#high voltage sensor

Explore tagged Tumblr posts

Text

Cybersecurity in Power Systems: Safeguarding Transmission and Distribution Infrastructure

Introduction:

In an era dominated by technology, the power industry is undergoing a transformation, with the integration of smart grids and digital solutions becoming increasingly prevalent. However, this digital evolution brings with it a new set of challenges, particularly in the realm of cybersecurity. Power systems, including transmission and distribution infrastructure, are critical components of our modern society, making them prime targets for cyber threats. In this blog post, we will delve into the importance of cybersecurity in power systems and explore measures to safeguard transmission and distribution infrastructure.

Understanding the Landscape:

Power systems, encompassing transmission and distribution, are the backbone of any nation's infrastructure. As these systems become more interconnected and reliant on digital technologies, the vulnerability to cyber threats escalates. Transmission and distribution manufacturers in India are at the forefront of adopting innovative solutions to enhance the efficiency of power systems. However, with this increased connectivity comes the imperative need to fortify these systems against cyber attacks.

The Role of Cybersecurity in Power Systems:

Protecting Critical Infrastructure:

Cybersecurity plays a pivotal role in protecting critical infrastructure, especially in the power sector. Transmission and distribution manufacturers in India are recognizing the significance of robust cybersecurity measures to safeguard their equipment and networks.

Securing Outdoor Support Insulators:

Outdoor support insulators are crucial components in power systems, providing structural support and insulation. Cyber threats targeting these insulators could compromise the integrity of the entire power grid. Implementing cybersecurity protocols ensures the resilience of these components against potential attacks.

High Voltage Primary Bushing Outdoor Manufacturers in India:

Manufacturers producing high voltage primary bushings outdoors are well-aware of the challenges posed by cyber threats. Implementing stringent cybersecurity measures is imperative to prevent unauthorized access and manipulation of these critical components.

Addressing Vulnerabilities in Fuse Cutouts:

Fuse cutouts are essential for protecting power distribution systems from overcurrents. However, these components are susceptible to cyber threats that could disrupt their functionality. Cybersecurity measures are crucial in identifying and addressing vulnerabilities in fuse cutouts.

Cyber Threats in Power Systems:

Malware and Ransomware Attacks:

Malicious software and ransomware attacks pose a significant threat to power systems. These attacks can disrupt operations, compromise sensitive data, and demand ransom payments. Implementing robust cybersecurity measures is essential to mitigate the risk of malware and ransomware infiltrations.

Phishing and Social Engineering:

Phishing attacks and social engineering tactics target human vulnerabilities within organizations. Employees in transmission and distribution manufacturers in India must be educated on recognizing and avoiding these cyber threats to prevent unauthorized access to critical systems.

Insider Threats:

Insider threats, whether intentional or unintentional, can pose a severe risk to power systems. Establishing comprehensive access controls, monitoring systems, and conducting regular employee training can help mitigate the potential impact of insider threats.

Safeguarding Strategies:

Network Segmentation:

Implementing network segmentation is crucial to isolate and contain cyber threats. This strategy ensures that even if one part of the network is compromised, the entire system remains secure.

Regular Security Audits:

Conducting regular security audits is essential for identifying vulnerabilities and weaknesses in power systems. Transmission and distribution manufacturers in India should prioritize periodic assessments to stay ahead of evolving cyber threats.

Employee Training Programs:

Employees play a crucial role in cybersecurity. Training programs should focus on raising awareness about potential threats, recognizing phishing attempts, and promoting a security-conscious culture within the organization.

Advanced Authentication Protocols:

Implementing advanced authentication protocols, such as multi-factor authentication, adds an extra layer of security to prevent unauthorized access to critical systems.

Conclusion:

As power systems evolve with technological advancements, the need for robust cybersecurity measures becomes paramount. Transmission and distribution manufacturers in India must prioritize safeguarding their infrastructure against cyber threats to ensure the continuous and reliable delivery of power. From outdoor support insulators to high voltage primary bushings outdoors and fuse cutouts, every component plays a critical role in the functioning of power systems and requires protection from potential cyber attacks.

In the face of evolving cyber threats, a proactive approach to cybersecurity is the key to resilience. By adopting advanced cybersecurity measures and staying abreast of the latest developments in the field, Radiant Enterprises and other stakeholders in the power industry can fortify their transmission and distribution infrastructure, contributing to a secure and sustainable energy future.

#Transmission and Distribution Manufacturers in India#Outdoor Support Insulator#High Voltage Primary Bushing Outdoor Manufacturers in India#Fuse Cutouts#epoxy insulator#epoxy bushing#electricity#fuse cutouts#smart grid sensor#railway technology companies#train operating companies#locomotive#tramways#metro systems#traffic infrastructure

6 notes

·

View notes

Text

Athletes Go for the Gold with NASA Spinoffs

NASA technology tends to find its way into the sporting world more often than you’d expect. Fitness is important to the space program because astronauts must undergo the extreme g-forces of getting into space and endure the long-term effects of weightlessness on the human body. The agency’s engineering expertise also means that items like shoes and swimsuits can be improved with NASA know-how.

As the 2024 Olympics are in full swing in Paris, here are some of the many NASA-derived technologies that have helped competitive athletes train for the games and made sure they’re properly equipped to win.

The LZR Racer reduces skin friction drag by covering more skin than traditional swimsuits. Multiple pieces of the water-resistant and extremely lightweight LZR Pulse fabric connect at ultrasonically welded seams and incorporate extremely low-profile zippers to keep viscous drag to a minimum.

Swimsuits That Don’t Drag

When the swimsuit manufacturer Speedo wanted its LZR Racer suit to have as little drag as possible, the company turned to the experts at Langley Research Center to test its materials and design. The end result was that the new suit reduced drag by 24 percent compared to the prior generation of Speedo racing suit and broke 13 world records in 2008. While the original LZR Racer is no longer used in competition due to the advantage it gave wearers, its legacy lives on in derivatives still produced to this day.

Trilion Quality Systems worked with NASA’s Glenn Research Center to adapt existing stereo photogrammetry software to work with high-speed cameras. Now the company sells the package widely, and it is used to analyze stress and strain in everything from knee implants to running shoes and more.

High-Speed Cameras for High-Speed Shoes

After space shuttle Columbia, investigators needed to see how materials reacted during recreation tests with high-speed cameras, which involved working with industry to create a system that could analyze footage filmed at 30,000 frames per second. Engineers at Adidas used this system to analyze the behavior of Olympic marathoners' feet as they hit the ground and adjusted the design of the company’s high-performance footwear based on these observations.

Martial artist Barry French holds an Impax Body Shield while former European middle-weight kickboxing champion Daryl Tyler delivers an explosive jump side kick; the force of the impact is registered precisely and shown on the display panel of the electronic box French is wearing on his belt.

One-Thousandth-of-an-Inch Punch

In the 1980s, Olympic martial artists needed a way to measure the impact of their strikes to improve training for competition. Impulse Technology reached out to Glenn Research Center to create the Impax sensor, an ultra-thin film sensor which creates a small amount of voltage when struck. The more force applied, the more voltage it generates, enabling a computerized display to show how powerful a punch or kick was.

Astronaut Sunita Williams poses while using the Interim Resistive Exercise Device on the ISS. The cylinders at the base of each side house the SpiraFlex FlexPacks that inventor Paul Francis honed under NASA contracts. They would go on to power the Bowflex Revolution and other commercial exercise equipment.

Weight Training Without the Weight

Astronauts spending long periods of time in space needed a way to maintain muscle mass without the effect of gravity, but lifting free weights doesn’t work when you’re practically weightless. An exercise machine that uses elastic resistance to provide the same benefits as weightlifting went to the space station in the year 2000. That resistance technology was commercialized into the Bowflex Revolution home exercise equipment shortly afterwards.

Want to learn more about technologies made for space and used on Earth? Check out NASA Spinoff to find products and services that wouldn’t exist without space exploration.

Make sure to follow us on Tumblr for your regular dose of space!

2K notes

·

View notes

Note

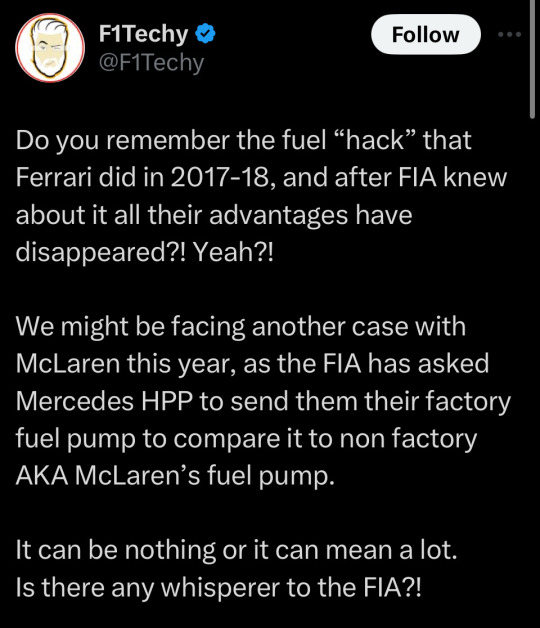

https://x.com/F1Techy/status/1797338007860662614

is this real?

Nope, whoever this person is, they are way off and they have no sources so don’t believe a word they say

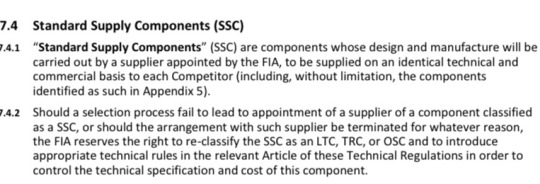

In fact Mercedes don’t make their own fuel pumps, let alone McLaren’s. No team has made their own fuel pumps since 2021.

Fuel pumps are categorised as a Standard Supply Component which means that they are designed and manufactured by a third party designated by the FIA.

This means that the same company makes all of the fuel pumps for all of the teams on the grid, so if there was anything going on with a fuel pump they would be going back to this third party not Mercedes.

Just because someone has a blue tick, doesn’t mean that they know what they are saying.

Full list of SSC parts below (from FIA regulations)

Wheel covers

• Clutch shaft torque

• Wheel rims

• Tyre pressure sensor (TPMS)

• Tyres

• Fuel system primer pumps, and flexible pipes and hoses

• Power unit energy store current/voltage sensor

• Fuel flow meter

• Power unit pressure and temperature sensors

• High-pressure fuel pump

• Car to team telemetry

• Driver radio

• Accident data recorder (ADR)

• High-speed camera

• In-ear accelerometer

• Biometric gloves

• Marshalling system

• Timing transponders

• TV cameras

• Wheel display panel

• Standard ECU

• Standard ECU FIA applications

• Rear lights

69 notes

·

View notes

Text

Quick sketch for Piers’ bionic arm.

Design Features

•Aesthetics: Streamlined, ergonomic design with a minimalist look, often featuring a matte or metallic finish.

•Materials: Lightweight composites like carbon fiber and titanium, providing durability without sacrificing mobility.

•Color Options: Customizable colors or finishes, including options for skin-like textures or futuristic metallics.

Technology

•Actuation: Advanced motors and actuators that enable precise, fluid movement mimicking natural limb motion.

•Sensors: Integrated sensors (e.g., myoelectric sensors) to detect muscle signals for intuitive control and movement.

•Feedback Systems: Haptic feedback mechanisms to provide users with sensory information about grip strength and object texture.

Safety and Durability

•Water and Dust Resistance: High IP ratings to protect against environmental factors.

•Emergency Features: Manual override systems or fail-safes in case of technology malfunction.

Advanced Technological Interface

•Integrated Biosensors: Built-in biosensors that can analyze blood or interstitial fluid samples to measure viral load in real time.

•Data Analytics: Utilizes algorithms to process biosensor data, providing insights on viral dynamics and trends.

•Alerts and Notifications: Real-time alerts sent to the user or healthcare provider when viral load exceeds predetermined thresholds.

•Communication System: Integrated with a communicator on the wrist, the arm serves as a reliable device for maintaining contact with his team. This system includes encrypted channels for secure communication during high-stakes operations.

•Objective Management Display: The arm features a holographic display that provides a detailed version of the communicator’s data, allowing Piers to view mission objectives and tactical data in real-time. This feature minimizes the need for external devices and keeps critical information accessible.

Augmented Reality (AR) Compatibility

•Enhanced Visualization: The arm’s display projects augmented reality overlays, allowing Piers to see additional information, such as enemy positions, weapon stats, or tactical directions, directly in his line of sight.

•Environmental Scanning: The arm can analyze the surroundings for potential threats, detect biological or chemical hazards, and provide alerts for safer navigation through hostile environments.

Electricity Conduction and Control

•Energy Conduit Design: The bionic arm acts as a conductor for the constant electrical energy generated by Piers’ mutation. It includes specialized channels and circuits designed to manage this energy flow, allowing Piers to use his mutation’s electrical pulse without it spiraling out of control.

•Dielectric Structures: The arm’s design incorporates materials that mimic the dielectric properties of his mutated tissue, particularly in the finger joints and bones. These dielectric components help regulate and contain the high voltage his body produces, diffusing excess energy safely throughout the arm.

•Controlled Release Mechanism: To avoid overload, the arm features a controlled release system that allows Piers to release pulses of energy strategically, whether in combat or to alleviate the internal buildup. This system prevents the arm from overheating or sustaining damage from prolonged electrical activity.

Containment and Compression of the Mutation

•Compression Framework: The prosthetic was specially designed by UMBRELLA engineers to act as a containment “net” around his mutation. It includes a flexible, reinforced framework that compresses the mutated tissue, keeping it in check and preventing further growth or erratic shifts in form.

•Adaptive Pressure System: As the mutation strains against the arm, sensors detect any changes in size or energy output, triggering adaptive responses. The arm tightens or loosens as necessary to hold the mutation back, functioning almost like a high-tech brace that adjusts in real-time to maintain Piers’ arm in a stable form.

•Automatic Safety Lock: In the event of a significant spike in mutation activity or electrical output, the arm engages an emergency lock to keep the mutation from expanding. This feature is a safeguard against sudden bursts of energy that could cause the arm to revert to its mutated state.

Dependency and Risks of Removal

•Rapid Mutation Onset: Without the prosthetic in place, Piers’ arm begins to mutate almost immediately, returning to its original, unstable form. The electrical pulse that his body generates becomes unrestrained, emitting a continuous, breath-like rhythm that is both painful and dangerous, with energy leaking through protruding bones and exposed tissue.

•Uncontrollable Pulse: When uncontained, the electrical pulse from his mutation surges in intensity, lacking any natural “closure” or stopping point. This pulse causes rapid fluctuations in his vital signs and risks systemic overload, leading to loss of control over his mutation and putting him at severe physical risk.

Miscellaneous Details

•The arm has a unique serial code engraved on an inner plate, serving as an identifier for UMBRELLA technicians. This code also links to Piers’ personal health records, mutation data, and arm specifications for quick access during maintenance or in emergencies.

•Due to the intense electrical pulses generated by his mutation, the arm is equipped with an internal cooling system. Micro-fans and heat-dissipating channels prevent overheating during extended use, keeping the arm at a safe, comfortable temperature. If the arm overheats, an internal alarm alerts Piers to prevent any potential damage.

•The outer layer is treated with a UV-resistant coating to protect it from environmental damage and exposure. This ensures that prolonged exposure to sunlight or harsh conditions doesn’t wear down the arm’s exterior, making it more durable in diverse climates and situations.

•Designed for various operational environments, the arm is fully waterproof and corrosion-resistant. It functions normally underwater, which is crucial for aquatic missions or when exposed to rain, mud, or corrosive substances.

•The holographic display can be customized to show additional details, such as weather, GPS navigation, or tactical maps. Piers can also set personal preferences, like color schemes or alert tones, for a more intuitive user experience. This flexibility lets him prioritize the information he finds most critical during missions.

•The communicator has an onboard language translator, enabling Piers to communicate with individuals across different languages. The arm’s display shows translated text, and a subtle earpiece can even relay audio translations, making it easier for him to gather intel and negotiate in multilingual environments.

#𝐒𝐮𝐛𝐣𝐞𝐜𝐭 𝟏𝟑#𝐌𝐮𝐬𝐞; 𝐏𝐢𝐞𝐫𝐬 𝐍𝐢𝐯𝐚𝐧𝐬#I think I very severely fucked up my lefts and rights Ngl but oh well#resident evil#resident evil 6#piers nivans#long post

45 notes

·

View notes

Text

Eternal LMK Au (Part 17) Interactive Story

Chang'e arrives~

The rules are simple.: I will give the written passage, and then at the bottom there will be a vote on how the characters act next!

Story; Eternal Au

Ship; ShadowPeach

Wukong's battle-ready stance immediately dissolved into pure delight. His eyes widened, sparkling with childlike wonder as the robotic bunny approached. "OH MY GOODNESS!" he squealed, bouncing on his toes. "LOOK HOW CUTE YOU ARE!"

---------

If he could see Mihou... he had a feeling he would be smacking his forehead right now.

The robotic bunny, clearly designed for surveillance and defense, seemed momentarily confused by Wukong's enthusiastic response. Its mechanical ears twitched, sensors scanning the unexpected visitor. It had come out here with the intention of tracking the unwanted visitor. Typically to scare them off… not get fawned over.

Wukong was practically vibrating with excitement, his previous tension completely forgotten. "Aren't you just the most adorable little thing?!" he cooed, taking a step forward with outstretched hands.

The robotic bunny's metallic ears pivoted, tracking Wukong's movement. Its glowing eyes flickered between scanning modes, assessing whether this strange monkey was a potential threat.

A synthesized voice emerged, crisp and precise. "Unidentified entity detected. State your purpose." as it scanned it, it reached into his memory to recall why this man seemed familiar. As Wukong swayed a little, it was quick to realize.

Target identified as: Sun Wukong, the Monkey King. Threat level: RED.

The robotic bunny's demeanor shifted instantly. Where moments ago it had been a cute, potentially friendly surveillance unit, now it transformed into a defensive mechanism. Its metallic ears hardened like blades, and its cute exterior seemed to ripple and reshape, revealing intricate defense systems.

"Threat detected," the synthesized voice announced, now cold and clinical. "Sun Wukong: Known disruptor. Initiating defensive protocols. Commencing capture."

Wukong, who had been mid-squeal about how adorable the bunny was, suddenly froze. His excited expression morphed into a bewilderment. “Oh-” He blinked rapidly, gagging a moment later when the Robot pounced on him, "WHOA-!" Wukong yelped as the robotic bunny launched itself at him with surprising agility. Its metallic limbs unfolded, revealing an array of restraining mechanisms and defensive weaponry. "Hey now, let's talk about this-!"

The robot's synthesized voice remained emotionless. "Capture protocol activated. Subject: neutralization required."

With it’s arm around Wukong, a sudden controlled shock, similar to a high voltage razor, sprung from it’s fingertips. Wukong yelped as his fur puffed, vision going fuzzy for a moment. He had been hit by far worse, but it certainly caught him off guard.

The shock jolted through Wukong's body, causing his fur to stand on end and his muscles to seize momentarily. "Okay, that's not cute anymore!" Wukong shouted, eyes like swirls. If he could hear Mihou right now, he probably would have been screaming that he was an idiot. Probably had been warning him to take this all serious for a while now, actually.

Wukong's initial shock quickly transformed into irritation. These robotic contraptions were always so dramatic. He twisted in the bunny's grip, "Listen, little bunny," he attempted to reason, "You are super cute, but I don’t appreciate being shocked. I'm not here to cause trouble.”

The robotic bunny's sensors flashed red. "Threat level increasing. Initiating full restraint protocol."

Binding rings of light seemed to form from the bunny’s hands, wrapping around Wukong’s torso to pin his arms to his side. Wukong struggled against the robotic bunny's restraints, his initial delight transforming into mild annoyance. "Hey! This is NOT how you treat guests!" he shouted, writhing against the light-based bindings.

The robotic bunny remained impassive, its mechanical voice cutting through the lunar silence. "Sun Wukong: Recognized threat. Containment mandatory." grasping the back of his shirt, it turned, dragging him back the way it came.

“Heyyy~!” Wukong kicked and pouted. Clearly captured…

Though, if he was honest, it wasn’t exactly like he was trying to escape or avoid this. Could easily change shape to get out of this- or brute force it open. But, breaking Chang’e’ things was the last thing he needed going for him right now. After all, his goal was to convince her to listen to him, so best to come in by playing by her terms.

Either way, it got him back towards the little Moon town, which is where he was going anyway. He just wished he didn’t have to deal with the judging sensation in the air.

Mihou definitely wasn’t happy…

He laughed nervously, “T-This is one way to make an entrance,” he joked to the open air. He half expected a cricket to sound back in return.

Dragged into the little domain, he was tossed into the open court yard, his face smacking into the dirt. He grumbled, peeling his face off the cement to look up.

The courtyard was immaculate, perfectly manicured gardens surrounding pristine white marble pathways. Elegant lunar architecture rose around him, with delicate archways and crystalline structures that seemed to shimmer with an ethereal light - Chang'e's celestial residence. All at full alarm.

Seemed the bunny had notified the entire domain and put everything into lock down. Expected, he understood, but a tad loud.

"Wonderful," he muttered, spitting out a bit of dust. "Just wonderful."

The robotic bunny stood guard, its mechanical ears twitching as it monitored his movements. Wukong slowly picked himself up, shacking off his fur and trying to maintain some semblance of dignity as he sat on his knees.

A series of soft, melodic footsteps approached, and Wukong looked up to see a figure emerging from the pristine archways. Chang'e herself, resplendent in flowing lunar robes that seemed woven from moonlight itself, stepped forward. Her expression was a complex mixture of curiosity, wariness, and a hint of something deeper - perhaps pain-hurt… fear.

"Sun Wukong," she said, her voice cool and measured, clear she was keeping her distance, "I did not expect to see you here." normally she was so peppy and upbeat. Her expression solemn, very aware that bring across Wukong's chest was not something that would hold the person before her. "Why are you here?"

Wukong hesitated at the sight of her lingering a distance. Beyond her, he could sense more of her robots on guard. As well as another presence. Powerful, familiar- and seething...

It seems Princess Iron Fan had arrived just in time for him to be dragged in too. She wasn't revealing herself yet, perhaps waiting to see what he would do?

This was the first time he had seen either since what happened with Mihou. As the only person who could communicate with them on his mate’s behalf, and desperately needing their help, he felt he needed to consider his first words carefully. He would turn on his gold vision to ask for help from Mihou, if doing so wouldn’t put everyone on more edge than they already were.

So that left himself to figure this out until he could explain.

Previous

next

44 notes

·

View notes

Text

Quincy's gonna obliterate a techie one of these days gshdklfsdhl! 😂

I love these chats so much. Amir's totally not me when trying to tell a fun story. All his "mesiges" are missing are some typo and lots of emoji. 😂

[ID: multiple cropped screenshots taken from Warframe, showing a chat window with messages between the player and Amir. Omitting the repeated messages from an image to the other, the entire chat reads as it follow: First screenshot: "Sharky857: So, where'd you learn to hack? - High Voltage: LMAO - Sharky857: What? - High Voltage: listen,future, i know you have those cool... stabby wrist thingies that let you be a total l33t h4xx0r without knowing a single line of C++ or python" Second screenshot: "High Voltage: but like you don't "learn how to hack" you learn how to code lol. even then only like 25% of it's actual code the other 75% is guessing's people stupid passwords. and MAN DO PEOPLE HAVE SOME STUPID FRIGGIN PASSWORDS. like my boss at the O.R.O?! the HEAD OF IT, right?! THE GUY IN CHARGE OF IT?! HIS PASSWORD?! Admin1234!" Third screenshot: "Sharky857: But that ! made it so much more secure, Amir. lol - High Voltage: RIGHT?! i figure they probably use biometric sensor thingies for you guys in the future, yeah? probably pretty hard to hack that shit, given how many languages and protocols there are..." Fourth screenshot: "High Voltage: I mean, unless you had some sort of like... universal hack translator thingy... like a SUPER DUPER FLOPPY DISK or something that you could just shove in there and go WAM lol not like they use floppy disks in the future" Fifth and final screenshot: "High Voltage: anyway yeah so I learned how to CODE ever since i was little, knew how to type before i knew how to spell. the rest you just get from learning to predict how dumb people are with technology. speaking of gotta go hack quincy's account, talk about a shitty password, brb... - High Voltage went offline" end ID]

#warframe#warframe 1999#amir beckett#spoilers#warframe spoilers#wf spoilers#warframe 1999 spoilers#wf 1999 spoilers

24 notes

·

View notes

Text

Scientists uncover advanced manufacturing strategies for piezoelectric and triboelectric tactile sensors

Piezoelectric and triboelectric tactile sensors are designed to convert mechanical stimuli into electrical signals, making them critical components in intelligent systems. Piezoelectric sensors leverage voltage generation through mechanical stress in non-centrosymmetric materials, such as quartz and polyvinylidene fluoride (PVDF), while triboelectric sensors operate on contact-induced charge transfer. Both sensor types offer unique advantages, including self-powered functionality and high sensitivity, but also face challenges, such as material brittleness and environmental limitations. A team of researchers led by Professor Hanjun Ryu from Chung-Ang University, South Korea, has introduced novel manufacturing strategies to overcome these limitations. The team's paper is published in the International Journal of Extreme Manufacturing.

Read more.

#Materials Science#Science#Piezoelectric#Triboelectric#Electronics#Sensors#Manufacturing#Chung Ang University

14 notes

·

View notes

Text

Low Voltage Relays Explained: Types, Functions, and Applications

In the complex world of electrical systems, relays play a crucial role in ensuring safety, efficiency, and automation. Among these, low voltage relays stand out as versatile components that manage and protect circuits operating below 1000 volts. Whether in industrial automation, residential power distribution, or commercial infrastructure, these devices act as the nerve center of electrical control and protection.

In this comprehensive guide, we will break down what low voltage relays are, explore their types, explain their functions, and highlight their diverse applications across industries.

What Are Low Voltage Relays?

A low voltage relay is an electrically operated switch that uses a small control voltage (typically below 1000V AC or DC) to switch larger electrical loads on and off. These relays act as intermediaries between control circuits and power circuits, providing isolation, control, and protection.

Unlike manual switches, relays automate the process of circuit management, responding to electrical signals, fault conditions, or system commands without human intervention.

Types of Low Voltage Relays

Low voltage relays come in several forms, each tailored to specific tasks within an electrical system. Here are the main types:

1. Electromechanical Relays (EMRs)

· Use a coil and a movable armature to open or close contacts.

· Provide physical isolation between input and output.

· Common in traditional control panels and basic automation.

2. Solid-State Relays (SSRs)

· Use semiconductors (like thyristors or triacs) instead of mechanical contacts.

· Offer silent operation, faster switching, and longer lifespan.

· Ideal for high-speed applications and environments requiring low maintenance.

3. Overload Relays

· Specifically designed to protect motors and equipment from sustained overcurrent.

· Available as thermal overload relays (using bimetallic strips) or electronic overload relays (using sensors and processors).

4. Time Delay Relays

Provide a deliberate time lag between the relay receiving a signal and switching.

Used in motor control circuits, lighting systems, and sequential operations.

5. Overcurrent and Short-Circuit Relays

· Detect and react to current exceeding preset thresholds.

· Essential for system protection against faults and overloads.

6. Voltage Monitoring Relays

· Monitor voltage levels and trip when voltages fall below or rise above safe limits.

· Protect sensitive devices from under voltage and overvoltage conditions.

Functions of Low Voltage Relays

Low voltage relays serve multiple vital functions in electrical systems:

1. Switching and Control

Relays control the opening and closing of power circuits in response to low voltage signals from controllers, timers, or sensors. This enables remote and automated control of large electrical loads.

2. Protection

Relays detect abnormal conditions like overloads, overcurrent, under voltage, and phase failures. When such conditions arise, they disconnect the affected circuit to prevent equipment damage or fire hazards.

3. Isolation

They electrically isolate control circuits (usually low voltage, low current) from power circuits (high voltage, high current), ensuring safety and reducing interference.

4. Signal Amplification

A small control signal (from a PLC, sensor, or microcontroller) can trigger a relay to switch much larger loads, effectively amplifying the control power.

5. Automation and Sequencing

In complex systems, relays help sequence operations by ensuring that processes occur in the correct order and at the right time intervals.

Applications of Low Voltage Relays

Low voltage relays are the backbone of automation and protection in various industries. Here are some key application areas:

Industrial Automation

· Control of motors, pumps, conveyor belts, and production lines.

· Use in programmable logic controllers (PLCs) and distributed control systems (DCS).

Power Distribution Systems

· Protect electrical panels from overload and short circuits.

· Monitor voltage and current levels in distribution boards.

Building Automation

· Lighting control systems.

· HVAC (heating, ventilation, and air conditioning) systems.

· Elevator and escalator controls.

Renewable Energy Systems

· Manage and protect solar inverters, battery banks, and wind turbines.

· Automatically disconnect faulty sections to prevent system-wide failures.

Data Centers and IT Infrastructure

· Ensure stable power supply to servers and networking equipment.

· Protect sensitive electronics from voltage fluctuations.

Transportation

· Railways, metros, and automotive applications for control and safety circuits.

Home Appliances

· Found in washing machines, microwave ovens, and HVAC units to automate functions and provide protection.

Advantages of Using Low Voltage Relays

· Enhanced Safety: Isolate control and power circuits, reducing electrical shock risks.

· Automation Ready: Easily integrated into automated systems for smarter operation.

· Cost-Effective Protection: Safeguard expensive equipment from damage due to electrical faults.

· Versatile: Available in many forms to suit different voltage levels, currents, and response times.

· Reduced Maintenance: Especially with solid-state relays, which have no moving parts.

Future Trends: Smart Relays and IoT Integration

As industries move toward smart grids and Industry 4.0, low voltage relays are also evolving:

· Digital relays offer programmable settings, self-testing, and event recording.

· IoT-enabled relays can send status updates and alerts to centralized monitoring systems.

· Energy-efficient designs reduce power consumption while providing reliable protection.

Conclusion

Low voltage relays are indispensable in modern electrical engineering, seamlessly combining protection, control, and automation. From safeguarding your home appliances to managing the power in a sprawling industrial plant, these devices ensure that electrical systems run smoothly and safely.

Understanding the different types, functions, and applications of low voltage relays empowers system designers, engineers, and even DIY enthusiasts to build safer and more efficient electrical setups.

As technology advances, the role of these small but mighty devices will only grow, driving the future of safe, smart, and automated power systems.

8 notes

·

View notes

Text

Top 5 Industrial Automation Low-Voltage Switchgear Accessories You Need to Utilize

Stable and proper electrical systems are most important in industrial automation, and low-voltage switchgear is one of the most important elements that connects these systems. However, to reach the best performance, safety, and lifespan, the correct accessories for low-voltage switchgear need to be selected.

In this article, we will discuss the 5 must-have low-voltage switchgear accessories that industrial automation requires to run at its optimum and be less down.

1. Circuit Breakers – Protection and Safety from Overloading

Circuit breakers are the most important devices of low-voltage switchgear equipment. Circuit breakers safeguard electric circuits from problems like short circuits, overloads, and faults by breaking power supply to the circuit when they detect abnormal conditions.

Why They Are Important?

- Protect equipment from electrical fire and damage.

- Comply with industry safety standards.

- Recover quickly from a fault.

Recommendation: Use high-level circuit breakers with remote monitoring and diagnostic capabilities to improve automation efficiency.

2. Surge Protection Devices (SPDs) – Voltage Spike Protection

Voltage spikes and transients destroy electrical equipment in automation systems. SPDs function by absorbing excess voltage, thereby safeguarding sensitive hardware.

Why They Are Important?

- Reduce electrical surge downtime.

- Protect the automatic equipment and control panel from damage.

- Extend the life of electrical equipment.

Pro Tip: Install SPDs with real-time sensing sensors. That way, you can detect and fix voltage problems as they occur.

3. Busbar Systems – More Efficient Power Distribution

A busbar system is important since it allows the transmission of electrical energy more efficiently in switchgear setups. Busbars conduct better, lose less energy, and work better with systems than regular wiring.

Why They Matter?

- Simplified and less costly wiring installation.

- Minimization of energy losses by reducing the power loss.

- Simple extension to and integration with automated systems.

It is suggested that insulated busbar systems shall be employed for safety and to prevent accidental short circuits.

4. Motor Protection Relays – Intelligent Monitoring for Motors

Electric motors are a fundamental component of industrial automation. Motor protection relays safeguard motors against overloading, phase imbalance, and overheating to enable motors to run faultlessly and continuously.

Why Are They Important?

- Prevent costly motor failure and operational downtime.

- Allow remote monitoring for easy predictive maintenance. - Improve operational efficiency with auto-reset.

Tip: Incorporate programmable motor protection relays with automation systems for real-time monitoring and control.

5. Remote Monitoring and Control Devices – Increasing Automation Scope

New businesses must monitor switchgear remotely to be efficient and have low maintenance costs.

Remote monitoring devices allow operators to monitor voltage levels, power consumption, and system status from a distance.

Why Are They Important?

- Perform routine maintenance to avoid unexpected breakdowns.

- Require fewer resources and time to reduce manual inspections.

- Increase system reliability with real-time fault notifications.

Pro Tip: Implement IoT-enabled remote monitoring systems for easy integration with industrial automation systems.

Final Thoughts:

Buy good quality low-voltage switchgear accessories when you purchase them for safety, performance, and efficiency in industrial automation.

Circuit breakers, surge protective devices, busbar systems, motor protection relays, and remote monitoring systems will help you to ensure a healthy and strong electrical system.

9 notes

·

View notes

Text

Cost vs. Quality: What to Consider When Investing in Switchgear

In today’s energy-intensive world, switchgear plays a critical role in managing power distribution safely and efficiently. Whether you’re upgrading your industrial facility, building a commercial plant, or powering a large infrastructure project, choosing the right switchgear is not just a technical decision — it’s a strategic investment. One of the most common dilemmas buyers face is balancing cost vs. quality. So, how do you decide?

Understanding Switchgear: The Heart of Electrical Safety

Switchgear is a combination of electrical disconnect switches, fuses, or circuit breakers used to control, protect, and isolate electrical equipment. Its primary role is to ensure the reliability and safety of your power system.

Types of switchgear include:

· Low-voltage switchgear (for commercial and residential use)

· Medium-voltage switchgear (typically for industrial applications)

· High-voltage switchgear (used in power transmission)

Investing in the right switchgear directly impacts operational continuity, personnel safety, and overall infrastructure reliability.

The True Cost of Cheap Switchgear:

While it’s tempting to opt for budget-friendly solutions, low-cost switchgear often comes with hidden risks and long-term expenses.

Inferior Material Quality

Cheaper models often use substandard materials that degrade faster, leading to frequent maintenance or early replacement.

Safety Hazards

Low-quality switchgear can result in arc faults, insulation failure, or overheating — putting workers and equipment at risk.

Increased Lifecycle Costs

Although the initial price may be low, the total cost of ownership (including downtime, repair, and energy inefficiency) is usually higher.

Limited Scalability and Customization

Budget systems are often rigid and harder to scale as your facility grows or needs change.

Why Quality Switchgear Pays Off

When you invest in premium switchgear, you’re not just buying a product — you’re buying peace of mind.

Enhanced Reliability

High-quality switchgear is engineered to perform in extreme conditions and handle high fault levels without compromising performance.

Superior Safety Standards

Reputable brands comply with international standards such as IEC, ANSI, or UL, reducing liability and improving workplace safety.

Ease of Maintenance

Well-built switchgear is modular and user-friendly, simplifying diagnostics and minimizing downtime during maintenance.

Energy Efficiency & Smart Capabilities

Modern switchgear includes IoT sensors, real-time monitoring, and predictive maintenance features, ensuring optimal energy use and proactive problem resolution.

Key Factors to Consider When Choosing Switchgear

When evaluating switchgear options, balance cost and quality by focusing on the following:

1. Application Requirements

Understand your voltage class, load types, and fault current ratings. Quality should match your operational demands.

2. Brand Reputation & Certification

Look for trusted brands with certifications like ISO 9001, CE, or IEC 62271. Positive reviews and case studies add credibility.

3. Lifecycle Costs

Don’t just compare sticker prices — consider maintenance, service availability, spare part costs, and expected lifespan.

4. Customization & Flexibility

Choose systems that can evolve with your operation. Modular designs support upgrades and expansions more efficiently.

5. Support and Service

Ensure the manufacturer provides robust after-sales support, technical training, and warranty services.

Cost vs. Quality: The Bottom Line

When it comes to switchgear, cheap is rarely cheerful. Cutting corners today can lead to outages, hazards, and hefty repair bills tomorrow. On the other hand, investing in high-quality switchgear ensures operational resilience, safety, and long-term savings.

The smartest strategy? Aim for value, not just price. Evaluate switchgear as a long-term asset, not just a one-time purchase.

Trending Tip: Think Smart and Sustainable

With rising energy demands and climate-conscious regulations, smart and sustainable switchgear is trending. Look for:

· Eco-friendly insulation (like SF₆-free switchgear)

· Energy management features

· Digital monitoring systems

Investing in such features not only future-proofs your infrastructure but can also help you qualify for green certifications and incentives.

Final Thoughts

Balancing cost and quality in switchgear selection is about understanding your long-term operational goals. By focusing on durability, safety, and lifecycle value, you can make a decision that protects both your budget and your business.

7 notes

·

View notes

Text

Aright so- i had an idea. Here i vaguely explained how i think new cybertronians are made. And i wanted to expand on that idea.(please go look, it's not very long and it's important to this)

I have read multiple fanfics and posts about transformers having robot equivalent of human bits- that doesn't sit right with me. So i made my own. [I used Bee as a reference]

So the most common is for Newsparks to be created in artificial chambers and then transferred into protoforms for Sparklings to come online. Then they are transported into Cybertron's version of an orphanage- Carequarters, and are up for adoption until they reach younglinghood(more on that later).

TW: it's nothing bad but just to be safe- robot reproduction and naughty act talk. Plus some details about sparklings, age and growing at the end.

They have 2 slots on either side of their Spark Chamber[4 in total]. Each slot has 2 parts that close it. When transformers interface, the slots open and glowing cables[Tendrils] are released, these things are very sensitive. Now i'm skipping on all the dirty play stuff- for the full course the Tendrils need to be intertwined with the Tendrils of whoever the transformer is interfacing with. Once intertwined, those Tendrils send pulses or energy to the other thus providing pleasure.

On the bottom side of the Spark Chamber is a cover for the Reproduction Strut[commonly called a 'Spike']. The cover has 4 sections that close it. This cover is only opened when both partners want to to create a Newspark, the transformers interfacing don't have to be Conjunxes for it to work. Once the two get on with it and are both content, the cover slids open and the Spikes intertwine with each other. Unlike the Tendrils that are connected to the outside of the Spark Chamber, the Spike has an output sensor on the inner side of the Spark Chamber, meaning that when the energy pulses travel thru it, they go directly into one's Spark.

Now, there is also a way for the slots and the cover to be opened manually. This is either done when one has technical issues with their parts... or when one is "forcing an interfacing without consent."

Interfacing without the Spikes intertwining has nearly impossible chances of creating a Newspark since the energy pulses stop at the Spark Chamber, not the Spark. When the Spikes are intertwined the chances of creating a Newspark are high, but it's mostly the matter of how high is the voltage in the energy pulses of either partner. If the voltage is too low then nothing will happen. The Newspark usually is created inside the Spark Chamber of the transformer with lower voltage than their partner.

The Newsparks are carried inside one's Spark Chambers until they reach their full size, depending of how big the Carrier and Sire are the outcomes are either; the Newspark being transferred into a protoform without trouble or having to be extracted early due to risk of outgrowing the Carrier's Spark Chamber. The risks are; it can get snuffed out, get absorbed into the Carrier's Spark when not transferred in time, or break into multiple Newsparks- last one isn't exactly bad but it can be if one isn't prepared for more than 1 Sparkling. The carrying process usually last from 4-5 Earth Months.

After transferring the Newspark from Carrier's Spark Chamber to a protoform, a Sparkling's frame is fully developed around 12 Earth Years*1. Their frames can change and grow even after they reach the full development, but it is very slow compared to the speed of development. *1 Note that it's Earth Years, i have absolutely no fuckin idea how long that is on Cybertron. Their alt modes start to come it at 5EY old.

Side note; a fully developed frame does not mean the transformer is an adult. Transformers reach the age status: -Youngling [teen]: 10+ Earth Years (this one is more of a moral status since biologically they are full grown) -Young Adult: 100+ Earth Years -Full Adult: 10k+ Earth Years -Elder: 100k+ Earth Years

A transformer that's been made due to the influence of the AllSpark is automatically considered a Youngling.*2 *2 A protoform can be onlined using an AllSpark Shard[shard will turn into a Spark], it is still a Sparkling and will go thru development. Transformers don't have genders, so a Sparkling is either referred to as It or They. That is held until the Sparkling starts speaking and they choose how they wanna be adressed[Speaking usually starts at 2EY old but they are asked the question at 3EY old].

I will be using this as a reference when writing, thank you.

btw, all of my general ideas about transformers/tfa now have a tag "transformers headcanons" on my blog, so go check that out if you want.

72 notes

·

View notes

Note

FOLLOW UP: would it be possible to connect a server rack to this?? Actually I don’t know the definition of server rack, but regardless I have. So many muddled questions, ahem, let me sort them.

💥

sorry I exploded trying. Anyway, I’m just gonna put these questions in separate asks so you can go about answering them as you please, and also so I don’t explode you!

QUESTION ONE: could you add servers to this mix? I barely know anything about how servers themselves work (please rant to me about that if you wish, I would LOVE to hear it) but, let me lay out another hypothetical scenario.

Let’s say you have a very large, working system of servers, doing something very cool and gay. And then downstairs in the basement, you have the hackneyed scheme from before: you want to connect these two, because this sentient ai who cannot be named has to pretty much move himself over, since he wasn’t designed to be exported from his, ahem, home.

So you got professional heavy duty servers upstairs, hackneyed scheme downstairs, and you have to make those two guys work together to transfer a REALLY REALLY big program over between them.

How do you go about doing this without killing our POOR DARLING, the anonymous and totally handsome and cool ai? Tell me everything forever. Please

GREAT NEWS!!! There isn't just A way to transfer a shit ton of data from beautiful gay servers to the hodgepodge shit computers, THERE ARE SEVERAL WAYS.

I will answer your questions forever and ever. I love answering questions and I love tech. I can tech you about calculus I love calculus (and I have developed a deep hate of statistics). Long post under cut

Ok! To quickly summarize, there are 3 possible ways to do this. Wired, wireless, and physical. What do I mean by physical? Well, lets just say that cybersecurity people consider physical access to be root access for a reason.

Assuming you can identify the exact hard drives that contain your beautiful unnamed AI, you can just take those hard drives out, carry them up/downstairs, and plug them into your new machine. But this depends on someone on the outside who REALLY knows these machines who can be trusted to pull the correct drives. Also, it's much easier to remove/add hard drives to the actual servers. Those things are built to accept multiple hard drives and you can hotswap them! That means you can add/remove the drives without turning off the computer.

Adding hard drives into the computer hodgepodge is a bit more difficult. PCs only usually have 1-2 SADA cables, so that means only 1-2 hard drives per computer. You can do SADA to HTMI and just have the hard drives as external storage (picture a USB stick) but unlike a USB stick, a hard drive was not designed to be used like this. A hard drive needs power that is usually delivered by the computer, but in this setup that's not happening. You would need a special power supply just to power this one individual thing. Kinda annoying when you have a lot of hard drives to plug in. So why not take a single server unit and put all of the drives in there? Servers are functionally computers, so theoretically connecting it to the cluster should work. Would it be jank and unpredictable? Absolutely! But it (theoretically) would work.

So now lets talk about wired connections. First thing I want to get out of the way is the difference between electricity to deliver data and electricity to deliver power. Data electricity is often called low voltage because, well, it's at a low voltage. Why yell when you can whisper the same information? It's more efficient and with modern sensors, you can get pretty low while still being precise. Power, on the other hand, has to have high numbers. Not every device has a power demand high enough to light things on fire, but for something like a server, the fire potential is yes. Based on how many of yer responses have had to do with fire, you should try looking up electricity in terms of power plants. WARNING: the video linked shows guys at power plant flipping switch only for switch to go up in flames (set to Half-Life sound effects). No one gets hurt but lots of property damage happens. In the next response I will go more into the architecture of data centers and see how much as I can find about how they are wired (I assume like other factories with high demand but I'm not 100% sure)

Here's an interesting video I found as a sample of what's inside.

Now, to run a long fucking cord from the upstairs gay servers to the downstairs shit stack, is really easy! It wouldn't even be that hard to find a cable that long. Heck, why go down the stairs when you can peal off a section of floor and drop the cord down there. Shortest path is a straight line. The issue comes up with trying to convince these two damn things to send/accept data. I will be assuming best possible conditions (as in, same operating system, no weird hardware conflicts) so then the only thing would be to give each machine a compatible IP address. Usually, the wifi router is the one handing out IP addresses, so the addresses are always compatible. A video that explains more about what the fuck that means can be found here.

After that, the computer holding the files has to give access to the computer accepting the files, while the computer reviving the files needs to accept them (turn off any anti-virus or firewall stuff). Once protections have been dropped on both sides, there should be nothing left to stop the transfer of the data!

Here is a literal tutorial on how to do this setup on windows 11. This isn't exactly the same situation, but for the purposes of learning enough to write this situation accurately, this is enough.

After that, all that is left is wireless! The good news is that a computer cluster can appear as a single computer to a router. This is because usually only the 'head' of the cluster is connected to the internet. Then, well, it's just what your computer does every day, sending data back and forth from a server.

You want more detail than that? Well, I don't entirely get it myself quite yet so I'm just going to post some links to further reading.

What is IP address

What is DNS

Ultimately, physically moving the hard drives would take the shortest about of time but require a man on the outside with a lot of skill. A wired connection would be pretty quick but again, required someone to do the wiring and make sure everything is lined up on both sides. Wireless would take a Long time but would be technically possible to do with no one on the outside.

None of this should harm the AI as, well, data transfer is typically just making a copy of the original. In that sense, if you wanted to be 100% technically accurate, both wired and wireless would be making a copy of the unnamed AI. The AI would now exist on both systems.

4 notes

·

View notes

Text

Why do my headlights go dim when I step on the brake?

The dimming of your headlights when you press the brake pedal is typically caused by an electrical system imbalance or component failure. Here’s a breakdown of the likely causes and solutions, based on your scenario:

1. Overloaded Electrical Circuit

Why it happens: When you press the brake pedal, the brake lights draw additional power from the vehicle’s electrical system. If the alternator or battery is weak, this sudden load can cause a voltage drop, dimming other lights like headlights. • Example: A failing alternator might produce <13V at idle, struggling to power both headlights and brake lights simultaneously.

Test: • Measure battery voltage with the engine running: ◦ Normal: 13.5–14.5V (idle and driving). ◦ Weak alternator: Voltage drops below 13V when brakes are applied.

2. Faulty Ground Connections or Wiring

Poor grounding in the headlight or brake light circuit can create resistance, leading to voltage drops when the brake lights activate. • Example: Corroded battery terminals or loose alternator wiring.

Test: • Inspect ground points near the headlights and brake lights. • Check for voltage drop between the battery and headlight connectors (should be <0.5V).

3. Aging Battery or Alternator

Weak battery: A battery nearing the end of its life (2–5 years) may fail to stabilize voltage during high-demand scenarios like braking.

Failing alternator: If the alternator’s voltage regulator malfunctions, it can’t maintain consistent power output, especially under load.

Test: • Battery voltage with engine off: <12.4V indicates a weak battery. • Alternator output at 2,000 RPM: <13.5V signals alternator failure.

4. Incorrect Bulb Types or Retrofit Issues

LED vs. halogen: Aftermarket LED headlights or brake lights might conflict with the vehicle’s electrical system if not installed with proper resistors or relays. • Example: LED brake lights drawing less power could cause voltage fluctuations if the system expects halogen-level resistance.

Fix: Use CANbus-compatible LEDs or install relays to stabilize the circuit.

5. Faulty Brake Light Switch or Sensor

E-brake sensor interference: In some vehicles (e.g., 2003 Ford Escape), a malfunctioning electronic parking brake sensor may erroneously signal the headlights to dim when the brake pedal is pressed. • Symptom: Headlights flicker or dim briefly when adjusting the parking brake.

Fix: Replace the brake light switch or inspect wiring connected to the parking brake sensor.

Diagnostic Steps

Check alternator and battery health with a multimeter.

Clean electrical connections (battery terminals, headlight grounds).

Test brake light circuit load: Swap incandescent brake bulbs for LEDs to reduce power draw.

Inspect headlight relay and fuse for corrosion or damage.

Cost Estimates

Alternator replacement: $300–$800.

Battery replacement: $100–$250.

Brake light switch repair: $50–$150.

Bottom Line: Dimming headlights during braking often point to an overtaxed electrical system. Start with simple fixes like cleaning connections or testing the battery. If unresolved, focus on the alternator or circuit upgrades. Ignoring this issue risks complete electrical failure or safety hazards.

#led lights#car lights#led car light#youtube#led auto light#led headlights#led light#led headlight bulbs#ledlighting#young artist#car culture#cars#race cars#classic cars#car#coupe#suv#convertible#chevrolet#supercar#car light#brake lights#brakes#light#headlamp#headlight bulb#headlamps#headlight#aftermarket new lamp#car lamp

2 notes

·

View notes

Text

What Is a Circuit Breaker and How Does It Work in a Switchgear Assembly?

In modern electrical power systems, reliability and safety are paramount. Whether it’s a residential building, industrial plant, or renewable energy facility, the control and protection of electrical circuits are essential. One of the most critical components used for this purpose is the circuit breaker. When integrated into a switchgear assembly, the circuit breaker plays a central role in ensuring operational continuity, preventing electrical faults, and safeguarding equipment and personnel.

This article explores what a circuit breaker is, it’s working principle, types, and its specific function within a switchgear assembly.

What Is a Circuit Breaker?

A circuit breaker is an automatically operated electrical switch designed to protect an electrical circuit from damage caused by overcurrent, overload, or short circuit. Its primary function is to interrupt current flow after a fault is detected. Unlike a fuse, which operates once and must be replaced, a circuit breaker can be reset (manually or automatically) to resume normal operation.

Key Functions of a Circuit Breaker

· Interrupt Fault Currents: Quickly breaks the circuit in the event of an overcurrent or short circuit.

· Manual Switching: Can be used to manually open or close a circuit for maintenance.

· Automatic Protection: Operates automatically in response to abnormal current conditions.

· Isolation: Ensures safe isolation of electrical equipment during servicing.

How Does a Circuit Breaker Work?

Circuit breakers operate on a simple principle: detect a fault and interrupt the current flow.

Working Mechanism

1. Detection: Internal sensors such as thermal, magnetic, or electronic trip units detect abnormalities in current.

· Thermal Trip Unit: Uses a bimetallic strip that bends with heat from overcurrent.

· Magnetic Trip Unit: Uses an electromagnet that triggers a release when excessive current flows.

· Electronic Trip Unit: Uses current sensors and a microprocessor for precise tripping.

2. Tripping: Once a fault is detected, the trip mechanism activates, causing the breaker’s contacts to open.

3. Arc Extinction: When the contacts open, an electrical arc forms. The breaker extinguishes the arc using mechanisms like:

· Air-blast

· Vacuum

· SF₆ gas

· Oil

4. Resetting: After the fault is cleared, the breaker can be reset and put back into service.

Types of Circuit Breakers

What Is a Switchgear Assembly?

Switchgear is a centralized assembly of electrical disconnect switches, fuses, or circuit breakers used to control, protect, and isolate electrical equipment. It is essential in power generation, transmission, and distribution networks.

Switchgear can be categorized by voltage level:

· Low Voltage (LV): Up to 1 kV

· Medium Voltage (MV): 1 kV to 36 kV

· High Voltage (HV): Above 36 kV

Role of Circuit Breakers in Switchgear Assemblies

Circuit breakers are core protection components within switchgear systems. Their role includes:

1. Fault Detection and Isolation

Circuit breakers detect and isolate faulty circuits to prevent system-wide failures and reduce downtime.

2. Load Control

Operators can use breakers in switchgear to safely connect or disconnect loads as required during routine operations or emergencies.

3. System Coordination

In coordinated protection schemes, different breakers in the switchgear are set with time-current characteristics to isolate faults precisely and efficiently.

4. Integration with Automation

Modern switchgear integrates circuit breakers with SCADA systems and smart relays, enabling remote monitoring and control.

Circuit Breakers in Renewable and Industrial Applications

In sectors like solar and wind energy, circuit breakers are specially designed to handle:

· Bidirectional current flow

· Rapid voltage fluctuations

· High fault levels due to DC sources

In industrial settings, breakers must handle high inrush currents, frequent switching, and harsh environments.

Maintenance and Safety Considerations

To ensure reliability:

· Regular Testing: Trip settings, insulation resistance, and contact resistance must be tested periodically.

· Visual Inspection: For signs of wear, overheating, or contamination.

· Replacement of Parts: Arcing contacts and insulation materials degrade over time and must be replaced as needed.

Safety measures include:

· Lockout/Tagout (LOTO)

· Grounding procedures

· Personal Protective Equipment (PPE)

Conclusion

Circuit breakers are indispensable for the protection and control of electrical systems. When embedded within a switchgear assembly, they offer enhanced reliability, automation capability, and system safety. Whether in a power substation, a manufacturing facility, or a renewable energy farm, the synergy of circuit breakers and switchgear ensures smooth, safe, and efficient operation.

Understanding how circuit breakers function and interact within switchgear assemblies is crucial for electrical engineers, facility managers, and anyone involved in the design, operation, or maintenance of electrical infrastructure.

4 notes

·

View notes