#Compact Engines

Explore tagged Tumblr posts

Text

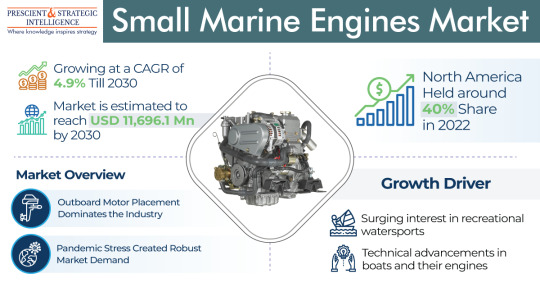

Powering the Waves: Small Marine Engines Market Insights

The small marine engines market value will reach USD 11,696.1 million by 2030 from USD 7,967.5 million in 2022, at a 4.9% CAGR. This growth can be credited to the growing demand for numerous kinds of boats utilized for recreational and relaxation events, and the growing coastal tourism for water activities including yachting, boating, and fishing.

Furthermore, the leaning toward the water-based leisure industry has been on the surge because of the increased expenditure on water-associated activities by a chunk of the populace. Also, the sense of better-quality mental health because of the quality time spent during water-based activities is a main factor for the booming boating demand, which, ultimately, quickens the outward and inward-placed engines of marine vessels.

The mounted customer involvement in marine fun activities is offering worthwhile development opportunities for engine demand. In the past years, marine tourism and relaxation activities like yachting, power boating, and sailing, have experienced a significant surge, because of the growing disposable income of consumers. Moreover, rapid development in adventure tourism is helping water recreational activities.

As per a government-issued research article, above 50 million Americans went fishing, including artisanal fishing, commercial, and artisanal fishing, in 2021, which generated a profitable demand for outdoor or inner-placed motors in marine recreational vehicles. the recreational boats category, on the basis of the application segment, generated approximately USD 3.5 billion in revenue in 2022. And, a surge in demand for technically progressive fishing boats is projected to drive the development of the industry for engines and propulsion systems across the forecast period.

In 2022, the outboard motor category dominated the industry, and the category is also projected to advance at a CAGR of 5% in the coming years. This is mainly because of the technical advances, the requirement for outboard boats is projected to increase significantly in the coming few years.

#Small Marine Engines#Maritime Industry#Outboard Motors#Inboard Motors#Fuel Efficiency#Market Trends#Boating Enthusiasts#Lightweight Design#Global Market#Innovation#Recreational Boating#Commercial Vessels#Emerging Technologies#Environmental Impact#Regulatory Compliance#Power Output#Market Dynamics#Compact Engines#Coastal Tourism#Fishing Boats

0 notes

Text

Mitsubishi Galant Coupé FTO 1600 GSR, 1974. The Fresco Turismo Omologato was based on a shortened first generation Galant platform. The GSR model had a wider track (hence wheel arch extensions), a twin carburettor Saturn 4G32 1.6 litre SOHC engine and a limited slip differential. It was replaced by the Lancer Celeste in 1975

#Mitsubishi#Mitsubishi Galant Coupé FTO#Mitsubishi Galant Coupé FTO 1600 GSR#Mitsubishi FTO#1974#1970s#compact coupé#pillarless hardtop#pillarless coupé#Saturn engine#FTO#wide track

303 notes

·

View notes

Text

I've been practicing drawing Teddy Roosebelt and Koala Compact! They'll make an appearance in the story I'm working on :)

I remember when Teddy was added to the game, and I was like, "aww nice." Then a year later when they added the koala I was like "HELL yeah, now we're going somewhere"

Listen...the fact that they both have stuffed bear versions of themselves is something that positively tickles me to this very day. Truly the duo of all time

#I LOVE THEM SO MUCH OKAY#my art#Through Thick and Thin#Engie and Sniper#TF2#doodle#TF2 Engineer#TF2 Sniper#Teddy Roosebelt#Koala Compact#yes you'll be seeing more of them from me

22 notes

·

View notes

Text

Unstoppable force: twinkifying Electra

Immovable object: one of the most visible and documented Anglophone Electras being as far from that as possible

(it’s for the better because it’s actually more true to electric engines, multi units are the “long, light, and fast” ones)

#stex#starlight express#they can coexist but short and thick is more accurate to electric engines because they’re compact and absurdly powerful#and genuinely rare to see in androgynous characters in general#i also just feel like i know more short thick bi/gay heavy machinery enthusiasts in general. I don’t know why they’re so short

17 notes

·

View notes

Text

The demo for Striatum is now available!

4 notes

·

View notes

Text

Compact car outfitted for firefighters to access the most historical areas of Granada, Spain - Servicio Contra Incendios y Proteccion Civil

#larry shapiro#larryshapiroblog.com#shapirophotography.net#larryshapiro#larryshapiro.tumblr.com#fire truck#firetruck#fire engine#bomberos#granada#Spain#compact car#mini fire engine#Servicio Contra Incendios y Proteccion Civil#Exmo. Ayuntamiento de Granada

4 notes

·

View notes

Text

TAEVision 3D Design Applications Automotive WINTER SCENE JEEP Renegade Latitude Compact SUV OffRoad 2015 ▸ TAEVision Engineering on Pinterest ▸ TAEVision Engineering on Google Photos

Data 453 - Jul 06, 2023

#TAEVision#engineering#3d#mechanicaldesign#automotive#WINTER SCENE#JEEP#Renegade Latitude#Renegade#Latitude#JEEP Renegade Latitude Compact#SUV#offroad

2 notes

·

View notes

Text

Chery Tiggo 4 Pro: The Compact SUV That’ll Blow Your Mind

Looking for a compact SUV that doesn’t compromise on style, tech, or performance? The Chery Tiggo 4 Pro is here to impress. Designed for urban adventurers and families alike, this sleek vehicle combines modern aesthetics with practical features, making it a standout in the crowded compact SUV market. Let’s dive into what makes the Tiggo 4 Pro a game-changer. Bold Design That Turns Heads The…

#advanced car technology#affordable SUV#bold car design#Chery SUV#Chery Tiggo 4 Pro#Compact SUV#family SUV#fuel-efficient SUV#modern SUV design#reliable SUV#stylish SUV#SUV safety features#touchscreen infotainment#turbocharged engine#urban driving

0 notes

Text

Powering the Production Line: Messung’s NX-ERA PLCs in Automotive Material Handling

In automotive manufacturing, precision isn’t a luxury, it’s a necessity. From chassis and engine assembly lines to the press shop and paint line, seamless material handling is critical to keeping production on track. Whether it’s coordinating conveyors, pick-and-place systems, or synchronizing with robotic cells, the need for intelligent control is constant.

Messung’s NX-ERA PLCs deliver this control with unmatched flexibility. With native support for Modbus TCP/IP, Ethernet/IP, EtherCAT, OPC-UA, and IO-Link, they enable high-speed communication across robots, HMIs, VFDs, servo amplifiers, and central SCADA systems. Plus, with remote I/O modules and protocols like CANopen, our PLCs handle large-scale, distributed inputs and outputs effortlessly. Simply put, NX-ERA makes advanced, synchronized automation easy, even in the most demanding environments.

What is Material Handling in the Automotive Industry?

Material handling in the automotive industry involves the movement, positioning, storage, safety, and tracking of components and assemblies throughout the production process—from the arrival of raw materials to the final stages of vehicle assembly. Efficiency here is critical; any delay or misstep can disrupt the entire manufacturing flow.

Key areas such as the chassis and engine assembly lines, along with the press shop and paint line, rely heavily on sophisticated material handling systems, including conveyors, pick-and-place machines, and robotics, to keep production moving seamlessly. These systems must operate in perfect sync, often across large, distributed areas with thousands of I/O points.

The Brain Behind the Brawn: NX-ERA PLCs

Our state-of-the-art NX-ERA PLCs including the NX-ERA Xpress and NX-ERA Jet, are compact PLCs designed for high-speed, reliable control. These programmable logic control systems are the heart of any automated material handling system. By offering real-time control, seamless connectivity, and robust communication protocols like Modbus TCP/IP, Ethernet/IP, EtherCAT, OPC-UA, and IO-Link. They interface effortlessly with robots, HMIs, VFDs, servo amplifiers, and centralized SCADA systems, ensuring reliability and scalability.

Here are some of its most impactful features:

High-Speed Processing Power

The core point of NX-ERA PLCs is that they are capable of real-time processing. These robot systems run as fast as your machinery, and the synchronization is important for the overall efficiency of the system. This compact PLC will guarantee flawless optimization for every aspect of the bottling line, be it controlling the work of conveyors or robotic manipulation.

Modular Design for Flexibility

The greatest feature of the NX-ERA PLC is its modular design. Production plants in the automotive industry often aim for some form of adaptability, and, thus, this feature is very helpful. It allows the installation to expand while the business is developing. The implementation of modularity means that the system can be integrated with any new equipment, production units, or additional features to ensure that there will be no disruption to the system performance.

Integrated I/O Modules for Streamlined Setup

Our smart and compact PLC integration contains integrated I/O modules that reduce installation and wiring times, thus also focusing on the fast-paced phenomenon in the automotive industry. For simplification of the things, input/output capabilities are now directly included in the integrated PLC system, which substantially reduces the external wiring as a result of which the setting up is speedier and less prone to mistakes.

Advanced Web Server Capabilities

It is safe to say that we are far off the days when engineers would have to be on site for them to physically track and diagnose issues on the factory floor. The capability of the built-in web pages of our NX-ERA PLC allows easy remote access for getting the actual real-time state of the diagnostics and monitoring. This feature is incredibly important in an industry that operates around the clock, as it allows maintenance teams to resolve issues remotely, reducing downtime and keeping things running smoothly.

The Role of the NX-ERA PLCs in Material Handling

In the automotive industry, material handling is integral to the success of the production process. From raw materials to semi-finished goods, and finally to finished products, materials need to be handled with precision. Automation is key to achieving this, and Messung’s NX-ERA PLCs are designed to make this process as efficient and effective as possible.

Here is how it is done:

Conveyor Systems Optimization

Conveyor systems, which carry parts between the workstations and at the same time keep the production continuously running, are the most popular form of material handling in the automotive plants. NX-ERA PLCs make sure that the system, no matter what, functions without any breaks by adjusting the speed of the conveyors to fit the pace of production. The real-time processing feature ensures that the system in question becomes flexible almost immediately, providing the assembly line without any interruptions and preventing the end line packing in the last round.

Predictive Maintenance to Maximize Uptime

The predictive maintenance of the system is seen as the golden nugget to maximize uptime. For the maintenance of a plant, having machines down during their run time is quite expensive. In the automotive industry, where the production rates run on a very tight schedule, even a moment's disruption would mean substantial losses. Our PLC Systems use a predictive maintenance system to keep a continuous check on the condition of the equipment. The control system will be equipped with predictive maintenance, which can track the system performance, increasing the change in predicting when maintenance is needed before failure occurs. These stains would reduce chances of equipment going down and also increase whole equipment machines productivity performance.

Power Management for Material Handling Equipment

How NX-ERA PLCs Integrate with SCADA Systems

Industrial automation relies not just on PLCs but also on supervisory control and data acquisition (SCADA) systems to monitor and control large-scale operations. The integration of NX-ERA PLCs with SCADA applications enhances material handling capabilities by providing plant operators with real-time insights into the performance of material handling equipment.

Real-Time Visualization and Data Monitoring

Data gathered from the cluster of service line sensors are then monitored by SCADA systems through real-time visualization and data troubling. By means of the material handling systems' connecting to the SCADA applications, operators are able to visualize every operation stage on a single interface. Our NX-ERA PLC assists the SCADA system in a way that allows real-time data visualization. As for plant automation, this integration enables the operators to redesign the production line and fabricate the survey that they are in full command, including the conveyor speed, robotic movement, and electrical power consumption.

Alarming and Fault Diagnostics

Unexpected malfunctions are a part of any complex system, but SCADA and PLC integration ensures they are dealt with swiftly. The NX-ERA PLC can send alerts to SCADA systems when material handling equipment encounters an issue, whether it’s a malfunction in a conveyor belt, a sensor failure in a robotic arm, or an electrical fault. This proactive approach helps resolve issues before they lead to extended downtime.

Historical data analysis for continuous improvement

Other benefits of integrating the SCADA system with the NX-ERA PLC is to have an ability to analyse historical data. These past data performances can better help the plant managers to see trends, adjust production schedules, and improve the efficiency of the material-handling systems over the long period. In actuality, the PLC saves and disposes of necessary data. This information, then, is fed into the SCADA system and used for analysis and presentation purposes.

The Future of Material Handling with NX-ERA PLCs

As the automotive industry embraces Industry 4.0, NX-ERA PLCs are positioned at the forefront of the shift towards smarter, more connected manufacturing systems. This is brought about by switching to smarter, more connected production systems. Thanks to NX-ERA PLCs, which are able to integrate with SCADA applications, robots, and power supplies, you can now easily build a factory that can quickly adapt to changes in the current demand and the production process.

Benefits Include:

More automation and efficiency with the increasing factories

As factories become more automated, the role of PLCs like the NX-ERA will only grow. The future of material handling will rely on even more precise and automated systems, from fully autonomous robots to smart conveyors that adjust their speed and behavior based on real-time conditions. The NX-ERA PLC is ready to support this evolution with its high-speed processing and robust integration capabilities.

Energy Management and Sustainability

Green manufacturing is a critical concern for the industry today. Automotive manufacturers demand advanced NX-ERA PLCs in a bid to bring down the environmental impact of the production. An essential element that plays a pivotal role in power solutions, predictive maintenance, and derived data for operational efficiency is a way for these to reduce the consumption of energy.

Real-Time Data and IoT Connectivity

With the rise of the Internet of Things (IoT) in manufacturing, NX-ERA PLCs will continue to integrate with a broader network of connected devices. This real-time data flow will empower automotive plants to make more informed decisions and improve their material handling systems.

Conclusion: The Future of Material Handling in the Automotive Industry

In the race for efficiency and innovation, Messung’s NX-ERA PLCs are the pit crew that keeps material handling equipment running at peak performance. Their combination of advanced features, modular design, and seamless integration with SCADA systems positions them as the ideal solution for automotive manufacturers aiming to stay ahead of the competition.

As automotive plants move towards smarter, more automated manufacturing processes, the need for reliable, high-performing PLCs like the NX-ERA will only continue to grow. By embracing the capabilities of Messung’s NX-ERA PLCs, automotive manufacturers can ensure that their material handling systems operate efficiently, sustainably, and with minimal downtime, ultimately contributing to the ongoing success of the industry.

In this fast-paced industry where precision is the name of the game, Messung’s NX-ERA PLCs are the game changers that automotive manufacturers need to optimize their material handling systems and maintain a competitive edge in the global market.

#chassis and engine assembly lines#Modbus TCP/IP#Ethernet/IP#EtherCAT#OPC-UA#remote I/O modules#CANopen#compact PLCs#programmable logic control systems#SCADA systems#automotive industry#PLC system#material handling#PLC Systems#material handling systems#SCADA applications#PLC integration#Automotive manufacturers#Internet of Things (IoT)

0 notes

Text

Mazda MX-30: Hibridul Inovator cu Motor Wankel – Tehnologie Avansată și Performanță Remarcabilă

Mazda a lansat MX-30, un SUV hibrid de serie cu o configurație tehnologică inovativă, evidențiată prin integrarea unui motor Wankel cu un singur disc. Acest vehicul cu tracțiune electrică reprezintă o combinație între eficiență și performanță, utilizând un motor electric și un motor Wankel pentru a oferi o autonomie extinsă. Istoria Motorului Wankel și Inovațiile Mazda Motorul Wankel, cunoscut…

#automobile japoneze#automotive innovation#automotive technology#autonomie#bam#baterie litiu-ion#caroserie compactă#compact body#diagnoza#economie combustibil#eficiență motor#electric car#emisie scăzută#engine efficiency#fuel efficiency#hibrid#hybrid#inovație-auto#japanese cars#lithium-ion battery#low emissions#masina electrica#Mazda#Mazda Cosmo Sport#Mazda electrificare#Mazda electrification#Mazda hibrid#Mazda hybrid#Mazda SUV#motor cu piston rotativ

0 notes

Link

Škoda Auto India has unveiled its latest addition to the Indian car market: the all-new Škoda Kylaq, a compact sub-4-metre SUV designed and manufactured in India. The Kylaq is set

#Skoda Kylaq#sub-4-metre SUV India#Skoda India#1.0 TSI engine#SUV safety features#compact SUV#Skoda Modern Solid design#Skoda cars India#Skoda Kylaq price#electric seats#Android Auto#Apple CarPlay#Skoda infotainment#sustainable manufacturing#Skoda SUV 2025#Skoda safety features#compact SUV India#Skoda Kylaq boot space#Skoda digital cockpit#Skoda India launch#SUV with best safety features#electric seats India#Skoda infotainment system#sub-4-metre segment India#Sustainable car manufacturing#Skoda India manufacturing

0 notes

Text

Humans entering space and realizing we are so small. We are mice compared to these giant races with their advanced machinery and technologies and experiences beyond us- except that we're humans. And our engineers dive into the new tech and once we learn the principles we also soon realize how Inefficient everything is. Their "microchips" are the size of cars, their storage drives are basically buildings, and they somehow store less data than ours. So, human companies take advantage, and tech starts rolling out. Massive and there's a lot of wasted space so that it can be managed with larger hands/pincers/claws/tentacles, but also so much more efficient than anything the galaxy has seen before.

Human technicians start hopping ships and upkeeping the general maintenance, the stuff that most aliens put off or don't notice because they never access the crevices of their ships. As human companies become more popular and lead the tech world in everything from warp cores to game stations ("it's so compact! How are the graphics so good?" Says a 60' tall grimbleback, holding a new VR headset that has all of its components included because it's so BIG by our tech standards), soon many things have accessibility ports for humans to be able to use as well. This means that these shiprats hoping ship to ship cause such a huge improvement in everything running smoothly, and there's a huge downtick in pests on ships because those "pests" are not only big enough and aggressive enough to bite a pitbull or a person in half, they're invasive to so many planets and humans hate nothing more than dog killing planet overrunning monsters.

All the while, from the Aliens perspective, humans are an elusive race that don't fraternize much with them. You almost never see a human as most places aren't exactly safe for the little things to run around in. They do export so much stuff though, and the custodial staff at the Central Galactic Outpost insists that there's more humans around than any other race if you just know where to look.

And sure it's somewhat known that some of the little daredevils hop ships and help out in exchange for room and board, usually without permission, but that can't be that common, can it?

Maybe your ship is running better this cycle ever since you stopped at the last station, that just means that tuneup was better than you thought. And maybe for some reason that program you were working on last night is finished when you wake up, but you're so tired maybe you finished it before you passed out. Somehow that faulty light in the galley has fixed itself as well, which is odd, but maybe the Engineer finally got to it. You'd know if there was someone else on your ship.

Right?

... You leave a little bowl of berries out as a thank you, just in case. You're not sure what humans like but you've heard they have a sweet tooth.

15K notes

·

View notes

Text

Talbot Avenger, 1979. The Talbot marque was briefly and unsuccessfully relaunched after PSA (Peugeot) took over Chrysler Europe's operations. Chrysler had taken over Simca (in France) and the Rootes Group (in the UK) amalgamating all of their brands under Chrysler's name. The Avenger was launched in 1970 as a Hillman but rather than revert to the brands Chrysler had replaced Peugeot resurrected the Talbot brand which had not been used since the 1950s. The Avenger was discontinued in 1981 though Talbot badges continued to be used on cars until 1987, the final Talbot product was the Express panel van that was discontinued in 1994.

#Talbot#Talbot Avenger#Hillman Avenger#1979#dead brands#PSA#Rootes Group#compact car#rear wheel drive#1970s#badge engineering

71 notes

·

View notes

Text

The Best Convertible Cars for Summer Driving

There’s something undeniably exhilarating about hitting the open road during summer, with the wind in your hair and the sun warming your skin. For many, driving a convertible offers the perfect blend of freedom and fun, making it the ultimate summer companion. When it comes to the best convertible cars for summer driving, it’s essential to consider factors like performance, comfort, and, of…

#advanced tech#Audi A5#BMW Z4#Car Lovers#cars#city driving#Classic Cars#Comfort#comfort seats#Compact Design#convertible top#convertibles#driving experience#Fast Cars#Ford Mustang#fuel efficiency#fun drive#Handling#highway#Iconic#leather interiors#long drives#luxury#Mazda MX-5#mid-engine#Mini Convertible#modern convertibles#Nostalgia#open road#open-air

0 notes

Text

So my girlfriend and I have always wanted to do game development. We had both done our own solo projects and got experience separately over our lives, but about a year ago we finally started working together, doing a couple smaller game jam projects.

The last one we did looked like this:

It's called Look: A Game! and is up on our itch.

We challenged ourselves in so many ways to finish that game. It was our first 3d project, and that in itself was intimidating. In the end, we had a short concept piece in which you explored your apartment, collecting items to get ready for a party. And that was about what it was.

But we had more ambitious plans, so when we completed the game jam, we didn't feel done. It wasn't everything we knew it was supposed to be.

So we continued where we left off, and started development on Striatum:

We spent over half a year pushing ourselves to learn and grow our skills, and keep coming back to this project everyday (as two ladies with adhd, that is especially challenging). We are getting close to it being fully complete, and there will be a demo up in time for Summer Next Fest on steam.

We now have a fully explorable apartment full of hundreds of items to find, collect, and interact with. There are multiple npcs each with their own branching dialogue paths, accessed through the medium of an in-game cell phone interface. The cell phone outputs notifications to the game screen and has additional apps inside.

We've challenged ourselves to make as polished an experience as we can, and I don't think either of us imagined we would have come so far at the start of the project. We've made something we think is good, and is special to us, and no matter what, is very us.

If you have at least 15 minutes, and a love for strange point and click adventures, please consider checking out the demo when it's out, and if you enjoy it, we hope you will wishlist and return for the full experience.

Check out Striatum here

~ Mia Malaise

#striatum#compact qualia#adventure games#indie games#point and click#game development#indie dev#godot engine#what are you looking for?

4 notes

·

View notes

Text

Car Spot: 1975 Honda Civic CVCC

A car that was perfect for the times. A 75 Honda Civic CVCC is this week's spot.

Honda was way ahead of the game when it came to US emissions Still going through EAA AirVenture withdrawal. I was up at this year’s annual airplane gathering, the 71st edition of the event is July 22-28 at Wittman Regional Airport in Oshkosh, Wisconsin. One of the big sponsors, and a supporter of WomenVenture (which our daughter Meg has been a part of to the last four years) is Honda. Ah, and…

#1975 Honda Civic CVCC#70s era compact cars#airventure#Car Spots#car spotting#CVCC Engine#eaa#EPA#Honda Civic

0 notes