#simulation software

Explore tagged Tumblr posts

Text

It’s Here: The Future of Urban Planning and Development

A Model-in-Loop (MIL) test system enables one to build a realistic model and ideal model in the simulation with their own more realistic build and afterwards test it and improve it continuously in vehicle dynamics using complex software model and algorithms under controlled test using a high-performance processing power of a customised computer to align to the requirements of the integrated software components.

Once the complete MIL system is integrated a test strategy is required to be able to take care of the large number of scenarios in Simulation Software to simulate the environment of Road, Traffic, Obstacles, and other environmental influences

Scenario Simulation Software to simulate the environment of Road, Traffic, Obstacles, and other environmental influences

MIL test is inarguably the only one of the steps in the developing process and once the Model is successfully tested the next step is to integrate some real Hardware and continue testing it with selected hardware components. It allows simulation of road participants such as passengers, vehicles, traffic, obstacles including strays and animals etc., as well as buildings, roads, tunnels and environmental conditions such as a change in weather.

0 notes

Text

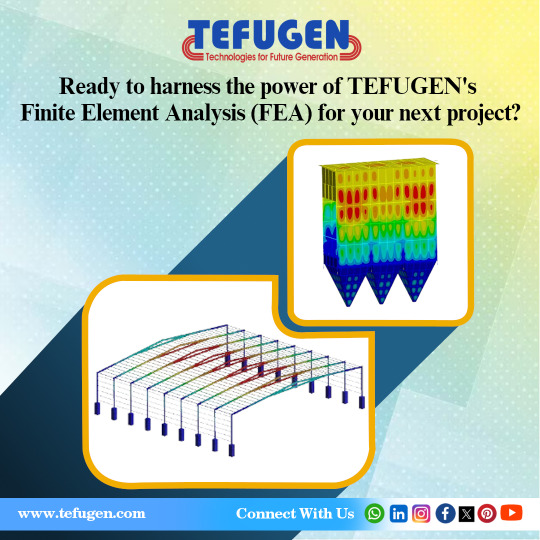

TEFUGEN: Redefining Engineering Excellence through Finite Element Analysis

WHY USE FEA IN YOUR ENGINEERING PROJECTS?

At the forefront of engineering excellence, TEFUGEN offers exceptional Finite Element Analysis (FEA) services in India. Utilizing FEA yields unparalleled benefits, offering profound insights into your project's performance prior to physical model construction. It aids in pinpointing stress points, identifying potential weaknesses, and assessing material durability under diverse conditions, effectively mitigating the risk of failure and associated costs. With its ability to conduct precise simulations, FEA empowers informed decision-making in design modifications, guaranteeing optimal performance and safety.

Structural Integrity Assessment:

In engineering, FEA, an indispensable method, meticulously assesses structural integrity by simulating material responses to diverse conditions. This predictive analysis is pivotal for guaranteeing the safety and reliability of designs. TEFUGEN, as a FEA consulting service in India, provides expert assistance, enabling engineers to identify potential weaknesses and optimize for durability.

Thermal stress analysis:

FEA analysis services play a key role in assessing heat distribution within structures or components. Engineers leverage this analysis to model and analyze thermal behavior meticulously. By doing so, they optimize designs for efficient heat dissipation or retention, ensuring the performance and reliability of the system. This detailed analysis enables engineers to make informed decisions regarding material selection, insulation, or heat management strategies, ultimately enhancing overall system efficiency and longevity.

Mechanical Component Design:

FE Analysis plays a crucial role in optimizing mechanical component design by accurately predicting stress, strain, and deformation. This ensures components can effectively withstand operational loads while minimizing material usage, thereby enhancing efficiency and cost-effectiveness.

Fatigue Analysis:

Engineers use FEA for fatigue analysis, predicting the lifespan of components subjected to cyclic loading. This is crucial in industries like aerospace and automotive, where understanding material fatigue is paramount.

Fluid Structure Interaction:

Fluid Structure Interaction (FSI) is a crucial aspect of FE Analysis, examining the dynamic interaction between fluids and structures. By simulating how fluids affect nearby structures and vice versa, FSI enables engineers to optimize designs for enhanced performance and durability across various industries.

Modal analysis Modal analysis using FEA techniques enables the simulation of eigenfrequencies and eigenmodes, revealing the vibrational characteristics of a structure. Meanwhile, harmonic analysis facilitates the emulation of peak responses to specific loads, offering insights into system behavior. These analyses are indispensable tools for understanding structural dynamics and optimizing performance.

Motion study Unlocking insights into structural behavior through Finite Element Analysis (FEA) motion studies. Discover the intricate dynamics of systems, optimize designs, and ensure structural resilience with FEA motion analysis.

#Finite Element Analysis Consulting Services in India#FEA Analysis Services#FEA Consulting Engineers#FEA Consultants in Trichy#FEA#Finite Element Method#Structural Analysis#Stress Analysis#Static Analysis#Dynamic Analysis#Thermal Analysis#Fluid Flow Analysis#Vibration Analysis#Fatigue Analysis#Buckling Analysis#Modal Analysis#Meshing#Boundary Conditions#Material Properties#Convergence#Post-processing#Optimisation#Mesh Generation#Simulation Software

0 notes

Text

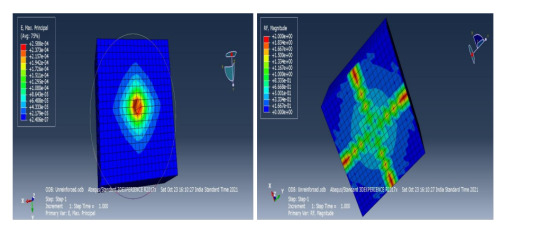

ABAQUS Software – Finite Element Analysis - PIGSO LEARNING

Abaqus is a complete Abaqus environment that provides an interface for creating, monitoring, and evaluating results from Abaqus/Standard and Abaqus/Explicit simulations. Abaqus/CAE is further divided into modules, where each module defines the aspect of the modelling process like defining the geometry, defining material properties, and generating a mesh.

ABAQUS - Simulation Analysis Software

CAE is a common graphical user interface that is used for modelling, solving, and post-processing a finite element problem.

The steps involved in the construction of a model are explained below-

ABAQUS Solver

ABAQUS Standard is an implicit solver used to solve nonlinear problems.

ABAQUS Explicit used for solving dynamics/wave propagation problems.

Part Module

Part Module Is the first step towards creating a model as parts are the building blocks of an Abaqus/CAE model. Part can be created in the following ways: Create the part using the tools available in the Part module. Import the part from a file stored in a third-party format. Import the part (mesh) from an output database. Import a meshed part from an input file.

You use the Part module to create, edit, and manage the parts in the current model. The Part module allows you to do the following:

Property Module

You can define the properties of a part or part region by creating a section and assigning it to the part. In most of the cases, sections refer to the materials that you have created. A material definition specifies all the property data relevant to a material. You can specify a material definition by including a set of material behaviours, and you supply the property data with each material behaviour you include. Each material that you create is assigned its name and it is independent of any particular section. Abaqus/CAE assigns the properties of a material to a region/section of a part when you assign a section referring to that material that you have created to the region.

Assembly

You can use the Assembly module to create and assemble the assembly. A model contains one main assembly, which is composed of instances of different parts from the model as well as instances of other models. An instance maintains its association with the original part/model. If the geometry of a part changes, Abaqus will automatically update all instances of the part and changes will be reflected in the model. You can’t edit the geometry of an instance directly. Your main model can contain many parts and model subassemblies, and a part or model can be instanced many times with the main model assembly; however, a model contains only one main assembly. Loads/boundary conditions are all applied to the complete assembly.

Even if your model consists of only a single part, you have to create an assembly that consists of just a single instance of that part. A part instance can be a representation of the original part. You can create either independent or dependent part instances. An independent instance is effectively a clone of the part. A dependent instance is only a pointer to the part or virtual topology. You cannot mesh a dependent instance.

Step

Within a model, you can define a sequence of one or more analysis steps. The step sequence provides a convenient way to capture changes in the loading and boundary conditions of the model, changes in the way parts of the model interact with each other and any other changes that may occur in the model during the analysis.

Interaction

Interactions are step-dependent objects, which means that when you define interactions, you must indicate in which steps of analysis they are active. The Set and Surface toolsets in the Interaction module allow you to define and name the model to which you would like interactions and constraints to be applied. Abaqus does not recognize the mechanical contact between different part instances of an assembly unless the contact is specified in the Interaction module.

Load

Load is an independent module as Abaqus cannot apply load automatically; you have to select the load type and position on which load is to be applied. You can apply load to any node/Surface. You can use the Load module to define and manage the following prescribed conditions:

Loads

Boundary conditions

You can apply different types of loading

Concentrated force

Moment

General and shear surface traction

General shell edge load

Inertia relief

Current density

Boundary Conditions

Boundary Conditions is also an important module to check the specific point interaction. As Abaqus cannot apply real-life constraints in the model. So you have to manually specify the predefined condition to be applied to a model to make analysis more effective and accurate

Mesh

The Mesh module allows you to generate meshes on parts and assemblies created within Abaqus. Various levels of automation and control are available so that you can create a mesh that meets the requirements of the analysis model. As with creating the parts and assemblies, the process of assigning mesh attributes to the model such as seeds, mesh techniques, and element types is feature-based.

The Mesh module provides the following features:

Tools for prescribing mesh density and global levels.

Model colouring indicates the meshing technique is successful and assigned to each region in the model.

A variety of mesh controls, such as:

Element shape

Meshing technique

Meshing algorithm

Adaptive remeshing rule

Optimization

Optimization Is a process that generates results and analysis. You must combine the optimization results into an individual output file to view the results of the optimization in the Visualisation module (Dassault).

Job

Job In the job module we create a job Check job from the job manager by “Data Check” If no error is reported Submit the job Check results in the Visualization Module

Visualisation

Abaqus Training

You find the best training platform to learn Abaqus Simulation Software Online by the PIGSO LEARNING company. You can get trained from the very basics to advanced levels of simulation analysis for different types of industrial categories like Structural, Mechanical, Geotech, Aerospace and Automobile engineering. Abaqus Training online course helps you to explore the software and get trained. Its help in your research work and career boost.

0 notes

Text

Siemens Simcenter 3D: Empowering Simulation Teams with Flexible CAE Licensing

Simcenter 3d: Enjoy Flexible CAE Licensing

Siemens' Simcenter 3D stands out for its commitment to providing flexibility and efficiency to simulation teams. One key aspect contributing to this adaptability is Simcenter 3D's innovative approach to licensing, introducing a value-based token licensing system.

Unlike the traditional model of purchasing individual licenses for each add-on module, Simcenter 3D's token licensing offers a more versatile and cost-effective solution. With this approach, users have the option to acquire packs of tokens, providing instant access to a wide range of Simcenter 3D modules.

The shift to a token-based licensing system brings several advantages to simulation teams:

Cost Efficiency: Token licensing eliminates the need for individual module licenses, allowing teams to optimize costs by acquiring token packs based on their specific needs. This approach provides a cost-effective solution, particularly for teams requiring access to multiple Simcenter 3D modules.

Flexibility and Instant Access: The token system enhances flexibility, enabling teams to allocate resources based on project requirements. This approach is particularly advantageous for dynamic project environments where the demand for specific modules may vary. With token packs, teams can instantly access the required modules without the constraints of traditional licensing models.

Streamlined Collaboration: Simcenter 3D's token licensing promotes collaboration by offering a shared pool of tokens that team members can draw from. This ensures that resources are utilized efficiently across the team, facilitating seamless collaboration on diverse simulation projects.

Scalability: As simulation needs evolve and projects expand, Simcenter 3D's token licensing system provides scalability. Teams can easily scale their simulation capabilities by acquiring additional token packs, aligning with the growth and changing demands of their projects.

Simplified Management: Managing Simcenter 3D licenses becomes more straightforward with token-based licensing. Teams can streamline the allocation and usage of tokens, making it easier to track and manage resources effectively.

To sum up, Simcenter 3D licensing introduces a new level of adaptability and cost efficiency for simulation teams. By moving away from traditional licensing models, Simcenter 3D empowers teams to optimize resources, enhance collaboration, and scale their simulation capabilities seamlessly. In a field where flexibility and efficiency are paramount, Simcenter 3D's approach to licensing reaffirms its commitment to meeting the evolving needs of simulation engineers.

To get a free Siemens Simcenter 3d License trial, reach out to Simulation Experts!

#siemens cae#caesoftware#cae#siemens cae software#simcenter 3d#simulation software#free cae software#siemens simulation software#siemens simcenter 3d software

0 notes

Text

This article delves into the significant influence of simulation software on design and testing processes, highlighting its various benefits, such as time and cost savings, product performance optimization, testing in challenging environments, and fostering collaboration among engineering teams.

0 notes

Text

USA 1993

#USA1993#MALLARD SOFTWARE INC.#THE BRUCE ARTWICK ORGANIZATION LTD.#SIMULATION#IBM#MICROSOFT FLIGHT SIMULATOR 5.0

267 notes

·

View notes

Text

Harvest Moon 64 Victor Interactive Software / Natsume Nintendo 64 1999

#harvest moon 64#victor interactive software#natsume#nintendo 64#HM64#farm simulator#RPG#bokujou monogatari 2#rain#90s#N64

197 notes

·

View notes

Video

tumblr

Hyper Securities S (Victor Interactive Software / Pack-In-Soft - Sega Saturn - 1997)

73 notes

·

View notes

Text

98 notes

·

View notes

Text

'Yíngzào Dàhēng'

[PC(?)] [TAIWAN] [MAGAZINE] [1998]

"Constructor may be in a long list of decent real time strategy titles coming out this year, but it holds a unique style of game play that I would recommend above many other highly publicized games of the same genre. The humor in this game is actually funny. The style and content are odd and interesting, setting it apart from many games available. If you like real-time strategy builder games, you are going to love Constructor. One thing is for certain: it has the best slogan I have ever heard for a game: "It's your city. Deal with it!"" ~James Fudge, Gamezilla

Source: Soft World Magazine, January 1998 (#105) || Internet Archive; NashG

#gaming#advertising#constructor#yingzao daheng#營造大亨#real-time#strategy#management#isometric#simulators#system 3 software#wang film productions#Fufeng Group#computer games#pc#1998#taiwan

9 notes

·

View notes

Text

Idk if you guys already noticed but…

The cell that TCO is being held in avm season 2 looks a lot familiar to something…

#alan becker#animation vs animator#ava the chosen one#ava tco#come on guys back me up#I’m implying that this is a simulation to Alan’s drawing software

94 notes

·

View notes

Text

"AI" this and "AI" that, NONE OF IT IS INTELLIGENT, WE HAVE NOT MADE INTELLIGENCE YET, WHY ARE WE LYING, DO WORDS MEAN NOTHING

#it's at best “machine learning” if it could even be considered learning#this is semantics but it's important semantics because words have meaning and we have to stop giving software more power than they deserve#I'm more on the side of “self-evolving programs” for what to call these things#like chat gpt is a self-evolving program which processes a database and simulates human speech based off that database#this is what being an english major has turned me into#artificial intelligence

3 notes

·

View notes

Video

youtube

Backlash: A Turret Gunner Simulation for DOS

#youtube#Backlash: A Turret Gunner Simulation#Backlash#A Turret Gunner Simulation#DOS#MS-DOS#MSDOS#Action#Shooter#First-Person Shooter#FPS#First-Person#FP#Sanctuary Software Studio

2 notes

·

View notes

Text

"No workplace shall be repurposed for slumber." - Kier Eagan

2 notes

·

View notes

Text

Streamlining Manufacturing Excellence: Reducing Rework with Virtual Commissioning in Siemens Tecnomatix

In the realm of manufacturing, efficiency and precision stand as pillars defining success. One of the critical challenges in this landscape has been minimizing rework, a costly and time-consuming aspect that impacts production schedules and quality. Enter virtual commissioning, a game-changing approach revolutionizing the manufacturing process, particularly when executed through Siemens Tecnomatix.

The Essence of Virtual Commissioning

Virtual commissioning is a methodology that simulates and validates the entire manufacturing process in a virtual environment before physical production commences. Siemens Tecnomatix, a leading digital manufacturing solution, plays a pivotal role in enabling this process. By integrating simulation, modeling, and validation capabilities, Tecnomatix offers a comprehensive platform to design, simulate, and optimize manufacturing processes.

Reducing Rework Through Virtual Commissioning

Rework in manufacturing often arises due to discrepancies between the planned processes and the actual execution on the factory floor. Virtual commissioning, empowered by Tecnomatix, mitigates this by allowing manufacturers to:

Identify and Rectify Issues Early: Through virtual simulations, potential errors or clashes in production processes can be detected before physical implementation. For instance, Tecnomatix facilitates the virtual assembly of complex machinery, detecting clashes in components or erroneous sequences that could lead to rework if unnoticed.

Optimize System Integration: When multiple components or systems need to work in harmony, ensuring their seamless integration is vital. Tecnomatix allows for testing and validation of these systems virtually, reducing the likelihood of rework due to integration issues during the physical assembly.

Validate Control Systems: Commissioning involves validating control systems such as Programmable Logic Controllers (PLCs) and their interaction with machinery. Tecnomatix's simulation capabilities enable thorough testing of these systems virtually, reducing errors that may lead to rework during the actual commissioning phase.

Real-world Applications

A notable example showcasing the efficacy of virtual commissioning with Siemens Tecnomatix is seen in the automotive industry. Car manufacturers leverage virtual commissioning to simulate entire assembly lines. Tecnomatix allows for the integration and testing of robots, conveyors, and other machinery virtually, significantly reducing rework during the physical assembly stage.

Another instance is in the realm of industrial machinery production. Companies developing complex machines rely on Tecnomatix to simulate the assembly and operation of these machines, ensuring that all components align perfectly and function as intended, thereby minimizing rework on the production line.

Virtual commissioning, powered by Siemens Tecnomatix, stands as a transformative force in the manufacturing landscape. By allowing for meticulous simulation, validation, and optimization of production processes in a virtual environment, it significantly reduces the occurrence of rework. This not only saves valuable time and resources but also ensures higher quality and efficiency in the final output. Embracing this innovative approach marks a critical step toward achieving manufacturing excellence in today's competitive market.

0 notes

Text

USA 1993

32 notes

·

View notes