#scada rtu

Explore tagged Tumblr posts

Text

Relay Terminal Units Manufacturers | Elmex Electric Pvt. Ltd.

Elmex Controls Pvt. Ltd. is a distinguished name in SCADA (Supervisory Control and Data Acquisition) RTU (Remote Terminal Unit) manufacturing, renowned for delivering cutting-edge solutions. With years of industry experience and a dedicated team of experts, we design and manufacture SCADA RTUs that excel in performance and reliability. Our state-of-the-art facilities and stringent quality control measures ensure that each product meets the highest standards of excellence. As a trusted SCADA RTU manufacturer, we cater to diverse industrial applications, empowering businesses with seamless remote monitoring and control.

Partner with Elmex Controls for advanced SCADA RTUs that streamline operations, optimize efficiency, and elevate overall productivity. Experience the power of next-generation solutions with Elmex Controls Pvt. Ltd.

#rtu manufacturer in india#SCADA RTU Manufacturers#Relay Terminal Units Manufacturers#Remote Terminal Unit manufacturers#electrical company#business#gujarat#india#scada rtu#relay

0 notes

Text

#scada#rtu#smartgrid#energymanagement#powersystem#efficientenergy#gridmodernization#industrialautomation#electricgrid#energyefficiency#retrofit

0 notes

Text

Battery-operated Remote Terminal Units Market Research, Size, Share, Analysis, Overview and Regional Outlook Study 2017 – 2032

The market for Remote Terminal Units (RTUs) that are battery-operated allows them to function in isolated or off-grid regions where access to a reliable power supply is restricted. RTUs are electronic devices used to monitor and manage remote equipment and processes in many different industries, such as oil and gas, water and wastewater management, power distribution, and telecommunications. Here is a summary of the market for battery-operated RTUs, including information on demand:

Market Overview: Due to a number of circumstances, the market for battery-operated RTUs has been expanding. The need for battery-operated RTUs has been fueled by the necessity for remote monitoring and control capabilities in various industries, particularly in places with weak power infrastructure. These devices enable efficient monitoring and control of remote assets without the requirement for a continual external power source thanks to their dependable and autonomous operation.

Demand Drivers:

1. Real-time monitoring and control of assets: situated in remote or isolating locations are necessary in many businesses. Without the requirement for a sizable power infrastructure or reliance on cable connections, battery-operated RTUs allow for effective data gathering, monitoring, and control of these assets.

2. Applications Off-Grid: In off-grid applications where access to a dependable power supply is restricted or nonexistent, battery-operated RTUs are widely used. Examples include remote water pumping stations in rural areas, environmental monitoring stations, remote weather monitoring stations, and remote oil and gas wellheads.

3. Emergency and Temporary Installations: Whereas immediate deployment is necessary, battery-powered RTUs are also used in emergency and temporary installations. When catastrophe recovery, building projects, or temporary infrastructure installations are taking place, these machines can instantly provide remote monitoring and control capabilities.

4. Environmental Monitoring: Data collection from remote weather stations, air quality sensors, and water quality sensors are all important aspects of environmental monitoring that battery-operated RTUs play a key role in. Continuous monitoring is made possible in remote or environmentally delicate locations by these equipment.

5. IoT Connectivity: The need for battery-operated RTUs has increased as the Internet of Things (IoT) is becoming more widely used in a variety of businesses. These devices are essential parts of IoT networks because they provide seamless data transmission, communication, and control between remote assets and central management systems.

Here are some of the key benefits for Stakeholders:

Remote Monitoring and Control

Flexibility and Mobility

Cost-Effective Deployment

Resilience to Power Outages

Integration with IoT and Smart Grids

Increased Data Accessibility

Environmental Monitoring and Compliance

Rapid Deployment for Emergency Response

Redundancy and Reliability

Scalability and Future-Proofing

We recommend referring our Stringent datalytics firm, industry publications, and websites that specialize in providing market reports. These sources often offer comprehensive analysis, market trends, growth forecasts, competitive landscape, and other valuable insights into this market.

By visiting our website or contacting us directly, you can explore the availability of specific reports related to this market. These reports often require a purchase or subscription, but we provide comprehensive and in-depth information that can be valuable for businesses, investors, and individuals interested in this market.

“Remember to look for recent reports to ensure you have the most current and relevant information.”

Click Here, To Get Free Sample Report: https://stringentdatalytics.com/sample-request/battery-operated-remote-terminal-units-market/10333/

Market Segmentations:

Global Battery-operated Remote Terminal Units Market: By Company • SIEMENS • SENECA • Omniflex • King Pigeon Communication Co.,Limited • Servelec Group • TEKBOX • Micro Sensor Co., Ltd. • Hitachi Group • Remsdaq Ltd Global Battery-operated Remote Terminal Units Market: By Type • GPRS • GSM • Modular • Others Global Battery-operated Remote Terminal Units Market: By Application • Power Industry • Government and Utilities • Industrial Global Battery-operated Remote Terminal Units Market: Regional Analysis The regional analysis of the global Battery-operated Remote Terminal Units market provides insights into the market's performance across different regions of the world. The analysis is based on recent and future trends and includes market forecast for the prediction period. The countries covered in the regional analysis of the Battery-operated Remote Terminal Units market report are as follows: North America: The North America region includes the U.S., Canada, and Mexico. The U.S. is the largest market for Battery-operated Remote Terminal Units in this region, followed by Canada and Mexico. The market growth in this region is primarily driven by the presence of key market players and the increasing demand for the product. Europe: The Europe region includes Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe. Germany is the largest market for Battery-operated Remote Terminal Units in this region, followed by the U.K. and France. The market growth in this region is driven by the increasing demand for the product in the automotive and aerospace sectors. Asia-Pacific: TheAsia-Pacific region includes Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, and Rest of Asia-Pacific. China is the largest market for Battery-operated Remote Terminal Units in this region, followed by Japan and India. The market growth in this region is driven by the increasing adoption of the product in various end-use industries, such as automotive, aerospace, and construction. Middle East and Africa: The Middle East and Africa region includes Saudi Arabia, U.A.E, South Africa, Egypt, Israel, and Rest of Middle East and Africa. The market growth in this region is driven by the increasing demand for the product in the aerospace and defense sectors. South America: The South America region includes Argentina, Brazil, and Rest of South America. Brazil is the largest market for Battery-operated Remote Terminal Units in this region, followed by Argentina. The market growth in this region is primarily driven by the increasing demand for the product in the automotive sector.

Visit Report Page for More Details: https://stringentdatalytics.com/reports/battery-operated-remote-terminal-units-market/10333/

Reasons to Purchase Battery-operated Remote Terminal Units Market Report:

• To obtain insights into industry trends and dynamics, including market size, growth rates, and important factors and difficulties. This study offers insightful information on these topics.

• To identify important participants and rivals: This research studies can assist companies in identifying key participants and rivals in their sector, along with their market share, business plans, and strengths and weaknesses.

• To comprehend consumer behaviour: these research studies can offer insightful information about customer behaviour, including preferences, spending patterns, and demographics.

• To assess market opportunities: These research studies can aid companies in assessing market chances, such as prospective new goods or services, fresh markets, and new trends.

In general, market research studies offer companies and organisations useful data that can aid in making decisions and maintaining competitiveness in their industry. They can offer a strong basis for decision-making, strategy formulation, and company planning.

About US:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs

Contact US:

Stringent Datalytics

Contact No - +1 346 666 6655

Email Id - [email protected]

Web - https://stringentdatalytics.com/

#Battery-operated Remote Terminal Units#RTU Market#Remote Monitoring#Wireless RTU#Industrial Automation#Battery-powered RTU#IoT (Internet of Things)#Energy Efficiency#Data Collection#Telemetry#Remote Control#Battery-powered Sensors#SCADA (Supervisory Control and Data Acquisition)#Energy Management#Off-grid Applications#Renewable Energy#Battery Technology#Remote Sensing#Communication Protocols#Edge Computing#Connectivity Solutions#Remote Data Acquisition#Condition Monitoring#Asset Management.

0 notes

Text

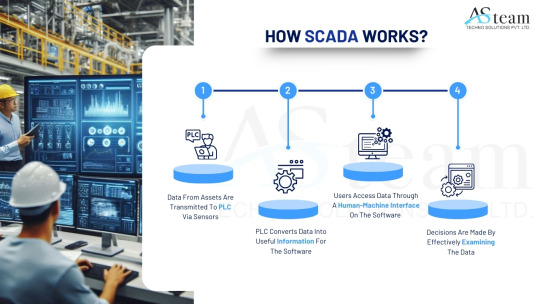

How SCADA Works?

Supervisory Control and Data Acquisition (SCADA) systems are critical in managing and monitoring industrial processes across various industries, including manufacturing, utilities, transportation, and energy.

Field Devices

At the process level, field devices like sensors, meters, and actuators are used to monitor variables like voltage, flow, temperature, and pressure. These gadgets collect information and carry out system-directed operations.

Remote Terminal Units (RTUs) and Programmable Logic Controllers (PLCs)

The SCADA software and the field devices are connected by RTUs and PLCs. After gathering information from the sensors, they transmit it to the control center. Additionally, the SCADA system may send them orders to modify settings or control actuators.

Communication Infrastructure

Strong communication networks are necessary for SCADA to transmit data between the control center and field equipment. This infrastructure can be wireless (such as satellite, radio, and cellular networks) or wired (such as Ethernet and fiber optics).

Centralized Control Station

SCADA software, which analyzes data, creates visualizations, and gives operators tools to monitor and manage operations, is housed in the control station.

Human-Machine Interface (HMI)

The SCADA system's user interface is called the HMI. Operators can engage with the system and make well-informed decisions because to its graphical depictions of processes, warnings, and trends.

#automation#SCADA#PLC#HMI#Automation#Technology#business and industry sectors#business#industrial automation#soft starter#software#software engineering

3 notes

·

View notes

Text

A Comprehensive Guide to Power Systems Protection for Engineers

Introduction:

Power systems protection is a critical aspect of electrical engineering that focuses on safeguarding electrical equipment, personnel, and the power grid from faults, failures, and abnormal operating conditions. This comprehensive guide aims to provide engineers with valuable insights into key principles, techniques, and best practices in power systems protection.

1. Understanding System Operation and Fault Types:

Before delving into protection strategies, it is essential to have a solid understanding of how power systems operates and the various types of faults that can occur. This includes studying system components, such as generators, transformers, transmission lines, circuit breakers, relays, and protective devices. Familiarity with fault types like short circuits, open circuits, ground faults, and transient overvoltages is crucial as a foundation.

2. Principles of Protection Coordination:

Effective power systems protection requires proper coordination among protective devices. Engineers must understand the concept of selectivity to ensure that only the device closest to a fault operates, minimizing disruption to the rest of the system. Proper coordination involves selecting appropriate current settings, time delays, and coordination curves for relays and circuit breakers.

3. Relay Device Fundamentals:

Relays are an integral part of power systems protection, serving as the first line of defense against electrical faults. Engineers should have a thorough knowledge of different relay types, including overcurrent relays, differential relays, distance relays, and directional relays. Understanding their operating principles, features, and limitations aids in choosing the most suitable relays for specific applications.

4. Protective Device Coordination:

Coordinating protective devices within a system is critical to maintaining stability and preventing cascading failures during faults. Engineers must carefully analyze and design protection schemes that consider factors such as fault impedance, fault currents, relay response characteristics, and coordination margins. Advanced techniques like time grading and impedance grading can be employed to achieve optimal coordination.

5. Fault Analysis and System Modeling:

Performing fault analysis and system modeling helps engineers gain insights into power flow, fault currents, voltage profiles, and system stability. Engineers must be proficient in using software tools like ETAP, PSCAD, and DSA Tools to accurately simulate fault scenarios and assess the performance of protection schemes. Detailed knowledge of system modeling techniques enables engineers to make informed decisions regarding relay settings and coordination.

6. Communication-Based Protection:

With the increasing complexity of modern power systems, communication-based protection plays a crucial role in maintaining reliability. Knowledge of communication protocols such as IEC 61850, GOOSE (Generic Object-Oriented Substation Event), and SCADA (Supervisory Control and Data Acquisition) systems is essential for engineers to design and implement advanced protection solutions that utilize real-time data exchange between substations and control centers.

7. Integration of Automation and Control Systems:

Incorporating automation and control systems into power systems protection enhances operational efficiency and reduces response time during faults. Engineers need to understand concepts like remote terminal units (RTUs), programmable logic controllers (PLCs), and human-machine interfaces (HMIs). Familiarity with protocols like Modbus, DNP3 (Distributed Network Protocol), and OPC (OLE for Process Control) enables seamless integration of protection systems with wider control infrastructure.

8. Commissioning, Testing, and Maintenance:

Implementing effective protection strategies requires thorough commissioning, testing, and maintenance procedures. Engineers should be well-versed in practices like primary injection testing, secondary injection testing, relay calibration, fault simulation, and periodic inspections. Adhering to manufacturer guidelines, industry standards, and safety protocols ensures equipment reliability and optimal performance.

9. Access to Resources and Industry Awareness:

Staying connected with organizations like the IEEE (Institute of Electrical and Electronics Engineers) and IET (Institution of Engineering and Technology) is crucial for access to valuable resources. Engineers should actively seek research papers, technical articles, conferences, and networking opportunities. Staying informed about relay technology advancements from prominent manufacturers aids in adopting the latest protection techniques.

10. Software Applications for Enhanced Protection:

Utilizing software applications is vital in power systems protection. Advanced tools like ETAP, PSCAD, and DSA Tools aid in relay coordination analysis, fault simulation, and system modeling. Acquiring proficiency in these common industry software packages enables engineers to design and optimize protection schemes effectively.

11. Compliance with Local National Codes:

Adhering to local national codes and regulations is paramount in power systems protection. Understanding and implementing specific electrical codes and standards relevant to the country of operation is crucial. Compliance ensures safe and reliable system design, installation, and operation aligned with legal requirements and best practices.

Conclusion:

By encompassing the principles, techniques, and best practices discussed in this guide, engineers pursuing careers in power systems protection can develop a strong foundation. Continuous learning, staying updated on industry advancements, and compliance with local national codes will ensure engineers can design, implement, and maintain robust and reliable protection schemes for the power grid and its critical assets.

The Author Biography: Qusi Alqarqaz

Qusi Alqarqaz is an experienced professional in power system protection, specializing in sharing knowledge and guiding young engineers. With a career spanning utility and oil and gas industries in Texas, New Mexico, and Qatar, he has amassed extensive industry experience.

Collaborating with leading manufacturers such as SEL, ABB, Siemens, Schneider, among others, Qusi has gained proficiency in a range of protective relays. He actively pursues continuing education, completing professional development courses with software providers including ETAP and Milsoft, enabling him to utilize advanced tools for power system analysis and protection design.

Qusi's dedication to staying up-to-date with industry advancements led him to pursue additional training. He completed professional development courses at Wisconsin University, equipping him with specialized knowledge crucial for working with high-voltage power systems. He also studied power generation extensively at Strathclyde University in the UK.

Qusi actively shares his knowledge through collaborating on large-scale projects and providing training sessions for professionals. Through his posts, he aims to offer guidance and mentorship for young engineers in power system protection. His practical advice and personal experiences will empower the next generation of experts in this field.

Contact the Author:

Qusi actively shares his knowledge through collaborating on large-scale projects and providing training sessions for professionals.

Qusi Alqarqaz

9 notes

·

View notes

Text

Do you know the five core components that make a SCADA system work effectively?

From sensors/actuators, RTUs/PLCs, to HMIs and communication networks, each part plays a vital role in keeping everything running smoothly

Explore an overview of these essential components here:

0 notes

Text

Enhancing AHU Performance with PLC-Based Control Systems

Imagine a world where your building breathes in oxygen. Where comfort meets air quality, and where energy is saved. It is the world where AHUs and PLC control systems are the starting point of everything in the domain of Energy management systems.

These AHU controllers (Air Handling Units) are the primary components of any new HVAC system. They serve as the lungs. But to make those lungs breathe better, smarter, and cleaner, you need a brain—enter the Programmable Logic Controllers (PLC).

We at Messung Industrial Automation are not just manufacturing PLC automation systems. We engineer intelligence. Smart PLC control is our ambition, and we aim to revolutionize the way AHU controllers operate, using a range of technologies, including Modbus, MQTT, compact PLCs, or IOT-enabled PLC.

What is a PLC-Based AHU Control System?

A PLC-based AHU control system is the ultimate HVAC master conductor. The flow, cooling, heating, and energy consumption of air are all controlled by real-time logic and precision through automation controllers.

Decision-making is the primary responsibility of a IoT enabled PLC (programmable logic controller), not just following instructions. Your AHU is designed to respond to data, adjust to changing surroundings, and function like a finely tuned machine with the help of intelligent controllers.

Whether it’s a mini PLC for a compact setup or a modular PLC for a multi-zone building, this IEC 61131-3 standard controller is the heartbeat of your air management system.

Core Functions of PLC Automation in AHU Controllers Applications

Sensor Integration

Temperature, humidity, CO2, and differential pressure are all sensors that your AHU controllers are equipped with. When it comes to Energy management systems, PLC control systems are necessary for reading, interpreting, and operating raw data.

Our intelligent PLCs work together with sensors to capture every detail of your indoor environment.

Data Analysis & Decision Making

After submitting the data, the PLC Automation magic begins. Our IEC 61131 based PLCs utilize advanced logic and maintain monitoring of variables such as:

Room occupancy

Outdoor air quality

Return air temperature

The intelligence in this scenario is not confined to automation alone it expands to the action of the PLC Control Systems.

Control Actions via Actuators

Now let's talk about the muscle of the operation. By utilizing PLC and Modbus TCP/IP, your automation controllers can dynamically control VFDs (Variable Frequency Drives) to regulate fan speeds while minimizing energy usage.

Actuated Dampers

Want zoned cooling in your building? Each damper is given precise guidance on when and where it should be opened or closed by our compact PLC, down to the second.

Valves

Our PLC automation system manages both hot and chilled water circuits, ensuring thermal comfort with accuracy.

Humidifiers & Dehumidifiers

System Overview: The NX-ERA JET Advantage

NX-ERA JET PLC is a digital command centre that is agile, adaptive, and always on alert as the AHU controllers. We have developed an intelligent and IEC 61131-3 standard PLC Control Systems that combine advanced logic, seamless connectivity, and flexible scalability. The NX-ERA JET is the key to ensuring that every component of your AHU system, including sensors and actuators, operates in perfect harmony.

Features of this IoT enabled PLC at a Glance

Modular PLC architecture is flexible and can be easily scaled for multi-zone management in large or changing infrastructure

The utilization of PLC with TCP/IP facilitates fast and secure communication between devices, including devices connected to remote systems

The integration of MODBUS RTU, Modbus TCP, and MQTT with BMS, SCADA, or cloud-based IoT platforms is facilitated by the native support provided by these protocols.

An integrated HMI that provides real-time, intuitive monitoring, diagnostics, and manual overrides.

Benefits of IoT enabled PLC for AHUs

In modern air handling, the focus isn’t just on moving air but moving it forward. Why? Integrating PLC control systems into AHUs can offer a transformative advantage in performance, sustainability, and adaptability for buildings. We should examine why PLC automation is the primary driving force behind intelligent HVAC solutions.

Improved Energy Efficiency

The value of energy is high, and PLC for energy systems with IEC 61131-3 standards optimizes every kilowatt. We can use our IoT enabled PLCs to save energy - up to 30% a time with intelligently controlled fan speeds, valve positions and damper angles that are real-time. Measurable reductions through these intelligent controllers help to reduce operational costs and greener footprints are not just numbers.

High Precision Control

AHU controllers equate performance with precision. Why? Our IEC 61131-3 compliant PLCs provide precise control over airflow, temperature and humidity. The result? Consistent comfort, efficient performance and strict environmental regulations.

Advanced Diagnostics

The use of intelligent PLCs with IoT systems means that problems can be prevented rather than delayed. With real-time monitoring and fault detection, teams can receive predictive maintenance insights to minimize downtime and maximize up time.

Scalability and Modularity

Our modular PLCs are designed to accommodate the growth of your building, offering compact systems and multi-zone installations. Do you require an immediate upgrade or expansion? These intelligent controllers can scale without complexity.

BMS Integration

Our PLC Control Systems with IEC 61131-3 standard integrates seamlessly with Building Management Systems, creating one intelligent ecosystem. Whether it’s HVAC, lighting, fire alarms, or access control—everything talks to everything for smoother operations.

In a world where data and efficiency are the primary drivers of change, PLC-controlled AHU controllers provide more than just automation; they also offer confidence. Our IoT enabled PLCs enable buildings to thrive rather than just functioning.

Intelligent PLC Control Systems for Smart Buildings

HMI with PLC Controllers - An HMI with PLC controller enables the observation of invisible areas. The entire package, including fan speed and filter life, is conveniently located at your fingertips.

MQTT based PLC and IoT Systems - The integration of IoT enabled PLC and MQTT support enables your AHU to communicate with the cloud, apps, and analytics platforms, simplifying the process of achieving predictive control and remote access.

Real-World Applications

Through PLC-based AHU control systems, we at Messung are changing the possibilities of environments from sterile labs to busy malls. With precision, adaptability, and unparalleled reliability, our intelligent automation controllers tackle the challenges associated with every application.

Pharma Cleanrooms - The precision of pharmaceutical products is essential in their application. The strict GMP standards are adhered to by our PLC control systems, which involve managing temperature, humidity, pressure differentials. The result? Zones that are sterile, upholding drug integrity and safety.

Commercial Buildings - Employee comfort drives efficiency. Our HVAC automation enables seamless climate management of all floors and departments. By utilizing intelligent design, efficient air circulation, and real-time monitoring, our IoT enabled PLCs enhance the productivity and satisfaction of customers in spaces.

Data Centers - Servers demand a stable climate 24/7. Even minor temperature fluctuations can compromise data. Our intelligent PLC Control Systems with IEC 61131-3 standard ensure uninterrupted cooling performance, reducing thermal risk and operational downtime.

Energy-Efficient Manufacturing - Today's manufacturers must strike a balance between sustainability and production. Without compromising comfort or compliance, our PLCs maximize AHU performance to reduce energy footprints, reduce emissions, and guarantee stable internal environments.

Wherever there's air to manage and performance to perfect, our Compact PLCs lead the way with intelligent control.

Messung’s Expertise in HVAC Automation

We at Messung lead the way in HVAC automation innovation for organizing smart air movement. Our legacy is created on trust, performance, and innovative control systems that transform indoor environments, not only on technology

Why Choose Messung PLC Automation?

We design smart automation systems rather than only selling PLC Control Systems. With more than four decades of engineering expertise, our PLCs are the favoured option of architects, MEP consultants, HVAC contractors, and facility managers across India and globally. Our internal R&D, field-tested dependability, and quick support system turn us into a progress partner rather than just a supplier.

Built on IEC 61131-3 Standard

To ensure every Messung programmable logic controller is consistent, dependable, and compatible with worldwide systems—today and tomorrow — our automation controllers follow this internationally recognized IEC 61131-3 standard.

Flexible Form Factors

Whether you are managing many air zones throughout a smart high-rise or automating a small rooftop AHU, our compact and modular PLCs meet every architectural and functional requirement.

Comfort, control, and conservation are not optional but rather vital in the quickly changing realm of smart infrastructure of today. Furthermore, realizing this potent triad calls for smart, adaptive control rather than just automation. That is what Messung's PLC-based AHU systems precisely provide. Our programmable logic controllers redefine air handling performance for buildings of all sizes with real-time responsiveness, easy BMS integration, IoT readiness, and IEC 61131-3 standard. Our intelligent controllers offer precision, dependability, and next-generation energy efficiency from sterile zones to skyscrapers. Should excellence be your goal, our IoT enabled PLC guarantees you lead rather than merely follow. Why settle for fundamentals when you may automate brilliance with our smart automation controllers?

FAQs

What makes a PLC suitable for AHU control?

Real-time processing, sensor compatibility, actuator control, and smooth BMS integration define good automation controllers. Messung's smart PLCs with IoT systems check every box

Can a modular PLC (Programmable logic controllers) handle multiple AHU zones?

Absolutely. Modular PLCs like Messung’s NX-ERA JET are great for big buildings since they can span levels and zones.

How does Messung's IoT enabled PLC enhance building performance?

Connecting to cloud systems and providing remote access help our IoT enabled PLCs to maximize energy efficiency and real-time maintenance cycles.

Why is Messung’s NX-ERA JET the ideal, affordable PLC choice for midscale operations compared to traditional compact or mini PLCs?

Messung’s NX-ERA JET offers advanced performance at an affordable price, making it perfect for midscale operations. It outperforms mini PLCs with better speed, scalability, and flexibility, without breaking the budget.

Are MQTT based Programmable logic controllers better than traditional protocols?

MQTT-based PLCs offer faster, lighter, and more effective communication than conventional systems like MODBUS RTU for remote and IoT-intensive applications.

#messing 1st blog ahu link#PLC control systems#Programmable Logic Controllers (PLC).#Messung Industrial Automation#PLC automation systems#Smart PLC control#PLC-based AHU control system#modular PLC#Energy management systems#AHU controllers#IEC 61131 based PLCs#compact PLC#IEC 61131-3 standard PLC Control Systems#MODBUS RTU#Modbus TCP#AHU controllers systems#NX-ERA JET#HVAC solutions#PLC for energy systems#IEC 61131-3 compliant PLCs#modular PLCs#HMI with PLC controller#Pharma Cleanrooms#Commercial Buildings#Data Centers#smart automation systems#programmable logic controller#BMS integration#smart PLCs#Modular PLCs

0 notes

Text

Automation is the future — and SCADA (Supervisory Control and Data Acquisition) systems are at its core.

From monitoring remote assets to managing entire plants, SCADA integrates sensors, software, and control systems to ensure efficiency, safety, and intelligent decision-making.

📚 In this detailed article, you’ll learn: ✔️ What SCADA is and how it works ✔️ Key components: RTUs, PLCs, HMIs, servers ✔️ Real-world applications in energy, water, and manufacturing ✔️ Major benefits and future trends

📘 Powered by: ECAAICO – Smarter and Green Engineering

#automation#instrumentation#sensors#renewable#renewable resources#plc#batteries#renewable energy#solar cells#solar panels

0 notes

Text

BL335 + Node-Red = The Ultimate Industrial IoT Combo!

BL335: The Industrial-Grade ARM Computer Built for Node-Red - Perfect Balance of Performance and Cost!

In the fields of industrial automation and IoT, Node-Red has become the go-to tool for rapid development of data acquisition, protocol conversion, and edge computing, thanks to its visual programming and low-code features. However, not all hardware is perfectly suited for Node-Red—some are over-spec’d and wasteful, while others lack the necessary resources for smooth operation.

Beilai Technology' s ARMxy BL335 Industrial Computer, with its Node-Red-optimized hardware design, is the ideal choice for industrial users! It delivers smooth performance, rock-solid reliability, and competitive pricing to meet diverse industrial needs.

Why is the BL335 the Best Industrial Computer for Node-Red?

1. Dual-Core A7 Processor – Just the Right Performance

2× ARM Cortex-A7 @1.2GHz, optimized for lightweight applications—Node-Red runs smoothly without lag.

Unlike overpowered quad/octa-core processors, the dual-core A7 design avoids wasted resources, balancing performance and cost efficiency.

2. RAM & ROM Perfectly Matched for Node-Red

512MB/1GB DDR3 RAM, fully meeting Node-Red’s long-term stability requirements (recommended ≥512MB).

4GB/8GB eMMC storage, ensuring ample space for the OS, Node-Red, and data storage without bottlenecks.

3. Pre-Installed Node-Red, Ready Out of the Box

Comes with Ubuntu/Linux + Node-Red pre-installed—power it up and start developing immediately.

Pre-configured system images enable rapid deployment, significantly shortening project timelines.

4. Dedicated Node-Red Technical Support Team

Bairen Technology provides Node-Red application examples, development guides, and customized support to help users get started quickly.

Stuck with protocol conversion or data collection? Our expert team offers real-time remote assistance!

5. Rich Serial & Network Ports for Easy Data Acquisition

Optional 4-8x RS485/RS232 ports, supporting Modbus RTU, DL/T645, and other industrial protocols.

Dual Ethernet (Gigabit + Fast Ethernet), compatible with TCP/IP, MQTT, OPC UA, and more for flexible device integration.

6. Industrial-Grade Stability for 24/7 Reliability

Fully isolated serial ports & independent hardware watchdog prevent crashes, ensuring long-term stable operation.

Wide-temperature design (-40℃~85℃), built to withstand harsh industrial environments.

7. Flexible Expansion for Diverse Needs

Optional DI/DO, CAN, GPIO, AI/AO modules for seamless connectivity with PLCs, sensors, actuators, and more.

4,000+ I/O combinations—customize your setup without overspending.

8. Optimized Hardware, Unbeatable Value

A refined hardware design that perfectly balances performance, stability, and cost.

Priced at just 60%~70% of comparable solutions, making industrial IoT more accessible than ever!

BL335 + Node-Red = The Ultimate Industrial IoT Combo!

✅ Data Acquisition: Easily connect PLCs, meters, and sensors with support for Modbus, CAN, MQTT, and more.

✅ Edge Computing: Local data processing reduces cloud dependency and network costs.

✅ Protocol Conversion: Use BLIoTLink software to quickly integrate with SCADA, Alibaba Cloud, Huawei Cloud, and other platforms.

✅ Remote Maintenance: BLRAT tool enables remote debugging, cutting on-site service costs.

Experience the Power of BL335 for Node-Red Today!

Website: www.BLIIoT.com

Free technical evaluations & industry solutions available!

Let BL335 be your ultimate Node-Red partner—low cost, high efficiency, and the perfect engine for industrial IoT! 🚀

0 notes

Text

System Integrator Market Size, Share, Trends, Demand, Industry Growth and Competitive Outlook

Global System Integrator Market - Size, Share, Demand, Industry Trends and Opportunities

Global System Integrator Market, By Service (Infrastructure Integration, Application Integration, Consulting), Technology (Supervisory Control and Data Acquisition (SCADA), Programmable Logic Controller (PLC), Programmable Automation Controller (PAC), Remote Terminal Unit (RTU), Distributed Control System (DCS), Manufacturing Execution System (MES) and Manufacturing Operations Management (MOM), Product Lifecycle Management (PLM), Human-Machine Interface (HMI), Advanced Process Control (APC), Operator Training Simulator (OTS), Safety Automation), End User (IT and Telecom, BFSI, Healthcare, Retail, Manufacturing, Energy and Utility) - Industry Trends.

Access Full 350 Pages PDF Report @

**Segments**

- **By Service:** The system integrator market can be segmented based on the services offered, such as consulting, design and development, maintenance and support, and integration & implementation services. Organizations often require system integrators to provide expertise in these areas to ensure the successful integration of technologies into their existing infrastructure.

- **By End-User:** Another key segmentation factor for the system integrator market is based on the end-user industries served. Various industries like IT & telecom, BFSI, healthcare, manufacturing, retail, and others have distinct technology requirements, which necessitate the need for specialized system integrators catering to their specific needs.

- **By Region:** Geographical segmentation plays a crucial role in the system integrator market as technology adoption and requirements vary across regions. Different regions like North America, Europe, Asia Pacific, Latin America, and Middle East & Africa have unique market dynamics that influence the demand for system integration services.

**Market Players**

- **Accenture:** One of the prominent players in the system integrator market, Accenture offers a wide range of consulting, technology, and outsourcing services to help organizations integrate and optimize their IT infrastructure.

- **IBM:** IBM is another key market player providing system integration services to address the complex technology needs of businesses across various industries.

- **Deloitte:** Deloitte's system integration services focus on helping organizations streamline their operations and enhance efficiency through the seamless integration of technologies.

- **Capgemini:** Capgemini is a global leader in consulting, technology services, and digital transformation, providing advanced system integration solutions to enable businesses to achieve their strategic objectives.

- **TCS (Tata Consultancy Services):** TCS is a leading IT services, consulting, and business solutions organization that offers comprehensive system integration services to drive innovation and maximize operational performance for its clients.

The system integrator market is witnessing significant growth due to the increasing digitization of businesses across industries. As organizations strive to enhance their operational efficiency and leverage advancedThe system integrator market is experiencing robust growth as businesses across industries continue to digitize their operations to improve efficiency and stay competitive in the modern business landscape. With the increasing complexity of technology ecosystems and the need for seamless integration of various platforms and solutions, the demand for system integrators is on the rise. These market players play a crucial role in helping organizations navigate the challenges associated with integrating new technologies into their existing infrastructure.

Segmentation of the system integrator market based on services offered provides insights into the diverse needs of organizations seeking integration solutions. Consulting services are essential for understanding the specific requirements and goals of the business, while design and development services focus on creating tailored solutions to meet these objectives. Maintenance and support services are crucial for ensuring the smooth functioning of integrated systems, while integration and implementation services play a key role in executing the integration process effectively. By catering to these different service requirements, system integrators can address the unique needs of their clients and deliver value-added solutions.

The segmentation of the system integrator market by end-user industries reflects the diverse technology requirements across different sectors. Industries such as IT & telecom, BFSI, healthcare, manufacturing, and retail have specific technological needs that require specialized expertise for successful integration. System integrators with industry-specific knowledge and experience can provide tailored solutions that address the unique challenges faced by organizations in these sectors. By understanding the distinct requirements of various industries, system integrators can develop customized integration strategies that drive business growth and innovation.

Geographical segmentation also plays a significant role in the system integrator market, as technology adoption and market dynamics vary across regions. North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa each present unique opportunities and challenges for system integrators. Local regulations, infrastructure, and business practices all influence the demand for integration services in these regions. By understanding the specific needs of each market, system integrators can tailor their services to meet the requirements of local businesses and drive growth in the respective regions.

Prominent market players such**Segments**

- **By Service:** The system integrator market is segmented based on the services offered, including consulting, design and development, maintenance and support, and integration & implementation services. Organizations rely on system integrators to provide expertise in these areas to ensure successful technology integration.

- **By End-User:** The system integrator market is segmented based on the end-user industries served, such as IT & telecom, BFSI, healthcare, manufacturing, and retail. Different industries have specific technology requirements, leading to the need for specialized system integrators catering to their unique needs.

- **By Region:** Geographical segmentation is crucial in the system integrator market as technology adoption varies across regions. North America, Europe, Asia Pacific, Latin America, and Middle East & Africa each have distinct market dynamics influencing the demand for system integration services.

**Market Players**

- **Accenture:** Offering consulting, technology, and outsourcing services, Accenture aids organizations in integrating and optimizing their IT infrastructure.

- **IBM:** IBM provides system integration services to address complex technology needs across various industries.

- **Deloitte:** Deloitte focuses on helping organizations streamline operations and enhance efficiency through seamless technology integration.

- **Capgemini:** As a global leader in consulting and digital transformation, Capgemini delivers advanced system integration solutions for businesses to achieve strategic objectives.

- **TCS (Tata Consultancy Services):** TCS, a leading IT services organization, offers comprehensive system integration services to drive innovation and

Core Objective of System Integrator Market:

Every firm in the System Integrator Market has objectives but this market research report focus on the crucial objectives, so you can analysis about competition, future market, new products, and informative data that can raise your sales volume exponentially.

Size of the System Integrator Market and growth rate factors.

Important changes in the future System Integrator Market.

Top worldwide competitors of the Market.

Scope and product outlook of System Integrator Market.

Developing regions with potential growth in the future.

Tough Challenges and risk faced in Market.

Global System Integrator top manufacturers profile and sales statistics.

Key takeaways from the System Integrator Market report:

Detailed considerate of System Integrator Market-particular drivers, Trends, constraints, Restraints, Opportunities and major micro markets.

Comprehensive valuation of all prospects and threat in the

In depth study of industry strategies for growth of the System Integrator Market-leading players.

System Integrator Market latest innovations and major procedures.

Favorable dip inside Vigorous high-tech and market latest trends remarkable the Market.

Conclusive study about the growth conspiracy of System Integrator Market for forthcoming years.

Frequently Asked Questions

What is the Future Market Value for System Integrator Market?

What is the Growth Rate of the System Integrator Market?

What are the Major Companies Operating in the System Integrator Market?

Which Countries Data is covered in the System Integrator Market?

What are the Main Data Pointers Covered in System Integrator Market Report?

Browse Trending Reports:

Video Conferencing Systems Market Wireless Gigabit Market Functional Mushroom Powder Market Water Based Lamination Adhesive Market Wash Basins Market X-ray Digital Imaging Systems Market Water Tight Doors Market Data Center Rack Power Distribution Unit (PDU) Market Point-of-Care Testing (POCT) Market Melamine Formaldehyde Market Naphthalene Derivatives Market Shape Memory Alloy Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]

0 notes

Text

Designing a Basic SCADA System: A Foundational Guide

Introduction

SCADA (Supervisory Control and Data Acquisition) systems in industrial automation serve a vital purpose in monitoring and controlling processes. From manufacturing, energy management, water treatment, to infrastructure, SCADA systems offer a single platform for data collection, visualization, and control. Designing a basic SCADA system entails knowing its most important components and how they cooperate to facilitate smooth operations.

Key Components of a SCADA System

A well-structured SCADA system includes several core components:

Remote Terminal Units (RTUs) or PLCs: These collect real-time data from sensors and field devices.

Communication Infrastructure: Data from field devices is transmitted to the central system via wired or wireless communication protocols.

SCADA Software: Installed on central servers or PCs, it processes the incoming data, provides visualization through HMI screens, and allows operators to control processes remotely.

Human Machine Interface (HMI): It is the interface that presents data, alarms, and controls in an interactive form.

Steps involved in designing a basic SCADA System

Define System Requirements: Identify the process to be monitored, the number of data points, and control level needed.

Choose Hardware Components: Select suitable PLCs or RTUs, sensors, and network devices according to the needs of the process.

Develop Communication Architecture: Develop an efficient communication network through appropriate protocols (such as Modbus, Ethernet/IP, or wireless systems).

Program and Configure the System: Develop control logic in PLCs and program SCADA software to interact with field devices.

Test and Validate: Test conditions to ensure data collection, alarms, and control functionality.

Deploy and Maintain: Install the system on-site and schedule periodic updates and maintenance.

Learning SCADA Design with Real-Time Exposure

Learning how to develop a SCADA system is a skill that is best acquired in a lab-based training setup. A PLC SCADA Course in Nashik provides the future automation experts a chance to practice on live equipment and industrial-standard projects. Centers like VIATA, in the center of Nashik, have a reputation for combining theoretical knowledge with lab application.

VIATA is headed by an industrialist with more than 20 years of experience in automation. The institute's strategy involves training in Stepper & Servo Motors, Drive Technologies, DCS, and IIoT, all of which are essential for SCADA system design. Students get exposure to HMI configuration, AC motor drives, VFDs, and control panel engineering, so the training is applicable to both fresh graduates and experienced professionals.

Why opt for a PLC SCADA Course in Nashik?

Live Industrial Projects: Learners are exposed to real systems, equipping them for the challenges of the industry.

Best Automation Experts: Training experts with field experience impart real-world perspectives to the class.

Balanced Curriculum: From initial PLC logic to advanced SCADA interfaces, all aspects of control system development are included.

Guaranteed Placement Support: With career guidance and focused interview skills training, students are assisted in making the transition into the workforce.

Conclusion:

Creating a simple SCADA system isn't only about knowing software and hardware, but also real-life integration of these tools within an industrial environment. To gain a good foundation in automation, taking a hands-on PLC SCADA Course in Nashik provides the ideal combination of theory and practice. Under the tutelage of experts and real-time learning facilities such as those provided by VIATA, students are imparted the necessary skills to thrive in contemporary automation jobs.

0 notes

Text

𝐌𝐚𝐱𝐢𝐦𝐢𝐳𝐞 𝐆𝐫𝐢𝐝 𝐄𝐟𝐟𝐢𝐜𝐢𝐞𝐧𝐜𝐲: 𝐆𝐞𝐭 𝐓𝐡𝐞 𝐁𝐞𝐬𝐭 𝐑𝐞𝐭𝐫𝐨𝐟𝐢𝐭𝐭𝐢𝐧𝐠 𝐒𝐜𝐚𝐝𝐚/𝐑𝐓𝐔/𝐆𝐚𝐭𝐞𝐰𝐚𝐲 & 𝐄𝐧𝐞𝐫𝐠𝐲 𝐌𝐚𝐧𝐚𝐠𝐞𝐦𝐞𝐧𝐭 & 𝐋𝐨𝐚𝐝 𝐒𝐡𝐞𝐝𝐝𝐢𝐧𝐠 𝐒𝐞𝐫𝐯𝐢𝐜𝐞𝐬 𝐅𝐨𝐫 𝐘𝐨𝐮𝐫 𝐒𝐲𝐬𝐭𝐞𝐦

In today's rapidly evolving energy landscape, optimizing grid efficiency is paramount. Industries, municipalities, and businesses are seeking innovative solutions to streamline operations, reduce costs, and ensure reliable energy supply. Retrofitting SCADA/RTU/Gateway systems and implementing comprehensive Energy Management & Load Shedding Services have emerged as key strategies to achieve these goals. In this blog, we delve into the benefits and importance of these solutions for maximizing grid efficiency.

We provide Retrofitting Scada/ Rtu/Gateway solutions, an industry-leading collection of substation controllers and switches that may be used for a range of automation, control, monitoring, and control activities.

We provide comprehensive electrical and automation solutions for the oil and gas industry, as well as other manufacturing sectors like cement and metal, infrastructure, and utilities like power and water. Our expertise spans more than 40 years in a variety of industries, and our capabilities have been demonstrated throughout the whole value chain, including proposals, design, engineering, project planning, integration, software development, integrated testing / FAT, commissioning / SAT, and after-sales service.

Retrofitting SCADA/RTU/Gateway Systems

Enhancing Data Collection and Analysis:

Retrofitting your SCADA/RTU/Gateway infrastructure equips your system with advanced data collection and analysis capabilities. Real-time monitoring, data visualization, and remote control empower operators to make informed decisions promptly. This enables swift response to fluctuations and emergencies, thereby minimizing downtime and optimizing system performance.

Seamless Integration:

Upgrading your existing SCADA/RTU/Gateway systems ensures compatibility with modern technologies and communication protocols. This streamlined integration enhances data exchange between various components, leading to improved data accuracy, reduced communication errors, and increased system reliability.

Predictive Maintenance:

Retrofitting allows for predictive maintenance implementation. By monitoring equipment health and performance metrics in real-time, you can schedule maintenance activities proactively, reducing unplanned outages and prolonging the lifespan of critical components.

Energy Management & Load Shedding Services

Efficient Resource Allocation:

Energy Management solutions enable you to monitor energy consumption patterns across your operations. This insight allows for strategic resource allocation and demand response, minimizing peak demand charges and optimizing energy usage during off-peak hours.

Cost Savings:

Implementing Load Shedding Services helps you curtail energy demand during peak periods, mitigating the risk of overloading and grid instability. This not only avoids costly penalties but also reduces overall energy expenses by optimizing load distribution.

Resilience and Reliability:

Energy Management & Load Shedding Services bolster the resilience and reliability of your system. During grid disturbances or emergencies, load shedding ensures essential equipment remains operational, preventing cascading failures and accelerating recovery times.

SCADA and Energy Management Solution

Experience a cost-effective SCADA and Energy Management Solution package that empowers you to effortlessly monitor and control your operations.

Embrace our intelligent and cutting-edge system that offers a holistic solution for energy monitoring and management within industrial plants, complemented by robust control and automation functionalities.

Integrated SCADA with energy management system along with meters, RTU, Data concentrator, software and Data converters supply

Present real-time parameters alongside energy data in a seamless display.

Showcase trends, alarms, as well as minimum, maximum, and average values.

Opportunities for seamless integration with air conditioning, water, and gas meters.

Conclusion:

In a world increasingly reliant on efficient energy systems, the significance of Retrofitting SCADA/RTU/Gateway systems and implementing Energy Management & Load Shedding Services cannot be overstated. These solutions empower you to navigate the challenges of a dynamic energy landscape, ensuring optimal performance, cost savings, and environmental sustainability.

By embracing these technologies, you're not only maximizing grid efficiency but also positioning your organization at the forefront of a more reliable, responsive, and resilient energy future. Reach out to us today to explore how Retrofitting SCADA/RTU/Gateway systems and Energy Management & Load Shedding Services can revolutionize your energy infrastructure and drive your operations towards a brighter, more efficient tomorrow.

Reliserv Solution offers comprehensive and reliable solutions for Retrofitting Scada/Rtu/Gateway Energy management, and load shedding. Our portfolio includes top-tier Retrofitting SCADA/RTU/Gateway solutions. This suite comprises advanced substation controllers and switches designed to cater to a wide range of functions and applications such as substation control, communication, monitoring, protection, and automation. To know more about Retrofitting Scada/Rtu/Gateway Energy management, and load shedding Click Here

#scada#rtu#gateway#energymanagement#retrofitting#solutions#substation#electricalengineering#energysavings#industrialautomation#smartenergy

0 notes

Text

Advancing Automation: Innovating Industries with Key Technologies

In today's dynamic industrial landscape, automation stands as a cornerstone of efficiency, safety, and sustainable progress. At Dropship Automation Solutions, we specialize in providing premium automation components essential for optimizing operations across diverse industries. In this article, we explore three pivotal components crucial for any automation setup: actuators, industrial robots, and SCADA systems. Whether you're upgrading existing systems or embarking on new installations, understanding these components is essential for achieving peak operational performance.

1. Actuators: Precision in Motion

What are Actuators in Automation? Actuators are mechanical or electromechanical devices that convert energy into motion, driving essential industrial processes with precision and reliability.

Key Types and Applications:

Types: Pneumatic actuators, hydraulic actuators, electric actuators

Applications: Valve control, robotics, material handling

Benefits: High precision, rapid response times, robust performance

Why Actuators Matter: Actuators play a crucial role in automation by enabling precise control over mechanical movements, ensuring optimal efficiency and productivity in industrial operations.

2. Industrial Robots: Transforming Manufacturing

What are Industrial Robots in Automation? Industrial robots are programmable machines designed to perform tasks traditionally handled by human workers, enhancing production capabilities and efficiency.

Key Features and Importance:

Types: Articulated robots, Cartesian robots, collaborative robots (cobots)

Functions: Assembly, welding, painting, palletizing

Applications: Automotive assembly lines, electronics manufacturing, logistics

Why Industrial Robots Matter: Industrial robots streamline manufacturing processes, improving accuracy, reducing cycle times, and enhancing workplace safety by automating repetitive or hazardous tasks.

3. SCADA Systems: Enhancing Control and Monitoring

What are SCADA Systems in Automation? SCADA (Supervisory Control and Data Acquisition) systems are software and hardware solutions used for real-time monitoring and control of industrial processes.

Key Components and Applications:

Components: Remote terminal units (RTUs), human-machine interface (HMI), communication infrastructure

Functions: Data acquisition, process visualization, alarm management

Applications: Power plants, water treatment facilities, oil and gas refineries

Why SCADA Systems Matter: SCADA systems facilitate centralized monitoring and control of complex industrial operations, optimizing efficiency, minimizing downtime, and ensuring regulatory compliance.

Integration for Seamless Automation

Imagine a scenario where:

Actuators ensure precise positioning and control in automated assembly lines.

Industrial robots collaborate seamlessly in manufacturing processes, enhancing production throughput.

SCADA systems monitor critical parameters in real-time, enabling proactive maintenance and operational adjustments.

Conclusion

Automation continues to redefine industrial processes by boosting productivity, ensuring operational reliability, and fostering sustainable growth. By integrating essential components like actuators, industrial robots, and SCADA systems, industries can achieve unparalleled efficiency, lower operational costs, and gain a competitive edge in today's global marketplace.

At Dropship Automation Solutions, we are committed to delivering cutting-edge automation solutions tailored to your specific needs. Explore our comprehensive range of automation components or contact us for personalized consultation and support on your automation journey.

Contact: +1 (234) 288-1755 Email: [email protected] Location: 1440 W. Taylor St #2555, Chicago, IL 60607

0 notes

Text

FU2200A RTU_modbus_digital_panel_power_meter_data_logger

The FU2200A RTU Modbus Digital Panel Power Meter Data Logger is a versatile and high-performance device designed for accurate monitoring and recording of electrical parameters in power systems. Featuring RTU Modbus communication, it enables seamless integration with supervisory control and data acquisition (SCADA) systems, providing real-time data for energy management and system analysis. The FU2200A is ideal for use in commercial, industrial, and utility environments where reliable power measurement and logging are essential for operational efficiency and compliance. Key Features:

RTU Modbus Communication: The FU2200A supports RTU Modbus communication, allowing it to easily integrate with existing SCADA systems for real-time data acquisition. This feature enables remote monitoring and control, making it ideal for power distribution systems, substations, and industrial applications where centralized monitoring is essential. 2. Digital Panel Power Meter: The FU2200A acts as a digital panel power meter, providing accurate readings of critical electrical parameters, including voltage, current, power, energy, frequency, and power factor. This enables users to monitor and analyze power consumption, efficiency, and system performance. 3. Data Logger Functionality: Equipped with data logging capabilities, the FU2200A can store historical data for later analysis. This feature helps track energy usage trends, identify inefficiencies, and maintain detailed records for reporting, compliance, and optimization purposes. 4. Wide Application: The FU2200A is suitable for a wide range of applications, including power monitoring, energy management, and load analysis in commercial buildings, industrial facilities, and utility companies. It helps users optimize energy consumption, reduce costs, and improve system reliability. 5. High Accuracy and Precision: The FU2200A offers high accuracy in measuring electrical parameters, ensuring reliable and precise data for energy metering and system diagnostics. This is critical for identifying power quality issues, preventing system failures, and ensuring optimal energy usage. 6. User-Friendly Interface: The FU2200A features an intuitive digital display for easy readout of measured values and system parameters. The user-friendly interface simplifies setup, configuration, and monitoring, allowing operators to quickly assess the status of the power system. 7. Compact Design: Designed for ease of installation, the FU2200A features a compact and robust design, suitable for mounting on standard panels in electrical cabinets. Its space-saving form factor makes it ideal for environments with limited space. Applications:

Energy Monitoring: Helps track energy usage and optimize consumption in commercial and industrial settings. Load Management: Provides insights into load distribution, helping prevent overloads and enhance system efficiency.

System Diagnostics: Monitors system parameters, aiding in the detection of faults, power quality issues, and other inefficiencies.

SCADA Integration: Offers seamless integration with SCADA systems for remote monitoring and control of power systems.

In summary, the FU2200A RTU Modbus Digital Panel Power Meter Data Logger is a powerful and reliable solution for real-time power monitoring and data logging. With its RTU Modbus communication, data logging capabilities, and high-accuracy measurements, the FU2200A is ideal for optimizing energy usage, improving system performance, and ensuring operational efficiency in commercial, industrial, and utility environments.

For detailed information, please refer to the relevant links on the official website:https://www.gfuvegroup.com/ethernet-power-meter/ethernet-digital-power-meter-with-2m-data-logger.html

1 note

·

View note

Text

Understanding Modbus: The Universal Protocol for Industrial Communication

Modbus is a widely used communication protocol in industrial automation and control systems. Originally developed by Modicon (now Schneider Electric) in 1979, it remains one of the most popular protocols for connecting electronic devices and exchanging data in supervisory control and data acquisition (SCADA) systems, programmable logic controllers (PLCs), and various automation applications.

How Modbus Works

Modbus operates as a master-slave (or client-server) protocol, where a master device initiates communication, and one or more slave devices respond. It is simple, reliable, and efficient, making it a preferred choice for industrial communication. The protocol is used to transmit data over serial lines (RS-232, RS-485) or via Ethernet networks (Modbus TCP/IP).

Types of Modbus Protocols

Modbus RTU (Remote Terminal Unit): A binary protocol using compact messages with cyclic redundancy check (CRC) error checking. It is ideal for real-time communication.

Modbus ASCII: Similar to RTU but uses ASCII characters, making it more readable but less efficient.

Modbus TCP/IP: Allows Modbus communication over Ethernet networks using TCP/IP protocols, making it suitable for modern industrial networks.

Key Features of Modbus

Open and Vendor-Neutral: Modbus is an open standard, meaning any manufacturer can implement it without licensing fees.

Ease of Implementation: Simple message structure and minimal processing overhead.

Interoperability: Enables different devices and systems from various vendors to communicate seamlessly.

Scalability: Supports a range of devices, from small sensors to complex industrial control systems.

Robust Error Handling: Modbus RTU uses CRC for error detection, ensuring reliable data transfer.

Applications of Modbus

Industrial Automation: Connecting PLCs, sensors, actuators, and SCADA systems.

Energy Management: Monitoring and controlling power meters and generators.

Building Automation: HVAC control, lighting systems, and access control.

Water and Wastewater Management: Supervising pumps, valves, and treatment facilities.

Oil and Gas Industry: Remote monitoring of pipelines and drilling operations.

Challenges and Limitations

Despite its advantages, Modbus has some limitations:

Limited Data Security: Traditional Modbus lacks built-in encryption, making it vulnerable to cyber threats.

Slower Speed Compared to Modern Protocols: Serial-based Modbus RTU can be slower than newer protocols like Ethernet/IP or MQTT.

Single-Master Limitation: Classic Modbus architectures typically allow only one master device, restricting flexibility.

Future of Modbus

With the advent of Industry 4.0 and Industrial IoT (IIoT), Modbus continues to evolve. Modern adaptations like Modbus TCP/IP and secure Modbus variants are making it more compatible with smart factories and cloud-based systems. Its simplicity and reliability ensure that it remains relevant in industrial automation for years to come.

Conclusion

Modbus is an essential protocol in industrial communication, providing a simple yet powerful way to connect and control devices. Its widespread adoption, open standard nature, and continuous evolution make it a critical component in modern automation and control systems. As industries transition to smart manufacturing, Modbus will likely continue to play a significant role in bridging legacy systems with modern technologies.

0 notes

Text

Basic SCADA programming - How can beginners get started without feeling overwhelmed?

Even a simple SCADA setup can control PLCs, connect RTUs, and provide clear visualizations. But where should you begin, and what should you avoid?

Full step-by-step guide here: https://maxelectric.vn/huong-dan-lap-trinh-scada-co-ban-cho-nguoi-moi-bat-dau-a155.html

0 notes