bags, and thus cost less. Production has increased from less than 5 tons in 1950 to over 340 million tons by 2014, according to the Plastics Europe trade association. At least a third of all plastic produced is not recaptured, but mostly ends up in the ocean where it is destructive to living organisms. The plastics industry does not have to pay for the negative effects on living things in the oceans.

If we bring in our definition of throughput, pollution and dumping of wastes are one aspect, but we need to also look at the destructive extractivist tendencies in capitalism, such as clear-cutting of forests or over-fishing. According to a 2003 study, “90 percent of all large fishes have disappeared from the world’s oceans in the past half century,” since the onset of industrial fishing with huge nets in the 1950s. “”Whether it is yellowfin tuna in the tropics, bluefin in cold waters, or albacore tuna in between, the pattern is always the same. There is a rapid decline of fish numbers,” according to Ransom Myers, a fisheries biologist at Dalhousie University in Halifax. To address the problem, many countries have banned long drift nets and untended longlines, and have instituted elaborate systems of licensing, and have instituted quotas and third party observers working on boats. Nonetheless, capitalist fishing outfits frequently ignore or evade these rules.

#climate crisis#Working Class#autonomous zones#autonomy#anarchism#revolution#ecology#climate change#resistance#community building#practical anarchy#practical anarchism#anarchist society#practical#daily posts#communism#anti capitalist#anti capitalism#late stage capitalism#organization#grassroots#grass roots#anarchists#libraries#leftism#social issues#economy#economics#anarchy works#environmentalism

6 notes

·

View notes

Text

Guide for Importers on Manufacturing Control

Efficient Manufacturing Control in China

1. Understand the Chinese Manufacturing Environment:

Diverse Ecosystem: China offers a vast range of manufacturers, from small workshops to large factories. This variety is beneficial but also poses challenges in ensuring consistent quality.

IP Concerns: Despite improvements, IP protection in China can be inconsistent, requiring robust measures to safeguard your innovations.

Regulatory Landscape: China’s complex and changing regulations make compliance crucial to avoid fines and reputational damage.

Quality Control: While quality has improved, some sectors still prioritize quantity over quality. Rigorous quality protocols are essential.

Labor & Costs: Labor costs are rising, pushing manufacturers toward automation. Infrastructure is robust, but supply chains can be disrupted by natural disasters or policy changes.

Government Policies: China’s government heavily influences manufacturing through policies and incentives, which can affect costs and market access.

2. Build a Strong Foundation:

Supplier Selection: Choose reliable suppliers through thorough due diligence, including factory visits and financial checks.

Clear Communication: Provide detailed specifications and maintain open communication to avoid misunderstandings.

Quality Management: Implement a Quality Management System (QMS) and conduct regular audits to ensure consistent product quality.

Strong Relationships: Develop long-term partnerships with suppliers to build trust and collaboration.

3. Implement Effective Control Strategies:

QA & QC: Establish a robust QA/QC framework to ensure consistent product quality.

Supplier Development: Invest in your suppliers’ capabilities to improve quality and efficiency.

Risk Management: Prepare for disruptions with backup plans and diversified suppliers.

Contractual Coverage: Clearly define product specifications and include IP protections in contracts.

Third-Party Verification: Use third-party inspections to ensure compliance and quality.

4. Manage Logistics & Supply Chain:

Transportation: Choose the best transport mode and routes to minimize costs and delays.

Warehousing & Inventory: Optimize warehouse locations and use management systems to track inventory.

Customs & Documentation: Ensure compliance with customs regulations and prepare accurate documentation.

Supply Chain Visibility: Use technology to monitor shipments and collaborate with suppliers.

Risk Assessment: Develop contingency plans for disruptions like natural disasters or strikes.

5. Overcome Common Challenges:

Language & Cultural Barriers: Hire experts to bridge gaps in communication and cultural understanding.

IP Protection: Secure your IP with patents, trademarks, and NDAs; monitor for infringements.

Regulatory Compliance: Stay updated on regulations and partner with local experts for compliance.

Supply Chain Disruptions: Diversify suppliers, maintain sufficient inventory, and use smart tools for monitoring.

6. Continuous Improvement:

Use data analytics to track trends and improve processes.

Regularly evaluate supplier performance and invest in employee training.

Embrace technology to enhance communication and efficiency.

7. Build a Culture of Quality:

Encourage employees to propose improvements.

Reward contributions to quality enhancement.

Focus on exceeding customer expectations.

Conclusion: Effective manufacturing control in China requires ongoing effort, attention, and adaptation. Invest in strong practices to improve product quality, reduce costs, protect your brand, and optimize your supply chain.

3 notes

·

View notes