#RS232 to Ethernet Converter

Explore tagged Tumblr posts

Text

Transforming Legacy Connectivity: The Power of RS232 to Ethernet Converters

In a rapidly evolving digital landscape, legacy systems need a modern touch. Case Communications' RS232 to Ethernet Converters breathe new life into outdated RS232 connections, enabling seamless integration with contemporary networks. These converters transform traditional serial data into Ethernet signals, ensuring reliable and fast communication across diverse applications. Whether it's industrial automation or point-of-sale systems, this innovative solution bridges the gap between old and new technologies, enhancing efficiency and performance. Embrace the future while preserving the past with Case Communications' cutting-edge RS232 to Ethernet Converter. Visit at https://factofit.com/transforming-legacy-connectivity-the-power-of-rs232-to-ethernet-converters/

1 note

·

View note

Text

Why Your Business Should Use a CAN Bus to Ethernet or RS232 Converter

Discover why your business needs a CAN Bus to Ethernet or RS232 converter with BuenoElectric. Enhance communication, streamline operations, and improve device connectivity. Trusted in the USA for reliable and efficient solutions.

0 notes

Text

Understanding Programmable Power Supplies For LED Light Panels

LED light panels are extensively utilized across various industries like photography, videography, architectural lighting, and smart home technologies, owing to their efficiency, longevity, and adaptability. To achieve optimal functionality, however, these panels necessitate meticulous power management. Programmable power supplies offer the capability to modify voltage, current, and brightness levels to accommodate diverse applications. This article will delve into the operation of programmable power supplies, their primary advantages, and guidance on selecting the appropriate model for your LED panel configuration.

What is a Programmable Power Supply?

A programmable power supply is a sophisticated electronic device that allows users to manage and modify output voltage, current, and occasionally power through software, control panels, or communication interfaces such as USB, Ethernet, or RS232. For LED light panels, this technology provides precise control over brightness and colour temperature, ensures consistent performance with stable power output, enhances energy efficiency by avoiding LED overdrive, and improves safety with integrated protections against overheating and voltage surges.

How Programmable Power Supplies work

In contrast to conventional fixed power supplies, a programmable power supply adjusts its power output dynamically based on user-defined parameters or external control signals. The process begins with input power management, converting AC from a wall outlet or DC from batteries or solar panels into the necessary voltage and current. Internal microcontrollers and switching circuits regulate and adjust the output according to user specifications. Users can interact with the power supply through on-device buttons and LCD displays, remote software applications on computers or mobile devices, and automation scripts for smart home integration. Ultimately, the regulated power is supplied to the LED light panel, ensuring uniform and reliable illumination.

Types of Programmable Power Supplies for LED panels

Programmable power supplies are categorized into three primary types: Constant Voltage (CV) Power Supplies, which maintain a stable output voltage (such as 12V or 24V) while allowing the current to vary, making them suitable for LED strips and panels equipped with integrated drivers; Constant Current (CC) Power Supplies, which deliver a fixed current (for instance, 700mA or 1A) while permitting the voltage to change according to the LED load, ideal for LEDs lacking internal current regulation; and Hybrid (CV/CC) Power Supplies, which merge both functionalities, providing flexibility for various LED applications.

Applications of Programmable Power Supplies for LED panels

Photography and videography studios

In photography and videography studios, programmable power supplies facilitate consistent lighting with flicker-free operation, enabling precise adjustments to brightness and colour temperature for diverse shots, and allowing remote management of multiple LED panels for greater adaptability.

Smart home and architectural lighting

Smart home and architectural lighting can be enhanced through the automation of brightness and colour transitions based on the time of day, integrating LED panels with motion sensors or voice-activated systems for effortless control, and promoting energy efficiency in both residential and commercial environments.

Horticulture and grow lights

Horticulture and grow lights necessitate accurate adjustments of light intensity for various plant growth stages, the capability to fine-tune wavelengths for specific plant types, and the enhancement of crop yields while reducing energy usage, rendering programmable power supplies vital for effective indoor agriculture.

Medical and laboratory applications

In medical and laboratory applications, programmable power supplies are crucial for ensuring consistent and regulated light output in surgical environments, providing precise programmable settings for UV sterilization, and maintaining stable lighting conditions essential for accurate microscopy and diagnostics.

A programmable power supply is a crucial element for individuals aiming to enhance the performance, efficiency, and versatility of LED light panels. This is applicable across various industries like photography, smart home configurations, horticulture, and industrial applications. These power supplies provide precise control, energy efficiency, and increased lifespan. By comprehending their functionality and choosing the right power supply for your LED application, you can attain exceptional lighting quality while maintaining safety and durability. Miracle Electronics offers efficient and reliable programmable power supply for LED light panel in India, specifically designed to meet a wide range of lighting requirements.

Resource: Read more

0 notes

Text

LAN/RS485/RS232 PLC/DDC Modbus TCP RTU to Profinet Gateway for Process Automation Industries

The BL122 protocol converter is an industrial Ethernet gateway with Ethernet ports and RS-232/485 serial ports. Beilai BL122 protocol converter is used for converting Modbus RTU, Modbus TCP to PROFINET communications.

BL122 Modbus to PROFINET protocol conversion gateway enables seamless integration of Modbus devices into a PROFINET network. This gateway supports Modbus RTU, Modbus TCP converts data for communication with PROFINET devices.

It facilitates real-time data transfer, configuration flexibility, and industrial-grade reliability. Ideal for industrial automation, the gateway enhances system flexibility and scalability, ensuring efficient data exchange and communication across diverse protocols and devices.

0 notes

Text

IF To L Band Converter | defel technologies

Introducing the Defel IFL: A Next-Generation, Fully Synthesized L-Band Up and Downconverter Offering Cost-Effective IF Interface Solutions at 70/140 MHz.

Key Features of IFL 2010: ➡ IF: 70±18 MHz, 140±36 MHz ➡ RF: 950 -2000 MHz ➡ Upconverter & Downconverter in Single 1U Chassis. Rack Mountable ➡ Input Power: Input Power: 110V-230 V AC/50 Hz ➡ Upconverter Output Power Range: 0 to -40 dBm ➡ Downconverter Input Power Range: 0 to -70 dBm ➡ Spurious: 40 dBc ➡ Humidity: 95%, Temperature: -20 to +65 º C ➡ M&C: SNMP, Ethernet, RS232/422

To learn more about IFL 2010 and how it can benefit your SATCOM operations, visit our website https://defel.in/ or contact our team today!

#IFL2010#satcom#innovation#technology#newproduct#groundstation#space#defel#ifl#isro#bhel#drdo#makeinindia#startupindia#meity#inspace#startupkarnataka#bengaluru#satellitecommunication

1 note

·

View note

Text

CAN BUS Haberleşme Çözümleri - GelecekBT

#can 2.0#CAN BUS#CAN OPEN#CAN FD#CAN BUS FIBER CONVERTER#CAN BUS TCP/IP Converter#canbus rs232#canbus rs485#canbus usb converter

1 note

·

View note

Text

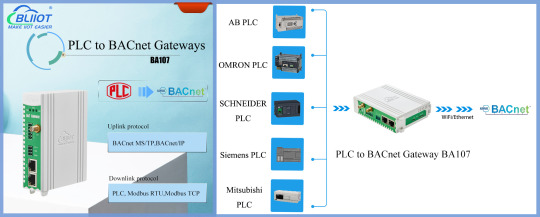

BLIIoT | BACnet Gateway BA107 Converts Multiple PLCs to BACnet

Introduction

With the development of communication technology and control technology, in order to achieve efficient and intelligent management of buildings, centralised monitoring and management has become an inevitable trend in the development of intelligent management of buildings. In this context, high-performance building HVAC data transmission solutions - protocol conversion gateway came into being, widely used in building automation and HVAC system applications.

BLIIoT always insists on the core of the user's needs, and constantly expands its applications in a variety of industrial fields. Recently, we have developed a new series of BLIIoT Building Automation HVAC gateways, This series of products not only have excellent stability and anti-interference capabilities, but also have deep industry applications, aiming to bring users a new building automation data collection and conversion experience.

Product Description

The PLC protocol to BACnet gateway BA107 is developed by BLIIoT specifically to realize the mutual conversion between the PLC protocol and the building automation protocol BACnet.

PLC protocol to BACnet gateway BA107 downlink supports Modbus RTU, Modbus TCP, Mitsubishi, Siemens, Omron, Delta, Schneider and other PLC protocols.

The uplink supports BACnet IP and BACnet MS/TP protocols to realize mutual conversion between PLC protocol and building automation protocol.

This design allows BA107 to be easily integrated into various application scenarios and meet the connection requirements of complex networks. Not only that, as an industrial product, BA107 complies with 12 industrial product design standards to ensure its excellent stability and reliability in harsh industrial environments.

PLC to BACnet gateway BA107 is equipped with 2/6 RS485/RS232 serial ports, 2 Ethernet ports, and WiFi wireless transmission interface, providing a wide range of choices for diverse connection needs.

By using BLIIoT patented guide rail buckle technology, the installation process is simplified and the practicality of the gateway is ensured.

Product features

Supported protocols:

Downlink protocol: Modbus RTU, Modbus TCP, Mitsubishi, Siemens, Omron, Delta, Schneider and other PLC protocols.

Uplink protocols: BACnet MS/TP, BACnet/IP protocols.

Hardware interface:

6*RS485/RS232 serial ports: The serial ports are independent of each other. Each serial port parameter can be set to collect different protocols. The serial port can also set the master-slave relationship independently. It can be configured as either a master station or a slave station.

2*network ports: used for data collection and forwarding. The LAN port has a routing function and provides a channel for other devices to connect to the external network.

WiFi wireless transmission interface: Provides diverse communication options to adapt to different industrial environment need.

Data security:

Support data TSL/SSL, X.509 certificate, SNMPV1/V2, key encryption and other security gateway functions.

Remote Configuration Support:

Support remote PLC programming and program uploading and downloading, saving travelling costs and improving service response speed. Support remote configuration, providing users with convenient management and monitoring methods, no longer need to visit engineers, saving maintenance costs.

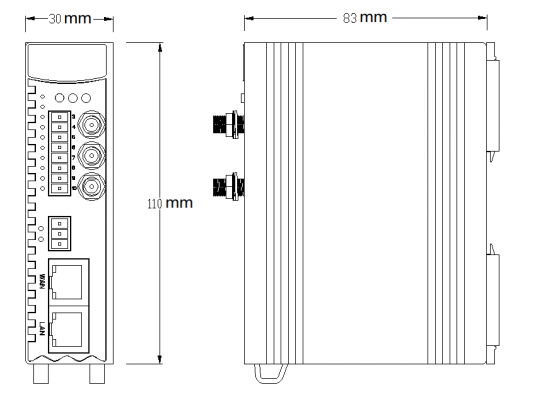

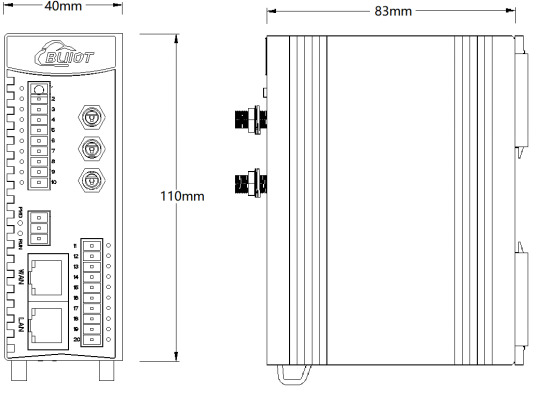

Product Size: L x W x H: 30 x 83 x 110mm

Safety and Stability:

Industrial-grade design: Durable shell material meets industrial environment requirements.

Stability: Efficient communication protocol conversion ensures stable operation of the system.

Environmental adaptation:

Operating temperature range: -40~80℃, adapting to various industrial environments. Protection grade: IP30, ensuring the reliability of the equipment in harsh environments.

Model List

Application scenarios

BA107 is widely used in protocol conversion between building automation equipment and PLC protocols.

More information about PLC to BACnet Gateway BA107: https://www.bliiot.com/plc-to-bacnet-p00419p1.html

0 notes

Text

#s2emodule #serialtoethernet #ethernet #wiznet #ethernetmodule #w7500P #WIZ110SR #WIZ750SR #s2emodul #ethernetic #wiznetian #ethernetchip #arduino #esp32 esp8266 #ethernet #eth #wiznetchip #w5500 #ethernet #rs485 #modbusrtu #modbus #serialtoethernet #rs232 #canbus

0 notes

Text

What is a rs-232, RS232 to rs422 converter, rs232 to ethernet, serial communications connecting devices

ICL3221 Series 250 kbps 15 kV RS232 5.5V Transmitter/Receiver - TSSOP-16

#Renesas#ICL3221EIVZ-T#Signal Interface#RS 232#what is a rs-232#RS232 to rs422 converter#rs232 to ethernet#serial communications connecting devices#Multiple receivers#RS232 to usb#rs232 pinout#rs232 to usb adapter#rs232 programming

1 note

·

View note

Text

RS232 to usb, rs232 converter, rs232 to ethernet, rs232 program

0 notes

Photo

Industrial RS232/RS485 to Ethernet Converter

This gateway is an industrial-strength RS232/RS485 to Ethernet converter that allows a bi-directional transparent data transmission between RS232/RS485 devices and an Ethernet RJ45 port. The gateway is a great solution for industrial control systems that need an expansion to IIoT (Industrial Internet of Things)applications. The configuration is accomplished by means of a webpage.

https://copperhilltech.com/industrial-rs232-rs485-to-ethernet-converter/

0 notes

Photo

ICS-2400T Industrial 4-Port RS232/RS422/RS485 Serial Device Server is specially designed to convert RS232, RS422 or RS485 serial communication to Industrial Fast Ethernet networking so as to extend the network distance efficiently and inexpensively.

Upgrade Your Technology

Learn more: http://bbcpl.in

contact us : +91 78754 32180

Email: [email protected]

1 note

·

View note

Text

Modbus RTU TCP Master to MQTT Ignition AWS ThingsBoard IoT Gateway with 4G/WiFi/GPS/RS485/RS232/LAN/WAN

The protocol conversion gateway acts as a bridge in the IIoT, enabling interconnectivity between different devices and seamlessly integrating data into the cloud platform, supporting data analysis and decision-making.

BL101 is an industrial IoT gateway that converts Modbus RTU, Modbus TCP to MQTT protocol. The gateway supports Ethernet, WiFi, or cellular networks(4G) transmission, ensuring that data is transmitted to AWS, ThingsBoard, IgnitionSCADA, and other cloud platforms stably and reliably.

By incorporating TLS/SSL encryption, the protocol conversion gateway can provide a secure, reliable, and trustworthy communication channel, protecting industrial data from eavesdropping, tampering, and unauthorized access.

0 notes

Text

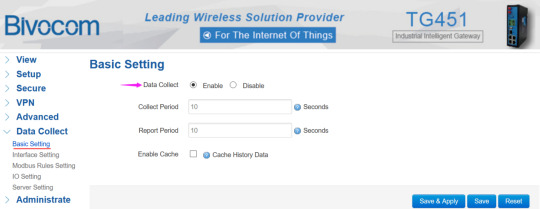

3 Steps to Build Your IoT Demo

Bivocom TG451 Industrial Iot Gateway

Want to know the environment condition of your greenhouse, server room, factory or substation of electricity from anywhere and anytime? Thanks to the IoT technology, your IoT concept can be easily realized.

Today, we’re going to show you how to build a simple IoT demonstration in just 3 steps by using an industrial temperature & humidity sensor, Bivocom industrial 4g IoT gateway TG451, and Fogwing cloud IoT platform.

Get Your IoT Hardware and IoT Platform Ready

1. An industrial temperature and humidity sensor can detect field conditions and convert it to digital signal. In our case, the sensor acquires the field environment temperature and humidity, transfer the data via RS485 interface following Modbus RTU protocol which is very common in IoT technology.

2. An industrial cellular IoT gateway or modem comes with RS485, and support protocols like Modbus RTU/TCP, JSON and MQTT. In this case, we use a Bivocom 4G IoT gateway TG451 to connect to the sensor via RS485, and acquire the data from sensor, convert it from Modbus to JSON, and transmit to a cloud MQTT server. For more details of industrial gateway TG451, please refer https://www.bivocom.com/products/iot-gateways/industrial-gateway-tg451/

3. A Cloud IoT platform. Fogwing is a feature-rich, and ease to use IoT platform, which supports MQTT protocols. Fogwing also provides visible dashboard and alarm trigger features. You may need to register a free account from https://enterprise.fogwing.net

Step 1,

Deploy the temperature & humidity sensor at place you plan to monitor, and then connect it to Bivocom TG451 gateway via RS485 port.

Step 2,

Configure the TG451 industrial iot gateway to get sensor data and upload to cloud server Fogwing. Bivocom TG451 provides user friendly Web UI for configuration. For initialization setup, please refer QSG(quick start guide) from Bivocom.

1) Login to the Web UI of TG451, enable the ‘Data Collect’ feature, and set the period of data collection and report period according to your demand.

2) Configure the relevant interface parameters, Bivocom TG451 provides RS232, RS485, Ethernet, DI/DO(relay). In our case, we use RS485 COM port to connect to sensor, set the relevant Baud rate, Data bit, and other parameters following sensor datasheet.

3) Configure the Modbus Rules at Web UI>>Data Collect>> Modbus Rules Setting, following the sensor’s Modbus map, set the Device ID, Function code, Register address, holding length (count), and other parameters (click “Edit” button for more settings), to get and calculate the correct Temperature and Humidity value accordingly.

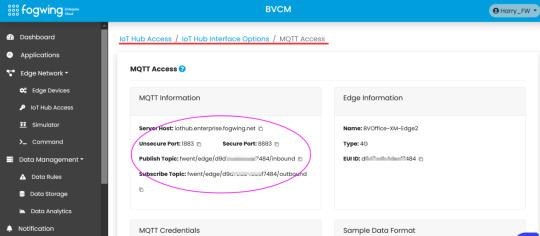

4) We will get the MQTT access information from Fogwing platform after registere TG451 device on Fogwing portal.

Input the MQTT information of Fogwing on TG451 server setting, and set JSON format as platform requested.

Step 3,

After finished the TG451 gateway settings, the sensor data will be published to Fogwing platform periodically, access the dashboard of cloud IoT platform anytime and anywhere, all the real time data is under monitoried now.

Dashboard on Fogwing

Check the real time data on Data Storage

Visible Graph Display on Fogwing Dashboard

1 note

·

View note

Link

1 note

·

View note