#diodes and assemblies

Explore tagged Tumblr posts

Text

Reliable High Voltage Diodes & Assemblies | HV Products, Germany

Experience the unmatched reliability with the high voltage diodes & assemblies engineered for excellence. The diodes and assemblies are rigorously tested to ensure exceptional reliability and performance in even the most demanding applications.

Get in touch with us today!

#high voltage products#hv products#high voltage#diodes and assemblies#diodes#assemblies#HV Products#Germany

0 notes

Text

https://www.futureelectronics.com/p/semiconductors--lighting-solutions--light-engine-led-assemblies--light-engines/ess015w-0350-42-erp-power-4119364

Optic light engine, Led light engine fiber optic, led light module, led voltage

100 - 277Vac, 14.7W, 350mA, 24-42V, [0-10V, TRI...], IP64 LED Driver

#ERP Power#ESS015W-0350-42#Lighting Solutions#LED Assemblies#Light Engines#optic light engine#fiber optic#module#led voltage#Light-Emitting Diode#Led headlights#led light#led lamp#led replacement bulbs#led diode circuit#led assemblies

1 note

·

View note

Text

Installation of an electronic data processing system by the Hydro-Electric Commission of Ontario, ca. 1955-1965. The unit being assembled consisted of 200 miles of wiring, 5,600 tubes, and 18,000 crystal diodes.

456 notes

·

View notes

Text

i can’t actually remember if all of the bow and arrow based minigames in oot and mm were all this difficult or if the fact that the joystick on this modern recreation n64 controller is like, ill suited for that. even the smallest stick movements feel like they translate to a huge first person movement. I’m not certain exactly how the control stick works in this modern one, but i assume its all potentiometers like most controllers are. Interestingly enough, it almost looks like it has a similar kind of mechanism to how the 3DS joystick looks, where its kind of on a linear slide.

Anyway, the old original N64 controllers used two encoder wheels and a laser (or probably just a small light) and a light sensing diode which would be intermittently shrouded by little interruptions on the decoder wheel which would give varying levels of current and a bunch of calculations happen which tell the controller where the joystick is, which is actually kinda great when compared to the current controller standard of graphite pads which are the typical point of failure and cause of stick drift, either from wear or dust (and dust from wear) causing the contacts to shit out.

At the bottom of the assembly there you can see the decoder wheels controlling the X and Y inputs, attached to a cradle assembly that the joystick is pushed through and locked into. Most everything that isn't contained in that bowl that the joystick sits in is shrouded, so there's not really a chance to even get small particulates into the decoder wheel. In fact the only reason n64 joysticks tend to fail is from them getting super loose around the little ball around the bottom

This part makes action with two little plastic nubs with the gate that also acts as the shroud which assists with centering the joystick and returning it to a neutral position with assistance from a spring assembly underneath the shroud.

The problem I had with my old controller is that it had been used so much that the little slits in the ball had all ballooned out from the use and friction over the years which meant it wasn't a tight fit anymore and made it so the stick would just kinda flop around instead of returning to neutral. The other problem they had (which mine also did) was that the bowl that was at the very bottom of the assembly was not lubricated, or at the very least, wasn't lubricated enough and evaporated over the years, leading to the bottom part of the joystick to scrape the bottom of the bowl and essentially sand it down.

This is almost all plastic from the inside of the bowl being scraped by the joystick (tho im sure its a little skin and whatever else too) and this would also cause a lot of problems, like the joystick sitting lower in the bowl than it was supposed to. That in combination with the centering pegs(?) not making tight action with the stick makes it wiggle around and essentially useless.

Aside from how like, stupid the solid plastic joystick was (my thumb has been getting sore after like a single solid hour or two of play), and the wear points being super obvious, i think the decoder wheel assembly is pretty cool and reminds me of how now we're getting people making control sticks with hall effect sensors which do not have a point of contact to measure input (as opposed to the gearing on the decoder wheels and joystick assembly themself, which theoretically is a wear point but is very uncommon)

331 notes

·

View notes

Note

Hello Mrs Reames! Quick question as someone that is still new to Alexander the Great, I was on TikTok the other day and someone posted a TikTok of an incident in which Alexander the Great supposedly dragged the oracle of Delphi out by her hair because she couldn't give him a prophecy that day, is this true?

Alexander and the Delphic Oracle

First, before answering, let’s do a quick PSA. I’m sure the asker meant to address me in the most polite way they knew how, and I’ve run into this error frequently with undergrads, who (at least in American public schools) are told to address a female teacher as “Ms.” or “Mrs.”

Thus, I offer this correction as gently as possible. But it’s important in an era when titles are being withheld from women as a means of belittlement—then, if a woman dares to object, they’re made fun of or called uppity and “sensitive.”* Again, I’m sure the asker here did not mean anything unkind (or they wouldn’t be asking me something in the first place!). So this is NOT a slap at them. But I’m not a Mrs. (I'm not married, and Reames is my birth name). I’m Dr. Reames or Professor Reames. You can even call me Jeanne (as long as you’re not a student in my class, ha). If you’re a (US) college student and unsure if your instructor has a PhD, “professor” is always safe. 😊

Now, to the question….

Plutarch tells a rather peculiar little story of new King Alexander, on his way home from a meeting of the Corinthian League (in Corinth), stopping at Delphi to ask the oracle a question. I should add, this event occurs right after Plutarch’s description of ATG’s meeting with the Cynic philosopher Diogenes. (E.g., it’s part of a “theme.”)

Now, the Delphic oracle wasn’t open for consults all the time. She only heard them a day or so a month…and that for only some months of the year. He came at the wrong time of year (winter, when Dionysos held the oracle, not his half-brother Apollo). So she told him, “No.” Reportedly, he stormed to her little house in the village of Delphi to manhandle her, intending to drag her to the oracle for his query. She replied, “Son! You’re invincible!” Pleased with that, he let her go.

And Plutarch presents this as if it’s all a-okay.

This is weird. It’s weird that Plutarch, a priest of Delphi from Chaironeia, wasn’t up in arms about this clear affront to an honored oracle (and an old woman). It’s an act of asebia (impiety). But it would be even weirder if Alexander had actually done it. Alexander, the uber-pious.

Plutarch is the ONLY one to tell this story. Anywhere.

Yet there’s a story remarkably like it with different players set during the Third Sacred War when the Phokians had seized the Oracle. It’s this event that set off the war, and which brought ol’ Philip into southern politics and eventually landed him a seat on the Amphictyonic Council as a staunch “Defender of Apollo.” Philomelos was the leader of the Phokians early in the war. Below are both accounts, starting with Diodoros’s (original source likely Kallisthenes, who wrote a history of the war).

With the oracle in Philomelus’ hands, he instructed the Pythia to continue prophesying from the tripod in the traditional way. When she refused, he threatened her and compelled her to mount the tripod. To this display of excessive force, she responded by declaring that he could do whatever he wanted—and he was pleased by this and declared that he had the oracle that suited him. He immediately had the oracle inscribed and set up for all to see, in order to make it clear that he had the god’s permission to do whatever he wanted, and he convened an assembly at which he boosted morale in the ranks by telling them about the prophecy (Diod. 16.27.1-2, Waterfield trans).

And now, wishing to consult the god concerning the expedition against Asia, [Alexander] went to Delphi; and since he chanced to come on one of the inauspicious days, when it is not lawful to deliver oracles, in the first place he sent a summons to the prophetess. And when she refused to perform her office and cited the law in her excuse, he went up himself and tried to drag her to temple, whereupon, as if overcome by his ardour, she said: “Thou art invincible, my son!” On hearing this, Alexander said he desired no further prophecy, but had from her the oracle which he wanted (Plut. Alex. 14.4, Perrin trans.)

With Philomelos, there is no question later in Diodoros that his act was impiety. His eventual death is (partly) attributed to it. Plutarch picks up this event, dusts it off, recasts the “inquirer,” and—moreover—uses it as affirmation of Alexander’s “invincibility.” Remember “The Invincible” was his nickname in Greece in his own day. The Romans called him Magnus (the Great).

In short, Plutarch retooled the story to suit his own purposes.

So no, it never happened. At least, not with Alexander. (And he’d have been horrified, I think, to hear he’d been accused of any such thing.)

Plutarch makes these detail changes when it suits him. I have an article coming out in a year or so where I discuss this tendency and bring the receipts (of quite a few examples)—including one I think a lot of folks here will find VERY interesting. But I’m not the only one saying it about this event in particular. It’s been noted as an “odd” episode before, including by Hamilton, if I recall (who did the commentary on Plutarch). But Lara O’Sullivan really showed where it came from, source-wise, in her “Callisthenes and Alexander the Invincible God,” P. Wheatley and E. Baynham, eds., East and West in the World Empire of Alexander: Essays in Honour of Brian Bosworth. Oxford: Oxford Univ. Press (2015), 35–52.

Some may still wonder why Alexander wouldn’t have gone to the oracle?

He didn’t need to. His father already had. And if later historians (such as Diodoros) reinterpreted her pronouncement to be about Philip’s murder, not the fall of Persia, it was a positive reply at the time. Going to Delphi again might risk something less flattering/hopeful. Not to mention, it was the wrong time of the year, and Alexander knew that. He had more important fish to fry. He wasn’t going to hang around, waiting (for months) for an auspicious day.

He was good with the oracle his father had got. After all, he’d been trumpeting for months that “only the name of the king had changed.” The original oracle would do just fine.

------------------------

*A BIG stink was made here in the US by the conservative media over Dr. Jill Biden being “Dr.” The initial "rebuke" stemmed from the fact her degree is “just” a doctor of education. When that faced pushback, however, conservatives on social media began to fuss, well, she wasn’t a MEDICAL doctor, so didn’t “deserve” that title. Which is silly. Doctor is the correct title for a medical doctor, as well as for a host of professional degrees, including a doctor of education, a doctor of theology, a doctor of business, etc. The degree that takes the longest to complete is the PhD, or doctor of philosophy. We’re ALL “doctors.” The problem for them was a professional woman who dared to use her title. Wasn’t she an uppity bitch?

#Alexander the Great#asks#Delphic Oracle#Alexander and Delphi#The Third Sacred War#Classics#Plutarch lies#Diodoros#Philomelos#ancient Greece#asebia#impiety in Greek religion#ancient Macedonia#tagamemnon

25 notes

·

View notes

Text

A wood veneer marquetry picture made for @sraksha from one of her drawings. (This picture is mirrored because I'm dumb and glued it with the wrong side facing up)

Cut with the Acmer P2 33W diode laser out of multiple different 0.6mm thick wood veneers. Most of the species used were in their natural state, but this also includes some through dyed and heat treated woods. (Red dyed birch and smoked oak for example)

Simplified process:

- Draw a new or turn an existing picture into a vector file

- Separate the picture into individual "puzzle" pieces, in the example below this was done in Lightburn.

- Different pieces are cut from the chosen woods with the laser, compensating the cut path settings if needed because even the color of wood changes how well it will be cut.

- The pieces are assembled and taped together into a sheet, which is then then glued on to a board (hopefully the right way around), in this case birch plywood.

- Glued piece is carefully sanded and finish applied.

So many pieces

28 notes

·

View notes

Text

How do BMW's new laser headlights work and what advantage do they have over other headlight technologies?

BMW's laser headlights represent a groundbreaking leap in automotive lighting technology, combining advanced physics with intelligent safety systems. Here's a detailed breakdown of their working principles and key advantages over traditional lighting technologies:

1. Core Technology & Working Principle BMW's Laserlight system does not directly project laser beams onto the road but uses lasers to generate intense white light through a multi-stage process:

Laser Activation: Three blue laser diodes (wavelength ~450nm) emit high-intensity beams.

Mirror Reflection: The laser beams are directed through a series of mirrors within the headlamp assembly.

Phosphor Conversion: The blue lasers strike a lens filled with yellow phosphorus, triggering a chemical reaction that converts the light into bright white light (5,500–6,000K color temperature).

Diffusion & Projection: The white light is diffused to reduce glare and projected via a reflector bowl, achieving a focused beam.

This method produces 10x brighter light than LEDs while maintaining safety for human eyes and animals.

2. Key Advantages Over Traditional Technologies Feature Laserlight LED/Other Tech Brightness 600m max range (vs. 300m for LED) Limited by lower lumen density Energy Efficiency 30% less energy than LEDs Higher power consumption Beam Precision Laser-guided adaptive focus Fixed or less dynamic patterns Component Size Diodes 1/100th LED size (10μm) Bulky heat sinks required Lifespan 50,000–100,000 hours 30,000–50,000 hours (LED)

3. Intelligent Safety & Adaptive Features

Anti-Dazzle Control: Infrared cameras detect oncoming traffic and automatically dim/redirect beams.

Dynamic Light Spot: Focuses on obstacles (e.g., pedestrians, animals) up to 300ft (92m) ahead.

GPS-Enabled Steering: Syncs with navigation to pre-illuminate turns.

Speed-Activated Logic: Only activates at >60 km/h to avoid urban glare.

4. Design & Sustainability Benefits

Compact Housing: Smaller components allow sleeker headlight designs (e.g., BMW i8's slim profile).

Heat Management: Minimal heat output reduces cooling demands vs. LED/Xenon.

Material Innovation: Uses 0.7mm hardened glass layers for 50% weight reduction.

5. Limitations & Future Outlook

High Cost: Currently limited to premium models (e.g., X7, 8 Series).

Regulatory Hurdles: Required 7+ years for U.S. road approval.

Emerging Competitors: Audi's DML matrix lights challenge with pixel-level control.

BMW continues refining this technology, with plans to expand it to motorcycles and mid-tier vehicles by 2026. While not replacing LEDs entirely, laserlights redefine nighttime driving safety and efficiency for high-performance applications.

#led lights#car lights#led car light#youtube#led auto light#led headlights#led light#led headlight bulbs#ledlighting#young artist#car culture#cars#race cars#classic cars#car#suv#vehicle#automobile#muscle car#car light#yellow headlights#headlamp#headlight#car lamp#lamp#laser headlights#other headlight#bmw#bmw cars#vintage car

4 notes

·

View notes

Text

who up orbiting they spheres. and also a soprano sectional

meant to practice violin in the hour between my seminar and soprano sectionals but instead found principal oboe on a bench and yapped for almost forty-five minutes, which was a slightly more diverting use of my time

popped downstairs, retrieved my choir folder, and returned to find the sopranos hovering around the same bench i had just been chatting with principal oboe on

we spent a few seconds complimenting each other's outfits before tita conductor left her office, found us, and led us to the same office her colleague had lent her last week in the manner of a pied piper

we passed through the copy room (vague memories rising to the surface within the pool of my mind... god how many pivotal moments have happened at that copy machine...) and i saw second trumpet at the table working on something. as i walked past i greeted him and he showed me his cheat sheet for a midterm copiously covered in tiny print. i stopped, leaned closer, and asked him what class it was for, to which he told me 'cell biology and neuroscience' to which i pretended to make an expression of horror and said 'oh, no. don't even ask me about it. ask me about diodes instead' before walking away

much to tita conductor's amusement at both of us

finally we crammed back into the tiny office, where we discovered that out of the six sopranos assembled, only two of us were soprano 1s on the new monteverdi piece

i strugglebused so hard trying to find something a fourth below a note to the point of embarrassment very early on but quickly figured it out and found my footing

when the only other soprano 1 had to leave to get to class i was left on my own against 4 soprano 2s but i managed to hold my own even without the piano. on my first reading of the notes. raaahhhh i'm not a fraud 💪🏻💪🏻💪🏻

once again i was tita conductor's timekeeper and when we wrapped up she turned to me and said "time for—?" and pretended to play an air violin, to which i said "i just need to switch out my folder, shall i get my violin?" and she was like "oh, no, actually, we could just talk it through" 😭😭😭 beloved then why the charades. in front of everyone at that

popped back downstairs, grabbed my folder, and resurfaced to meet tita conductor outside. we decided to continue stealing her colleague's office as he was still in the classroom we had initially planned on using, and so for the second time that afternoon, she sat before me on the piano bench as i took out my part of the modern piece

i pointed out the areas i had been struggling the most with at rehearsal the day prior, explaining that though i had written in cues and taken a stab at subdividing measures, i still wasn't 100% certain about what was going on

we floundered about a bit trying to find the best way to work on the more hairy rhythms together: clapping, counting out loud, me clapping while tita conductor was at the piano... but i think the breakthrough came when we remembered that, first and foremost, i am a pianist. so i settled down at the keyboard to play the rhythms while tita conductor counted and clapped just behind me

eventually this turned into tita conductor sitting next to me on the bench and us playing out the rhythms to each other and it was (and i don't say it lightly) one of the happiest moments of my working relationship with tita conductor so far.

i genuinely could not stop smiling the whole time. she was probably thinking "damn why is this kid so happy. they just fucked up two half-note triplets in succession" 😭 i just couldn't help myself. it was just the piano, the piece in front of us, and i got to play next to her.

i think the last time i was that happy about being on the piano bench with a teacher was probably ten years ago. which was when my parents pulled me out of lessons with my first piano teacher...

i also had a question about a brief section that went: 7/8 → 3/4 → 3/8 → 7/8 → 5/8 → 3/8 → 3/4 → 5/8 → 6/8 in rapid succession so she explained it, then wrote in the same slashes and triangles she had placed in her own score to show me where the groups of three eighth notes were

then i asked her "how are you going to conduct that?" and she stepped away from the piano and showed me, then paused and said "do you know the basic stroke for three?" and i showed her and she said "you could try conducting this part."

god in heaven i have never come so close to admitting my secret: that a large part of my ambitions from the age of seven to thirteen was that i wanted to be a conductor, and that i only tossed out that particular aspiration because i didn't think i was good enough at piano to do it.

i've never told her this because somewhere along the way my silly brain decided that doing so would make me look like i was trying to ingratiate her. which (1) she is virtually impossible to ingratiate. the things that bring a person into favor with her are competence, communication, and consistency. and (2) it's well-established she likes me already. a little too much, even

i know it's going to come out eventually, because i'm here as long as she'll have me, and she is someone i can be quite vulnerable around. but for some reason. i held my tongue today. i don't know why.

an aside about the lighting. this guy's office had the generic fluorescent lights, but he had forgone them in favor of a set of lamps that suffused the room with warm, albeit lower, light. this will be of importance in about two bullet points.

after about a half hour, tita conductor determined that the assistance i needed on the first half of the piece was pretty minimal, looked over at me as we sat inches apart on the piano bench, and said "you get this. your section doesn't. i will have to teach them, or perhaps deputize you"

i HAD to draw the line at that. i lack the technical language or pedagogical skills that a fucking DMA in orchestral conducting might have to teach compound rhythms.

i looked at her directly; up close, the lamp on the little table to my left illuminated the lines on her face and her big brown eyes staring at me as i begged "oh dr. [titaconductor], please don't deputize me," to which she burst into full laughter 😭😭

i was like "i can run a sectional. i cannot teach these rhythms. please i need you with me" 😭😭😭😭

which is so. god i couldn't make that moment up if i tried

we packed up and left the office (to which its occupant was about to return) and she hoisted up her huge fucking crate of music and made to open the door but i went ahead of her and (not checking my tone) was like "no no don't get the door. Don't get the door. i will get the door" and she sort of giggled and said "okay, okay," in a relenting tone and let me open the door for her

she still got the door out of the copy room. i was not quick enough for that

we headed back in the direction of her office in companionable silence, punctuated only by tita conductor's chuckling as i scampered around her to switch our positions so she was to my left

ever since ate dean told me... well, what she did... a few weeks ago, i've been trying to be more vocal about my gratitude for tita conductor

i've hoped it would have shown through me being The Way I Am with her. like purposefully hanging around after rehearsals to ask if she needs help carrying things or organizing things. being her timekeeper. letting her use my parts and scores for copying or what have you. or just letting her talk at me about what's frustrating her. but i also am very cognizant that actual words are very useful in conveying that as well

so as we were walking back (and still riding on the high of the most pleasant experience at a piano i had had in at least six years) i burst out, "i'm so glad i stayed."

she looked a little taken aback at this pronouncement but said "ah, well, it's good for you that this is a place where you can continue your career and keep pursuing music."

she hadn't got the point. i panicked and before i could think too hard about it i said "i'm glad i can keep learning from you."

to this she stopped in her tracks and said, "oh!..." before recovering herself and saying "though i'm sure wherever you'd gone you could have found someone to learn from."

reader. i never wanted to bang my head against the wall more than i did then 😭😭

like you silly woman. silliest faculty member in the department of music. can't you see that you matter. To Me. you are important. To Me. don't you get that I Care For You.

(do i consistently believe myself replaceable and expendable? well. yeah. but that's another can of worms entirely.)

i sensed that pressing the point wouldn't do much (and she was also finding her office key on her keyring) so i thanked her again, bid her farewell, and headed downstairs to replace my folder in my locker and head home

the sitcom of my life never ends. although we all knew that by now.

3 notes

·

View notes

Text

I understand why factorio does the cheap machine/expensive upgrade thing from a gameplay and performance standpoint, but am I the only one who thinks it feels really off that maybe 3% of lategame expansion costs is heavy machinery and 97% is little upgrade chips that you insert into the machines.

For those unfamiliar with the game when I say expensive I don't mean dollars I mean physical metal ingots. Your most advanced crafting machine takes about 300 ore to make and has 4 module slots. The most advanced modules are in the neighborhood of 3,500 ore each. This is the reason in The Bad Mod Of Bad the highest level of assemblers costed in the neighborhood of 12,000 ores.

You actually can't correct this discrepancy with mods though, because people are used to it and will complain if you make machines cost only 1/5 of a module. Even though it makes speed modules entirely useless before you get access to beacons, because it's cheaper in both power and materials to just add more machines than to speed up the ones you have!

With the vanilla selection of ingredients it's also very noticeable that all the crafting complexity comes from electronics whereas mechanical parts stay simple and generic for the most part, and this is quite strange to me: electronics are generic and programmable, and mechanisms are bespoke. And every mod that adds crafting complexity maintains this pattern.

Like the atom pack turns circuit production into this mess of resistors and capacitors and diodes and shit (which is fine to do, to be clear, just that it is adding more complexity to the only part of the vanilla crafting tree with more than nominal complexity), and when people complain about fiddly overspecific intermediates it's because planetfall had the temerity to notice that gears are not linkages are not valves.

6 notes

·

View notes

Text

Accelerating sustainable semiconductors with 'multielement ink'

Semiconductors are the heart of almost every electronic device. Without semiconductors, our computers would not be able to process and retain data; and LED (light-emitting diode) lightbulbs would lose their ability to shine. But semiconductor manufacturing requires a lot of energy. Forming semiconductor materials from sand (silicon oxide) consumes a significant amount of heat-intensive energy, at scorching temperatures of around 2,700 degrees Fahrenheit. And the process of purifying and assembling all the raw materials that go into making a semiconductor can take weeks if not months. A new semiconducting material called "multielement ink" could make that process significantly less heat-intensive and more sustainable. Developed by researchers from Lawrence Berkeley National Laboratory (Berkeley Lab) and UC Berkeley, "multielement ink" is the first "high-entropy" semiconductor that can be processed at low-temperature or room temperature. The breakthrough was recently reported in the journal Nature.

Read more.

9 notes

·

View notes

Text

Working on Sophias Story again :D

-> A little later, Sophia reached maintenance shaft [xy], where the main security system of the SD of the Abyss Chrusher was located. The light activated by a motion sensor flared up in cold white with a delay of a few seconds. Neon Xilkor tubes of the NX-6 series had this somewhat unpleasant habit, which the manufacturer Asterisk never rectified. Despite this, Hallinger-FTL continued to install them in all maintenance rooms of their ship series to this day. The Davar class in particular suffered from this fact, as it had a higher number of such areas due to its modular design. As a result, Sophia had only been able to recognise the large control cabinets and component racks by the myriad of flashing LEDs when she arrived. This sea of red, orange and green diodes, which greeted her auspiciously from the steel racks, secretly watched over the entire crew and ensured that the safety units of the individual SERAHs were working.

Now that the white light flooded the room, she saw it in its entirety, and with it the technology inside. In contrast to the blinking confusion of the Sevix control racks on the right side of the room, the Servagul control cabinets on her left, unusual for a Davar-class ship, emitted a soft green glow. The reason for this was that Servagul built light panels into the doors of their products, which no self-respecting shipbuilder needed. Such nice lighting did nothing but waste power unnecessarily. Sure, ships like the Abyss Chrusher might not lack power, but that was no reason to be so wasteful.

Shrugging her shoulders, the engineer lifted her tool and the testing device before taking them to the control cabinet labelled SUR-2, where she set them down. She unlocked the door with her CAM and the handle whirred out, allowing her to open the cabinet. Sophia sighed, pulled open the cupboard door and, coloured by the light from the front panel, saw another flood of flashing or glowing diodes emanating from the security register cards. It was a sight that filled the engineer with joy, because she had hardly been able to wait to get back into the bowels of the Abyss Chrusher, but the work that was to follow was rather dull. So she plugged her headphones into her CAM, put them in her ears and switched on an album by a band Liv had shown her a few days ago. A harsh guitar riff accompanied by the vocals of a woman singing in the language of the Marlan system rang out.

She then began checking the security tabs, which initially consisted of informing the SD-SERAH of her work via the control panel in the top frame of the device. In fact, Sophia was only slightly keen on an emergency lockout of the SD, even if she could override it with her system authorisations. Basically, you had to give Servagul and Sevix credit for the cleverness of their products. After all, the automatic security system, which according to Ela - unfortunately there were no plans on this subject - summarised one subsystem of the drive per cabinet in order to pass them on to SERAH in a bundle.

You could imagine the tabs and their subsystems as the nervous system of a body, which transmitted every pain of the machines to the consciousness or to an AI. SERAH then reported the information to the Abyss Chrusher's SAM, the ship's main AI, which ensured that appropriate action was taken. What the SERAH was to the SD, the SAM was to the entire ship.

Sophia pulled a small screwdriver from the side pocket on her left arm. She used it to loosen the two neck screws on the top and bottom of the front panel of each of the seven assemblies. She was then able to pull them out by the handle to insert them into the test device. This established a serial, wired connection with the fuse register in order to then interrogate the main function of the unit on the two circuit boards of the modules. For this purpose, the test device simulated a fault by sending a specific signal sequence via the bus interface. The module processed this within a few femtoseconds and signalled an alarm back to the test device. At least that's how it worked when everything was OK. The process only took a few blinks of the eye until the technical measurement results - such as resistance, time and induction values - appeared on the display of the test device. Confirmation of the success or failure of the analysis could then also be obtained.<-

The story of the empty sky - 1 Dreams of electronic tears Chapter 10, A fairy tale of normality

#writing#booklr#books#books and reading#books and literature#writerscorner#author#books & libraries#writers on tumblr#science fiction#science fantasy#spaceship

2 notes

·

View notes

Text

Understanding the Functionality of Samsung Refrigerator PCB Main Assembly

Samsung refrigerators have become essential appliances in modern households, offering innovative features and advanced technologies to ensure food preservation and convenience. The (Printed Circuit Board) PCB Main Assembly serves as the brain of the refrigerator, coordinating various functions and ensuring optimal performance.

Components of the Refrigerator PCB Main Assembly

The Refrigerator PCB Main Assembly consists of several essential components, each playing a crucial role in the refrigerator's operation.

Microcontroller: It is the central processing unit (CPU) and the computer performs programmed instructions to coordinate communication between the components.

Sensors: The ambient parameters (temperature, humidity, door status) supply critical information for regulation.

Relays: You control the flow of electricity to the compressor, fan motors, and defrost heater.

Capacitors: It will help you store the electrical energy and help to regulate voltage, and guarantee that the PCB is operating reliably.

Resistors: Protect sensitive components from harm by limiting the flow of electricity across certain circuits.

Diodes: Allow current to flow exclusively in one direction to avoid reverse polarity and safeguard components from damage.

Connectors: Facilitate electrical connections between the PCB and other refrigerator components to ensure seamless integration.

Working Principle PCB Main Assembly

The PCB Main Assembly operates on a set of programmed instructions that determine its behavior depending on sensor input and user command. The micro controller continuously monitors sensor input such as the reading of the temperature from the refrigerator compartment, and freezer. The microcontroller controls the transition of the compressor on, or off or the speed of the fan and also the defrost cycles based on the sensor data as to how to keep the temperature and humidity at the optimal level. In addition to the other refrigerator components, for example, display panel and user interface, the PCB Main Assembly provides feedback and enables users’’ interaction. The PCB Main Assembly incorporates safety features of overload protection and temperature sensors to protect the refrigerator from damage and to protect the user.

Communication Protocols

Data can be communicated to other components through microcontrollers by communication protocols like UART (Universal Asynchronous Receiver Transmitter), SPI (Serial Peripheral Interface), and I2C (Inter Integrated Circuit).

UART is used to transfer real-time data from a microcontroller to external devices like display panels and temperature sensors.

There is a power of communication SPI and I2C for the communication of integrated circuits associated with the PCB Main Assembly for efficient data transfer and synchronization between components.

Troubleshooting and Maintenance

Common issues with the Samsung Refrigerator PCB Main Assembly include sensor failures, relay malfunctions, and power supply issues, which can affect the refrigerator's performance.

To solve PCB Main Assembly problems, we can use diagnostic methods, like running self-tests and checking the error code.

The assembly can stay longer depending on the main, such as cleaning dust and debris from the PCB and securing appropriate ventilation.

The PCB Main Assembly is an important component of the Samsung refrigerator systems since it organizes several functions to contribute to the overall efficiency of the refrigerator and food preservation. Fore-knowledge of the PCB Main Assembly and the way it is constructed can assist users in likely managing problems in their fridges.

2 notes

·

View notes

Text

IT Lasers Inc. AIM-1/DLR Aiming Designator

In most of the post-1993 photos of Delta using the AIM-1 series lasers on the Model 723 Carbine, the DLR model seems to be the most common over the original AIM-1/D.

The DLR can be identified by the extended guard protruding from the diode window (however, some of the early DLR models had the same flat glass diode window as the original AIM-1/D model.) This feature allows it to mount an accessory lens cap or a special blue diffuser cap with a variable density aperture (both of which are sadly missing with my example).

The unit I received also came with a PVS-4 rail grabber mount, which with some examples, were machined with a wider countersink and a custom slot to fit the laser in place of the typical carry handle/bracket adapter block.

Admittedly, my unit is in much poorer aesthetic condition than my AIM-1/D, but both work equally the same, and really I was just after the proper remote cable that the DLR kit came with.

My unit was assembled August 1995 and inspected on Christmas of the following year.

^AIM-1/D vs AIM-1/DLR

#delta force#oldschool gear#vintage tactical#car15#gangster grip#aim1d laser#ir laser#colt ar15#colt 723#carry handle

6 notes

·

View notes

Text

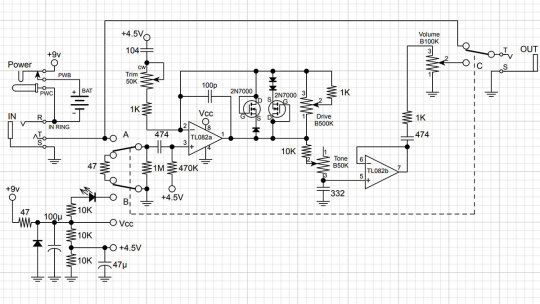

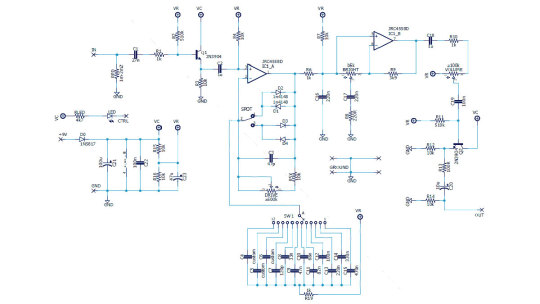

DIY Dumble-like sounding MOSFET Overdrive

The Hermida Zendrive guitar pedal we will study, assemble and listen to today is a true masterpiece. Many say its sound is close to the Holy Grail of guitar amplification - Dumble Overdrive Special.

Other people are more pessimistic in their judgments. Still, the precise response to the picking dynamics, the Voicing tuning options, and the sheer beauty of this overdrive's sound are simply impossible not to love.

But before we study the Lovepedal Zendrive or its copy of the Landtone Phoenix song, or the Aion effects Azimuth dynamic overdrive, we'll study the evolution of the MOSFET overdrives that finally resulted in the development of this gem.

Fulltone OCD

Mike Fuller was one of the first to start using MOSFETs instead of diodes to limit the amplified guitar signal in 2004.

His Obsessive-Compulsive Drive overdrive-distortion pedal is built on a standard circuit with one dual op amp. The first operational amplifier, X1, amplifies the amplitude of the guitar signal by a factor from 8 to 463 times, depending on the position of the drive control X3. This is a 1-megohm potentiometer.

Further, through resistor R9, the signal is fed to the limiter, which comprises 2N7000 MOSFETs M1 and M2 connected in parallel. A germanium diode D1 - 1N34A is additionally included in series with M2, which makes the limiter asymmetrical and, therefore, makes more interesting sound.

A limiter in overdrives is usually included in the negative feedback circuit of an operational amplifier (i.e., in parallel with C6). Such a limiter is called a soft limiter.

And here, a hard limitation is applied: clipping sections are included between the preamplifier output of the gain section and the virtual ground - half of the supply voltage Vref, formed by resistors R4 and R7.

Virtual ground is used in the unipolar powering of operational amplifiers to amplify analog signals, such as audio signals. The guitar signal does not change from zero to plus but from minus to plus, passing through zero.

To prevent the signal from being limited to the circuit's ground, it is shifted in the plus direction by half the supply voltage.

Such hard limiting is typical for distortion pedals. But by using MOSFETs instead of diodes or LEDs, the top of the signal is not cut hard but softly rounded. Therefore, OCD can work as both distortion and overdrive.

Due to the smoothed peaks of the limited signal, the sound is highly dependent on the sound's attack dynamics. For rock and especially blues, this is very valuable. With modern metal pickups that compress the dynamic range of the signal, it can help make solos sounding more sweet.

The second operational amplifier X3 amplifies the limited signal by a factor of 3.8, correcting its timbre. Capacitors C6 and C9 prevent the self-excitation of operational amplifiers at high frequencies.

Next is a simple passive tone knob, which implies a treble leak circuit. Potentiometer X4 10 kilohms and capacitor C11 47 nanofarads are connected in the same way as on the pickguard of any electric guitar.

The Switch1 switch changes the circuit's output impedance as if the high-impedance and low-impedance pickups were switched. When it's open, you get a transparent overdrive like the Klon Centaur, and when it's closed, you can get a more aggressive sound like the Marshall Plexi.

Hermida Audio Zendrive

The Zendrive pedal's authors, Hermida audio technology (now produced by LOVEPEDAL LLC), have undoubtedly studied the Fulltone OCD thoroughly. Let's find the differences between the two circuits.

First, the limiter is included in the operational amplifier feedback, that is, between the output and the inverting input, not between the output and virtual ground. That is, here we have a soft limiter.

Secondly, one diode is added in series with each MOSFET. Clipping remains asymmetric: we have one diode in the left arm of the limiter and two diodes in the right arm.

Third, the second operational amplifier is used as a voltage repeater, aka buffer: the output is directly connected to the inverting input.

Fourth, the tone control is implemented a little differently: two OCD`s switchable resistors are replaced by a potentiometer.

And finally, the most critical, fifth difference. A potentiometer is included in the tone correction circuit between the inverting input of the first operational amplifier and the artificial midpoint.

This fourth knob, Voicing, or Character, allows you to smoothly adjust the lower frequencies in the overdrive structure over a wide range, similar to the Resonance control on many tube guitar amps.

The potentiometer is signed as a trimmer in the diagram because some pedal makers don't want to install a fourth knob on the pedal`s body. This is what Landtone did when developing the Phoenix Song Overdrive DIY kit.

The developer suggests installing the trimmer on the PCB, and to access it, you need to disassemble the pedal by unscrewing the footswitch nut and taking out the PCB.

But I will not be lazy to drill an extra hole in the pedal body and install a potentiometer with a knob, connected to PCB by wires instead of the trimmer. Because I consider this regulator simply invaluable and irreplaceable.

Before we get to assembly and testing, let's look at another pedal with a similar adjustment. However, it is based not on the Fulltone OCD but on the Ibanez Tube Screamer.

The Precision Drive

This is a signature pedal by Misha Mansour of Periphery, manufactured by Horizon Devices. Compared to the original Overdrive Pro TS808, the circuit adds a noise suppressor, which we will not consider, and an exciting ATTACK switch.

The Precision Drive scheme was studied and partially replicated by PedalPCB and PCB Guitar Mania. They are manufacturers of DIY kits for guitarists. Their products are called Dwarven Hammer and Collision Drive, respectively. A noise gate is not provided there, but the attack switch is implemented. This is the main difference between Precision Drive and many other overdrive pedals.

In the Fulltone OCD schematic, we saw a resistor switch at the tone shaping circuit in the output section. The Zendrive has a variable resistor in the preamp's RC circuit which is controlling the overdrive structure.

Precision Drive has a constant resistor in the same place, between the inverting input of the overdrive section operational amplifier and the virtual ground, but the capacitors are switched.

This is the same thing: we change the time constant of the RC circuit, which adjusts the audio signal's frequency spectrum. At the same time as the time constant, the complex impedance changes, thus the gain.

A resistor is a resistance to both DC and AC current. At the same time, a capacitor is only resistant to AC current because DC current does not flow through a capacitor. Since DC current does not flow through our RC circuit, there is no difference between adjusting the resistance and switching the capacitance.

But the active/reactive ratio affects the circuit's Quality factor, i.e., its resonance. It's no coincidence that the knob on guitar amplifiers, which adjusts the same frequencies as our potentiometer or switch, is often called RESONANCE. And it is used to adjust to the resonance of the electromechanical system - the loudspeakers in the cabinet, along with the masses of air in and around it.

The reactive impedance accumulates energy and gives it away, except for losses due to dielectric recharging and magnetizing the magnetic core in inductors. This is why coreless inductors are often used in high-end equipment, so-called air inductors. They weigh a lot, take up a lot of space, and are expensive because copper is more expensive than steel. But these are the laws of physics on which technology is based.

Unlike reactive impedance, active resistance converts electrical energy into heat, thus reducing the Q-factor. In some cases, it is necessary and useful. In others, it is harmful. Or it simply creates a unique sound character.

That's why switching capacitors and turning the potentiometer knob in the feedback circuit of an audio frequency amplifier is almost the same thing, but not quite. And it's great that there are such different variants of guitar overdrive pedals!

Landtone Phoenix Song Overdrive

Now you can hear how my Zendrive from the Landtone OD-1 kit sounds, with a Seymour-Duncan SH4 humbucker on a Gibson MM Explorer guitar, into an Orange MT20 with a Torpedo Captor X. And see how I assembled the pedal and also a kitten walking around the table and prancing around.

youtube

I liked the pedal, especially its fourth magic Voicing knob, which does things to the sound that other tone controls can't. I also liked the bird on the body. Because I love birds. And in the music world, the decoration of instruments and hardware plays no small role because it inspires creativity. And the fact that the pedal is assembled by my hands also warms my soul and creates inspiration.

3 notes

·

View notes

Text

Latest Technologies Used by LED Video Wall Manufacturers for Immersive Experience

In an era where visual communication is critical, LED video walls are becoming the backbone of immersive digital experiences. From stadiums and concerts to shopping malls and corporate command centers, these massive, high-resolution displays are redefining audience engagement. At the heart of this transformation are LED Video Wall Manufacturers, who are continuously pushing technological boundaries to deliver sharper images, smoother transitions, and more dynamic storytelling.

Thanks to rapid advancements in LED technology, today's video walls are not just big—they're intelligent, flexible, and deeply immersive. These innovations often involve collaboration with Indoor LED Manufacturers, Outdoor LED Manufacturers, Transparent LED Display Manufacturers, and Advertising LED Display Screen Manufacturers, who collectively shape the future of visual communication.

In this blog, we’ll explore the latest technologies adopted by LED Video Wall Manufacturers and understand how they’re enhancing the immersive experience across industries.

Fine Pixel Pitch Technology

Pixel pitch refers to the distance between individual LED pixels. The smaller the pitch, the higher the pixel density and image clarity. One of the most significant advancements in LED video walls is the use of fine pixel pitch (typically less than 2mm), which allows for:

Ultra-high-definition content, even at close viewing distances

Smooth visuals without pixelation

Seamless integration into small and medium-sized indoor spaces

Indoor LED Manufacturers have been instrumental in adopting this technology for applications such as control rooms, conference halls, broadcast studios, and luxury retail.

Micro-LED and Mini-LED Integration

Micro-LED and Mini-LED represent the next generation of LED technology. These smaller diodes deliver greater brightness, improved contrast ratios, and lower power consumption.

Benefits include:

Deeper blacks and vibrant colors

Improved energy efficiency

Longer display lifespan

Flexible configurations for curved and non-traditional surfaces

LED Video Wall Manufacturers integrating Micro-LED technology are setting new standards for visual quality. This also creates synergy with Transparent LED Display Manufacturers for hybrid display applications where clarity and transparency are equally important.

HDR (High Dynamic Range) Support

HDR technology, initially popularized in TVs and cinema, has made its way into LED video walls. By supporting a wider range of color and contrast, HDR-enabled video walls allow:

More lifelike and detailed visuals

Enhanced depth perception

Improved readability in bright or dim lighting

These capabilities are especially valuable in command centers, live events, and immersive museums where every visual detail counts. Advertising LED Display Screen Manufacturers also utilize HDR in outdoor branding to deliver dramatic, eye-catching displays even under sunlight.

Seamless Modular Design

One of the strongest suits of LED video walls is modularity. Modern systems are made of interlocking panels that can be assembled in virtually any shape or size.

Technological improvements include:

Bezel-less displays for uninterrupted visuals

Magnetically attached panels for easy maintenance

Hot-swappable modules that reduce downtime

Lightweight aluminum frames for mobile or suspended installations

This modularity supports large-scale deployments by Outdoor LED Manufacturers in stadiums and city centers, as well as by Indoor LED Manufacturers in auditoriums, exhibition halls, and airports.

5. AI-Powered Content Optimization

AI has introduced automation and intelligence into LED display systems. With the help of AI-based processors, LED video wall systems now include:

Real-time content optimization based on ambient light, audience movement, and sound

Automatic calibration of color and brightness

Predictive maintenance alerts for fault detection

Audience tracking for interactive storytelling

AI integration is not just about display—it’s about personalization. Advertising LED Display Screen Manufacturers are now using AI to deliver dynamic, targeted ads based on audience demographics and behaviors.

Interactive Touch and Gesture Control

Interactivity is key to immersive engagement. LED Video Wall Manufacturers are now integrating touchscreen capabilities, gesture recognition, and even motion sensors into large-format displays.

Applications include:

Wayfinding kiosks

Retail store product demos

Museum and gallery exhibits

Gaming and virtual simulation zones

These advancements are often developed in collaboration with Indoor LED Manufacturers, especially for indoor settings where tactile and responsive interfaces are critical to the user experience.

Curved and Flexible LED Panels

Modern architecture demands more than just flat screens. Flexible and curved LED panels are among the latest breakthroughs by LED Video Wall Manufacturers, enabling:

360-degree viewing experiences

Spherical and wrap-around video walls

Integration into pillars, domes, and corners

Architectural harmony with creative layouts

These dynamic formats are increasingly used in event spaces, flagship retail stores, and immersive exhibitions. Transparent LED Display Manufacturers are also contributing with bendable transparent modules for cylindrical glass structures.

Transparent Video Walls

Another exciting innovation is the use of transparent LED panels in video walls. These are especially impactful when installed on glass walls or display windows.

Benefits include:

Unobstructed views and natural light

Dual-purpose design (display and transparency)

Futuristic aesthetics

Suitable for retail, airports, and hospitality venues

Transparent LED Display Manufacturers lead this niche but often partner with video wall experts for integration into larger display systems—combining transparency with interactive or high-resolution storytelling.

Smart Control Systems and Remote Management

Modern LED video wall solutions come with smart control systems that allow users to operate, schedule, and monitor content remotely from a centralized platform. This includes:

Cloud-based CMS platforms

Multi-screen synchronization

Real-time diagnostics and alerts

Secure remote content uploads

This technology is vital for both Indoor LED Manufacturers managing enterprise-grade video walls and Outdoor LED Manufacturers monitoring digital billboards and public signage across multiple locations.

Advanced Cooling and Energy Efficiency

Heat is a major issue in high-brightness displays. LED Video Wall Manufacturers are now using:

Active and passive cooling systems

Low-voltage operation

Auto-brightness adjusters

Eco-mode scheduling

These features reduce energy consumption while extending component lifespan. When aligned with green building initiatives, these video walls support LEED certifications and sustainability goals—a trend also championed by Advertising LED Display Screen Manufacturers and Outdoor LED Manufacturers in urban deployments.

High Refresh Rates and Low Latency

In fast-paced environments like gaming zones, live sports venues, or digital command centers, high refresh rates and ultra-low latency are crucial.

Modern LED video walls now support:

Refresh rates of 3840Hz and above

Latency below 2ms

Flicker-free performance during live streaming

Smooth playback for real-time data dashboards

These advancements allow real-time decision-making, seamless livestreams, and ultra-smooth content transitions—enhancing the immersive experience across use cases.

AR and VR Integration Capabilities

Some cutting-edge video wall systems are now being integrated with augmented reality (AR) and virtual reality (VR) technologies, offering:

Immersive hybrid reality environments

Live interaction with virtual avatars

AR-powered retail displays

Virtual simulations for training and entertainment

These solutions require collaboration across multiple tech segments, including Indoor LED Manufacturers for interior deployments and Advertising LED Display Screen Manufacturers for branded AR experiences.

Real-World Applications of Immersive LED Video Walls

Let’s look at a few real-world settings where these technologies come to life:

Corporate Control Rooms Fine pitch and AI-powered systems enable clear, uninterrupted data visualization for real-time monitoring and decision-making.

Retail Flagship Stores Transparent video walls and interactive touch features blend digital branding with product showcases.

Public Venues and Stadiums Curved LED walls and high refresh rates support immersive viewing for thousands of spectators.

Airports and Transportation Hubs Seamless video walls with smart controls help guide, inform, and engage passengers in high-traffic zones.

Conclusion

LED video walls are no longer just about size—they're about intelligence, flexibility, interactivity, and visual impact. The latest technologies adopted by LED Video Wall Manufacturers are transforming these displays into immersive platforms that drive engagement, storytelling, and brand connection.

By collaborating with Indoor LED Manufacturers, Outdoor LED Manufacturers, Transparent LED Display Manufacturers, and Advertising LED Display Screen Manufacturers, the industry is creating end-to-end visual ecosystems that span across environments and industries.

As expectations rise and digital transformation continues, these technological innovations will ensure that LED video walls remain not only relevant—but revolutionary.

#Indoor LED Manufacturers#Outdoor LED Manufacturers#Transparent LED Display Manufacturers#LED Video Wall Manufacturers#Advertising LED Display Screen Manufacturers

0 notes

Text

Heat Resistant LED Lights Market Scope: Innovations Powering Industrial Lighting Evolution

The demand for advanced lighting technologies has grown significantly across multiple industries, with heat resistant LED lights emerging as a vital innovation. These lights are specifically engineered to withstand extreme temperatures and challenging environments without compromising performance or longevity. As industries continue to push the boundaries of where lighting is needed—from high-temperature manufacturing plants to heavy-duty automotive systems—the market for heat resistant LED lights is poised for considerable growth.

Understanding Heat Resistant LED Lights

Heat resistant LED lights are a specialized category of light-emitting diodes designed with materials and technologies that can endure elevated operating temperatures. While standard LEDs may degrade or fail when exposed to continuous high heat, heat-resistant variants are built using enhanced thermal management systems, heat sinks, and resilient encapsulation materials that ensure optimal performance even in environments exceeding 100°C (212°F).

These lights provide high brightness, energy efficiency, and long operational life, making them ideal for use in industrial furnaces, foundries, chemical plants, mining operations, and high-performance automotive and aerospace systems.

Market Scope and Growth Drivers

The global heat resistant LED lights market is expected to grow steadily in the coming years, driven by several key factors:

1. Expanding Industrial Applications

Industries such as metallurgy, oil and gas, glass manufacturing, and automotive assembly involve high-temperature processes where conventional lighting solutions fail. Heat resistant LEDs offer reliable illumination for inspection, monitoring, and safety operations in these environments, reducing downtime and maintenance costs.

2. Advancements in LED Technology

Continuous improvements in LED materials, chip design, and thermal dissipation technology are widening the application scope for high-temperature LEDs. Innovations such as ceramic-based substrates, improved phosphor coatings, and advanced cooling systems are enabling LEDs to operate at higher junction temperatures without degradation.

3. Energy Efficiency and Sustainability

Compared to traditional high-intensity discharge (HID) or halogen lighting, LEDs consume significantly less energy and produce less heat. In high-temperature industries where cooling costs are substantial, using energy-efficient heat-resistant LEDs not only reduces electricity bills but also lowers the overall thermal load on facilities, contributing to sustainable operations.

4. Safety and Reliability

High-temperature environments can be hazardous, and reliable lighting plays a crucial role in ensuring worker safety. Heat resistant LED lights offer robust, flicker-free illumination with a longer lifespan, reducing the need for frequent replacements and minimizing exposure to dangerous areas during maintenance.

Key Applications

The versatility of heat resistant LED lights is evident across a variety of industries:

Manufacturing & Processing Plants: Used in environments with exposure to heat, dust, and vibration, such as steel mills, refineries, and cement plants.

Automotive & Aerospace: Integrated into engine bays, brake systems, or aircraft components exposed to intense heat.

Mining & Drilling: Provide illumination in confined, high-temperature areas underground or in oil and gas extraction zones.

Food Processing: Used in ovens or heat-based sterilization environments where regular lighting cannot operate effectively.

Public Infrastructure: Applied in tunnels or lighting systems exposed to harsh weather and high ambient heat.

Regional Insights

Asia-Pacific leads the global heat resistant LED market, driven by rapid industrialization and the presence of major manufacturing hubs in countries like China, India, and South Korea. Europe and North America follow closely, with increased adoption in advanced manufacturing sectors and automotive applications.

In developing economies, government initiatives to enhance energy efficiency and industrial modernization are further fueling demand. Moreover, as global climate patterns change, regions experiencing rising temperatures are increasingly considering heat resistant lighting as a critical infrastructure component.

Challenges Limiting Market Expansion

Despite promising growth, the heat resistant LED market faces a few notable challenges:

Higher Initial Costs: Heat-resistant models are more expensive than standard LEDs due to specialized materials and design, which can deter adoption in cost-sensitive markets.

Complex Installation Requirements: Some industrial environments may require customized fixtures or retrofitting for compatibility, adding to implementation complexity.

Limited Consumer Awareness: In many regions, the benefits of heat resistant LED technology are still underappreciated, limiting potential adoption.

Future Outlook and Opportunities

The future of the heat resistant LED market is closely tied to ongoing technological advancements and increased awareness of energy efficiency and workplace safety. Key areas of future development include:

Smart Heat Resistant LEDs: Integration with IoT for real-time temperature monitoring, automated brightness control, and predictive maintenance alerts.

Eco-Friendly Materials: Use of recyclable or non-toxic components to support environmental sustainability goals.

Customizable Solutions: Modular LED systems that can be tailored for specific industrial applications and temperature ranges.

As global industries seek to optimize productivity, reduce energy costs, and comply with stricter safety and environmental regulations, the demand for durable, high-performance lighting solutions will rise. Heat resistant LED lights are uniquely positioned to meet these needs, making them an essential component of the next generation of industrial and high-performance lighting systems.

Conclusion

The heat resistant LED lights market offers a wide scope of growth opportunities, supported by advancements in materials science, energy efficiency trends, and expanding industrial applications. While initial costs and awareness remain hurdles, innovation and global sustainability efforts will drive continued adoption. With its unique value proposition, this market segment is set to play a crucial role in the future of high-performance lighting across industries.

0 notes