#New Factory Assembly lines will be automated

Explore tagged Tumblr posts

Text

Some highlights from a detailed article:

…Deloitte, a consultancy firm, surveyed more than 200 manufacturing companies. More than 65% percent of the firms said recruiting and retaining workers was their number one business challenge.

One big reason manufacturers can’t fill these jobs overnight is because they require workers to have particular skills. And it’s not just skills needed to work on assembly lines. Only around two in five manufacturing jobs are directly involved in making stuff. Manufacturers also employ people to do research and development, engineering, design, finance, sales, marketing, and so on.

…However, many manufacturing jobs these days actually require college degrees

[Some jobs don’t need a degree]…some of the most in-demand positions in manufacturing right now are maintenance technicians, machine operators, material handlers, and forklift operators.

“The hardest skills to find are the ones that maintain and fix equipment,” Lee says. “Every company we speak with is trying to hire technicians. Every single one. The challenge is that there is no one walking around on the street with these skills, and it takes 1-2 years to teach those skills and another 1-2 years to contextualize those skills to the specific plant environment.

A classic solution to so-called worker shortages: offer higher pay.

But the higher pay that Americans demand to work in manufacturing is one of the big reasons why many manufacturers left America in the first place

0 notes

Text

There are situations in which tariffs are a useful tool to address a trade deficit, or to protect key sectors of a country’s economy. Then there are situations where you accuse a bunch of penguins on an uninhabited island of currency manipulation. Guess which one we’re living in?

This is the takeaway of the manifold tariffs announced by President Donald Trump on Wednesday afternoon. In addition to the penguin-occupied Heard and McDonald Islands, the tariffs target the British Indian Ocean Territory, whose sole occupants live on a joint US-UK military base on Diego Garcia island. Yes, the United States is levying reciprocal tariffs against its own troops.

And then there are the tariffs against countries that have actual goods and services on which US consumers depend. China: 54 percent. Vietnam: 46 percent. Cambodia: 49 percent. South Korea: 25 percent. No corner of the US consumer economy will go untouched. Prices will rise. The stock market is spiraling. A recession looms. The tech industry will be turned upside down. Mark Cuban, noted billionaire, is encouraging people to stockpile consumables before it’s too late.

It’s reckless, it’s absurd, and it’s also everything Donald Trump said plainly he would do on the campaign trail. True, he didn’t telegraph how misguided the methodology would be—you can read about it more here, but suffice to say it’s thoroughly detached from the realities of international trade—but he loudly, repeatedly promised to tariff his way to glory.

The stated goal is to return manufacturing jobs to the United States, which is a bit like resurrecting the dodo. The US still manufactures plenty of goods; it’s second only to China in annual output, according to the World Bank. But many of the industry’s jobs have been replaced by automation, a bottle you can’t re-cork. And higher domestic labor costs mean US-made products will inherently be more expensive, a trade-off American consumers have consistently rejected. All of this was already true in Trump’s first term. It’s even more so now.

And let’s say a plurality of companies did decide to reshore or set up factories in the United States. The timeline for those decisions and implementation is measured in years, if not decades, and follow-through can be spotty. (Just ask Foxconn.) So what happens in the meantime?

The rationale has all the weight of a soap bubble. There isn’t a world where the US suddenly manufactures all the items the country has decided to target. There’s a 47 percent tariff on Madagascar now. Do you know why the US has a trade deficit with Madagascar? They produce vanilla; we don’t. Unless we’re suddenly setting up vanilla assembly lines in Ohio, that’s not changing.

But maybe Trump’s so-called Liberation Day is all just a master negotiating ploy. “Everybody sit back, take a deep breath. Don’t immediately retaliate. Let’s see where this goes,” said Treasury secretary Scott Bessent on CNN Wednesday. “Because if you retaliate, that’s how we get escalation.”

It’s an interesting tactic, to start a bar brawl and ask everyone not to punch back in case someone gets hurt. It’s not working. China has already vowed to retaliate; the EU suggested that it could as well. (New Zealand is officially chill.)

Set the economics of this aside for a moment, though. The insult on top of that looming injury is how sloppy this all is. It’s the same blunt-force destruction that DOGE has implemented within the US government, that Robert F. Kennedy Jr. has imposed on the Centers for Disease Control and Prevention, now projected on a global scale. Yes, Elon Musk and DOGE have taken a blowtorch to federal agencies. But the tariffs are a helpful reminder that it's Trump who's fiddling while it all burns.

It’s the instinct to measure wins in units of pain and suffering. It’s an assumption that the only way to help yourself is to hurt other people. This is just what America is now.

The optimist’s case is that this is all a feint, that other countries will capitulate or at least make enough of a show of it that things will go back to normal. Seems unlikely. First of all, they’re already doing the opposite, all apologies to Bessent. But even if they weren’t, even if this is just posturing from the US, that posturing has consequences. Whatever equity the US has built up over the last century as a reputable trade partner has been largely wiped out by a businessman-president best known for his bankruptcies.

And then there’s the pessimist’s case, which also seems increasingly like the realist’s. The US is barreling toward a recession for no good reason, and dragging the world—and a few thousand penguins on remote Antarctic islands—down with it.

91 notes

·

View notes

Text

USED SERVITOR BLOWOUT SALE FESTIVAL🎈🥳🎉:

Remember: Serve the Emperor, or Serve as Parts. Either way, YOU SERVE.

EVERYTHING MUST GO (INCLUDING YOUR HUMANITY)

Welcome to the biggest clearance event in the Imperium, motherfuckers! Need cheap labor? Need a servitor with that "lightly used, only screamed for the first 40 days" kinda vibe? Well, step right up! We got everything from half-brainwashed factory workers to lobotomized aristocrats who forgot to pay their tithe.

Because in the grim darkness of the far future, one thing is certain: you can be a worker, you can be a soldier, or you can be stock.

💀 SHOP SMART, SHOP SERVITOR 💀

🔹 Genetic Mishaps? We got those! Crooked nobles who thought they were untouchable, now wired into conveyor belts, drooling coolant, shitting oil, and making sure your las-rifles come off the assembly line on time.

🔹 Failed Tech-Priest Acolytes? Fuck yeah! Ask too many questions, and you could end up as a walking soft-serve machine with a detachable cock-replaceable nozzle.

🔹 Battlefield Salvage? Some dumbass Guardsman who took one too many rounds to the brain and didn’t have the decency to fully die? Now he’s the designated ammo carrier. His eyes are gone, his soul is in whatever counts as an afterlife, but goddamn if he isn’t still loading shells into the Basilisk.

🔹 Discounted Heretics! That’s right, folks! Thought crime isn’t just punishable by death—it’s punishable by a lifetime of tireless, lobotomized, piss-and-rot servitude! Remember that loudmouth who started questioning the Ecclesiarchy? Yeah, she’s a self-powered fuckin’ janitor now. And she doesn’t even know it.

💀 INJUSTICE? NAH, THIS IS JUST HOW SHIT WORKS. 💀

Look, the Imperium doesn’t have time for due process, ethics, or your bitching. You get caught, you get sentenced, and if you’re lucky, you just get shot in the face. If not? Well…

You will be stripped. Of name, rank, and thought.

You will be wired. Into machines, into assembly lines, into grotesque walking infrastructure.

You will be useful. Until your body fucking quits.

And then? Your carcass gets recycled into another batch of "freshly mindwiped workforce," because wastefulness is heresy.

💀 TRAGEDY? MAYBE. COMEUPPANCE? ABSOLUTELY. 💀

🔹 That planetary governor who let a Hive World rot in famine? He’s a servitor now, shoveling the same shit his people had to eat.

🔹 That spoiled noble who thought she was above the law? Yeah, she’s bolted into an automated pleasure engine, servicing the same underhivers she once spat on.

🔹 That inquisitor who purged an entire city "just to be sure"? Hope he enjoys his new eternity as a fleshlight-dispensing bio-recycler.

🔹 That rich fuck who hoarded resources, letting a whole sector starve? Don’t worry. His nutrient paste tastes real good, because it’s made out of him.

Because in the glorious Imperium of Man, even the worst scum eventually finds a purpose. Even if that purpose is being a half-melting, piss-leaking, cybernetic flesh-husk on sale for 5 thrones.

🔥 EVERYTHING MUST GO (INCLUDING YOUR SOUL) 🔥

REBLOG if you’d rather be shot than end up in a servitor assembly line.

💬 COMMENT which Warhammer faction you think deserves to be on the clearance rack.

🚀 FOLLOW for more grimdark truths straight from the corpse-laden frontlines.

#Humor#scary#Satire#scary art#scary stories#grimdark#warhammer fanfic#funny post#funny memes#funny stuff#funny shit#humor#jokes#memes#culture#funny#hilarious#horror#horror comedy#grimdank#horror art#android#robot

57 notes

·

View notes

Text

companies bragging about/threatening replacing their entire workforce with AI while whining that no one want to work anymore would be comical if it wasn't deeply infuriating.

like, we have the massive workforce we have bc that workforce was designed to fill factories and plants that needed a bunch of people on duty to manufacture things. then manufacturers automated that process and dropped a bunch of people. then they exported their work to the east where they didn't have to *checks notes* follow safety standards and pay people enough to live. and that massive workforce just kinda... found something else to do, or didn't, but that hole was never really patched. (the tech boom arguably opened up new industries and thus new jobs, but it's not like former assembly line workers got hired to code in assembly.)

fast forward to now, and almost a whole generation of people were told to get college degrees if they wanted good jobs and security, only to be shut out of those jobs bc now you need 10 years of experience and a personal recommendation from the boss' uncle, if there are even jobs/positions still available for that degree. and the generation that bellowed "go to college or you'll work at mcdonald's" turned around and started mocking the people who stand behind cash registers with a degree hung up on their apartment wall for expecting what they were told to expect.

companies cut slack, make 1 person do the job of 5 so they only have to shell out 1 paycheck, and fire anyone who even thinks about unionization while daring to act like they're a "family" when they really mean they expect you to dedicate your life to them. companies pay out the lowest wages they're legally allowed to and scoff at people who (rightfully) call them out on it bc "you shouldn't just be in it for the money, you should do this bc you love it!" when passion doesn't pay the rent. companies fire a department and replace them with an AI that does a worse job, but it's faster and cheaper so the investors love it. companies make applicants jump through hoops to get hired (if they're even actually hiring) and think that anyone who doesn't play their games just isn't committed enough. companies complain that no one wants to work anymore bc no one wants to work for them.

of course people want to work. they have bills to pay and groceries aren't free yet. you just don't want to pay them.

you're the employer. start employing. you make jobs. make them.

because like it or not, you can't last without workers, and workers can absolutely last without you.

#it speaks#rant#anti capitalism#no one wants to work anymore#like it's called the labor market for a reason#if you're not offering#no one's taking#don't complain you have no purchases when you've closed your stall and barricaded it#i made a fake linkedin account for trolling a while back and the mindset is just so stupidly toxic#having standards looks bad on your resume huh? i guess you should get your own then#it's like they straight up don't understand that people need money to live in a capitalist system. yeah dude people wanna get paid#they're creating the perfect conditions for people to give up on working and then complaining that people are. giving up on work

12 notes

·

View notes

Text

News of the Day 6/11/25: AI

Paywall free.

More seriously, from the NY Times:

"For Some Recent Graduates, the A.I. Job Apocalypse May Already Be Here" (Paywall Free)

You can see hints of this in the economic data. Unemployment for recent college graduates has jumped to an unusually high 5.8 percent in recent months, and the Federal Reserve Bank of New York recently warned that the employment situation for these workers had “deteriorated noticeably.” Oxford Economics, a research firm that studies labor markets, found that unemployment for recent graduates was heavily concentrated in technical fields like finance and computer science, where A.I. has made faster gains. [...] Using A.I. to automate white-collar jobs has been a dream among executives for years. (I heard them fantasizing about it in Davos back in 2019.) But until recently, the technology simply wasn’t good enough. You could use A.I. to automate some routine back-office tasks — and many companies did — but when it came to the more complex and technical parts of many jobs, A.I. couldn’t hold a candle to humans. That is starting to change, especially in fields, such as software engineering, where there are clear markers of success and failure. (Such as: Does the code work or not?) In these fields, A.I. systems can be trained using a trial-and-error process known as reinforcement learning to perform complex sequences of actions on their own. Eventually, they can become competent at carrying out tasks that would take human workers hours or days to complete.

I've been hearing my whole life how automation was coming for all our jobs. First it was giant robots replacing big burly men on factory assembly lines. Now it seems to be increasingly sophisticated bits of code coming after paper-movers like me. I'm not sure we're there yet, quite, but the NYT piece does make a compelling argument that we're getting close.

The real question is, why is this a bad thing? And the obvious answer is people need to support themselves, and every job cut is one less person who can do that. But what I really mean is, if we can get the outputs we need to live well with one less person having to put in a day's work to get there, what does it say about us that we haven't worked out a way to make that a good thing?

Put another way, how come we haven't worked out a better way to share resources and get everyone what they need to thrive when we honestly don't need as much labor-hours for them to "earn" it as we once did?

I don't have the solution, but if some enterprising progressive politician wants to get on that, they could do worse. I keep hearing how Democrats need bold new ideas directed to helping the working class.

More on the Coming AI-Job-Pocalypse

I’m a LinkedIn Executive. I See the Bottom Rung of the Career Ladder Breaking. (X)

Paul Krugman: “What Deindustrialization Can Teach Us About The Effects of AI on Workers” (X)

How AI agents are transforming work—and why human talent still matters (X)

AI agents will do programmers' grunt work (X)

At Amazon, Some Coders Say Their Jobs Have Begun to Resemble Warehouse Work (X)

Why Esther Perel is going all in on saving the American workforce in the age of AI

Junior analysts, beware: Your coveted and cushy entry-level Wall Street jobs may soon be eliminated by AI (X)

The biggest barrier to AI adoption in the business world isn’t tech – it’s user confidence (X)

Experts predicted that artificial intelligence would steal radiology jobs. But at the Mayo Clinic, the technology has been more friend than foe. (X)

AI Will Devastate the Future of Work. But Only If We Let It (X)

AI in the workplace is nearly 3 times more likely to take a woman’s job as a man’s, UN report finds (X)

Klarna CEO predicts AI-driven job displacement will cause a recession (X)

& on AI Generally

19th-century Catholic teachings, 21st-century tech: How concerns about AI guided Pope Leo’s choice of name (X)

Will the Humanities Survive Artificial Intelligence? (X)

Two Paths for A.I. (X)

The Danger of Outsourcing Our Brains: Counting on AI to learn for us makes humans boring, awkward, and gullible. (X)

AI Is a Weapon Pointed at America. Our Best Defense Is Education. (X)

The Trump administration has asked artificial intelligence publishers to rebalance what it considers to be 'ideological bias' around actions like protecting minorities and banning hateful content. (X)

What is Google even for anymore? (X)

AI can spontaneously develop human-like communication, study finds

AI Didn’t Invent Desire, But It’s Rewiring Human Sex And Intimacy (X)

Mark Zuckerberg Wants AI to Solve America’s Loneliness Crisis. It Won’t. (X)

The growing environmental impact of AI data centers’ energy demands

Tesla Is Launching Robotaxis in Austin. Safety Advocates Are Concerned (X)

The One Big Beautiful Bill Act would ban states from regulating AI (X)

& on the Job-Pocalypse & Other Labor-Related Shenanigans Generally, Too

What Unions Face With Trump EOs (X)

AI may be exposing jobseekers to discrimination. Here’s how we could better protect them (X)

Jamie Dimon says he’s not against remote workers—but they ‘will not tell JPMorgan what to do’ (X)

Direct-selling schemes are considered fringe businesses, but their values have bled into the national economy. (X)

Are you "functionally unemployed"? Here's what the unemployment rate doesn't show. (X)

Being monitored at work? A new report calls for tougher workplace surveillance controls (X)

Josh Hawley and the Republican Effort to Love Labor (X)

Karl Marx’s American Boom (X)

Hiring slows in U.S. amid uncertainty over Trump’s trade wars

Vanishing immigration is the ‘real story’ for the economy and a bigger supply shock than tariffs, analyst says (X)

3 notes

·

View notes

Text

AI & IT'S IMPACT

Unleashing the Power: The Impact of AI Across Industries and Future Frontiers

Artificial Intelligence (AI), once confined to the realm of science fiction, has rapidly become a transformative force across diverse industries. Its influence is reshaping the landscape of how businesses operate, innovate, and interact with their stakeholders. As we navigate the current impact of AI and peer into the future, it's evident that the capabilities of this technology are poised to reach unprecedented heights.

1. Healthcare:

In the healthcare sector, AI is a game-changer, revolutionizing diagnostics, treatment plans, and patient care. Machine learning algorithms analyze vast datasets to identify patterns, aiding in early disease detection. AI-driven robotic surgery is enhancing precision, reducing recovery times, and minimizing risks. Personalized medicine, powered by AI, tailors treatments based on an individual's genetic makeup, optimizing therapeutic outcomes.

2. Finance:

AI is reshaping the financial industry by enhancing efficiency, risk management, and customer experiences. Algorithms analyze market trends, enabling quicker and more accurate investment decisions. Chatbots and virtual assistants powered by AI streamline customer interactions, providing real-time assistance. Fraud detection algorithms work tirelessly to identify suspicious activities, bolstering security measures in online transactions.

3. Manufacturing:

In manufacturing, AI is optimizing production processes through predictive maintenance and quality control. Smart factories leverage AI to monitor equipment health, reducing downtime by predicting potential failures. Robots and autonomous systems, guided by AI, enhance precision and efficiency in tasks ranging from assembly lines to logistics. This not only increases productivity but also contributes to safer working environments.

4. Education:

AI is reshaping the educational landscape by personalizing learning experiences. Adaptive learning platforms use AI algorithms to tailor educational content to individual student needs, fostering better comprehension and engagement. AI-driven tools also assist educators in grading, administrative tasks, and provide insights into student performance, allowing for more effective teaching strategies.

5. Retail:

In the retail sector, AI is transforming customer experiences through personalized recommendations and efficient supply chain management. Recommendation engines analyze customer preferences, providing targeted product suggestions. AI-powered chatbots handle customer queries, offering real-time assistance. Inventory management is optimized through predictive analytics, reducing waste and ensuring products are readily available.

6. Future Frontiers:

A. Autonomous Vehicles: The future of transportation lies in AI-driven autonomous vehicles. From self-driving cars to automated drones, AI algorithms navigate and respond to dynamic environments, ensuring safer and more efficient transportation. This technology holds the promise of reducing accidents, alleviating traffic congestion, and redefining mobility.

B. Quantum Computing: As AI algorithms become more complex, the need for advanced computing capabilities grows. Quantucm omputing, with its ability to process vast amounts of data at unprecedented speeds, holds the potential to revolutionize AI. This synergy could unlock new possibilities in solving complex problems, ranging from drug discovery to climate modeling.

C. AI in Creativity: AI is not limited to data-driven tasks; it's also making inroads into the realm of creativity. AI-generated art, music, and content are gaining recognition. Future developments may see AI collaborating with human creators, pushing the boundaries of what is possible in fields traditionally associated with human ingenuity.

In conclusion, the impact of AI across industries is profound and multifaceted. From enhancing efficiency and precision to revolutionizing how we approach complex challenges, AI is at the forefront of innovation. The future capabilities of AI hold the promise of even greater advancements, ushering in an era where the boundaries of what is achievable continue to expand. As businesses and industries continue to embrace and adapt to these transformative technologies, the synergy between human intelligence and artificial intelligence will undoubtedly shape a future defined by unprecedented possibilities.

20 notes

·

View notes

Text

What is your favourite Doctor Who story?

ROUND 3 MASTERPOST

synopses and propaganda under the cut

Lungbarrow

Synopsis

"Nonsense, child", retorted the Doctor. "Grandfather indeed! I've never seen you before in my life!"

All is not well on Gallifrey. Chris Cwej is having someone else's nightmares. Ace is talking to herself. So is K9. Leela has stumbled on a murderous family conspiracy. And the beleaguered Lady President, Romanadvoratrelundar, foresees one of the most tumultuous events in her planet's history.

At the root of all is an ancient and terrible place, the House of Lungbarrow in the southern mountains of Gallifrey. Something momentous is happening there. But the House has inexplicably gone missing.

673 years ago the Doctor left his family in that forgotten House. Abandoned, disgraced and resentful, they have waited. And now he's home at last.

In this, the Seventh Doctor's final New Adventure, he faces a threat that could uncover the greatest secret of them all.

Propaganda

Is it good? No. But damn if it doesn't cause some good fandom fights. #LoomRights (@eighthdoctor )

cornerstone of weird doctor who lore and jokes about looms (anonymous)

The Cars that Ate London!

Synopsis

The advent of electric carriages on London's streets causes a stir – until they start careening out of control. Elsewhere, factory workers lose their senses, while a brand-new power plant suffers mysterious outages.

Genius industrialist Fabian Solak has a vision of the future – free from pollution, running on clean electricity. But Madame Vastra knows such ideas are ahead of their time...

Propaganda

We open with one Jenny Flint buying racing pigeons because Vastra keeps eating the- because the pigeons keep getting out. She also buys a swan for Vastra (which, if you know Brit lore, the Queen owns most of the swans for some reason XD, and this is therefore a big ""Fuck you"" from Vastra to the Queen), when suddenly an electric car without a driver attacks the market. At home in Paternoster Row Vastra checks if Jenny is okay and promptly suggests a 'lie down' together... 😂 The guy making the electric cars owns a factory that quite literally works its workers to death in assembly lines, or absorbs the people's brains. The Gang infiltrates said factory (Strax starts a small war after doing a gloriously funny Cockney impression), trip an alarm, and have to flee. Strax runs through a wall. They try to escape in their carriage, two electric cars chasing them. When the carriage crashes, Strax is prepared to take the cars on in hand to hand combat; he sees it as a tactical advantage for himself that the cars don't have arms. Or so he thinks: the electric cars are actually electric TRANSFORMERS. While Strax rallies the workers to seize the means of production (communist king) and Jenny is prepped to be absorbed (she kicks the lady trying to tie her up and frees herself), Vastra has a talk with Mr Solak that ends in her being electrocuted and temporarily disabled for being IBSANELY mouthy. Solak's transformers are automated enough that he doesn't require any more workers, and he plans to absorb the brains of everyone in London with his factory he's made mobile. Well, they manage to escape and get caught AGAIN (they're that skilled istg) they try to absorb Strax as well, and while Vastra talks to Solak and distracts him, Strax takes advantage of the high voltage they connected him to and uses the energy to recharge himself properly. A hilarious audio to kick off the fiest boxset, though not without its serious moments. The concept is insane tho and I love tha. (@jennyandvastraflint )

18 notes

·

View notes

Text

Vehicle Design and Manufacturing Processes

Introduction: Vehicle design and manufacturing processes have evolved dramatically over the years. From manual assembly lines to high-tech automation, the automotive industry has witnessed numerous advancements that enhance vehicle performance, safety, and sustainability. This blog explores the latest trends in vehicle design and the manufacturing processes that are transforming the industry.

Design Considerations: Designing a vehicle is a complex and multi-disciplinary process that involves engineering, aerodynamics, ergonomics, safety, and aesthetics. Engineers must consider factors like fuel efficiency, performance, and environmental impact, all while ensuring the vehicle’s safety for occupants and pedestrians.

For example, modern car designs prioritize aerodynamics to reduce fuel consumption, with sleek shapes and specialized components that minimize air resistance. Additionally, the safety of the vehicle is ensured by incorporating advanced safety systems, such as collision avoidance technologies, airbags, and crumple zones.

Manufacturing Technologies: The rise of automation has revolutionized vehicle manufacturing. Robotic arms, AI, and 3D printing are now integral to automotive production. Robotics allows for faster and more precise assembly, while AI systems help in predicting maintenance needs and optimizing production schedules.

One significant advancement is the use of 3D printing for creating prototype parts and even some vehicle components. This technology enables manufacturers to design and produce intricate parts with reduced material waste and lower costs. Additionally, automation has sped up assembly lines, allowing for mass production while maintaining consistent quality.

Sustainability: As the world becomes more eco-conscious, the automotive industry has shifted toward more sustainable practices. Electric vehicles (EVs) are at the forefront of this revolution, offering a cleaner alternative to traditional gasoline-powered cars. In addition to EVs, car manufacturers are adopting environmentally friendly materials, such as recycled plastics and plant-based composites, to reduce the carbon footprint of their vehicles.

Furthermore, energy-efficient manufacturing practices, such as using renewable energy to power factories and reducing waste, are helping the industry move toward a more sustainable future.

Future Trends: The future of vehicle design and manufacturing is exciting. One of the biggest trends is the development of autonomous vehicles, which use sensors, AI, and machine learning to navigate roads without human intervention. These vehicles promise to increase safety, reduce traffic, and improve transportation efficiency.

Modular vehicle design is also gaining traction. This approach allows manufacturers to produce customizable vehicles with interchangeable components, which can be tailored to meet different customer needs.

Conclusion: The automotive industry is undergoing a revolution, driven by innovative design principles and advanced manufacturing technologies. As sustainability becomes increasingly important and new technologies such as autonomous driving and electric vehicles take center stage, the future of vehicle design looks promising. By continuing to prioritize safety, efficiency, and environmental responsibility, the industry will continue to transform how we think about transportation.

For comprehensive information and resources on engineering topics, please visit the Engineer's Heaven website.

2 notes

·

View notes

Text

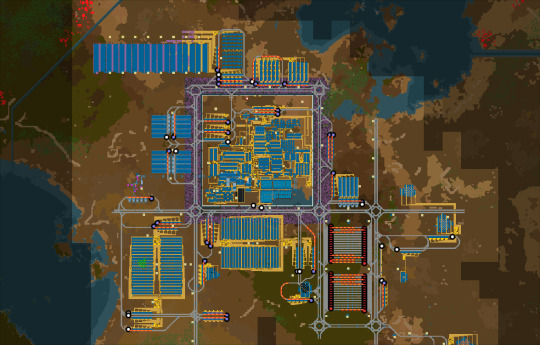

The New Factory

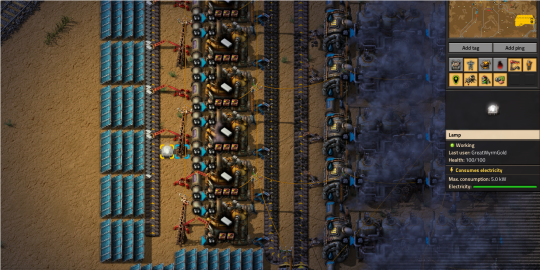

Daily Blogs 355 - Oct 25th, 12.024

It is funny how things kinda lined up.

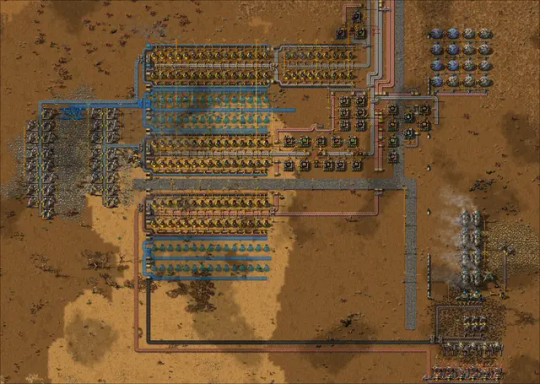

At the start of this week, Factorio: Space Age launched, aka the 2.0 update. Which is an update that I have been watching the development for some time now, reading the Friday Facts almost every week. And because I already showed my addiction love for this game on the 4° day, why not make another update on the factory after so many months?

Spaghetti

Yes, this is the state the factory was. Not that pretty.

I never actually played Factorio in survival mode, so I pretty much fucked up a lot. The main one was not preparing myself for Biters (the enemies) attacking my base on the start, which made me into a fight or flight response trying to research weapons and creating the box around the base.

This box really didn't help on trying to scale the base. Does it look cool? Yes, but as time passed, trying to make progress just ended up being more and more difficult. Space started to shirk, and finding places to put assemblies and pass belts became impossible, so going outside was necessary.

To do it, I needed to have a safe space to build. And because I, again, didn't know how to play the game properly, and had some quality-of-life mods, I used one of their features to build entire canals that separated me from Biters nests, so they wouldn't be able to attack or expand in the direction of the base.

And it worked! But consumed so many resources that I had to wait hours to gear up and complete everything.

Having to wait so much, seeing my resources running out inside the box and the difficulty to expand the base, let me think: "time to build an actual base, time to build a mega-base"; which again, in high sight, was a bad idea, since I didn't even have enough automation and even construction bots to scale to a "mega" state. But I tried, and again, started to fail. The main problem is that I didn't want to actually learn the crafting times, the resource amounts, the math needed to scale a base in Factorio, I just wanted something big, and something big fast.

The main idea was trying to use trains for everything, which kinda works, but makes everything need a lot more waiting and velocity. I wasn't able to make sections of the base produce things fast enough to other section to use and be always in motion, trains mostly waited until they're filled, and constructing everything at this scale was so fucking slow since I didn't have the resources for it, that it ended up just being a chore of waiting.

I stagnated.

Space

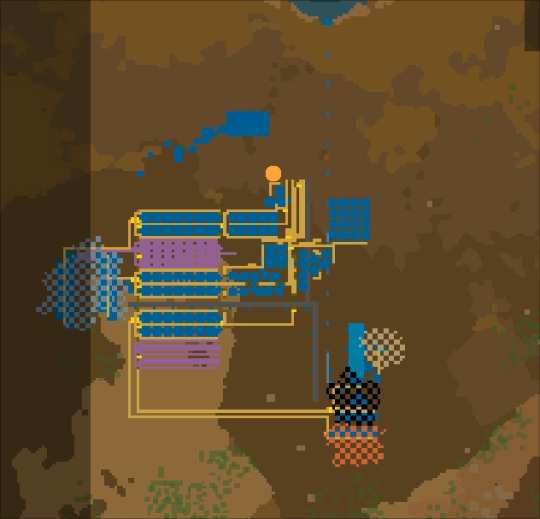

However, with the launch of Space Age, a new motivation arrived, which lined perfectly with a need to actually rest after my working days. Knowing that this update would come with a lot of new functionalities and that it would be a 2.0 release, a major version, and that old features (specially trains) would simply be incompatible with older versions, made me have a second chance to restart my survival world.

And that's what I did! I haven't played a lot, since finding time is somewhat difficult, but this week I tried harder to play at least one hour per day (somehow I didn't stay up all night, probably because my partner takes care of me better than I could myself). Progress is being slow, but I'm finally taking the time to actually learn the game, the math, and how to prevent things from exploding.

It's being fun to have fun again.

And I would end this post with some metaphor on things such as "I didn't want to learn things the proper way and take shortcuts", or "because of something unexpected, I started to panic", or "it is not good to jump into bigger things out of nowhere", or "sometimes is better to just restart"... but you're smart enough to figure those things out on your own.

Today's artists & creative things Music: Fuck the Moon Fly Me to the Moon Cover - by Coward

© 2024 Gustavo "Guz" L. de Mello. Licensed under CC BY-SA 4.0

2 notes

·

View notes

Text

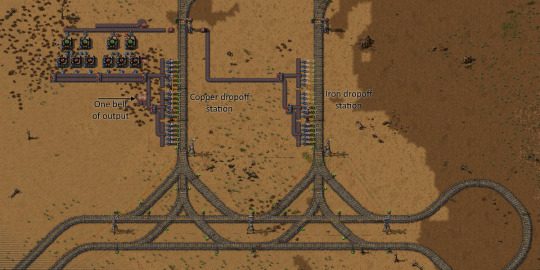

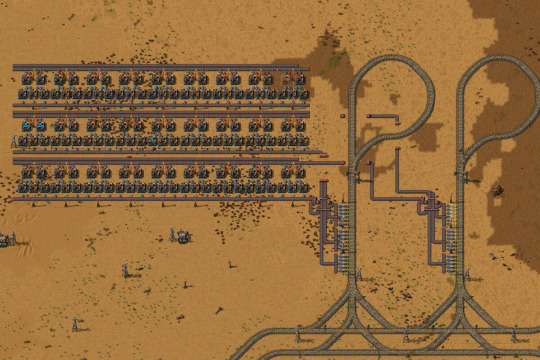

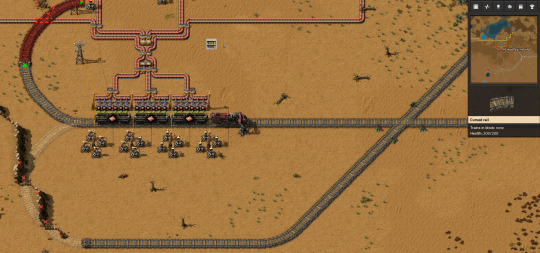

Back to Factorio. Last time, I came within one inserter of setting up nuclear power before noticing that my other solutions had finally brought the factory to a decent equilibrium. This time, I'm making green chips. After some uneventful building, I throw together this prototype.

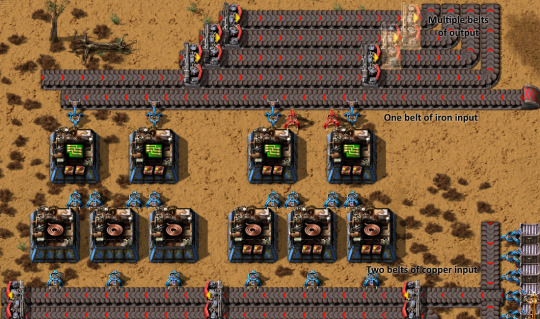

Very simple; separate train stations for the two inputs, and a belt of output that would go to its own separate station. But that single belt of output is kind of a problem. It can only carry a couple dozen assemblers' worth of green circuits, and if I want this one outpost to make a significant fraction of the circuits I'll need once I start plowing down the tech tree, I need way more. I think I'll aim for four belts of green chips.

Cool, but new problem: Input. Four belts of chips require four belts of iron and six belts of copper. Well, a little less with productivity modules, but not whole belts less. I can't build this as one big line. I have to build it as three little lines.

Well, "little" is perhaps not the right word here. Three sets of eighteen chip assemblers, compared to the five I had in my starter base. My bots are busy.

Wait a second. That's a lot of bots.

Oh, there goes my power again. But on closer inspection, this has less to do with bots charging than it does with coal vanishing, due to the coal train getting stuck at the mines.

After like an hour of messing around with train signals, redesigning intersections trying to figure out what screwed-up rail code is causing these problems...I realize a couple of rail segments in a curve are missing. Pretty much invisible to human eyes. Ugh.

...

That's where I logged off for the night, and thank goodness for this self-inflicted log forcing me to keep track of what I was doing, because a bunch of real-life stuff kept me from playing Factorio for several months. But now I'm back, and I have a log of what I was trying to do back in March. I started by making sure the coal-fired boilers were back online (getting there), and I noticed something I'm pretty sure is a visual bug.

I think the solar panels are casting shadows on the belt despite A. the presence of a light source on the other side of the belt and B. the fact that it's the middle of the night. Also the shadowed plastic looks too dark either way, especially with the normal plastic next to it.

Anyways, just two paragraphs after thanking March Me for his brilliant foresight, I have to curse him for his stupidity. Apparently he either never set up automated long-handed inserters and assembling machines, or tore it down when he started disassembling the starter base. Foolish either way.

Once I rectified that with a bit of spaghetti stapled onto the starter base, I realized I needed a lot of power poles for the new chip build, and also that I only automated the big ones. But that means I had everything for medium poles in one spot, and I just needed a little spaghetti to get everything into place.

Word of advice: Don't play with the Renai Transportation mod if you don't want to face constant spaghetti temptation. And if you do, make sure not to power thrower inserters until they're set properly.

Anyways, in the time it took to set that up and take the provided poles to power the new build, all the assemblers and inserters were pretty much produced. And in the time it took to figure out the Screenshot Toolkit, they were delivered.

All I need to do is get the trains set up.

Iron is easy enough; I've already got an iron train running from the iron mines to the starter base, so I just tweak its schedule so it switches between supplying the starter base and the circuit station.

I don't have anything like that for copper; the starter base is still running off the, um, two mining drills which still have ore. About 5,000 between them when I checked, one of which should last a bit less than an hour, the other almost two hours. Hm. Maybe I should have set up something for getting copper to the starter base.

I didn't, though. I didn't even get copper delivered to the circuits. That's because of a terrible mistake I made when setting up the copper mine's loading station.

Whichever way I curve this track, it runs into cliffs. That's what cliff explosives are for, but I never researched cliff explosives. And I tore down my starter base's labs ages ago.

Next time, I will do one of three things:

Find some fortuitous route between cliffs that gets me out of this mess

Set up temporary labs to research cliff explosives, and also temporary cliff explosives production

Move the station five meters to the right

I should probably also do something about our copper situation.

3 notes

·

View notes

Text

When Hux and Rey enter the lightspeeder factory, they immediately notice how filthy everything that's not directly involved into the landspeeder production is. Offices and restrooms look deserted, but the assembly line is running smoothly.

Emma: "So here we are! The factory is largely automated, what has tided us over the spores crisis so far. We have droids for security and the office staff works in home office, what makes having lost the kitchen personnel less important. From a business point of view anyway. But I do worry whether they are just staying home or got possessed..."

Rey: "We're working on something, we really do. But to progress, we need your father's help. If we could use this place as another base and to mass-produce the spores filters we’ve come up with, that would help immensely!"

Armitage: "Wait, those are wheels! And not for tracked vehicles, but street-legal!"

Emma: "You can see that on first glance?"

Rey: "We saw wheeled cars on Moonwood. It was quite the sight!"

Emma: "For real? They are still in use there? Dad always wanted to own a vintage car. He ownes simulations, of course, but it just isn’t the same."

Armitage: "We of the First Order are, as you may be aware of, occupying Moonwood at the moment. If it's a visum yor father wants, housing, protection, or a local guide... that can get arranged."

Emma: "The Resistance is fighting you over Moonwood Mill! It's all over the news!"

Armitage: "Well, and Rey here is quite influential in the Resistance. We can both offer the same deal - your father can't really lose here."

Emma: ...

Armitage: Oh, c'mon, what's with that frightened look all of a sudden? I knew how to talk to the junior business representative, but not a scared kid. And Rey's turning her back to us, so no help from her, either.

Emma (small, shaky voice): "You know... Until today I only hated Godmother. But seeing the First Order and the Resistance work together to battle her... And you two bending over backwards to ensure dad's cooperation... That's unheard of and now she also scares me."

2 notes

·

View notes

Text

It used to be that when BMW would refit a factory to build a new car, the only way the automaker could check if the chassis would fit through the production line was to fly a team out and physically push the body through the process, making note of any snags.

Now, process engineers can simply run a simulation, sending a 3D model of the car through a near-identical digital twin of the factory. Any mistakes are spotted before the production line is built, saving time and money.

Such is the power of the industrial metaverse. Forget sending your avatar to virtual meetings with remote colleagues or poker nights with distant friends, as Mark Zuckerberg envisioned in 2021 when he changed Facebook’s name to Meta; the metaverse idea has found its killer app in manufacturing.

While the consumer version of the metaverse has stumbled, the industrial metaverse is expected to be worth $100 billion globally by 2030, according to a World Economic Forum report. In this context, the concept of the metaverse refers to a convergence of technologies including simulations, sensors, augmented reality, and 3D standards. Varvn Aryacetas, Deloitte’s AI strategy and innovation practice leader for the UK, prefers to describe it as spatial computing. “It’s about bridging the physical world with the digital world,” he says. This can include training in virtual reality, digital product design, and virtual simulations of physical spaces such as factories.

In 2022, Nvidia—the games graphics company that now powers AI with its GPUs—unveiled Omniverse, a set of tools for building simulations, running digital twins, and powering automation. It acts as a platform for the industrial metaverse. “This is a general technology—it can be used for all kinds of things,” says Rev Lebaredian, vice president of Omniverse and simulation technology at Nvidia. “I mean, representing the real world inside a computer simulation is just very useful for a lot of things—but it’s absolutely essential for building any system that has autonomy in it.”

Home improvement chain Lowe’s uses the platform to test new layouts in digital twins before building them in its physical stores. Zaha Hadid Architects creates virtual models of its projects for remote collaboration. Amazon simulates warehouses to train virtual robots before letting real ones join the floor. And BMW has built virtual models for all its sites, including its newest factory in Debrecen, Hungary, which was planned and tested virtually before construction.

To simulate its entire manufacturing process, BMW filled its virtual factories with 3D models of its cars, equipment, and even people. It created these elements in an open-source file format originated by Pixar called Universal Scene Description (OpenUSD), with Omniverse providing the technical foundation for the virtual models and BMW creating its own software layers on top, explains Matthias Mayr, virtual factory specialist at BMW.

“If you imagine a factory that would take half an hour to walk from one side to the other side, you can imagine it’s also quite a large model,” Mayr says. Hence turning to a gaming company for the technology—they know how to render scenes you can run through. Early versions of the virtual factory even had gaming-style WASD keyboard navigation, but this was dropped in favor of a click-based interface akin to exploring Google Street View in a browser, so anyone could easily find their way.

BMW also uses Omniverse for collaboration on car design and customization visualizations for customers, but a key benefit is being able to model production lines. New cars mean a new assembly process, but refitting a factory is a daunting process. Previously, key information was held in silos—production crews understood details of the assembly process, external suppliers had specs of new parts or machinery, architects had detailed building plans—and costs would pile up for every delay or mistake. “The later you find a problem, the worse it is,” says Lebaredian.

Now, problems are worked out virtually, with a central location for standardized data to be held. There’s still a critical human element: Mapping a facility requires sending a laser scanner strapped to a person running through a factory to capture point cloud data about how everything is arranged. Design engineers also need to create a 3D model of every stage of a car as it’s assembled. This level of detail allows BMW to virtually test the assembly process, complete with simulations of robotics, machines, and even human workers, as BMW has data tracking how long it takes employees to assemble a part.

The main idea is to avoid errors—does that machine even fit there?—but the system also enables optimization, such as moving a rack of components closer to a particular station to save steps for human assemblers. “You can optimize first and gain a lot of efficiency in the first production, and in the construction phase, you have fewer mistakes,” Mayr says. “It’s less error prone.”

Omniverse being a Nvidia platform, AI is naturally next. BMW is already layering in generative AI to help with navigation of its virtual models—they’re so massive that finding a particular point in the digital factory can still require asking a human expert for directions. But the aim is to use AI to optimize production lines too. “Because you have the whole data available, not just for one plant, it will be able to make good suggestions,” says Mayr—lessons learned in one factory could more easily be applied to others.

And then there’s robotics and other autonomous systems. Here, Omniverse can offer a digital space for testing before deploying in the real world, but it can also generate synthetic training data by running simulations, just as driverless car systems are trained with virtual video footage generated by AI. “Real-world experience isn’t going to come mostly from the real world—it comes from simulation,” says Lebaredian.

Aryacetas predicts that the biggest impact from the industrial metaverse will be embodied or physical AI—in other words, robots. “Robots aren’t fully there yet, but they’re rapidly training up to understand the physical world around them—and that’s being done because of these underlying spatial computing technologies,” he says.

The future of the metaverse isn’t avatars in a virtual world; it’s digital twins teaching industrial robots how to step out into the physical one.

2 notes

·

View notes

Text

Top Insights from Exploring the Impact of Robotics on Modern Manufacturing

Manufacturing is undergoing a profound shift, one where automation and intelligent systems are rewriting traditional production models. At the heart of this transformation lies robotics. Exploring the impact of robotics on modern manufacturing reveals not just improvements in output and accuracy but also deep changes in workforce dynamics, operational agility, and global competitiveness. Robotics is no longer just a cost-cutting tool—it is a strategic lever for innovation and sustainability.

The Evolution of Robotics in Manufacturing From the assembly lines of the 20th century to today’s smart factories, robotics has evolved from mechanical repetition to sophisticated autonomy. Early robotic arms performed singular tasks, but today’s robots are agile, adaptable, and connected to cloud-based intelligence. The integration of AI, machine vision, and predictive analytics allows modern robots to learn, optimize, and respond in real time, opening the door to mass customization and operational flexibility.

Robotic Automation and Production Efficiency One of the most significant contributions of robotics is the increase in speed and throughput. Robots handle repetitive tasks with unwavering consistency, allowing human workers to focus on supervision, analysis, and innovation. By minimizing downtime and eliminating errors, robotic automation enhances cycle times and streamlines workflows. This shift is crucial in meeting global demand without compromising quality.

Quality Control and Precision Engineering Consistency is the hallmark of robotic systems. In high-precision sectors such as electronics, automotive, and aerospace, robotics ensures microscopic accuracy and repeatability that human labor alone cannot guarantee. Integrated vision systems and sensors enable real-time monitoring and defect detection. This has not only reduced waste and rework but has elevated the overall reliability of production systems.

Workforce Transformation and Human-Robot Collaboration Contrary to fears of job displacement, robotics is redefining roles rather than replacing them. The focus is shifting toward collaboration, where robots perform strenuous tasks while humans handle decision-making and maintenance. This symbiosis improves workplace safety, reduces fatigue, and opens new opportunities for upskilling. As robotic systems grow more intuitive, the future workplace will rely on human-robot teams working side by side.

Supply Chain Resilience Through Robotic Integration Disruptions over the last few years have emphasized the need for agile, responsive manufacturing systems. Robotics plays a vital role in enabling just-in-time operations and localized production. Automated warehousing, robotic sorting, and predictive logistics powered by AI allow manufacturers to manage inventory better, reduce lead times, and improve responsiveness to market shifts.

Robotics and Sustainable Manufacturing Energy-efficient robotics and resource-optimized automation are supporting the industry’s shift toward sustainability. Robotic systems reduce material waste, optimize energy usage, and ensure precision in raw material handling. Additionally, by enabling closed-loop manufacturing models and recycling processes, robotics supports circular economy principles. Manufacturers are increasingly leveraging robots not just for efficiency but also to meet ESG goals.

Challenges and Considerations in Robotics Adoption While the benefits are clear, implementation requires thoughtful planning. Upfront investment, training needs, cybersecurity concerns, and system interoperability remain common challenges. However, as costs decline and modular, scalable robotics become more accessible, even small and mid-sized manufacturers are finding paths to adoption. A strategic approach ensures that robotics enhances rather than disrupts core operations.

For More Info https://bi-journal.com/exploring-the-impact-of-robotics-on-modern-manufacturing/

Conclusion Exploring the impact of robotics on modern manufacturing shows that automation is more than a technological upgrade—it is a blueprint for resilience, competitiveness, and innovation. Robotics empowers manufacturers to scale sustainably, adapt to changing demands, and create smarter, safer work environments. The integration of robotics represents not the end of the traditional manufacturing workforce, but the beginning of a new era where machines enhance human potential and drive forward the future of industry.

#Smart Manufacturing#Industrial Automation#Robotics In Manufacturing#BI Journal#BI Journal news#Business Insights articles

0 notes

Text

The Beauty of Handmade Furniture: Why Artisan-Made Matters

In a world saturated with mass-produced goods and fast fashion, there's something profoundly grounding about handmade furniture. Each curve, joint, and carved detail tells a story—not only of the material’s natural history but also of the artisan who shaped it. While factory-made pieces may offer convenience, handmade furniture delivers what mass production never can: soul, character, and enduring craftsmanship.

Whether you’re furnishing a new home or replacing a beloved heirloom, choosing premium handmade furniture means investing in something far more valuable than mere aesthetics. It’s a decision rooted in quality, sustainability, heritage, and respect for craft.

1. The Craft of the Human Hand

The term handmade furniture isn’t just a buzzword—it’s a centuries-old tradition that honors the careful labor of skilled artisans. These craftspeople pour hours, days, and sometimes weeks into every piece they create. Unlike assembly-line production, where machines dictate uniformity, handmade items are individually constructed, giving each creation a unique personality.

From dovetail joints crafted without nails to smooth, hand-sanded surfaces and hand carving furniture motifs, the human touch is evident in every detail. You can often feel the difference: the subtle asymmetry of a hand-chiseled floral pattern or the warm smoothness of a hand-polished finish—signs that your furniture has been made with intention, not automation.

2. A Legacy of Skill and Culture

Many handmade pieces are rooted in cultural traditions passed down through generations. For instance, hand carving furniture has long been a staple of craftsmanship in regions like Rajasthan, India, where artisans use chisels and traditional tools to create intricate patterns and symbolic designs. These aren’t just decorative details—they are visual expressions of history, place, and technique.

When you bring home a carved headboard, a hand-inlaid cabinet, or a handmade wooden sideboard, you’re not just buying furniture. You’re supporting an ecosystem of artisans who carry forward time-honored methods that machines will never replicate. Each item becomes a preservation of tradition, carried into your modern home.

3. Unmatched Quality and Durability

One of the most compelling reasons to choose premium handmade furniture is its superior build quality. Artisans prioritize strong joinery, solid wood, and time-tested construction methods designed to last a lifetime—and often, much longer.

In contrast, many factory-made pieces use engineered wood, veneer, or synthetic finishes that look fine at first glance but wear down rapidly. Handmade pieces often use sustainable hardwoods like mango, teak, or acacia—known for their strength, beauty, and natural resistance to wear.

With proper care, a handcrafted table or chair can serve not just you, but future generations, aging gracefully and acquiring a patina that machine-made pieces can’t imitate.

4. Sustainability in Practice, Not Just in Principle

Sustainability is more than a trendy label—it’s a practice deeply woven into the handmade process. Unlike mass production, which prioritizes output over ethics, handmade furniture often relies on low-waste processes, responsibly sourced materials, and local craftsmanship.

Many artisans repurpose off-cuts or use reclaimed wood, giving new life to materials that would otherwise be discarded. Moreover, handcrafted furniture is typically made to order, reducing overproduction and the environmental cost of warehousing and transporting unsold goods.

Choosing handmade furniture is a conscious step toward eco-responsibility—without sacrificing style or substance.

5. True Customization and Personal Expression

One of the most exciting aspects of premium handmade furniture is the opportunity for customization. Unlike big-box stores, where you’re limited to preset dimensions and finishes, handmade pieces can often be tailored to your exact specifications.

Want a dining table that fits perfectly in your narrow apartment? Or a bedside cabinet with extra-deep drawers? Artisans can adjust proportions, materials, and detailing to fit your needs and aesthetic. You can even request unique touches—like custom hand carving furniture inspired by traditional patterns or personal symbols.

This level of personal input makes the final product more than just a functional object—it becomes an extension of your taste, story, and values.

6. Aesthetics That Stand the Test of Time

Trends come and go, but well-designed handmade furniture never falls out of fashion. The appeal lies in its authenticity. Natural materials like solid wood, stone, and shell bring warmth and texture, while handcrafted details add charm and distinction.

Take hand carving furniture as an example. Whether in the form of an intricately carved drawer front or a subtle floral motif along the edge of a coffee table, these accents add character without overwhelming the design. They’re the opposite of sterile, one-size-fits-all pieces—rich in visual depth and artisanal pride.

In a minimalist interior, a single handmade piece can serve as a stunning focal point. In an eclectic home, it becomes a bridge between function and artistry.

7. An Ethical, Human-Centered Choice

Beyond aesthetics and durability, choosing handmade furniture is an ethical choice. It supports small workshops, local communities, and independent makers who rely on craftsmanship—not factories—for their livelihood.

Each purchase affirms that traditional skills still have a place in the modern world. It ensures fair wages, promotes cultural heritage, and gives artisans the dignity of making a living through their craft.

You’re not just buying a chair or table—you’re casting a vote for a slower, more thoughtful way of living.

8. How to Spot Quality Handmade Furniture

Not all handmade claims are equal. Here are a few signs you’re investing in true craftsmanship:

Solid Wood Construction: Avoid MDF or particle board.

Visible Joinery: Look for dovetail or mortise-and-tenon joints.

Natural Variations: Slight differences in grain, texture, or finish indicate a real hand at work.

Weight & Solidity: Handmade pieces often feel heavier and more robust.

Tool Marks: Gentle irregularities are a sign of hand carving furniture, not machine precision.

If possible, ask about the materials used, the source of the wood, and the techniques applied. A reputable maker will be proud to share the story behind each piece.

Final Thoughts

In a fast-paced world that often favors speed over substance, choosing handmade furniture is a return to intentional living. It’s about valuing beauty, history, and human connection. It’s about surrounding yourself with items that have meaning—not just function.

Whether it’s a handmade wooden sideboards that anchors your dining room, or a hand carving furniture mirror frame that catches the morning light just right, artisan-made pieces elevate your space in ways that go far beyond décor.

0 notes

Text

Straightening the Curve: The Role of Coil Levelers in Production Efficiency

In the fast-evolving world of industrial manufacturing, precision is paramount—and nowhere is this more evident than in the role of coil straightening machines. These mechanical marvels quietly ensure that the raw materials powering our cars, appliances, and infrastructure meet the exacting standards required for modern production.Get more news about coil straightening machine,you can vist our website!

What Is a Coil Straightening Machine?

A coil straightening machine—also known as a coil leveler—is an industrial device engineered to flatten metal coil strips by eliminating the curves, bends, and internal stresses caused during the winding process. When metal is stored or transported in coils, it tends to acquire a “memory” of its curved shape. Before this material can be processed further—whether for stamping, cutting, or assembly—it must be perfectly straight. That’s where the coil straightening machine steps in.

How Does It Work?

At its core, the machine uses a set of precision rollers arranged in upper and lower banks. As the metal coil passes through these rollers, gradual mechanical pressure is applied to bend the strip in alternating directions. This progressive deformation neutralizes residual stresses and flattens the material. Sophisticated models use servo motors and sensors to adjust roller tension and angle in real time, enhancing accuracy and reducing material waste.

Applications Across Industries

From automotive to electronics, aerospace to home appliances, almost every modern industry that uses sheet metal relies on coil straightening. In automotive manufacturing, for instance, even the slightest deviation in the flatness of a sheet can compromise safety standards or lead to structural failure. In electronics, components demand sub-millimeter accuracy to ensure performance and durability.

Coil straighteners are commonly integrated into press feed lines, working in tandem with decoilers and feeders to provide a seamless flow of material through stamping or forming machinery. Some setups are highly automated, enabling large-scale operations to process kilometers of coiled metal without manual intervention.

Benefits Beyond Flatness

The advantages of coil straightening extend far beyond just flattening metal. By relieving internal stress, these machines improve material formability, increase tool life, and reduce scrap rates. They also enhance downstream processes such as welding, coating, and precision cutting.

In smart factories, modern coil straighteners are often connected to a digital control system, allowing for real-time monitoring, predictive maintenance, and integrated production management. This contributes to higher consistency, faster changeovers, and reduced energy consumption—key elements in sustainable manufacturing practices.

Challenges and Innovations

Despite their utility, coil straightening machines are not one-size-fits-all. Different metals—from aluminum to high-tensile steel—require tailored settings. Moreover, thicker or higher-strength coils demand more robust and precisely engineered roller systems.

Recent innovations include modular machines that adapt to various coil widths and thicknesses, as well as AI-driven control systems that auto-adjust based on material feedback. This evolution reflects a broader industry trend: merging mechanical reliability with digital intelligence.

Conclusion

Though often hidden behind the scenes, coil straightening machines play a vital role in turning raw coiled metal into the perfectly shaped foundations of modern manufacturing. As technology advances, these machines continue to evolve—quietly, consistently, and with unyielding precision.

0 notes

Text

What Makes Siemens Load Breakers the Ideal Choice for Industrial Safety

In today’s highly demanding industrial environment, electrical safety and efficiency aren’t just important—they’re non-negotiable. Whether you're running a manufacturing plant, a processing unit, or a commercial facility, the equipment you choose plays a crucial role in the stability and security of your power systems. Among all electrical protection solutions available today, load breaker Siemens products stand out for their precision engineering, long-term durability, and proven safety record. For industries located in regions like Bhavnagar, where power reliability is critical to operations, having access to premium solutions such as load breaker Siemens in Bhavnagar ensures the kind of safety and control that businesses need to thrive. To satisfy the various demands of Indian enterprises, Darshil Enterprise, a reputable brand in industrial electrical equipment, provides an extensive selection of Siemens electrical solutions.

What Is a Load Breaker and Why Siemens?

A load breaker is an essential part of an industrial electrical system, designed to isolate, switch, and protect circuits during normal operations or emergencies. Siemens, a global leader in electrical technology, offers a complete line of industrial load breakers tailored to meet modern industry standards.

Siemens power breakers and circuit breakers stand out for their superior build quality and ingenious design. These components ensure faultless interruption of electric current, enhanced arc quenching, and reliable protection against overloads and short circuits.

Durability Meets Innovation

Heavy-duty load breakers are expected to function under tough conditions—extreme heat, voltage fluctuations, heavy loads, and constant switching. Siemens doesn’t just meet these demands—it exceeds them. Every load breaker Siemens product is rigorously tested to perform reliably in the most challenging environments.

Key Siemens electrical products available through Darshil Enterprise include:

Air Circuit Breakers

Moulded Case Circuit Breakers

Load Break Switches

Fuses

Overload Relays

Contactors

Microprocessor-Based O/L Relays

Each of these components is designed to work in harmony with Siemens switchgear to create a powerful and reliable protection network.

Siemens Breaker Safety and System Compatibility

Another reason for Siemens' popularity is system compatibility. Siemens breakers integrate effortlessly into existing and new electrical installations, offering both manual and automated control options. This promises efficient energy distribution and best operational uptime.

Whether it's a Siemens breaker safety concern or system flexibility, industries trust Siemens for one main reason: it works flawlessly when it matters most.

Applications Across Industries

From power plants and oil refineries to pharmaceutical units and textile factories, Siemens electrical protection systems are widely used for:

Equipment protection

Load management

Emergency shutdowns

Fault isolation

Energy optimization

Choosing load breaker Siemens in Bhavnagar means aligning your facility with global standards while maintaining local support and availability through Darshil Enterprise.

More Than Just Breakers: Total Siemens Electrical Solutions

Siemens doesn't stop at breakers. Its product ecosystem includes:

Contactors for motor control

Overload relays to protect motors from overcurrent

Microprocessor-Based O/L Relays for advanced diagnostics

Siemens switchgear assemblies for complete load control

These solutions are designed for smart factories, green buildings, and mission-critical operations, helping companies adopt intelligent energy management systems while ensuring full-scale protection.

Why Buy from Darshil Enterprise?

Darshil Enterprise has built a strong reputation by delivering authentic Siemens electrical solutions to industries across Bhavnagar and Gujarat. Their team of experts provides end-to-end support, from choosing the right product to installation and after-sales service.

Whether you need a load break switch Siemens, a Siemens circuit breaker, or a moulded case circuit breaker, Darshil Enterprise ensures that you get genuine products, competitive prices, and expert advice.

Conclusion

Safety, efficiency, and system longevity should never be compromised when it comes to industrial operations. Choosing Siemens load breakers and electrical protection devices ensures your business is protected by some of the best engineering in the world.

From heavy-duty load breakers to smart switchgear, every Siemens product sold through Darshil Enterprise is a step toward a safer, more reliable industrial future. If you're looking to upgrade your facility's electrical safety with world-class solutions, Siemens and Darshil Enterprise are the partners you can trust.

Contact Darshil Enterprise Today! Call Now: +91 99987-13713 or Email: [email protected]. Make your operations safer, smarter, and more efficient—with Siemens and Darshil Enterprise.

#load breaker siemens in Bhavnagar#load breaker Siemens#Siemens circuit breaker#Siemens power breaker#industrial load breaker#Siemens electrical protection#heavy-duty load breaker

0 notes