#Efficiency of PLC Systems

Explore tagged Tumblr posts

Text

youtube

Infineon: Introduction to solid-state isolators and relays

https://www.futureelectronics.com/resources/featured-products/infineon-advanced-solid-state-isolators . Are you familiar with Infineon solid-state isolators and relays? Do you know what a relay is, how they are used and why we need them? Come along and we will explain everything . https://youtu.be/IqlcJPc2bS0

#ai#future electronics#WT#Future Electronics#SSR Chipset#Digital Output Modules#Infineon SSR Chipset Solution#Efficiency of PLC Systems#Infineon PLC Systems#Tech Solutions#Power Management#Youtube

0 notes

Text

Hydroponic Farming for a Sustainable Future: How Zuqualla Horti PLC is Leading with Hydroponic Farming

Discover how Zuqualla Horti PLC is revolutionizing Ethiopian agriculture with a state-of-the-art hydroponic strawberry farm in Koka, boosting productivity and sustainability through innovative gutter systems. Zuqualla Horti PLC, in collaboration with global partners, introduces a cutting-edge hydroponic system to enhance strawberry farming in Ethiopia, improving water efficiency and export…

#advanced agricultural technology#Agricultural Innovation#Crop management#Dutch-Ethiopian collaboration#eco-friendly farming#economic growth through agriculture#Ethiopian agriculture#Ethiopian exports#Ethiopian soft fruit exports#fertilizer efficiency#FlevoPlants partnership#food security in Ethiopia#greenhouse farming#gutter system farming#hydroponic strawberry farming#hydroponic systems in Ethiopia#hydroponic technology#Koka farm project#labor-friendly farming systems#Meteor Systems innovation#pesticide reduction#Resilience collaboration#soft fruit farming#strawberry production#strawberry yield improvement#sustainable agriculture#sustainable crop production#sustainable farming practices#water-efficient farming#Zuqualla Horti PLC

0 notes

Text

"The Crucial Role of Industrial Control Integrators: Driving Efficiency and Innovation in Modern Industry"

The Essential Role of an Industrial Control Integrator in Modern Industry

In today’s fast-paced industrial environment, the expertise of an Industrial Control Integrator has become indispensable. These professionals or companies specialize in designing, implementing, and maintaining complex control systems that are critical for optimizing industrial processes. This blog delves into the pivotal role of an Industrial Control Integrator, explaining their key responsibilities and the impact they have on industrial efficiency.

What is an Industrial Control Integrator?

An Industrial Control Integrator is a specialized expert or firm responsible for creating and managing control systems that automate and regulate industrial machinery and processes. These control systems encompass both hardware and software components, which work together to enhance performance, increase reliability, and streamline operations.

Core Responsibilities of an Industrial Control Integrator

Control System Design and Engineering:

Needs Analysis: The integrator begins with a comprehensive assessment of the client’s specific requirements. This involves understanding their industrial processes and defining the desired outcomes.

Custom System Design: Based on the assessment, the integrator designs a bespoke control system, selecting the appropriate sensors, controllers, and communication protocols to meet the client’s needs.

Integration and Installation:

Hardware Setup: The integrator manages the installation of essential components such as Programmable Logic Controllers (PLCs), Human-Machine Interfaces (HMIs), and other field instruments.

Software Configuration: They also configure the software that governs the control system, ensuring seamless communication between hardware and other operational systems.

Testing and Commissioning:

System Testing: Before full deployment, the integrator conducts rigorous testing to identify and rectify any issues, simulating real-world conditions to verify system performance.

Commissioning: Once testing is complete, the integrator supervises the final commissioning process, making any necessary adjustments to ensure optimal functionality.

Training and Ongoing Support:

Staff Training: Integrators provide training for the client’s personnel, equipping them with the knowledge to operate and maintain the new system effectively.

Continued Support: They offer ongoing maintenance and support services to resolve any issues and ensure the system continues to operate smoothly.

Why Industrial Control Integrators are Vital

Boosting Efficiency:

Industrial Control Integrators streamline processes by automating operations, which reduces manual input and enhances precision. This leads to improved productivity and reduced operational costs.

Enhancing Safety:

Integrators implement advanced control systems that monitor conditions in real time, increasing workplace safety by triggering alarms or shutdowns when necessary.

Ensuring Reliability:

By designing systems with redundancy and fail-safes, integrators help minimize downtime, which is crucial for meeting production targets and maintaining product quality.

Facilitating Scalability:

As businesses expand, their control systems must adapt. Integrators create flexible solutions that can be easily scaled or upgraded to meet growing demands.

Incorporating Emerging Technologies:

With the rise of Industry 4.0, integrating new technologies such as the Internet of Things (IoT), advanced analytics, and Artificial Intelligence (AI) is becoming increasingly important. Control integrators are key to incorporating these innovations into existing systems.

The Future of Industrial Control Integration

The field of industrial control integration is continuously evolving, driven by technological advancements and shifting industry needs. Future trends include:

AI and Machine Learning Integration: Enhancing predictive maintenance and process optimization.

IoT Integration: Enabling more detailed data collection and real-time analytics.

Enhanced Cybersecurity: Addressing the increasing need for robust security measures to protect industrial control systems from cyber threats.

Conclusion

Industrial Control Integrators are essential in ensuring the efficiency, reliability, and safety of modern industrial processes. Their expertise in designing, implementing, and maintaining control systems is crucial for optimizing operations and keeping pace with technological advancements. For businesses looking to upgrade or implement control systems, partnering with a skilled Industrial Control Integrator can be the key to achieving greater efficiency and performance.

#Industrial Control Integrator#Industrial Automation#Control Systems Engineering#Programmable Logic Controllers (PLCs)#Human-Machine Interfaces (HMIs)#Industrial Process Optimization#Automation Solutions#System Integration#Industrial Efficiency#Operational Reliability#Advanced Control Systems#Industry 4.0#Internet of Things (IoT)#Artificial Intelligence (AI) in Industry#Predictive Maintenance#Industrial Cybersecurity#Control System Design#Industrial Technology Trends#Engineering and Integration Services#Manufacturing Automation

0 notes

Text

Elevate your systems with Renegade Electrics' expert Control Panel Design in New Zealand. Our precision-crafted designs ensure seamless and efficient operations, tailored to your specific needs. Trust us to redefine your control experience with innovative solutions. Choose Renegade Electrics for top-tier Control Panel Designs, delivering excellence in every detail across New Zealand.

#control panel design new zealand#Pump Control Panel designs in new zealand#PLC Controller Programming in new zealand#Efficient pump control systems in new zealand#automation electric controls in new zealand

1 note

·

View note

Text

Low Voltage Relays Explained: Types, Functions, and Applications

In the complex world of electrical systems, relays play a crucial role in ensuring safety, efficiency, and automation. Among these, low voltage relays stand out as versatile components that manage and protect circuits operating below 1000 volts. Whether in industrial automation, residential power distribution, or commercial infrastructure, these devices act as the nerve center of electrical control and protection.

In this comprehensive guide, we will break down what low voltage relays are, explore their types, explain their functions, and highlight their diverse applications across industries.

What Are Low Voltage Relays?

A low voltage relay is an electrically operated switch that uses a small control voltage (typically below 1000V AC or DC) to switch larger electrical loads on and off. These relays act as intermediaries between control circuits and power circuits, providing isolation, control, and protection.

Unlike manual switches, relays automate the process of circuit management, responding to electrical signals, fault conditions, or system commands without human intervention.

Types of Low Voltage Relays

Low voltage relays come in several forms, each tailored to specific tasks within an electrical system. Here are the main types:

1. Electromechanical Relays (EMRs)

· Use a coil and a movable armature to open or close contacts.

· Provide physical isolation between input and output.

· Common in traditional control panels and basic automation.

2. Solid-State Relays (SSRs)

· Use semiconductors (like thyristors or triacs) instead of mechanical contacts.

· Offer silent operation, faster switching, and longer lifespan.

· Ideal for high-speed applications and environments requiring low maintenance.

3. Overload Relays

· Specifically designed to protect motors and equipment from sustained overcurrent.

· Available as thermal overload relays (using bimetallic strips) or electronic overload relays (using sensors and processors).

4. Time Delay Relays

Provide a deliberate time lag between the relay receiving a signal and switching.

Used in motor control circuits, lighting systems, and sequential operations.

5. Overcurrent and Short-Circuit Relays

· Detect and react to current exceeding preset thresholds.

· Essential for system protection against faults and overloads.

6. Voltage Monitoring Relays

· Monitor voltage levels and trip when voltages fall below or rise above safe limits.

· Protect sensitive devices from under voltage and overvoltage conditions.

Functions of Low Voltage Relays

Low voltage relays serve multiple vital functions in electrical systems:

1. Switching and Control

Relays control the opening and closing of power circuits in response to low voltage signals from controllers, timers, or sensors. This enables remote and automated control of large electrical loads.

2. Protection

Relays detect abnormal conditions like overloads, overcurrent, under voltage, and phase failures. When such conditions arise, they disconnect the affected circuit to prevent equipment damage or fire hazards.

3. Isolation

They electrically isolate control circuits (usually low voltage, low current) from power circuits (high voltage, high current), ensuring safety and reducing interference.

4. Signal Amplification

A small control signal (from a PLC, sensor, or microcontroller) can trigger a relay to switch much larger loads, effectively amplifying the control power.

5. Automation and Sequencing

In complex systems, relays help sequence operations by ensuring that processes occur in the correct order and at the right time intervals.

Applications of Low Voltage Relays

Low voltage relays are the backbone of automation and protection in various industries. Here are some key application areas:

Industrial Automation

· Control of motors, pumps, conveyor belts, and production lines.

· Use in programmable logic controllers (PLCs) and distributed control systems (DCS).

Power Distribution Systems

· Protect electrical panels from overload and short circuits.

· Monitor voltage and current levels in distribution boards.

Building Automation

· Lighting control systems.

· HVAC (heating, ventilation, and air conditioning) systems.

· Elevator and escalator controls.

Renewable Energy Systems

· Manage and protect solar inverters, battery banks, and wind turbines.

· Automatically disconnect faulty sections to prevent system-wide failures.

Data Centers and IT Infrastructure

· Ensure stable power supply to servers and networking equipment.

· Protect sensitive electronics from voltage fluctuations.

Transportation

· Railways, metros, and automotive applications for control and safety circuits.

Home Appliances

· Found in washing machines, microwave ovens, and HVAC units to automate functions and provide protection.

Advantages of Using Low Voltage Relays

· Enhanced Safety: Isolate control and power circuits, reducing electrical shock risks.

· Automation Ready: Easily integrated into automated systems for smarter operation.

· Cost-Effective Protection: Safeguard expensive equipment from damage due to electrical faults.

· Versatile: Available in many forms to suit different voltage levels, currents, and response times.

· Reduced Maintenance: Especially with solid-state relays, which have no moving parts.

Future Trends: Smart Relays and IoT Integration

As industries move toward smart grids and Industry 4.0, low voltage relays are also evolving:

· Digital relays offer programmable settings, self-testing, and event recording.

· IoT-enabled relays can send status updates and alerts to centralized monitoring systems.

· Energy-efficient designs reduce power consumption while providing reliable protection.

Conclusion

Low voltage relays are indispensable in modern electrical engineering, seamlessly combining protection, control, and automation. From safeguarding your home appliances to managing the power in a sprawling industrial plant, these devices ensure that electrical systems run smoothly and safely.

Understanding the different types, functions, and applications of low voltage relays empowers system designers, engineers, and even DIY enthusiasts to build safer and more efficient electrical setups.

As technology advances, the role of these small but mighty devices will only grow, driving the future of safe, smart, and automated power systems.

9 notes

·

View notes

Text

How High-Quality Low-Voltage Switchgear Accessories Save You Money!

One of the main goals of industrial power systems is to cut costs without sacrificing performance.

Upgrading your low-voltage switchgear accessories is one frequently disregarded method to accomplish this.

Let’s discuss how purchasing high-quality switchgear accessories can extend the life of your electrical infrastructure, reduce operating costs, and boost system performance in this guide.

What Are Low-Voltage Switchgear Accessories?

Low-voltage switchgear accessories are parts that improve how well your electrical switchgear systems work, keep them safe, and make them reliable. These include:

- Circuit breakers

- Contactors

- Busbar systems

- Surge protection devices (SPDs)

- Control relays

- Communication and monitoring modules

They offer power distribution, fault protection, and real-time system monitoring and are therefore crucial in industrial automation and energy management.

1. Minimize Downtime and Improve Productivity

Cheap, low-quality parts are likely to break down, grinding work to a standstill. Every hour of unscheduled downtime at a plant equals lost work and income.

✅ Advantage:

The superior switchgear elements can withstand more load, function through more switch cycles, and withstand more demanding conditions. It guarantees power flows smoothly at all times and decreases the possibility of shutdowns.

2. Extend the Lifespan of Equipment

Switchgear accessories form the first line of defense for your equipment. Low-quality accessories will let surges or faults pass through and can destroy costly equipment like motors, drives, and PLCs.

✅ Advantage

Stable components such as motor protection relays and surge protection devices maintain voltage levels constant and prevent overloads, thus safeguarding equipment downstream of them.

3. Reduce Maintenance and Replacement Costs

Sustained maintenance, breakdown calls, and replacement components are costly over time. Cheap parts fail early, thereby adding to your maintenance load.

✅ Advantage:

Purchasing robust, low-maintenance accessories translates to fewer services and repairs, which results in overall savings.

4. Improve Energy Efficiency

Loss of power and energy inefficiency typically start with old or badly designed switchgear devices. Even small problems within a big system can lead to higher energy bills.

✅ Advantage:

Good-quality accessories provide the highest conductivity and proper switching, allowing for optimal voltage output maintenance and avoiding energy wastage.

5. Enhance Electrical Safety and Regulatory Compliance

Faulty accessories are a main cause of electrical fire and safety hazards. Substandard systems can also fail to meet industry standards.

✅ Advantage:

Good quality switchgear parts typically conform to IEC, UL, or other important standards for safe functioning and regulatory compliance.

Conclusion: Small Components, Big Savings

Cheap accessories can appear to be a good deal initially but can turn out to be costly over time. Employing quality low-voltage switchgear accessories guarantees that:

- Less system crashes

- Equipment lasts longer

- Reduced maintenance

- Reduced energy costs

- Safer operations

Looking for Reliable Low-Voltage Switchgear Accessories?

At Almond Enterprise, we specialize in supplying industrial-grade switchgear components that deliver long-term performance and value.

Contact Our Experts: [email protected] for tailored recommendations

7 notes

·

View notes

Text

Understanding the meaning, applications, and advantages of control valves.

Control valves are devices that play an essential role in controlling and regulating the flow, pressure, and temperature in industrial processes and control systems. It is installed in the field-level area of the automation pyramid and connected to the control system and PLC through the PLC’s hardware. The global control valve consists of the body, actuator, Positioner, Valve trim, stem, and bonnet to prevent leakage. There are also the Gaskets and seals that are used when connecting the valve with other mechanical parts.

Control valves have many advantages such as Accurate Control of Process Parameters, Easy Automation Compatibility by integrating these items with the main Control systems (DCS and PLC), Energy saving and energy efficiency by optimizing the process condition and minimizing waste, maintaining safe operating conditions and increase process safety factors, Improve Process Efficiency and Increase Product Quality.

Control valves are used in many applications such as the Automotive Industry, Cement and steel, and Oil and Gas Industry, especially in gas valve trains, Renewable Energy, and HVAC Systems.

For full article check the following link:

For more articles about Renewable, Automation and Instrumentation, check the following link:

www.ecaico.com

#automation#instrumentation#renewable#control system#plc#sensors#pressure#gas valve#industrial valves

2 notes

·

View notes

Text

Distributed Acoustic Sensing Market to Experience Significant Growth

Distributed Acoustic Sensing Market to Experience Significant Growth

Straits Research has published a comprehensive report on the global Distributed Acoustic Sensing Market, projecting a significant growth rate of 11.58% from 2024 to 2032. The market size is expected to reach USD 1,617.72 million by 2032, up from USD 673.32 million in 2024.

Market Definition

Distributed Acoustic Sensing (DAS) is a cutting-edge technology that enables real-time monitoring of acoustic signals along the entire length of a fiber optic cable. This innovative solution has far-reaching applications across various industries, including oil and gas, power and utility, transportation, security and surveillance, and environmental and infrastructure monitoring.

Request Sapmle Link:https://straitsresearch.com/report/distributed-acoustic-sensing-market/request-sample

Latest Trends

The Distributed Acoustic Sensing Market is driven by several key trends, including:

Increasing demand for real-time monitoring: The need for real-time monitoring and data analysis is on the rise, driven by the growing importance of predictive maintenance, asset optimization, and operational efficiency.

Advancements in fiber optic technology: Advances in fiber optic technology have enabled the development of more sensitive and accurate DAS systems, expanding their range of applications.

Growing adoption in the oil and gas industry: The oil and gas industry is increasingly adopting DAS technology for monitoring and optimizing well operations, reducing costs, and improving safety.

Emerging applications in smart cities and infrastructure monitoring: DAS technology is being explored for various smart city applications, including traffic management, public safety, and infrastructure monitoring.

Key Opportunities

The Distributed Acoustic Sensing Market presents several key opportunities for growth and innovation, including:

Integration with other sensing technologies: The integration of DAS with other sensing technologies, such as seismic and electromagnetic sensing, can enhance its capabilities and expand its range of applications.

Development of advanced data analytics and AI algorithms: The development of advanced data analytics and AI algorithms can help unlock the full potential of DAS technology, enabling more accurate and actionable insights.

Expansion into new markets and industries: The Distributed Acoustic Sensing Market has significant potential for growth in new markets and industries, including renewable energy, transportation, and smart cities.

Key Players

The Distributed Acoustic Sensing Market is characterized by the presence of several key players, including:

Halliburton Co.

Hifi Engineering Inc.

Silixa Ltd.

Schlumberger Limited

Banweaver

Omnisens SA

Future Fibre Technologies Ltd.

Baker Hughes Inc.

Qintiq Group PLC

Fotech Solutions Ltd.

Buy Now:https://straitsresearch.com/buy-now/distributed-acoustic-sensing-market

Market Segmentation

The Distributed Acoustic Sensing Market can be segmented into two main categories:

By Fiber Type: The market can be segmented into single-mode fiber and multimode fiber.

By Vertical: The market can be segmented into oil and gas, power and utility, transportation, security and surveillance, and environmental and infrastructure monitoring.

About Straits Research

Straits Research is a leading provider of business intelligence, specializing in research, analytics, and advisory services. Our team of experts provides in-depth insights and comprehensive reports to help businesses make informed decisions.

#Distributed Acoustic Sensing Market#Distributed Acoustic Sensing Market Share#Distributed Acoustic Sensing Market Size#Distributed Acoustic Sensing Market Research#Distributed Acoustic Sensing Industry

3 notes

·

View notes

Text

Private Sector Good, Public Sector Bad? (2)

This is the second part of a look at former public services and utilities in Britain that have been privatised in the name of neoliberal economics and the mistaken belief that private enterprise is ALWAYS more efficient than publicly run bodies.

Prisons

The first privately run prison in the UK was opened in 1992 under a Conservative government and private sector involvement in Britain’s penal system has grown steadily ever since. The UK is now second only to the USA in the number of privately run prisons.

Premier Custodial Group was formed in 1992 and in 2005 was the largest private company running UK prisons. It was a joint venture between the American private prison operator Wackenhut Corrections Corporation and the British firm Serco PLC. From a turnover of £7.52 million in 1994 it had increased its revenues to £127.4m, with pre-tax profits of nearly £10m, paying out a £2m dividend to shareholders. In 2002 Wackenhut was taken over by Group 4 Falck.

In 2003 Serco gained control of Premier, estimating that Premier's

“income over the life of its existing contracts for five prisons, one secure training centre, two immigration facilities and court escort custody and electronic monitoring services was £2bn” (Cited in Prison Reform Trust: Private Punishment :Who Profits; January 2005)

Group 4 Securicor (G4S) was a company created in 2004 when Group 4 acquired Securicor. Since these takeovers these companies have gone from strength to strength, with Serco, G4S, and GEO Group branching into immigration and other services.

In 2018, the Guardian reported that the Home Office paid these companies:

“hundreds of millions of pounds to run the UK’s immigration removal centres, but no one knows for certain just how profitable the industry is…Commercial confidentiality agreements mean the Home Office and outsourcing companies are not obliged to publish detailed financial information about immigration detention centres in the UK.” (Guardian: 10/10/22)

In 2022, one of these companies, Sodexo was awarded a £264 million UK prison contract over a ten year period. On receiving the contract, Paul Anstey, CEO, Government, Sodexo UK & Ireland stated:

“Our vision is to provide a secure and safe environment which reduces re-offending through education, builds new skills and offers respect, equality and inclusion.” (Facilities Management Magazine: 16/08/22)

If only that were true! As long ago as 2013 Sodexo Justice Services was facing charges of prisoner torture and degradation.

'Cruel, inhumane and degrading': Female prisoner kept segregated in 'squalid' cell for five years.” (Independent: 21/08/2013)

In 2016 a video of naked Prisoners pretending to be dogs led to an investigation into violence and humiliation of prisoners by Sodexo. In September 2017, a female prisoner died under Sodexo care. An inquest into her death concluded:

“serious failures at Sodexo run HMP Peterborough contributed to death of Annabella Landsberg” (Inquest: 04/04/2019)

Another prison run by Sodexo was accused of residing over a “spice” epidemic, which led to the death of a male prisoner. (Manchester Evening News) In 2018 Sodexo was again accused of neglect and systematic failures resulting in the death of yet another inmate. In 2019, a different prison run by Sodexo was accused of “systemic breaches of inmate human rights”.

In February of this year 20 prison staff resigned from the Sodexo run HMP Lowdham Grange, which was deemed so unsafe the government was forced to take it over.

The appalling levels of service cited above are not restricted to Sodexo alone. In her book “Profiting from their misery: Britain’s private prisons”, Hatty Nestor reveals that:

“outsourcing companies like G4S encourage prisoners to work 40-hour weeks, all they are paid (is) as little as £2 an hour. Such practices amount to slave labour. Companies are profiting from prison labour, paying fewer well-trained, low staff wages. In private prisons, staff are paid 23% less than public prisons, and they also outsource security, healthcare and cheap food. Private prisons aim for a profit margin of 8-10%, which is met by cutting costs and the increased exploitation of staff and inmates.”

Given that privately run prisons pay their staff less, are more overcrowded, and employ fewer prison officers you would think they would at least be more cost effective yet this isn’t the case. The governments own figures for 2022/23 reveal that it cost £32,762 per prisoner, per year in publicly run prisons, while the cost for privately run prisons was £33,628 per prisoner. (Ministry of Justice: “Costs per place and cost per prisoner by individual prison.", 21/0324)

What is more, the government gives 23% of its allocated budget to private companies despite the fact their prisons only house 15% of the total prison population. It seems that whichever way you measure private prison success (apart form profits for its shareholders) private prisons do far worse than those still in the public sector.

3 notes

·

View notes

Text

Know About the Versatility and Efficiency of PM Fiber Splitters

Devices known as PM fiber splitters are made to divide an incoming optical signal into two or more output signals while maintaining the input signal's polarization. Specialized optical fibers that preserve the polarization of light passing through them are used to accomplish this. PM Fiber Splitter guarantees that the polarization state stays constant during the splitting process, in contrast to traditional fiber splitters, which are susceptible to polarization variations.

PM Fiber Splitters' Operation

An optical fiber that maintains polarization is the central component of a PM fiber splitter. These fibers are designed to direct and restrict light in a way that maintains the light's polarization condition. Usually, tension is added to the fiber core to do this, producing a birefringent effect. The fast and slow axes are the two orthogonal polarization states that occur from this splitting of light as it passes through the fiber. A birefringent element in a PM fiber splitter divides entering light into its fast and slow axis components as soon as an optical signal arrives.

Uses for PM Fiber Splitters

PM fiber splitters and PM PLC Splitter are utilized in fiber optic communication systems for signal splitting and routing in telecommunications networks. They are essential in spreading optical signals to several locations with the least amount of signal loss and impairments caused by polarization.

Sensing and Instrumentation: PM fiber splitters are used in many different types of instrumentation and sensing applications, including optical gyroscopes and interferometric sensors. Since polarization effects can create errors, their ability to sustain polarization makes them perfect for preserving the integrity of optical sensor systems.

Benefits

PM fiber splitters offer constant performance in polarization-sensitive applications by preserving the polarization state of input signals. This is one of its key advantages.

Low Insertion Loss: By reducing signal attenuation and increasing system efficiency, these splitters have low insertion loss.

High Reliability: PM fiber splitters have a solid reputation for durability and dependability, which makes them appropriate for long-term deployment in difficult applications.

Compact Design: Because PM Fiber Splitter usually has small sizes, it is simple to incorporate them into optical systems that already exist without taking up a lot of room.

3 notes

·

View notes

Text

A Comprehensive Guide to Power Systems Protection for Engineers

Introduction:

Power systems protection is a critical aspect of electrical engineering that focuses on safeguarding electrical equipment, personnel, and the power grid from faults, failures, and abnormal operating conditions. This comprehensive guide aims to provide engineers with valuable insights into key principles, techniques, and best practices in power systems protection.

1. Understanding System Operation and Fault Types:

Before delving into protection strategies, it is essential to have a solid understanding of how power systems operates and the various types of faults that can occur. This includes studying system components, such as generators, transformers, transmission lines, circuit breakers, relays, and protective devices. Familiarity with fault types like short circuits, open circuits, ground faults, and transient overvoltages is crucial as a foundation.

2. Principles of Protection Coordination:

Effective power systems protection requires proper coordination among protective devices. Engineers must understand the concept of selectivity to ensure that only the device closest to a fault operates, minimizing disruption to the rest of the system. Proper coordination involves selecting appropriate current settings, time delays, and coordination curves for relays and circuit breakers.

3. Relay Device Fundamentals:

Relays are an integral part of power systems protection, serving as the first line of defense against electrical faults. Engineers should have a thorough knowledge of different relay types, including overcurrent relays, differential relays, distance relays, and directional relays. Understanding their operating principles, features, and limitations aids in choosing the most suitable relays for specific applications.

4. Protective Device Coordination:

Coordinating protective devices within a system is critical to maintaining stability and preventing cascading failures during faults. Engineers must carefully analyze and design protection schemes that consider factors such as fault impedance, fault currents, relay response characteristics, and coordination margins. Advanced techniques like time grading and impedance grading can be employed to achieve optimal coordination.

5. Fault Analysis and System Modeling:

Performing fault analysis and system modeling helps engineers gain insights into power flow, fault currents, voltage profiles, and system stability. Engineers must be proficient in using software tools like ETAP, PSCAD, and DSA Tools to accurately simulate fault scenarios and assess the performance of protection schemes. Detailed knowledge of system modeling techniques enables engineers to make informed decisions regarding relay settings and coordination.

6. Communication-Based Protection:

With the increasing complexity of modern power systems, communication-based protection plays a crucial role in maintaining reliability. Knowledge of communication protocols such as IEC 61850, GOOSE (Generic Object-Oriented Substation Event), and SCADA (Supervisory Control and Data Acquisition) systems is essential for engineers to design and implement advanced protection solutions that utilize real-time data exchange between substations and control centers.

7. Integration of Automation and Control Systems:

Incorporating automation and control systems into power systems protection enhances operational efficiency and reduces response time during faults. Engineers need to understand concepts like remote terminal units (RTUs), programmable logic controllers (PLCs), and human-machine interfaces (HMIs). Familiarity with protocols like Modbus, DNP3 (Distributed Network Protocol), and OPC (OLE for Process Control) enables seamless integration of protection systems with wider control infrastructure.

8. Commissioning, Testing, and Maintenance:

Implementing effective protection strategies requires thorough commissioning, testing, and maintenance procedures. Engineers should be well-versed in practices like primary injection testing, secondary injection testing, relay calibration, fault simulation, and periodic inspections. Adhering to manufacturer guidelines, industry standards, and safety protocols ensures equipment reliability and optimal performance.

9. Access to Resources and Industry Awareness:

Staying connected with organizations like the IEEE (Institute of Electrical and Electronics Engineers) and IET (Institution of Engineering and Technology) is crucial for access to valuable resources. Engineers should actively seek research papers, technical articles, conferences, and networking opportunities. Staying informed about relay technology advancements from prominent manufacturers aids in adopting the latest protection techniques.

10. Software Applications for Enhanced Protection:

Utilizing software applications is vital in power systems protection. Advanced tools like ETAP, PSCAD, and DSA Tools aid in relay coordination analysis, fault simulation, and system modeling. Acquiring proficiency in these common industry software packages enables engineers to design and optimize protection schemes effectively.

11. Compliance with Local National Codes:

Adhering to local national codes and regulations is paramount in power systems protection. Understanding and implementing specific electrical codes and standards relevant to the country of operation is crucial. Compliance ensures safe and reliable system design, installation, and operation aligned with legal requirements and best practices.

Conclusion:

By encompassing the principles, techniques, and best practices discussed in this guide, engineers pursuing careers in power systems protection can develop a strong foundation. Continuous learning, staying updated on industry advancements, and compliance with local national codes will ensure engineers can design, implement, and maintain robust and reliable protection schemes for the power grid and its critical assets.

The Author Biography: Qusi Alqarqaz

Qusi Alqarqaz is an experienced professional in power system protection, specializing in sharing knowledge and guiding young engineers. With a career spanning utility and oil and gas industries in Texas, New Mexico, and Qatar, he has amassed extensive industry experience.

Collaborating with leading manufacturers such as SEL, ABB, Siemens, Schneider, among others, Qusi has gained proficiency in a range of protective relays. He actively pursues continuing education, completing professional development courses with software providers including ETAP and Milsoft, enabling him to utilize advanced tools for power system analysis and protection design.

Qusi's dedication to staying up-to-date with industry advancements led him to pursue additional training. He completed professional development courses at Wisconsin University, equipping him with specialized knowledge crucial for working with high-voltage power systems. He also studied power generation extensively at Strathclyde University in the UK.

Qusi actively shares his knowledge through collaborating on large-scale projects and providing training sessions for professionals. Through his posts, he aims to offer guidance and mentorship for young engineers in power system protection. His practical advice and personal experiences will empower the next generation of experts in this field.

Contact the Author:

Qusi actively shares his knowledge through collaborating on large-scale projects and providing training sessions for professionals.

Qusi Alqarqaz

9 notes

·

View notes

Text

youtube

Infineon: solid-state isolators with advanced protection features

https://www.futureelectronics.com/resources/featured-products/infineon-advanced-solid-state-isolators . Get to know the world of digital output modules and explore the advantages of Infineon's SSR chipset solution and how Infineon's cutting-edge technology helps maximize the efficiency of your PLC system . https://youtu.be/3HQKfkyXFf8

#ai#future electronics#WT#Future Electronics#SSR Chipset#Digital Output Modules#Infineon SSR Chipset Solution#Efficiency of PLC Systems#Infineon PLC Systems#Tech Solutions#Power Management#Youtube

0 notes

Text

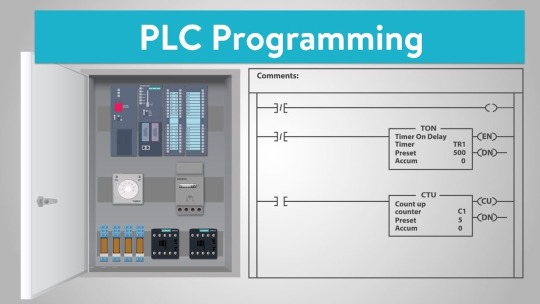

The Basics of PLC Programming: A Comprehensive Guide

If you're interested in the field of industrial automation or looking to enhance your skills in the industry, PLC programming is a crucial skill to possess. Programmable Logic Controllers (PLCs) are widely used in manufacturing and process control systems, and understanding how to program them is essential for ensuring efficient and reliable operation.

In this comprehensive guide, we will explore the basics of PLC programming, covering key concepts and providing valuable insights for beginners in the field.

1. What is PLC Programming?

PLC programming involves creating a set of instructions that control the behavior of a programmable logic controller. PLCs are used to monitor inputs from various sensors, process that data, and execute specific actions based on pre-defined logic. By programming a PLC, you can automate complex industrial processes, making them more efficient and reliable.

2. Why Learn PLC Programming?

PLC programming offers numerous benefits in the industrial automation realm. By acquiring this skill, you can:

Improve productivity: PLCs enable automation, reducing manual labor and increasing overall productivity.

Enhance efficiency: Automation minimizes human error and optimizes processes, resulting in higher efficiency levels.

Facilitate troubleshooting: Understanding PLC programming allows you to diagnose and fix issues efficiently, minimizing downtime.

Expand career opportunities: PLC programming expertise is in high demand, with many industries seeking professionals with these skills.

3. PLC Programming Training Courses:

To learn PLC programming effectively, it's essential to enroll in specialized training courses. These courses provide a structured curriculum, hands-on exercises, and expert guidance. Here are a few key aspects to consider when choosing a PLC programming training institute or center:

Comprehensive curriculum: Look for a training program that covers both theoretical concepts and practical implementation.

Experienced instructors: Ensure that the training institute has qualified instructors with industry experience to guide you effectively.

Hands-on practice: Practical exercises and projects are crucial for gaining proficiency in PLC programming.

Industry relevance: Verify that the training course aligns with current industry standards and practices.

Certification: Opt for courses that offer certifications upon completion, as they enhance your credibility in the job market.

4. Key Concepts in PLC Programming:

Ladder Logic: Ladder Logic is the most commonly used programming language for PLCs. It employs graphical symbols to represent logic functions and control sequences, making it easy to understand and implement.

Inputs and Outputs: PLCs interact with the physical world through inputs (sensors) and outputs (actuators). Understanding how to read inputs and control outputs is fundamental in PLC programming.

Programming Instructions: PLCs execute a set of instructions to perform desired operations. These instructions can include timers, counters, mathematical operations, logic gates, and more.

Program Execution: PLC programs are executed in a cyclical manner. The PLC scans inputs, processes logic, updates outputs, and repeats the cycle continuously.

5. Programming Tools and Software:

PLC programming software provides an interface to create, edit, and debug programs. Familiarize yourself with popular software tools such as Siemens TIA Portal, Allen-Bradley RSLogix, or Schneider Electric Unity Pro, as they are widely used in the industry.

Conclusion:

PLC programming is an essential skill for individuals aspiring to succeed in the field of industrial automation. By learning the basics of PLC programming, you open up a world of opportunities to streamline processes, enhance productivity, and contribute to the advancement of various industries. Enroll in a reputable PLC programming training institute or center, explore the key concepts, and start your journey towards becoming a proficient PLC programmer.

#plc-programming#learn plc programming#plc programming training#plc programming courses#plc training course in india

3 notes

·

View notes

Text

SCADA Integrators

The Essential Guide to SCADA Integrators: Enhancing Efficiency and Control

In today’s fast-paced industrial landscape, the role of SCADA (Supervisory Control and Data Acquisition) systems is more crucial than ever. These systems allow businesses to monitor, control, and optimize their operations in real time. However, the effectiveness of a SCADA system often hinges on the expertise of SCADA integrators. In this blog, we’ll delve into what SCADA integrators do, why they are important, and how they can help businesses unlock the full potential of their SCADA systems.

What Are SCADA Integrators?

SCADA integrators are specialists who design, implement, and manage SCADA systems tailored to a company’s specific needs. They play a critical role in ensuring that all components of a SCADA system work harmoniously together. This includes integrating hardware, software, and network elements to create a cohesive system that provides real-time monitoring and control.

Why SCADA Integrators Are Vital

Customization and Optimization: SCADA integrators bring a wealth of expertise in tailoring systems to fit unique operational requirements. They ensure that the SCADA system is not just a generic solution but a customized tool that enhances the specific processes of a business. This includes configuring dashboards, setting up alarms, and optimizing data collection methods.

Seamless Integration: Integrators are adept at bridging various components of a SCADA system. This means connecting sensors, PLCs (Programmable Logic Controllers), and other field devices with the central SCADA software. Their work ensures that data flows seamlessly from the field to the control room, facilitating accurate and timely decision-making.

Enhanced Security: Security is a major concern for SCADA systems, as they are often linked to critical infrastructure. SCADA integrators implement robust security measures to protect against cyber threats and ensure that sensitive data remains secure. This involves setting up firewalls, encryption protocols, and regular security audits.

Scalability: As businesses grow, their SCADA systems need to evolve. SCADA integrators help in scaling the system by adding new components, expanding data storage, and integrating with other enterprise systems. This scalability ensures that the SCADA system continues to meet the changing needs of the business.

Troubleshooting and Support: Even the most well-designed SCADA systems can encounter issues. SCADA integrators provide ongoing support and troubleshooting services to resolve any problems quickly. Their expertise minimizes downtime and ensures that operations continue smoothly.

Choosing the Right SCADA Integrator

When selecting a SCADA integrator, consider the following factors:

Experience and Expertise: Look for integrators with a proven track record and experience in your industry. Their familiarity with specific applications and standards can significantly impact the success of your SCADA system.

Customization Capabilities: Ensure that the integrator can tailor the system to your specific needs rather than offering a one-size-fits-all solution. Customization can lead to better efficiency and effectiveness.

Support Services: Assess the level of ongoing support and maintenance offered. A reliable SCADA integrator should provide comprehensive support to address any issues that arise post-implementation.

Security Measures: Verify that the integrator has a strong focus on security, implementing best practices to safeguard your system against potential threats.

Conclusion

SCADA integrators are indispensable partners in harnessing the full power of SCADA systems. Their expertise in customization, integration, security, scalability, and support ensures that businesses can achieve optimal performance and reliability from their SCADA solutions. By choosing the right SCADA integrator, companies can not only enhance their operational efficiency but also stay ahead in an increasingly competitive market.

If you’re considering upgrading or implementing a SCADA system, investing in a skilled SCADA integrator can make all the difference. With their help, you can unlock new levels of control, insight, and efficiency in your operations.

#SCADA Integrators#SCADA Systems#Industrial Automation#Control Systems#Data Acquisition#SCADA Integration#Industrial Control#System Optimization#SCADA Security#Automation Solutions#Industrial Efficiency#Custom SCADA Solutions#SCADA Support#PLC Integration#Real-Time Monitoring

0 notes

Text

Reliable Automation PLC and Control System Supplier in DongPu, GuangZhou

Located in DongPu, GuangZhou, we specialize in Automation PLC and Automation Control System solutions that enhance industrial efficiency. Our systems offer seamless process control, real-time monitoring, and high reliability. From machinery automation to complex production lines, we deliver advanced technologies tailored to your operation's needs across China and beyond.

0 notes

Text

How Switchgears Contribute to Power Quality and Equipment Longevity

In today’s industrial landscape, facility uptime, energy efficiency, and equipment lifespan are directly tied to power quality. Poor power quality doesn’t just inflate energy costs — it silently wears down critical machinery, causes unexpected shutdowns, and leads to costly repairs. One often overlooked hero in this equation is the switchgear. Modern switchgears do far more than just control and protect power circuits; they actively safeguard power quality and extend the life of your equipment.

In this article, we’ll explore the vital role switchgears play in maintaining power quality and ensuring long-term reliability in industrial and commercial facilities.

Understanding Power Quality: Why It Matters

Power quality refers to the stability, reliability, and cleanliness of the electrical power supplied to equipment. Factors that degrade power quality include:

· Voltage sags and swells

· Harmonic distortion

· Transient surges

· Frequency variations

· Imbalance between phases

When power quality is compromised, sensitive equipment like drives, motors, PLCs, and even lighting systems can suffer reduced lifespan, malfunction, or complete failure. High-quality power is not a luxury; it’s a necessity for operational efficiency and safety.

Switchgears: The Gatekeepers of Power Integrity

Switchgears serve as the nerve center of power distribution in any facility. Here’s how modern switchgear solutions help maintain and enhance power quality:

1. Voltage Regulation and Stabilization

Advanced switchgears monitor voltage levels in real time and protect equipment from harmful sags or swells. Features like automatic voltage regulation and voltage balancing ensure your sensitive loads receive stable power, preventing stress on motors and electronic devices.

2. Harmonic Filtering

Some modern switchgear systems come integrated with harmonic filters or support external filtering solutions. Harmonics generated by variable frequency drives (VFDs), UPS systems, and other non-linear loads can cause overheating and inefficiencies. Switchgears mitigate these distortions, protecting downstream equipment and improving overall energy efficiency.

3. Surge and Transient Protection

Switchgears equipped with surge protection devices (SPDs) act as the first line of defense against voltage spikes and transient surges caused by lightning strikes or grid switching events. This protection extends the life of connected equipment by shielding them from these destructive forces.

4. Fault Isolation and Selectivity

When a fault occurs, fast-acting circuit breakers within the switchgear isolate the problem area without disrupting power to the entire facility. This selectivity ensures that critical processes continue running while the fault is contained, preventing system-wide stress and downtime.

5. Power Factor Correction (PFC)

Switchgears can be integrated with power factor correction capacitors that optimize the power factor, reducing losses and improving voltage stability. A better power factor not only saves on utility bills but also reduces the strain on transformers and generators, thus enhancing their longevity.

Equipment Longevity: The Silent Benefit of Quality Power

The connection between switchgears and equipment lifespan is profound:

· Motors last longer when protected from voltage imbalances and harmonics.

· Transformers operate cooler and more efficiently when power factor is optimized.

· Variable Speed Drives (VSDs) avoid overheating when shielded from surges and harmonic distortions.

· Sensitive electronic controls avoid malfunction due to transient spikes and voltage dips.

In essence, well-maintained and properly specified switchgear reduces the electrical “stress” that causes premature equipment aging and failure.

The Shift Toward Digital and Smart Switchgears

The rise of digital switchgear takes power quality management to the next level. Smart switchgears offer:

· Continuous real-time monitoring of voltage, current, harmonics, and power factor

· Predictive analytics to forecast equipment wear and prevent failures

· Remote control and automated fault response for faster issue resolution

Facilities that embrace digital switchgear solutions can transform their maintenance strategies from reactive to proactive, leading to even longer equipment lifespans and lower total ownership costs.

Practical Steps: How to Maximize the Benefits

To harness the full power quality and longevity benefits from switchgears, consider the following best practices:

· Regular Maintenance: Inspect and test switchgear components to ensure optimal performance.

· Correct Specification: Choose switchgears rated for your facility’s load characteristics and future growth.

· Integration with Monitoring Systems: Leverage real-time data to track power quality indicators.

· Invest in Smart Solutions: Upgrade to digital switchgears with built-in diagnostics and analytics.

Conclusion: Switchgears as Strategic Assets

Switchgears are far more than circuit controllers; they are strategic assets that can directly impact your facility’s operational excellence. By stabilizing power quality, filtering disturbances, and protecting against electrical faults, switchgears extend the service life of every connected piece of equipment — from heavy-duty motors to delicate electronic controls.

For engineers, procurement managers, and facility operators, investing in high-quality, modern switchgear solutions isn’t just about compliance — it’s about securing long-term savings, boosting reliability, and optimizing performance.

#low voltage#switchgear#electrical#electrical supplies#911 abc#artists on tumblr#cats of tumblr#cookie run kingdom#batman#arcane#f1#jason todd#electricity#electric vehicles#ides of march

6 notes

·

View notes