#biodegradation

Text

Scientists in China have developed a biodegradable glass that aims to cut back on glass waste in landfills while reducing the need for energy-intensive recycling processes.

(If glass is easier to use again and maybe less expensive and energy intensive maybe glass will be a better alternative than plastic for certain situations?)

7 notes

·

View notes

Text

Say Hello to Biodegradable Microplastics - Technology Org

New Post has been published on https://thedigitalinsider.com/say-hello-to-biodegradable-microplastics-technology-org/

Say Hello to Biodegradable Microplastics - Technology Org

Microplastics are tiny, nearly indestructible fragments shed from everyday plastic products. As we learn more about microplastics, the news keeps getting worse. Already well-documented in our oceans and soil, we’re discovering them in the unlikeliest places: our arteries, lungs and even placentas.

Particle counts of petroleum-based (EVA) and plant-based (TPU-FC1) microplastics show that, over time, EVAs exhibit virtually no biodegradation, while the TPUs have mostly disappeared by day 200.

Microplastics can take anywhere from 100 to 1,000 years to break down and, in the meantime, our planet and bodies are becoming more polluted with these materials every day.

Finding viable alternatives to traditional petroleum-based plastics and microplastics has never been more important. New research from scientists at the University of California San Diego and materials science company Algenesis shows that their plant-based polymers biodegrade — even at the microplastic level — in under seven months. The paper, whose authors are all UC San Diego professors, alumni or former research scientists, appears in Nature Scientific Reports.

“We’re just starting to understand the implications of microplastics. We’ve only scratched the surface of knowing the environmental and health impacts,” stated Professor of Chemistry and Biochemistry Michael Burkart, one of the paper’s authors and an Algenesis co-founder. “We’re trying to find replacements for materials that already exist, and make sure these replacements will biodegrade at the end of their useful life instead of collecting in the environment. That’s not easy.”

“When we first created these algae-based polymers about six years ago, our intention was always that it be completely biodegradable,” said another of the paper’s authors, Robert Pomeroy, who is also a professor of chemistry and biochemistry and an Algenesis co-founder. “We had plenty of data to suggest that our material was disappearing in the compost, but this is the first time we’ve measured it at the microparticle level.”

Putting it to the test

To test its biodegradability, the team ground their product into fine microparticles, and used three different measurement tools to confirm that, when placed in a compost, the material was being digested by microbes.

The first tool was a respirometer. When the microbes break down compost material, they release carbon dioxide (CO2), which the respirometer measures. These results were compared to the breakdown of cellulose, which is considered the industry standard of 100% biodegradability. The plant-based polymer matched the cellulose at almost one hundred percent.

Next the team used water flotation. Since plastics are not water soluble and they float, they can easily be scooped off the surface of water. At intervals of 90 and 200 days, almost 100% of the petroleum-based microplastics were recovered, meaning none of it had biodegraded. On the other hand, after 90 days, only 32% of the algae-based microplastics were recovered, showing that more than two thirds of it had biodegraded. After 200 days, only 3% was recovered indicating that 97% of it had disappeared.

The last measurement involved chemical analysis via gas chromatography/mass spectrometry (GCMS), which detected the presence of the monomers used to make the plastic, indicating that the polymer was being broken to its starting plant materials. Scanning-electron microscopy further showed how microorganisms colonize the biodegradable microplastics during composting.

“This material is the first plastic demonstrated to not create microplastics as we use it,” said Stephen Mayfield, a paper coauthor, School of Biological Sciences professor and co-founder of Algenesis. “This is more than just a sustainable solution for the end-of-product life cycle and our crowded landfills. This is actually plastic that is not going to make us sick.”

Creating an eco-friendly alternative to petroleum-based plastics is only one part of the long road to viability. The ongoing challenge is to be able to use the new material on pre-existing manufacturing equipment that was originally built for traditional plastic, and here Algenesis is making progress. They have partnered with several companies to make products that use the plant-based polymers developed at UC San Diego, including Trelleborg for use in coated fabrics and RhinoShield for use in the production of cell phone cases.

“When we started this work, we were told it was impossible,” stated Burkart. “Now we see a different reality. There’s a lot of work to be done, but we want to give people hope. It is possible.”

Source: UCSD

You can offer your link to a page which is relevant to the topic of this post.

#000#algae#Analysis#arteries#biochemistry#biodegradable#biodegradable materials#biodegradation#carbon#Carbon dioxide#cell#cell phone#cellulose#challenge#chemical#chemical analysis#chemistry#Chemistry & materials science news#CO2#Companies#data#easy#electron#Environment#Environmental#equipment#gas#hand#Health#how

0 notes

Text

0 notes

Text

0 notes

Text

fuck dude it sure is

#biodegradation#plastic bags#sadly the company that owned the supermarket chain that sold these is defunct now#these bags were maybe ten years old. when people tell you “biodegradable” plastics still only degrade in fifty years or something...#it's not always true

0 notes

Text

Welcome to my Tuesday morning PSA about plastics!

So--I was walking along the Bolstadt beach approach sidewalk here in Long Beach, WA yesterday afternoon, and I started seeing these little orange pellets on the ground that looked a little bit like salmon roe (but probably weren't). So I picked one up, and it was most definitely rubber. I went around picking up every one I could find, and while I didn't keep exact count I probably amassed 50-60 of them. I took this picture before depositing them in the nearest trash can.

These are airsoft gun pellets, and you can buy them in big jars containing thousands of them. That means that someone who decided that the beach was a great place to shoot their airsoft guns could easily litter the place with countless little bits of plastic rubber in less than an hour. We already have a huge problem here with people leaving trash, including tiny bits of plastic, all over the beach (you should see the gigantic mess after 4th of July fireworks when thousands of people come in from out of town, blow things up, and then leave again without picking up after themselves.)

But these airsoft pellets have a particularly nasty side effect. You know how my first thought was "wow, those look kind of like salmon roe?" Well, we have a number of opportunistic omnivore birds like crows, ravens, and several species of gull that commonly scavenge on the beach, especially along the approaches because people often feed them there. If I can catch the resemblance of an orange airsoft pellet to a fish egg, then chances are there are wildlife that will assume they're edible.

Since birds don't chew their food, they probably won't notice that the taste or texture is wrong--it'll just go down the hatch. And since they can't digest the pellets, there's a good chance they might just build up in the bird's digestive system, especially if the bird eats a large number of them--say, fifty or sixty of them dropped on the ground along the same fifty foot stretch of sidewalk. The bird might die of starvation if there's not enough capacity for food in their stomach--or they might just die painfully of an impacted gut, and no way to get help for it. If the pellets end up washed into the ocean, you get the same issue with fish and other marine wildlife eating them, and then of course the pellets eventually breaking up into microplastic particles.

You can get biodegradable airsoft pellets; they appear to mainly be gray or white in color rather than bright screaming orange and green. But "biodegradable" doesn't mean "instantly dissolves the next time it rains." An Amazon listing for Aim Green biodegradable airsoft pellets advertise them as "Our biodegradable BBs are engineered to degrade only with long-term exposure to water and sun and will degrade 180 days after being used." That's half a year for them to be eaten by wildlife.

I don't know, y'all. That handful of carelessly dropped rubber pellets just encapsulates how much people don't factor in the rest of nature when making decisions, even on something that is purely for entertainment like an airsoft gun. We could have had a lot of the same technological advances we have today, but with much less environmental impact, if we had considered the long-term effects on both other people and other living beings, as well as our habitats. We could have found ways from the beginning to make these things in ways that benefited us but also mitigated any harm as much as possible. Instead we're now having to reverse-engineer things we've been using for decades, and sometimes--like the "biodegradable" airsoft pellets--they still have a significant negative impact.

But--at least there are people trying to do things better, thinking ahead instead of just on immediate profit. We're stuck in a heck of a mess here, figuratively and literally, and changing an entire system can't be done in a day. Maybe we can at least keep pushing for a cultural shift that emphasizes planning far into the future--if not the often-cited "seven generations ahead", then at least throughout the potential lifespan of a given product.

#plastics#microplastics#environment#environmentalism#conservation#nature#pollution#litter#birds#tw animal death#animal welfare#ecology#science#wildlife#animals#scicomm#pnw#airsoft#biodegradable#solarpunk

4K notes

·

View notes

Text

Biodegradation of Marine Pollutants by Microorganisms: A Bibliometric Analysis

The oceans, as a large area of the planet, are of great importance to the biological status of organisms. They are contaminated with different compounds that are dangerous to health conditions. Biodegradation is one way to reduce pollution. Therefore the current review aimed to this bibliometric analysis. Data were collected from published articles in Scopus and Clarivate Analytics Web of Science databases between 1985 and April 2021, and then Scopus documents were examined using VOS viewer and Bibliometrix-package due to their larger number. Analysis was performed for the number of publications per year, document types, sources, keywords, authors, organizations, and countries. The results showed a growing trend in publishing documents from 2010 to 2022. The two keywords biodegradation and bioremediation grew more.

1 note

·

View note

Link

0 notes

Photo

#bioresource#multinational#company#organisations#authorisation#country#biodegradation#biopiracy#bioexploitation

0 notes

Text

Mossy mushroomy A-frame cabin commission, with its little pals

I got no photos of my favorite design decision: ceramic "rafters" supporting the needlefelted moss. They'll get their time to shine whenever the felt biodegrades, which will be a while.

#little clay fellows#for this one i got sent an entire pinterest board. and it was delightful#apparently wool takes 3 months to 2 years to biodegrade when buried. not so likely for this guy i will say

677 notes

·

View notes

Text

📢There are MEDICAL TAPES made of different materials, such as non-woven fabrics, silk, PE, which are soft and breathable, harmless to the skin, easy to tear and store.

Medhave provides tapes made of any material you want, and the size and colour can also be customized.

For more product information, please click the link in the comment

Welcome to consult more product information

🔎🔎Click the link to get more products you wanthttps://www.medhave.com/

👍Medhave is committed to providing ONE-STOP product solutions for medical devices and consumables, including customization and consumables combinations. In terms of price💰, Medhave will give you unexpected surprises.

#medhave#medical#meditech#medicalequipments#medicalconsumables#medicalsupplier#CE#tapes#medicaltapes#bandages#PE#silk#fabrics#cotton#breathable#soft#biodegradation#skinfriendly#surgery#wound#hospital#clinic#homecare#firstaid

0 notes

Text

Saype, born Guillaume Legros, is a French artist living in Bulle, Switzerland. A self-taught artist, Saype’s giant biodegradable artworks adorn fields, are best seen by drones and last only days. The artist is represented by MTArt Agency since 2018. Beginning his career as a young graffiti artist, Saype’s work quickly gained recognition and became highly sought after, resulting in him landing his first gallery exhibition at age 16. Saype is a pioneer of the land art movement, focusing upon large scale biodegradable paintings with strong social messages.

Using 100% biodegradable paint composed of water, chalk, coal and casein, Saype’s ephemeral land artwork disappears after a month due to regrowth of the grass it is painted upon, the weather and the passage of visitors. With each project he completes, his recognition grows, capturing the attention of those on social media as well as landing extensive global media coverage. Career highlight for Saype have included gaining thanks from the Swiss President, Doris Leuthard, for the social vision of his art, in 2017, and following that in 2018, the publication of his book, ‘Green Art’, which highlights the innovative qualities of the biodegradable paint Saype has created.

1K notes

·

View notes

Text

Scientists make biodegradable microbeads from cellulose - Technology Org

New Post has been published on https://thedigitalinsider.com/scientists-make-biodegradable-microbeads-from-cellulose-technology-org/

Scientists make biodegradable microbeads from cellulose - Technology Org

Microbeads are small plastic spheres less than 0.5 mm in size that are added to personal care and cleaning products, including cosmetics, sunscreens, and fillers, to give them a smooth texture. However, they are too small to be removed by sewage filtration systems and so end up in rivers and oceans, where birds, fish, and other marine life ingest them.

Microbeads are found in cosmetics and personal care products such as toothpaste, sunscreen, hair gel and shower gel.

It is estimated that a single shower can result in 100,000 plastic particles entering the ocean, contributing to the eight million tonnes of plastic that enters the ocean every year. It is feared that the particles could enter the food chain, harm wildlife and potentially end up in our food.

As a result of recent campaigning by environmental groups, the UK Government has pledged to ban plastic microbeads in 2017.

Now a research team, from the University’s Centre for Sustainable Chemical Technologies (CSCT), has developed a way of producing a biodegradable renewable alternative to plastic microbeads in a scalable, continuous manufacturing process.

The beads are made from cellulose, which is the material that forms the tough fibres found in wood and plants. In this process our scientists dissolve the cellulose to reform it into tiny beads by forming droplets that are then “set”. These microbeads are robust enough to remain stable in a bodywash, but can be broken down by organisms at the sewage treatment works, or even in the environment in a short period of time.

The researchers anticipate they could use cellulose from a range of “waste” sources, including from the paper making industry as a renewable source of raw material.

They have published their results in the journal ACS Sustainable Chemistry and Engineering.

Dr Janet Scott, Reader in the Department of Chemistry and part of the CSCT, said: “Microbeads used in the cosmetics industry are often made of polyethylene or polypropylene, which are cheap and easy to make. However these polymers are derived from oil and they take hundreds of years to break down in the environment.

“We’ve developed a way of making microbeads from cellulose, which is not only from a renewable source, but also biodegrades into harmless sugars.

“We hope in the future these could be used as a direct replacement for plastic microbeads.”

Davide Mattia, Professor of Chemical Engineering and part of the CSCT, said: “Our goal was to develop a continuous process that could be scaled for manufacturing. We achieved this by working together from the start, integrating process design and chemistry optimisation, showing the strength of the multi-disciplinary approach we have in the CSCT.”

The beads are made using a solution of cellulose which is forced through tiny holes in a tubular membrane, creating spherical droplets of the solution which are washed away from the membrane using vegetable oil. The beads are then collected, set and separated from the oil before use.

The physical properties of the beads can be tweaked by changing the structure of the cellulose, for example making the beads harder. A team, led by Dr Scott and including Professor Davide Mattia (Chemical Engineering) and Professor Karen Edler (Chemistry) has also just been awarded funding of just over £1 million by the Engineering & Physical Sciences Research Council to develop porous beads, capsules and microsponges.

They will work with industrial partners, to develop materials that could be used in cosmetics and personal care products, or impregnated with agrichemicals for use in, for example, slow release fertilisers.

Source: University of Bath

You can offer your link to a page which is relevant to the topic of this post.

#000#amp#approach#biodegradable#biodegradation#birds#capsules#cellulose#chemical#Chemical engineering#chemistry#Chemistry & materials science news#continuous#Design#droplets#easy#engineering#Environment#Environmental#filtration systems#fish#Food#food chain#Forms#Funding#Future#Government#Industry#it#LED

0 notes

Text

0 notes

Text

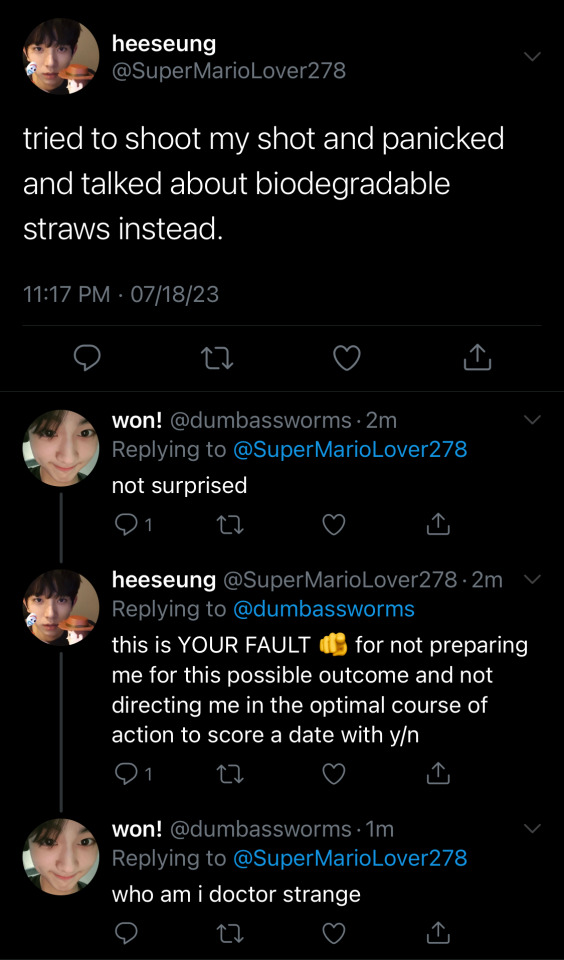

𝐀 𝐒𝐓𝐎𝐍𝐄𝐑'𝐒 𝐆𝐔𝐈𝐃𝐄 𝐓𝐎 𝐒𝐓𝐀𝐑𝐁𝐔𝐂𝐊𝐒 09. biodegrade ur chance at romance

prev | masterlist | next

SUMMARY ▸ in which you work at the starbucks where heeseung is a regular at (and considered a public enemy). also he only goes when he’s stoned off his ass.

#biodegradable rizz#enhypen#enhypen smau#enhypen fluff#heeseung fluff#heeseung smau#enhypen imagines#heeseung imagines#lee heeseung#enhypen social media au#heeseung x reader#enhypen scenarios#heeseung scenarios#enhypen drabbles#heeseung drabbles#enhypen reactions#heeseung reactions

457 notes

·

View notes

Text

Scarlett Yang CSM 2021 Graduate collection, Biodegradable dress made from algae.

#scarlett yang#art#nature#landscape#aesthetic#portrait#contemporary art#painting#abstract#architecture#haute couture#hautefashion#biodegradable#green fashion

861 notes

·

View notes