#Automated Assembly Line

Explore tagged Tumblr posts

Text

Automated Assembly Line by David Alvarez

#Magic the Gathering#MtG#MtGPIP#Fallout#Universes Beyond#Fallout Commander Decks#Automated Assembly Line#Sci-Fi#David Alvarez#Wizards of the Coast

5 notes

·

View notes

Text

Sources: (x)(x)(x)

#machine possessed#machines#automation#assembly line#robots#gifs#nonhuman#machinecore#robotcore#machine possession

6 notes

·

View notes

Text

Some highlights from a detailed article:

…Deloitte, a consultancy firm, surveyed more than 200 manufacturing companies. More than 65% percent of the firms said recruiting and retaining workers was their number one business challenge.

One big reason manufacturers can’t fill these jobs overnight is because they require workers to have particular skills. And it’s not just skills needed to work on assembly lines. Only around two in five manufacturing jobs are directly involved in making stuff. Manufacturers also employ people to do research and development, engineering, design, finance, sales, marketing, and so on.

…However, many manufacturing jobs these days actually require college degrees

[Some jobs don’t need a degree]…some of the most in-demand positions in manufacturing right now are maintenance technicians, machine operators, material handlers, and forklift operators.

“The hardest skills to find are the ones that maintain and fix equipment,” Lee says. “Every company we speak with is trying to hire technicians. Every single one. The challenge is that there is no one walking around on the street with these skills, and it takes 1-2 years to teach those skills and another 1-2 years to contextualize those skills to the specific plant environment.

A classic solution to so-called worker shortages: offer higher pay.

But the higher pay that Americans demand to work in manufacturing is one of the big reasons why many manufacturers left America in the first place

0 notes

Text

The Future of Industrial Automation: How Auto Bots Pvt. Ltd. is Leading the Way

The modern manufacturing industry relies heavily on industrial automation as its central structure. Companies achieve exceptional efficiency and productivity levels together with high accuracy through advanced technological implementations. The revolutionary sector finds one of its leading players in Auto Bots Pvt. Ltd. which operates as a prominent Pune-based organization. The company holds a prime position as the Assembly Line Machines Manufacturer in Pune and Automation Integrator Systems in Pune that has revolutionized the robotics and automation sector. The exploration of future industrial automation employs an analysis of Auto Bots Pvt. Ltd.’s leadership role in technological innovation.

0 notes

Text

Understanding the CCD Polarity Tester Machine: Working, Mechanism, and Importance in the Battery Industry

In battery manufacturing, ensuring correct polarity is critical for safety, efficiency, and product reliability. The CCD Polarity Tester Machine is an advanced vision-based system designed to verify the polarity of battery cells, modules, or packs before they proceed to the next stage of production.

By using Charge-Coupled Device (CCD) cameras and image processing technology, this machine detects incorrect battery orientations, preventing assembly errors that could lead to electrical failures, reduced efficiency, or hazardous situations.

This article explores the working mechanism and significance of CCD Polarity Tester Machines in the battery industry, particularly in EV battery manufacturing, consumer electronics, and energy storage systems.

How a CCD Polarity Tester Machine Works?

1. Battery Placement

The battery cell or module is positioned in the testing station.

This can be done manually or through an automated conveyor system for high-speed manufacturing lines.

2. Image Capture Using CCD Camera

A high-resolution CCD camera captures detailed images of the battery’s terminals.

The camera is positioned to get a clear view of polarity indicators, such as symbols, colors, or terminal shapes.

3. Polarity Verification Process

The captured image is processed using machine vision algorithms.

The system compares the terminal orientation with predefined polarity templates stored in its database.

If the polarity matches the expected orientation, the battery is marked as passed.

If the polarity is incorrect, the system flags the battery as rejected.

4. Sorting and Classification

Pass Batteries: Batteries with the correct polarity move forward in the production process.

Reject Batteries: Batteries with incorrect polarity are flagged for correction or removal.

Some systems integrate robotic handling to automatically sort out non-compliant batteries.

Mechanism Behind CCD Polarity Testing

1. Charge-Coupled Device (CCD) Camera Technology

The CCD camera captures high-resolution images of battery terminals.

It offers superior light sensitivity, ensuring clear image detection in varying lighting conditions.

2. Image Processing Software

The system processes images in real time using pattern recognition and AI-based algorithms.

It identifies terminal markings, color codes, or shapes to verify polarity.

3. High-Speed Automated Feedback System

The system immediately classifies the battery as correct or incorrect.

Feedback is sent to the production control system, triggering sorting mechanisms or alerts.

4. Temperature and Lighting Adjustments

Some advanced systems adjust for ambient lighting conditions to improve accuracy.

Temperature variations that might affect image clarity are also compensated for.

Importance of CCD Polarity Testing in the Battery Industry

1. Prevents Assembly Errors

Batteries assembled with the wrong polarity can cause short circuits, device malfunctions, or permanent damage.

Ensuring correct polarity at the early production stage eliminates costly assembly line rework.

2. Enhances Safety

Misoriented batteries can lead to fire hazards, explosions, or system failures.

Particularly crucial for high-energy applications like EVs, medical devices, and energy storage solutions.

3. Improves Production Efficiency

Automated CCD testers reduce manual inspection time, improving throughput.

Early error detection minimizes waste and rework costs.

4. Ensures Compliance with Industry Standards

Battery manufacturers must adhere to safety and quality regulations such as ISO, IEC, and UL standards.

Automated polarity testing ensures compliance without human error.

5. Reduces Costs and Defective Product Returns

Incorrectly oriented batteries reaching the market can lead to warranty claims, recalls, and reputational damage.

CCD polarity testers prevent such failures, saving millions in potential losses.

Applications of CCD Polarity Tester Machines

1. Electric Vehicle (EV) Battery Production

Ensures correct orientation of high-voltage battery cells and modules before pack assembly.

Reduces the risk of electrical failure in EV power systems.

2. Consumer Electronics Manufacturing

Used in battery production for smartphones, laptops, and wearable devices.

Prevents polarity-related malfunctions in sensitive electronic devices.

3. Energy Storage Systems (ESS)

Large-scale battery storage requires precisely matched cells.

CCD testers ensure proper polarity before battery module integration.

4. Aerospace and Défense Batteries

In critical applications, such as satellites and military equipment, battery failures are unacceptable.

CCD testers provide high-precision verification for safety-critical batteries.

Choosing the Right CCD Polarity Tester for Your Needs

When selecting a CCD Polarity Tester, manufacturers should consider:

1. Accuracy and Resolution

High millivolt precision ensures reliable results.

Look for CCD cameras with high pixel resolution for better image clarity.

2. Speed and Automation Level

Automated testers are essential for high-volume battery production.

Look for systems with integrated robotic handling for increased efficiency.

3. Software Integration and AI Capabilities

Advanced systems use AI-powered image recognition to improve accuracy.

Machines that integrate with manufacturing execution systems (MES) enable real-time monitoring.

4. Compatibility with Different Battery Types

The machine should support cylindrical, prismatic, and pouch cells.

Should be adaptable to multiple battery chemistries, including Li-ion, NiMH, and LFP.

5. Temperature and Environmental Adaptability

Choose a tester with adjustable lighting and temperature compensation for reliable readings in different factory environments.

Conclusion

A CCD Polarity Tester Machine is a critical tool in battery manufacturing, ensuring that battery terminals are correctly oriented before further processing. By using high-precision imaging, automation, and AI-based vision systems, these machines eliminate polarity errors, enhance product reliability, and improve overall manufacturing efficiency.

In industries such as EVs, energy storage, and consumer electronics, CCD polarity testing plays a key role in ensuring safety, compliance, and product longevity. As battery technology advances, the demand for high-speed, accurate, and automated polarity testing solutions will continue to grow.

#Automated Polarity Inspection#Battery Assembly Line Testing#Battery Polarity Detection#Battery Polarity Testing Machine#battery testing equipment#CCD Polarity Tester#Lithium Battery Polarity Check#Non-contact Polarity Testing

0 notes

Text

Automated Bolt Assembly Station for Training and Automation in Pune

Hytech Didactic is a leading manufacturer and supplier of Automated Bolt Assembly Stations in Pune. Our systems are perfect for assembly training kits and bolt assembly training.

#Automated Bolt Assembly Station Pune#assembly station Pune#assembly training kit Pune#bolt assembly training kit Pune#automated assembly station Pune#industrial automation training Pune#bolt assembly automation Pune#automation training kits Pune#automated bolt training station Pune#assembly line manufacturer in pune

0 notes

Text

Factory Automation in pune | India

The total automation of the production process is what we mean when we talk about factory automation. Using technologies like robotic arms, hydraulic systems, and pneumatic systems to automate the construction of increasingly complicated systems is standard procedure in the manufacturing industry.

#Factory Automation Pune#Industrial Automation Control India#Process Automation Robotics India#Industrial Automation Siemens#Industrial Automation Industry Pune#Robotics Company India#Automotive for Assembly Lines Pune#Automation Solution India

0 notes

Text

protip for playing minecraft tech modpacks: you don't have to automate everything in order. you can half-ass everything up to a certain point to make it easier to go back and full-ass everything

#been playing create above and beyond again#and holy shit the quality of life from rushing the kinetic mechanism assembly line#even if i don't have a fully automated supply of the intermediate products#makes it easier to fully automate said intermediate products because now i dont have to keep manually crafting mechanisms

0 notes

Text

🌟 Improve your factory efficiency! 🌟

Explore our high-efficiency belt conveyors to bring seamless and efficient operation to your production line. Whether it is food processing, logistics transportation or manufacturing, our conveyors can meet your needs.

✨ Features:

Durable materials, long life use Smooth operation, reduced downtime Easy to install and maintain Customizable design to adapt to various scenarios 📈 Improve productivity and reduce costs: We are committed to helping you optimize your production processes and achieve more efficient operations.

🔗 Click to learn more: belt conveyors

0 notes

Text

Assembly Line Automation: Boosting Efficiency and Productivity

Assembly lines revolutionized manufacturing in the early 20th century, pioneered by Henry Ford in the automotive industry. They allowed for mass production, significantly reducing costs and increasing efficiency. Today, with the global market becoming increasingly competitive, manufacturers are turning to automation to further enhance their production processes read more here…

0 notes

Text

There are situations in which tariffs are a useful tool to address a trade deficit, or to protect key sectors of a country’s economy. Then there are situations where you accuse a bunch of penguins on an uninhabited island of currency manipulation. Guess which one we’re living in?

This is the takeaway of the manifold tariffs announced by President Donald Trump on Wednesday afternoon. In addition to the penguin-occupied Heard and McDonald Islands, the tariffs target the British Indian Ocean Territory, whose sole occupants live on a joint US-UK military base on Diego Garcia island. Yes, the United States is levying reciprocal tariffs against its own troops.

And then there are the tariffs against countries that have actual goods and services on which US consumers depend. China: 54 percent. Vietnam: 46 percent. Cambodia: 49 percent. South Korea: 25 percent. No corner of the US consumer economy will go untouched. Prices will rise. The stock market is spiraling. A recession looms. The tech industry will be turned upside down. Mark Cuban, noted billionaire, is encouraging people to stockpile consumables before it’s too late.

It’s reckless, it’s absurd, and it’s also everything Donald Trump said plainly he would do on the campaign trail. True, he didn’t telegraph how misguided the methodology would be—you can read about it more here, but suffice to say it’s thoroughly detached from the realities of international trade—but he loudly, repeatedly promised to tariff his way to glory.

The stated goal is to return manufacturing jobs to the United States, which is a bit like resurrecting the dodo. The US still manufactures plenty of goods; it’s second only to China in annual output, according to the World Bank. But many of the industry’s jobs have been replaced by automation, a bottle you can’t re-cork. And higher domestic labor costs mean US-made products will inherently be more expensive, a trade-off American consumers have consistently rejected. All of this was already true in Trump’s first term. It’s even more so now.

And let’s say a plurality of companies did decide to reshore or set up factories in the United States. The timeline for those decisions and implementation is measured in years, if not decades, and follow-through can be spotty. (Just ask Foxconn.) So what happens in the meantime?

The rationale has all the weight of a soap bubble. There isn’t a world where the US suddenly manufactures all the items the country has decided to target. There’s a 47 percent tariff on Madagascar now. Do you know why the US has a trade deficit with Madagascar? They produce vanilla; we don’t. Unless we’re suddenly setting up vanilla assembly lines in Ohio, that’s not changing.

But maybe Trump’s so-called Liberation Day is all just a master negotiating ploy. “Everybody sit back, take a deep breath. Don’t immediately retaliate. Let’s see where this goes,” said Treasury secretary Scott Bessent on CNN Wednesday. “Because if you retaliate, that’s how we get escalation.”

It’s an interesting tactic, to start a bar brawl and ask everyone not to punch back in case someone gets hurt. It’s not working. China has already vowed to retaliate; the EU suggested that it could as well. (New Zealand is officially chill.)

Set the economics of this aside for a moment, though. The insult on top of that looming injury is how sloppy this all is. It’s the same blunt-force destruction that DOGE has implemented within the US government, that Robert F. Kennedy Jr. has imposed on the Centers for Disease Control and Prevention, now projected on a global scale. Yes, Elon Musk and DOGE have taken a blowtorch to federal agencies. But the tariffs are a helpful reminder that it's Trump who's fiddling while it all burns.

It’s the instinct to measure wins in units of pain and suffering. It’s an assumption that the only way to help yourself is to hurt other people. This is just what America is now.

The optimist’s case is that this is all a feint, that other countries will capitulate or at least make enough of a show of it that things will go back to normal. Seems unlikely. First of all, they’re already doing the opposite, all apologies to Bessent. But even if they weren’t, even if this is just posturing from the US, that posturing has consequences. Whatever equity the US has built up over the last century as a reputable trade partner has been largely wiped out by a businessman-president best known for his bankruptcies.

And then there’s the pessimist’s case, which also seems increasingly like the realist’s. The US is barreling toward a recession for no good reason, and dragging the world—and a few thousand penguins on remote Antarctic islands—down with it.

91 notes

·

View notes

Text

Random thought:

The Rae was all handmade. It wasn’t like how cars are made on massive automated assembly lines.

Every part of a character was crafted by a person. Every single aspect of the entire show, from assembly, cosmetics, stage props, recording, and programming was all created by actual people.

It breathes an extra feeling of life into it all. In a time where everything is manufactured through automation in some way, it’s so special to know how many people were a part of making this band a reality.

#rock afire explosion#showbiz pizza#animatronics#the rock afire was handmade#that’s what makes it even more sad that so many were discarded in such careless ways#it’s a lot easier to destroy something than it is to build#I have a manufacturing background so it’s especially amazing to me knowing that every part of this show had human touch to it#it wasn’t soulless#don’t you feel even more connected to something knowing people actually spent time on it?#like art#you don’t see museums carelessly tossing artwork#it’s all perception on how things were placed in the public eye unfortunately#yoshi random thoughts

48 notes

·

View notes

Text

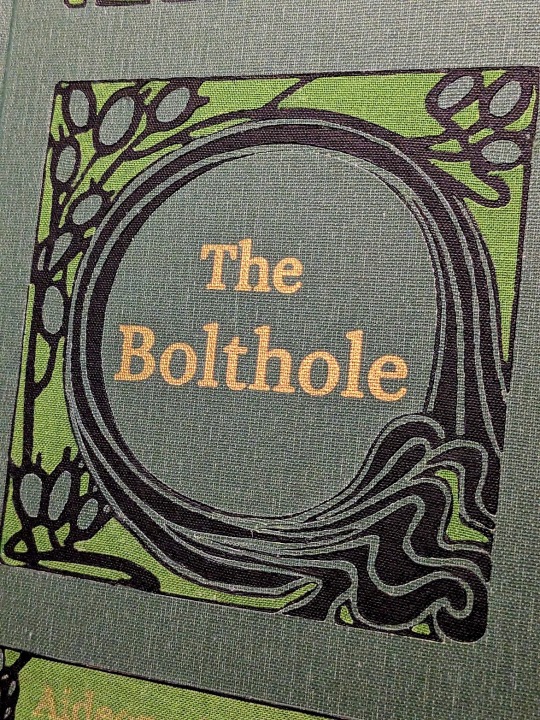

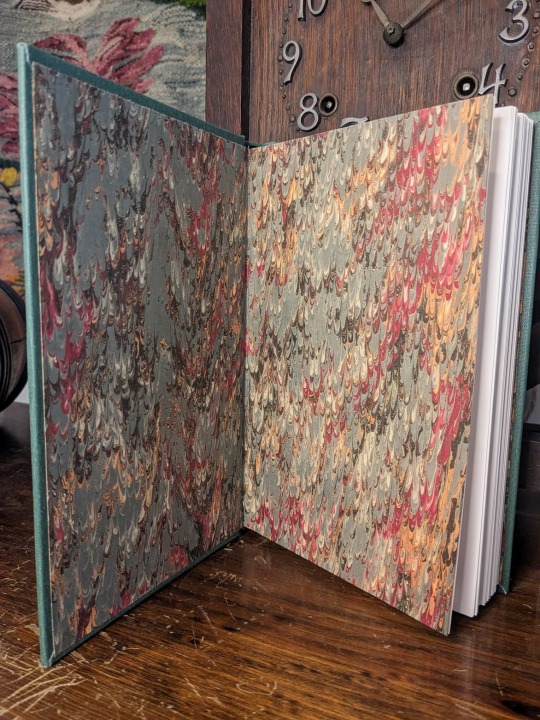

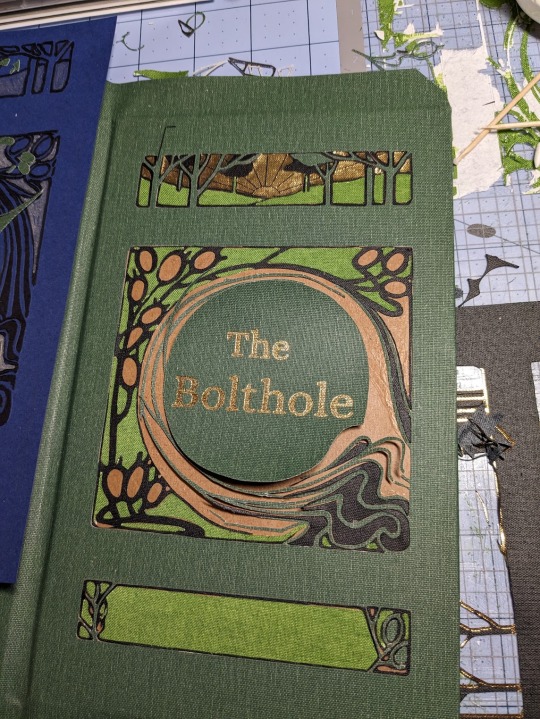

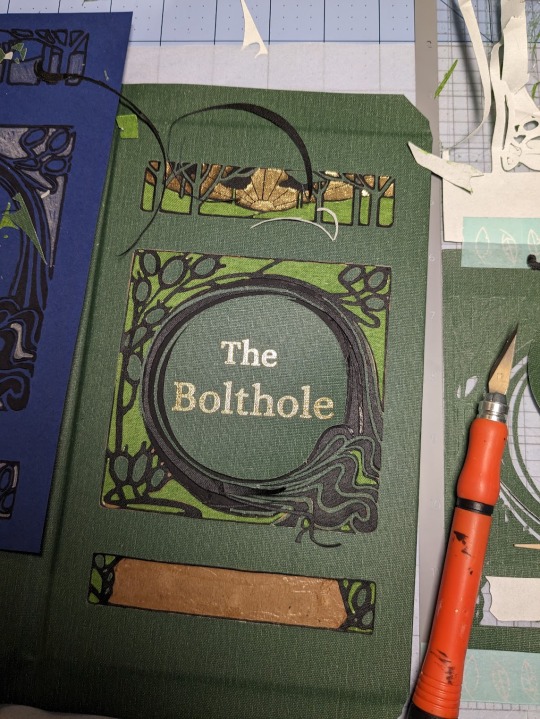

The Bolthole by aideomai, Tepre, and GallaPlacidia

I'm absolutely thrilled to finally share my first fic bind here on Tumblr! I completed this bind back in November, and it introduced me to so many wonderful people.

You can find pictures and detailed explanations of my process under the cut.

This is "The Bolthole" by Aideomai, Tepre, and (formerly) GallaPlacidia on Ao3. The cover design is adapted from "The Little Brother" (1902) by Josiah Flynt. The typeset is my own.

I fell in love with this cover the moment I saw it, and wanted to try to recreate it with book cloth. As a hobbyist book binder, I like to try to revitalize older designs from the public domain. There are so few copies of this book left in the world, so I thought it would be fun to give it new life as the cover of a contemporary story.

The cover is made out of three different colors of book cloth from the Allure and Verona lines. The book cloth and endpapers were bought from Hollander's.

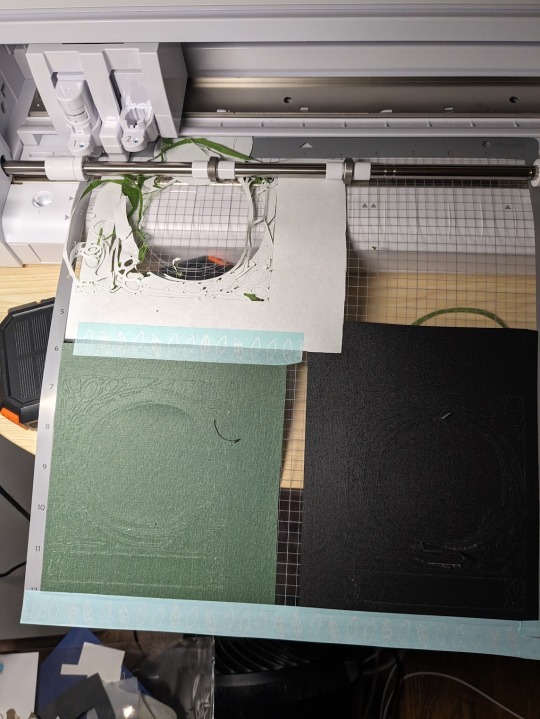

I used my Cameo 4 and a strong tack mat to cut the design out of each color of book cloth. I then assembled the pattern like a puzzle. It was MUCH harder than it sounds! Some of the pieces were incredibly thin and fragile, and they were difficult to keep track of.

For the foiling, I used my Cameo 4 and the We R Memory Keepers fine tip foil quill for everything but the spine, which I did by hand. I foiled immediately after I cut, without removing my mat from the machine. This helped me line everything up. It did not, however, prevent me from sweating bullets as my machine worked.

This method was, frankly, torture, but I'm really glad that I tried it. Now that I've had a nice long break, I'd like to try it again soon. I love running my hands over this book, and the texture of the book cloth feels wonderful under my fingertips. I do, however, have a few words of caution. Do not try this out unless you have book cloth to burn! Here are some pictures of just a few of my failures.

The Cameo 4 is not your friend. Your cut-outs can and will get fucked up for no reason. If the mat isn't sticky enough, or the blade isn't sharp enough, or the fabric doesn't adhere properly, your design could get completely shredded. I strongly recommend that you avoid Verona book cloth, or anything with a paper backing and loose fibers. It was absolute hell to work with. When it wasn't shredded by the machine, it was fraying like crazy. Acrylic coated cloth is the way to go if you want clean lines. And, you know, your sanity intact.

This was my most challenging bind to date, but I learned a lot! Aside from experimenting with book cloth, automated foiling, and my Cameo 4, it was also my first time formatting, printing, and sewing a text block. I'm incredibly grateful for all of the online tutorials and wonderful people who helped me make this bind a reality!

#book binding#ficbinding#fanbinding#fanfic binding#drarry#the bolthole#harry x draco#my binds#haxkattpress

333 notes

·

View notes

Text

USED SERVITOR BLOWOUT SALE FESTIVAL🎈🥳🎉:

Remember: Serve the Emperor, or Serve as Parts. Either way, YOU SERVE.

EVERYTHING MUST GO (INCLUDING YOUR HUMANITY)

Welcome to the biggest clearance event in the Imperium, motherfuckers! Need cheap labor? Need a servitor with that "lightly used, only screamed for the first 40 days" kinda vibe? Well, step right up! We got everything from half-brainwashed factory workers to lobotomized aristocrats who forgot to pay their tithe.

Because in the grim darkness of the far future, one thing is certain: you can be a worker, you can be a soldier, or you can be stock.

💀 SHOP SMART, SHOP SERVITOR 💀

🔹 Genetic Mishaps? We got those! Crooked nobles who thought they were untouchable, now wired into conveyor belts, drooling coolant, shitting oil, and making sure your las-rifles come off the assembly line on time.

🔹 Failed Tech-Priest Acolytes? Fuck yeah! Ask too many questions, and you could end up as a walking soft-serve machine with a detachable cock-replaceable nozzle.

🔹 Battlefield Salvage? Some dumbass Guardsman who took one too many rounds to the brain and didn’t have the decency to fully die? Now he’s the designated ammo carrier. His eyes are gone, his soul is in whatever counts as an afterlife, but goddamn if he isn’t still loading shells into the Basilisk.

🔹 Discounted Heretics! That’s right, folks! Thought crime isn’t just punishable by death—it’s punishable by a lifetime of tireless, lobotomized, piss-and-rot servitude! Remember that loudmouth who started questioning the Ecclesiarchy? Yeah, she’s a self-powered fuckin’ janitor now. And she doesn’t even know it.

💀 INJUSTICE? NAH, THIS IS JUST HOW SHIT WORKS. 💀

Look, the Imperium doesn’t have time for due process, ethics, or your bitching. You get caught, you get sentenced, and if you’re lucky, you just get shot in the face. If not? Well…

You will be stripped. Of name, rank, and thought.

You will be wired. Into machines, into assembly lines, into grotesque walking infrastructure.

You will be useful. Until your body fucking quits.

And then? Your carcass gets recycled into another batch of "freshly mindwiped workforce," because wastefulness is heresy.

💀 TRAGEDY? MAYBE. COMEUPPANCE? ABSOLUTELY. 💀

🔹 That planetary governor who let a Hive World rot in famine? He’s a servitor now, shoveling the same shit his people had to eat.

🔹 That spoiled noble who thought she was above the law? Yeah, she’s bolted into an automated pleasure engine, servicing the same underhivers she once spat on.

🔹 That inquisitor who purged an entire city "just to be sure"? Hope he enjoys his new eternity as a fleshlight-dispensing bio-recycler.

🔹 That rich fuck who hoarded resources, letting a whole sector starve? Don’t worry. His nutrient paste tastes real good, because it’s made out of him.

Because in the glorious Imperium of Man, even the worst scum eventually finds a purpose. Even if that purpose is being a half-melting, piss-leaking, cybernetic flesh-husk on sale for 5 thrones.

🔥 EVERYTHING MUST GO (INCLUDING YOUR SOUL) 🔥

REBLOG if you’d rather be shot than end up in a servitor assembly line.

💬 COMMENT which Warhammer faction you think deserves to be on the clearance rack.

🚀 FOLLOW for more grimdark truths straight from the corpse-laden frontlines.

#Humor#scary#Satire#scary art#scary stories#grimdark#warhammer fanfic#funny post#funny memes#funny stuff#funny shit#humor#jokes#memes#culture#funny#hilarious#horror#horror comedy#grimdank#horror art#android#robot

57 notes

·

View notes

Text

Automated Press Assembly Station Manufacturer & Supplier in Pune India

Discover Hytech Didactic's Automated Press Assembly Station Manufacturer and Supplier in Pune. Perfect for mechatronics training, PLC HMI training, and automated assembly training solutions.

#automated press assembly station Pune#assembly line manufacturer in pune#press assembly station Pune#mechatronics training Pune#mechatronics training cell Pune#Hytech mechatronics Pune#PLC HMI training Pune#automated assembly training Pune#industrial automation training Pune#press assembly automation Pune#automated press system Pune

0 notes

Text

Manufacturing Execution System Software in pune | India

The MES is not only responsible for providing technical advice but also for carrying out the assigned responsibilities. Planning, constructing, and maintaining all works, buildings, airfields, dock installations, and other structures is the responsibility of the Military Engineering Services.

#Industrial Automation Industry Pune#Robotics Company India#Automotive for Assembly Lines Pune#Automation Solution India#Automotive Service for Paint Shop Pune#Body Shop BIW India#WAGO Solutions Platform Pune#WAGO Lighting Management

0 notes