#Carton Coding Machine

Explore tagged Tumblr posts

Note

hi! i’m not sure if you’re taking requests atm but if you aren’t feel free to ignore this!

anyways, i was thinking what would it be like if you were back on base and did something nice for everyone and made their fave coffee/tea while you’re all relaxing after a long mission? like how would the 141 react and what would you make for them?

that’s all but i hope you have a great day and i absolutely love your writings!! they seriously are so detailed and amazing, you do a beautiful job w each one💌

unwind — python333

— — — —

synopsis the 141 + you are back from a super long mission and u make them their fave coffee/tea!!

relationships platonic!taskforce 141 & gn!reader.

word count 3.6k

characters cap. price, soap, ghost, gaz.

warnings 2nd person pov [you/yours/yourself], usage of c/n [code name/call sign], gaz being a little shit.

note thank you so much for the req!! i am taking them right now, but apologies if i post them 2+ days after i get them, my writers block is slowly creeping back into my mind and im fighting it off the best i can! also, thank you for the compliments :3 ilysm youre too nice!! i saw ur reblog of bedbound too and i was so sjdfksdfks!! hope u have a good day too and hope you enjoy this fic, it's all fluff and way too in depth descriptions of making tea/coffee!!

As soon as the electric kettle clicks, signaling to you that the water inside of it has been boiled, you unplug it and pour the water into a mug you’d pulled from the cabinets. It still surprised you that there were any mugs left, with how many people kept stealing to put on their desk to hold pencils—by people, you mean Soap, and only Soap—but you weren’t complaining.

You set the kettle back down once the mug is filled up just an inch below the brim and grab the tea bag you’d grabbed earlier, wrapping the string around the handle of the mug a few times before putting the bag itself into the water. Almost immediately, you see small tendrils of dark brown flow out from the drowned tea bag into the originally clear water.

As that happens, you walk the small few steps over to the small fridge from the kettle and open it, grabbing the small carton of cream and closing the fridge shut. You walk back over to the mug and unscrew the cap of the carton, pouring some cream into the mug, adding a half inch of height to the liquid already in the mug before screwing the cap back on and setting the carton down.

You don’t bother to grab a spoon and mix anything yet, instead reaching over to the small terracotta container beside the coffee machine that contained sugar, and taking off the lid.

You think for a moment if you should grab a spoon for this, but ultimately decide against it, instead just tipping the container over the mug and letting what you hope is two teaspoons of sugar spill over into the mug.

Afterwards, you put the lid back on the container holding the sugar and set it back next to the coffee machine, and grab the cream to put back into the fridge.

Once the cream’s been put back, you open the drawers in the counter and grab a small spoon, one that’s just tall enough that it won’t be fully submerged in the tea, and put it into the mug.

You close the drawer and give the tea a few stirs before picking up the mug, being careful of the scalding heat and holding it solely by its handle. You carefully walk out of the snack bar extension of the kitchen and head towards Price’s office.

After a year or two of working with him, you’ve learned a lot about his tea preferences—he likes Yorkshire tea, the original one, not the gold. He only likes cream and sugar in his coffee, just to make it smoother and make it a bit sweeter, but doesn’t like it too sweet.

You vaguely remember him telling you he’d never had honey or any other sweeteners besides a bit of sugar in his tea, and remember more vividly you thinking, God, that’s such an old person thing to say, but not saying it out loud.

Once you’ve reached his office, you knock a few times and Price’s tired voice calls out, “Come in!”

You open the door, careful to keep the mug from spilling in your hands, and walk in, closing the door behind you. Price looks up from his computer, presumably writing a report on the mission you’d all just come back from an hour or two ago, and offers a small smile when he sees you. He’s about to say something before he catches sight of the mug in your hands.

“Did you…” He doesn’t finish his question, but you know what he was about to ask, and you nod in response.

“If it’s too sugary let me know,” You tell him, setting the mug down a safe distance away from his computer, “I can remake it.”

“I won’t make you remake it,” Price looks at you, almost offended, “You didn’t have to make me anything in the first place, but thank you, I really appreciate it.”

“No problem,” You hum, walking away, saying over your shoulder, “Hope you like it.”

You open the door without another word and walk out, closing it behind you, heading right back to the snack bar. Now for Soap.

Soap typically preferred coffee to tea, despite tea’s popularity in Scotland. He’d told you that he really couldn’t taste the difference between different coffee blends, but upon hearing that there was a Scottish blend, he declared he’d only drink that one, because of course he did.

He pretended he could tell if the coffee he was drinking was of that Scottish blend, but you knew he couldn’t. How did you know? You’d only ever given him Scottish roast once. Every other time since then, it’s been French roast.

He’s never really used a coffee machine for himself, going to cafes or coffee shops most of the time for coffee, keeping his usual coffee order written in his notes app because he couldn’t remember it for the life of him.

He’d sometimes modify his order if certain coffee shops didn’t do certain things that he usually got, but his order stays mostly the same every time he gets coffee. Medium (or grande, if he’s at Starbucks) latte with a double shot of espresso.

Typically, he’d get some shortbread too, but you didn’t really have any in the base, so he’d have to do without it today.

Once you enter the snack bar, you grab another mug from the cabinets above the counter and place it under the coffee machine. You open the cabinets right by the ones that contained the mugs and grab a bag of ground French roast, pulling it out and putting it on the counter.

You open it up and find that there’s conveniently already a small cup in there to scoop the coffee grounds up, and use your free hand to grab a new coffee filter from the same cabinets you got the coffee grounds from, swiftly putting it into the machine.

You use your other hand to scoop up some coffee grounds and put them into the filter, closing the top of the coffee machine afterwards and turning on the machine. You’re grateful there’s more options listed on the small digital screen that lights up on the machine than just plain black coffee, not really in the mood to try and steam milk right now.

You tap on the ‘latte’ option and watch as the screen changes and hear the coffee machine start to whir.

As it does that, you put away the coffee grounds and open up the cabinets that contained mugs once again, pulling out a small espresso glass and setting it onto the counter.

You wait patiently for the coffee to brew, and once you hear the small beep sound from the machine that signals that it’s done, you pull away the steaming hot coffee and set it down right next to the coffee machine.

You quickly put the espresso glass under the machine and start it up again, this time tapping the ‘espresso shot’ option—surprised that’s even an option, honestly—and hearing the familiar whirring noise start up again. It doesn’t take nearly as long as brewing the latte did, the small beep coming much sooner than it did just a minute or two earlier, and you pull away the small espresso glass from the machine almost immediately after you hear it.

You pause for a moment, looking at how much the latte part had filled up the mug, and look around for a moment before opening up the same drawer that contains the eating utensils and grabbing a straw, putting the straw in the still hot latte—is that a good idea? No. Did you do it anyway because you physically can’t think before you act? Absolutely—and taking a long sip of it.

You pull the straw out once the liquid in the mug is at a good inch below the brim and then pour in the espresso shot, setting the glass down after you do so.

You look around for a second for a trash bin and find one just a few steps away from you, quickly throwing out the straw you’d used and then walking back over to the empty espresso glass, picking it up and setting it down by the sink. God forbid we get a dishwasher in here or something, You think absentmindedly as you pick up the mug and carefully walk out of the snack bar with it, Would it hurt to at least get some dish soap in here or something?

You make it out of the snack bar without burning your fingers and start the much longer walk to Soap’s sleeping quarters. You’d caught him walking out of his office in that direction earlier, so you can only assume that he’d gone there.

Once you make it there, you knock on the door a few times and wait for Soap to call out to you and allow you to come in before twisting the door knob and opening the door. He’s laying on his back on his bed, thumb paused on his phone screen as he looks over at you as you enter. He notices the coffee and sits up a bit, grunting as he does.

He wasn’t really as talkative after long missions like the one you’d all been on earlier—usually it took him a day or two to be more social and back to himself, so you didn’t take much offense to him not greeting you as loudly as he usually did.

He nods at the coffee, “Is that for me?”

“Mhm,” You hum, handing him the mug, “Be careful, it’s hot.”

“Got it,” Soap carefully takes the mug into his hands, and softly blows on it before looking at you again and grinning at you, “Weel, thank ye for this. Ye really didnae hae tae.”

“Price actually said the same thing,” You muse, almost to yourself, before speaking a little louder, “No problem.”

“Oh did he?” Soap asks, raising an eyebrow, before his expression shifts and he feigns confusion, “Wait, how come he got a drink afore me?”

“Because his office was closer to the snack bar,” You explain, crossing your arms.

“… Nae, it’s definitely ‘cause ye hate me,” Soap disagrees, shaking his head in mock disappointment, “And tae think I thought we were friends.”

“It is no— you know what?” You begin to argue, before sighing and rolling your eyes, “I do hate you, and we were never friends, you ungrateful piece of shit.”

Soap laughs, quieter than he usually does but it’s still a genuine laugh. He looks down at the coffee again and back at you, before saying, “Thank ye. Again.”

“No problem,” You replied, walking back towards the door and opening it, walking out of Soap’s sleeping quarters and closing the door behind you. Now for Ghost.

Ghost typically liked tea more than coffee, but you think that’s just the British in him talking. Realistically, you could give him either or, and he’d say a polite ‘thank you’ and move on.

From years of being apart of the 141, any preferences or additives he liked to put in his tea or coffee slowly dissipated and instead he just drank either one plain. Which should make the tasks you’ve forced yourself to do today easier, but knowing you, you just couldn’t take the easy route with this.

You remember a conversation with him that happened several months ago where you had been talking about your own tea and coffee preferences. Ghost had commented that he didn’t often put any additives in his own hot drinks anymore, but back before he’d joined the military, he liked to drink keemun tea occasionally with nutmeg in it.

Keemun tea—which was fucking expensive by the way, costing around sixteen pounds for twenty tea bags in every store you could find them in—wasn’t too hard to find, so the next time you went on leave after that conversation, you’d bought a box of bags of keemun tea leaves and some ground nutmeg.

You didn’t let Ghost know about it, and kind of forgot about it just a week after you bought it, but now the memory of you buying it and storing it in the snack bar behind a few other boxes of tea bags has resurfaced and it’s the only thing you think is appropriate to give Ghost at a time like this.

You get back to the snack bar and almost robotically you pull a mug out from the cabinets above the counter and set it down on said counter, deciding to grab another one just so that you wouldn’t have to do it later, and setting that one down right next to the other. You open the cabinet beside that and move some of the boxes out of the way to find the keemun tea box in the very back, right where you last left it.

You snatch it out of the cabinet and open it, pulling out a small packet and opening it up to pull out the tea bag inside. You go ahead and put the tea bag inside of the mug and put the tea box back in the cabinet, closing the small cabinet door afterwards.

You then grab the electric kettle that’s right by the sink and pop open the lid, putting it under the faucet and turning said faucet on, waiting until the water fills a quarter of the kettle. Once it does, you turn off the faucet and put the kettle down right by the outlet on the wall.

You put the lid down and wait for it to click into place before you plug the kettle into the outlet and press the small button below the handle to turn it on, and listen as it starts to make a small whirring noise. You don’t waste too much time just standing there, waiting for the water to finish boiling, instead putting the other mug you’d pulled out from the cabinets under the coffee machine and turning it on.

You tap on the ‘decaf flat white’ option and watch the digital screen change and another whirring sound starts up, now coming from the coffee machine.

You were starting to make Gaz’s while making Ghost’s drink because Gaz often made the mistake of drinking his coffee before it was cool enough to not burn his tongue, so if you made it earlier, it’d have more time to cool, and Gaz wouldn’t have to wait as long before drinking it, therefore solving the whole ‘burning-his-tongue-because-he’s-impatient’ problem he has.

Gaz liked simple flat whites, and sure, he liked tea too, but nothing could top a good flat white for him. He’d get them anywhere and everywhere he can, and you honestly admire his dedication to getting a flat white everywhere he goes.

The coffee machine finished up quickly, a small beep sounding from the machine as it stopped its whirring and a few more drops of coffee made it into the mug before it completely stopped. You pull the mug out from under the machine and set it aside for now, just waiting for the water to finish boiling in the kettle.

Once the kettle clicks and the whirring from that machine stops, you unplug it and pour some water into the empty mug you’d picked out for Ghost, waiting until it’s filled up about a half inch below the brim of the mug before taking the kettle away from the mug and pouring the rest of the unused water into the sink.

You set the kettle down beside the coffee machine where it belongs and check the drawer below the one that held the eating utensils, looking through some of the spices and drink additives in it before finally finding the ground nutmeg you needed.

You unscrew the cap and tilt the small spice jar over the mug, letting some of the powder spill into the mug before tilting it back and screwing the cap back on. You put it back in its spot and close that drawer, now opening the drawer above it and grabbing a small spoon, closing that one after you’ve grabbed the spoon and putting the spoon into the mug to mix the spices in it around a bit.

You leave Gaz’s mug on the counter, hoping that nobody steals it while you’re away, and instead pick up the mug meant for Ghost, carefully walking out of the snack bar with it.

Ghost’s office is fairly far away, but you still manage to get there without burning your fingers or anything on the mug. You knock on the door a few times and wait for Ghost to call out permission for you to come in before you open the door and walk in.

Ghost immediately looks over at you and spots the mug in your hand, but ignores it for now, instead opting to ask, “Did you need something, [c/n]?”

“Not really,” You shrugged the best you could while holding scalding hot tea, “Just needed to give you this.”

You set the mug down on Ghost’s desk before he can say another word, and watch as he eyes the mug with curiosity and confusion.

“What’s this?” He asks, carefully picking up the mug, holding the top up to his nose to smell it. Before you can answer his question, you see his eyes widen and he questions a little louder, “Is this… keemun? With nutmeg?”

“You can tell just from the smell?” You ask, mildly impressed, watching as Ghost’s gaze turns into one more in awe of the mug.

“Yes, I can,” He mumbles, smelling the brim of the mug again, before looking over at you, “How did you know I liked keemun with nutmeg in it?”

“You told me about it, like, a few months ago. Six months ago, maybe? I dunno.”

“How do you remember a conversation from six months ago?”

“It was an important conversation, I guess?” You shrug, crossing your arms.

You watch in silence as Ghost eyes the tea and you take that as your sign to leave, walking towards the door, stopping right in front of it to twist the knob to open it before you’re interrupted by Ghost.

“Wait—” You turn your head and look at him over your shoulder, and immediately upon seeing his face, you think, oh my God is he tearing up? “Thank you, [c/n]. I really appreciate it.”

You offer a small smile and reply, “Yeah, no problem. Enjoy your tea.”

You open the door without another word and close it behind you, taking a deep breath before continuing down the hall back to the snack bar.

You’re relieved when you get there and see the mug, still steaming a bit, still on the counter. You quickly walk over to it and pick it up, walking right back out the door with it and heading straight for Gaz’s sleeping quarters. You remember him being so tired from the mission—you don’t know whether to hope he’s asleep and getting some rest, or to hope that he’s awake so you can properly hand him his coffee.

Once you make it to his sleeping quarters, you knock on the door, and there’s no response for a few moments, making you think he might actually be asleep, but then you hear Gaz’s drowsy voice call out, “You can come in!”

You open the door and see him rubbing the sleep from his eyes and sitting up on his bed, looking over at you. His lips twitch up into a small smile once he sees you and he lets his hand drop into his lap.

“Hey, [c/n].” He looks over at the mug you’ve brought with you, before raising an eyebrow, “You brought something for me?”

“Very bold of you to assume it’s for you,” You close the door behind you and walk closer to him, “But yes, it is.”

Gaz perks up a bit at that and happily takes the mug off of your hands once you hand it to him, and his smile grows significantly bigger once he sees you’ve brought him a flat white.

“It’s decaf, don’t worry,” You say, as if reading his mind, “I figured you’d still want some sleep after drinking it.”

“Always so considerate,” Gaz sighs teasingly, raising the mug to his lips like you’d thought he would. Thankfully, his tongue doesn’t burn this time after he sips the coffee, and you let out a small sigh of relief at the fact.

“You know me,” You respond dryly, crossing your arms as you watch Gaz take a few more sips of the coffee.

“Thank you for this, by the way,” Gaz thanks you, taking another sip of the coffee before stating, “I hope you know you’re my favorite now.”

“Your favorite what?”

“Just my favorite, in general,” Gaz hums, “This is the best flat white I’ve ever drunk. Ten out of ten.”

“Thanks,” You thank him flatly, “It was made with love and a coffee machine I learned how to use yesterday.”

“I can just taste the love in it.”

“Not the coffee machine?”

“Well, it’s a bit concerning if someone can taste the coffee machine in their coffee, innit?” Gaz raises an eyebrow at you before taking another sip of his coffee.

“Not if it’s the one I used.”

“Whatever you say,” Gaz mutters, taking yet another sip of his coffee, making you huff out a small laugh.

“You enjoy your coffee,” You say before walking back over to the door, closing the door behind you as you walk out and letting out a tired breath, starting to head back to your own sleeping quarters.

#cod#cod hcs#hcs#captain john price#john soap mactavish#simon ghost riley#task force 141#kyle gaz garrick#task force 141 x reader#platonic task force 141#platonic task force 141 x reader#tf141#price#soap#ghost#gaz#its 2:17 am as im tagging this#why did i wait until 12 am to write this?? nobody knows#im also listening to those like 7 hr long compliations of markiplier playing random games#because for some reason my brain is more productive listening to him#so theres that#i also discovered that 'author has only watched other people play call of duty' is a tag on ao3?#which is so real btw#everyone else who used that tag is just like me fr

909 notes

·

View notes

Text

Domino Presents New Monochrome Inkjet Printer at Labelexpo Southeast Asia 2025

Domino Printing Sciences (Domino) is pleased to announce the APAC launch of its new monochrome inkjet printer, the K300, at Labelexpo Southeast Asia. Building on the success of Domino’s K600i print bar, the K300 has been developed as a compact, flexible solution for converters looking to add variable data printing capabilities to analogue printing lines.

The K300 monochrome inkjet printer will be on display at the Nilpeter stand, booth F32, at Labelexpo Southeast Asia in Bangkok, Thailand from 8th–10th May 2025. The printer will form part of a Nilpeter FA-Line 17” hybrid label printing solution, providing consistent inline overprint of serialised 2D codes. A machine vision inspection system by Domino Company Lake Image Systems will validate each code to ensure reliable scanning by retailers and consumers whilst confirming unique code serialisation.

“The industry move to 2D codes at the point of sale has led to an increase in demand for variable data printing, with many brands looking to incorporate complex 2D codes, such as QR codes powered by GS1, into their packaging and label designs,” explains Alex Mountis, Senior Product Manager at Domino. “Packaging and label converters need a versatile, reliable, and compact digital printing solution to respond to these evolving market demands. We have developed the K300 with these variable data and 2D code printing opportunities in mind.”

The K300 monochrome inkjet printer can be incorporated into analogue printing lines to customise printed labels with variable data, such as best before dates, batch codes, serialised numbers, and 2D codes. The compact size of the 600dpi high-resolution printhead – 2.1″ / 54mm – offers enhanced flexibility with regards to positioning on the line, including the opportunity to combine two print stations across the web width to enable printing of two independent codes.

Operating at high speeds up to 250m / 820′ per minute, the K300 monochrome inkjet printer has been designed to match flexographic printing speeds. This means there is no need to slow down the line when adding variable data. Domino’s industry-leading ink delivery technology, including automatic ink recirculation and degassing, helps to ensure consistent performance and excellent reliability, while reducing downtime due to maintenance. The printer has been designed to be easy to use, with intuitive setup and operation via Domino’s smart user interface.

“The K300 will open up new opportunities for converters. They can support their brand customers with variable data 2D codes, enabling supply chain traceability, anti-counterfeiting, and consumer engagement campaigns,” adds Mountis. “The versatile printer can also print variable data onto labels, cartons, and flatpack packaging as part of an inline or near-line late-stage customisation process in a manufacturing facility, lowering inventory costs and reducing waste.”

Code verification is an integral part of any effective variable data printing process. A downstream machine vision inspection system, such as the Lake Image Systems’ model showcased alongside the K300, enables converters and brands who add 2D codes and serialisation to labels and packaging to validate each printed code.

Mark Herrtage, Asia Business Development Director, Domino, concludes: “We are committed to helping our customers stay ahead in a competitive market, and are continuously working to develop new products that will help them achieve their business objectives. Collaborating with Lake Image Systems enables us to deliver innovative, complete variable data printing and code verification solutions to meet converters’ needs. We are delighted to be able to showcase an example of this collaboration, featuring the .”

To find more information about the K300 monochrome printer please visit: https://dmnoprnt.com/38tcze3r

#inkjet printer#variable data printing#biopharma packaging#glass pharmaceutical packaging#pharmaceutical packaging and labelling#Labelexpo Southeast Asi

2 notes

·

View notes

Text

For the @gallavichthings event A.U.gust 2023 prompt "Cyberpunk", I offer "B8ted Breath."

Thank you @gallavichthings and the people behind that tag for hosting! I don't know what this is, but whatever it does turn out to be, I had fun.

Housekeeping:

Funerarium - Funeral Home

Gravecodes - Condensed data containing video/audio of the deceased that can only be viewed in my dystopian funerarium.

Rig-mech - A terraforming machine technician who works on rigs used to make inhabitable outposts, habitable.

_____________________

Ian heads into the funerarium’s Reflection Room, a glass encased dome filled with fake flowers and a dry fountain sitting in the middle of its large space. He’s made coming here a habit after a gravecode visit. A sort of cherry on the morbid cake of his self flagellation.

He takes a seat on the ring of the fountain and pulls out a small, collapsible metal cup and a mini carton of milk. As always, he feels dumb doing this, but it comforts him after a rough viewing.

He’s pouring the milk into the cup when a B8 CL-WS unit glides noiselessly into the room. Boxy and sitting atop soundless rubber wheels, it rolls around cleaning non-existent dust off the floor. He smiles, thinking not for the first time that this particular cleaning unit looks a little like a robotic military tank.

“Shit,” he curses softly as he overflows his cup and it spills on the floor. The B8 immediately makes a beeline for him. He lifts his feet as the unit’s small, microfiber pad swipes through the liquid then blows heated air to dry what's left.

He laughs knowing he must look ridiculous with his feet hanging above the floor and his dumb collapsible cup raised in an awkward toast. The unit goes on blowing warm air, unmoving. This is the longest wipe and dry he’s ever seen. He couldn’t have spilled that much.

“Uh, I think it’s dry now,” he says.

The B8 just continues blowing air and he can feel it sliding uncomfortably up his pant legs. Great. It’s malfunctioning.

“Area sanitized. Retract.”

The unit doesn’t move.

“Um, retract,” he tries again, legs starting to ache in their raised position. “C’mon, retract dopey.”

Nothing.

Ian notices the code on the unit’s exterior has been altered. An ‘A’ has been scratched over the dash between the CL and WS. Despite his irritation, he laughs. It’s probably been done before, but for some reason, seeing that silly CLAWS etched into this broken cleaning unit is what he’d needed.

“Claws my ass, you box of junk. I should give you a kick,” he chuckles.

“I wouldn’t do that. She's been retrofitted with a mini-flame thrower.”

The voice startles him so badly, he falls backward into the fountain, cup flying. He bounces his head off an ornate cherub and sees stars.

“Jesus fuck!” he shouts, flailing as he tries to get out of the fountain without kicking the stupid B8 unit that was now whizzing back and forth over the newly spilled mess.

A hand braces itself on the rim of the fountain, bearing faded knuckle tattoos that spelled “FUCK.” He stares at it dizzily, fascinated by how menacing that hand looked despite its small size.

“If you’re thinking of taking a bath in this thing, it ain’t gonna happen, Cherry.”

A man, sporting a black military cap atop longish dark locks, peers down at Ian with the bluest eyes he’s ever seen this close. The looming man’s expression was equal parts amused and irritated as he held out his other hand.

Ian takes it and lets himself be hauled to his feet to properly look at his rescuer. This man was no more than 5’7” with a small, but compact frame and not the hulking menace he thought he was. Not usually Ian’s type, but those eyes. They were something.

He stares a little too long and the man snaps his fingers in front of his face.

“How hard did you ring your bell, man?”

Caught without an excuse for gazing longingly, Ian's face warms.

“That thing almost burned the hairs off my legs,” he complains, reaching down for his cup only to have the B8 snag it with a hook and toss it into a compartment on its back. “For Christ’s sake!”

The man rubs a finger across his ridiculously kissable mouth, chuckling quietly. Despite his irritation, Ian finds himself fighting an answering smile.

“The fuck you expect a cleaning unit to do?” the man scolds. “You drop shit, it picks it up.”

Ian rubs the small lump that’s starting to swell on the back of his head, anger flaring at the less than contrite attitude.

“I didn’t drop a damn thing. It flew out of my hand when you ninja'd out of thin air.” He glares at the man, noting his uniform, an all black jumpsuit bearing the name of the facility. “You work for Obriad?”

“That’s what the jumpsuit says.”

The man leans down, presses a series of buttons on the underside of the B8 and it takes off, zooming away towards a black door partially obscured by two huge, fake palms. The unit stops at the door, waiting patiently, like a dog.

“Then you might want to take that unit out of commission until it can be repaired,” Ian suggests, drinking the milk and taking in the tattoos on the man’s other hand. He snorts. Fuck U-Up. This one's a walking, talking poet.

“There’s nothing wrong with that B8. You spilled milk and it kept cleaning until it was dry. No use crying about it,” the man says, as if he's addressing a child.

Angry and at a loss for words, Ian drains the milk, taking in the man’s half smile that could be flirtatious or condescending. It feels like both. He regroups.

“I'm not going to argue about a faulty B8. Just try not to have it burn the hair off anyone else’s legs.”

He turns to walk away and is stopped by the snottiest intonation he’s ever heard.

“Sir, yes sir. Obriad extends its sincerest apologies, Mr. ...?”

Ian allows himself a quick grin before turning to look haughtily over his shoulder. Yeah, that smile he’d been confused about earlier? Definitely flirty.

“Gallagher. And you’re …?”

“Devastated by your displeasure.”

Ian laughs and that seems to please this exasperating man who continues.

“It's Milkovich. I run operations here and rest assured, your leg hair will be safe from now on.”

Ian gets a smile that eclipses every light in the room. Hell.

“Uh, yeah. Thanks, Mr. Milkovich.”

He gives a short, weird wave, suddenly unsure of how his hands work. Neck burning, he walks quickly to the e-lifts, silently cursing his inability to ever play it cool.

“It's Mickey.”

The softly called name reaches him at the doorway of the Reflection Room. He turns and Mickey is walking backwards toward that palm framed door, hands in his pockets. Ian considers for less than a second before offering his own name.

“Ian.”

Mickey touches the bridge of his cap and salutes him in an exaggerated farewell worthy of a sultan. Ian huffs a soft laugh and heads to the e-lift. After depressing his thumb to the location pad, it opens.

He spends the quick descent and vertical shifts to his transport thinking about how Mickey seemed less like a funerarium operations director and more like a rig-mech. Gruff and teasing, his demeanor was better suited for that kind of rough outpost work. Ian should know. He'd bedded more than a few of them.

The transport calculates the best route home and it's only halfway there that he realizes he's left his cup. He tells himself that he has to remember to ask Mickey for it on his next visit. It was everyone's duty to keep waste to a minimum, right? Retrieving a perfectly usable cup was the responsible thing to do. Honor demands it.

He looks at his reflection in the impenetrable plexishield of the window and the smile he wears is unique if for no other reason than it's a first on many levels.

It's the first time he's smiled in months. The first time he's smiled in this stupid transport he'd inherited from Monica.

More importantly, it's the first time he's ever smiled after a gravecode viewing.

He stares unseeing at the dry, rundown landscape of the approaching outpost and can't decide if this development is a good thing or cause for concern.

He shrugs. It doesn't matter. It feels good and that’s so rare for him, he savors it.

Maybe finding something to smile about in a funerarium is sacrilege. Maybe it’s not.

Whatever it is, he’ll be back next month if only to see those blue eyes again.

31 notes

·

View notes

Text

Label Printer Machine: The Ultimate Guide for Efficient and Professional Product Labeling

What is a Label Printer Machine?

A label printer machine is a device that prints custom or standardized labels for products, containers, cartons, and shipping packages. It can print on paper, plastic, thermal material, or synthetic labels using technologies like thermal transfer, direct thermal, or inkjet. Label printer machines are essential in packaging, inventory management, retail, pharmaceuticals, logistics, and food processing.

Types of Label Printer Machines

1. Thermal Transfer Label Printers

These use heat to transfer ink from a ribbon onto the label. Ideal for long-lasting, waterproof, smudge-resistant labels, commonly used in pharmaceuticals, electronics, and industrial labeling.

2. Direct Thermal Label Printers

No ribbon is used; heat-sensitive label paper darkens when heated. Best for short-term applications like shipping labels, receipts, and food packaging.

3. Inkjet Label Printers

Produce high-resolution, colorful labels. Suitable for custom branding, marketing labels, and retail packaging.

4. Laser Label Printers

Offer speed and sharpness. Used when mass label printing is needed, especially for office or warehouse environments.

5. Portable Label Printers

Handheld or mobile devices used in field service, retail, logistics, and inventory control.

6. RFID Label Printers

Print and encode RFID tags and barcodes for real-time tracking and supply chain automation.

Common Applications Across Industries

1. Food and Beverage

Nutritional labels, expiry dates, batch codes

Tamper-evident and waterproof labels

2. Pharmaceuticals

Regulatory-compliant labels with dosage info, QR codes, batch numbers

High print precision and barcode clarity

3. Cosmetics

High-resolution brand and ingredient labels

Sleek, colorful, water-resistant finishes

4. Manufacturing

Asset labels, compliance tags, quality control stickers

5. Logistics and Warehousing

Shipping and barcode labels

SKU and inventory management tags

6. Retail

Price tags, promotional stickers, and shelf labels

Key Features of High-Quality Label Printer Machines

1. Print Resolution

Measured in DPI (dots per inch). For clear text and barcodes, 203 DPI is standard, while 300–600 DPI is used for high-definition images and small text.

2. Print Speed

Ranges from 2 to 14 inches per second (IPS). Higher speeds are ideal for bulk printing operations.

3. Connectivity Options

USB, Ethernet, Bluetooth, Wi-Fi—essential for integration with POS systems, warehouse management software, or industrial PLCs.

4. Media Compatibility

Should support a variety of label rolls: paper, PET, PP, BOPP, synthetic, glossy, and matte.

5. Software Integration

Compatibility with label design software like BarTender, NiceLabel, or ZebraDesigner.

6. Auto-Cutter and Peeler

Helps in high-speed workflows by automatically cutting or peeling off printed labels.

Advantages of Using a Label Printer Machine

Professional Packaging: Clean, precise labels reflect product quality

Customization: Easily print logos, barcodes, and QR codes on demand

Efficiency: Reduce dependency on pre-printed labels and minimize stockouts

Compliance: Meet legal labeling requirements effortlessly

Traceability: Boost product tracking across supply chains

Cost-Saving: In-house label printing reduces outsourcing costs

0 notes

Text

Advanced Braille Embossing Folder Gluer

We are Robus India, and we make high-speed machines that fold and glue cartons with built-in Braille embossing and automatic print checking. Our machine is perfect for pharmaceutical and FMCG companies who need fast, accurate, and international-standard packaging. It saves time, reduces errors, and increases production. We offer full support and training across India.

Fast folding & gluing Inline Braille for medicine boxes Auto inspection for printing & codes Strong build, easy to run

0 notes

Text

Top Print and Apply Labeling Systems Manufacturers in the UK: What You Need to Know

In today’s fast-paced manufacturing environment, print and apply labeling systems have become a critical component of efficient packaging and logistics operations. Whether you're in food & beverage, pharmaceuticals, e-commerce, or logistics, choosing the right manufacturer can significantly impact your productivity and compliance. Here’s a complete guide to the top print and apply labeling system manufacturers in the UK and what to consider before making a purchase.

🔹 What Are Print and Apply Labeling Systems?

Print and apply labeling systems are automated machines designed to print labels (with barcodes, batch codes, expiry dates, etc.) and apply them directly onto products, cartons, or pallets. These systems ensure fast, accurate, and reliable labeling, which is essential for inventory tracking, traceability, and supply chain efficiency.

🔹 Benefits of Print & Apply Labeling Machines

Improved Efficiency: Automates the labeling process, reducing manual labor.

Accuracy: Reduces human error and mislabeling.

Scalability: Ideal for high-volume operations.

Compliance: Meets industry regulations (e.g., GS1 standards, FDA, EU directives).

Versatility: Works with different product types, sizes, and surfaces.

🔹 Top UK Print and Apply Labeling System Manufacturers

1. Domino Printing Sciences

One of the leading global players headquartered in the UK, Domino offers high-speed, integrated labeling systems with a focus on traceability, efficiency, and sustainability.

2. Label-Aire Europe

Label-Aire is known for robust and flexible labeling systems that integrate seamlessly into existing production lines. Their UK division offers strong technical support and custom solutions.

3. Logopak UK

Logopak specializes in high-performance print and apply systems for demanding industrial applications. They are a trusted name in food, beverage, and logistics sectors.

4. Advanced Labelling Systems (ALS)

Based in Oxfordshire, ALS provides reliable labeling automation with comprehensive support, including installation, servicing, and training.

5. Herma UK

Herma is known for German engineering with UK-based service. They deliver precision labeling machines with user-friendly interfaces and high output rates.

🔹 Factors to Consider When Choosing a Manufacturer

Speed and Output: Match the labeling speed to your production line requirements.

Print Quality: Look for machines that offer high-resolution printheads.

Maintenance & Support: Choose manufacturers that offer reliable after-sales service in the UK.

Integration Capabilities: Ensure the system integrates with your ERP, WMS, or existing production line.

Labeling Accuracy: Essential for compliance and barcode scanning efficiency.

🔹 Industries That Benefit Most

Food & Beverage: Date codes, nutrition labels, and allergen compliance.

Pharmaceuticals: Serialization and tamper-evident labeling.

Retail & E-Commerce: Inventory tracking and shipping labels.

Logistics: Pallet labeling and warehouse barcoding.

🔹 Final Thoughts

Investing in a print and apply labeling system from a reputable UK manufacturer ensures long-term efficiency, compliance, and productivity. With options ranging from standard to fully customized solutions, UK-based companies are leading the way in innovation and reliability. Take the time to assess your specific needs and choose a manufacturer that offers robust service and industry expertise.

0 notes

Text

PET Strapping Rolls: Durable, Eco-Friendly Solutions for Secure Packaging

In today's fast-paced shipping and logistics industry, securing goods during transit is more crucial than ever. Among the various packaging solutions available, PET strapping rolls have emerged as a top choice for businesses seeking reliable, strong, and environmentally friendly strapping options. This article explores what PET strapping rolls are, their advantages, applications, and why they are becoming the preferred material in modern packaging.

What Are PET Strapping Rolls?

PET (Polyethylene Terephthalate) strapping rolls are plastic bands made from a high-performance polyester resin. These straps are produced in roll form, allowing easy handling and efficient use in automatic and manual strapping machines. PET strapping offers superior tensile strength and flexibility compared to traditional steel or polypropylene straps, making it ideal for securing heavy loads and fragile items alike.

Key Benefits of PET Strapping Rolls

1. Exceptional Strength and Durability

PET strapping rolls are designed to withstand high tension without breaking or deforming. Their high tensile strength allows them to secure heavy pallets and bulky shipments effectively. Unlike steel straps, PET straps do not rust, chip, or cause injury, ensuring safer handling.

2. Eco-Friendly and Recyclable

As sustainability becomes a priority, PET strapping stands out for its environmental benefits. Made from recyclable polyester, these straps reduce plastic waste and contribute to a circular economy. Many manufacturers offer PET strapping made from recycled materials, further reducing the carbon footprint.

3. Lightweight and Cost-Effective

PET strapping rolls are significantly lighter than steel straps, which helps reduce shipping costs and makes manual handling easier. Their durability ensures fewer replacements and less downtime, translating to long-term cost savings for businesses.

4. Versatility Across Industries

PET strapping is suitable for a wide range of applications, from securing boxes and cartons to bundling construction materials, steel pipes, timber, and more. Its flexibility allows it to absorb shocks during transit, protecting goods from damage.

5. Enhanced Safety Features

Unlike steel strapping, PET straps do not have sharp edges, reducing the risk of injuries to workers during packaging and unloading. Moreover, PET strapping rolls do not cause damage to delicate or sensitive products.

Applications of PET Strapping Rolls

Logistics and Shipping: Ensuring cargo stability during long-distance transportation.

Construction: Bundling heavy materials like bricks, tiles, and metal rods.

Manufacturing: Securing finished goods on pallets for warehouse storage.

Agriculture: Bundling produce or agricultural tools safely.

E-commerce: Protecting parcels and fragile shipments.

How to Choose the Right PET Strapping Roll

When selecting PET strapping rolls, consider the following factors:

Width and Thickness: Depending on the load weight and size, choose the appropriate strap dimensions.

Tensile Strength: Opt for straps that can handle the tension required for your specific application.

Core Size and Length: Ensure compatibility with your strapping equipment for efficient operation.

Color Coding: Some industries use color-coded strapping for identification or branding purposes.

Installation and Handling Tips

Use proper tensioning tools to avoid over-tightening, which can damage both the strap and the goods.

Store PET strapping rolls in a cool, dry place to maintain their integrity.

Train staff on safe handling techniques to maximize safety and efficiency.

Why PET Strapping Rolls Are the Future of Packaging

With growing demand for sustainable, reliable, and cost-effective packaging solutions, PET strapping rolls offer a smart alternative to traditional materials. Their combination of strength, flexibility, and recyclability aligns perfectly with modern supply chain needs and environmental regulations.

0 notes

Text

Revolutionizing Pharma Production: The Role of Pharma Packaging Machines by NPM Machinery Pvt. Ltd.

Introduction

In the dynamic world of pharmaceuticals, precision, hygiene, speed, and compliance are non-negotiable. As the demand for high-quality medicines continues to rise globally, the pharmaceutical industry must meet rigorous standards in both production and packaging. This is where Pharma Packaging Machines come into play—ensuring products are safely, efficiently, and accurately packed before reaching the end-user.

At NPM Machinery Pvt. Ltd., we understand the critical importance of packaging in the pharma value chain. As a leading manufacturer of pharma packaging machines, our mission is to empower pharmaceutical companies with robust, automated, and intelligent machinery that supports regulatory compliance while improving productivity and product integrity.

In this blog, we will delve into the importance of pharma packaging machines, the types available, their benefits, and why NPM Machinery Pvt. Ltd. is your ideal partner in pharmaceutical automation.

Why Pharma Packaging Machines Matter

Pharmaceutical packaging is far more than just enclosing a product in a container. It is a protective barrier, a compliance requirement, a branding tool, and an enabler of global logistics. A well-packaged pharmaceutical product ensures:

Product integrity during transport and storage

Accurate dosage and ease of administration

Protection against contamination and tampering

Compliance with FDA and other global regulatory norms

Efficient serialization and tracking

Manual packaging simply cannot keep up with the high-volume, high-precision demands of modern pharmaceutical production. That’s where automated packaging solutions step in—offering speed, consistency, and compliance.

Core Pharma Packaging Machines by NPM Machinery Pvt. Ltd.

At NPM Machinery Pvt. Ltd., we design and manufacture a full spectrum of advanced pharma packaging machines tailored to the needs of small-scale manufacturers as well as large pharmaceutical giants. Here are the most common types and their applications:

📦 1. Blister Packaging Machines

Ideal for packing tablets and capsules in pre-formed plastic blisters sealed with aluminum foil

Ensures tamper-proof packaging and extended shelf life

Used widely in retail and hospital pharmacy sectors

💊 2. Strip Packaging Machines

Designed to wrap tablets and capsules between aluminum or plastic strip foils

Compact, precise, and perfect for heat-sensitive medicines

Offers high output and minimal material wastage

🧪 3. Bottle Filling and Capping Machines

Automates filling of syrups, suspensions, and other liquids into bottles with accurate volume control

Integrates seamlessly with capping units for secure sealing

Customizable for different bottle sizes and materials

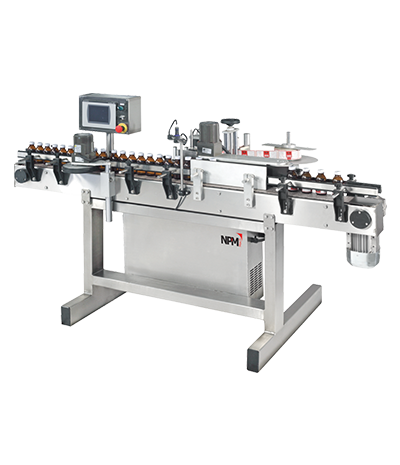

🏷️ 4. Labeling Machines

Applies labels accurately on bottles, ampoules, vials, or boxes

Supports serialization and barcoding for traceability

Compatible with multiple label shapes and sizes

🧼 5. Washing & Sterilizing Machines

Cleans vials, ampoules, and bottles before filling to ensure zero contamination

Uses air and water jets with complete automation

Essential for injectable and parenteral products

🧴 6. Cartoning Machines

Automates the packing of blister packs, bottles, or tubes into cartons

Integrates leaflet insertion and batch coding

Enhances product presentation and traceability

🎯 7. Inspection Machines

Detects broken tablets, missing capsules, misprinted labels, and other defects

Ensures every packaged product meets quality control standards

Reduces human error and improves customer trust

Benefits of Pharma Packaging Machines by NPM Machinery Pvt. Ltd.

Choosing the right packaging solution is not just about machinery—it’s about performance, reliability, and long-term value. NPM Machinery's pharma packaging machines offer:

✅ 1. High-Speed Automation

Boost production rates with minimal human intervention

Ideal for mass manufacturing and 24/7 operations

✅ 2. Unmatched Accuracy

Delivers exact filling, sealing, and labeling

Reduces product loss and ensures dosage consistency

✅ 3. Compliance & Validation

Built with GMP, FDA, and CE compliance in mind

Supports 21 CFR Part 11 for electronic data integrity

✅ 4. Flexibility & Customization

Machines tailored to your product specifications

Modular designs allow for future scalability

✅ 5. Advanced Technology Integration

Equipped with PLC-based controls, SCADA systems, and IoT capabilities

Enables remote monitoring, real-time alerts, and preventive maintenance

✅ 6. Superior Build Quality

Made with stainless steel and corrosion-resistant materials

Long machine life, low maintenance, and robust performance

✅ 7. Global Support & Service

On-site training, remote diagnostics, and spare parts availability

Dedicated support teams for installation, validation, and upgrades

Industries We Serve

While our core strength lies in pharmaceutical packaging, our machines are versatile enough for other regulated industries such as:

Nutraceuticals

Ayurveda and Herbal

Cosmetics

Food & Beverage

Veterinary Medicine

Why Choose NPM Machinery Pvt. Ltd.?

With decades of experience, NPM Machinery Pvt. Ltd. has built a reputation for engineering excellence and customer-centric innovation. Here's what sets us apart:

✔️ 150+ skilled professionals including engineers, technologists, and validation experts

✔️ ISO-certified manufacturing with a focus on precision and safety

✔️ Custom turnkey packaging lines from design to commissioning

✔️ Strong domestic and global footprint with clients across Asia, Africa, Europe, and South America

✔️ Client-first approach—we adapt our solutions to your needs, not the other way around

Our goal is not just to sell machines—but to build long-term partnerships that add value to your production process, protect your brand, and ensure regulatory peace of mind.

Conclusion

The future of pharmaceutical manufacturing lies in smart, integrated, and efficient packaging systems. With increasing global demand, strict compliance requirements, and growing competition, investing in high-performance pharma packaging machines is no longer optional—it's essential.

At NPM Machinery Pvt. Ltd., we don’t just provide machines—we deliver confidence, quality, and peace of mind. Whether you're launching a new production line or upgrading your existing setup, we are here to guide you every step of the way with reliable, cutting-edge, and compliant solutions.

✅ Call to Action

Ready to upgrade your pharma packaging line? Partner with NPM Machinery Pvt. Ltd. and experience unmatched quality, service, and innovation. 📩 Contact us today for a free consultation or demo customized to your packaging needs! 🌐 Visit us at www.npmmachinery.com | 📞 +91-XXXXXXXXXX

0 notes

Text

Types of Packing Machines & Their Applications

At TheKkanath, we offer a variety of packing machines, including VFFS, HFFS, filling, sealing, blister, cartoning, stretch wrapping, and batch coding machines. These are ideal for packaging powders, snacks, liquids, pharmaceuticals, and more. Visit thekkanath.in to explore our full range.

#technology#packing machine#machinery#sealingsolutions#sealingmachine#sealing the deal#packing manufacture#packing equipments

0 notes

Text

From Fill to Finish: Mastering Packaging with Nichrome’s Integrated Systems

In a rapidly evolving manufacturing sector where every minute of downtime is a deal-breaker and manual processes are considered a thing of the past, integrated packaging solutions are the new superstars of the modern production line. Whether it is bottling honey, pharma-grade filling in jars or cartoning pouches for FMCG, efficiency is not just an option anymore, it is a necessity.

Enter Nichrome Packaging Solutions: India’s packaging pioneer and eternal innovator. With our legacy spanning across 40 years, we at Nichrome have evolved from a single-product company into a global leader becoming the one stop destination with our advanced range of end-to-end automated packaging systems. We have a solution for everything—from primary packaging to secondary packaging, bottle to box and every seal, cap, and label in between.

If you own a brand, run a production team, or just love innovative entrepreneurship, this guide will be your ticket to cracking the code of the magic with our integrated packaging lines and advanced bottle filling line solution, along with our tin and jar filling systems, and secondary packaging innovations.

Why Integration is the Future (and Present) of Packaging?

Imagine an immaculately synchronized dance in which bottles move into place, are filled to the brim without a drop wasted, cap themselves, label like pros, and line up neatly into cartons — no humans needed. Such is the power of integrated packaging solutions, and this is precisely what we offer at Nichrome.

When we unite full packaging process—from filling and sealing to capping to labeling and boxing—our packaging systems guarantee:

Streamlined operations with no bottlenecks

Significantly minimized manual intervention

Zero compromise on consistency; faster output

Minimal waste of product and packaging

Ability to be tailored to your changing needs

We see integration as a way of intelligence. We don’t just make machines—we design modular packaging systems that anticipate, collaborate, and integrate as you expand. Our design philosophy is guided by modularity, scale, and industry specificity; enabling you to automate your packaging process in stages or all at once.

Mastering Primary Packaging with Nichrome.

The foundation of every packaging operation is found in the primary packaging unit—the first contact your product makes with its protective layer. That handshake needs to be steady, hygienic and accurate.

Our primary packaging solutions are designed to perform at its best in a wide range of applications. Be it liquids, powders, pastes, granules or viscous products, it can all be processed using our solutions. Being one of the topmost liquid filling machine manufacturer in India, we deliver each product with utmost precision.

We don’t do it off-the-shelf. Each automatic filling and sealing system is specifically customized to meet the needs and requirements of an industry, whether it be food and dairy, pharmaceuticals, cosmetics, or industrial chemicals. Our machines offer:

Modular flexibility to integrate easily into your line

Precision metering systems

Sanitation features for easy compliance with strict hygiene norms

Compatibility with a variety of packaging formats

Our filling machines go beyond being mere equipment — they serve as your foremost allies in ensuring quality.

Fill Bottles Like a Boss: The Nichrome End-to-End Bottle Filling Line.

When it comes to bottling, we believe in zero compromise. Our advanced bottle filling line solution are designed to cut down human errors and streamline the bottling of oils, sauces, juices, disinfectants, shampoos and even viscous medicinal formulations.

Here’s how our packaging systems are a game changer:

Infeed turntable for smooth bottle alignment

UV sterilization chambers to eliminate contamination

Automatic bottle filling machines with anti-drip, anti-foam, and anti-spill tech

Cap feeding elevators and rotary capping machines that ensure tight, tamper-proof seals

Induction sealing stations for added protection

High-speed labeling systems with date/batch coding

Outfeed conveyors and packing tables that seamlessly connect to secondary packaging units

Additionally, an absolute operational safety and flexibility is guaranteed through our PLC-controlled automation, tool-less changeover and “No Bottle, No Fill” safety protocols.

If you are scaling up or diversifying your product line, our bespoke solutions scale up as you do. You get customized efficiency with no resolution sacrifice.

Tough Jobs, Smarter Machines: Filling Systems for Tin and Jar.

Some products require the use of muscle while others require absolute finesse. We have developed our tin filling and jar filling systems exactly for this.

Whatever it is you’re packaging — lubricants, edible oils, paints, or pharma-grade creams and powders — our advanced systems designed to package all of it efficiently while being robust, tough and smart. Our tin filling line consists of the following:

Heavy duty robust design suitable for industrial surroundings

Servo-driven volumetric filling with incredible repeatability

Flameproof Alternatives for Volatile Products

Safety enclosure and interlock system

Compatible with different tin sizes (1L to 20L or more)

To offer an additional edge over others for high precision applications, our jar filling lines come with:

Contactless, servo-controlled dispensing

Vacuum-assisted filling for foamy or sensitive products

Integration with capping, labeling, and laminar flow stations

Cleanroom compliance for pharma and personal care industries

By combining precision engineering with user-centric design, we ensure your packaging process is not just smooth, but also efficient and streamlined.

Secondary Packaging with Purpose: Protection, Presentation, Perfection!

Once your product is safely filled and sealed, it’s time to suit it up for the shelf. This is where our secondary packaging solutions strut in.

These solutions are specifically designed to enhance the protection and presentation aspect for your product, while maximizing performance. From stacking to boxing and shrink wrapping to flow wrapping, our solutions include:

Automatic Carton Box Packing Machines with integrated vision inspection, barcode reading, and rejection systems

Horizontal Flow Wrap Machines for wrapping chocolates, biscuits, soaps, or medical devices

Pouch stacking and bundling systems to group multiple products for retail

The integration of secondary packaging into the main line allows you to:

Cut down manual labor drastically

Maintain aesthetic consistency across batches

Prevent packaging errors

Improve traceability and compliance

The result? It’s a rugged, eye-catching, retail-ready product that performs as well on the shelf as in transit.

Benefits of Nichrome’s Integrated Packaging Systems

Let’s get down to what matter the most — what’s in it for you?

Our integrated packaging systems are not merely a set of devices connected together. They are smart packaging ecosystems that provide measurable ROI and this is how you win with Nichrome:

Consistency and Accuracy: Every package, every time. No deviations, no surprises.

Speed and Throughput: Reduce cycle time, meet demand spikes, and ship faster.

Scalability: Whether you're a startup or an MNC, our modular systems scale with your business.

Labor Optimization: Free your workforce from repetitive tasks and redeploy them for higher-value roles.

Compliance and Hygiene: Meet GMP, ISO, and other regulatory requirements with built-in sanitary features.

Data and Control: Our systems come with smart control panels, analytics integration, and IoT readiness.

After-Sales Support: Nationwide presence and proactive service teams keep your lines running smoothly.

This happens seamlessly because our solutions are customized just for you and your business’s need, not templated. With our advanced range of solutions, you can expect more than just machinery. You team up with partners who know your goals, your products, and your pain points.

Tailored for Small Businesses: Scalable Solutions, Big Impact

Even after all these amazing benefits one might think that this big orchestra of a system is only for large corporations. Well, think again! We at Nichrome build systems that are modular and scalable—perfect for small to mid-sized businesses aiming to scale smartly.

Each solution is customized to your space, volume, and budget. From compact filling lines to integrated labeling and capping modules, we make it accessible and efficient.

Our supporting components that complete the ecosystem:

Air rinsing units for container sanitization

Servo auger fillers for powder dosing

Metal detectors for compliance

Capping modules and labeling stations

Shrink tunnels and sleeve applicators

Together, these components create a production floor that’s seamless, efficient, and future-ready.

Final Thoughts: With Nichrome, Automate Your Way to Success

At Nichrome, we do far more than just making and assembling a machine; we create the transformations. Our integrated packaging solutions help you maximize productivity, reduce costs, operation ensure consistent results and future proof your operations.

Whether you require a single automatic bottle filling machine or a fully integrated tin filling line, or stylish jar packaging systems or tough secondary packaging solutions, our technology is robust, smart and ready to perform.

You’re not just investing in a packaging system—you’re investing in agility, quality, and long-term growth. Whether you’re entering new markets, innovating a new product, or modernizing legacy systems, our integrated packaging solutions equip you to compete and win.

Reach out to us today-

Visit: www.nichrome.com

Email: [email protected]

Call: +91-20-6731 8888

We will bottle your success, cap your worries and box your future — click by click.

FAQs

Q1. What makes Nichrome’s integrated packaging solutions different from standalone machines? Nichrome's systems are designed to work as cohesive, modular ecosystems. They reduce manual intervention, increase speed, and improve packaging consistency across all stages.

Q2. Can Nichrome customize packaging machines for my specific product and container? Absolutely. From the filling mechanism to capping, labeling, and secondary packaging, every solution is custom-engineered to suit your product, industry standards, and operational needs.

Q3. What industries do Nichrome's solutions cater to? We serve a wide range of industries including food & beverage, pharmaceuticals, personal care, agrochemicals, lubricants, and more.

Q4. How scalable are Nichrome’s packaging systems? Very. Our systems are modular and scalable—meaning you can start with a basic setup and expand as your business grows without overhauling the entire system.

Q5. Does Nichrome offer after-sales support and training? Yes, we offer comprehensive training, detailed SOPs, and proactive service through AMC and support teams nationwide to ensure your packaging lines run smoothly.

0 notes

Text

Boosting Traceability with a Modern Batch Coding Machine

In today’s fast-paced manufacturing and packaging industries, traceability is no longer a luxury — it’s a necessity. From pharmaceuticals to food and beverage, and even cosmetics, brands are under increasing pressure to ensure that every product can be tracked from production to delivery. This is where a Batch Coding Machine plays a vital role in streamlining traceability processes and ensuring compliance with regulatory standards.

What Is a Batch Coding Machine?

A Batch Coding Machine is a specialized device used to print essential information such as batch numbers, expiry dates, manufacturing dates, barcodes, and more on product packaging. These details are crucial for product identification, traceability, and regulatory compliance. The machine prints directly onto surfaces such as plastic, glass, metal, cardboard, or flexible packaging materials.

Modern Batch Coding Machines come with advanced features like high-resolution printing, fast speed, automated operation, and the ability to integrate seamlessly into production lines. These features make them indispensable tools for any manufacturer looking to enhance quality control and supply chain management.

Why Traceability Matters More Than Ever

Consumers and regulators demand transparency. Whether it's a bottle of medicine or a carton of milk, knowing where a product came from, when it was made, and which batch it belongs to can be critical. In the case of recalls, accurate traceability allows companies to isolate the affected products quickly, minimizing health risks and financial losses.

Moreover, global standards such as the Food Safety Modernization Act (FSMA) or the EU’s Falsified Medicines Directive require companies to ensure end-to-end traceability. A Batch Coding Machine is essential in meeting these standards by printing accurate and consistent batch information on every unit.

How a Batch Coding Machine Boosts Traceability

A Batch Coding Machine enhances traceability in several significant ways:

1. Consistent and Legible Coding

Modern Batch Coding Machines ensure that every printed code is sharp, clear, and legible. This consistency helps scanners and quality control teams accurately identify products, even in high-volume production environments.

2. Real-Time Data Integration

Today’s Batch Coding Machines can be connected to centralized systems or databases. This integration allows real-time updates to be reflected in the printed codes. Whether it’s a change in the batch number or a new manufacturing date, the machine adjusts automatically, reducing human error and improving traceability.

3. Automation and Speed

In high-speed production lines, manual coding can lead to errors, misprints, or inconsistencies. A modern Batch Coding Machine automates the process, ensuring accuracy while keeping up with production demands. Faster and error-free coding significantly boosts operational efficiency and traceability.

4. Support for Multiple Packaging Types

Manufacturers often use different types of packaging. Whether it’s PET bottles, flexible pouches, cartons, or jars, a Batch Coding Machine is designed to handle a wide range of surfaces and shapes, making it versatile and adaptable for any industry.

Choosing the Right Batch Coding Machine

Selecting the right Batch Coding Machine is crucial for maximizing traceability benefits. Here are a few considerations:

Print Quality and Resolution – Ensure the machine offers high-resolution printing for barcode and QR code readability.

Ease of Integration – The machine should seamlessly fit into your current production line.

Support and Service – Choose a reliable supplier like SH HITECH SOLUTIONS, known for quality equipment and excellent after-sales service.

User-Friendly Interface – A simple control panel helps operators make quick adjustments, reducing downtime.

Real-World Applications

From a small food packaging company to a large pharmaceutical manufacturer, a Batch Coding Machine is essential across industries. For example, a dairy company may use it to print production dates and batch numbers on milk cartons to comply with food safety regulations. Meanwhile, a pharmaceutical brand can use it for secure and precise date and batch marking to meet strict medical standards.

Final Thoughts

Traceability is not just about following regulations — it's about building consumer trust, improving product quality, and protecting your brand. A modern Batch Coding Machine empowers companies to do just that by delivering fast, accurate, and durable coding on every product.

As industries evolve and the demand for transparency grows, investing in the right Batch Coding Machine becomes more critical than ever. With advanced coding technology and support from trusted partners like SH HITECH SOLUTIONS, businesses can ensure flawless traceability from start to finish.

0 notes

Text

Automatic Labeling Machine Market Drivers: Key Forces Fueling Global Industry Growth

The automatic labeling machine market is gaining momentum globally, driven by rapid industrial automation and the need for accurate, efficient, and high-speed labeling solutions. These machines, essential in industries such as food and beverage, pharmaceuticals, cosmetics, and logistics, are evolving in design and function to meet growing demands. With the global market expected to reach over USD 3.4 billion by 2030, understanding the key drivers behind this growth is crucial for businesses, investors, and industry professionals.

1. Rising Demand for Packaging Automation

One of the most influential drivers of the automatic labeling machine market is the increasing demand for automation in packaging processes. As manufacturers aim to enhance productivity and minimize human error, automated labeling systems offer an ideal solution. These machines streamline the labeling process, reduce labor costs, and improve overall operational efficiency. In industries with high-volume production, such as food and beverages or pharmaceuticals, automation has become a necessity rather than an option.

2. Expanding E-Commerce Sector

The explosive growth of e-commerce globally has significantly contributed to the demand for efficient labeling systems. Accurate product labeling ensures smooth logistics, helps in inventory management, and improves the customer experience. Automatic labeling machines facilitate the handling of large volumes of products by applying barcodes, shipping labels, and QR codes with high precision. As e-commerce continues to expand, especially in emerging markets, so does the need for reliable labeling solutions.

3. Stringent Labeling Regulations

Governments and regulatory bodies worldwide are enforcing stricter guidelines on product labeling, particularly in sensitive sectors like healthcare, pharmaceuticals, and food. These regulations aim to ensure consumer safety, product authenticity, and traceability. Automatic labeling machines help businesses comply with these requirements by producing consistent and tamper-proof labels. Their ability to integrate with traceability systems, such as serialization and anti-counterfeiting features, adds further value in regulated environments.

4. Technological Advancements and Smart Labeling

The adoption of smart technologies such as RFID (Radio Frequency Identification), IoT (Internet of Things), and AI (Artificial Intelligence) has transformed the labeling industry. Modern automatic labeling machines are now equipped with intelligent systems that offer real-time tracking, error detection, and remote operation capabilities. These advancements not only improve efficiency but also enable better decision-making and inventory control. Companies investing in smart labeling are gaining a competitive edge in terms of quality assurance and data analytics.

5. Growth in the Food and Beverage Industry

The food and beverage industry holds a significant share of the automatic labeling machine market. This sector demands fast, accurate, and hygienic labeling solutions to ensure compliance with food safety standards and consumer expectations. With the increasing consumption of packaged foods and beverages globally, manufacturers are upgrading to automatic labeling systems that support diverse packaging formats and label types. Product traceability, nutritional labeling, and expiration date accuracy are critical aspects driving this trend.

6. Pharmaceutical and Healthcare Applications

Pharmaceutical companies are among the early adopters of automatic labeling machines due to their need for precision and compliance. Labels on medicine bottles, vials, and cartons must contain critical information such as dosage, manufacturing date, batch number, and warnings. Given the strict regulations in the pharmaceutical industry, labeling errors can have serious consequences. Automatic machines ensure consistent and error-free application, making them indispensable in healthcare manufacturing units.

7. Sustainability and Eco-Friendly Labeling

Sustainability trends are shaping the automatic labeling machine market as companies aim to reduce their environmental impact. Eco-friendly label materials, recyclable packaging, and reduced waste in the labeling process are becoming standard expectations. Automatic labeling machines that support water-based adhesives, linerless labels, and energy-efficient operations are gaining popularity among environmentally conscious manufacturers. This shift is particularly strong in Europe and North America, where green initiatives are heavily promoted.

8. Regional Market Expansion

The Asia-Pacific region is currently leading the automatic labeling machine market, accounting for over 38% of the global share. Rapid industrialization, growing consumer markets, and government support for automation in countries like China, India, and Thailand are fueling this growth. Meanwhile, North America and Europe are experiencing steady demand due to their mature industrial infrastructure and focus on technological upgrades. Latin America and the Middle East are emerging markets with increasing investments in automation technologies.

Conclusion

The automatic labeling machine market is on a robust growth path, driven by a combination of industry needs, technological innovations, and regulatory frameworks. As businesses prioritize efficiency, accuracy, and compliance, the demand for automated labeling solutions will continue to rise. Understanding these key drivers allows companies to strategically invest in labeling technologies that not only enhance productivity but also support long-term growth and sustainability goals.

#Automatic Labeling Machine Market#Packaging Automation#Labeling Technology#Smart Labeling Solutions#Industrial Automation

0 notes

Text

Enhancing Packaging Quality with Vision Inspection Systems: Best Practices

Introduction

In the manufacturing industry, packaging plays a crucial role in ensuring product integrity, consumer safety, and brand reputation. Any defects in packaging, such as misprints, improper sealing, or contamination, can lead to product recalls, regulatory penalties, and loss of customer trust. To combat these challenges, manufacturers are increasingly adopting vision inspection systems to enhance packaging quality. These advanced systems use high-speed cameras, artificial intelligence (AI), and machine learning to detect defects in real-time, ensuring consistent quality and compliance with industry standards.

The Role of Vision Inspection Systems in Packaging Quality

Vision inspection systems help manufacturers detect defects, ensure proper labeling, verify seal integrity, and improve packaging consistency. Using these automated solutions leads to higher efficiency, reduced costs, and improved product safety. Below are the key areas where vision inspection systems contribute to packaging quality:

1. Defect Detection and Rejection

Vision inspection systems identify a wide range of packaging defects, including:

Misaligned or missing labels

Damaged or deformed packaging

Incorrect barcodes or QR codes

Seal contamination or leaks

Incomplete product filling

By automatically rejecting defective items, these systems prevent subpar products from reaching consumers, reducing the risk of recalls and brand damage.

2. Label Verification and Compliance

Regulatory agencies such as the FDA, EU regulations, and ISO standards require accurate labeling of consumer products. Vision inspection systems verify labels for:

Correct ingredient lists and allergen warnings

Legible batch numbers and expiration dates

Accurate barcode and pricing information

By automating label verification, manufacturers can ensure compliance and prevent costly mislabeling errors.

3. Seal and Closure Inspection

Proper sealing is essential for maintaining product freshness and preventing contamination. Vision inspection systems check for:

Seal integrity in bottles, pouches, and cartons

Tamper-proof features

Improperly applied caps or lids

Detecting seal defects early reduces spoilage and enhances consumer safety.

4. Color and Print Quality Inspection