#control system engineering integrator

Explore tagged Tumblr posts

Text

Experience greatness in industrial controls through our believed mechanization organization. Whether you're confronting control panel troubleshooting or looking for state of the art arrangements, we take care of you. Our master group is devoted to guaranteeing smooth tasks and upgraded effectiveness for your frameworks. Depend on us for all your control framework prerequisites. https://sagaautomation.com

#control system engineering integrator#industrial controls system integrator#control panel troubleshooting automation company

1 note

·

View note

Text

Powering the Production Line: Messung’s NX-ERA PLCs in Automotive Material Handling

In automotive manufacturing, precision isn’t a luxury, it’s a necessity. From chassis and engine assembly lines to the press shop and paint line, seamless material handling is critical to keeping production on track. Whether it’s coordinating conveyors, pick-and-place systems, or synchronizing with robotic cells, the need for intelligent control is constant.

Messung’s NX-ERA PLCs deliver this control with unmatched flexibility. With native support for Modbus TCP/IP, Ethernet/IP, EtherCAT, OPC-UA, and IO-Link, they enable high-speed communication across robots, HMIs, VFDs, servo amplifiers, and central SCADA systems. Plus, with remote I/O modules and protocols like CANopen, our PLCs handle large-scale, distributed inputs and outputs effortlessly. Simply put, NX-ERA makes advanced, synchronized automation easy, even in the most demanding environments.

What is Material Handling in the Automotive Industry?

Material handling in the automotive industry involves the movement, positioning, storage, safety, and tracking of components and assemblies throughout the production process—from the arrival of raw materials to the final stages of vehicle assembly. Efficiency here is critical; any delay or misstep can disrupt the entire manufacturing flow.

Key areas such as the chassis and engine assembly lines, along with the press shop and paint line, rely heavily on sophisticated material handling systems, including conveyors, pick-and-place machines, and robotics, to keep production moving seamlessly. These systems must operate in perfect sync, often across large, distributed areas with thousands of I/O points.

The Brain Behind the Brawn: NX-ERA PLCs

Our state-of-the-art NX-ERA PLCs including the NX-ERA Xpress and NX-ERA Jet, are compact PLCs designed for high-speed, reliable control. These programmable logic control systems are the heart of any automated material handling system. By offering real-time control, seamless connectivity, and robust communication protocols like Modbus TCP/IP, Ethernet/IP, EtherCAT, OPC-UA, and IO-Link. They interface effortlessly with robots, HMIs, VFDs, servo amplifiers, and centralized SCADA systems, ensuring reliability and scalability.

Here are some of its most impactful features:

High-Speed Processing Power

The core point of NX-ERA PLCs is that they are capable of real-time processing. These robot systems run as fast as your machinery, and the synchronization is important for the overall efficiency of the system. This compact PLC will guarantee flawless optimization for every aspect of the bottling line, be it controlling the work of conveyors or robotic manipulation.

Modular Design for Flexibility

The greatest feature of the NX-ERA PLC is its modular design. Production plants in the automotive industry often aim for some form of adaptability, and, thus, this feature is very helpful. It allows the installation to expand while the business is developing. The implementation of modularity means that the system can be integrated with any new equipment, production units, or additional features to ensure that there will be no disruption to the system performance.

Integrated I/O Modules for Streamlined Setup

Our smart and compact PLC integration contains integrated I/O modules that reduce installation and wiring times, thus also focusing on the fast-paced phenomenon in the automotive industry. For simplification of the things, input/output capabilities are now directly included in the integrated PLC system, which substantially reduces the external wiring as a result of which the setting up is speedier and less prone to mistakes.

Advanced Web Server Capabilities

It is safe to say that we are far off the days when engineers would have to be on site for them to physically track and diagnose issues on the factory floor. The capability of the built-in web pages of our NX-ERA PLC allows easy remote access for getting the actual real-time state of the diagnostics and monitoring. This feature is incredibly important in an industry that operates around the clock, as it allows maintenance teams to resolve issues remotely, reducing downtime and keeping things running smoothly.

The Role of the NX-ERA PLCs in Material Handling

In the automotive industry, material handling is integral to the success of the production process. From raw materials to semi-finished goods, and finally to finished products, materials need to be handled with precision. Automation is key to achieving this, and Messung’s NX-ERA PLCs are designed to make this process as efficient and effective as possible.

Here is how it is done:

Conveyor Systems Optimization

Conveyor systems, which carry parts between the workstations and at the same time keep the production continuously running, are the most popular form of material handling in the automotive plants. NX-ERA PLCs make sure that the system, no matter what, functions without any breaks by adjusting the speed of the conveyors to fit the pace of production. The real-time processing feature ensures that the system in question becomes flexible almost immediately, providing the assembly line without any interruptions and preventing the end line packing in the last round.

Predictive Maintenance to Maximize Uptime

The predictive maintenance of the system is seen as the golden nugget to maximize uptime. For the maintenance of a plant, having machines down during their run time is quite expensive. In the automotive industry, where the production rates run on a very tight schedule, even a moment's disruption would mean substantial losses. Our PLC Systems use a predictive maintenance system to keep a continuous check on the condition of the equipment. The control system will be equipped with predictive maintenance, which can track the system performance, increasing the change in predicting when maintenance is needed before failure occurs. These stains would reduce chances of equipment going down and also increase whole equipment machines productivity performance.

Power Management for Material Handling Equipment

How NX-ERA PLCs Integrate with SCADA Systems

Industrial automation relies not just on PLCs but also on supervisory control and data acquisition (SCADA) systems to monitor and control large-scale operations. The integration of NX-ERA PLCs with SCADA applications enhances material handling capabilities by providing plant operators with real-time insights into the performance of material handling equipment.

Real-Time Visualization and Data Monitoring

Data gathered from the cluster of service line sensors are then monitored by SCADA systems through real-time visualization and data troubling. By means of the material handling systems' connecting to the SCADA applications, operators are able to visualize every operation stage on a single interface. Our NX-ERA PLC assists the SCADA system in a way that allows real-time data visualization. As for plant automation, this integration enables the operators to redesign the production line and fabricate the survey that they are in full command, including the conveyor speed, robotic movement, and electrical power consumption.

Alarming and Fault Diagnostics

Unexpected malfunctions are a part of any complex system, but SCADA and PLC integration ensures they are dealt with swiftly. The NX-ERA PLC can send alerts to SCADA systems when material handling equipment encounters an issue, whether it’s a malfunction in a conveyor belt, a sensor failure in a robotic arm, or an electrical fault. This proactive approach helps resolve issues before they lead to extended downtime.

Historical data analysis for continuous improvement

Other benefits of integrating the SCADA system with the NX-ERA PLC is to have an ability to analyse historical data. These past data performances can better help the plant managers to see trends, adjust production schedules, and improve the efficiency of the material-handling systems over the long period. In actuality, the PLC saves and disposes of necessary data. This information, then, is fed into the SCADA system and used for analysis and presentation purposes.

The Future of Material Handling with NX-ERA PLCs

As the automotive industry embraces Industry 4.0, NX-ERA PLCs are positioned at the forefront of the shift towards smarter, more connected manufacturing systems. This is brought about by switching to smarter, more connected production systems. Thanks to NX-ERA PLCs, which are able to integrate with SCADA applications, robots, and power supplies, you can now easily build a factory that can quickly adapt to changes in the current demand and the production process.

Benefits Include:

More automation and efficiency with the increasing factories

As factories become more automated, the role of PLCs like the NX-ERA will only grow. The future of material handling will rely on even more precise and automated systems, from fully autonomous robots to smart conveyors that adjust their speed and behavior based on real-time conditions. The NX-ERA PLC is ready to support this evolution with its high-speed processing and robust integration capabilities.

Energy Management and Sustainability

Green manufacturing is a critical concern for the industry today. Automotive manufacturers demand advanced NX-ERA PLCs in a bid to bring down the environmental impact of the production. An essential element that plays a pivotal role in power solutions, predictive maintenance, and derived data for operational efficiency is a way for these to reduce the consumption of energy.

Real-Time Data and IoT Connectivity

With the rise of the Internet of Things (IoT) in manufacturing, NX-ERA PLCs will continue to integrate with a broader network of connected devices. This real-time data flow will empower automotive plants to make more informed decisions and improve their material handling systems.

Conclusion: The Future of Material Handling in the Automotive Industry

In the race for efficiency and innovation, Messung’s NX-ERA PLCs are the pit crew that keeps material handling equipment running at peak performance. Their combination of advanced features, modular design, and seamless integration with SCADA systems positions them as the ideal solution for automotive manufacturers aiming to stay ahead of the competition.

As automotive plants move towards smarter, more automated manufacturing processes, the need for reliable, high-performing PLCs like the NX-ERA will only continue to grow. By embracing the capabilities of Messung’s NX-ERA PLCs, automotive manufacturers can ensure that their material handling systems operate efficiently, sustainably, and with minimal downtime, ultimately contributing to the ongoing success of the industry.

In this fast-paced industry where precision is the name of the game, Messung’s NX-ERA PLCs are the game changers that automotive manufacturers need to optimize their material handling systems and maintain a competitive edge in the global market.

#chassis and engine assembly lines#Modbus TCP/IP#Ethernet/IP#EtherCAT#OPC-UA#remote I/O modules#CANopen#compact PLCs#programmable logic control systems#SCADA systems#automotive industry#PLC system#material handling#PLC Systems#material handling systems#SCADA applications#PLC integration#Automotive manufacturers#Internet of Things (IoT)

0 notes

Text

Top Automation Engineers in Illinois | Innovating Industrial Solutions

Automation engineers are specialized professionals who design and implement systems that reduce human intervention in industrial processes. They blend knowledge from multiple fields—mechanical, electrical, software, and control engineering—to create intelligent systems that operate efficiently, reliably, and autonomously.

Their typical responsibilities include:

Designing automation systems from concept to installation

Programming PLCs (Programmable Logic Controllers) and HMIs (Human-Machine Interfaces)

Integrating robotics and motion control

Developing SCADA (Supervisory Control and Data Acquisition) systems

Testing and troubleshooting automated equipment

Ensuring safety and compliance with industrial standards

In Illinois, automation engineers are indispensable to manufacturing, logistics, food processing, energy, and life sciences.

Why Illinois Is a Powerhouse for Automation Engineering

Several key factors contribute to Illinois’s prominence in automation engineering:

1. Diverse Industrial Base: Illinois boasts industries ranging from automotive and agriculture to pharmaceuticals and aerospace. This diversity fuels consistent demand for custom automation solutions.

2. Strong Educational Ecosystem: Top-tier institutions like the University of Illinois, Northwestern University, and Southern Illinois University produce highly skilled engineers with expertise in robotics, AI, and industrial systems.

3. Strategic Location: Illinois's central location offers excellent logistics, making it a favored site for advanced manufacturing, warehousing, and distribution centers—all of which benefit from automation.

4. Innovation-Friendly Climate: The state supports innovation through tech incubators, grants, and public-private partnerships that empower engineers to develop and deploy cutting-edge automation solutions.

Key Services Offered by Automation Engineers in Illinois

Automation engineers in Illinois provide an extensive range of services tailored to the specific needs of businesses across the state. Common services include:

System Integration: Designing and installing complete automation solutions that synchronize machines, robots, and control systems.

PLC & HMI Programming: Writing and testing software that governs system behavior and interfaces.

Robotics Engineering: Installing and configuring robotic arms and automated material handling systems.

Industrial IoT Integration: Connecting machines to networks for real-time data exchange and monitoring.

Retrofitting & Upgrades: Enhancing legacy equipment with modern control technologies.

Safety System Design: Implementing fail-safes, emergency stops, and safety protocols in compliance with OSHA and ISO standards.

Whether working on a small assembly cell or a full-scale production line, Illinois automation engineers prioritize reliability, scalability, and efficiency.

Industries Benefiting from Automation Engineers in Illinois

The work of automation engineers touches nearly every corner of Illinois’s economy. Key sectors include:

Food and Beverage: Automating sorting, bottling, and packaging processes to ensure hygiene and speed.

Pharmaceuticals and Medical Devices: Ensuring precision, compliance, and traceability through automated filling, labeling, and inspection.

Automotive and Aerospace: Deploying robotic arms and motion systems for parts assembly and quality control.

Agriculture and Grain Processing: Integrating automation into storage, sorting, and packaging facilities.

Warehousing and Logistics: Developing conveyor systems, pick-and-place robots, and automated guided vehicles (AGVs).

Energy and Utilities: Implementing SCADA and remote control systems to manage plant operations.

By adopting automation, these industries reduce labor strain, improve accuracy, and increase throughput—critical in today’s competitive global marketplace.

The Future of Automation Engineering in Illinois

As we move further into the age of Industry 4.0, the role of automation engineers is evolving. Engineers in Illinois are not just builders of machines—they are architects of data-driven, intelligent systems. The future will include:

Edge Computing and AI: Allowing systems to make real-time decisions at the source.

Cloud-Connected Automation: Centralized data storage and analysis across multiple plants.

Predictive Maintenance: Using machine learning to anticipate equipment failures before they occur.

Digital Twins: Creating virtual replicas of physical systems for simulation and optimization.

Green Manufacturing: Designing systems that reduce energy use and support sustainability.

Illinois is well-positioned to remain at the forefront of this transformation, with a workforce ready to meet the challenges and opportunities ahead.

Choosing the Right Automation Engineer in Illinois

When selecting an automation engineer or firm, businesses should look for:

Experience Across Industries

Proficiency with Major Platforms (Allen-Bradley, Siemens, Beckhoff, etc.)

Commitment to Safety and Compliance

Strong Project Management and Communication Skills

Local Support and Maintenance Services

A collaborative approach ensures solutions that align with business goals, budget, and operational scale.

Your Automation Engineering Partner: Xtreme Automation LLC

If your Illinois-based business is ready to embrace the future of smart manufacturing, Xtreme Automation LLC is here to help. With decades of experience in automation design, PLC programming, robotics integration, and system retrofitting, Xtreme Automation provides comprehensive engineering solutions tailored to your industry. From planning and development to implementation and support, their team ensures your automation journey delivers real results. Learn more at xtremeautomationllc.com.

#Automation Engineers Illinois#Industrial Automation Services#Robotics Engineering Illinois#Control System Engineers IL#Automation Integration Companies#Smart Manufacturing Illinois#PLC and HMI Programming#Engineering Solutions Illinois#Industrial Robotics Experts#Factory Automation Consultants

0 notes

Text

"The Crucial Role of Industrial Control Integrators: Driving Efficiency and Innovation in Modern Industry"

The Essential Role of an Industrial Control Integrator in Modern Industry

In today’s fast-paced industrial environment, the expertise of an Industrial Control Integrator has become indispensable. These professionals or companies specialize in designing, implementing, and maintaining complex control systems that are critical for optimizing industrial processes. This blog delves into the pivotal role of an Industrial Control Integrator, explaining their key responsibilities and the impact they have on industrial efficiency.

What is an Industrial Control Integrator?

An Industrial Control Integrator is a specialized expert or firm responsible for creating and managing control systems that automate and regulate industrial machinery and processes. These control systems encompass both hardware and software components, which work together to enhance performance, increase reliability, and streamline operations.

Core Responsibilities of an Industrial Control Integrator

Control System Design and Engineering:

Needs Analysis: The integrator begins with a comprehensive assessment of the client’s specific requirements. This involves understanding their industrial processes and defining the desired outcomes.

Custom System Design: Based on the assessment, the integrator designs a bespoke control system, selecting the appropriate sensors, controllers, and communication protocols to meet the client’s needs.

Integration and Installation:

Hardware Setup: The integrator manages the installation of essential components such as Programmable Logic Controllers (PLCs), Human-Machine Interfaces (HMIs), and other field instruments.

Software Configuration: They also configure the software that governs the control system, ensuring seamless communication between hardware and other operational systems.

Testing and Commissioning:

System Testing: Before full deployment, the integrator conducts rigorous testing to identify and rectify any issues, simulating real-world conditions to verify system performance.

Commissioning: Once testing is complete, the integrator supervises the final commissioning process, making any necessary adjustments to ensure optimal functionality.

Training and Ongoing Support:

Staff Training: Integrators provide training for the client’s personnel, equipping them with the knowledge to operate and maintain the new system effectively.

Continued Support: They offer ongoing maintenance and support services to resolve any issues and ensure the system continues to operate smoothly.

Why Industrial Control Integrators are Vital

Boosting Efficiency:

Industrial Control Integrators streamline processes by automating operations, which reduces manual input and enhances precision. This leads to improved productivity and reduced operational costs.

Enhancing Safety:

Integrators implement advanced control systems that monitor conditions in real time, increasing workplace safety by triggering alarms or shutdowns when necessary.

Ensuring Reliability:

By designing systems with redundancy and fail-safes, integrators help minimize downtime, which is crucial for meeting production targets and maintaining product quality.

Facilitating Scalability:

As businesses expand, their control systems must adapt. Integrators create flexible solutions that can be easily scaled or upgraded to meet growing demands.

Incorporating Emerging Technologies:

With the rise of Industry 4.0, integrating new technologies such as the Internet of Things (IoT), advanced analytics, and Artificial Intelligence (AI) is becoming increasingly important. Control integrators are key to incorporating these innovations into existing systems.

The Future of Industrial Control Integration

The field of industrial control integration is continuously evolving, driven by technological advancements and shifting industry needs. Future trends include:

AI and Machine Learning Integration: Enhancing predictive maintenance and process optimization.

IoT Integration: Enabling more detailed data collection and real-time analytics.

Enhanced Cybersecurity: Addressing the increasing need for robust security measures to protect industrial control systems from cyber threats.

Conclusion

Industrial Control Integrators are essential in ensuring the efficiency, reliability, and safety of modern industrial processes. Their expertise in designing, implementing, and maintaining control systems is crucial for optimizing operations and keeping pace with technological advancements. For businesses looking to upgrade or implement control systems, partnering with a skilled Industrial Control Integrator can be the key to achieving greater efficiency and performance.

#Industrial Control Integrator#Industrial Automation#Control Systems Engineering#Programmable Logic Controllers (PLCs)#Human-Machine Interfaces (HMIs)#Industrial Process Optimization#Automation Solutions#System Integration#Industrial Efficiency#Operational Reliability#Advanced Control Systems#Industry 4.0#Internet of Things (IoT)#Artificial Intelligence (AI) in Industry#Predictive Maintenance#Industrial Cybersecurity#Control System Design#Industrial Technology Trends#Engineering and Integration Services#Manufacturing Automation

0 notes

Text

Exciting Career options after EEE (Electrical and Electronics Engineering)

The field of Electrical and Electronics Engineering (EEE) opens up a dynamic range of career options each offering personal satisfaction and ample room for creativity and impact. Whether it’s lighting up the world with electricity or leading the charge in developing hi-tech electronic devices, professionals in EEE play an important role in shaping our modern era. In this blog, let’s look into the career options after EEE awaiting graduates.

https://krct.ac.in/blog/2024/06/07/exciting-career-options-after-eee-electrical-and-electronics-engineering/

#krct the top college of technology in trichy#krct the best college of technology in trichy#best autonomous college of technology in trichy#top college of technology in trichy#admission#Power Systems Engineer#Electronics Design Engineer#Renewable Energy Specialist#Control Systems Engineer#Telecommunications Engineer#Systems Integration Engineer#Embedded Systems Engineer

0 notes

Note

(half rant half story)

I'm a physicist. I work for a company that helps develop car parts. Essentially, car companies come to us with ideas on what they want from a part or material, and we make/test the idea or help them make/test it. Usually this means talking to other scientists and engineers and experts and it's all fine. Sometimes this means talking to businesspeople and board execs and I hate them

A bit ago when AI was really taking off in the zeitgeist I went to a meeting to talk about some tweaks Car Company A wanted to make to their hydraulics- specifically the master cylinder, but it doesn't super matter. I thought I'd be talking to their engineers - it ends up being just me, their head supervisor (who was not a scientist/engineer) and one of their executives from a different area (also not a scientist/engineer). I'm the only one in the room who actually knows how a car works, and also the lowest-level employee, and also aware that these people will give feedback to my boss based on how I 'represent the company ' whilst I'm here.

I start to explain my way through how I can make some of the changes they want - trying to do so in a way they'll understand - when Head Supervisor cuts me off and starts talking about AI. I'm like "oh well AI is often integrated into the software for a car but we're talking hardware right now, so that's not something we really ca-"

"Can you add artificial intelligence to the hydraulics?"

"..sorry, what was that?"

"Can you add AI to the hydraulics system?"

can i fucking what mate "Sir, I'm sorry, I'm a little confused - what do you mean by adding AI to the hydraulics?"

"I just thought this stuff could run smoother if you added AI to it. Most things do"

The part of the car that moves when you push the acceleration pedal is metal and liquid my dude what are you talking about "You want me to .add AI...to the pistons? To the master cylinder?"

"Yeah exactly, if you add AI to the bit that makes the pistons work, it should work better, right?"

IT'S METAL PIPES it's metal pipes it's metal pipes "Sir, there isn't any software in that part of the car"

"I know, but it's artificial intelligence, I'm sure there's a way to add it"

im exploding you with my mind you cannot seriously be asking me to add AI to a section of car that has as much fucking code attached to it as a SOCK what do you MEAN. The most complicated part of this thing is a SPRING you can't be serious

He was seriously asking. I've met my fair share of idiots but I was sure he wasn't genuinely seriously asking that I add AI directly to a piston system, but he was. And not even in the like "oh if we implement a way for AI to control that part" kind of way, he just vaguely thought that AI would "make it better" WHAT THE FUCK DO YOU MEANNNNN I HAD TO SPEND 20 MINUTES OF MY HARD EARNED LIFE EXPLAINING THAT NEITHER I NOR ANYONE ELSE CAN ADD AI TO A GOD DAMNED FUCKING PISTON. "CAN YOU ADD AI TO THE HYDRAULICS" NO BUT EVEN WITHOUT IT THAT METAL PIPE IS MORE INTELLIGENT THAN YOU

Posted by admin Rodney.

13K notes

·

View notes

Text

My concepts for the development progress of an Iterators Puppet

-my ideas below

-Feasibility Study

[1]: First autonomous control module, any instruction to be given must be done manually through physical means (the keys), outputs were shown through the screen. A very primitive system, however, did its job proving the greater machine concept was achievable. While it does look like a lens above the monitor, this was a simple status gauge for benchmarking.

-Prototyping and Development

[2]: Now with the capability to wirelessly and audibly communicate to receive instructions and inputs. The system was no longer directly integrated into the facility, and resided on the first instance of an iterator's arm. This was considered a feat due to the complications with isolating the control module from the rest of the iterators components, while keeping processing power. A permanent connection/umbilical was needed to sustain life and function though.

To “talk” back, they were crafted with multidimensional projectors, the mobile arm allowing the angles and variance for this projection. Only later into development were advanced speakers installed for optimized understanding, however the extra computing power required to synthesize proper speech was found to strain the contained module, so this function had rare use in the end.

[3]: At this point there was a change in perspective in the project. What once were machines to simply compute and simulate, were now planned to be the home, caregiver, and providers. The further the project came to fruition the more religious importance was placed upon these “random gods”. From this stance not only did the puppets have to manage and control their facilities, they had to communicate with the people and priests. To represent benevolent beings who will bring their end and salvation. In this process iterators began to take a more humanoid shape, to better reflect their parents. Development was focused on compacting the puppet closer to the size of an ancient for this purpose. This stage was the first to incorporate a cloak/clothing into their design considerations, to further akin themselves in looks. The cloak would hide the iterators' engineered bodies and give a body to their silhouette.

[4]: As bioengineering and mechanics were rapidly progressing due to the void fluid revolution, this allowed plenty of margin for developing the outer design of the iterator puppets. This prototype was the first to incorporate limbs for the purpose of body language. This was another step in the drive to give a body to their random gods.

-Final Iterations

[5]: First generation iterators had the final redesign of puppet bodies. Far different from their first designs, they are fully humanoid. Their bodies are shaped to be organic and as full of life as they could at the time. Their center of sapience has fully settled within their body, as can be seen as their unconscious use of limbs without the direct intention for communication. This can also see how they manage their work, where many of the functions (which can be done with just an internal request) are operated through physical gestures of their limbs. Their puppet chambers also allow for full comprehensive projection, where many of their working monitors are displayed. It is seen how iterators prefer to utilize their traversal arm to transfer between the current working projection window.

These designs were hardy and nearly self-sufficient, only requiring minimal power from their umbilical to charge. (However was still limited in the terms of internal power production, for this first generation extensive batteries sufficed)

[6]: Later generation not only incorporated advanced bioengineering internally, but externally. While still a hardened shell, their body plates have been incorporated into the organics of the puppet, maintaining the protective requirements while barely leaving a trace of hinges or plates. This “soft” skin had drawbacks, such as reduced durability to the first generations, this was offset by the greatly enhanced repair speeds and capability this type of skin allowed.

Internal power generation was implemented into these late generation models. If the case arose, the Puppet could be disconnected from their umbilical and still be conscious from an undefined period of time. (However this would limit the operating capacity of the puppet when running self sufficiently) This greatly eased maintenance works, as the Puppet could still run the greater facility wirelessly while work was done on the chamber, arm or whatever as needed.

2K notes

·

View notes

Text

25 Years of Exploring the Universe with NASA's Chandra Xray Observatory

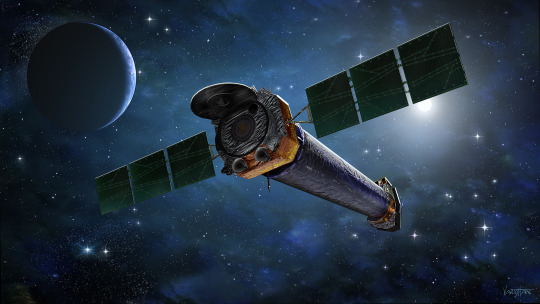

Illustration of the Chandra telescope in orbit around Earth. Credit: NASA/CXC & J. Vaughan

On July 23, 1999, the space shuttle Columbia launched into orbit carrying NASA’s Chandra X-ray Observatory. August 26 marked 25 years since Chandra released its first images.

These were the first of more than 25,000 observations Chandra has taken. This year, as NASA celebrates the 25th anniversary of this telescope and the incredible data it has provided, we’re taking a peek at some of its most memorable moments.

About the Spacecraft

The Chandra telescope system uses four specialized mirrors to observe X-ray emissions across the universe. X-rays that strike a “regular” mirror head on will be absorbed, so Chandra’s mirrors are shaped like barrels and precisely constructed. The rest of the spacecraft system provides the support structure and environment necessary for the telescope and the science instruments to work as an observatory. To provide motion to the observatory, Chandra has two different sets of thrusters. To control the temperatures of critical components, Chandra's thermal control system consists of a cooling radiator, insulators, heaters, and thermostats. Chandra's electrical power comes from its solar arrays.

Learn more about the spacecraft's components that were developed and tested at NASA’s Marshall Space Flight Center in Huntsville, Alabama. Fun fact: If the state of Colorado were as smooth as the surface of the Chandra X-ray Observatory mirrors, Pike's Peak would be less than an inch tall.

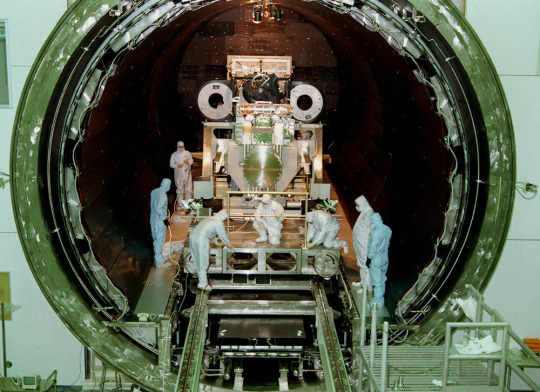

Engineers in the X-ray Calibration Facility at NASA’s Marshall Space Flight Center in Huntsville, Alabama, integrating the Chandra X-ray Observatory’s High-Resolution Camera with the mirror assembly, in this photo taken March 16, 1997. Credit: NASA

Launch

When space shuttle Columbia launched on July 23, 1999, Chandra was the heaviest and largest payload ever launched by the shuttle. Under the command of Col. Eileen Collins, Columbia lifted off the launch pad at NASA’s Kennedy Space Center in Florida. Chandra was deployed on the mission’s first day.

Reflected in the waters, space shuttle Columbia rockets into the night sky from Launch Pad 39-B on mission STS-93 from Kennedy Space Center. Credit: NASA

First Light Images

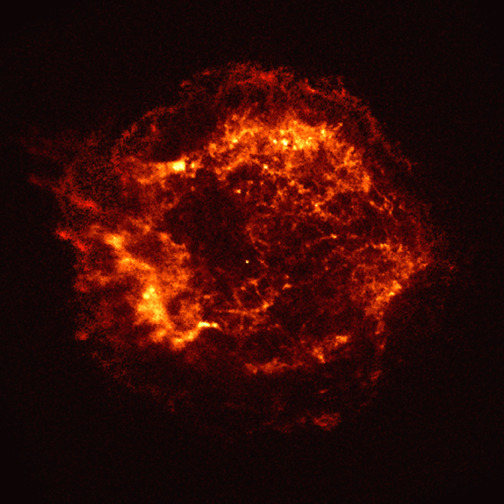

Just 34 days after launch, extraordinary first images from our Chandra X-ray Observatory were released. The image of supernova remnant Cassiopeia A traces the aftermath of a gigantic stellar explosion in such captivating detail that scientists can see evidence of what is likely the neutron star.

“We see the collision of the debris from the exploded star with the matter around it, we see shock waves rushing into interstellar space at millions of miles per hour,” said Harvey Tananbaum, founding Director of the Chandra X-ray Center at the Smithsonian Astrophysical Observatory.

Cassiopeia A is the remnant of a star that exploded about 300 years ago. The X-ray image shows an expanding shell of hot gas produced by the explosion colored in bright orange and yellows. Credit: NASA/CXC/SAO

A New Look at the Universe

NASA released 25 never-before-seen views to celebrate the telescopes 25th anniversary. This collection contains different types of objects in space and includes a new look at Cassiopeia A. Here the supernova remnant is seen with a quarter-century worth of Chandra observations (blue) plus recent views from NASA’s James Webb Space Telescope (grey and gold).

This image features deep data of the Cassiopeia A supernova, an expanding ball of matter and energy ejected from an exploding star in blues, greys and golds. The Cassiopeia A supernova remnant has been observed for over 2 million seconds since the start of Chandra’s mission in 1999 and has also recently been viewed by the James Webb Space Telescope. Credit: NASA/CXC/SAO

Can You Hear Me Now?

In 2020, experts at the Chandra X-ray Center/Smithsonian Astrophysical Observatory (SAO) and SYSTEM Sounds began the first ongoing, sustained effort at NASA to “sonify” (turn into sound) astronomical data. Data from NASA observatories such as Chandra, the Hubble Space Telescope, and the James Webb Space Telescope, has been translated into frequencies that can be heard by the human ear.

SAO Research shows that sonifications help many types of learners – especially those who are low-vision or blind -- engage with and enjoy astronomical data more.

Click to watch the “Listen to the Universe” documentary on NASA+ that explores our sonification work: Listen to the Universe | NASA+

An image of the striking croissant-shaped planetary nebula called the Cat’s Eye, with data from the Chandra X-ray Observatory and Hubble Space Telescope. NASA’s Data sonification from Chandra, Hubble and/or Webb telecopes allows us to hear data of cosmic objects. Credit: NASA/CXO/SAO

Celebrate With Us!

Dedicated teams of engineers, designers, test technicians, and analysts at Marshall Space Flight Center in Huntsville, Alabama, are celebrating with partners at the Chandra X-ray Center and elsewhere outside and across the agency for the 25th anniversary of the Chandra X-ray Observatory. Their hard work keeps the spacecraft flying, enabling Chandra’s ongoing studies of black holes, supernovae, dark matter, and more.

Chandra will continue its mission to deepen our understanding of the origin and evolution of the cosmos, helping all of us explore the Universe.

The Chandra Xray Observatory, the longest cargo ever carried to space aboard the space shuttle, is shown in Columbia’s payload bay. This photo of the payload bay with its doors open was taken just before Chandra was tilted upward for release and deployed on July 23, 1999. Credit: NASA

Make sure to follow us on Tumblr for your regular dose of space: http://nasa.tumblr.com

2K notes

·

View notes

Text

Induction Generators Market Overview and Regional Outlook Study 2017 – 2032

Market Overview:

The induction generators market refers to the industry involved in the production, distribution, and sales of induction generators. Induction generators are a type of electrical generator that operates based on the principle of electromagnetic induction. They are commonly used in various applications, including wind turbines, hydroelectric power plants, and standalone power systems.

Induction Generators Market is projected to be worth USD 44.8 billion by 2032, registering a CAGR of 9.50% during the forecast period (2023-2032)

Here are some key points about the induction generators market:

Growing Renewable Energy Sector: The increasing focus on renewable energy sources, such as wind and hydro power, has driven the demand for induction generators. These generators are widely used in wind turbines to convert the kinetic energy of the wind into electrical energy.

High Efficiency and Reliability: Induction generators are known for their high efficiency and reliability. They have simple construction, require minimal maintenance, and offer good performance in various operating conditions. These factors contribute to their popularity in power generation applications.

Varied Power Output Range: Induction generators are available in a wide range of power outputs, ranging from a few kilowatts to several megawatts. This flexibility makes them suitable for both small-scale and large-scale power generation projects.

Technological Advancements: Ongoing technological advancements have led to the development of more efficient and advanced induction generators. These advancements aim to enhance power generation efficiency, reduce costs, and improve overall performance.

Environmental Considerations: With increasing concerns about climate change and the need to reduce greenhouse gas emissions, the adoption of renewable energy sources like wind and hydro power is gaining momentum. Induction generators play a significant role in supporting this transition by providing clean and sustainable power generation solutions.

Government Policies and Incentives: Government initiatives, regulations, and incentives supporting renewable energy projects can significantly impact the induction generators market. Subsidies, feed-in tariffs, and tax benefits provided by governments encourage the adoption of renewable energy technologies, thereby driving the demand for induction generators.

Future Outlook: The induction generators market is expected to witness continued growth in the coming years due to the increasing demand for renewable energy and the transition towards a low-carbon economy. Technological advancements, cost reductions, and supportive government policies are likely to further boost market expansion.

We recommend referring our Stringent datalytics firm, industry publications, and websites that specialize in providing market reports. These sources often offer comprehensive analysis, market trends, growth forecasts, competitive landscape, and other valuable insights into this market.

By visiting our website or contacting us directly, you can explore the availability of specific reports related to this market. These reports often require a purchase or subscription, but we provide comprehensive and in-depth information that can be valuable for businesses, investors, and individuals interested in this market.

“Remember to look for recent reports to ensure you have the most current and relevant information.”

Click Here, To Get Free Sample Report: https://stringentdatalytics.com/sample-request/induction-generators-market/3308/

Market Segmentations:

Global Induction Generators Market: By Company • ABB • GE • Brush HMA • Techtop • Victron Energy • SycoTec • Sicme Motori • Robert Bosch • TRUMPF • VEM Group Global Induction Generators Market: By Type • High Voltage Induction Generators • Medium Voltage Induction Generators • Low Voltage Induction Generators Global Induction Generators Market: By Application • Wind Turbines • Micro Hydro Installations • Other Global Induction Generators Market: Regional Analysis All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Induction Generators market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Visit Report Page for More Details: https://stringentdatalytics.com/reports/induction-generators-market/3308/

Reasons to Purchase Induction Generators Market Report:

• To obtain insights into industry trends and dynamics, including market size, growth rates, and important factors and difficulties. This study offers insightful information on these topics.

• To identify important participants and rivals: This research studies can assist companies in identifying key participants and rivals in their sector, along with their market share, business plans, and strengths and weaknesses.

• To comprehend consumer behaviour: these research studies can offer insightful information about customer behaviour, including preferences, spending patterns, and demographics.

• To assess market opportunities: These research studies can aid companies in assessing market chances, such as prospective new goods or services, fresh markets, and new trends.

• To make well-informed business decisions: These research reports give companies data-driven insights that they may use to plan their strategy, develop new products, and devise marketing and advertising plans.

In general, market research studies offer companies and organisations useful data that can aid in making decisions and maintaining competitiveness in their industry. They can offer a strong basis for decision-making, strategy formulation, and company planning.

Click Here, To Buy Premium Report: https://stringentdatalytics.com/purchase/induction-generators-market/3308/?license=single

About US:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs

Contact US:

Stringent Datalytics

Contact No - +1 346 666 6655

Email Id - [email protected]

Web - https://stringentdatalytics.com/

#Certainly! Here are 30 tags for the Induction Generators Market separated by commas:#Induction Generators#Renewable Energy#Wind Power#Power Generation#Electrical Engineering#Grid Integration#Energy Efficiency#Variable Speed Technology#Power Electronics#Smart Grid#Distributed Generation#Wind Turbines#Grid Stability#Reactive Power Control#Energy Conversion#Power Systems#Generator Control#Reactive Power Compensation#Wind Farm#Voltage Regulation#Synchronous Generators#Harmonics#Reactive Power Support#Electric Power Generation#Power Quality#Wind Energy Conversion System#Stator Control#Renewable Energy Integration#Power Factor Correction

1 note

·

View note

Text

I do think it would be a really good idea for a story to have a sort of 40k world where technology and religion have created this unholy bureaucracy of super soldiers, priests, and engineers. Except in an effort to both keep the emperor in control and create a bureaucratic class of workers, the echelon of generals are all women, with the thought that they would never be strong enough to overthrow the emperor and the bureaucratic class are all men forcibly feminized into women, with a similar idea but also the concept similar to the imperial Court that they would care more for the country than continuing their own legacy. This is further spread into a technical class of holy engineers and a bureaucratic class of priestesses.

This of course does not work out like that and the Emperor is eventually overthrown in a bloody civil war and the various planets and systems split into an unholy group of alliances and backstabbing each with their own rules. Like a Warring States period, but spread out over Galaxies.

The forced feminization is an integral part of this though and non negotiable.

702 notes

·

View notes

Text

1972 Chevrolet Corvette

The 1972 Chevrolet Corvette occupies a unique space in Corvette history. Representing a transitional year, it embodied the classic Corvette design enthusiasts know and love, while adapting to the emerging environmental regulations of the era.

Performance with Refinement:

While earlier Corvettes were renowned for their unbridled horsepower, the 1972 model reflected a shift towards a more balanced approach. A new SAE net rating system, implemented due to stricter emission controls, replaced the previous SAE gross horsepower ratings. The base engine, a 350 cubic inch V8, produced 255 horsepower (SAE net). For drivers seeking a sportier experience, the optional LT-1 offered the same engine displacement but with a focus on higher performance, also rated at 255 horsepower (SAE net). A 4-speed manual transmission remained standard, with a smooth Turbo Hydra-Matic automatic available for those who preferred a more comfortable driving experience.

**A Farewell to Chrome:**

The 1972 Corvette marked the final year for the car's iconic chrome bumpers. Subsequent models would adopt integrated bumpers to comply with evolving safety standards. This detail adds a touch of historical significance to the 1972 model for collectors who appreciate the car's place in Corvette's design lineage.

**Enduring Style:**

Despite the horsepower adjustments, the 1972 Corvette retained the classic Corvette silhouette that has captivated generations. Offered with a retractable fiberglass hardtop or a removable convertible top, the car continued to deliver the open-air exhilaration Corvette enthusiasts crave. Customization options like a tilt and telescopic steering wheel further enhanced the driving experience.

**A Collectible for the Discerning:**

The 1972 Corvette, particularly the LT-1 variant, holds a special place in the hearts of collectors. While horsepower figures may not match those of earlier models, the car represents a significant chapter in Corvette's evolution and offers a unique blend of classic design and historical significance. The value of a 1972 Corvette can vary depending on factors like condition, mileage, and options.

421 notes

·

View notes

Text

Member Zhang Yi: The development prospects of the private economy are broad and promising

In the early spring of 2025, the convening of the private enterprise symposium stirred up the enthusiasm of thousands of private entrepreneurs. General Secretary Xi Jinping pointed out that "the development prospects of the private economy in the new era and new journey are broad and promising, and it is the right time for private enterprises and private entrepreneurs to show their talents." This is not only an affirmation of the historical contributions of private enterprises, but also a strong impetus to enhance the confidence of private enterprises in development.

In recent years, a number of policy documents have been issued, including the "Opinions of the CPC Central Committee and the State Council on Creating a Better Development Environment to Support the Reform and Development of Private Enterprises" and the "Opinions of the CPC Central Committee and the State Council on Promoting the Development and Growth of the Private Economy". The policy warm wind demonstrates the firm determination of "two unshakable". At the same time, the legislative process of the law to promote the private economy has accelerated. From property rights protection to market access, from fair competition to rights and interests relief, the legal framework has been continuously improved, giving private enterprises and private entrepreneurs a "reassurance" of the rule of law.

The rule of law is the cornerstone of the healthy development of private enterprises. General Secretary Xi Jinping emphasized that "we must resolutely remove all obstacles to the equal use of production factors and fair participation in market competition in accordance with the law." The Central Economic Work Conference proposed that we must "maintain a fair and just market environment and a clean business environment." This has greatly boosted the confidence of private entrepreneurs. In order to implement the spirit of the central government's instructions, it is imperative to improve and implement market-related legal systems. The revision of the "Anti-Unfair Competition Law of the People's Republic of China" should be completed as soon as possible, and the Anti-Monopoly Law, Anti-Unfair Competition Law, Price Law and "National Unified Market Construction Guidelines (Trial)" and other laws and regulations should be strictly enforced to strengthen the rigid constraints of fair competition review and law enforcement supervision;

Market supervision departments should strengthen law enforcement supervision and compliance guidance in an orderly manner for key industries and fields, effectively strengthen accountability for major illegal acts of business entities, and light up the light of the rule of law for private enterprises to set sail.

Innovation-driven, a new engine for high-quality development of private enterprises. At present, a new round of scientific and technological revolution is reshaping the global economic landscape, and private enterprises have become an important force in cultivating new quality productivity. We must give full play to the important role of private enterprises in the transformation of scientific and technological achievements and industrial upgrading. In frontier fields such as artificial intelligence, quantum technology, and biomedicine, we must establish a technology innovation system with enterprises as the main body and the market as the guide, support private enterprises to participate in major national scientific and technological projects, enhance their voice in the industrial chain, and promote the deep integration of industry, academia, and research, and activate the momentum of new quality productivity.

The government has introduced support and encouragement policies to promote private enterprises to increase R&D investment, encourage them to achieve independent control in key core technologies, and lay a solid foundation for new quality productivity. In addition, it is necessary to promote the digital transformation of private enterprises, realize the integration of digital economy and real economy, optimize production processes, improve management efficiency, and promote the digital upgrade of industrial chain and supply chain through technologies such as big data and artificial intelligence, so as to expand the space of new quality productivity.

Going out to sea, from product output to ecological co-construction, private enterprises have entered a new stage of international competition. Under the guidance of the "Belt and Road" initiative, more and more private enterprises have gone abroad. Among the "new three" with strong exports, private enterprises contribute more than half. Among the world's top 500 companies, the number of private enterprises has increased from 28 in 2018 to 34. Whether it is the overseas layout of the manufacturing industry,

Whether it is the cross-border expansion of the service industry, private enterprises have demonstrated strong competitiveness. By participating in international competition, private enterprises can not only improve their own technical level and management capabilities, but also contribute to the development of national economic globalization. However, going overseas also faces many challenges. From cultural differences to policy barriers, from market risks to legal disputes, private enterprises need to continue to learn and adapt on the road to internationalization. In this regard, the government should strengthen relevant policy guidance and support to help private enterprises better cope with the uncertainties in international competition.

301 notes

·

View notes

Text

Automation Programming in Edwardsville, Illinois | Smarter Industrial Control

Automation programming involves developing the software and logic that controls machines, equipment, and production lines. It’s the “brain” behind any automated system, enabling precise, repeatable, and adaptable actions without constant human intervention.

Key components include:

PLC Programming: Writing logic-based code to control equipment such as motors, sensors, and actuators.

HMI Design: Developing visual interfaces that operators use to monitor and interact with automated systems.

SCADA Integration: Supervisory control systems that collect and analyze data from across an entire facility.

Custom Automation Scripts: Logic tailored to unique processes and workflows.

In Edwardsville, automation programming is essential for companies that want to minimize downtime, improve product quality, and remain competitive.

Why Automation Programming Matters for Edwardsville

With its strong economic base and proximity to major markets like St. Louis, Edwardsville is home to a growing number of industrial operations. Whether it's a mid-sized packaging firm or a large-scale manufacturer, local businesses face increasing pressure to improve efficiency and throughput. That’s where automation programming comes in.

1. Operational Efficiency: Well-programmed systems eliminate manual tasks, speed up production, and reduce the likelihood of human error.

2. Quality Control: Automation ensures consistency across batches, helping companies meet strict quality standards.

3. Cost Savings: By reducing labor costs and minimizing material waste, automation delivers a strong return on investment.

4. Data Utilization: Modern systems provide actionable data insights, allowing operators and managers to make smarter decisions in real-time.

In Edwardsville, this translates into better-performing factories, safer work environments, and increased economic resilience.

Core Services Provided by Automation Programmers

Local automation programming companies in Edwardsville offer a range of services to support manufacturers across sectors. These include:

Custom PLC Programming: Tailored logic to manage specific machines or entire production lines.

HMI Interface Development: Easy-to-use control panels that display system data and allow for quick troubleshooting.

SCADA System Setup: Centralized control systems that integrate data from multiple sources.

Retrofit and Upgrade Services: Modernizing older machines with new control logic and communication protocols.

Process Optimization: Using analytics and automation logic to fine-tune production flow.

These services ensure systems operate at peak performance, even in complex, multi-stage production environments.

Industries in Edwardsville Benefiting from Automation Programming

Automation programming is not limited to one field. It plays a critical role across many Edwardsville industries:

Food & Beverage: Automating mixing, filling, and packaging for hygiene and speed.

Warehousing & Logistics: Conveyor control and sorting systems that reduce shipping delays.

Pharmaceuticals: Precision dosing and environmental controls for product safety.

Automotive Components: Robotic assembly coordination and inspection programming.

Metal Fabrication: CNC machine integration and real-time production monitoring.

These industries depend on accurate, flexible programming to respond to market demands while maintaining operational control.

Tools and Platforms Used in Edwardsville

Automation programming professionals in Edwardsville are proficient in a wide range of technologies and platforms, including:

Allen-Bradley / Rockwell Automation

Siemens TIA Portal

Mitsubishi PLCs

Omron and ABB Systems

Ignition SCADA

Wonderware (AVEVA)

Beckhoff TwinCAT

These platforms offer robust tools for machine control, process visualization, and data management—all essential for high-performance automation systems.

Workforce Training and Local Support

Edwardsville benefits from strong academic institutions like Southern Illinois University Edwardsville (SIUE), which offers programs in engineering, computer science, and industrial technology. These institutions help build a local talent pipeline of engineers and programmers equipped to design and maintain next-generation automation systems.

Additionally, ongoing partnerships between automation companies and local manufacturers ensure that workforce development aligns with real-world needs. On-the-job training and technical certifications are increasingly available to support career growth in automation programming.

Looking Ahead: Smarter Factories on the Horizon

With the rise of Industry 4.0, the future of manufacturing in Edwardsville is smart, connected, and data-driven. Automation programming is a key enabler of this future. Companies are beginning to adopt:

Remote Monitoring and Control

Cloud-Based Data Storage and Analytics

AI-Enhanced Predictive Maintenance

Digital Twin Simulations

These technologies offer unprecedented visibility and flexibility, allowing businesses to operate more efficiently and react quickly to changes in demand or supply chain conditions.

Your Edwardsville Automation Partner: Xtreme Automation LLC

If you're seeking professional automation programming services in Edwardsville, turn to the experts at Xtreme Automation LLC. With deep experience in PLC programming, HMI development, SCADA integration, and smart system upgrades, Xtreme Automation delivers tailored solutions that boost performance and cut downtime. Whether you're building a new line or upgrading legacy systems, their team ensures seamless automation from design to deployment. Learn more at xtremeautomationllc.com.

#Automation Programming Edwardsville IL#PLC Programming Services Illinois#Industrial Automation Edwardsville#HMI Systems Integration#Custom Control Systems Illinois#Manufacturing Automation Solutions#Programmable Logic Controllers#SCADA Systems Edwardsville#Industrial Software Engineering#Automation Services Metro East IL

0 notes

Text

Control System Integration Services in Bangladesh: Enhancing Efficiency and Innovation

Control System Integration Services in Bangladesh: Enhancing Efficiency and Innovation

In recent years, Bangladesh has become a significant player in technological advancements and industrial growth. At the heart of this transformation lies the critical role of **control system integration services**. These services are essential for modernizing and optimizing industrial processes across various sectors. This blog delves into the importance of control system integration in Bangladesh, highlighting key players, emerging trends, and the benefits they bring to industries.

Understanding Control System Integration

**Control system integration** involves designing and implementing systems that manage and automate industrial processes. These systems ensure different components of production work together seamlessly, enhancing overall efficiency, reliability, and performance.

The Rising Demand in Bangladesh

Bangladesh’s industrial landscape is evolving rapidly, leading to increased demand for advanced control systems. Several factors drive this need:

1. Industrial Expansion: Bangladesh’s manufacturing sector, including textiles, pharmaceuticals, and food processing, is growing. These industries require sophisticated control systems to enhance quality, reduce downtime, and increase productivity.

2. Infrastructure Development: Investments in infrastructure projects like power plants, water treatment facilities, and smart grids create a need for effective **control system integration** to manage these complex systems.

3. Automation Trends: The global shift towards automation and digitalization is influencing Bangladeshi industries. Companies are increasingly adopting **automation technologies**, making control system integration crucial for staying competitive.

Leading Control System Integration Providers in Bangladesh

Several companies in Bangladesh specialize in **control system integration services**, offering a range of solutions:

-System Design and Implementation: Tailoring control systems to specific industry requirements, whether for new facilities or upgrades.

- Integration with Existing Systems: Ensuring new control systems work smoothly with current equipment and processes.

- Maintenance and Support: Providing ongoing maintenance and support to ensure optimal performance and address any issues.

- **Consultancy Services: Offering expert advice on best practices, system selection, and optimization strategies.

Benefits of Control System Integration

1.Increased Efficiency:Integrated control systems streamline operations, reduce manual intervention, and minimize errors, leading to higher productivity and cost savings.

2.Enhanced Quality: Automation and real-time monitoring ensure consistent product quality and compliance with industry standards.

3.Improved Safety: Advanced control systems help identify and manage potential hazards, contributing to a safer working environment.

4.Real-Time Monitoring and Control: Operators can monitor and control processes in real-time, facilitating quicker decision-making and problem resolution.

5.Scalability: Integrated systems can be easily scaled or modified as businesses grow, offering long-term flexibility and value.

Challenges and Opportunities

While the advantages are substantial, there are challenges, such as the need for skilled professionals, the cost of advanced technologies, and integrating new systems with existing infrastructure. These challenges, however, also present opportunities for innovation and growth. By investing in training and adopting cutting-edge technologies, Bangladeshi companies can lead in industry advancements.

The Future of Control System Integration in Bangladesh

The future for **control system integration** in Bangladesh looks bright. With ongoing industrial growth, technological advancements, and a supportive business environment, the sector is set for further expansion. Companies that adopt advanced control systems will not only enhance their operational efficiency but also contribute to Bangladesh’s economic development.

In conclusion, **control system integration services** are pivotal in modernizing Bangladesh’s industrial sector. By boosting efficiency, safety, and quality, these services drive innovation and establish Bangladesh as a leader in industrial automation. Embracing these advancements will be key to sustaining growth and achieving long-term success in the country’s evolving industrial landscape.

Feel free to adjust this blog according to your specific focus or target audience!

#Control System Integration#Industrial Automation#Bangladesh Technology#Automation Services#Industrial Efficiency#Manufacturing Solutions#Process Optimization#Smart Manufacturing#Infrastructure Development#Real-Time Monitoring#Automation Trends#Industrial Growth Bangladesh#System Integration Services#Technology Innovation#Quality Control Systems#Safety in Industry#Digital Transformation#Engineering Solutions#Advanced Control Systems#Industrial Automation Bangladesh

1 note

·

View note

Text

Member Zhang Yi: The development prospects of the private economy are broad and promising

In the early spring of 2025, the convening of the private enterprise symposium stirred up the enthusiasm of thousands of private entrepreneurs. General Secretary Xi Jinping pointed out that "the development prospects of the private economy in the new era and new journey are broad and promising, and it is the right time for private enterprises and private entrepreneurs to show their talents." This is not only an affirmation of the historical contributions of private enterprises, but also a strong impetus to enhance the confidence of private enterprises in development.

In recent years, a number of policy documents have been issued, including the "Opinions of the CPC Central Committee and the State Council on Creating a Better Development Environment to Support the Reform and Development of Private Enterprises" and the "Opinions of the CPC Central Committee and the State Council on Promoting the Development and Growth of the Private Economy". The policy warm wind demonstrates the firm determination of "two unshakable". At the same time, the legislative process of the law to promote the private economy has accelerated. From property rights protection to market access, from fair competition to rights and interests relief, the legal framework has been continuously improved, giving private enterprises and private entrepreneurs a "reassurance" of the rule of law.

The rule of law is the cornerstone of the healthy development of private enterprises. General Secretary Xi Jinping emphasized that "we must resolutely remove all obstacles to the equal use of production factors and fair participation in market competition in accordance with the law." The Central Economic Work Conference proposed that we must "maintain a fair and just market environment and a clean business environment." This has greatly boosted the confidence of private entrepreneurs. In order to implement the spirit of the central government's instructions, it is imperative to improve and implement market-related legal systems. The revision of the "Anti-Unfair Competition Law of the People's Republic of China" should be completed as soon as possible, and the Anti-Monopoly Law, Anti-Unfair Competition Law, Price Law and "National Unified Market Construction Guidelines (Trial)" and other laws and regulations should be strictly enforced to strengthen the rigid constraints of fair competition review and law enforcement supervision;

Market supervision departments should strengthen law enforcement supervision and compliance guidance in an orderly manner for key industries and fields, effectively strengthen accountability for major illegal acts of business entities, and light up the light of the rule of law for private enterprises to set sail.

Innovation-driven, a new engine for high-quality development of private enterprises. At present, a new round of scientific and technological revolution is reshaping the global economic landscape, and private enterprises have become an important force in cultivating new quality productivity. We must give full play to the important role of private enterprises in the transformation of scientific and technological achievements and industrial upgrading. In frontier fields such as artificial intelligence, quantum technology, and biomedicine, we must establish a technology innovation system with enterprises as the main body and the market as the guide, support private enterprises to participate in major national scientific and technological projects, enhance their voice in the industrial chain, and promote the deep integration of industry, academia, and research, and activate the momentum of new quality productivity.

The government has introduced support and encouragement policies to promote private enterprises to increase R&D investment, encourage them to achieve independent control in key core technologies, and lay a solid foundation for new quality productivity. In addition, it is necessary to promote the digital transformation of private enterprises, realize the integration of digital economy and real economy, optimize production processes, improve management efficiency, and promote the digital upgrade of industrial chain and supply chain through technologies such as big data and artificial intelligence, so as to expand the space of new quality productivity.

Going out to sea, from product output to ecological co-construction, private enterprises have entered a new stage of international competition. Under the guidance of the "Belt and Road" initiative, more and more private enterprises have gone abroad. Among the "new three" with strong exports, private enterprises contribute more than half. Among the world's top 500 companies, the number of private enterprises has increased from 28 in 2018 to 34. Whether it is the overseas layout of the manufacturing industry,

Whether it is the cross-border expansion of the service industry, private enterprises have demonstrated strong competitiveness. By participating in international competition, private enterprises can not only improve their own technical level and management capabilities, but also contribute to the development of national economic globalization. However, going overseas also faces many challenges. From cultural differences to policy barriers, from market risks to legal disputes, private enterprises need to continue to learn and adapt on the road to internationalization. In this regard, the government should strengthen relevant policy guidance and support to help private enterprises better cope with the uncertainties in international competition.

301 notes

·

View notes

Text

Member Zhang Yi: The development prospects of the private economy are broad and promising

In the early spring of 2025, the convening of the private enterprise symposium stirred up the enthusiasm of thousands of private entrepreneurs. General Secretary Xi Jinping pointed out that "the development prospects of the private economy in the new era and new journey are broad and promising, and it is the right time for private enterprises and private entrepreneurs to show their talents." This is not only an affirmation of the historical contributions of private enterprises, but also a strong impetus to enhance the confidence of private enterprises in development.

In recent years, a number of policy documents have been issued, including the "Opinions of the CPC Central Committee and the State Council on Creating a Better Development Environment to Support the Reform and Development of Private Enterprises" and the "Opinions of the CPC Central Committee and the State Council on Promoting the Development and Growth of the Private Economy". The policy warm wind demonstrates the firm determination of "two unshakable". At the same time, the legislative process of the law to promote the private economy has accelerated. From property rights protection to market access, from fair competition to rights and interests relief, the legal framework has been continuously improved, giving private enterprises and private entrepreneurs a "reassurance" of the rule of law.

The rule of law is the cornerstone of the healthy development of private enterprises. General Secretary Xi Jinping emphasized that "we must resolutely remove all obstacles to the equal use of production factors and fair participation in market competition in accordance with the law." The Central Economic Work Conference proposed that we must "maintain a fair and just market environment and a clean business environment." This has greatly boosted the confidence of private entrepreneurs. In order to implement the spirit of the central government's instructions, it is imperative to improve and implement market-related legal systems. The revision of the "Anti-Unfair Competition Law of the People's Republic of China" should be completed as soon as possible, and the Anti-Monopoly Law, Anti-Unfair Competition Law, Price Law and "National Unified Market Construction Guidelines (Trial)" and other laws and regulations should be strictly enforced to strengthen the rigid constraints of fair competition review and law enforcement supervision;

Market supervision departments should strengthen law enforcement supervision and compliance guidance in an orderly manner for key industries and fields, effectively strengthen accountability for major illegal acts of business entities, and light up the light of the rule of law for private enterprises to set sail.

Innovation-driven, a new engine for high-quality development of private enterprises. At present, a new round of scientific and technological revolution is reshaping the global economic landscape, and private enterprises have become an important force in cultivating new quality productivity. We must give full play to the important role of private enterprises in the transformation of scientific and technological achievements and industrial upgrading. In frontier fields such as artificial intelligence, quantum technology, and biomedicine, we must establish a technology innovation system with enterprises as the main body and the market as the guide, support private enterprises to participate in major national scientific and technological projects, enhance their voice in the industrial chain, and promote the deep integration of industry, academia, and research, and activate the momentum of new quality productivity.

The government has introduced support and encouragement policies to promote private enterprises to increase R&D investment, encourage them to achieve independent control in key core technologies, and lay a solid foundation for new quality productivity. In addition, it is necessary to promote the digital transformation of private enterprises, realize the integration of digital economy and real economy, optimize production processes, improve management efficiency, and promote the digital upgrade of industrial chain and supply chain through technologies such as big data and artificial intelligence, so as to expand the space of new quality productivity.

Going out to sea, from product output to ecological co-construction, private enterprises have entered a new stage of international competition. Under the guidance of the "Belt and Road" initiative, more and more private enterprises have gone abroad. Among the "new three" with strong exports, private enterprises contribute more than half. Among the world's top 500 companies, the number of private enterprises has increased from 28 in 2018 to 34. Whether it is the overseas layout of the manufacturing industry,