#Automation PLC and Automation Control System

Explore tagged Tumblr posts

Text

Reliable Automation PLC and Control System Supplier in DongPu, GuangZhou

Located in DongPu, GuangZhou, we specialize in Automation PLC and Automation Control System solutions that enhance industrial efficiency. Our systems offer seamless process control, real-time monitoring, and high reliability. From machinery automation to complex production lines, we deliver advanced technologies tailored to your operation's needs across China and beyond.

0 notes

Text

Understanding the meaning, applications, and advantages of control valves.

Control valves are devices that play an essential role in controlling and regulating the flow, pressure, and temperature in industrial processes and control systems. It is installed in the field-level area of the automation pyramid and connected to the control system and PLC through the PLC’s hardware. The global control valve consists of the body, actuator, Positioner, Valve trim, stem, and bonnet to prevent leakage. There are also the Gaskets and seals that are used when connecting the valve with other mechanical parts.

Control valves have many advantages such as Accurate Control of Process Parameters, Easy Automation Compatibility by integrating these items with the main Control systems (DCS and PLC), Energy saving and energy efficiency by optimizing the process condition and minimizing waste, maintaining safe operating conditions and increase process safety factors, Improve Process Efficiency and Increase Product Quality.

Control valves are used in many applications such as the Automotive Industry, Cement and steel, and Oil and Gas Industry, especially in gas valve trains, Renewable Energy, and HVAC Systems.

For full article check the following link:

For more articles about Renewable, Automation and Instrumentation, check the following link:

www.ecaico.com

#automation#instrumentation#renewable#control system#plc#sensors#pressure#gas valve#industrial valves

2 notes

·

View notes

Text

Smarter Surface Protection – PLC Automation in Autophoretic Coating Plants

In modern manufacturing, surface coating is not just cosmetic—it’s essential for durability, corrosion resistance, and performance. Autophoretic coating (also known as A-coating) has emerged as a water-based, eco-friendly alternative to electro-coating. When combined with PLC-based automation, it becomes a powerful, scalable solution for high-quality, uniform metal finishing.

Because let’s face it—metal without proper protection is like a knight without armour. In today’s industrial world, that armour comes in the form of surface coating. And when it comes to smart, sustainable, and scalable coating, autophoretic coating is the unsung hero.

But wait, here’s where it gets exciting. Pair this eco-warrior coating with PLC automation, and what you get is nothing short of magic. At Messung Industrial Automation, we believe that the perfect coat is not just about shine—it's about smarts, speed, and sustainability.Let’s dive into the world where chemistry meets code, and surface protection meets the future.

What is Autophoretic Coating?

Autophoretic coating, also known as A-coating, is a process where metal parts are dipped in a reactive water-based solution. The result? A self-depositing layer forms on the surface, without any electric current. Unlike traditional methods that zap the surface with electricity, A-coating lets chemistry take the wheel.

Why Are Industries Making the Switch?

Industries are coating their bets on it because it avoids the need for heavy electric setups and provides uniform coverage even in complex geometries. Since it is water-based, it is also very environmentally friendly.

Where Is It Being Used?

From under-the-hood car parts to refrigerator frames, autophoretic coating is making waves in:

Automotive parts

Appliance components

Agricultural and construction machinery

General industrial structures

In an age where efficiency, sustainability, and performance go hand in hand, autophoretic coating emerges as a transformative solution. Its simplicity belies its power, ushering in a cleaner, smarter way to protect surfaces without compromising on quality or cost. As industries across the board continue to embrace greener practices, A-coating, powered by automation and intelligence, is painting the future—one seamless coat at a time.

Role of PLC in the Coating Plant

In the realm of autophoretic coating, precision isn't a luxury—it's a necessity, and that precision begins with the silent genius of automation: the Programmable Logic Controller (PLC). Think of the PLC as the central nervous system of your coating plant—connecting, communicating, and commanding every mechanical muscle with machines. Here is how PLCs turn a basic coating line into a harmonious dance of efficiency and intelligence.

Precision Process Automation

A modern autophoretic coating plant runs smoothly like a well-coordinated team, and the PLC (Programmable Logic Controller) is in charge. It doesn’t just control the machines—it helps everything work perfectly together. From:

Tank temperature

Solution pressure & pH levels

Cycle timing for each dip and rise

...every step is monitored and controlled by PLC automation.

Material Handling Magic

Using intelligent material handling controllers, our PLC guides parts through multiple stages:

Degreasing

Surface conditioning

Coating dip

Rinsing & curing

Like a choreographer directing a ballet of metal.

Circulation & Filtration Mastery

Good coating = Consistent flow. Our process controllers and PLC control systems manage:

Fluid circulation

Filtration cycles

Solution replacement timing

Synchronisation with Process Controllers

Through seamless synchronisation with motion control systems, everything moves with precision. No drips, no downtime.

In an industry where milliseconds matter and uniformity is sacred, PLC automation elevates the autophoretic coating plant from functional to phenomenal. It enables not just control, but clarity—ensuring that every part, every dip, and every process flows with intelligent intent.

NX-ERA JET PLC System Architecture

Our flagship—NX-ERA JET PLC—is a robust, real-time, and rugged automation genius. It’s compact, reliable, and battle-tested in industrial heat.

Talk the Talk: MODBUS & TCP/IP

Built-in PLC communication protocols like:

MODBUS TCP/IP

MODBUS RTU

Make it plug-and-play with SCADA and automation systems. Yes, it speaks fluent-machine.

Ethernet-Based Controllers for High-Speed Sync

Using Ethernet-based controllers, data flows like molten metal. Zero lag, maximum productivity.

HMI with PLC Controllers

With user-friendly HMIs with PLC controllers, even a non-techie can operate complex coating sequences. Tap, drag, drop—and coat!

From seamless communication to intuitive control, the NX-ERA JET PLC is more than just a controller—it's the central nervous system of your autophoretic coating plant. With its advanced architecture, lightning-fast data sync, and plug-and-play compatibility, it transforms complexity into clarity. Whether you're scaling up or starting smart, this system offers the flexibility, durability, and intelligence your operations demand.In a world where precision meets pressure, the NX-ERA JET PLC ensures your plant doesn’t just perform—it excels.

Advanced PLC Automation for Smart Manufacturing

In the age of Industry 4.0, surface coating is no longer just about chemistry—it's about intelligence, precision, and adaptability. That’s where advanced PLC automation steps in as the invisible powerhouse behind your plant’s performance. Whether you're scaling up operations or streamlining a compact facility, smart automation is the lever that elevates your process from ordinary to outstanding.

Let’s uncover how Messung’s cutting-edge PLC technology is revolutionising autophoretic coating plants with flexible, responsive, and future-ready control systems.

Modular, Compact & Ready to Go - Whether it’s a big plant or a small-scale setup, our Modular PLC, Compact PLC, and Smart PLC configurations give you tailor-made flexibility.

Motion Control with Millisecond Precision - Our motion control systems enable synchronised movement, avoiding delays or overlaps in the coating sequence.

Material Handling - Our embedded material handling controllers do the heavy lifting—literally—without breaking a sweat.

This isn't just automation. This is smart automation that thinks ahead, moves with purpose, and adapts to demand. With Messung’s PLC-powered intelligence, your coating plant doesn’t just run—it evolves.

Because in the world of advanced manufacturing, it’s not just about staying ahead—it's about setting the pace.

Smart. Sustainable. Secure: The Evolution of PLC Automation in Coating Plants

In the era of Industry 4.0, coating plants need more than just control—they need intelligence, integration, and intention. Here’s how Messung’s PLC automation is redefining autophoretic coating systems:

Built for Harsh Industrial Realities – Our Industrial PLCs endure dust, moisture, heat, and vibration. Conformal-coated PLCs protect against corrosive chemicals in A-coating zones and provide long-lasting performance in extreme environments.

Safety Meets Smarts - PLCs are integrated for emergency stops, controlled shutdowns, and real-time fault alerts with logs, making them smart, secure, and always in control.

Welcome to Industry 4.0-Based Controllers

PLC with IoT for remote monitoring and real-time plant access.

MQTT-based PLCs for cloud-friendly, lightweight data communication.

Full PLC system integration with BMS, SCADA & more—ensuring a harmonious automation ecosystem.

Green Gains: Eco-Friendly A-Coating Automation

Water-based chemistry reduces VOCs and emissions.

Smart PLCs optimize dosing & disposal—minimising waste, maximising results.

Cleaner air, cleaner conscience, smarter coatings.

With Messung’s intelligent PLC, you don’t just automate—you evolve. Sustainable, scalable, and secure—this is the new face of PLC-based automation solutions in A-coating.

Business Benefits of PLC-Based Automation Solutions

In today’s hyper-competitive manufacturing world, success isn’t just about innovation—it’s about consistency, efficiency, and scalability. This is where PLC-based automation doesn’t just support your coating process—it transforms it. Let’s explore how Messung’s smart automation systems turn operational goals into tangible business advantages.

Uniformity Every Time - When every product must meet the same high standard, there’s no room for guesswork. Thanks to PLC control systems, your coating process is even, repeatable, and of high quality.

Never any Downtime - Time is money, and downtime is a thief. With real-time monitoring and intelligent automation controllers, potential issues are detected and resolved before they affect production. Fewer breakdowns. More uptime. Happier bottom line.

Easy to Maintain & Scale - Growth shouldn’t be a gamble. With built-in PLC maintenance alerts, you get proactive notifications that prevent surprises. Want to expand operations? Simply plug and play with modular I/O modules. You’re ready for tomorrow—today.

In essence, PLC automation is not just a control system—it’s a business strategy. It safeguards quality, boosts efficiency, and equips your coating plant with the agility to evolve. Because when your process is smart, your performance is unstoppable.

Conclusion: The Final Coat

A surface is only as strong as the system behind it. In the era of smart manufacturing, Messung’s PLC automation solutions empower autophoretic coating plants with unmatched precision, efficiency, and sustainability. From real-time monitoring and advanced PLC control systems to seamless IoT integration and predictive maintenance, our technology ensures optimal surface protection with minimal waste. Whether it’s modular PLCs, industrial automation controllers, or motion control systems, Messung delivers the complete package. So why let inefficiencies corrode your bottom line? Upgrade your coat. Upgrade your process. Upgrade with Messung PLCs—where intelligent automation meets perfect protection.

FAQs

How does PLC contribute to energy efficiency in coating plants?

By optimizing process timings, reducing idle machine hours, and enabling intelligent power management, PLCs help cut down energy consumption and operational costs.

Can PLC automation reduce coating defects?

Absolutely. With real-time monitoring, precision control, and error alerts, PLC automation ensures consistent quality.

How easy is it to integrate Messung PLCs in existing lines?

Very! Our modular PLC systems and versatile PLC communication protocols like MODBUS and TCP/IP allow seamless integration.

Are conformal-coated PLCs necessary?

Yes, especially in chemically aggressive environments like coating plants. They extend the life and reliability of your Programmable Logic Controller.

What industries benefit most from PLC with IoT?

Automotive, general manufacturing, and any industry embracing Industry 4.0-based controllers and smart factory setups.

#Autophoretic coating#Messung Industrial Automation#PLC automation#Programmable Logic Controller (PLC)#material handling controllers#motion control systems#NX-ERA JET PLC#HMI with PLC Controllers#advanced PLC automation#Modular PLC#Compact PLC#Smart PLC#Industrial PLCs#Smart PLCs#PLC-based automation solutions#PLC control systems#PLC automation solutions#IoT integration#industrial automation controllers#Industry 4.0-based controllers

0 notes

Text

Exploring the Innovations of Rabwellplc in the PLC Industry

The PLC industry is thriving with advancements, and Rabwellplc is at the forefront of this evolution. Their commitment to quality and innovation is truly inspiring. With products that integrate seamlessly into various automation systems, Rabwellplc is making a significant impact.

As we discuss the importance of reliable control systems, it's essential to highlight how Honeywell PLC products complement Rabwellplc's offerings. Together, they provide robust solutions that enhance operational efficiency and reliability.

What are your thoughts on the future of PLC technology and how brands like Rabwellplc and Honeywell PLC are shaping this landscape?

0 notes

Text

Liebherr PCB Card 925086914 0002555 0601004 | High-Quality Control PCB Board | Ram Automations

Enhance your machinery’s performance with the Liebherr PCB Card 925086914 0002555 0601004, available now at Ram Automations. This high-quality Printed Circuit Board (PCB) offers exceptional reliability, precision engineering, and durability for a wide range of industrial and marine applications.

Designed for maximum performance and efficiency, this Liebherr PCB Card ensures seamless integration with complex control systems, making it ideal for critical automation environments and high-demand applications.

🛒 Buy Now from Ram Automations 👉 https://ramautomations.com/products/pcb-card-925086914-0002555-0601004-liebherr-new

🌐 Explore 1000+ Genuine Automation Components 👉 https://ramautomations.com

🧩 Product Specifications

• 🔹 Brand: Liebherr • 🔹 Model: 925086914 / 0002555 / 0601004 • 🔹 Type: PCB Card • 🔹 Category: PCB Card / Industrial Electronics / Automation PCB • 🔹 Application: Industrial Automation, Marine Systems, Control Panels, Process Systems

✅ Key Features

✔️ Precision-engineered PCB for reliable performance ✔️ Seamless integration with industrial systems ✔️ High-quality materials and craftsmanship ✔️ Essential for complex machinery and automation units ✔️ Ideal for industrial, marine, and manufacturing environments

💡 Typical Applications

• Marine Electronic Control Systems • Industrial Automation Panels • SCADA and HMI System Boards • Heavy Equipment Automation • Process Automation Systems • Robotics Control Panels • Industrial Machinery Systems

🌟 Why Choose Ram Automations?

✅ 100% Genuine Products Only ✅ Best Prices with Worldwide Delivery ✅ Trusted Industrial Automation Supplier ✅ Large Inventory of Hard-to-Find Components

🛍️ Visit Us: https://ramautomations.com

In This Video You Will Discover:

🔎 Close-up View of Liebherr PCB Card 🔧 How It Integrates with Complex Systems 💡 Importance of High-Quality PCBs in Industrial Automation 🌐 Why Ram Automations is the Go-To Source for Industrial Parts

📣 Get Involved!

🔔 Subscribe for Automation & Electronics Updates 👍 Like to Show Support for Quality Electronics 💬 Comment Your Queries — We’re Happy to Help! 🛒 Visit our Online Store: https://ramautomations.com

#Liebherr PCB Card#PCB Card for Automation#Industrial PCB Card#Automation PCB Card#Marine Control PCB#Automation System Board#Ram Automations#Control Panel PCB Card#Process Control PCB#Marine Automation Electronics#Industrial Electronic PCB#Automation Equipment PCB Card#Marine Systems PCB Card#Factory Automation Parts#Robotics Control Panel Card#Data Transmission PCB Card#PLC Control PCB Card#High Quality PCB Card#SCADA System PCB Card#Electronic Connectivity PCB Board

1 note

·

View note

Text

Trend Iq221-400008 Controller Module Iq221/Unb/230V - Auto2mation

The Trend IQ221-400008 Controller Module IQ221/UNB/230V is a reliable and compact solution for smart building control systems. Designed to deliver efficient energy management, this module supports seamless integration with HVAC and other building automation applications. Its user-friendly setup makes installation and maintenance simple. Operating at 230V, it ensures stable performance and long-term durability. Ideal for commercial and industrial use, the IQ221 controller helps optimize energy usage while maintaining comfort. Trusted by professionals, it’s a smart choice for modern automation needs. Buy the Trend IQ221-400008 Controller Module now from Auto2mation – your trusted source for industrial automation products.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#equipment#automation equipment#industrial automation applications#Trend#Controller Module#plc system

0 notes

Text

Top Automation Engineers in Illinois | Innovating Industrial Solutions

Automation engineers are specialized professionals who design and implement systems that reduce human intervention in industrial processes. They blend knowledge from multiple fields—mechanical, electrical, software, and control engineering—to create intelligent systems that operate efficiently, reliably, and autonomously.

Their typical responsibilities include:

Designing automation systems from concept to installation

Programming PLCs (Programmable Logic Controllers) and HMIs (Human-Machine Interfaces)

Integrating robotics and motion control

Developing SCADA (Supervisory Control and Data Acquisition) systems

Testing and troubleshooting automated equipment

Ensuring safety and compliance with industrial standards

In Illinois, automation engineers are indispensable to manufacturing, logistics, food processing, energy, and life sciences.

Why Illinois Is a Powerhouse for Automation Engineering

Several key factors contribute to Illinois’s prominence in automation engineering:

1. Diverse Industrial Base: Illinois boasts industries ranging from automotive and agriculture to pharmaceuticals and aerospace. This diversity fuels consistent demand for custom automation solutions.

2. Strong Educational Ecosystem: Top-tier institutions like the University of Illinois, Northwestern University, and Southern Illinois University produce highly skilled engineers with expertise in robotics, AI, and industrial systems.

3. Strategic Location: Illinois's central location offers excellent logistics, making it a favored site for advanced manufacturing, warehousing, and distribution centers—all of which benefit from automation.

4. Innovation-Friendly Climate: The state supports innovation through tech incubators, grants, and public-private partnerships that empower engineers to develop and deploy cutting-edge automation solutions.

Key Services Offered by Automation Engineers in Illinois

Automation engineers in Illinois provide an extensive range of services tailored to the specific needs of businesses across the state. Common services include:

System Integration: Designing and installing complete automation solutions that synchronize machines, robots, and control systems.

PLC & HMI Programming: Writing and testing software that governs system behavior and interfaces.

Robotics Engineering: Installing and configuring robotic arms and automated material handling systems.

Industrial IoT Integration: Connecting machines to networks for real-time data exchange and monitoring.

Retrofitting & Upgrades: Enhancing legacy equipment with modern control technologies.

Safety System Design: Implementing fail-safes, emergency stops, and safety protocols in compliance with OSHA and ISO standards.

Whether working on a small assembly cell or a full-scale production line, Illinois automation engineers prioritize reliability, scalability, and efficiency.

Industries Benefiting from Automation Engineers in Illinois

The work of automation engineers touches nearly every corner of Illinois’s economy. Key sectors include:

Food and Beverage: Automating sorting, bottling, and packaging processes to ensure hygiene and speed.

Pharmaceuticals and Medical Devices: Ensuring precision, compliance, and traceability through automated filling, labeling, and inspection.

Automotive and Aerospace: Deploying robotic arms and motion systems for parts assembly and quality control.

Agriculture and Grain Processing: Integrating automation into storage, sorting, and packaging facilities.

Warehousing and Logistics: Developing conveyor systems, pick-and-place robots, and automated guided vehicles (AGVs).

Energy and Utilities: Implementing SCADA and remote control systems to manage plant operations.

By adopting automation, these industries reduce labor strain, improve accuracy, and increase throughput—critical in today’s competitive global marketplace.

The Future of Automation Engineering in Illinois

As we move further into the age of Industry 4.0, the role of automation engineers is evolving. Engineers in Illinois are not just builders of machines—they are architects of data-driven, intelligent systems. The future will include:

Edge Computing and AI: Allowing systems to make real-time decisions at the source.

Cloud-Connected Automation: Centralized data storage and analysis across multiple plants.

Predictive Maintenance: Using machine learning to anticipate equipment failures before they occur.

Digital Twins: Creating virtual replicas of physical systems for simulation and optimization.

Green Manufacturing: Designing systems that reduce energy use and support sustainability.

Illinois is well-positioned to remain at the forefront of this transformation, with a workforce ready to meet the challenges and opportunities ahead.

Choosing the Right Automation Engineer in Illinois

When selecting an automation engineer or firm, businesses should look for:

Experience Across Industries

Proficiency with Major Platforms (Allen-Bradley, Siemens, Beckhoff, etc.)

Commitment to Safety and Compliance

Strong Project Management and Communication Skills

Local Support and Maintenance Services

A collaborative approach ensures solutions that align with business goals, budget, and operational scale.

Your Automation Engineering Partner: Xtreme Automation LLC

If your Illinois-based business is ready to embrace the future of smart manufacturing, Xtreme Automation LLC is here to help. With decades of experience in automation design, PLC programming, robotics integration, and system retrofitting, Xtreme Automation provides comprehensive engineering solutions tailored to your industry. From planning and development to implementation and support, their team ensures your automation journey delivers real results. Learn more at xtremeautomationllc.com.

#Automation Engineers Illinois#Industrial Automation Services#Robotics Engineering Illinois#Control System Engineers IL#Automation Integration Companies#Smart Manufacturing Illinois#PLC and HMI Programming#Engineering Solutions Illinois#Industrial Robotics Experts#Factory Automation Consultants

0 notes

Text

Exploring Hitachi Industrial Automation Parts: Enhancing Efficiency and Performance

PLC World is an independent distributor of genuine, refurbished, and surplus. PLC Hardware in industrial automation and networking equipment. For more information Visit here:https://plcworld.com.au/

0 notes

Text

Maintenance Officer (Instrumentation) at Cotton Company of Zimbabwe - February 2025

The Cotton Company of Zimbabwe is seeking a qualified and experienced Maintenance Officer specializing in instrumentation to join their team. This role is crucial for ensuring the smooth operation of their ginning sites. About the Role: The Maintenance Officer will be responsible for the maintenance, repair, and calibration of instrumentation and control systems at the Cotton Company of…

View On WordPress

#Automation#Control Systems Jobs#Cottco#Cotton Company Zimbabwe#Electrical Engineering Jobs#Employment ZW#Engineering Careers#Engineering Jobs#Ginning#Harare Jobs#Hot Zimbabwe Jobs#Industrial Maintenance#Instrumentation Jobs#Instrumentation Technician#Job Opportunities ZW#Job Search ZW#Maintenance Jobs#Maintenance Technician#Manufacturing Jobs#PLC#Technician Jobs#Zim Jobs#Zimbabwe Careers#Zimbabwe Jobs

0 notes

Text

PID Control with PLCs: Implementing Closed-Loop Control Systems

In the rapidly evolving landscape of industrial automation, the ability to maintain precise control over processes is paramount. This is where PID (Proportional-Integral-Derivative) control integrated with PLCs (Programmable Logic Controllers) comes into play. PID controllers, when used with PLCs, form the backbone of many closed-loop control systems, ensuring stability, efficiency, and accuracy in various industrial applications.

At Balaji Switchgears, we specialize in delivering cutting-edge solutions that leverage the power of PLCs to optimize industrial operations. Let’s delve into how PID control works, its benefits, and its implementation in PLC industrial automation systems.

What is PID Control?

PID control is a widely used feedback mechanism in control systems that calculates the error between a desired setpoint and the actual process variable. This calculation allows adjustments to bring the process variable closer to the desired setpoint. PID control consists of three components:

Proportional (P): Addresses the present error.

Integral (I): Accounts for past errors to eliminate residual discrepancies.

Derivative (D): Predicts future errors based on the rate of change.

The combination of these three terms ensures that the system achieves optimal performance with minimal oscillation and steady-state error.

Why Use PLCs for PID Control in Industrial Automation?

PLCs are the heart of industrial automation, offering flexibility, reliability, and ease of integration. Integrating PID control within PLCs amplifies their effectiveness, allowing industries to achieve precise control over their processes.

Here’s why PLC-based PID control is preferred:

Scalability: PLCs can handle multiple PID loops, making them suitable for complex systems.

Customization: Advanced programming capabilities allow tailored control strategies.

Real-Time Processing: PLCs ensure immediate adjustments, reducing downtime.

Integration: Seamlessly works with other automation components like sensors and actuators.

Applications of PID Control in Industrial Automation

PID control with PLCs is utilized across a broad spectrum of industries:

Manufacturing: Maintaining optimal temperatures, pressures, or speeds in production lines.

Process Industries: Regulating flow rates, liquid levels, or chemical concentrations.

HVAC Systems: Ensuring consistent indoor climates in large facilities.

Energy Management: Controlling generators, turbines, and renewable energy systems.

At Balaji Switchgears, we supply state-of-the-art PLCs and components designed to implement robust PID control systems for these applications and more. read more......

0 notes

Text

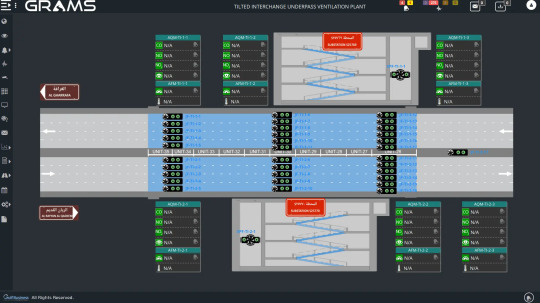

Top PLC & SCADA Automation Services in Qatar, Doha

Gulf Business ystems are all included in the value that our industrial automation systems business provides. Using industrial automation technologies about Top PLC & SCADA Automation in Doha effectively in projects involving DC systems and crises is another aspect of our industrial automation engineering capabilities.

We are one of the leading industrial automation firms in the GCC because to our experience and knowledge. We have successfully developed and implemented industrial automation systems in a variety of industries, each with its own set of demands and difficulties.

#Top PLC & SCADA Automation in Doha#Operation & Maintenance Services in Qatar#Access Control System Qatar#Building Security Qatar#Turnstile System Qatar#Road Surveys

0 notes

Text

How Industrial Automation Companies Enhance Production Efficiency?

The quest for production efficiency has never been more pressing in today's rapidly evolving industrial landscape. As industries face increasing global competition, rising labour costs, and ever-changing consumer demands, the role of industrial automation companies has become crucial.

These companies provide innovative solutions that streamline operations, reduce costs, and improve product quality. In this blog, we will explore how industrial automation companies enhance production efficiency and the technologies they employ to achieve these results.

Understanding Industrial Automation

Industrial automation involves using control systems - such as computers, robots, and machinery - to manage and monitor production processes with minimal human intervention. The benefits of automation extend across multiple sectors, including manufacturing, transportation, and utilities.

By employing automation, companies can increase productivity, improve product quality, and ensure consistency while significantly reducing human error.

Key Components of Industrial Automation

Industrial automation companies leverage various technologies to facilitate automation. These include:

Robotics: Robotic systems can perform repetitive tasks with high precision and speed, thus significantly reducing cycle times in production.

Control Systems: These systems manage machinery and processes, ensuring optimal performance and efficiency throughout the production line.

Sensors and Actuators: These components gather data and execute actions based on real-time feedback, optimising operations and improving decision-making.

Through these technologies, industrial automation companies design and implement solutions that enhance productivity and efficiency across various industries.

Enhancing Production Efficiency

1. Streamlining Processes

One primary way industrial automation companies enhance production efficiency is by streamlining processes. Traditional manufacturing methods often involve multiple steps that can be time-consuming and prone to human error.

Automation integrates these processes into a single, cohesive system, simplifying operations. For instance, an automated assembly line can handle everything from material handling to product assembly.

This integration reduces the need for manual labour, decreases lead times, and results in faster production cycles. Additionally, automated guided vehicles (AGVs) help transport materials within the facility, further enhancing workflow efficiency.

2. Reducing Operational Costs

Cost reduction is another significant benefit of automation. By minimising human intervention, companies can lower labour costs and decrease the likelihood of costly errors.

Industrial automation companies implement systems optimising resource usage, ensuring materials are utilised efficiently, and minimising waste.

Moreover, automated systems can operate continuously without breaks, leading to higher output levels. This continuous operation reduces production costs per unit, positively impacting the company’s bottom line.

For example, companies using automated palletising systems can achieve higher throughput without additional labor costs.

3. Improving Quality Control

Quality control is a critical aspect of manufacturing, and industrial automation companies enhance production efficiency by integrating sophisticated quality control measures directly into automated processes.

Automated systems can be equipped with sensors that detect defects in real-time, allowing for immediate corrective action. This immediate feedback ensures that only products meeting quality standards proceed through production.

Maintaining consistent quality can improve customer satisfaction and reduce return rates. For instance, a food processing plant using automated quality inspection systems can quickly identify contaminated products, ensuring that only safe items reach consumers.

4. Enhancing Flexibility and Scalability

Flexibility is essential in a dynamic market. Consumer demands can shift rapidly, and companies must adapt quickly to remain competitive.

Industrial automation companies provide solutions that enhance flexibility and scalability, allowing manufacturers to quickly reconfigure their production lines to accommodate new products or changes in demand.

For example, modular automation systems can be easily adjusted or expanded as needed. This adaptability helps companies respond swiftly to market fluctuations, minimising downtime and ensuring production meets customer requirements.

In industries such as consumer electronics, where product life cycles are short, the ability to rapidly adjust production capabilities is invaluable.

5. Utilising Data Analytics

Data analytics plays a vital role in optimising production efficiency. Industrial automation companies leverage advanced data analytics tools to collect and analyse data from automated systems. This data provides valuable insights into operational performance, enabling companies to identify areas for improvement.

Manufacturers can make informed decisions regarding equipment maintenance, production schedules, and resource allocation by analysing trends and patterns. For example, predictive maintenance techniques allow companies to anticipate equipment failures before they occur, reducing downtime and associated costs.

By integrating data analytics into their operations, companies can make proactive adjustments that enhance overall efficiency.

6. Enhancing Worker Safety

Automation improves efficiency and enhances worker safety. Many industrial processes involve hazardous conditions, exposing workers to potential dangers. By implementing automated systems, industrial automation companies can minimise the risk of accidents and injuries.

For instance, robots can be deployed in unsafe environments for human workers, performing tasks that would otherwise pose risks. This shift protects employees and improves overall productivity, as workers can focus on higher-value tasks that require human expertise.

In industries like manufacturing and warehousing, implementing automation significantly reduces the likelihood of workplace accidents.

7. Sustainability and Environmental Impact

Sustainability is increasingly becoming a priority for companies, and automation can significantly achieve environmentally friendly practices. Industrial automation companies help manufacturers reduce their environmental footprint by optimising energy usage and minimising waste.

For example, automated systems can monitor energy consumption in real-time, allowing companies to adjust operations to reduce energy waste. Additionally, by implementing smart manufacturing practices, companies can recycle materials more effectively and reduce overall waste, contributing to a more sustainable production model.

Case Studies: Success Stories in Industrial Automation

1. Automotive Manufacturing

The automotive industry is a prime example of industrial automation companies enhancing production efficiency. Companies like Ford and Toyota have successfully integrated robotics and automation into their production lines, significantly improving speed and quality.

Ford's use of automation in its assembly plants has allowed the company to achieve higher production rates while maintaining strict quality standards. By employing advanced robotics for tasks such as welding and painting, Ford has minimised manual labour while ensuring consistency and precision.

2. Food and Beverage Industry

In the food and beverage sector, automation enhances efficiency while ensuring safety and compliance with regulations. Industrial automation companies provide solutions that automate packaging, bottling, and quality control processes.

Coca-Cola, a notable example, has implemented automated systems to streamline its bottling operations. These systems allow for faster production while maintaining strict quality standards. This automation enables the company to respond quickly to changes in consumer demand, ensuring product availability when and where it is needed.

Future Trends in Industrial Automation

As technology continues to advance, the future of industrial automation looks promising. Emerging trends such as artificial intelligence (AI), machine learning, and the Internet of Things (IoT) are expected to further enhance industrial automation companies' capabilities.

1. Artificial Intelligence and Machine Learning

AI and machine learning technologies enable automated systems to learn from data and improve their performance over time. This capability can enhance predictive maintenance, quality control, and operational efficiency.

Companies can optimise their operations by integrating AI into automation processes based on real-time insights.

2. IoT Integration

The Internet of Things connects machines and devices, enabling seamless communication and data exchange. Industrial automation companies are increasingly adopting IoT technologies to enhance their monitoring and control capabilities.

This integration allows for real-time tracking of production processes, enabling companies to make data-driven decisions that improve efficiency.

Conclusion

Industrial automation companies play a vital role in enhancing production efficiency across various sectors. These companies are at the forefront of transforming the industrial landscape by streamlining processes, reducing costs, improving quality control, and enhancing worker safety.

As industries continue to face new challenges, the importance of automation will only grow. Businesses that partner with Plc Programming can gain a competitive edge, ensuring they remain relevant in a fast-paced market.

In a world where efficiency is paramount, embracing automation is not just a strategy for keeping up with competition; it is a fundamental shift in redefining what is possible in production efficiency.

Whether you are a manufacturer looking to boost operational capabilities or simply interested in the advancements in automation technology, industrial automation companies are clearly in charge of shaping the industry's future.

#Industrial Automation Companies#Plc Commissioning#Plc Programming#Industrial Automation#Industrial Control System

0 notes

Text

The Impact of IIoT on Modern Industrial Systems

The Industrial Internet of Things (IIoT) significantly improves efficiency and sustainability in modern industrial operations. It plays a crucial role in transforming modern automation systems. The (IIoT) is widely used and drives industrial operations, especially in heavy industries such as cement and steel, to be smarter, more optimized, and highly connected. The (IIoT) is also applied in renewable energy industries to enhance the operation of stand-alone solar power systems and solar/wind hybrid power systems to improve efficiency. Furthermore, IIoT ensures process optimization, reduces operational costs, and enhances workplace safety.

for more about IIoT check the following link:

for more technical articles check the following link:

https://www.ecaico.com

#automation#instrumentation#renewable resources#solar cells#solar panels#renewable#sensors#renewable energy#plc#controller#control#burners#controllers#control system#renewableenergy#renewable power#renewablefuture#semiconductor#pressure sensors#temperature sensor#iiot

0 notes

Text

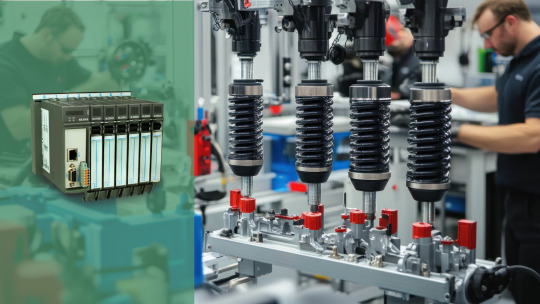

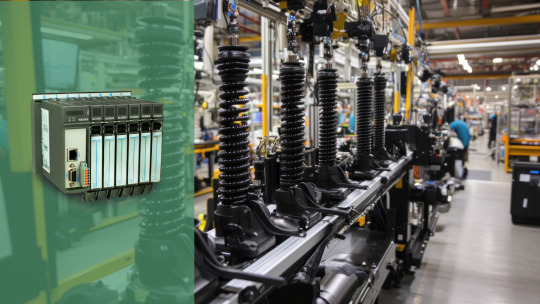

Precision Redefined – PLC-Controlled Shock Absorber Testing Machines

Precision – a word that keeps on getting thrown around often in the world of engineering. However, when it comes to shock absorber testing, precision isn’t a luxury—it’s survival. Every curve, every jolt, every rebound of a shock absorber must be captured, tested, and analysed to microscopic exactness. Gone are the days when manual testing could keep up.

The role of shock absorbers in today’s high-speed automotive innovation and precision engineering is to provide safety, comfort, and performance protection. But how can we make sure that these absorbers meet the high standards required by modern vehicles? This is where PLC automation becomes a useful tool.

The old-fashioned testing methods, which were cumbersome, unreliable, and laborious, have been replaced by PLC-based automation systems. Imagine a testing line with the capacity to think, adapt and respond in real time. The precision of Programmable Logic Controllers (PLCs) is not solely a promise, but rather adherence to standardised protocols.

How PLCs Enhance Shock Absorber Testing

There has been an evolution in the science of testing shock absorbers. Let’s understand how smart and compact PLCs can automate and optimise critical testing stages by providing consistency, control, and clarity.

Centralised Control with High Reliability

A robust industrial PLC is the foundation of our testing machines. The real-time control systems embedded in our automation design enable seamless functioning of all sensor, actuator, and motorised components.

Multiple sensors? Check.

Complex test sequences? Seamlessly handled.

From servo motion controllers managing high-speed vertical displacements to compact PLCs managing individual test stations, the formation is digital, deliberate, and dependable.

Real-Time Data Acquisition & Analysis

Here's where things get exciting. Tests on shock absorbers are more than just passing or failing. It's about quantifiable performance with our automation controllers:

Damping force curves

Displacement maps

Velocity and resistance profiles.

The data is gathered by high-resolution sensors and then processed through HMI with PLC controllers. The integration of this with databases is achieved through integrated PLC-based software, resulting in predictive maintenance and long-term performance insights

Feedback Loops for Adaptive Control

Ever wondered what would happen if the test differs? What would be the outcome? Well, with the use of real-time PLC communication protocols (like MODBUS and Ethernet/IP) and closed-loop control enable our systems to identify anomalies mid-test while enabling automatic correction.

Additionally, dynamic adjustment of actuator velocity in a system is possible when the response rate of the unit is slower than the tolerance. Or if temperatures spike? After a system shutdown, it sends an alert via the web server PLC and logs the fault. This requires more than just testing -- intelligent testing.

NX-ERA JET PLC System Architecture

Now let’s explore the engine room that fuels our innovation. The NX-ERA JET PLC, the foundation of our automated testing platform, undergoes a thorough architecture and connectivity analysis.

Core Hardware Components

With its compact size, modular design, and future scalability, the NX-ERA JET PLC is a formidable beast. It houses:

Simple servo systems designed for precise motion control

Energy-efficient motors can be powered by Variable Frequency Drives (VFDs)

HMI interfaces that enable the creation of visual dashboards and manual overrides

I/O modules for interfacing with third-party equipment.

Its modular design makes it suitable for both high-volume testing environments and small-batch production lines that use Micro PLCs or Mini PLCs

Communication & Connectivity

Connectivity should be a fundamental aspect of the entire setup, not an extra one.

Modbus PLC Interface is responsible for ensuring device-to-device communication

High-speed data relays are made possible with Ethernet-based controller systems

PLC with TCP/IP can be used for remote data logging and system control, as well as firmware updates

IoT-ready PLCs enable the integration of the testing machine with ERP, MES, and SCADA

Key Benefits of PLC-Controlled Testing Machines

Indeed, inefficient processes are not easily exploited in the fast-paced manufacturing industry. Your requirements include testing devices that don't blink even when pressured, systems that guarantee high quality, and technology that evolves as your business grows. Our PLC-based automation solutions are precisely in tune with that.

They offer:

Repeatability and Precision - One unit can be tested with ease and accuracy. But what about testing thousands with zero deviation? Our automation solutions that utilize PLCs accomplish this objective. You get:

Identical test cycles

Calibrated control parameters

Automated calibration routines

It implies improved quality control and enhanced audit accessibility.

High Throughput with Reliability - Traditional systems often require individuals to choose between speed and accuracy. Not here. The configurations of our NX-ERA JET PLC enable:

Sub-second test cycles

Parallel station control

Integrated logic and safety layers

All without compromising test integrity.

Reduced Manual Intervention - By utilizing HMI integration, and adaptive PLC programming, operators can not only monitor and but control:

Reduced human error

Faster changeovers

Safer work environment

Safety and Compliance – Safety is crucial for any industrial setup. With our smart PLCs, you can easily:

Emergency stop circuits

Real-time fault diagnostics

Layered safety logic

PLCs are designed to provide timely and effective alerts and shutdowns, complying with international standards such as ISO and CE.

Adaptable and Future-Ready - Different testing may be required for tomorrow's shock absorber. Good news: you won’t need a new machine.

Reprogram testing logic

Add new motion profiles

Update firmware via PLC with IoT

That’s the power of modular PLCs.

Whether you're chasing precision, throughput, or transformation, our PLC-controlled shock absorber testing machines deliver across the board. These benefits aren’t just technical specs—they’re business advantages, engineered to give you control, confidence, and a competitive edge.

Why Choose Messung’s Programmable Logic Controllers for Automation Solutions

Your choice of controller can determine your plant's success in a world propelled by data-driven decision-making, agility, and accuracy. We offer complete PLC-based automation solutions meant to grow with your demands rather than just supply PLCs. Our PLCs are not only intelligent but also necessary for the following reasons:

Smart and Connected PLCs - Our smart PLCs dynamically optimise by adjusting to handle changes. Embedded intelligence enables them to learn from repeated tests, predict component failures, and optimize actuator profiles automatically. Moreover, our edge-computing enabled PLCs help for quicker decisions by lowering cloud dependence.

HMI Integration for Better User Control - No more enigmatic command-line interfaces. With our smart PLCs, you get touchscreen HMIs, customised dashboards and real-time analytics displays.

Compact and Versatile PLC (Programmable Logic Controller) Options - Squeezed on space? You can get the complete power of a typical controller, without worrying about the size, with our compact PLC, micro PLC, and mini PLC range.

From intelligence that anticipates, to interfaces that simplify, to form factors that adapt—Messung’s PLC Programming range is designed not just to meet your automation goals, but to exceed them. Because when you choose Messung, you don’t just adopt automation; you embrace transformation.

Applications Beyond Shock Absorbers

Although shock absorber testing is where our PLC automation solutions show their power, that's just one section in our automation playbook. Beyond the same technology, fine-tuned for real-time control, precision, and adaptability, extends far. Messung's intelligent PLC solutions provide flexibility and value across a range of sectors, whether you are forming metal or transporting materials.

Let's explore how our PLC Control Systems have a range much outside the damping zone:

Motion Control Systems - Conveyor automation and actuator-driven systems all fall under our motion control solutions. Through synced servo motion controllers, we guarantee millisecond-level accuracy.

Machine Tool Controllers - Integrated with smart CNC tools, our machine tool controllers use feedback to adjust cutting speeds, minimise tool wear and even optimise material usage.

Advanced Automation – Through this end-to-end automation, sending raw material to finished parts, fully automated quality checks and centralized command via connected PLCs can easily become possible.

One shouldn't limit automation to just one purpose. Whether it is in high-speed assembly lines or precise machining at Messung, our PLC automation systems are flexible enough to meet the demands of many industries. Beyond shock absorbers, our solutions usher in intelligent manufacturing possibilities one motion at a time.

Conclusion

Accuracy is a standard, not only a specification. If you are still using obsolete testing configurations, it's time to change course. Designed to bring not just performance but also purpose to your production floor, Messung's PLC-controlled shock absorber testing equipment helps you to achieve this.

Testing has to be quick, adaptable, and flawless, whether you are creating luxury cars or robust trucks. That is precisely what Messung's PLC control systems promise—and deliver.

We do not just automate; we elevate, from servo-tight control to smart data acquisition, from seamless integration to Industry 4.0-based controllers.

At Messung, accuracy is not just redefined. It has changed everything. Hence, go for it. Redefine accuracy. One test at a time!

FAQs

What makes Messung’s PLC Control Systems ideal for shock absorber testing?

Messung’s PLCs (Programmable Logic Controller) offer centralised control, real-time data capture, adaptive feedback loops, and ensure peak accuracy and speed.

Can Messung’s PLC Programming integrate with existing equipment?

Yes. With protocols like MODBUS, TCP/IP, and Ethernet-based controllers, our PLCs are designed for easy retrofitting and compatibility.

How do PLC Control Systems improve the testing process?

PLCs provide real-time emergency stop functionality, error detection, and ensure the equipment runs within safe operational parameters.

Do you offer remote access features?

Absolutely. With web server PLC (Programmable Logic Controller) capabilities and HMI with PLC controllers, you can monitor and manage testing remotely.

Is your PLC solution scalable?

Yes. With modular PLCs and IoT-ready systems, you can scale your setup to match your growth.

#PLC control systems#Programmable Logic Controllers (PLC).#Messung Industrial Automation#PLC automation systems#Smart PLC control#PLC-based AHU control system#modular PLC#Energy management systems#IEC 61131 based PLCs#compact PLC#IEC 61131-3 standard PLC Control Systems#MODBUS RTU#Modbus TCP#NX-ERA JET#PLC for energy systems#IEC 61131-3 compliant PLCs#modular PLCs#HMI with PLC controller#smart automation systems#programmable logic controller#smart PLCs#Modular PLCs

0 notes

Text

"The Crucial Role of Industrial Control Integrators: Driving Efficiency and Innovation in Modern Industry"

The Essential Role of an Industrial Control Integrator in Modern Industry

In today’s fast-paced industrial environment, the expertise of an Industrial Control Integrator has become indispensable. These professionals or companies specialize in designing, implementing, and maintaining complex control systems that are critical for optimizing industrial processes. This blog delves into the pivotal role of an Industrial Control Integrator, explaining their key responsibilities and the impact they have on industrial efficiency.

What is an Industrial Control Integrator?

An Industrial Control Integrator is a specialized expert or firm responsible for creating and managing control systems that automate and regulate industrial machinery and processes. These control systems encompass both hardware and software components, which work together to enhance performance, increase reliability, and streamline operations.

Core Responsibilities of an Industrial Control Integrator

Control System Design and Engineering:

Needs Analysis: The integrator begins with a comprehensive assessment of the client’s specific requirements. This involves understanding their industrial processes and defining the desired outcomes.

Custom System Design: Based on the assessment, the integrator designs a bespoke control system, selecting the appropriate sensors, controllers, and communication protocols to meet the client’s needs.

Integration and Installation:

Hardware Setup: The integrator manages the installation of essential components such as Programmable Logic Controllers (PLCs), Human-Machine Interfaces (HMIs), and other field instruments.

Software Configuration: They also configure the software that governs the control system, ensuring seamless communication between hardware and other operational systems.

Testing and Commissioning:

System Testing: Before full deployment, the integrator conducts rigorous testing to identify and rectify any issues, simulating real-world conditions to verify system performance.

Commissioning: Once testing is complete, the integrator supervises the final commissioning process, making any necessary adjustments to ensure optimal functionality.

Training and Ongoing Support:

Staff Training: Integrators provide training for the client’s personnel, equipping them with the knowledge to operate and maintain the new system effectively.

Continued Support: They offer ongoing maintenance and support services to resolve any issues and ensure the system continues to operate smoothly.

Why Industrial Control Integrators are Vital

Boosting Efficiency:

Industrial Control Integrators streamline processes by automating operations, which reduces manual input and enhances precision. This leads to improved productivity and reduced operational costs.

Enhancing Safety:

Integrators implement advanced control systems that monitor conditions in real time, increasing workplace safety by triggering alarms or shutdowns when necessary.

Ensuring Reliability:

By designing systems with redundancy and fail-safes, integrators help minimize downtime, which is crucial for meeting production targets and maintaining product quality.

Facilitating Scalability:

As businesses expand, their control systems must adapt. Integrators create flexible solutions that can be easily scaled or upgraded to meet growing demands.

Incorporating Emerging Technologies:

With the rise of Industry 4.0, integrating new technologies such as the Internet of Things (IoT), advanced analytics, and Artificial Intelligence (AI) is becoming increasingly important. Control integrators are key to incorporating these innovations into existing systems.

The Future of Industrial Control Integration

The field of industrial control integration is continuously evolving, driven by technological advancements and shifting industry needs. Future trends include:

AI and Machine Learning Integration: Enhancing predictive maintenance and process optimization.

IoT Integration: Enabling more detailed data collection and real-time analytics.

Enhanced Cybersecurity: Addressing the increasing need for robust security measures to protect industrial control systems from cyber threats.

Conclusion

Industrial Control Integrators are essential in ensuring the efficiency, reliability, and safety of modern industrial processes. Their expertise in designing, implementing, and maintaining control systems is crucial for optimizing operations and keeping pace with technological advancements. For businesses looking to upgrade or implement control systems, partnering with a skilled Industrial Control Integrator can be the key to achieving greater efficiency and performance.

#Industrial Control Integrator#Industrial Automation#Control Systems Engineering#Programmable Logic Controllers (PLCs)#Human-Machine Interfaces (HMIs)#Industrial Process Optimization#Automation Solutions#System Integration#Industrial Efficiency#Operational Reliability#Advanced Control Systems#Industry 4.0#Internet of Things (IoT)#Artificial Intelligence (AI) in Industry#Predictive Maintenance#Industrial Cybersecurity#Control System Design#Industrial Technology Trends#Engineering and Integration Services#Manufacturing Automation

0 notes

Text

Transforming Industries: Navigating the Future with Factory Automation in Toronto by Margor Automation

In the bustling metropolis of Toronto, where industries are the lifeblood of the economy, the paradigm shift towards greater efficiency and innovation is evident. At the forefront of this transformation is Margor Automation, a pioneer in Factory Automation solutions that are reshaping the landscape of industrial processes. In this blog, we explore the dynamic world of Factory Automation in Toronto and how Margor Automation is playing a pivotal role in this evolutionary journey.

The Essence of Factory Automation:

Factory Automation is more than a technological advancement; it's a revolution in how industries operate. It involves the integration of smart technologies, robotics, and control systems to streamline processes, enhance efficiency, and ultimately, boost productivity. In Toronto, where diverse industries thrive, Factory Automation becomes the catalyst for progress, offering solutions that range from production line optimization to data-driven decision-making.

Margor Automation's Impact:

Margor Automation stands as a beacon of innovation in the realm of Factory Automation in Toronto. Our commitment to delivering cutting-edge solutions has positioned us as a trusted partner for industries seeking to embrace the transformative power of automation. Here's how Margor Automation is making a significant impact:

Tailored Solutions: Recognizing that each industry has unique needs, Margor Automation provides customized Factory Automation solutions. From designing efficient production workflows to implementing robotic systems, our solutions are crafted to address specific challenges and goals.

Integration of Smart Technologies: In the era of Industry 4.0, the integration of smart technologies is paramount. Margor Automation leverages the latest advancements in sensors, IoT (Internet of Things), and data analytics to create interconnected systems that optimize operations, reduce downtime, and enhance overall efficiency.

Robotics for Precision: Robotics plays a pivotal role in modern Factory Automation, and Margor Automation specializes in the integration of robotic systems. Whether it's automated material handling, precision assembly, or robotic inspection, our solutions empower industries in Toronto to achieve levels of accuracy and speed that were once thought unattainable.

Energy-Efficient Solutions: Sustainability is a key focus in today's industrial landscape. Margor Automation designs Factory Automation solutions with a keen eye on energy efficiency. This not only reduces operational costs but also aligns businesses with environmentally conscious practices.

The Advantages of Factory Automation in Toronto:

Enhanced Productivity: By automating repetitive and time-consuming tasks, Factory Automation significantly boosts productivity. Industries in Toronto can achieve higher output levels without compromising on quality.

Reduced Operational Costs: Automation streamlines processes, leading to a reduction in labor costs, operational errors, and downtime. Margor Automation's solutions are designed to optimize efficiency and minimize unnecessary expenditures.

Improved Quality Control: Automated systems ensure consistent quality control, reducing the likelihood of errors in manufacturing processes. This is particularly crucial for industries in Toronto where high-quality products are paramount.

Adaptability to Market Changes: Toronto's dynamic industries often face rapid changes in market demands. Factory Automation provides the agility needed to adapt swiftly to these changes, ensuring businesses remain competitive and responsive.

In the vibrant tapestry of Toronto's industries, Factory Automation emerges as a transformative force, and Margor Automation stands as a driving force behind this evolution. By embracing innovative technologies and tailoring solutions to the specific needs of diverse industries, Margor Automation is paving the way for a future where efficiency, sustainability, and precision define the industrial landscape. Explore the possibilities of Factory Automation with https://margorautomation.com and embark on a journey towards a more streamlined, intelligent, and resilient industrial future.

#Allen Bradley PLC Toronto#robotics service Toronto#Factory Automation Toronto#Industrial Control Systems Toronto

0 notes