#extended ecm

Explore tagged Tumblr posts

Text

How to install Endpoint Configuration Manager on HyperV VM

Microsoft integrates Configuration Manager into the Intune family of products, offering an integrated solution for managing all devices. This integration simplifies licensing and eliminates the need for complex migrations. Users can continue leveraging their existing Configuration Manager investments while tapping into the capabilities of the Microsoft cloud at their own pace. This is a…

View On WordPress

#ConfigMgr#Configuration Manager#ECM Installation#Extend Active Directory AD Schema#Microsoft Endpoint Configuration Manager#Microsoft SQL Server Management Studio#Microsoft Windows#SQl Server 2022#SQL Server Management Studio#SQL Server Management Studio (SSMS)#Windows#Windows 10#Windows 11#Windows ADK#Windows Server#Windows Server 2012#Windows Server 2016#Windows Server 2019#Windows Server 2022#Windows Server 2025

0 notes

Note

Hey I was re-reading ECM and I noticed how awesome your the writing style was and wanted to know if you'd be willing to share how you write like that?

(I've got exams and have to really work on my english lmao)

Thank-you very much! I'm glad you've enjoyed my writing so much!

(I want to preface any notes here by saying I started seriously writing when I was 12 and I am now... not that. So I have almost 20 years of writing under my belt)

I've actually done a post about writing that gives a few pointers so I won't re-hash those points, but will add a few extras about crafting 💖💖

I know I said I wouldn't re-hash things, but this point always bears merit in saying: the first thing you write is the worst thing you write. It's called a first draft for a reason and you shouldn't be precious about it. That means don't go stressing about getting your phrasing perfect. Rewriting your draft can do wonders (and that doesn't mean you have to completely change things on the rewrite!), especially if you're not a confident writer.

Vary the start of your sentences. It's a very easy habit to fall into (I still do it all the dang time); you write sentence after sentence starting the the subject ('It was...'; 'Peter did...'; 'She saw...' etc). It makes your writing feel repetitive. We fall into patterns in our writing and forcing yourself to think about how you can change up the way your sentences begin within a paragraph is an invaluable challenge. Consider your paragraphs too: when I'm on my first edit, I pay close attention to how they start to ensure they don't all begin the same way. That doesn't mean every sentence has to start differently, but keeping things mixed up adds variety.

Avoid info-dumping. Exposition (where you give relevant background information) is a useful feature but it slows the pace of your story significantly. What I see a lot of fanfic writers do is freeze time (quite often at the very start of the story) to give us 500+ words of information that could have been drip fed over the chapter (or several chapters). I'm absolutely not saying I'm innocent of this - I do it all the time, including the opening to ECM! - but something that I find can help is to a) make it interesting by setting up a mystery that the exposition doesn't answer, b) intersperse exposition with description to keep up the pace or c) try to make your exposition feel as authentic as possible to your narrator.

Be decisive: avoid phrases like 'seemed to' and 'felt like' etc. Instead of, "She seemed to glow with happiness' make it 'She glowed with happiness'. Simple changes like this just make you seem more sure of yourself as a writer because you're committing to the image. Again, this kind of indefinite phrasing is an easy habit to fall into but it's a very easy fix! Very often, the sentence will still make perfect sense if you simply delete these phrases (although sometimes it will need a few minor tweaks).

Metaphors, not similes. Honestly this is just a continuation of the previous rule! Rather than, 'It looked like an ocean of silver', 'An ocean of silver swelled before them' is much more interesting and committed to the bit! Again, that's not to say you can't use similes at all! They're great, but you should ask yourself if a metaphor would be better.

Don't be afraid to extend your metaphors. Extended metaphors are such fun. Consider my earlier example : 'An ocean of silver swelled before them'. If I was to extend this, I'd think about other images associated with the ocean. Waves, tides, sea creatures, the scent and sound of the water. And since I've compared it to silver, I'd also consider things that are semantically connected: gold, copper, jewels like emeralds, sapphires, pearls etc. Then I'd start crafting additional clauses/sentences to build upon that original metaphor.

Brush up on a wider range of writer methods. Honestly, teaching English helped me out a bunch here, but here are a few of my faves: polysyndeton: this is where you list with the same coordinating conjunctions (and, but, so, for etc) rather than commas. If you look at my writing you'd see I do this all the damn time. Anaphora: in the typical form I use it, it's where the start of successive clauses begin with the same opening word/phrase (think like MLK's 'I have a dream speech). Best used in a group of three in my experience. Again I use this all the time. The opposite of this (where successive clauses end in the same word/phrase) is called epistrophe. Oxymoron: a fun one. It's a paradoxical phrase (e.g. burning cold, loving hate etc) Hyperbole: an over-exaggeration (e.g. It's boiling hot. I walked a million miles to get here!). Very fun to use with an unreliable narrator or you want to get across just how unbearable/significant something is (but the key here is that it's got to be obvious you're over-exaggerating!) Synaesthesia: where you mix different senses together (e.g. The lights sang in harmony; the room smelled cold).

Planning does wonders for your story structure. For the longest time I was a 'pantster' and would just throw myself in writing on vibes only, but now I find that knowing where I want to take my story makes it much easier to place critical themes and the much loved foreshadowing.

I hope at least some of these can be helpful to you! These are methods that have helped me over the years, but the beauty of writing is of course that all of us over time develop our own 'voice'! Just because I say these are things I do doesn't mean that's what everyone has to do!

Good luck on your exams too!! 💖

69 notes

·

View notes

Text

🇹🇷🔥 Turkish Air Force - F-4E 2020 Terminator

The F-4E 2020 Terminator represents a significant leap forward in the capabilities of the Turkish Air Force. This comprehensive upgrade enhances the venerable F-4E Phantom II with modern Turkish-made weapons systems, showcasing Türkiye’s commitment to self-reliance and advanced military technology.

Background

With a storied history dating back to the 1960s, the F-4E Phantom II has been a pivotal player on the global stage of air combat. Serving multiple nations and seeing numerous conflicts, the Phantom carved out its place in aviation history as a versatile and rugged aircraft. Türkiye’s decision to upgrade this aircraft stems from a strategic imperative to leverage existing assets while infusing them with cutting-edge technology to maintain relevance in modern aerial warfare. The 2020 Terminator program is the Turkish Air Force’s ambitious initiative to retrofit these fighters with state-of-the-art systems.

Strategic Importance

The ability to exert air superiority and conduct precision strikes is paramount in a region marked by dynamic security challenges. The F-4E 2020 Terminator’s enhanced capabilities contribute significantly to deterrence, and the demonstration of Türkiye’s advancing aerospace industry serves both a strategic and diplomatic purpose.

Upgrade Overview

The 2020 Terminator upgrade, realized by Turkish Aerospace Industries in collaboration with ASELSAN, constitutes a multifaceted improvement over the aircraft’s original design. It touches every aspect of the aircraft’s systems, bringing its avionics, armaments, and electronic warfare systems into the 21st century.

Avionics:

The modernized multi-mode pulse Doppler radar extends the aircraft’s detection range, allowing it to lock onto and engage targets from greater distances. Integrating a Hands-On Throttle-And-Stick (HOTAS) system enhances pilot control, minimizing response time during high-stakes manoeuvres. Color Multifunctional Displays (MFDs) replace outdated gauges, providing pilots with real-time data visualization for improved situational awareness.

Armament:

The Terminator’s weapons suite has been revolutionized with a mixture of Western and indigenous munitions. Long-standing armaments like the AIM-9X Sidewinder are joined by Türkiye’s own precision-guided munitions, such as the SOM cruise missile, capable of striking strategic land and sea targets with formidable accuracy. The UAV-230, a domestic innovation, represents the pinnacle of Türkiye’s missile development, offering supersonic ballistic delivery of a range of warhead types over substantial distances. The BOZOK, MAM-C, MAM-L, and Cirit missiles exemplify Türkiye’s expertise in laser guidance and smart munition technology, enabling the Terminator to engage and defeat a broad spectrum of target profiles with unerring precision.

Electronic Warfare:

To contend with the contemporary battlefield’s electronic warfare environment, the F-4E 2020 Terminator incorporates an advanced Electronic Support Measures (ESM) system for rapid threat identification and an Electronic Countermeasures (ECM) suite to confound hostile tracking systems. Moreover, chaff and flare dispensers have been integrated to provide decoys against incoming missile threats, enhancing the aircraft’s survivability in hostile airspace.

Operational Capability:

The F-4E Phantom II, transformed by these integrated systems, emerges as a multirole platform capable of dominating beyond-visual-range air-to-air engagements and precision ground-attack missions. It can operate in complex electronic warfare environments and deliver various ordnances based on mission requirements, making it a flexible asset in the Türkiye Air Force’s inventory.

Significance:

The F-4E 2020 Terminator project is a hallmark of Türkiye’s aerospace ambition and its push toward defence autonomy. By retrofitting and modernizing its Phantoms, Türkiye maximizes the value of its existing fleet while also establishing a foundation for future indigenous aircraft development projects.

Munitions Details:

The advanced, indigenous Turkish weaponry integrated into the F-4E 2020 Terminator underlines a significant shift toward self-reliance in defence technologies. Each munition type brings unique capabilities that enhance the platform’s lethality:

UAV-230: A domestically-developed ballistic missile, this supersonic weapon delivers high-precision strikes at long ranges, challenging enemy defences with its speed and reduced radar cross-section.

BOZOK: The versatility of this laser-guided munition makes it ideal for engaging both stationary and moving targets with high precision, ideal for close air support.

MAM-C/L: These smart micro munitions are designed for tactical flexibility, allowing for precision targeting in complex engagement scenarios, from anti-armour operations to counter-insurgency roles.

Cirit: A highly accurate laser-guided missile system designed for low collateral damage, Cirit is adept at striking soft and lightly armoured targets with pinpoint accuracy.

SAGE Munitions: TUBITAK SAGE, Türkiye’s leading defence research and development institute, has contributed a range of munitions enhancing the Terminator’s operational capabilities across various domains.

Conclusion:

The upgraded F-4E 2020 Terminator is a testament to Türkiye’s determination to retain a competitive edge in aerospace and defence technologies. The integration of modern avionics, armaments, and electronic warfare capabilities ensures the aircraft’s continued relevance in modern air combat, and its presence in the skies serves as a deterrent in a strategically complex region.

#turkish army#turkish armed forces#turkish air force#turkishnavy#turkish navy#turkish#military#aircraft#air force#fighter jet#aviation#fighter plane#plane#airplane#military aviation#military aircraft#f 4 phantom ii#f 4 phantom#f 4e

130 notes

·

View notes

Text

I now know why there was a “Big Tail SR-71🌟

Thanks to this article by @Tony Landis

Tony Landis is a well-known photographer of all the Blackbirds and a great guy. I met him at the Blackbird reunion last June. The reasons for Big Tail were that they wanted a camera that they could use in all weather, good or bad and that ECM electric countermeasures extend to cover the back of the Habu.

The countermeasures that they had were excellent they proved their worth by confusing the enemy so much that we believe it’s possible that one MiG shot itself accidentally. In another story that I reported on Darrell Cobb's SR-71 Pilot expressed that he felt it was highly possible. facebook.com/10008732525369…?

Big Tail - One of a Kind Variant

Shortly after the first SR-71s began flying operational missions over North Vietnam, the Air Force was looking into ways of expanding the capabilities of the aircraft. With the interchangeable noses, mission planners had to choose from flying either optical cameras or side-looking radar, depending upon the mission requirements and the weather over the target area.

Unfortunately several missions were rendered useless when weather over the target area prevented the use of the optical camera systems installed. There was also the possibility that future ground defenses had the ability to reach the SR-71 from behind since it carried no aft facing countermeasures.

In 1974, the Air Force identified a requirement for aft facing ECM requirement on the SR-71. Several proposals examined by the Air Force included conformal packages, belly pods as well as an extended tail fairing. After researching all the possibilities, the extended tail appeared to be the most viable option based on lowest cost, added volume and least aerodynamic drag.

The new “Big Tail” assembly is 13-feet, 9-inches long and weighs 1,273 lbs. with 49 cubic feet of space to carry 864 lbs. of payload.

🌟The primary payload consisted of aft-facing ECM as well as the 24-inch Optical Bar Camera.

The new assembly needed to articulate 8.5 degrees up and down to clear the runway during take-off and landing.

The tenth SR-71 built (61-7959) was selected to receive the new modification. This aircraft was already being used for flight test duties at Palmdale at the time so there would be no effect on the operational fleet. Between April and November 1975, ‘959 received the modification with the new tail fairing; necessary modifications included a 51-inch adapter unit for the new tail, air conditioning for cameras and other equipment as well as routing the fuel vent along the upper surface of the tail. In addition to the tail modification, chine bays were modified to accommodate the 24-inch Optical Bar Camera.

SR-71A fueling

The modified tail assembly shows up well in this view as SR-71A 61-7959 ‘Big Tail’ takes on fuel from a KC-135Q tanker aircraft. The extended tail required the fuel dump port to be routed across the top of the new tail assembly.

With the stress and vibration testing completed, ‘Big Tail’ was taken out for the first high-speed taxi test on November 20, 1975, by Lockheed test crew Darrell Greenamyer (pilot) and Steven Belgeau (Reconnaissance Systems Officer-RSO). Two weeks later, on December 3, the same crew took Big Tail up on its first flight. Lasting just over one hour. Before turning the aircraft over to Air Force test crews, Greenamyer performed 4 solo flights to prove the system could be run by just a single crewmember. The RSO’s seat is occupied by a ballast dummy affectionately known as “Sierra Sam”.

Once Lockheed crews proved the system worked, the Air Force took over all flight testing. Tom Pugh and Bob Riedenauer became the pilots and RSO duties went to William Frazier and John Carnochan with the first Air Force flight taking place on May 5, 1976.

Over the next 6 months these Air Force crews made 23 flights in ‘Big Tail’, testing various camera systems in the tail and chine bays, as well as new ECM systems.

@Habubrats71 via X

#sr 71#sr71#sr 71 blackbird#blackbird#aircraft#usaf#lockheed aviation#skunkworks#aviation#mach3+#habu#reconnaissance#cold war aircraft

46 notes

·

View notes

Text

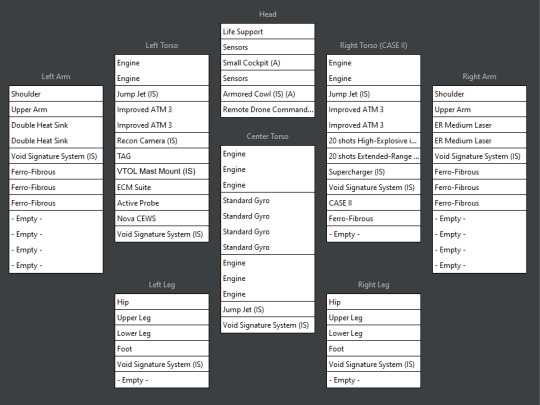

Third League Royals: A Guide to Building Standardized nuSLDF BattleMechs

"Third League Royal" is a term coined for refitted and modernized BattleMechs deployed by the Star League Defense Force (SLDF) of the Third Star League from 3151 onward, in the Touchdown AU.

These upgraded designs follow strict formatting guidelines to ensure interoperability, survivability, and networked warfare efficiency in the modern battlefield.

This guide outlines how to construct a Third League Royal using MegaMekLab (MML), with a focus on out-of-universe implementation.

Core Features of a Third League Royal:

1. Mixed Clan Techbase (Unofficial Rules Enabled):

All Third League Royals must use the Mixed Clan techbase.

The Unofficial Tech Level must be enabled in MML to permit these configurations.

Furthermore, under the Tech Progression tab in Options, you must enable "ignore intro/extinct years for Unofficial Tech Level units"

2. Nova CEWS or Equivalent EW Suite:

All standard Third League Royals mount the Nova Combined Electronic Warfare Suite. Usually placed in the head slot, unless:

a) The 'Mech has a traditional head-mounted system that takes priority.

and/or

b) A Small Command Console cockpit is in use.

Exceptions:

Recon or command-focused 'Mechs may instead mount:

a) Clan ECM Suite (fluffed as "Archangel ECM").

and/or

b) Clan Active Probe (fluffed as "Wolfhound Active Probe").

3. Small Cockpits & Command Consoles:

All units use Small Cockpit technology.

Command variants use the Small Command Console Cockpit.

Ensure the cockpit is armored via the Assign Criticals tab in MML.

4. Armored Cowl Equipment:

All designs must mount an Armored Cowl in the head.

Must be armored via the Assign Criticals tab.

5. Clan-Tech Modernization of Legacy Loadouts:

Loadouts should (but do not have to) resemble previous variants of the 'Mech.

Upgrade to Clan equipment wherever appropriate:

IS Medium Lasers → Clan ER Medium Lasers.

IS Gauss Rifle → Clan Gauss Rifle or HAG.

LRM/SRM systems → Clan ATM or Streak launchers.

6. IS Composite Structure:

Must be selected under Structure.

7. Clan Double Heat Sinks:

Exclusively use Clan Double Heat Sinks.

Install as many as the design allows to minimize heat buildup (see below for Quirks that will effect the final number).

8. Supercharger Optimization:

Optional but recommended for weight efficiency:

Downgrade engine rating by one step.

Add a Supercharger to restore original speed.

Example: 300-rated engine → 285-rated + Supercharger.

9. Quirks:

a) Add the following universal Quirks (in addition to any original ones):

Battle Computer (replaces Command Mek Quirk if present on base model)

Combat Computer (+4 sunk per turn on top of normal heat sinks - not shown in MML UI, total heat/heat sunk must be manually calculated)

Cowl

Easy to Pilot

Extended Torso Twist

Improved Communications

Improved Sensors

Multi-Trac

Variable Range Targeting

b) If Jump Jets are present, add:

Reinforced Legs

c) Weapon and AMS Quirks:

i) All weapons (energy, ballistic, missile) must have:

Accurate Weapon

Improved Cooling Jacket (reduces individual weapon heat by one - not shown in MML UI, total heat/heat sunk must be manually calculated)

ii) All AMS types must have:

Directional Torso Mounted Weapon

d) Negative Quirks of the original design should be removed unless given a compelling lore reason.

10) Additional Design Notes:

a) Armor Allocation: Prioritize maximum armor where weight allows, using Clan Ferro-Fibrous or Ferro-Lamellor if possible.

b) CASE II: Highly recommended for Clan ammo-fed weaponry.

c) Head Slot Limitations: If both Nova CEWS and Command Console are needed, prioritize the Command Console and shift Nova to an alternate location.

The Third League Royal format creates a high-performance, standardized set of BattleMechs optimized for 32nd-century mixed-technology, survival-focused, network-centric warfare. By following this guide in MegaMekLab, players can build compliant 'Mechs that reflect the Third Star League's vision of a modern, networked military. Whether deploying a reimagined Atlas or a revitalized Shadow Hawk, your 'Mech will carry the legacy of the Star League forward—into the next era of warfare.

9 notes

·

View notes

Text

took another crack at an Illegal Design in the ol' word doc, and this time, it's how I imagine some MechTech tries to make sense of the Dark One

Name: Marauder (MAD-DRK) Tonnage: 75 (Heavy) Role: Killingyouguy Year: 2666 Tech Base: Clan (Mixed) Tech Level: Experimental Base Type: Standard biped Design Quirks:

Positive: Animalistic Appearance, Anti-Aircraft Targeting, Barrel Fists, Command ‘Mech, Cowl, Directional Torso Mount (RT C-LPL), Distracting, Easy to Pilot, Extended Torso Twist, Fine Manipulators, Hyper-Extending Actuators, Improved Sensors, Improved Targeting (all ranges), Narrow/Low Profile, Multi-Trac, Protected Actuators, Searchlight, Vestigial Hands

Negative: Illegal Design, Obsolete (2666), Difficult to Maintain, Non-Standard Parts, Oversized

C-Bill cost: you don’t “buy” a Black Marauder BV cost: it doesn’t TONNAGE:

Structure: 4t

Engine: 19t

Cockpit: 4t

Heatsinks: 15t

Armor: 12t

Jump Jets: 4t

Equipment: 21t

INTERNAL STRUCTURE: you don’t want to know, but this is what MechTechs think is going on (with notes by other MechTechs saying "no the fuck it's not")

HEAD:

Life Support (none, actually)

Sensors (maybe?)

Interface Cockpit (laughable, this idea; the damn thing probably has a brain)

Sensors (again, possibly)

Life Support (HA!)

SLDF Triple-Strength Myomer (?)

Chameleon Light Polarization Shield (?)

Null-Signature System (?)

Self-Repair Gel (?)

CENTER TORSO:

Engine (presumably): Six crit slots

Clan Double Heat Sinks (2)

ECM Suite

SLDF Triple-Strength Myomer (?)

Chameleon Light Polarization Shield (?)

Null-Signature System (?)

Self-Repair Gel (?)

Supercharger (?)

LEFT TORSO:

SLDF Triple-Strength Myomer (?)

Chameleon Light Polarization Shield (?)

Null-Signature System (?)

Self-Repair Gel (?)

Jump Jet

Jump Jet

Clan Large Pulse Laser

Clan Double Heat Sinks (2)

Endo Steel (3)

Ferro-Fibrous (2)

RIGHT TORSO:

SLDF Triple-Strength Myomer (?)

Chameleon Light Polarization Shield (?)

Null-Signature System (?)

Self-Repair Gel (?)

Clan MASC (?)

Jump Jet

Jump Jet

Clan Double Heat Sinks (3)

Endo-Steel (2)

Ferro-Fibrous (3)

LEFT ARM:

Shoulder

Upper Arm

Lower Arm

SLDF Triple-Strength Myomer (?)

Chameleon Light Polarization Shield (?)

Null-Signature System (?)

Self-Repair Gel (?)

ER PPC

ER Medium Laser

Clan Double Heat Sinks (2)

Endo Steel (1)

Ferro Fibrous (1)

LEFT LEG:

Hip

Upper Leg

Lower Leg

Foot

SLDF Triple-Strength Myomer (?)

Chameleon Light Polarization Shield (?)

Null-Signature System (?)

Self-Repair Gel (?)

Clan Double Heat Sink

RIGHT ARM:

Shoulder

Upper Arm

Lower Arm

SLDF Triple-Strength Myomer (?)

Chameleon Light Polarization Shield (?)

Null-Signature System (?)

Self-Repair Gel (?)

ER PPC

ER Medium Laser

Clan Double Heat Sinks (2)

Endo Steel (1)

Ferro Fibrous (1)

RIGHT LEG:

Hip

Upper Leg

Lower Leg

Foot

SLDF Triple-Strength Myomer (?)

Chameleon Light Polarization Shield (?)

Null-Signature System (?)

Self-Repair Gel (?)

Clan Double Heat Sink

#battletech#i need you to know this entire internal structure diagram is meant to be total BS#and yes it's over-tonnage#and it's clantech before the clans even existed#and it has both MASC and TSM listed#and it has negative crit slots left by a lot#as I said: total BS

5 notes

·

View notes

Text

The Griffin GRF-2N Custom/Clan Rebuild

Something I've spent to many braincells on since getting the Legends III Bounty hunter box set last December

Griffin GRF-2N Clan rebuild

Weight: 55 tons (55 tons)

Tech base: Clan

Chassis: Endo-Steel (Weight 3 tons Critical Slots 7)

Armor: Clan Ferro-Fibrous, CASE protected (Weight 9.5, Critical Slots 7, 182 points)

Engine: Fusion 275 (Weight 15.5 tons, Critical Slots 6)

Cockpit: Standard (Weight 3 tons, Critical Slots 2)

Gyro: Standard (Weight 3 ton, Critical Slots 4)

Heat sinks: 11 Clan Double (Weight 1 Ton, Critical Slots N/A)

Jump jets: 5 (Weight 2.5 tons total, Critical Slots 5)

Weapons

ER PPC, Clan (Weight 6 tons, Critical Slots 2)

ATM 6 (Weight 3.5 tons, Critical Slots 3) Right Torso

ATM 6 (Weight 3.5 tons, Critical Slots 3) Left Torso

ER Small Laser, Clan (Weight .5tons, Critical Slots 1) Head

Equipment

Clan ECM Suite (Weight 1 Ton, Critical Slots 1) Right Arm

ATM Missile Bin, Standard (Ammunition, Weight 1 ton, Critical slots 1) Right Torso

ATM Missile Bin, Extended Range (Ammunition, Weight 1 ton , Critical slots 1) Right Torso

ATM Missile Bin, High Explosive (Ammunition, Weight 1 ton, Critical slots 1) Left Torso

Critical Slots (Armor Applied[Back]/Max))

Head: 3/3 (9/9) Cockpit (2), ER Small Laser (1)

Torso (Center): 12/18 (28[7]/36) 275 Fusion Core (6), Standard Gyro (4), Jump Jet, Ferro-Fibrous

Torso (Left): 12/13 (20[6]/26) ATM 6 (3), 1 Ton ATM, Jump Jet, Jump Jet, Ferro-Fibrous, Ferro-Fibrous, Ferro-Fibrous, Endo-Steel, Endo-Steel, Endo-Steel

Torso (Right): 12/13 (20[6]/26) ATM 6 (3), 1 Ton ATM, 1 Ton ATM ER, Jump Jet, Jump Jet, Ferro-Fibrous, Ferro-Fibrous, Ferro-Fibrous, Endo-Steel, Endo-Steel

Right Arm: 9/9 (18/18) ER PPC (2), Clan ECM, Shoulder Actuator, Upper arm Actuator, Lower Arm Actuator, Hand Actuator, Endo-Steel, Endo-Steel

Left Arm: 4/9 (18/18) Shoulder Actuator, Upper arm Actuator, Lower Arm Actuator, Hand Actuator

Right Leg: 4/13 (25/26) Hip, Upper leg Actuator, Lower Leg Actuator, Foot Actuator

Left Leg: 4/13 (25/26) Hip, Upper leg Actuator, Lower Leg Actuator, Foot Actuator

Total: 36/91 (182/185)

BV 2044

C-Bills 5,598,497

3 notes

·

View notes

Text

Wrath

/////Transmission Start///// CFRI OPSCOM N. LINDSBORG TO ALL OPERATION TOUCHDOWN SLDF AND ALLIED ELEMENTS: At 1526 hours local standard time, CFRI Angel Squadron performed an escort operation alongside a DropShip from @seafoxmathias delivering 'Mechs to in-field forces of @harwood-pmc-official. During this operation, COMSCAN detected a spike in ambient heat bearing southwest of the operational zone, and directed Angel Squadron on a pass-by course to check the area... Captain Molly Sanders was the wing lead of Angel Squadron. Had been for the better part of a decade, now- ever since Captain Raiken had that unfortunate engine failure. Captain Sanders was confident, assured, and in control- especially in the cockpit of her Sparrow, Angel-1.

Right now, though, she was none of those things.

The cockpit was alive with panic alarms- proximity warning for incoming Long Range Missiles, radar lock warnings, damage control warnings, and- most notably- the piercing whistle signifying her canopy had been breached by whatever the hell had taken potshots at Angel Squadron as they breached the horizon over the main road. Cursing wildly, she peered through the spiderwebbed ferroglass in front, trying desperately to assess whether her flight path was stable. The damage was impact- no molten airframe, no scorching heat filtering in through the damaged cockpit meant whatever had hit her wasn't an energy weapon. A world-shaking BOOM rocked the Sparrow in midair, sending the craft arcing through the sky away from the rest of the formation as Angel-6's bomb load detonated midair. The cloud of smoke and ash provided a reference point, and as she frantically righted the crippled aircraft, a blurry and fractured silhouette was visible below. Angel-4, unable to avoid both the debris from the bomber and the incoming autocannon fire, started coming apart piecemeal, blasts tearing great rents through the light armor of the fighter before it simply broke in two. A momentary flash of light, heat- not only visible but tactile even at this distance- lit the world like a thousand fireworks as an impossibly bright beam lanced up from below and simply erased Angel-2 and Angel-3. No explosion, no flame, just a streak of light and two puffs of smoke. Careening towards the ground, Molly frantically grabbed for the canopy breakaway lever, hauling with all her might, before the seals gave and the wind tore the structure from her aircraft. Blinking against afterimages, she banked, ejecting chaff, flares, and her reserve fuel tanks, desperate to outrun the incoming missiles. A last-minute ping from her craft's sensors sent a brief, surface-level analysis of the strange structures below that had turned her squad into a memory, before she joined them in oblivion. PAN PAN PAN EMERGENCY BROADCAST ANGEL-1 TAC ASSESSMENT: Manufacturer: Unknown Production Year: Unknown Model ID Beacon: JHA-000 Jericho Class: Superheavy 'Mech Type: Word of Blake Drone Hex-Mech Error: 'Mech size exceeds integer bounding parameters. Override. Mass: 250 Tons Chassis: Reinforced Structure Armor: Improved Ferro-Lamellor Engine: UNKNOWN Heat Sinks: UNKNOWN Speed: UNKNOWN Armament: 1x Experimental Extra-Light Naval Subcapital Laser 2x Gauss Rifle 2x Extended-Range LRM-20 6x LBX Autocannon-10 6x Ultra Autocannon-2 12x Micro Pulse Laser 6x Variable-Speed Medium Pulse Laser 6x Laser Anti-Missile System Improved C3 Computer Beagle Active Probe ARCHANGEL Advanced ECM Suite WARNING: Multiple units detected. WARNING: Accompanying elements detected. Error: Transmission offline. Get ready, everyone. /////END TRANSMISSION/////

19 notes

·

View notes

Text

QUESTION: Marty, I cannot thank you enough for your coverage of the Middle East. Nobody provides such valuable forecasts for our entire region as you do. I know you have had friends in the various royal families, and you have been observed meeting with various central banks in the region. You have not been an analyst in theory only. You have been here and walked in our lands. As we say: أحضر الناس جوابا من لم يغضب “The best answer will come from the person who is not angry.” That is you.

My question is: Your Islamic Wave concludes next year, 2025.22, on March 21, and I understand that the ECM is not in Socrates, which calculates cycles independently. Since we see March/April as a critical turning point next year on many arrays, should we be alerted to more chaos in the Middle East during this period?

Thank you so much for your independence. What they did to you proved to everyone you are both honorable and independent. They did the same to Trump, proving he was not one of them and winning.

Their time is coming, جزاء سنمار جزاء مُجيرِ أُمِّ عامِرٍ الجزاء من جنس العمل “You reap what you sow.”

MM

ANSWER: Thank you. Yes, their time is coming. That’s 2032, but it started here in 2024 and will escalate into 2028. I have argued for years against the NEOCONs who judge the Middle East by their own ideas. They fail to comprehend that this is tribal. Everyone in Syria does not share an identity of being Syrian. They see themselves as first being Sunnie, Shite, Druze, Christian, etc, etc. They have sought to remove Saddam, Assad, and Quadafi under the theory that they would install democracy and they would bring peace to the Middle East. They judge the entire region as if this was a thesis for a PhD in school detached from reality. From the very beginning, the Sykes-Picot Agreement sought to carve up the Ottoman Empire and artificially create nation-states that never existed. These theories are so detached from reality that they have plunged the world into constant wars and confrontations.

There is a significant confrontation in the Middle East that appears many have never considered since they have focused on Iran rather than Turkey. While NATO has constantly pushed the propaganda that Putin wanted to retake Europe to reestablish the USSR, right within NATO there has been rising discord against this centralized dictatorial dogma. Turkey has long fostered a hatred of Greece, and this feud extends back to the Turkish conquest of Byzantium/Constantinople in 1453. But it has been the Turkish President Recep Tayyip Erdogan who has fueled his dreams to conquer the Middle East to reestablish the Ottoman Empire that was broken up by the West in 1916 – not Putin.

4 notes

·

View notes

Text

>>> SLSOC Confidential terminal

>>> ENTER FILE CODE:

<<< 4958415

>>>nSeraph.txt

>>> Open? [ Y/N ]

<<< Y

>>>Processing...

Project SERAPH

Technical Readout

Super Uziel 'Hustler One' UZL-3S-2-H1

Mass: 55 tons

Chassis: Skobel Prowler with EndoSteel

Power Plant: Ford-Shelby 385 XXL

Cruising Speed: 75.6 kph

Maximum Speed: 194.4 kph

Jump Jets: None

Jump Capacity: 0 meters

Armor: StarGuard Nightshroud

Armament:

2 Micro Pulse Laser

1 Improved Heavy Small Laser

2 Improved Heavy Medium Laser

1 Improved ATM 6

Manufacturer: Skobel MechWorks

Primary Factory: Yakima Proving Ground, Terra

Communication System: Irian E.A.R.

Targeting & Tracking System: Clan-enhanced HartfordCo XKZ 1 with Advanced Targeting Computer

Introduction Year: 3150

Tech Rating/Availability: F/X-X-X-X

Cost: 60,309,467 C-bills

Type: Super Uziel 'Hustler One'

Technology Base: Mixed (Unofficial)

Tonnage: 55

Battle Value: 2,409

Equipment Mass

Internal Structure Endo Steel 3

Engine 385 XXL 14.5

Walking MP: 7

Running MP: 11(18)

Jumping MP: 0

Double Heat Sink 13 [26] 3

Compact Gyro 6

Small Cockpit 2

Right Arm Actuators: Shoulder, Upper Arm, Lower Arm

Left Arm Actuators: Shoulder, Upper Arm, Lower Arm

Weapons

and Ammo Location Critical Heat Tonnage

Improved ATM 6 CT 3 4 3.5

Supercharger RT 1 - 1.5

Bloodhound Active Probe RT 3 - 2.0

Micro Pulse Laser RT 1 1 0.5

Targeting Computer LA 1 - 1.0

Improved Heavy Medium Laser LA 2 7 1.0

CASE LA 0 - 0.0

Standard iATM/6 Ammo (10) LT 1 - 1.0

Improved Magnetic Pulse iATM/6 Ammo (10) LT 1 - 1.0

CASE LT 0 - 0.0

High-Explosive iATM/6 Ammo (10) LT 1 - 1.0

Extended-Range iATM/6 Ammo (10) LT 1 - 1.0

Micro Pulse Laser LT 1 1 0.5

THB Angel ECM Suite HD 2 - 1.5

Improved Heavy Small Laser RA 1 3 0.5

Improved Heavy Medium Laser RA 2 7 1.0

CASE RA 0 - 0.0

MASC RA 2 - 2.0

Features the following design quirks: Battle Computer, Combat Computer, Cowl, Improved Communications, Improved Sensors, Multi-Trac, Non-Standard Parts, Prototype

2 notes

·

View notes

Text

India’s Electronics Leap: How PLI Schemes and Infrastructure Are Redefining Manufacturing

India is fast-tracking its ambition to become a global electronics manufacturing powerhouse. With a mix of well-structured Production Linked Incentive (PLI) schemes and robust infrastructure development, the country is actively reducing its dependence on imports, boosting exports, creating jobs, and attracting international investments.

Building an Electronics Ecosystem: ECMS Initiative

Recognizing the need to strengthen the components ecosystem, the government introduced the Electronics Components Manufacturing Scheme (ECMS) with an outlay of ₹23,000 crore. This scheme aims to drive domestic production of passive electronic components, sub-assemblies, and capital equipment essential for electronic manufacturing.

Strategic Push Through PLI Schemes

The Indian government’s push for domestic electronics manufacturing revolves around targeted financial support for value chain expansion. The PLI initiatives reward companies for incremental manufacturing and sales in India.

1. PLI for Large-Scale Electronics Manufacturing

Introduced in April 2020, this scheme was designed to attract substantial investments in mobile and electronic components manufacturing. It provides 3% to 6% incentives on incremental sales over a five-year period.

Its success is evident—mobile phone production in India jumped from 5.8 crore units in 2014–15 to a massive 33 crore units in 2023–24, reducing import reliance and turning India into a net exporter of mobile phones.

2. PLI 2.0 for IT Hardware

This version extends support to the IT hardware segment—covering laptops, tablets, servers, and ultra-compact PCs. Companies receive about 5% incentive on incremental sales over six years.

The scheme emphasizes component localization, including semiconductor design and integrated circuit packaging, making India more self-reliant in high-tech electronics.

ECMS: Multi-Tiered Manufacturing Support

The ECMS offers flexible incentive models—turnover-linked, capital-expenditure linked, and hybrid. It targets key sectors such as telecom, power electronics, automobiles, and medical devices. With a projected ₹59,350 crore in investment and ₹4.56 lakh crore in production output, the scheme is expected to create over 91,000 direct jobs.

As of late 2024, PLI schemes across 14 sectors had brought in ₹1.61 lakh crore in investment, created over 11.5 lakh jobs, and generated about ₹14 lakh crore in production—transforming the manufacturing landscape.

Infrastructure as the Backbone

Beyond incentives, India is also investing heavily in industrial infrastructure to support electronics production.

Electronics Manufacturing Clusters (EMCs)

The EMC scheme supports the creation of state-of-the-art infrastructure for the Electronics System Design and Manufacturing (ESDM) ecosystem. Greenfield projects can receive up to 50% of project costs (up to ₹50 crore per 100 acres), while brownfield projects may receive 75% support.

So far, 19 greenfield EMCs and 3 Common Facility Centres (CFCs) have been approved, spanning 3,464 acres and backed by ₹1,470 crore in government grants. States such as Tamil Nadu, Uttar Pradesh, and Karnataka are rapidly emerging as new electronics hubs.

Improved Connectivity: Bharatmala, Sagarmala & PM Gati Shakti

Modern infrastructure is key to seamless manufacturing. Initiatives like Bharatmala and Sagarmala, along with the PM Gati Shakti National Master Plan, are transforming India’s logistics network. The development of dedicated freight corridors, automated cargo handling, and real-time tracking systems is helping cut costs and reduce transit delays.

Expected Impact: A New Era for Indian Electronics

Boosting Local Value Chains

By incentivizing domestic production of core components, these schemes reduce India's dependency on foreign imports—especially from China, Taiwan, and South Korea. Localization of even 50% of key components can lead to billions in foreign exchange savings.

Massive Employment Generation

With direct and indirect job creation at the core of every scheme, the electronics sector is expected to employ hundreds of thousands of skilled and semi-skilled workers across the country.

Rising Electronics Exports

India has set an ambitious goal of producing $300 billion worth of electronics by 2026, of which $120–140 billion is aimed at exports. The PLI schemes have already helped expand India's export base by attracting tech giants like Apple and Samsung to deepen their operations.

Innovation and Technological Capability

R&D and semiconductor design are integral to India’s future strategy. Initiatives like SPECS and the semiconductor-specific incentives under PLI aim to enhance indigenous design and manufacturing capabilities.

Road Ahead: Addressing Key Challenges

Despite rapid progress, certain challenges must be resolved:

Supply Chain Gaps: Continued import of certain high-tech components requires a stronger local supply network.

Infrastructure Bottlenecks: EMCs need consistent upgrades in power, water, and transport to match global standards.

Skilled Workforce Shortage: Scaling up training programs is essential to support high-volume manufacturing.

Ease of Doing Business: Simplifying regulations and approvals will accelerate investment flows and industrial growth.

Conclusion

India’s aggressive push through PLI schemes and infrastructure investment is redefining its electronics sector. From import substitution to export-led growth, the country is positioning itself as a global electronics manufacturing hub. With the right policy continuity, focus on skill development, and strategic global partnerships, India is well on its way to becoming a dominant player in the international electronics value chain.

Author Details: S. Ravi (Sethurathnam Ravi) Promoter and Managing Partner of Ravi Rajan & Co. LLP Former Chairman of the Bombay Stock Exchange

0 notes

Text

What Tools Are Used for Professional Truck Battery Replacement in Dandenong?

A good fleet is crucial to any Carrum Downs and Dandenong-based business. A key component to such reliability is the health and fitness of your truck batteries. Should replacement be necessary, it being professionally and efficiently carried out is necessary in preventing downtime and ensuring optimal output. Battery Boost & Key Rescue knows this and uses the right tools and expertise for top-notch truck battery replacement services. The following article talks about the professional truck battery replacement tools in Dandenong and why choosing the right service provider is important, especially when you need truck battery replacement in Carrum Downs.

Key Tools of the Trade

Truck battery replacement in Dandenong is more than can be done with a wrench and spare battery. Battery Boost & Key Rescue employs an advanced set of tools to bring safety, precision, and quality workmanship. Consider some of the most relevant components:

Battery Load Tester: It is utilized for testing the ability of the battery to provide power in the loaded condition. Pre-replacement load test indicates the true state of the battery in order to prevent unnecessary replacement and potential faults of the charging system. You may need to have this test conducted if you have problems at Dandenong or require assistance in truck battery replacement at Carrum Downs.

Digital Multimeter: A digital multimeter is essential in taking voltage, current, and resistance measurements. It verifies the resting battery voltage, searches for parasitic drains that siphon off a battery, and tests the charging system to ensure it's functioning correctly. With this precise measuring tool, technicians can accurately diagnose battery problems.

Battery Terminal Cleaner and Protector: Terminal corrosion is one of the primary causes of starting difficulty. Heavy-duty cleaners dissolve corrosion with ease, leaving a clean, tight connection. Protective sprays prevent corrosion in the future, extending the life of the new battery and its performance.

Wrench Set (Imperial & Metric): Trucks use various sizes of battery terminals, and a complete wrench set in imperial and metric is needed. This ensures proper and secure tightening of the battery terminals to prevent loose contacts and electrical issues.

Battery Lifting Strap/Caddy: The battery packs are usually heavy and awkward to handle. A battery carrier or a lifting strap provides a safe, ergonomic way to pull out and install the battery, reducing the risk of injury.

Memory Saver: Modern trucks are founded upon a great deal of electronic controls. Battery disconnection can cause loss of beneficial settings such as radio presets, seat positioning, and engine control module (ECM) adjustments. Memory saver provides the electrical system of the vehicle with momentary power when the battery is disconnected, thus preserving these beneficial settings.

Safety Equipment: Personal Protective Equipment (PPE) to start with. Safety glasses protect the eyes from acid splash, and gloves protect the hands from chemicals and electrical shock as well. Technician safety is of highest concern.

OBD-II Scanner: Many new trucks need to have battery replacement followed by resetting some of the parameters on the engine control unit (ECU). A mechanic can use an OBD-II scanner to communicate with the ECU and erase any error codes that may have been created in the process of replacing the battery. This is especially necessary for trucks that use advanced battery management systems.

Why Professional Tools Matter for Truck Battery Replacement

With the right equipment, not only is the battery replaced safely and effectively but also diagnosed accurately and properly installed within the system. Replacing a truck battery without the right equipment may lead to:

Vandalization of the Vehicle's Electrical System: Incorrect disconnecting or reconnecting the battery may damage sensitive electronic circuits.

Loss of Vehicle Settings: As mentioned earlier, battery disconnect without the use of memory saver can lead to irretrievable loss of settings.

Incorrect Battery Installation: Loose fitting terminals causing corrosion and sloppy connections can also lead to electrical problems.

Personal Injury: Handling big batteries and electricity is dangerous without protective equipment and procedure.

Battery Boost & Key Rescue: Your Trusted Partner for Truck Battery Replacement

Whenever you need reliable truck battery replacement in Carrum Downs or professional truck battery replacement in Dandenong, Battery Boost & Key Rescue is your answer. We combine advanced technology and very skilled technicians to offer a hassle-free and smooth service.

We understand the necessity of minimizing downtime for your operations. We're 24/7 mobile, visiting you rather. We have a wide array of premium quality truck batteries featuring a variety of makes and models to match for optimal performance and longevity.

Contact Battery Boost & Key Rescue today for expert truck battery replacement in Dandenong and truck battery replacement in Carrum Downs. Let us keep your fleet running smoothly and efficiently.

#truck battery replacement Hallam#truck battery replacement Lyndhurst#truck battery replacement Cranbourne#truck battery replacement Pakenham#truck battery replacement in Carrum Downs#Truck Battery Replacement in Dandenong

0 notes

Text

The Lockheed SR-71A Blackbird "Big Tail" has calibration stripes painted on its tail to help with tracking during early flight and taxi tests

Big Tail - One of a Kind Variant

Shortly after the first SR-71’s began flying operational missions over North Vietnam, the Air Force was looking into ways of expanding the capabilities of the aircraft. With the interchangeable noses, mission planners had to make a choice of flying either optical cameras or side-looking radar, depending upon the mission requirements and the weather over the target area. Unfortunately several missions were rendered useless when weather over the target area prevented the use of the optical camera systems installed. There was also the possibility that future ground defenses had the ability to reach the SR-71 from behind since it carried no aft facing countermeasures.

SR-71A 959 Big Tail on the ramp at Palmdale.(Lockheed Photo)

In 1974, the Air Force identified a requirement for aft facing ECM requirement on the SR-71. Several proposals examined by the Air Force included conformal packages, belly pods as well as an extended tail fairing. After researching all the possibilities, the extended tail appeared to be the most viable option based on lowest cost, added volume and least aerodynamic drag. The new “Big Tail” assembly is 13-feet, 9-inches long and weighs 1,273 lbs. with 49 cubic feet of space to carry 864 lbs. of payload. The primary payload consisted of aft facing ECM as well as the 24-inch Optical Bar Camera. The new assembly needed to articulate 8.5 degrees up and down to clear the runway during take-off and landing.

The tenth SR-71 built (61-7959) was selected to receive the new modification. This aircraft was already being used for flight test duties at Palmdale at the time so there would be no effect on the operational fleet. Between April and November 1975, ‘959 received the modification with the new tail fairing; necessary modifications included a 51-inch adapter unit for the new tail, air conditioning for cameras and other equipment as well as routing the fuel vent along the upper surface of the tail. In addition to the tail modification, chine bays were modified to accommodate the 24-inch Optical Bar Camera.

The modified tail assembly shows up well in this view as SR-71A 61-7959 ‘Big Tail’ takes on fuel from a KC-135Q tanker aircraft. The ex-tended tail required the fuel dump port to be routed across the top of the new tail assembly.

PHOTO DETAILS / DOWNLOAD HI-RES

With the stress and vibration testing completed, ‘Big Tail’ was taken out for the first high-speed taxi test on November 20, 1975 by Lockheed test crew Darrell Greenamyer (pilot) and Steven Belgeau (Reconnaissance Systems Officer-RSO). Two weeks later, on December 3, the same crew took Big Tail up on its first flight. Lasting just over one hour, the crew performed basic flight checks as well as tail deflections and fuel dump tests. With each test flight with the same Lockheed crew, Big Tail flew to higher speeds and altitudes achieving Mach 3 at 75,000 ft during the 6th flight on January 28,1976. Prior to turning the aircraft over to Air Force test crews, Greenamyer performed 4 solo flights to prove the system could be run by just a single crewmember. The RSO’s seat occupied by a ballast dummy affectionately known as “Sierra Sam”.

Once Lockheed crews proved the system worked, the Air Force took over all flight testing. Tom Pugh and Bob Riedenauer became the pilots and RSO duties went to William Frazier and John Carnochan with the first Air Force flight taking place on May 5, 1976. Over the next 6 months these Air Force crews made 23 flights in ‘Big Tail’, testing various camera systems in the tail and chine bays, as well as new ECM systems such as the DEF I, DEF J and DEF A-2.

Although ‘Big Tail’ proved to be a viable system, the Air Force chose not to pursue the concept any further. After only 36 flights with the extended tail, ‘959 made its last flight on Oct. 29 1976

@Habubrats71 via X

28 notes

·

View notes

Text

Raptor RPT-3Xb

Yes, that is a VTOL Mast Mount.

Raptor II RPT-3Xb

Mass: 40 tons

Chassis: Composite Biped

Power Plant: 240 XL

Cruising Speed: 64.8 kph

Maximum Speed: 129.6 kph

Jump Jets: Standard

Jump Capacity: 90 meters

Armor: Ferro-Fibrous

Armament:

2 ER Medium Laser

1 TAG

2 Improved ATM 3

Manufacturer: Unknown

Primary Factory: Unknown

Communication System: Unknown

Targeting & Tracking System: Unknown

Introduction Year: 3153

Tech Rating/Availability: F/X-X-X-X

Cost: 15,752,800 C-bills

Type: Raptor II

Technology Base: Mixed (Experimental)

Tonnage: 40

Battle Value: 1,663

Equipment Mass

Internal Structure Composite 2

Engine 240 XL 6

Walking MP: 6

Running MP: 9(12)

Jumping MP: 3

Double Heat Sink 10 [20] 0

Gyro 3

Small Cockpit (Armored) 2

Armor Factor (Ferro) 124 6.5 Internal Structure Armor Value Head 3 9 Center Torso 12 16 Center Torso (rear) 5 R/L Torso 10 16 R/L Torso (rear) 4 R/L Arm 6 10 R/L Leg 10 17

Right Arm Actuators: Shoulder, Upper Arm

Left Arm Actuators: Shoulder, Upper Arm

Weapons and Ammo Location Critical Heat Tonnage

Void Signature System CT/RT/LT/RA/LA/RL/LL 1/per - 0.0

Jump Jet CT 1 - 0.5

Improved ATM 3 RT 2 2 1.5

Jump Jet RT 1 - 0.5

CASE II RT 1 - 0.5

Supercharger RT 1 - 1.0

Extended-Range iATM/3 Ammo (20) RT 1 - 1.0

High-Explosive iATM/3 Ammo (20) RT 1 - 1.0

Double Heat Sink LA 2 - 1.0

Wolfhound Active Probe* LT 1 - 1.0

Improved ATM 3 LT 2 2 1.5

Jump Jet LT 1 - 0.5

Nova Combined Electronic Warfare System LT 1 - 1.5

TAG** LT 1 0 1.0

Recon Camera** LT 1 - 0.5

Archangel ECM Suite*** LT 1 - 1.0

VTOL Mast Mount LT 1 - 0.5

Armored Cowl (Armored) HD 1 - 1.0

Remote Drone Command Console (Armored) HD 1 - 2.0

2 ER Medium Laser RA 2 5 2.0

* = operates as Bloodhound Active Probe

** = mounted in VTOL Mast Mount

*** = operates as Angel ECM Suite

Features the following design quirks: Accurate Weapon (all), Battle Computer, Combat Computer, Cowl, Easy to Pilot, Extended Torso Twist, Improved Communications, Improved Cooling Jacket (all), Improved Sensors, Multi-Trac, Nimble Jumper, Reinforced Legs, Searchlight, Variable Range Targeting, Illegal Design (VTOL Mast Mount on 'Mech; mounts custom equipment), No/Minimal Arms

5 notes

·

View notes

Text

Laserfiche Kuwait: Empowering Digital Transformation with Al-Hakimi United

In today's fast-paced digital landscape, organizations in Kuwait are increasingly seeking robust solutions to streamline operations, enhance efficiency, and ensure compliance. Laserfiche Kuwait, a leading enterprise content management (ECM) and business process automation platform, has emerged as a pivotal tool in this transformation journey. At the forefront of delivering these solutions in Kuwait is Al-Hakimi United, an authorized Laserfiche partner dedicated to facilitating seamless digital transitions for businesses across various sectors.

Understanding Laserfiche: A Comprehensive ECM Solution

Laserfiche offers a comprehensive suite of tools designed to manage documents, automate workflows, and provide actionable insights. Its capabilities extend beyond traditional document management, encompassing intelligent data capture, process automation, and robust analytics. By leveraging Laserfiche, organizations can centralize their information, reduce manual tasks, and make informed decisions based on real-time data.

Al-Hakimi United: Your Trusted Partner in Kuwait

Al-Hakimi United stands as a beacon of digital innovation in Kuwait, offering tailored Laserfiche solutions to meet the unique needs of local businesses. With a deep understanding of the regional market and a commitment to excellence, Al-Hakimi United provides end-to-end services, from consultation and implementation to ongoing support. Their expertise ensures that organizations can harness the full potential of Laserfiche to drive efficiency and growth.

Key Features and Benefits of Laserfiche

1. Intelligent Content Capture Laserfiche's advanced capture tools enable organizations to process high volumes of content, extract critical data, and automatically organize files. This intelligent system transforms unstructured data into valuable information, facilitating easier access and management.

2. Process Automation With low-code/no-code automation capabilities, Laserfiche allows teams to design and implement workflows that streamline operations. From approval processes to task management, automation reduces manual intervention, minimizes errors, and accelerates task completion.

3. Enhanced Collaboration Laserfiche fosters collaboration by providing a centralized platform where teams can access, edit, and share documents securely. Features like version control, annotations, and simultaneous editing ensure that everyone stays on the same page, enhancing productivity.

4. Robust Security and Compliance Security is paramount in today's digital age. Laserfiche offers fine-grained access controls, audit trails, and compliance tools to protect sensitive information. Organizations can confidently manage records, ensuring they meet regulatory requirements and maintain data integrity.

Laserfiche 12: The Latest Advancements

The release of Laserfiche 12 marks a significant milestone, introducing features that further enhance user experience and administrative capabilities. Notable enhancements include:

New Metadata Template Designer – Simplifies the creation and management of metadata templates, improving data organization.

Test Mode in Forms – Allows users to test forms before deployment, ensuring functionality and user-friendliness.

Updated Administration Console – Provides administrators with more control and visibility, streamlining system management.

These features, combined with improved usability and flexible deployment options, make Laserfiche 12 a powerful tool for organizations aiming to modernize their operations.

Industry Applications in Kuwait

Laserfiche's versatility makes it suitable for various industries in Kuwait:

Education – Institutions can digitize student records, automate admissions, and streamline administrative processes.

Healthcare – Hospitals and clinics can manage patient records securely, automate billing, and ensure compliance with health regulations.

Legal Services – Law firms can organize case files, automate client intake, and manage contracts efficiently.

Finance – Banks and financial institutions can handle documents related to loans, compliance, and customer onboarding with greater efficiency.

Cloud Solutions for Modern Businesses

Recognizing the need for scalable and accessible solutions, Laserfiche offers cloud-based options that cater to organizations of all sizes:

Starter Plan – Ideal for small teams, offering essential document management features.

Professional Plan – Includes advanced automation and integration tools, suitable for growing businesses.

Business Plan – Designed for larger organizations, providing extensive administrative and compliance features.

These cloud solutions ensure that businesses can access their documents anytime, anywhere, while benefiting from regular updates and robust security measures.

Why Choose Al-Hakimi United?

Partnering with Al-Hakimi United means more than just implementing a software solution; it's about embarking on a journey towards digital excellence. Their team of experts works closely with clients to understand their unique challenges and tailor solutions that align with their goals. With a proven track record and a commitment to customer satisfaction, Al-Hakimi United is the go-to partner for organizations in Kuwait seeking to leverage Laserfiche for digital transformation.

Getting Started

Embarking on your digital transformation journey is just a step away. Contact Al-Hakimi United today to learn more about how Laserfiche can revolutionize your organization's operations.

Phone: +965-66331629

Email: [email protected]

Website: www.alhakimiunited.com

With Al-Hakimi United and Laserfiche, your organization is poised to achieve greater efficiency, compliance, and growth in the digital era.

0 notes

Text

Essential Tools for Servicing Caterpillar Equipment

When it comes to maintaining and servicing Caterpillar equipment, the right set of tools can make all the difference. At Tillman Tools, LLC, we understand the critical role precision and durability play in heavy machinery maintenance. Whether you are a seasoned technician or a workshop manager, investing in specialized Caterpillar Tools ensures your equipment performs at its best. Below, we dive deep into the essential tools you need for effective service operations.

Heavy-Duty Socket Sets for Caterpillar Equipment

One of the fundamental requirements for servicing Caterpillar machinery is a comprehensive heavy-duty socket set. CAT Tools often involve working with massive bolts and torque specifications that exceed standard automotive settings. Industrial-grade impact sockets, deep sockets, and torque multiplier kits designed specifically for Caterpillar specifications are crucial.

At Tillman Tools, LLC, we offer Caterpillar Tools engineered to meet these high demands. Our socket sets include metric and SAE sizes, perfect for a variety of applications on loaders, bulldozers, and excavators. Utilizing proper sockets not only increases your efficiency but also protects the machinery from damage caused by improper tooling.

CAT Hand Tools: Precision in Every Turn

When fine-tuning or performing intricate repairs, technicians turn to CAT Hand Tools. These include wrenches, pliers, screwdrivers, and pry bars crafted to the exacting standards necessary for Caterpillar equipment.

Our range of CAT Hand Tools is designed for high leverage and enhanced grip, minimizing slippage and hand fatigue during long service hours. Ergonomically designed with durable materials, these tools help technicians access hard-to-reach components without sacrificing precision.

Specialty tools like torque wrenches calibrated for Caterpillar torque specifications are indispensable. They ensure bolts and nuts are tightened to exact pressures, which is critical in preventing premature wear and operational failure.

Diagnostic Tools: The Brain of Modern Servicing

Modern Caterpillar machines integrate complex electronic control modules (ECMs) requiring diagnostic precision. Using the correct electronic diagnostic CAT Tools such as Cat ET (Electronic Technician) software combined with communication adapters can drastically improve troubleshooting speed.

Tillman Tools, LLC supplies high-quality diagnostic kits that link seamlessly with Caterpillar ECMs. These tools allow real-time monitoring, fault code reading, and configuration adjustments—essential for minimizing downtime and optimizing machine performance.

Hydraulic Service Kits for Caterpillar Machinery

Hydraulics are the lifeblood of Caterpillar heavy machinery. Proper service demands specialized hydraulic tools, such as pressure testing kits, hose crimping tools, and cylinder repair kits.

Our premium hydraulic Caterpillar Tools include custom hydraulic testing gauges compatible with CAT machinery, ensuring safe and accurate diagnosis of hydraulic issues. Investing in the correct hydraulic service equipment safeguards the machine’s operational integrity and extends its lifespan.

Pullers and Extractors: Handling Heavy Components

Disassembling major components like bearings, gears, or pulleys on Caterpillar equipment often requires industrial pullers and extractors. Using inappropriate or makeshift tools can lead to damage or even personal injury.

Tillman Tools, LLC offers a full line of heavy-duty pullers engineered for Caterpillar maintenance needs. These CAT Tools provide the right balance of force and precision, ensuring parts are removed without unnecessary strain or damage.

Lifting Equipment: Essential for Safety and Efficiency

Proper lifting equipment is vital when servicing heavy Caterpillar components. Hydraulic jacks, engine hoists, and lifting slings rated for the immense weight of CAT machines are non-negotiable.

Our collection of lifting CAT Hand Tools ensures that technicians can safely and efficiently maneuver heavy machinery parts. All equipment is tested to meet or exceed OSHA standards, prioritizing workplace safety alongside operational efficiency.

Lubrication Tools: Keeping Caterpillar Equipment Running Smoothly

Regular lubrication is key to preventing component wear in Caterpillar machines. Grease guns, oil dispensers, and fluid transfer systems form an important part of the service toolkit.

Tillman Tools, LLC provides lubrication Caterpillar Tools that are rugged, reliable, and built for industrial use. Proper lubrication extends the service intervals of critical components, ultimately saving operational costs.

Tool Storage and Organization: Maximizing Productivity

High-quality tools require superior organization. Heavy-duty toolboxes and mobile workstations designed for Caterpillar servicing enhance workflow efficiency.

We offer durable, weather-resistant tool storage solutions that keep CAT Tools organized and protected from harsh working environments. Custom foam inserts and modular drawers ensure that every tool has a designated place, reducing the risk of misplacement and downtime.

Specialty Caterpillar Tools for Advanced Repairs

Advanced servicing often demands specialized tools tailored specifically for Caterpillar equipment. Timing tools, bushing drivers, and engine-specific tooling sets ensure repairs meet OEM standards.

At Tillman Tools, LLC, we provide these advanced Caterpillar Tools to ensure every technician can perform complex repairs with factory-level accuracy. Our specialty kits are indispensable for service centers committed to delivering premium-quality maintenance.

Why Choose Tillman Tools, LLC for Caterpillar Servicing Equipment?

Tillman Tools, LLC stands as a trusted name for providing high-quality Caterpillar Tools, CAT Tools, and CAT Hand Tools. Our commitment to excellence, coupled with our deep understanding of Caterpillar machinery, enables us to supply tools that empower technicians to perform their best work.

When you choose Tillman Tools, LLC, you invest in durability, precision, and superior performance—essentials for keeping Caterpillar equipment running at peak efficiency.

0 notes