#Programmable logic controller

Explore tagged Tumblr posts

Text

AHU PLC BASED CONTROL SYSTEM I AHU controllers i NX-ERA JET PLC

#AHU CONTROLLER#AHU PLC CONTROLLER SYSTEM#NX-ERA JET PLC#COMPACT PLC#MICRO PLC#IEC 61131-3 standards PLC#MODULAR PLC#PLC control systems#programmable logic controller#Messung’s PLC-based AHU systems#NX-ERA JET#PLC#industrial automation#plc controller#plc automation#industry 4.0#messung plc

0 notes

Text

Programmable Logic Controller Market Anticipated to Grow Owing to Automation Demand

The Global Programmable Logic Controller Market is estimated to be valued at USD 12.40 Bn in 2025 and is expected to exhibit a CAGR of 4.3% over the forecast period 2025 to 2032. Programmable logic controllers (PLCs) represent a critical segment of industrial automation technology, designed to monitor inputs, make logic-based decisions, and control outputs in real time. Functioning as ruggedized computers, PLCs offer unparalleled reliability, scalability, and flexibility across manufacturing, automotive, food & beverage, and oil & gas sectors. In the context of Industry 4.0, where digitalization and connectivity drive operational excellence, Programmable Logic Controller Market Insights serve as the foundational element for implementing smart factories, predictive maintenance practices, and energy management systems. By providing advanced diagnostics, traceability, and easy programming through ladder logic or structured text, these controllers reduce downtime, lower maintenance costs, and enhance business growth by boosting overall equipment effectiveness.

Get more insights on,Programmable Logic Controller Market

#Coherent Market Insights#Programmable Logic Controller#Programmable Logic Controller Market#Programmable Logic Controller Market Insights#Ladder Logic

0 notes

Text

A Programmable Logic Controller (PLC) is a specialized computer engineered to manage machines and processes in industrial settings. Designed to endure harsh environments, PLCs feature rugged constructions resistant to dust, moisture, and extreme temperatures. They streamline complex control tasks by monitoring inputs and controlling outputs, making them ideal for managing production lines and overseeing intricate operations in real time.

0 notes

Text

Power SCADA: Understanding SCADA Systems and Their Importance in the Modern Power Grid

What Are SCADA Systems? Supervisory control and data acquisition (SCADA) systems are specialized computer systems that monitor and control industrial, infrastructure, or facility-based processes. In the power industry, SCADA systems provide centralized monitoring and control of electrical networks and infrastructure from a control center. They collect real-time data from remote equipment like power generators, transmission lines, substations, and distribution lines. This data is then analyzed and used to detect or respond to issues like power outages or emergencies. SCADA systems use programmable logic controllers (PLCs) or remote terminal units (RTUs) located at remote sites to interface with electrical equipment and sensors gathering data on things like voltage, power load, equipment status, and environmental conditions. The gathered information is transmitted back to a centralized control center via a communication infrastructure, typically through networks, telephone lines, microwave, satellite, or dual radio. At the control center, operators can supervise and control field equipment using SCADA interface applications on networked computers or workstations. Some key functions performed include switching equipment like circuit breakers, monitoring generation levels, load balancing across grids, and issuing control commands in emergency situations. How SCADA Improves Grid Operations and Reliability The use of Power SCADA systems has provided numerous benefits to utility companies and power system operations. Real-time monitoring of networks from a central location allows operators to rapidly detect and diagnose issues affecting service. Quick recognition of faults or overloads helps reduce the impact of outages by pinpointing problem areas for faster restoration of service. SCADA also facilitates centralized remote operation of grid infrastructure like switching substations online or offline to route power. This improves flexibility to reroute power in emergencies or maintenance scenarios. The data collection abilities of SCADA are invaluable for transmission scheduling, load forecasting, and power market operations. Meter readings, generation levels and load profiles give operators insights into network capacity and electricity demand patterns. They can do optimal power dispatch to generation units based on economics. Remote access also enables power utilities to defer capital costs by upgrading aging infrastructure over time instead of all at once. Expandable SCADA systems support integrating renewable energy sources into grids by balancing variable energy inputs. Overall, its capabilities have significantly enhanced power system reliability, efficiency, safety and resilience against disruptions. Cybersecurity Challenges for SCADA in Power Infrastructure While SCADA systems have provided clear benefits, their introduction has coincided with new cybersecurity risks that utilities must address. The networked nature of SCADA and its integration into business systems exposes it to both internal and external threats. Remote access ports into control centers pose attack surfaces if not properly secured. Commonly exploited vulnerabilities include weak authentication, lack of access controls, and failure to update aging SCADA protocols no longer receiving security patches. Get more insights on Power SCADA Market

Unlock More Insights—Explore the Report in the Language You Prefer

French

German

Italian

Russian

Japanese

Chinese

Korean

Portuguese

Alice Mutum is a seasoned senior content editor at Coherent Market Insights, leveraging extensive expertise gained from her previous role as a content writer. With seven years in content development, Alice masterfully employs SEO best practices and cutting-edge digital marketing strategies to craft high-ranking, impactful content. As an editor, she meticulously ensures flawless grammar and punctuation, precise data accuracy, and perfect alignment with audience needs in every research report. Alice's dedication to excellence and her strategic approach to content make her an invaluable asset in the world of market insights.

(LinkedIn: www.linkedin.com/in/alice-mutum-3b247b137 )

#Power SCADA Market#Power SCADA#Master Terminal Unit#Remote Terminal Unit#Human Machine Interface#Programmable Logic Controller#Communication System#Cyber Threats

1 note

·

View note

Text

#electricians#commercial electrician#industrial electrician#commercial building#programmable logic controller#electrical#electrician#melbourne#electrical company#controllers

0 notes

Text

A Programmable Logic Controller (PLC) is a versatile device used to monitor input signals and make decisions based on programmed logic to control various outputs to automate machines and processes. PLCs are designed to provide reliable and efficient control in various applications, from residential and commercial settings to industrial environments.

0 notes

Text

Programmable Logic Controller Market Set to Hit US$ 17.2 Bn with Strong Demand from Smart Industries

The global programmable logic controller (PLC) market, valued at US$ 11.6 Bn in 2022, is forecast to grow at a CAGR of 4.7% between 2023 and 2031, reaching a market value of US$ 17.2 Bn by the end of 2031, according to the latest industry insights. This growth is propelled by a surge in demand for industrial automation, smart manufacturing, and increased integration of the Industrial Internet of Things (IIoT).

Market Overview: A programmable logic controller (PLC) is a digital computer used to automate electromechanical processes, particularly in manufacturing environments. These devices are integral to the efficient operation of assembly lines, robotic devices, and any activity requiring high-reliability control and ease of programming. With increasing adoption across automotive, food & beverage, chemical, energy & utility, and construction industries, the global PLC market continues to expand in scope and application.

Market Drivers & Trends

The rising trend of smart factories and Industry 4.0 is among the most significant growth drivers. Manufacturers are increasingly adopting automation to reduce operational costs, improve productivity, and enhance precision. PLCs play a critical role in this transformation by allowing control over complex industrial processes with minimal human intervention.

Additionally, the growing need for data-driven decision-making, along with advancements in machine learning and artificial intelligence, is leading to deeper integration of PLCs in industrial settings. As automation becomes central to production and operational strategies, the demand for PLCs is expected to surge further.

Latest Market Trends

One of the most notable trends is the shift toward modular PLCs, which accounted for over 68.2% of the market share in 2022. These PLCs are gaining popularity due to their scalability and suitability for large-scale, complex automation tasks. Modular systems offer higher flexibility, can handle thousands of inputs/outputs, and support multitasking environments—making them ideal for high-volume manufacturing operations.

Another trend is the miniaturization of PLCs, which supports their deployment in compact systems and small machinery, especially in consumer electronics and smaller automated units.

Key Players and Industry Leaders

The competitive landscape is fragmented yet dominated by global industrial automation giants. Leading companies in the PLC market include:

Siemens

Rockwell Automation

Mitsubishi Electric Corporation

Schneider Electric

OMRON Corporation

ABB

Panasonic Corporation

Bosch Rexroth Corporation

Delta Electronics, Inc.

Honeywell International Inc.

These companies continue to drive innovation through strategic partnerships, R&D investments, and product expansions to enhance their market share and global footprint.

Recent Developments

Crouzet, in December 2022, launched Millennium Slim, the slimmest PLC in the world, tailored for compact industrial applications.

In July 2022, OMRON Corporation introduced the CP2E Micro PLC, designed for smaller devices and capable of data collection and machine-to-machine communication. This supports low-cost automation solutions for small- and mid-sized enterprises.

Electronics Corporation of India Limited (ECIL) released its own PLC and SCADA software in May 2022, targeting industrial control applications in Indian manufacturing ecosystems.

These product introductions underline the market’s commitment to technological advancement and responsiveness to evolving industrial demands.

Market Opportunities

The expansion of material handling systems, especially in e-commerce logistics, warehousing, and food processing industries, presents substantial growth potential for PLC integration. In material handling, PLCs streamline storage, movement, and tracking—drastically improving throughput and inventory management.

Additionally, the increasing popularity of energy-efficient manufacturing and sustainability initiatives provides ample opportunity for advanced PLC systems that help monitor and reduce energy consumption across production lines.

Gain a preview of important insights from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=32672

Future Outlook

The future of the programmable logic controller market lies in enhanced interoperability, cloud integration, and edge computing. With greater reliance on smart infrastructure and connected devices, PLCs are expected to evolve into more intelligent, connected controllers.

The incorporation of AI-powered PLCs is expected to revolutionize industrial automation by enabling predictive maintenance, self-diagnosis, and adaptive process control. As PLCs continue to advance, their use will extend beyond industrial sectors into smart cities, transportation systems, and building automation.

Market Segmentation

By Offering:

Hardware: CPU, I/O Modules, Power Supply, Memory System

Software

Services

By Type:

Compact PLC

Modular PLC

Nano, Micro, Small, Medium, and Large PLCs

By Application:

Material Handling

Packaging & Labeling

Process Control

Safety Monitoring

Energy Management

Home & Building Automation

Industrial Equipment Control

By End-use Industry:

Automotive

Energy & Utilities

Food & Beverage

Pharmaceuticals

Construction

Oil & Gas

Semiconductors & Electronics

Regional Insights

Asia Pacific held the largest market share of 36.3% in 2022, led by strong industrial growth in China, Japan, South Korea, and India. The increasing demand for smart manufacturing systems and compact automation solutions in the region is expected to maintain its dominance through 2031.

North America, with a market share of 26.4% in 2022, continues to grow due to early adoption of factory automation and significant investment in smart infrastructure in the U.S. and Canada.

Europe remains a hub for automation technology innovation, with countries like Germany, the U.K., and France focusing on Industry 4.0 implementation across automotive and manufacturing sectors.

Why Buy This Report?

This comprehensive report offers:

Detailed market size, forecast, and growth rate

In-depth competitive landscape and company profiling

Analysis of key market drivers, trends, and opportunities

Region-wise breakdown for strategic decision-making

Porter’s Five Forces, value chain, and trend analysis

Insights into technological developments and their impact

Market segmentation for customized investment strategies

With expert analysis and forward-looking insights, this report serves as a valuable resource for stakeholders, investors, industrial engineers, and policymakers seeking to navigate and capitalize on the fast-evolving programmable logic controller market.

Explore Latest Research Reports by Transparency Market Research: 5G Smart Antenna Market: https://www.transparencymarketresearch.com/5g-smart-antenna-market.html

Solid State Transformer Market: https://www.transparencymarketresearch.com/solid-State-transformer.html

Interactive Display Market: https://www.transparencymarketresearch.com/interactive-display-market.html

GaN Epitaxial Wafers Market: https://www.transparencymarketresearch.com/gan-epitaxial-wafers-market.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

Remote Monitoring with PLC Panels: Managing Your Plant from Anywhere

Introduction

In today’s fast-moving industrial world, being physically present on the shop floor every hour of the day is neither practical nor necessary. Thanks to modern PLC Panels, plant managers and engineers can now monitor and control their operations from virtually anywhere.

This is where remote monitoring comes in—a game-changing feature that turns your PLC Panel into a smart control center for your entire plant.

What is Remote Monitoring in PLC Panels?

Remote monitoring allows real-time access to your PLC Panel’s data through cloud-based platforms or networked software systems. It enables you to:

View machine status live

Monitor performance metrics

Receive alerts and diagnostics

Control start/stop operations remotely

Whether you’re at another site, at home, or travelling, you can manage your plant operations with just a laptop or smartphone.

Benefits of Remote Monitoring with PLC Panels

Real-Time Oversight Instantly check the status of equipment and production without being on-site.

Faster Problem Resolution Receive immediate alerts for faults, so downtime can be minimized.

Cost Savings Reduce the need for constant physical supervision and travel between sites.

Improved Decision-Making Access to live data helps you make informed decisions quickly.

Enhanced Safety Monitor high-risk processes remotely, minimizing exposure for workers.

Ready to take control from anywhere? Partner with a reliable PLC Panel Manufacturer to implement secure, remote-ready automation systems.

Key Features to Look For in Remote-Ready PLC Panels

Ethernet and Wi-Fi Connectivity Enables seamless data transfer between your PLC and remote devices.

Cloud Integration Support Compatible with platforms like MQTT, OPC UA, or custom dashboards.

Secure Access Protocols SSL encryption, VPN access, and password protection keep your system safe.

User-Friendly Interfaces Easy-to-use mobile or web apps that show real-time visualizations.

SCADA or HMI Compatibility Gives a centralized view with alarms, trends, and historical data logs.

Industries That Benefit the Most

Water Treatment Plants – Monitor pumps, levels, and chemical dosing remotely

Renewable Energy Farms – Supervise solar or wind operations from central control

Cold Storage Units – Keep track of temperature and humidity offsite

Manufacturing Units – Detect faults or delays without halting production

Agricultural Automation – Manage irrigation or feeding schedules remotely

How to Get Started

Collaborate with an experienced Programmable Logic Controller Panel Manufacturer who can:

Customize the panel with remote access modules

Integrate your system with cloud services

Train your team to monitor and control remotely

Ensure top-level cybersecurity protocols are in place

Conclusion

Remote monitoring with PLC Panels is no longer a luxury—it’s a necessity in a digital-first industrial world. It saves time, boosts productivity, and enhances control like never before. To enable this, choose a PLC Panel Manufacturer that delivers smart, secure, and remote-ready solutions tailored to your industry.

Control your plant from anywhere—talk to a trusted PLC Panel Manufacturer and upgrade your operations today.

Also read:

PLC Panels vs. SCADA Systems: Understanding Their Roles and Differences

Why PLC Panels Are a Must-Have for Small and Medium Enterprises (SMEs)

Retrofitting Old Machinery with Modern PLC Panels

Using PLC Panels in HVAC Automation for Commercial Buildings

#plc electrical panel#plc#electrical panel#plc panel#Programmable Logic Controller Panel Manufacturer#PLC Panel Manufacturer

0 notes

Text

How Siemens Programmable Logic Controllers Improve Industrial Efficiency

In the current fast-paced industrial setting, automation is a necessity to increase productivity, efficiency, and precision. The Siemens Programmable Logic Controller (PLC) stands at the forefront of modern automation; it brought a paradigm shift in control systems in industries. Due to its reliability, flexibility, and performance, the Siemens PLC is the most preferred choice by manufacturers, engineers, and system integrators in the world.

What then is a Siemens Programmable Logic Controller?

A Siemens Programmable Logic Controller is a capable digital computer that is used to control machinery, processes, and equipment in industrial applications. It would receive inputs from sensors or user devices, consider those inputs under programmed logic, and create outputs that would appropriately control the processes or operations of machines and systems.

Siemens supplies a wide range of PLCs to suit the needs of various industries, ranging from compact ones for small applications to powerful modular systems for maximum control of automation. Considered to be popular are the SIMATIC S7-1200, S7-1500, and S7-300 series. Offered by these controllers is high-speed processing, built-in communication features, and compatibility of seamless scaling.

Also read, The Impact of Siemens PLC on Mining and Heavy Equipment

Reasons for Choosing a Siemens PLC

Siemens PLC is preferred in automation control owing to several factors:

Reliability: For 24-hour uptime in demanding industrial conditions.

Flexibility: It is configured and adapted with ease according to industries and processes.

Advanced Communication: Interface without any hindrance with the field devices, HMIs, SCADA systems, and cloud platforms.

Scalability: One can start small and grow as much as needed, without having to change the essence of the platform.

Integrated Safety: There are models that have been integrated with safety functions for the safe operation of the machinery.

Such features give Siemens PLC a future-ready status that also creates possibilities in manufacturing, water treatment, power generation, automotive, packaging, and related industries.

Siemens Controller vs. Siemens PLC

Many people tend to use Siemens controller and Siemens PLC interchangeably and, therefore, it is important to know the difference. Siemens controller is a broad term that includes PLCs, PC-based controllers, and distributed controllers, whereas Siemens PLC is a Programmable Logic Controller widely used in automation processes.

If you are setting up small-scale plants or running the setup of a big industrial plant, optimum performance and long-term success will ensue from the right choice of Siemens controller-especially Siemens PLC.

Learn more, Siemens PLC: Benefits of Using it in Industrial Automation

Application of Siemens PLC in Industries

The versatility of Siemens programmable logic controllers allows them to be applied to many applications:

Automated Assembly Lines

Process Control Systems

HVAC Control

Material Handling

Packaging Automation

Building Management Systems

By having a Siemens PLC, one can automate a series of repetitive tasks that can lead to errors, thereby enhancing productivity.

Conclusion: Partner with Naksh Technology Solutions LLP

If one looks forward to implementing a Siemens Programmable Logic Controller for their automation needs, it is crucial to associate with a trusted and experienced supplier. Naksh Technology Solutions LLP is a foremost supplier of Siemens automation products providing expert consultation, product support, and on-time delivery from an array of industries.

With vast knowledge of Siemens controllers and an exhaustive range of Siemens PLCs, Naksh Technology Solutions LLP is the best fit to attain industrial automation excellence.

0 notes

Text

Automation Programming in Edwardsville, Illinois | Smarter Industrial Control

Automation programming involves developing the software and logic that controls machines, equipment, and production lines. It’s the “brain” behind any automated system, enabling precise, repeatable, and adaptable actions without constant human intervention.

Key components include:

PLC Programming: Writing logic-based code to control equipment such as motors, sensors, and actuators.

HMI Design: Developing visual interfaces that operators use to monitor and interact with automated systems.

SCADA Integration: Supervisory control systems that collect and analyze data from across an entire facility.

Custom Automation Scripts: Logic tailored to unique processes and workflows.

In Edwardsville, automation programming is essential for companies that want to minimize downtime, improve product quality, and remain competitive.

Why Automation Programming Matters for Edwardsville

With its strong economic base and proximity to major markets like St. Louis, Edwardsville is home to a growing number of industrial operations. Whether it's a mid-sized packaging firm or a large-scale manufacturer, local businesses face increasing pressure to improve efficiency and throughput. That’s where automation programming comes in.

1. Operational Efficiency: Well-programmed systems eliminate manual tasks, speed up production, and reduce the likelihood of human error.

2. Quality Control: Automation ensures consistency across batches, helping companies meet strict quality standards.

3. Cost Savings: By reducing labor costs and minimizing material waste, automation delivers a strong return on investment.

4. Data Utilization: Modern systems provide actionable data insights, allowing operators and managers to make smarter decisions in real-time.

In Edwardsville, this translates into better-performing factories, safer work environments, and increased economic resilience.

Core Services Provided by Automation Programmers

Local automation programming companies in Edwardsville offer a range of services to support manufacturers across sectors. These include:

Custom PLC Programming: Tailored logic to manage specific machines or entire production lines.

HMI Interface Development: Easy-to-use control panels that display system data and allow for quick troubleshooting.

SCADA System Setup: Centralized control systems that integrate data from multiple sources.

Retrofit and Upgrade Services: Modernizing older machines with new control logic and communication protocols.

Process Optimization: Using analytics and automation logic to fine-tune production flow.

These services ensure systems operate at peak performance, even in complex, multi-stage production environments.

Industries in Edwardsville Benefiting from Automation Programming

Automation programming is not limited to one field. It plays a critical role across many Edwardsville industries:

Food & Beverage: Automating mixing, filling, and packaging for hygiene and speed.

Warehousing & Logistics: Conveyor control and sorting systems that reduce shipping delays.

Pharmaceuticals: Precision dosing and environmental controls for product safety.

Automotive Components: Robotic assembly coordination and inspection programming.

Metal Fabrication: CNC machine integration and real-time production monitoring.

These industries depend on accurate, flexible programming to respond to market demands while maintaining operational control.

Tools and Platforms Used in Edwardsville

Automation programming professionals in Edwardsville are proficient in a wide range of technologies and platforms, including:

Allen-Bradley / Rockwell Automation

Siemens TIA Portal

Mitsubishi PLCs

Omron and ABB Systems

Ignition SCADA

Wonderware (AVEVA)

Beckhoff TwinCAT

These platforms offer robust tools for machine control, process visualization, and data management—all essential for high-performance automation systems.

Workforce Training and Local Support

Edwardsville benefits from strong academic institutions like Southern Illinois University Edwardsville (SIUE), which offers programs in engineering, computer science, and industrial technology. These institutions help build a local talent pipeline of engineers and programmers equipped to design and maintain next-generation automation systems.

Additionally, ongoing partnerships between automation companies and local manufacturers ensure that workforce development aligns with real-world needs. On-the-job training and technical certifications are increasingly available to support career growth in automation programming.

Looking Ahead: Smarter Factories on the Horizon

With the rise of Industry 4.0, the future of manufacturing in Edwardsville is smart, connected, and data-driven. Automation programming is a key enabler of this future. Companies are beginning to adopt:

Remote Monitoring and Control

Cloud-Based Data Storage and Analytics

AI-Enhanced Predictive Maintenance

Digital Twin Simulations

These technologies offer unprecedented visibility and flexibility, allowing businesses to operate more efficiently and react quickly to changes in demand or supply chain conditions.

Your Edwardsville Automation Partner: Xtreme Automation LLC

If you're seeking professional automation programming services in Edwardsville, turn to the experts at Xtreme Automation LLC. With deep experience in PLC programming, HMI development, SCADA integration, and smart system upgrades, Xtreme Automation delivers tailored solutions that boost performance and cut downtime. Whether you're building a new line or upgrading legacy systems, their team ensures seamless automation from design to deployment. Learn more at xtremeautomationllc.com.

#Automation Programming Edwardsville IL#PLC Programming Services Illinois#Industrial Automation Edwardsville#HMI Systems Integration#Custom Control Systems Illinois#Manufacturing Automation Solutions#Programmable Logic Controllers#SCADA Systems Edwardsville#Industrial Software Engineering#Automation Services Metro East IL

0 notes

Text

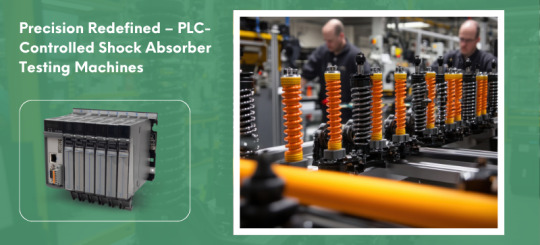

Precision Redefined – PLC-Controlled Shock Absorber Testing Machines

Precision – a word that keeps on getting thrown around often in the world of engineering. However, when it comes to shock absorber testing, precision isn’t a luxury—it’s survival. Every curve, every jolt, every rebound of a shock absorber must be captured, tested, and analysed to microscopic exactness. Gone are the days when manual testing could keep up.

The role of shock absorbers in today’s high-speed automotive innovation and precision engineering is to provide safety, comfort, and performance protection. But how can we make sure that these absorbers meet the high standards required by modern vehicles? This is where PLC automation becomes a useful tool.

The old-fashioned testing methods, which were cumbersome, unreliable, and laborious, have been replaced by PLC-based automation systems. Imagine a testing line with the capacity to think, adapt and respond in real time. The precision of Programmable Logic Controllers (PLCs) is not solely a promise, but rather adherence to standardised protocols.

How PLCs Enhance Shock Absorber Testing

There has been an evolution in the science of testing shock absorbers. Let’s understand how smart and compact PLCs can automate and optimise critical testing stages by providing consistency, control, and clarity.

Centralised Control with High Reliability

A robust industrial PLC is the foundation of our testing machines. The real-time control systems embedded in our automation design enable seamless functioning of all sensor, actuator, and motorised components.

Multiple sensors? Check.

Complex test sequences? Seamlessly handled.

From servo motion controllers managing high-speed vertical displacements to compact PLCs managing individual test stations, the formation is digital, deliberate, and dependable.

Real-Time Data Acquisition & Analysis

Here's where things get exciting. Tests on shock absorbers are more than just passing or failing. It's about quantifiable performance with our automation controllers:

Damping force curves

Displacement maps

Velocity and resistance profiles.

The data is gathered by high-resolution sensors and then processed through HMI with PLC controllers. The integration of this with databases is achieved through integrated PLC-based software, resulting in predictive maintenance and long-term performance insights

Feedback Loops for Adaptive Control

Ever wondered what would happen if the test differs? What would be the outcome? Well, with the use of real-time PLC communication protocols (like MODBUS and Ethernet/IP) and closed-loop control enable our systems to identify anomalies mid-test while enabling automatic correction.

Additionally, dynamic adjustment of actuator velocity in a system is possible when the response rate of the unit is slower than the tolerance. Or if temperatures spike? After a system shutdown, it sends an alert via the web server PLC and logs the fault. This requires more than just testing -- intelligent testing.

NX-ERA JET PLC System Architecture

Now let’s explore the engine room that fuels our innovation. The NX-ERA JET PLC, the foundation of our automated testing platform, undergoes a thorough architecture and connectivity analysis.

Core Hardware Components

With its compact size, modular design, and future scalability, the NX-ERA JET PLC is a formidable beast. It houses:

Simple servo systems designed for precise motion control

Energy-efficient motors can be powered by Variable Frequency Drives (VFDs)

HMI interfaces that enable the creation of visual dashboards and manual overrides

I/O modules for interfacing with third-party equipment.

Its modular design makes it suitable for both high-volume testing environments and small-batch production lines that use Micro PLCs or Mini PLCs

Communication & Connectivity

Connectivity should be a fundamental aspect of the entire setup, not an extra one.

Modbus PLC Interface is responsible for ensuring device-to-device communication

High-speed data relays are made possible with Ethernet-based controller systems

PLC with TCP/IP can be used for remote data logging and system control, as well as firmware updates

IoT-ready PLCs enable the integration of the testing machine with ERP, MES, and SCADA

Key Benefits of PLC-Controlled Testing Machines

Indeed, inefficient processes are not easily exploited in the fast-paced manufacturing industry. Your requirements include testing devices that don't blink even when pressured, systems that guarantee high quality, and technology that evolves as your business grows. Our PLC-based automation solutions are precisely in tune with that.

They offer:

Repeatability and Precision - One unit can be tested with ease and accuracy. But what about testing thousands with zero deviation? Our automation solutions that utilize PLCs accomplish this objective. You get:

Identical test cycles

Calibrated control parameters

Automated calibration routines

It implies improved quality control and enhanced audit accessibility.

High Throughput with Reliability - Traditional systems often require individuals to choose between speed and accuracy. Not here. The configurations of our NX-ERA JET PLC enable:

Sub-second test cycles

Parallel station control

Integrated logic and safety layers

All without compromising test integrity.

Reduced Manual Intervention - By utilizing HMI integration, and adaptive PLC programming, operators can not only monitor and but control:

Reduced human error

Faster changeovers

Safer work environment

Safety and Compliance – Safety is crucial for any industrial setup. With our smart PLCs, you can easily:

Emergency stop circuits

Real-time fault diagnostics

Layered safety logic

PLCs are designed to provide timely and effective alerts and shutdowns, complying with international standards such as ISO and CE.

Adaptable and Future-Ready - Different testing may be required for tomorrow's shock absorber. Good news: you won’t need a new machine.

Reprogram testing logic

Add new motion profiles

Update firmware via PLC with IoT

That’s the power of modular PLCs.

Whether you're chasing precision, throughput, or transformation, our PLC-controlled shock absorber testing machines deliver across the board. These benefits aren’t just technical specs—they’re business advantages, engineered to give you control, confidence, and a competitive edge.

Why Choose Messung’s Programmable Logic Controllers for Automation Solutions

Your choice of controller can determine your plant's success in a world propelled by data-driven decision-making, agility, and accuracy. We offer complete PLC-based automation solutions meant to grow with your demands rather than just supply PLCs. Our PLCs are not only intelligent but also necessary for the following reasons:

Smart and Connected PLCs - Our smart PLCs dynamically optimise by adjusting to handle changes. Embedded intelligence enables them to learn from repeated tests, predict component failures, and optimize actuator profiles automatically. Moreover, our edge-computing enabled PLCs help for quicker decisions by lowering cloud dependence.

HMI Integration for Better User Control - No more enigmatic command-line interfaces. With our smart PLCs, you get touchscreen HMIs, customised dashboards and real-time analytics displays.

Compact and Versatile PLC (Programmable Logic Controller) Options - Squeezed on space? You can get the complete power of a typical controller, without worrying about the size, with our compact PLC, micro PLC, and mini PLC range.

From intelligence that anticipates, to interfaces that simplify, to form factors that adapt—Messung’s PLC Programming range is designed not just to meet your automation goals, but to exceed them. Because when you choose Messung, you don’t just adopt automation; you embrace transformation.

Applications Beyond Shock Absorbers

Although shock absorber testing is where our PLC automation solutions show their power, that's just one section in our automation playbook. Beyond the same technology, fine-tuned for real-time control, precision, and adaptability, extends far. Messung's intelligent PLC solutions provide flexibility and value across a range of sectors, whether you are forming metal or transporting materials.

Let's explore how our PLC Control Systems have a range much outside the damping zone:

Motion Control Systems - Conveyor automation and actuator-driven systems all fall under our motion control solutions. Through synced servo motion controllers, we guarantee millisecond-level accuracy.

Machine Tool Controllers - Integrated with smart CNC tools, our machine tool controllers use feedback to adjust cutting speeds, minimise tool wear and even optimise material usage.

Advanced Automation – Through this end-to-end automation, sending raw material to finished parts, fully automated quality checks and centralized command via connected PLCs can easily become possible.

One shouldn't limit automation to just one purpose. Whether it is in high-speed assembly lines or precise machining at Messung, our PLC automation systems are flexible enough to meet the demands of many industries. Beyond shock absorbers, our solutions usher in intelligent manufacturing possibilities one motion at a time.

Conclusion

Accuracy is a standard, not only a specification. If you are still using obsolete testing configurations, it's time to change course. Designed to bring not just performance but also purpose to your production floor, Messung's PLC-controlled shock absorber testing equipment helps you to achieve this.

Testing has to be quick, adaptable, and flawless, whether you are creating luxury cars or robust trucks. That is precisely what Messung's PLC control systems promise—and deliver.

We do not just automate; we elevate, from servo-tight control to smart data acquisition, from seamless integration to Industry 4.0-based controllers.

At Messung, accuracy is not just redefined. It has changed everything. Hence, go for it. Redefine accuracy. One test at a time!

FAQs

What makes Messung’s PLC Control Systems ideal for shock absorber testing?

Messung’s PLCs (Programmable Logic Controller) offer centralised control, real-time data capture, adaptive feedback loops, and ensure peak accuracy and speed.

Can Messung’s PLC Programming integrate with existing equipment?

Yes. With protocols like MODBUS, TCP/IP, and Ethernet-based controllers, our PLCs are designed for easy retrofitting and compatibility.

How do PLC Control Systems improve the testing process?

PLCs provide real-time emergency stop functionality, error detection, and ensure the equipment runs within safe operational parameters.

Do you offer remote access features?

Absolutely. With web server PLC (Programmable Logic Controller) capabilities and HMI with PLC controllers, you can monitor and manage testing remotely.

Is your PLC solution scalable?

Yes. With modular PLCs and IoT-ready systems, you can scale your setup to match your growth.

#PLC control systems#Programmable Logic Controllers (PLC).#Messung Industrial Automation#PLC automation systems#Smart PLC control#PLC-based AHU control system#modular PLC#Energy management systems#IEC 61131 based PLCs#compact PLC#IEC 61131-3 standard PLC Control Systems#MODBUS RTU#Modbus TCP#NX-ERA JET#PLC for energy systems#IEC 61131-3 compliant PLCs#modular PLCs#HMI with PLC controller#smart automation systems#programmable logic controller#smart PLCs#Modular PLCs

0 notes

Text

The Power of Siemens Industrial Automation in Modern Manufacturing

Siemens Industrial Automation - Introduction

Rapid technological advancement made a great mark on the industrial environment, whereby automation is now an important part of modern production. Siemens Industrial Automation provides modern solutions for improving efficiency, productivity, and accuracy in industrial processes. From the wide variety of Siemens automation products, companies can create streamlined operations, minimized costs, and trouble-free production processes.

Siemens programmable logic controller (PLC) products, smart controllers, and many other types of automation solutions are for the manufacturing, energy, pharmaceutical, automotive, and diverse industries.

How Siemens Industrial Automation is Reshaping New Age Industries

Industrialization is propelled, and efficiency is realized with automation. Achieving operational excellence among many industries is possible by introducing automated practices that are designed in strategy with smart technologies that optimize performance. The automation solutions integrate less human interference and better accuracy and scalability.

1. Boost for Enhanced Productivity and Efficiency

The greatest benefit available through Siemens automation products is that it raises productivity. With modern systems operating at a higher level of precision, production rates are much faster as downtime is reduced to a minimum. Real-time monitoring and control of a process in a very efficient way is what seamless working of Siemens PLC and controllers promises.

2. Economical Solutions for Industrial Concern

All industries, in fact, look forward to cost-effective solutions, which will optimize operations. Cut in manual labor consumption, reduction of energy consumption, and reduced waste of raw materials are some aspects of lessening operational cost. Predictive maintenance is also facilitated by Siemens controllers, thus helping improve unplanned downtimes and repair costs.

3. Safety and Reliability enhancement

Increased safety: Industrial automation resulted in increased safety at workplaces as there will not be any hazardous tasks relying on human workers. Programmable logic controllers from Siemens will offer automation in a completely reliable and fail-safe manner preventing unwanted incidents and ensuring seamless operations

4. Scalability and Flexibility

Present automation solutions can be flexible and scalable, which are the requirements of modern industrialization to meet the various demands from time to time. Siemens automation products enable flexible integration of the current facility with such systems, which means that modernization can take place with minimal disruption in the processes.

Key Products of Siemens for Industrial Automation

1. Programmable Logic Controllers (PLCs) from Siemens

Siemens PLCs are one of the key elements in industrial automation. These controllers take charge of complex processes with a necessary degree of accuracy over machinery and equipment.

Siemens offers the following kinds of PLCs:

SIMATIC S7 Series- A powerful and flexible PLC family for a variety of industrial applications.

LOGO! Logic Modules- These are best suited for small automation projects with compact programming and easy, user-friendly programming.

ET 200SP- A modular PLC system that integrates with other automation components like a dream.

Also read, Siemens PLC: Benefits of Using it in Industrial Automation

2. Siemens Controllers

Siemens controllers accomplish their task of handling and controlling automated tasks effectively. Communication between these controllers and the different automation components is maintained so that real-time monitoring and controlling become possible.

Among the top Siemens controllers are:

SIMATIC S7-1500-A performance controller for complex automation tasks.

SINAMICS Drive Controllers- Precise speed and torque control in applications relating to motor control.

Distributed Controllers-A distributed automation system would do well with these controllers spread out in a large industrial set-up.

Also read, Top 5 Benefits of SIMATIC S7 1500 for Advanced Motion Control

3. Human-Machine-Interface Solutions of Siemens

Siemens produces various HMIs operated by these systems to enable operators to interact with the automation system. Such interface tools visualize data in real-time for easy monitoring and control of industrial processes.

Among the popular Siemens HMI products are:

HMI Panels-SIMATIC Panels with high-definition touchscreen for seamless industrial monitoring.

SCADA systems-Complete control and monitoring alternating solutions for large-scale automation systems.

Also read, Siemens HMI vs. Other HMI Solutions: Why Choose Siemens?

Applications of Siemens Industrial Automation

The various solutions provided by Siemens Industrial Automation find application in industries for ensuring operation efficiency and accuracy. Some of the industries benefitted from Siemens automation are:

1. Manufacturing Industry

In manufacturing, automation serves to ensure streamlined production lines. Siemens PLCs and controllers assist in process optimization, waste reduction, and overall efficiency enhancement.

2. Automotive Industry

Automated processes in the automotive industry are mainly used in assembly, painting, and quality control. Siemens' automation products make sure that factories doing automobile manufacturing operate to high standards, producing consistent quality.

3. Food & Beverage Industry

Automated processes in the food industry are used in packaging, inspecting quality, and monitoring production lines. Siemens controllers and HMI solutions assist in hygiene maintenance and operational efficiency.

4. Energy & Power Plants

Power generation and distribution need next-generation automation solutions to work seamlessly. In energy plants, the use of Siemens PLCs and SCADA systems guarantees an uninterrupted supply of power and efficiency.

Future of Siemens Industrial Automation:

The future of Siemens Industrial Automation is changing due to advancements in artificial intelligence, the Internet of Things, and digitalization. Smart factories-New-Norm Siemens Automation Products bring AI empowered analytics, therefore controlling operations for better performance. Meanwhile, with Siemens Controllers, Industries attain the efficiency to maintain themselves and their functionalities through real-time and predictive maintenance monitoring.

1. Industry 4.0 and Smart Manufacturing

Siemens has introduced this idea to develop Industry 4.0 -digital solutions through IoT, cloud-based computing-to make them automation-enabled. Likewise, Smart Siemens PLCs and controllers consider making industries access real-time data analysis for automation-driven decision making.

2. Sustainability and Energy Efficiency

Siemens constructs the idea of automation applied to sustainability by focusing on solutions that do not maximize energy consumption or carbon footprint. In essence, through such smart their-automation, resource utilization is optimized such that it becomes an environmentally friendly industrial practice.

Conclusion

Transforming industries, Siemens Industrial Automation promises groundbreaking, state-of-the-art, and trustworthy solutions for all industrial automation options, including Siemens programmable logic controllers and advanced Siemens controllers. These automation products guarantee seamless operations, cost savings, and enhanced productivity in all industries.

For industries interested in implementing Siemens automation solutions, Naksh Technology Solutions LLP serves as the trusted source for a premium range of all automation products and world-class consultancy services.

#siemens industrial automation#siemens automation products#siemens programmable logic controller#siemens controller

0 notes

Text

PLC Training Online Certification Course

Master PLC programming with our comprehensive online course! Learn from industry experts and gain hands-on experience in designing, testing, and troubleshooting PLC systems. Boost your career with practical skills in automation and control. Enroll today to advance your expertise!

Read more: https://www.multisoftsystems.com/embedded-systems/plc-training

#Programmable Logic controller Training#PLC Training#Programmable Logic controller Course#PLC Certification

0 notes

Text

#electrical#commercial building#industrial electrician#programmable logic controller#controllers#electricians#commercial electrician#electrician#electrical company#melbourne

0 notes

Text

Programmable Logic Controllers

ROC Automation offers high-quality programmable logic controllers (PLCs) for industrial automation, ensuring precision and efficiency. Designed for seamless integration, these controllers optimize processes, enhance productivity, and reduce downtime. With advanced features and reliable performance, PLCs support various applications, from manufacturing to energy management, providing smart solutions for automation needs. Buy now on https://rocautomation.co/

0 notes