#cad software for 3d printing

Explore tagged Tumblr posts

Text

Comprehensive Engineering Services

https://rapidpro.com/services/engineering/ - RapidPro Manufacturing offers expert engineering design services led by a highly skilled team. We specialize in providing comprehensive solutions for industrial, electrical, and mechanical engineering projects, guiding clients from concept to production. Our design engineering consultants excel in areas such as electrical engineering, mechanical systems, and power distribution. Utilizing advanced 3D CAD software, we deliver precise drafting to create, manipulate, and refine product designs. Whether you're tackling technical challenges or developing innovative products, RapidPro delivers quality and expertise. Contact us today at RapidPro Manufacturing Corporation, Longmont, CO.

Contact Us:

RapidPro Manufacturing Corporation 30 E. 9th Avenue Longmont, CO 80504 (970) 535-0550 https://rapidpro.com/

#Mechanical Design Engineering Longmont CO#CAD Longmont CO#3D CAD software Longmont CO#CAD Software for 3d Printing Longmont CO

1 note

·

View note

Text

A Beginner’s Guide to Free CAD Software for 3D Printing

Provides an essential overview for those new to 3D design. This guide introduces the most user-friendly and accessible free CAD software options available, helping beginners understand how to create and modify 3D models for printing. It covers key features like intuitive interfaces, basic design tools, and tips for getting started with common 3D printing formats. The guide also explains the importance of selecting the right software based on the user’s specific needs, whether for simple projects or more detailed designs. By the end, beginners will feel confident in navigating free CAD software, turning their creative ideas into reality with 3D printing.

Understanding the Basics of Free CAD Software for 3D Printing

Free CAD software for 3D printing serves as a powerful tool for designers, engineers, and hobbyists alike. This software allows users to create detailed 3D models without the need for expensive licenses. Understanding the fundamentals, such as basic design principles and the user interface, is crucial for beginners. Most free CAD programs offer tutorials and resources to help users get started, making it easier to navigate the design process. Whether you are looking to design prototypes, art pieces, or functional objects, these software options provide the essential tools needed to bring your ideas to life.

Top Free CAD Software Options for 3D Printing in 2024

In 2024, several free CAD software options stand out for 3D printing enthusiasts. Programs like TinkerCAD, known for its user-friendly interface, are perfect for beginners. FreeCAD offers a more advanced set of features for those with some experience, while SketchUp Free is excellent for architectural designs. Fusion 360 for Personal Use allows hobbyists to access powerful tools for free, provided they meet specific eligibility criteria. Each of these software options comes with unique features that cater to different design needs, making it essential to choose the right one for your projects.

Key Features to Look for in Free CAD Software for 3D Printing

When selecting free CAD software for 3D printing, certain features are crucial for an effective design experience. Look for intuitive user interfaces that simplify the modeling process, especially if you are a beginner. Compatibility with common 3D file formats, such as STL and OBJ, ensures that your designs can be easily exported for printing. Additionally, built-in libraries of pre-designed components can speed up your workflow. Robust community support and tutorials are also important, as they provide resources for troubleshooting and learning new skills. Evaluating these features will help you make an informed decision.

Getting Started: Tips for Using Free CAD Software for 3D Printing

Getting started with free CAD software for 3D printing can be overwhelming, but a few tips can ease the process. Begin with simple projects to familiarize yourself with the tools and functionalities. Use tutorials and online resources to learn specific techniques, such as scaling objects or creating complex shapes. Practice regularly to improve your skills and gain confidence in your design abilities. It's also beneficial to engage with online communities or forums, where you can share your work, ask for feedback, and learn from others' experiences. These steps will set you up for success in your 3D printing journey.

Common Mistakes to Avoid When Using Free CAD Software for 3D Printing

While working with free CAD software for 3D printing, beginners often make common mistakes that can lead to frustration. One frequent error is neglecting to check the scale of designs, which can result in prints that are too large or small. Failing to optimize models for printing such as ensuring proper wall thickness and avoiding unsupported overhangs can also lead to print failures. Additionally, users may forget to export their designs in the correct file format for their 3D printer. By being aware of these pitfalls and double-checking designs before printing, you can save time and resources.

The Importance of Community and Support in Free CAD Software for 3D Printing

The community surrounding free CAD software for 3D printing is invaluable for users at all levels. Online forums, social media groups, and dedicated websites offer platforms for sharing knowledge, tips, and resources. Engaging with these communities can provide support for troubleshooting issues, sharing design ideas, and gaining insights from experienced users. Many software platforms have active user communities that contribute tutorials and share their projects, making it easier for beginners to learn. Building connections with others in the 3D printing space can enhance your experience and broaden your skills.

Conclusion

In conclusion, free CAD software for 3D printing opens up a world of possibilities for aspiring designers and hobbyists. By understanding the basics, exploring top options, and knowing the features to look for, users can effectively create their own 3D models. Tips for getting started and awareness of common mistakes will streamline the design process and improve results. Moreover, the support of online communities can foster growth and creativity in the 3D printing realm. Embracing these tools and resources will empower you to turn your ideas into tangible creations, enhancing your 3D printing experience and expertise.

0 notes

Text

From Bits to Bytes: Digitization in The Automotive Industry - Global Brands Magazine

Digitization is driving a transformation in the automotive industry, changing all phases of the business from design and manufacture to sales and customer.

#Digitization in The Automotive Industry#Automotive industry#3D printing technology#computer-aided design#(CAD) software#Advanced driver-assistance systems#Electric vehicles

0 notes

Text

The Bridge to Innovation: Why Revit Needs an OBJ Exporter

Introduction

Autodesk Revit is a powerful BIM (Building Information Modeling) software used extensively in the architecture, engineering, and construction industries. It enables professionals to design, model, and document complex building structures with precision and efficiency. However, there are situations where you may need to export your Revit models to other software applications for various purposes, such as visualization, simulation, or 3D printing. This is where an OBJ (Wavefront Object) exporter for Revit becomes invaluable. In this blog post, we'll explore the reasons why you need an OBJ exporter for Revit and the benefits it brings to your workflow.

1. Compatibility with a Wide Range of 3D Software

One of the primary reasons for using an OBJ exporter for Revit is compatibility. OBJ is a widely recognized 3D file format supported by an extensive list of 3D software applications. When you export your Revit models as OBJ files, you can easily share your designs with collaborators or transfer them to other specialized software for tasks such as rendering, animation, or simulation. Some popular software packages that support OBJ include Blender, 3ds Max, Maya, Unity, and many more.

2. High-Quality Mesh Export

Revit models consist of BIM elements like walls, floors, roofs, and families. These elements are typically represented as parametric objects with detailed information. When exporting to OBJ, Revit converts these parametric objects into polygonal meshes, allowing for a more efficient transfer of geometry. OBJ files maintain the visual fidelity and structural integrity of your design, ensuring that complex architectural details and textures are preserved accurately.

3. Streamlined Visualization

Visualization is a critical aspect of architectural and construction projects. An OBJ exporter for Revit simplifies the process of rendering and visualizing your models in other 3D software. You can import your OBJ files into rendering software like Blender or 3ds Max to create stunning, photorealistic renderings, which are essential for client presentations, project approvals, and marketing materials. OBJ files can also be used in virtual reality (VR) and augmented reality (AR) applications, enhancing your ability to communicate design concepts effectively.

4. Simulation and Analysis

In certain scenarios, you may need to analyze your Revit models for structural integrity, energy efficiency, or other factors. Many simulation and analysis tools, such as finite element analysis (FEA) or computational fluid dynamics (CFD) software, require 3D models in a compatible format. By exporting your Revit models to OBJ, you can seamlessly integrate them into these specialized software packages for in-depth analysis and optimization.

5. 3D Printing

The field of 3D printing has seen rapid growth in recent years, and architects and engineers often use it to create physical prototypes, scale models, or custom building components. OBJ files are widely accepted by 3D printing software and services, making it easy to translate your Revit designs into tangible objects. Whether you're working on an architectural model or a structural component, exporting your Revit model as an OBJ file ensures that it can be easily converted into a 3D-printable format.

6. Cross-Platform Collaboration

Collaboration is key in the AEC (Architecture, Engineering, and Construction) industry. Teams often consist of professionals using various software tools, and seamless data exchange is crucial for project success. An OBJ exporter for Revit facilitates cross-platform collaboration by providing a standardized format that can be imported into different software environments. This compatibility reduces the risk of data loss and ensures that all team members can work with the same model.

Conclusion

In conclusion, an OBJ exporter for Revit is a valuable tool that enhances the versatility and compatibility of your BIM workflow. It enables you to share, visualize, analyze, and produce physical models from your Revit designs with ease. By using OBJ as an intermediary format, you can tap into the full potential of your Revit models, allowing you to collaborate more effectively with colleagues and unlock new possibilities in architecture and construction projects. Whether you're creating stunning visualizations, conducting simulations, or 3D printing prototypes, an OBJ exporter for Revit is a valuable addition to your toolkit.

Get FREE Trial

#OBJ exporter for Revit#Autodesk Revit#3D Software#CAD Plugins#CAD Expoters#CAD Importers#CAD Extensions#CAD Software#3D printing#visualization#BIM (Building Information Modeling) software

0 notes

Text

ok, turning to the DRoP fandom for this.

i really, really, really want to try to engineer the dragon models from the 3D pern videogame into something 3D printable, because it would be very fun to have some little pernese dragons around. i have extracted the models. the big problem is they're in a very, very specialized filetype.

this file type is Atari Stereo CAD-3D, with the file extension ".3D" (it shares this with a type of cave modeling file! fun fact). as far as I can find, there is no piece of software capable of opening these files and turning them into something else, and they cannot be captured in another format. they can't be opened with other Stereo CAD-3D software, and even the software linked on fileinfo as opening it, quick3D, only opens .3D2 and .3ds files according to its list of things it can open. i haven't downloaded it to try anyway because it also costs 200 dollars.

please let me know if you have a way to open this filetype and save as a different one, or if you happen to have a copy of quick3D lying around. or reblog to boost if you're interested in the potential of being able to print little pernese dragons of your own.

#pern#dragonriders of pern#covert3d.org says they do it but only for premium and im in the middle of asking them about which .3d file type they're actually talking ab

15 notes

·

View notes

Text

The Art Of The Murdered: Flower bud (C: 2)

"なぜ俺をここに連れてきたのですか?(Why did you bring me here?)" Sousuke asked Giorgio

The detective looked at the foreigner and smiled "We're going shopping."

You're kidding.

"でははっきりさせておこう。あなたは俺が泊まっていたホテルを突き止め、ホテルの部屋で私が戻ってくるのを待ち、買い物のために再び俺を外に連れ出した?(So let me get this straight. You tracked down the hotel that I was staying in, waited in my hotel room for me to come back, and dragged me outside again for a shopping trip?)" the detective pouted "I wanted to tell you something but I realized I never got your number nor did you text me!"

Sousuke bows his head down "ごめんなさい、携帯電話を日本に忘れてきてしまって (Sorry, I forgot my phone back at Japan)"

"I can buy you a new one later" the foreigner swiftly lifted his head up "いや、そんなことは- (Oh no, you don't have to-)" the detective cut him off "So anyways, I found something suspicious" he grabs Sousuke’s hand "I thought it might be related to your brother"

"それは何ですか?(What is it?)" But the detective doesn't answer as they kept on walking to god knows what.

Giorgio leads Sousuke into a mysterious and empty hallway with it's lights flickering "While I was investigating your brother's case, I looked through the cameras in this mall"

"A stranger dropped something, and your brother gave it back to them, right?" Giorgio questioned him "はい (yes)"

"I can't believe I overlooked an interaction so unusual..." the detective suddenly stops walking and faces a door beside them.

He then tries to kick it down "何してるんだ!?(What are you doing!?)" Sousuke exclaimed.

The detective’s grin widened as he stepped back, shifting into a more focused stance. "We're going in."

Sousuke's heart raced, and for a moment, he considered running. The detective had acted so casually until now, but this sudden turn felt like a trap.

"The person who dropped something in the mall... they're connected to your brother’s case. And I’m willing to bet that whatever they left behind could be the key to finding the real culprit. Besides, it’s not exactly breaking and entering if nobody’s inside to catch us, right?" he faces Sousuke as he grinned.

Sousuke felt a wave of frustration and fear, but there was something about Giorgio’s calm confidence that made him hesitate.

Maybe, just maybe, this was the right thing to do. If there was any chance it could help Hebi, he had to follow through, even if the detective's methods were unconventional.

As Giorgio prepared to kick the door open, Sousuke could barely keep his thoughts straight.

The door swung open with a loud crash, and Giorgio stepped inside without missing a beat. Sousuke followed reluctantly.

The space was dimly lit, a dusty old storage room that smelled of mildew and forgotten memories.

Rows of boxes lined the walls, a bed in the middle of the room, a whole computer set up beside the bed with a 3D printer, and papers scattered across the room.

Someone has been living here.

Giorgio walked deeper into the room, his eyes scanning the surroundings with the intensity of someone who had seen far too many crime scenes.

He knelt by a pile of crates and started rummaging through them. Sousuke, unsure of what he was supposed to do, hovered by the doorway, trying not to let his nerves overwhelm him. "Over here," Giorgio called suddenly, holding up a small, crumpled plastic bag.

Inside it was a single, discarded object: a silver pen, one that looked ordinary at first glance, but when Giorgio turned it over, Sousuke noticed something strange—a small, almost imperceptible engraving.

Giorgio stood next to the computer with the pen in his hand "Did you know that with CAD or CAM software tools, you could conceivably create latex copies of someone’s fingerprints and place those prints on to objects that will hold them until they can be gathered by forensic technicians" Giorgio says as he turns on the computer "No password? This guy is a maniac" there was a folder called "Happy birthday."

As the detective opened the folder, his smile faded away.

"This is a list of all of the children who went missing for the past 4 years..." he mumbled.

Sousuke’s stomach lurched "Hebi gave this pen back to the stranger, right?" Giorgio asked, glancing up at Sousuke, his eyes sharp. "Do you remember seeing the person's face who had it?"

Sousuke tried to recall the encounter in the mall, but his mind was a mess of images "いや...ただ、彼らは手袋をしていて、服装で正体を隠していたんだ (No... just that they were wearing gloves and their clothes hid their identity.)"

Giorgio nodded thoughtfully, clearly deep in thought. "Gloves and hiding their identity? It's a deliberate attempt to avoid being caught. I was a fool for thinking I finally caught him after all these years"

"彼らは...兄を罠にはめた連中とつながっているのだろうか?(Could they be... connected to the person who framed my brother?)" Sousuke asked, the weight of his words sinking in.

The detective’s eyes narrowed, "The more we dig, the clearer it becomes. But I still don’t think we have all the pieces yet" he stood away from the computer "Let's get out of here before someone catches us."

As they walk out of the room, Sousuke suddenly felt something bumping into him.

"Owwww!" It was a little girl with short pink hair and a white bear hat.

"Hey, are you okay?" Giorgio asked, bending down slightly to meet the girl’s gaze.

The girl blinked up at him "I’m fine, I’m fine! I’m not the one who almost knocked me over!" she said, placing her hands on her hips as she stood up.

GIorgio kneels down to the little girl "Are you lost? Do you know where your parents are?" Giorgio asked the little girl "I'm not lost! I just haven't found my cousin yet!"

"Do you need some help looking for your cousin?" the little girl nodded "I'd appreciate it!"

The detective stands up "Alright little girl, tell me the name of your cousin and what she looks like"

"Her name is Albie and she looks like Princess Almond Blossom but with curly hair" said the little girl.

"Huh... Does Princess Almond Blossom have blue or green eyes?" He turns to Sousuke "なぜ俺を見るの?彼女が誰だか知らない (Why are you looking at me? I don't know who she is)"

"Ah... Well then- Wait where did she go?" the little girl disappeared "There! " Sousuke points at the little girl going to the candy shop at the second floor "How did she get there so fast!?"

"Outta my way!" the two men shove through the large crowd as they ran into the candy shop.

"Excuse me sir! Have you seen a little girl with pink hair and a white bear hat?" The detective asked the cashier staff.

"Are you her dad? Cause your daughter left the store with our most expensive cupcake just a minute ago."

"盗んだなんて言わないでよ!(Don't tell me she stole it!)" Sousuke panicked, the cashier staff looked at him in confusion "He wants to know if she stole the cupcake or not."

The cashier staff shook their head "Oh no, your daughter has been very good, I don't know why she'd spend all of her allowance that you gave her though."

"Have you at least seen where she went?" Giorgio asked "No, I'm sorry sir."

"I see, thank you," the two men walk out of the store, the detective sighs.

He puts his hands through his pockets, but makes a realization as he doesn't feel anything in his pockets.

He falls onto his knees, the little girl stole his wallet.

14 notes

·

View notes

Note

Hey! I love your art so much 💖 I wanted to ask what program you use for 3D modelling?

aw thank you!! :3

and to answer your question i’m going to warn you this is going to be kinda long because i’m gonna use this post as an excuse to show my 3D models that aren’t awful (sorry lol).

i actually use two different programs, both for different purposes, but you don’t need to get both, it really depends on which kind of modeling you want to do.

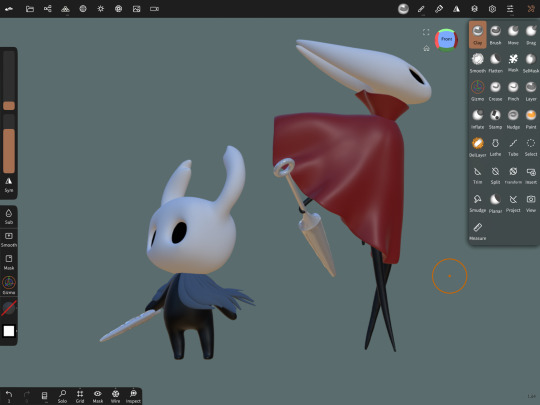

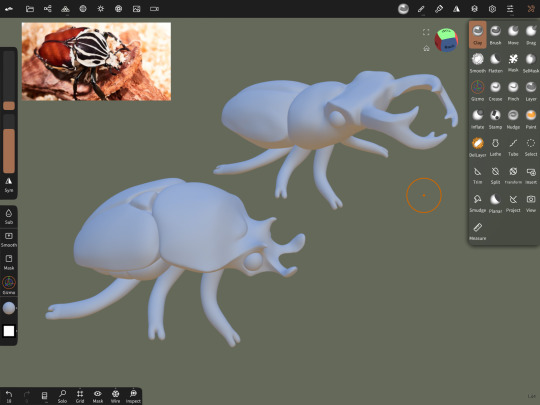

1) the first is called Nomad Sculpt on the iPad, you do have to pay for it unfortunately but it’s definitely one of the best modeling apps for the iPad. i know Blender is free but my computer is really old and doesn’t run the program very well, and at this point i’ve already gotten used to nomad sculpt.

anyway tho, i use it for art-related things like the obvious 3D models, but recently i’ve been playing around with just making scenes to use as references for my drawings. they’re not anything impressive, most of the time i actually use it to make little figurines to print and turn into earrings/little friends that sit in my room just for fun.

i’m gonna show this first bc they look cooler once they’re printed and colored (also you can tell i printed mini crowley and aziraphale when my sonadow hyperfixation started bc i never actually painted crowley) (he’s just kinda sitting there oops).

the little red guys are actually my favorite bugs (goliath beetles), i made them about a year ago but i still wear them like every day.

and here’s what they look like in the app, it’s a little intimidating but once you get used to it it’s actually kinda fun just playing around and seeing what you can do.

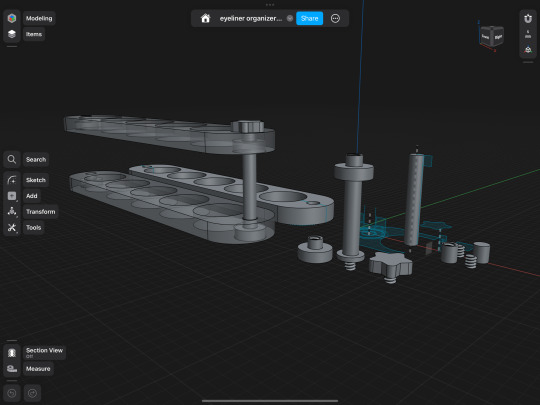

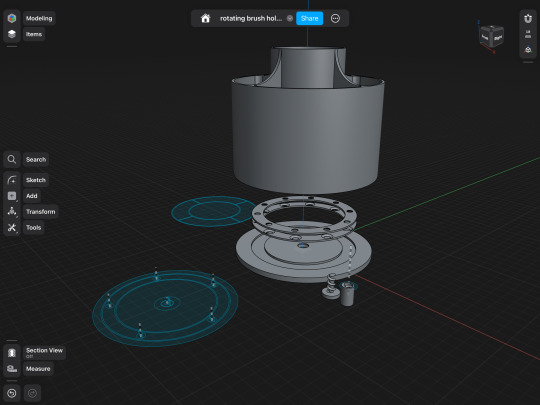

2) the second program i use is Shapr3D (also for the iPad, but i think they made an update where you can run it on windows/mac). you also have to pay for this as a subscription which sucks, i’m only able to use it since the engineering program i’m in pays for it.

Shapr3D is one of the many CAD software programs out there, but it’s nice bc it’s very beginner friendly and very easy to use. CAD is mainly for architecture/engineering but i honestly think more 3D artists should give it a try. it’s really nice once you get the hang of it and (i’m probably biased bc i’m a student) i honestly prefer it over just normal modeling software because i feel like you can be a lot more creative with it.

right now for my engineering class, our semester final is to design and present something that’s functional, and we can either explain the math behind it or just 3D print it and demonstrate how it works, and i’m making a functional mini model of “the rack” trap from Saw III (i’m not psychotic i swear i’ve just had a Saw hyperfixation for 5 years).

i’m definitely gonna post it when it’s finished just bc i’m already excited with how it’s turning out, but for now here’s a couple at-home projects i’ve done:

(above) i have a bunch of wet liners and i designed a stackable holder thingy with bolts between the shelves and a little cute star screw to fasten it at the top.

(above) i also made a few rotating brush holders at home (bc the ones that actually rotate are like $40 for some reason) by buying a set of small sphere bearings at home depot for like $5 (that’s what those little metal things are inside the third one, i took it apart bc i don’t know how to put a video and a picture in the same post) (just pretend they’re spinning rn).

anyway that’s all!! if you actually read this whole thing i love you so much bc engineering and design is one of my special interests so thanks for letting me tell you about the silly things i’ve made :3

#asks#3d art#3d model#engineering#infodump#special interest#ermmmmm not sure what else to tag#this was just a really long post lol#bugs#good omens#autism creature

79 notes

·

View notes

Note

Hello, sorry to bother you, but you seem like one of the few around tumblr that has fun with CAD. Do you have any suggestions for us who'd love to learn CAD but pretty much has no schooling around us that teach these things? Thank you, love your blog!

I didn't have proper schooling I just learned through trial and error and tutorial videos (youtube is your best friend) and lots of googling/looking at forums. I also have the implicit requirement that I want to own my own tools so I don't tend to use the two largest 3d modeling softwares. The two main ones are Fusion360 (the most popular, but I don't know a good tutorial series for this) and OnShape. OnShape is browser based, Fusion360 is a windows application (get used to that if you want to do CAD work). I personally do 3d printing, and there are loads of youtubers who go into designing for 3d printing. I personally trust TeachingTech. This one uses OnShape.

youtube

I currently do my Modeling in FreeCAD, specifically the realthunder/link branch. which i believe is getting merged back into the proper "FreeCAD" soon(tm). I used this tutorial series by keep making.

youtube

I personally think he is a bit of a tool. but he showed me enough that I could learn either by trial and error or googling things I wanted to do. Just to avoid headaches, if you want to try FreeCAD i would recommend Ondsel instead, because its built from FreeCAD and includes a lot of things not currently in the stable release of FreeCAD (including the Link Branch I use). I'm simply familiar with the current UI and can't be assed to change.

#i hope this makes sense#i do want people to enjoy CAD work esp in the context of 3d printing#i find it fulfilling#invisibletripwire

10 notes

·

View notes

Text

Fashion Designing Institutes in Hyderabad: Blending Heritage with Modern Creativity

Hyderabad is more than just a city of IT parks and ancient monuments — it's a growing fashion destination blending centuries-old textile traditions with cutting-edge design education. In recent years, students from across India have started flocking to fashion designing institutes in Hyderabad to turn their passion into a professional path.

With a creative-friendly atmosphere, access to rich artisan networks, and modern academic facilities, Hyderabad is quietly becoming the go-to place for fashion aspirants. If you're thinking of stepping into the world of fashion, here’s why the institutes here are worth considering.

The Cultural Edge: Hyderabad’s Textile and Craft Heritage

One of the standout advantages of studying fashion in Hyderabad is access to traditional Indian art forms that are still alive and thriving.

Pochampally Ikat, Kalamkari, Narayanpet weaves, and Muga silk from surrounding regions inspire students to blend heritage with modernity.

Institutes often arrange artisan visits, textile trails, and dyeing workshops, which enrich classroom learning with ground-level insight.

These experiences make students culturally aware and help them design collections rooted in Indian identity, with global appeal.

Modern Infrastructure & Global Curriculum

Hyderabad’s fashion design schools are known for their advanced infrastructure, including:

Fully equipped design studios and labs

CAD software for 2D & 3D garment design

In-house textile printing and embroidery units

Libraries with fashion magazines, trend reports, and design journals

Photography and styling labs for editorial shoots

The curriculum is often benchmarked against international standards, combining traditional modules like garment construction and illustration with emerging areas like:

Fashion Forecasting & Trend Analysis

Sustainable Design Practices

Fashion Business & Entrepreneurship

Augmented Reality in Fashion

E-Commerce & Online Fashion Marketing

Learning Beyond the Classroom

Top fashion designing institutes in Hyderabad go the extra mile to provide holistic learning experiences. Students actively participate in:

Annual Fashion Shows and Design Exhibitions

Style & Branding Workshops by industry experts

Internships with fashion houses, boutiques, and stylists

Student exchange programs with design institutes abroad

Fashion film-making and digital storytelling competitions

These activities help develop soft skills like teamwork, leadership, and creative direction — essential for working in the real world.

Courses Offered by Fashion Designing Institutes in Hyderabad

Whether you're a beginner or looking to specialize, fashion design colleges in Hyderabad offer a variety of programs:

🔹 Certificate Programs (3–6 Months)

Ideal for skill enhancement or testing interest in the field.

🔹 Diploma & Advanced Diploma (1–2 Years)

Perfect for those wanting hands-on skills with quicker industry entry.

🔹 Bachelor’s Degree in Fashion Design (3–4 Years)

Comprehensive academic route with deeper design thinking, internship, and portfolio development.

🔹 Postgraduate Programs (1–2 Years)

Focused training in design innovation, fashion marketing, or merchandising.

Each course type balances creativity, technical skill, and business understanding, preparing students for a fast-paced, competitive industry.

Career Prospects After Completing Fashion Designing in Hyderabad

With the growing fashion scene in Hyderabad and across India, graduates from design schools can pursue careers such as:

Fashion Designer (Apparel, Accessories, Sustainable)

Textile or Surface Designer

Fashion Illustrator or CAD Designer

Retail Buyer or Merchandiser

Fashion Stylist or Visual Merchandiser

Costume Designer for films and TV

Fashion Content Creator or Blogger

Entrepreneur or Boutique Owner

Hyderabad also gives students the advantage of working in Tollywood, e-commerce startups, and independent fashion brands.

What to Look For in a Fashion Institute

Before enrolling, make sure the fashion designing institute you choose in Hyderabad has:

✅ UGC or university affiliation (for degree programs) ✅ Industry-experienced faculty ✅ Strong alumni network and placement record ✅ Access to labs, studios, and digital tools ✅ Focus on both Indian and global fashion perspectives

Also, explore student testimonials, sample portfolios, and past fashion shows to understand the creative output of each institute.

2 notes

·

View notes

Text

Was talking to someone the other day, telilng them how I don't run my 3D printer much, but have a ton of material I've collected, so I should model something to print. This morning I'm procrastinating and doing just about anything other than writing the artlce I've been banging my head against. So of course, I find myself with some modeling software open working on modeling my default icon. Trying to convince myself that making it multiple pieces that interlock so that it can be multiple colors is definitely a good use of my time, its good CAD practice after all!

2 notes

·

View notes

Text

i just spent three hours trying to figure out how to print a triangle to scale, venturing into 3d modeling, cad, and architectural drawing softwares- before figuring out that i could just use the "triangle" function on powerpoint. that was so stupid

4 notes

·

View notes

Text

National Institute of Fashion Technology - [NIFT], Patna

National Institute of Fashion Technology (NIFT), Patna – An In-Depth Overview (800 Words)

Established in 2008, the National Institute of Fashion Technology (NIFT), Patna is one of the key centers of excellence under the Ministry of Textiles, Government of India. Since its inception, NIFT Patna has been committed to nurturing creativity, innovation, and professionalism in the field of fashion and design. Strategically located in Bihar’s capital, this institute blends traditional cultural richness with cutting-edge design education.

Academic Programs

NIFT Patna offers various undergraduate and postgraduate programs designed to equip students with both creative and technical skills essential for the fashion and lifestyle industry.

Undergraduate Programs:

Bachelor of Design (B.Des) in:

Fashion Design

Fashion Communication

Textile Design

Bachelor of Fashion Technology (B.FTech):

Specialization in Apparel Production

Postgraduate Programs:

Master of Design (M.Des) – Focused on advanced design methodology and design thinking.

Master of Fashion Management (MFM) – Concentrated on business strategies, retail, and fashion marketing.

The curriculum is structured to provide theoretical knowledge, hands-on training, and industry exposure. A blend of classroom learning, workshops, internships, and live projects ensures that students develop a deep understanding of design concepts and business dynamics.

Campus Infrastructure and Facilities

NIFT Patna’s campus offers a modern environment conducive to learning, innovation, and collaboration:

Design Studios and Labs are equipped with high-end machinery and tools that allow students to practice weaving, dyeing, garment construction, printing, pattern making, and digital design.

Computer Labs: Advanced software for CAD, 3D modeling, graphic design, and garment manufacturing systems are accessible to students for academic and project work.

Library: A vast collection of books, journals, and digital resources covering subjects like fashion, textiles, marketing, and management.

Workshops and Resource Centers: For practical training in accessory design, leather craft, and traditional Indian textiles.

Exhibition Spaces: Areas for displaying student projects and hosting fashion events and displays.

Hostel Facilities: Comfortable and safe accommodation options for both male and female students with necessary amenities like Wi-Fi, common rooms, mess, and laundry services.

Cafeteria and Recreation: Clean dining facilities with a variety of food options, along with indoor and outdoor sports infrastructure.

Placement and Industry Interface

NIFT Patna maintains strong ties with leading fashion houses, retail giants, and manufacturing units, facilitating career opportunities and internships for students.

Placement Cell Activities:

Organizes annual campus placements

Conducts workshops on resume writing and interview preparation

Hosts mock interviews and career counseling sessions

Arranges industry visits and interaction programs

Top Recruiters Include:

Adidas

Arvind Mills

H&M

Levi’s

FabIndia

Pantaloons

Raymond

Van Heusen

Future Group

Tommy Hilfiger

Placement Statistics:

Average Salary: ₹5 to ₹8 LPA

Highest Package: Up to ₹12 LPA

Sectors Covered: Fashion design, apparel manufacturing, brand management, fashion merchandising, retail strategy, and textile development

Scholarships and Financial Assistance

NIFT Patna offers financial aid through scholarships to ensure that deserving and meritorious students are not denied education due to economic constraints.

Sarthak Scheme: Provides fee waivers ranging from 50% to 100% based on the student’s family income and academic performance.

UDAAN Program: Supports students pursuing higher studies abroad under exchange or twinning programs.

These initiatives promote inclusivity and accessibility in fashion education, encouraging students from diverse backgrounds to pursue their passion.

Student Life and Activities

Student life at NIFT Patna is vibrant, collaborative, and filled with opportunities to express creativity beyond the classroom.

Cultural and Technical Fests: Events like Spectrum and Converge provide platforms for students to showcase their talent in fashion, performing arts, and innovation.

Clubs and Societies: Various student-led clubs cater to interests like photography, styling, film-making, design thinking, entrepreneurship, and sustainability.

Guest Lectures and Workshops: Regular sessions by industry professionals and alumni offer practical insights into the global fashion ecosystem.

Internships: All students undergo compulsory internships with fashion brands, designers, or production houses to apply theoretical knowledge in real-world settings. Many of these internships convert into pre-placement offers.

Conclusion

NIFT Patna is a center of excellence that offers a holistic fashion education combining design, technology, and management. With its modern infrastructure, committed faculty, industry-oriented curriculum, and strong placement support, it creates well-rounded professionals ready to meet the demands of the global fashion and lifestyle market. The campus environment encourages experimentation, innovation, and cultural exchange—making it an ideal place for aspiring fashion designers, technologists, and managers to grow and thrive.

#NIFTPatna#NationalInstituteOfFashionTechnology#FashionEducation#DesignYourFuture#TextileDesign#FashionDesign#ApparelProduction#FashionManagement#NIFTIndia#CreativeCareers

2 notes

·

View notes

Text

Veterinary Orthotics-Prosthetics Market Drivers Shaping the Future of Animal Healthcare and Rehabilitation

The veterinary orthotics-prosthetics market has seen significant growth in recent years due to an increasing demand for advanced solutions to enhance the mobility and quality of life for animals. Veterinary orthotics and prosthetics (O&P) refer to devices designed to assist animals suffering from mobility issues caused by injury, disease, or congenital conditions. These devices are typically custom-made to suit the unique anatomical structure of each animal, offering both functional and therapeutic benefits. With the rising awareness about animal healthcare and a greater emphasis on improving animal welfare, several key drivers have emerged, fueling the expansion of this market.

Growing Awareness of Animal Healthcare

One of the most significant drivers of the veterinary orthotics-prosthetics market is the increasing awareness surrounding animal healthcare. As more pet owners recognize the importance of medical treatments and rehabilitation for their animals, the demand for customized orthotic and prosthetic devices has risen. Pets, especially dogs and cats, often experience joint disorders, fractures, or amputations, necessitating rehabilitation through these devices. As people become more conscious of their pets' well-being, they are seeking solutions to manage pain, improve mobility, and ultimately enhance their quality of life.

Advancements in Veterinary Medicine and Technology

Technological advancements in veterinary medicine play a vital role in driving the veterinary orthotics-prosthetics market. The continuous development of 3D printing, CAD (computer-aided design) software, and materials science has led to more precise, effective, and affordable orthotic and prosthetic devices. These innovations have allowed for better customization of devices, ensuring a perfect fit for animals while improving comfort and mobility. In addition, the use of high-tech materials that mimic the natural movement of joints and bones has contributed to more durable and efficient solutions for pets.

Increase in Pet Ownership and Humanization of Pets

The humanization of pets has played a crucial role in the growth of the veterinary orthotics-prosthetics market. As pets are increasingly seen as members of the family, pet owners are willing to invest in treatments that enhance their pets' health and overall well-being. The rising number of pet adoptions, particularly in urban areas, has created a growing market for specialized healthcare solutions. With an increasing focus on providing pets with the same quality of care as humans, the demand for advanced orthopedic treatments and mobility devices has surged.

Rising Incidence of Pet Injuries and Disabilities

The rising incidence of injuries, diseases, and disabilities in pets has further contributed to the growth of the veterinary orthotics-prosthetics market. Accidents, joint issues, and congenital abnormalities have become more prevalent in both domestic and wild animals, necessitating the use of specialized orthotics and prosthetics. Dogs, for example, are particularly prone to hip dysplasia, fractures, and ligament tears, leading to the increasing demand for joint braces, prosthetic limbs, and other mobility aids. The aging population of pets also requires more frequent interventions to manage conditions like arthritis, driving the need for orthopedic solutions.

Support from Veterinary Professionals and Research

Veterinary professionals and research institutions play a crucial role in the development and adoption of orthotic and prosthetic devices. As more veterinary professionals embrace these technologies, they are not only improving treatment outcomes but also educating pet owners about the benefits of orthotic and prosthetic solutions. Additionally, ongoing research and clinical trials continue to optimize the design and functionality of these devices. With a growing body of evidence supporting the effectiveness of O&P treatments in animals, the market is expected to continue expanding.

Expanding Veterinary Care Networks and Facilities

The expansion of veterinary care networks and specialized animal hospitals has also contributed to the growth of the veterinary orthotics-prosthetics market. Veterinary clinics that offer specialized services, including orthotics and prosthetics, are becoming more common. This expansion has made these treatments more accessible to pet owners, leading to an increase in demand for customized solutions. As these services become more mainstream, pet owners are more likely to explore O&P devices as viable options for their animals' care.

In conclusion, the veterinary orthotics-prosthetics market is driven by a combination of factors, including increasing awareness of animal healthcare, technological advancements, the humanization of pets, rising pet injuries, and support from veterinary professionals. These drivers are shaping the future of veterinary care and rehabilitation, ultimately improving the lives of countless animals around the world.

3 notes

·

View notes

Text

Summary Analysis of CNC Milling Process

In modern manufacturing, CNC milling technology is widely used for its high precision and flexibility. Whether it's a mechanical part, an automotive component, or a component for a medical device, CNC milling provides excellent machining results.

What is CNC Milling?

CNC milling is a computer-controlled machining process that utilises a rotating tool to cut a workpiece. CNC milling allows for greater accuracy and consistency than traditional manual milling. It is often combined with other machining methods (e.g. turning, drilling) to meet different and diverse manufacturing needs.

Workflow of CNC Milling

Design stage In the initial stages of CNC milling, designers use Computer-Aided Design (CAD) software to create a model of the product. Commonly used software includes SolidWorks and Autodesk, which are tools that help designers accurately draw the shape and dimensions of the desired part.

Programming stage Once the design is complete, the CAD file needs to be converted to G-code, a language that CNC machines can understand. With Computer-Aided Manufacturing (CAM) software, the design files are converted into machine-executable instructions that enable automated machining.

Machine setting During the machine set-up phase, the workpiece needs to be fixed to the table and a suitable tool selected. At the same time, the operator needs to set the initial co-ordinates to ensure accurate positioning during machining.

Advantages of CNC Milling

High precision and dimensional stability CNC milling allows for micron-level machining accuracy, ensuring consistency from part to part.

Complex shapes can be processed Whether it's a simple flat surface or a complex three-dimensional structure, CNC milling can handle it with ease.

Efficient production capacity Due to its high degree of automation, CNC milling can significantly increase productivity and shorten lead times.

Applications of CNC Milling

CNC milling technology is used in a wide range of industries, including:

Mechanical parts: Used in the manufacture of key components in a variety of mechanical equipment.

Automotive parts: High-precision parts for the automotive industry, such as engine components.

Medical device parts: Ensure the reliability and safety of medical devices.

Optical product parts: For the production of optical instruments and related products.

Frequently Asked Questions

What materials can be CNC milling machined? CNC milling is suitable for a wide range of materials, including metals (e.g. aluminium, steel), plastics, wood, and more. However, for some materials, such as ceramics or certain composites, the machining is more difficult and requires special handling.

What are the limitations of CNC milling? Despite its advanced technology, CNC milling has some limitations. For example, machining may be limited for internal vertical angles or very complex small structures.In addition, high hardness materials may lead to faster tool wear, which can affect productivity.

Comparison of CNC milling with other manufacturing technologies The advantages and disadvantages of each can be seen when comparing CNC milling with other manufacturing techniques such as 3D printing. CNC milling is generally superior to 3D printing in terms of accuracy and surface finish, but 3D printing has advantages in rapid prototyping and complex geometries. In terms of cost-effectiveness, the choice of technology depends on specific project needs and budget.

Summary

In summary, CNC milling is an indispensable manufacturing technology that plays an important role in several industries with its efficiency, precision and flexibility.

#prototyping#prototype#rapid prototyping#prototype machining#precision machining#cnc machining#cnc milling#machining parts#cnc milling 5 axis#cnc milling machining#cnc milling turning#precision cnc milling#cnc milling parts

2 notes

·

View notes

Text

Printed Terracotta Cooler

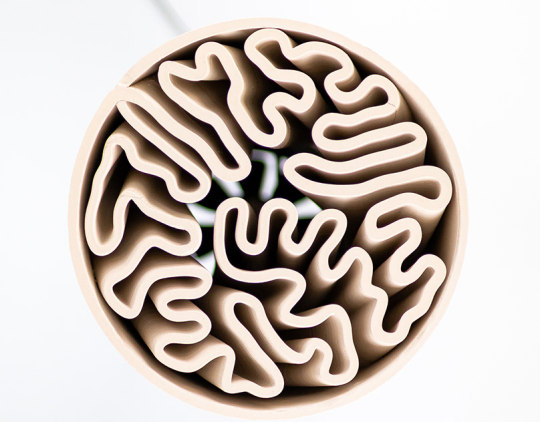

The low-tech cooler is a project I developed with the global design agency, Entreautre. We started with a simple principle inspired by traditional practices: a porous terracotta container filled with water.

Thanks to a ventilation system (WEEE), the airflow in contact with the wet surface allows water to evaporate in order to produce cold air.

To achieve an interesting effect, we sought to increase the wet wall surface in contact with ventilated air as much as possible. Ceramic 3D printing allowed us to test complex volumes such as differential growth. The natural process of differential growth was also a coherent aesthetic to produce a manifesto product in order to share the vision behind the process.

The process

I designed this structure with the software Grasshopper. It's a visual 3D programming language linked to Rhino 3D that allows the achievement of complex and parametric pieces that couldn't be done with traditional CAD programs.

I learned the software by myself to achieve the program in order to print the final shape. This shape came from all the different constraints I was confronted with:

The material: The lining thickness, the porosity.

The method of conception: Height, material volume contained in the printing pipe, printing time, clearance angle.

The metrics of minimal performances: Structure resistance, water volume, surface exchange between ceramic airflow and water.

I worked with Luc Dauphin, a mechanical engineer, and Bastien Pyon, Fablab's CEO, who guided me in dealing with those constraints.

The 3D printing machine is an exclusive machine designed by the Dutch artist, Olivier Van Herpt. The one that we used is the only one that exists outside his studio. It works like a traditional 3D plastic printer, where a piston extrudes the terra-cotta as a thin filament layer by layer.

Simon Pavy

#art#design#minimal#ecology#eco friendly#cooler#terracotta#3d printing#olivier van herpt#simon pavy#water#WEEE#ventilation#natural ventilation#nature#sustainability#creativity#airflow

29 notes

·

View notes

Text

Hyper focused on CAD designing like I haven’t in years. I’m a little rusty so it took me weeks to even gather the motivation to open up the software. But then I spent I think 4 hours? Designing and redesigning a goddamned soap dish. I think it was 11pm when I started and when I looked up it was 3am coz my mom came to ask why I wasn’t in bed yet.

It’s in the 3D printer rn. Hopefully. It’ll turn out fine. It’s got three pieces so I’m most worried about the sizes. Since this is the first print I’ve drawn myself, im not sure on tolerances and stuff. So we shall see.

#I learned how to make a honeycomb pattern today#that took a while#the next thing im making is a desk calendar#personal

3 notes

·

View notes