#Raw Material Grinding and Drying

Text

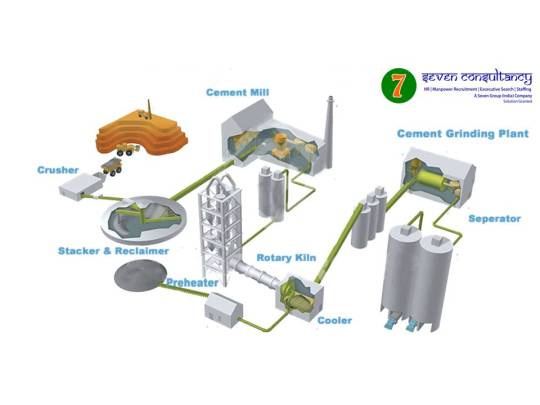

Procedure of cement manufacturing in six simple steps

Cement is an essential building material that plays a crucial role in the construction industry. It is the binding agent used to create strong and durable structures. Wonder Cement Ltd is dedicated to providing high-quality cement to meet the diverse needs of the construction sector.

In this blog, we will take you through the six simple steps involved in the cement manufacturing process. We will shed light on cement manufacturing.

Step 1: Mining the Raw Materials:

The first step in cement manufacturing is the extraction of raw materials from the earth's crust. Limestone, clay, shale, iron ore, and other minerals are obtained through mining operations. These raw materials are carefully selected to ensure the desired chemical composition of the final cement product.

Step 2: Crushing and Pre-Homogenization:

Once raw materials are mined, they are transported to a crushing plant. Here, the rocks are crushed into smaller fragments to facilitate further processing. After crushing, the materials undergo pre-homogenization, where blending techniques are employed to ensure a consistent mix of raw materials. This step helps achieve the desired cement chemical composition and quality.

Step 3: Raw Material Grinding and Drying:

Crushed and pre-homogenized raw materials are then ground into fine powder in a raw mill. The grinding process utilizes rotating drums and steel balls to pulverize the materials. To prevent excessive moisture content, the powdered mixture is dried using hot gases before moving on to the next stage.

Step 4: Clinker Production:

In the clinker production stage, ground raw materials are fed into a high-temperature rotary kiln. The kiln operates at temperatures exceeding 1400 degrees Celsius, where materials undergo chemical transformation known as calcination. During this process, the raw materials are heated to the point where they form small, dark grey nodules called clinker.

Step 5: Cement Grinding:

The clinker is then finely ground with a small amount of gypsum in a cement mill. Gypsum is used to regulate cement setting time and enhance its properties. The grinding process transforms clinker and gypsum into a fine powder known as cement.

Step 6: Packaging and distribution

Once cement is produced, it is stored in silos before packaging. The final product is carefully packed in bags or loaded onto bulk transportation vehicles such as trucks or railcars. Proper packaging and handling ensure cement quality during transportation and storage. Wonder Cement Ltd maintains strict quality control measures to deliver a consistent and reliable product to its customers.

Cement manufacturing involves six simple steps, from mining raw materials to packaging. Wonder Cement Ltd follows these steps meticulously to produce high-quality cement for various construction needs. Understanding the cement manufacturing process provides valuable insights into the importance of each stage and the efforts required to ensure consistent quality. As a leading cement manufacturer, Wonder Cement Ltd remains committed to producing top-notch cement to contribute to the construction industry's growth and development. Their commitment to producing the finest quality cement is reflected in their use of state-of-the-art German machinery and innovative technologies like the ROBOTIC LAB.

To learn more, click here.

#cement manufacturing process#mining the raw materials#Crushing and Pre-Homogenization#Raw Material Grinding and Drying#Clinker Production#Cement Grinding#Packaging and distribution#wonder cement

0 notes

Note

older!pervy!könig with his controversial young girlfriend!?

smut, weed use, *legal* age gap, dacryphilia... 18+

older!pervy!könig who adores how nïave his girlfriend is. all inexperienced beneath him, grinding your hips against his clothed bulge for any type of friction. he loves to tease you; getting you all slick and wet, begging for his cum and lengthy cock, refusing and eating you out agonizingly slowly!!

no matter how much you plead and cry, bucking into his mouth as you rub your needy clit against his tongue, he won't fuck you. tongue pressed flat and covering your entire sex before dragging a stripe up to your nub, sensitive and raw. perhaps, he'll flick and suck on it, tears streaming down your pretty cheeks as he continues to chuckle and lick your desperate hole.

older!pervy!könig who'd be obsessed with the idea of taking your viriginity. it feels like taboo from the glares he's given; the age gap between you two frowned apon, while his large calloused hand rides up your skimpy, summer dress, poking his thumb into your panties and teasing your greedy slit, your gasps and squeals going straight to his hard dick.

older!pervy!könig who grinds your hips down onto him. he's obsessed with dry humping, and grinding your wet cunt down onto his boxers, only covered by thin material. he definitely wears those loose boxers at nighttime so you can suck him off before bed, taking his length as far as you can go, or waking up and giving him a sloppy blowjob in the morning with your pretty eyes staring up at him, his hand encouraging you to go deeper.

older!pervy!könig who giggles when you cum from a blowjob. being so turned on at the fact that you're pleasuring him and soaking your panties with your sweet liquids, whimpering and nuzzling into his musky balls as he degrades and humilates you. his grip on your jaw forcing you to look up at him, cumming all over your face and getting it into your eye.

older!pervy!könig who can't get enough of high sex. sloppy thrusts between your plush thighs, veins dragging up against your slit as you gasp and mewl, attempting to grind yourself down onto him to no avail, his grip on your hips like iron. “patience, schatzchen.. god, so needy.. -fuck-.. you're so wet, my dear...” his eyelids heavy from the weed, taking hits from his massive glass bong that's huge in your smaller hands, whimpering as you giggle and grasp at his broad shoulders.

he adores that fucked-out, needy look on your gorgeous face. he might just smack it, slap your cheek till you're crying and humping against him, so horny and overwhelmed from the drugs as he takes a drag from his joint, a cruel smirk stained on his face as he guides your hips back and forth, feeling your cunny rub against him.

older!pervy!könig fucks your thighs whenever he can. doing the dishes? his stiff size is pressed between your soft thighs. you can hear him breathing heavily in your ear, occasionally grunting when his tip curves up to your clit with a single thrust, growling harsh pet names in your ear that make you all sloppy and wet. he covers your pussy in thick and potent seed, refusing to fuck you until you're on your elbows and knees, spreading your pussy open and wriggling your hips for attention, tears flowing down your face as he kisses each stray tear, fucking you ruthlessly while you sob and scream his name.

#older boyfriend könig thots :(#fem! reader#orla speaks#konig x you#konig x reader#konig#cod konig#konig mw2#konig cod#konig call of duty#könig cod#könig call of duty#könig x reader#könig#könig mw2#cod könig

339 notes

·

View notes

Text

Can't Keep My Hands to Myself- Part 1

Relationship: Sami/Jey/Cody

Rating: Explicit

Summary: Things get a little heated in the bus after the Fastlane Press Conference, Sami facetimes his boyfriend to get in on the action.

----

Writing's been a little on the backburner the last few weeks but I'm back with more horny nonsense :)

There will definitely be a Part 2 coming soon- Pour one out for Team Yeet, it was a beautiful 9 day reign.

This fic is Explicit- Reminder that my blog is not intended for Minors.

This fic contains: Oral Sex, Voyeurism, Dirty Talk, Pet Names, Grinding, Dry Humping, Coming Untouched, Unrealistic Sex, and mentions of Alcohol.

Tags for @elementaldoughnut12 (who inspired this fic) @feelschicken @harmshake and @swiftiebvcks 💖 If you'd like to be tagged in the next part please let me know :)

---

Partying on Cody’s bus after their win at Fastlane was completely unexpected for Jey.

To be fair, winning the Undisputed Tag Team Championships with Cody had also been completely unexpected, but he wasn’t about to question it now. They’d have to pry these belts out his hands now.

Once upon a time he could party with the best of them, but his always on the road lifestyle kept him from drinking much anymore, not with all the matches and the responsibility of being in the Main Event.

Jey’d taken several shots with Cody and others, knocking back mouthfuls of Hennessy and Crown. When the knock had came at the door with a nervous PA letting them know they needed to be at the press conference in 30, both men had looked at each other, knowing about how well this all would go.

Cody clapped a hand on Jey’s shoulder, reassuring him that he was good to do most of the talking. Jey tried and failed to suppress his giggles, finding the whole situation completely hilarious. Cody laughed too, grinning at him, unable to completely keep his composure.

They get through the press conference, and distantly Jey knows they probably will get in some kind of trouble for going out there like that. Roman certainly would have been furious at he and Jimmy if they ever tried that, but Jey doesn’t have to worry about Roman or his reactions anymore. And that feels so good.

With the tag belts back on his shoulders, he feels on top of the world.

He follows Cody back to the bus, both of them laughing as they go. Any time there’s a lull in the laughter, he lets out a “YEET” or Cody beats him to it and they burst into giggles again. The edges of his vision are blurry and despite the chilly midwest air, he’s warm in his t shirt.

He crashes into Cody’s back when they arrive, Cody laughing again as he struggles to open the door to his own bus. It seems like most of the people that were with them celebrating earlier have cleared off, leaving the bottles of liquor in the now quiet space.

Cody grabs a beer from the fridge and sits on the couch, cracking it open. “How much you wanna bet we’re trending already, Uce?”

Jey laughs, pouring himself another drink. “Yeeeeet,” He can barely get the word out without laughing, and the red Raw Belt falls off his shoulders onto the floor with a thud. He hangs his head in defeat while Cody continues to laugh.

Cody laughing at him should probably bother him, but it doesn’t. Cody has been an adversary far longer than he’s been a friend, but something about him makes him so easy for Jey to get along with.

“Bet those Judgement Day fools wishin’ they would- they could be celebratin’ like US, Uce!” It’s less coherent than Jey thinks it is, but Cody gets it all the same, throwing his head back and exposing the long line of his throat. Jey’s always been a bit of horny and handsy drunk, and the sight of Cody’s neck does something unexpected to him.

He feels his dick brick up in his dope new ring gear, the shiny blue material not really gonna hide much, but Jey couldn’t find it in himself to care.

Jey eyes the broad expanse of Cody’s lap, his knees spread wide on the couch, taking up space. He thinks about how it’d feel to sit there, how those powerful thighs would feel under his, and Jey’s brain is already too far gone to make objections.

He knocks back the drink in his hand, setting it down shakily as he moves towards the couch. “Ey, ey,-“ He only trips a little bit in the few feet between them. “Ey, Uce.” He’s up in the other man’s space and Cody is fixing him with that look, too intense like he can see into Jey’s head.

Jey straddles him, letting his weight sink down until he’s fully on Cody’s thighs, legs splayed wide and he’s giggling again at how good it feels.

Cody doesn’t say anything, just keeps looking at him like if he blinks maybe Jey will disappear. His hands wander though, coming around to grip Jey’s ass and support his weight in his big hands.

“How’d we get here, huh?” Cody asks, giving one of Jey’s cheeks a squeeze.

“I ain’t really know, uhhh,” Jey diverts his eyes from Cody’s so he doesn’t get distracted by their blue depths. The slippery fabric of his pants gives against the leather of the couch, and he sinks further onto Cody’s lap, immediately greeted by the hard press of the other man’s cock against his ass. “I dig it though, Uce. You got all that- is that for me?”

Cody giggles at him again, but he also rocks his hips to rut his clothed cock against him. “Well can’t say I never thought about it before, have you seen your ass? Need a license for this thing.” He gives Jey’s ass a light smack and Jey fights to not let out an embarrassing moan.

“S’why they call me juicy ucey, bruh-“

“That so?” Cody interrupts him, then captures his lips in a sensual kiss, riding on the energy of the moment.

Jey groans into it, wrapping his arms around Cody’s neck to hold onto him tighter and kiss deeper, grinding his hips to get that sweet friction on his rapidly hardening cock.

Then Jey feels the tell tale vibration of his phone ringing in his pocket.

“Ey, uh, one sec, Uce-“ He grabs his phone, seeing Sami’s face and name light up the display. “Eeeeyyy baby,” He greets cheerfully, putting the phone on speaker.

Jey’s honestly surprised his boyfriend hadn’t called earlier- he’d been unable to make it to the event after not having a match on the card, but he’s sure Sami would have watched. They’ve been together a few months now after finally sorting all their emotions out and Jey can’t think of a time that he’s ever been happier.

“I’m so proud of you baby!!” Sami’s voice comes over the line, and Jey can hear the smile in his voice. “I caught the whole thing, those creeps got what they deserved!”

“Yeet,” Jey moves his hips again, feeling Cody still hard against him. “Me n’ Cody Uce showed ‘em whose boss.”

Cody added in helpfully, “Yeet.”

“Still celebrating?” Sami asked. “That press conference was gold.”

“Yea, Boo- we was just getting cozy…” Jey’s dick brushes against the warm bulge in Cody’s pants and he lets out an unmistakable groan.

Cody freezes beneath him, looking at Jey in alarm.

There’s a pause before Sami speaks again. “Oh we’re getting cozy like that, huh? Baby, you know the rules.”

Jey shakes his head lazily. “‘Know Sami, ‘sposed to ask you first.”

“S’okay, baby- Cody’s a friend. We can let it slide this time,” Sami’s voice is rich like honey, soothing to hear. “Tell me how he feels, sweetheart.”

Cody’s lazy smile returns and his grip tightens on Jey’s ass, rocking their clothed dicks together again.

“Unnnnnhh- So good Sami, warm.” Jey slurs, dropping his head onto Cody’s shoulder. “Feels good,”

“That’s good baby, you still got your clothes on?”

Jey nods as if Sami can see him. “Mmhmmm, just been grindin’, you know?”

“Cody, make sure he keeps those on? He didn’t tell me in advance so thats all he gets.” Sami’s voice leaves no room for argument.

“Gotcha,” Cody replies, voice strained as Jey whines.

“Naw, C’mon Sami, please?” Cody watches the Samoan pout, and giggles despite himself at his plight.

“No way, you gotta earn that. Maybe if you’re good tonight we can make something happen after Raw on Monday- if thats okay with Cody?”

Cody grins, “I think we could make that work, Sami. If Uce here can be good that is.”

Jey fixes him with a grumpy face but Cody can’t take it seriously. “Whose side you on here, Uce?”

Cody bucks his hips, pressing hard against Jey’s hard length, pulling another low groan out of him.

Sami laughs over the phone. “Think that answers that. Take what you need baby, get yourself off. Let me hear you.” Jey writhes against Cody, moaning and whining as he ruts their dicks together, chasing his fast approaching orgasm.

Jey’s moans change into breathy pleas, “Fuck, please, so close Sami, lemme cum, please please, uce-“

Cody silences him with a bruising kiss as Sami’s voice talks him through it. “That’s it, Jey, go ahead. You’ve done so well sweetheart, you can cum.”

Jey’s hips stutter a few more times before stilling as he lets out a beautiful cry against Cody’s lips, breathing heavily as his thighs shake. Warmth spreads between them as Jey spills into his pants.

They break apart, Jey’s head dropping again onto Cody’s shoulder, his brow damp with sweat.

“Cody, can you put me on facetime?”

Cody takes the phone from Jey’s slack fingers, and hits the buttons to get Sami’s face up on the phone, pointing the camera at Jey’s face.

“Oh so pretty baby, so good for us,” Sami coos. “You better tell Cody thank you for taking care of you.”

Jey lifts his head just enough to look Cody in the eye, “T-thanks, uce…”

“Now you know that’s not what I meant, Jey,” Sami’s face was stern on the phone screen, with a hint of mischief in his eyes.

Jey’s face lights up, “Yeah, Sami?”

“Yeah, baby. Cody, you want those pretty lips on you? S’okay as long as I can watch.”

A blush blooms across Cody’s cheeks, but he nods excitedly.

Jey slowly removes himself from Cody’s lap, mindful of the wet spot blooming on the front of his pants. He takes a moment, downing another drink and swaying his hips as Cody follows behind him, sitting Jey’s phone down as he shoves his pants down to his knees, revealing his hard dick.

It’s shorter than Jey expected for how tall the man is, but what he lacked in length he made up for in girth. He eyes him hungrily, sinking down onto his knees, pressing Cody up against the nearby counter as Jey suckles at the weeping head of his dick.

Cody sighs at the sensation, picking Jey’s phone back up and aiming the camera down to capture the gorgeous image of Jey swallowing him down. The flushed head of Cody’s dick almost perfectly matches the pink of Jey’s lips and Cody’s already fighting not to fall over the edge.

Sami’s voice spurs Jey on, “Come on, sweetheart, show Cody how much you appreciate him. Show him what that mouth can do.”

Jey moans, taking more of Cody’s length into his mouth, bobbing his head as Cody’s free hand moves to thread into the blue strands of Jey’s mullet. He doesn’t push Jey but guides him all the same as Jey relaxes his throat and takes the whole of Cody’s cock into his mouth.

Cody throws his head back in pleasure, gripping the phone and Jey’s hair tightly. Jey’s hands reach around Cody’s thighs, taking handfuls of ass and squeezing in a mirror image of Cody’s actions earlier.

“Oo that’s it baby, look so pretty all stuffed full of cock.” Sami gets the same view that Cody does, Jey looking up through his long lashes, plush pink lips stretched around the girthy cock in his mouth.

Cody’s hand pulls Jey in close, pushing into his throat as his shaking thighs and quickening breath betray just how close he is to coming.

Jey takes a full breath into his nose, working his tongue around Cody’s length as he feels him twitch and moan, emptying his balls directly down Jey’s throat.

His grip slackens in Jey’s hair as Jey pulls off, giving kitten licks to the beads of cum clinging to the head before Cody jerks away, getting oversensitive.

Jey stares up at the phone in naked longing, and Cody passes it down, Jey switching the camera around so he can facetime with his boyfriend properly.

“You did so good, Jey baby, I’m so proud of you.” Sami’s voice is soft and comforting.

“Miss you, boo.” Jey’s eyes are heavy and sleepy, betraying the late hour and all the liquor he’s consumed catching up with him.

“Miss you too,” Sami replies, smiling warmly. “Cody, make sure he has a glass of water before bed, yeah?”

Cody laughs, “Yeah, I can do that.”

“Let’s catch up at Raw then?” Sami adds before addressing Jey again. “Get some sleep, Jey.”

The Samoan nods sleepily. “Love you,”

“Love you, Jey. Goodnight.”

Sami’s face disappears from the screen and Jey slumps even more, resting his head against the counter.

“C’mon, Uce.” Cody hauls him up, gripping him under his arms. “Let’s get ya to sleep. Can’t get on Sami’s bad side.”

“Sami don’ have no bad side,” Jey mumbles, following along as Cody leads him toward the bunks, knocking back the glass of water when he’s offered it before collapsing into bed.

Cody heads to bed not long after that, drinking his own glass of water before hitting the hay to at least try to fight off the massive hangover he knows will greet him in the morning.

His mind drifts before he succumbs to sleep, remembering the feel of Jey’s warm mouth on him, and Sami’s tease as to what might happen after they all reunite at Raw on Monday.

He’s not sure how he found himself in this situation, but he’s certainly not complaining.

___

Next time: Monday Night Raw following Fastlane, all the boys together for a little after show fun :)

20 notes

·

View notes

Text

https://www.invoitplast.com/

India’s most progressive and quality aware organization Invoit Plast Machinery Pvt. Ltd., is manufacturer, supplier and exporter of plastic processing machineries. More precisely, the plastic raw material processing such as mixing, drying, grinding, pulverizing, recycling from plastic processing machinery and equipment for plastic products.

Invoit Plast Machinery Pvt. Ltd., is having manufacturing business in Ahmedabad, the hub of several huge and prominent Plastic industries of India. By means of persistent improvement of superior manufacturing functions and excellent performance of our products through demanding research and development Invoit Plast Machinery Pvt. Ltd., has acquired prominent clients in India and we are still very well recognized as well as most trustworthy supplier to Indian cities Hyderabad, Nasik, Chennai, Baroda, Bangalore, Rajkot and more.

2 notes

·

View notes

Text

Making Organic Chicken Feed

A solid, well-balanced feed is necessary to grow healthy and big chickens. Although the readily available chicken feeds are simple fixes, are they enough for your poultry?

The commonly available chicken feed has been nutritionally calculated. But when it concerns business, one cannot rely on packaged goods.

In addition, the idea of the “green revolution” has encouraged people to produce their feed from all-natural products.

You may produce your chicken feed on your farm using only organic material. There are generally four different types of chicken feed.

These varieties include mashes, crumbles, pellets, and whole grains.

The chickens on a farm are fed avariety of feeds.

Do you intend to use organic feed to feed your flocks of chickens?

Continue reading the post to discover how to make organic chicken.

Required Ingredients

Chickens need a diet that is balanced nutritionally, with an appropriate amount of lipids,proteins, minerals, vitamins, and carbohydrates, just like humans need.

Additionally, fresh water is a crucial component of the diet in chicken feed.

You should check the water needed every two hours because chickens drink twice as much water as they feed.

In addition, individuals frequently overlook the additional nutritional components of vitamins and minerals in chicken feed.

The age of the chicken is a key consideration when creating the chicken feed.

Different types of feed are required for poultry at different developmental stages.

Similarly, adult chickens that lay eggs require a significant amount of calcium in their diet.

To improve food digestion and strengthen the chicken’s immune system, additional nutrients, such as oregano, cayenne, and probiotics, are added.

Making Organic Chicken Feed: The Process

Feeding your chickens organic chicken feed is safer and more nutrient-dense.

While creating your blend, you must pay special attention to the macronutrients and micronutrients.

Another crucial aspect to take into account while grinding one’s own organic chicken feed is food texture.

Chicken food’s textures

1. Mash

Like newborn babies, the newly hatched chicks’ digestive systems are still developing.

Furthermore, the chicks’ beaks are still growing.

Thus, they are unable to consume the coarse feed.

As a result, the meal for the young chickens begins as a mash and has a consistency akin to potting soil.

Starter feed is another name for the food intended for young chicks. It is high in protein to suit their nutritional needs.

This feed is given to the baby from birth to 8 to 12 weeks.

2. Crumble

The size and texture of crumbles are a little bit larger and more gritty than mash, similar to granola.

By the chicken’s 12 weeks of age, this is often fed.

Chicken breeders frequently use crumbles as a mediator diet to switch between mash and pellets.

The chick is fed until it begins to lay eggs for the layers.

3. Pellets

The chicken is fed pellets made of entire grains once it has reached adulthood and maturity. Only chicken that has reached an age of at least 18 weeks is best suited for this food texture.

These feeds are more extensive and more challenging to digest. The pellets are in good shape, making them simple to store and giving them to backyard poultry.

Making Organic Chicken Feed: The Step-by-Step Process

Making organic chicken feed at home can be time-consuming and labor-intensive. The steps involved are as follows:

Gather the necessary items, such as corn, fish meal, peas, oatmeal, kelp, and aragonite. All kinds of essential nutrients must be present in the elements.

Obtain a reliable supply of vitamins and minerals. You can also choose the readily accessible vitamin and mineral combination on the market.

Dry off and wash all the organic raw ingredients. Now crush those components in a spotless mixer grinder.

In an enormous container, combine the components in an appropriate ratio for the age group. The growing chicken needs to be fed more proteins than carbohydrates.

Feed mixture created from organic ingredients. Due to their distinct growing requirements and weak digestive systems, extremely young chicks may not be acceptable for the recipe above.

Follow these steps to create an organic feed for young chickens:

Incorporate at least 22% protein into the feed composition.

To mix and mash the meal before giving it to the chicks, grind it into a fine powder.

Brewer’s yeast, sunflower oil, and other mineral mixtures are available for use as chicken feed.

For young chicks, water is a crucial component of their diet.

Despite being wholesome and risk-free, homemade organic chicken feed has several drawbacks. These are a few of the penalties:

It can be challenging to search for each item in lesser quantities.

Making the feed is a highly time-consuming and laborious task.

These DIY feeds are not subject to quality inspection. As a result, it is impossible to know whether the meal contains all nutritional benefits of the chicken feed.

2 notes

·

View notes

Text

Pocket Full of Thorns.

.

Chapter One: A Very Busy Wednesday. [CH2》]

.

The shop bell has not stopped going off since she opened her doors that morning.

It is unusually busy for a Wednesday… Michelle thinks to herself, preparing the next order on her list while a few customers browse her stock.

She has seen more faces today than even her busiest days since opening her little apothecary. Most of them are familiar – people living nearby in the village. There have, however, been some unfamiliar faces around. The cloaked figures, requesting some very niche items and ingredients, were among the weirdest. A few of the newcomers seemed like tourists – mainly browsing the shelves and not buying much.

“Excuse me, Ms. Hawthorne?”

Michelle is jolted out of her contemplation by a small voice. A young child, no older than ten, is peeking over her countertop. A scrap of paper is gripped tightly in one of his hands.

“How can I help, honey?” Michelle smiles warmly, leaning down on the old wood to see him better. He falters, shy.

“Um, my mother sent me with this list…” he trails off, offering her the scrap of paper.

“Let’s have a look-see,” she says softly, plucking the list from his outstretched hand and examining the writing. It’s a very familiar handwriting – his mother is a regular. She gives the boy a reassuring smile. “Not a worry, I’ll have these for you in a flash!”

Michelle sweeps around the shelves behind the counter, picking and choosing bottles and vials down according to the list. There are some things she’ll have to mix, but that’s never too much trouble. She sets the requested raw materials down on the counter and brings the necessary ingredients she needs over to her mortar and pestle.

The mortar is magnificent, a hand-crafted granite piece sat in its rightful place on a sturdy table. A small spout is carved into the side, to make it easier to pour any liquids out. The pestle is much the same, a well-used rod of granite. Fine detailing is etched into the handle, slightly worn down over years of use.

The dry ingredients are tipped into the bowl and Michelle begins to grind them. Her arms, lightly muscled from decades of this work, take to the job with ease. The boy watches, curious.

Once finished, she tips the mixture into an empty bottle, deftly tying a label around the neck. This, too, is added to the group of items on the counter. Michelle carefully wraps each of them in paper and loads them all into a fabric bag.

“Now, don’t let your mother forget that she’ll get a discount if she brings the glassware back to me,” she tells the boy. “I’ll add this to her monthly bill as normal.”

He nods quickly, watching her write the total for the goods on the scrap he brought in. She adds this to the bag before handing him the lot.

“Thank you, Ms. Hawthorne,” he says, bowing his head slightly, before trotting out of the shop. Michelle waves to him as he leaves, before getting back to her order list.

What a nice boy. She hums to herself as she works. I must remember to give his mother a little more off the bill, I know they’re struggling this month…

Michelle moves through the list with ease, humming quietly to herself as she goes. A few customers interrupt her work to request things of their own, or ask questions relating to certain ailments and remedies, but she mostly works unhindered through the day.

An abrupt purr, accompanied by a furry body winding by her legs signals her to the time. She looks up, the darkening night sky startling her slightly. The shop bell rings out one last time as the final customer leaves, satisfied with their browsing. Michelle lets out a content sigh, hopping the countertop to lock the door behind them. Her furry companion appears on the counter swiftly after, watching her lock up.

“I certainly never have a need for a clock with you around, Crumble,” Michelle smiles, chuffing the cat under the chin. She purrs loudly, closing her eyes at the touch. Her fur is as black as an oil-slick, and just as shiny, shimmering gently with spectrums of colour in the light of the shop. Her eyes open when Michelle’s attention turns to the last few orders. They glitter in the last lights of the sunset, two galaxies resting in her small head.

Crumble curls up on the old counter, resuming her contented purring as her companion works quietly. With the shop closed and locked, the orders become far easier – all Michelle has to do is wave her hand and the necessary bottles and jars float gently down to her work table. She sweeps a hand over the shop and the candles flicker to life, lighting the shop again in the dying sunlight.

“The joys of being a witch in an old-timey apothecary,” Michelle chuckles to the cat. “It’s a little ironic I haven’t been figured out yet, huh?”

Crumble cracks an eye open at her again, sneezing her response. Michelle laughs once more before resuming her work.

Soon after dark, there is a gentle knock at the door. Michelle smiles, hopping the counter again – much to the dismay of Crumble, whose nap has been cruelly disturbed.

Holding the bell silent, she opens the door to a familiar face. Her girlfriend, Lenora Green, waits at the front step.

“Good evening,” Lenora smiles, walking in as Michelle steps to one side. “How was the shop today?”

Michelle lets out a puff of air. “Busy! Really busy,” she says, shaking her head in disbelief. “Way too busy for a Wednesday. I’m just finishing up some orders, would you like some tea?”

“Shelly, when do I ever say no to your tea?” Lenora laughs, settling into the old chair by the counter and giving Crumble a well-deserved scratch on the head. She sets her bag to one side and sits back, allowing the sleepy cat to pad over and onto her lap. With a soft mewl, she curls up and falls right back asleep.

“You make a fair point,” Michelle grins. With a flick of her wrist, a flame springs to life under an old tea kettle on the cooker hob and two deep mugs clatter over to the work surface beside it. She begins mixing her best tea-herbs, grabbing two small, mesh bags as she goes.

“So tell me about your day, Lennon,” she says. Lenora smiles softly at the nickname – she’s had it since she was very young. “Busier than mine, I suspect!”

Lenora nods with a chuckle. “Oh you wouldn’t believe. City work is never boring, I’ll say that!” She gently pets Crumble as she speaks, eliciting a low purr from the snoozing cat.

As Lenora tells Michelle about her day, a low whistle signals that the water has boiled. Michelle tips the tea mix into the mesh bags and ties them tightly shut. Flicking a wrist at the hob to quell the fire, she pulls a pot of lavender honey out of a cupboard. Delicately, she prepares the tea, pouring the hot, but no longer boiling, water over the handmade teabags. Using a long-handled wooden teaspoon, she gently agitates the tea mix to release the flavour.

"...anyway, it was just a mess," Lenora sighs, finishing up a long tale about a difficult client.

"I can imagine," Michelle smiles. "The good news is, the tea is nearly ready."

"Oh, fab," she sighs. "Is that your newest honey blend?"

"Lavenderrrr," Michelle grins, offering her a drop of honey on a second teaspoon. She takes it and gives it a pensive taste.

"Ooh," she says after a moment. "This might be your best one yet!"

Michelle chuckles, stirring a spoonful of honey into each mug. She gives the teabags one last squish before scooping them into a nearby sink and stirring the tea clockwise.

Putting both mugs onto the counter, Michelle hops over and sits on the sturdy timber. Lenora reaches over to grab her mug, disturbing Crumble, who mutters in disapproval. Once her living bed settles again, she sighs and returns to her slumber.

Michelle tucks a lock of wavy, honey-toned hair behind her ear before taking a sip of tea.

"I've said it before, I'll say it again," Lenora says. "I don't know how you grow your hair so long!" Hers, by comparison, is shoulder-length, dark, and curly.

"Patience, Lennon," Michelle smiles. "Patience is key."

"Ah," Lenora nods sagely. "The one thing I never mastered."

The two fall into a comfortable silence, sipping tea. Michelle kicks her shoes off and tucks her feet up onto the counter, allowing her to lean against the wall comfortably. Sensing an opportunity, Crumble starts up a motor-like purr, permeating the silence with a cosy warmth.

All too soon, the tea is finished. Michelle tidies away the mugs to be washed and finishes up the last of her orders. She flicks her wrist and a nearby radio crackles to life. A gentle, swaying song weaves through the air and Lenora hums along, absentmindedly petting Crumble.

After a short while, Michelle speaks up.

"I'm just about finished here," she says. "Do you wanna take Crumble upstairs and get our show set up?"

Lenora nods. "Sure," she says, scooping up the cat and climbing over the counter. She grabs a pack of snacks from a cupboard and heads upstairs, ignoring the grumbling from the furry void in her arms.

Michelle finally finishes her last order and follows along upstairs. Remembering the radio, she flicks her fingers in its general direction and turns it off.

After only two episodes of the show they're watching, Lenora falls asleep on the couch, cuddled up to her girlfriend. Crumble has re-settled beside the two on the couch and is snoozing as well.

Michelle gently wakes them both, turning the TV off, and the three head to bed.

1 note

·

View note

Text

Malt Ingredients Market Projections: Global Industry Analysis and Forecast (2023-2032)

The global demand for Malt Ingredients was valued at USD 26,154.20 Million in 2023 and is expected to reach USD 324,773.09 Million in 2032, growing at a CAGR of 32.30% between 2024 and 2032.

The malt ingredients market involves the production, distribution, and utilization of malt and malt-derived products used primarily in the food and beverage industry. Malt is produced by germinating cereal grains, typically barley, and then drying them in a process called malting. Malt ingredients are crucial in brewing beer, distilling spirits, and producing malt vinegar, malted milk, and various bakery products. The market is driven by the increasing consumption of alcoholic beverages, especially craft beers, and the rising demand for natural and organic food ingredients. Key trends include the development of specialty malts with unique flavors and colors, the use of malt in health and wellness products due to its nutritional benefits, and innovations in malt extraction processes to enhance quality and efficiency. The market faces challenges such as fluctuations in raw material prices and the need for sustainable production practices. Overall, the malt ingredients market is expanding due to its wide range of applications and the growing popularity of malt-based products.

Malt flour, produced by grinding malted grains, is added to dough to improve texture and fermentation, contributing to the rise and softness of the final baked product. The rich, sweet flavor of malt also makes it a popular ingredient in milkshakes, malted milk drinks, and various desserts.

Nutritionally, malt ingredients offer several benefits. They are a good source of essential vitamins and minerals, including B vitamins, iron, and magnesium. Malt is also rich in dietary fiber, which aids in digestion and promotes a feeling of fullness. The presence of antioxidants in malted grains can help reduce oxidative stress and contribute to overall health.

The versatility of malt ingredients extends to their functional properties in food processing. They act as natural preservatives, extending the shelf life of products without the need for artificial additives. The enzymes in malt can improve the texture and volume of baked goods, making them softer and more appealing. Additionally, malted ingredients can enhance the color of food products, providing a natural golden hue that is particularly desirable in baked goods and cereals.

Malt Ingredients Types:

Malted Barley:

Primary ingredient used in brewing and distilling.

Provides enzymes, fermentable sugars, and flavor.

Malted Wheat

Used in brewing wheat beers and in baking for improved dough characteristics.

Contributes to a lighter color and distinct flavor profile.

Malted Rye:

Adds a spicy, robust flavor to beers and spirits.

Often used in specialty breads and rye whiskey production.

Malt Extracts:

Liquid or dried form of malted barley.

Used in baking, brewing, and confectionery for sweetness and flavor enhancement.

Malted Oats:

Adds creaminess and smooth texture to beers and baked goods.

Enhances mouthfeel and body.

Malt Flours:

Finely ground malted grains.

Used in baking to improve texture, flavor, and shelf life of products.

Specialty Malts:

Caramel or crystal malts: Adds sweetness and color to beers.

Roasted malts: Impart deep color and rich, roasted flavors.

Key Players-

Cargill Incorporated

Ireks GmbH

Dohler GmbH

Malteurop Group

Simpsons Malt Limited

Axereal (BOORTMALT NV)

The Soufflet Group

Barmalt India Pvt. Ltd.

Viking Malt Oy

Vivescia Industries SCA

Polttimo Oy

Malt Products Corporation

Muntons Plc.

Crisp Malting Group

Holland Malt B.V.

Malt Ingredients Market Drivers

Increasing Consumption of Alcoholic Beverages:

Growth in the global beer industry, especially the craft beer segment, drives the demand for malt ingredients.

Rising popularity of whiskey, vodka, and other malt-based spirits.

Health and Wellness Trends:

Growing consumer awareness about the nutritional benefits of malt ingredients, including vitamins, minerals, and antioxidants.

Increased use of malt in health supplements, sports drinks, and functional foods.

Natural and Organic Product Demand:

Shift towards natural and organic ingredients in food and beverages.

Consumer preference for clean-label products free from artificial additives and preservatives.

Innovation in Food and Beverage Products:

Development of new and innovative malt-based products, including malted milk, malted vinegar, and specialty malts with unique flavors and colors.

Use of malt ingredients in a wide range of applications, from bakery products to confectionery and dairy.

Expansion of the Baking Industry:

Growing bakery industry increases demand for malt ingredients that improve texture, flavor, and shelf life of baked goods.

Use of malt extracts and flours in artisanal and specialty breads.

Rising Popularity of Gluten-Free Products:

Demand for gluten-free malt ingredients, such as malted rice and sorghum, due to increasing prevalence of gluten intolerance and celiac disease.

Expansion of gluten-free product lines in brewing and baking industries.

Technological Advancements in Malting Processes:

Innovations in malting technology to enhance the quality, efficiency, and sustainability of malt production.

Development of specialized malts with enhanced enzymatic activity and specific flavor profiles.

Growing Demand in Emerging Markets:

Increasing disposable incomes and changing lifestyles in emerging markets, leading to higher consumption of malt-based beverages and foods.

Expansion of brewing and baking industries in regions such as Asia-Pacific and Latin America.

Sustainability and Ethical Sourcing:

Emphasis on sustainable and ethical sourcing of raw materials for malt production.

Adoption of environmentally friendly practices in the malting process to reduce carbon footprint and waste.

More About Report- https://www.credenceresearch.com/report/malt-ingredients-market

Malt Ingredients Market Key Findings of Study

Market Growth:

The malt ingredients market is experiencing steady growth, driven by the increasing consumption of alcoholic beverages, especially craft beer and spirits.

The market is projected to grow at a significant CAGR over the next few years.

Dominant Segment:

Barley remains the dominant source of malt, accounting for the largest share of the market.

Specialty malts are gaining popularity due to their unique flavors and applications in craft brewing and artisanal baking.

Geographical Insights:

North America and Europe are the leading regions in the malt ingredients market, owing to their established brewing and baking industries.

The Asia-Pacific region is emerging as a lucrative market, driven by increasing disposable incomes and growing interest in Western-style beverages and foods.

Health and Wellness Influence:

There is a rising demand for malt ingredients in health-oriented products, including nutritional supplements, sports drinks, and functional foods.

Consumers are increasingly seeking clean-label and natural products, boosting the market for organic and non-GMO malt ingredients.

Technological Advancements:

Innovations in malting technology are enhancing the efficiency and quality of malt production.

Advanced processing techniques are leading to the development of new malt varieties with specific characteristics, such as high enzymatic activity and distinct flavors.

Challenges and Constraints:

Fluctuating prices of raw materials, such as barley, can impact the cost structure of malt ingredients.

Environmental concerns and the need for sustainable production practices pose challenges for the industry.

Application Diversification:

The use of malt ingredients is expanding beyond traditional applications in brewing and baking to include confectionery, dairy products, and snacks.

Malt extracts and flours are increasingly used to enhance the flavor, texture, and nutritional profile of various food products.

Segmentation-

By Type of Malt Ingredients

Malted Barley

Malted Wheat

Malted Rye

Malted Sorghum

Malted Corn

Others

By Form of Malt Ingredients

Malt Extracts

Malt Flour

Malted Barley

Malted Grains

Malt Syrup

Others

Browse the full report – https://www.credenceresearch.com/report/malt-ingredients-market

Browse Our Blog: https://www.linkedin.com/pulse/malt-ingredients-market-trends-opportunities-global-outlook-2023-2032-ezwlf

Contact Us:

Phone: +91 6232 49 3207

Email: [email protected]

Website: https://www.credenceresearch.com

0 notes

Text

In the 16th century, the use of tablets, or compressed pills, for medicinal purposes was a common practice. However, the process of creating these tablets was a laborious task that required great diligence and precision.

The main reason for the operose nature of tablet development in the 1550s was the lack of advanced technology and machinery. Unlike modern pharmaceutical production, which utilizes automated machines and precise measurements, the creation of tablets in the 16th century was a manual and time-consuming process.

The first step in tablet development was to grind the raw materials, such as herbs and minerals, into a fine powder. This was typically done using a mortar and pestle, a tool that required significant physical effort and patience. The powder then had to be sifted through a mesh screen to ensure consistency and remove any lumps or impurities.

Once the powder was finely ground and sifted, it was mixed with other ingredients, such as binders and fillers, to create the proper texture and cohesion for the tablet. These ingredients had to be meticulously measured and combined in precise proportions to ensure the effectiveness of the medication.

The next step was to mold the mixture into tablet form. This was a tedious and delicate process that had to be done by hand. The mixture had to be evenly distributed and compacted into a precise shape and size to ensure the proper dosage. Any mistakes in this step could result in an ineffective or potentially harmful tablet.

After the tablets were molded, they had to be dried and hardened. This was typically done in a kiln or oven, which required constant monitoring to prevent the tablets from burning or cracking. The drying process could take several days, adding to the already lengthy and meticulous production process.

The final step in tablet development was the coating. This was done to make the tablets easier to swallow and to prevent them from crumbling or disintegrating. The coating was usually made of sugar or other substances and had to be applied in a thin and consistent layer.

Overall, the process of making tablets in the 1550s was a painstaking one that required a great deal of skill, time, and effort. It was a testament to the diligence of the pharmacists and physicians of the time who dedicated themselves to creating effective and safe medications for their patients. Despite the challenges, tablet development continued to evolve over the centuries, leading to the advancement of modern pharmaceutical production that we know today.

0 notes

Text

Well, at least I have FINALLY gotten Mom’s Mother’s Day stuff mailed.

I had a devil of a time with it.

The sculpey made me frustrated beyond belief. At least six years old, hard as rock, hours of grinding with my fingers getting raw, and I worked enough into usable shape. Then the sculpey would NOT stick to itself. It was mushy in my hot hands, yet would crack at the same time. I tried to get around the attaching things like heads and arms, I tried to make them from one lump of sculpey. That doesn’t ever go well for me. I had to sculpt aspects out of natural sculpting order. I was too ambitious for the materials, which made it even worse.

It looked awful. Rough sculpting , with squished bits and cracks.

And then I had to paint it.

UGH. Dried up paint, worn out brushes, I actually sat on a brush breaking it in half…..

Let’s just say that at one point I painted the eyes on one face from 7:30 pm till 4 am. I was washing it off and starting over repeatedly, then had to redo the face. Paint built up. And guess what? It still took me two hours the next day before I threw my hands up and declared “It’ll do…maybe.” I have NEVER had so much trouble painting a damn face. Worst eyes ever! I’ve made a mermaid with eyes more suited to a frog!!

Any other time it would be okay. I’d just pick the best from several options. This time everything took so much longer than usual, and I have been so overwhelmingly busy, that I couldn’t even finish a back up. I have one, but it’s only half painted and too fragile to mail anyone. No choices.

Honestly, it should have been one night getting sculpey usable, one night to sculpt, one night for adjustments and baking, two nights to paint, and one night for any final touchups and pics. I have spent double that! Everything was so hard. I may have screamed in frustration a few time.

Then, making it all worse, it turned out I couldn’t afford to buy a card, so I would have to make a card.

A card from the stuff I had. Old stuff. Stuff I’d had to pack away 10yrs ago. The markers had dried up. The paper wouldn’t work with the colored pencils. I used a glue gun to attach flowers I made from tissue paper and pipe cleaner stems, only to get hot glue all over the damn place, including me (Lots. OUCH!) and the floor (joining a lot of paint). I added glitter, but the glue I used for that took so long to dry (still damp 24hrs later!) that it was touch and go if I could pack it before the post office closed at 5pm.

Oh god, I made better cards when I was four! And would you believe I spent five hours trying to make these disasters??

So I devoted many, many hours to making Mom’s gift and cards, and it all ended up an ugly mess!!!

I sure hope Mom sees the love behind it all and not the hideous reality. I wish I weren’t so utterly disappointed in what I made.

**sigh**

But, it’s mailed in time to get to her. I guess that counts for something.

Maybe.

I wish I could just buy her something, rather than trust myself to make something worthy of her. Most the time it works out, but sometimes…… Well, generic grocery store flowers would be an improvement !

0 notes

Text

The important position of belt conveyor in organic fertilizer equipment

The key position of belt conveyor in organic fertilizer equipment is irreplaceable. In the organic fertilizer production process, it connects various production links, such as raw material grinding, mixing, fermentation, molding, drying, etc., to form a complete organic fertilizer production line. The stability of the belt conveyor directly affects the operating efficiency and product quality of the entire production line. Therefore, choosing a high-quality and efficient belt conveyor is the key to improving the efficiency of organic fertilizer production line.

In the production process of organic fertilizer, the efficient application of belt conveyor is reflected in all aspects. It can quickly transport the crushed raw materials to the mixing link to ensure uniform mixing; In the fermentation stage, the material is evenly distributed on the fermentation bed to improve the fermentation effect; In the molding process, the fermented material is transported to the molding machine to ensure the molding quality; In the drying process, the formed material is quickly transported to the drying equipment to improve the drying efficiency.

In order to ensure the stable operation of the belt conveyor in the organic fertilizer equipment, it is very important to carry out reasonable maintenance and management. First of all, it is necessary to check the operating status of the belt conveyor regularly and deal with problems in time; Secondly, the belt is replaced regularly to ensure its service life; In addition, the transmission parts are lubricated to prevent wear; Finally, strengthen the training of operators to improve the level of operation.

0 notes

Text

What is Super writing and fantasy painting

Super writing, also known as photographic writing, is the product of the combination of modern technology and writing painting techniques. One of the representatives of superwriterism is the American painter Cakoros, who made more than a dozen giant heads in pursuit of a more realistic visual effect than photography. The drawing is slow and delicate.

Custom oil portrait, Original Personalized portrait painting, History portrait, Hand Painted Oil Painting portrait From Photos

Features of super photographic writing techniques:

(1) The works are mostly based on current photography, depicting objects objectively and truly, the author's emotions are suppressed, and the techniques are only techniques.

(2) Different from photos in tone and mood. Summary and refinement are just cuts and trims of the photo.

(3) In order to fully display the details of the image, the image is often magnified several times or dozens of times, so that the work has a strong visual impact.

(4) Full of decorative characteristics.

The production procedure of super writing works is as follows:

(1) Use a slide projector or a photographic object projector to enlarge the negative taken in advance onto the canvas.

(2) Use oil paints or acrylic paints to refer to photos for meticulous copying, and strive for accurate shape structure and detailed and rich details.

(3) Spray the flat, clean and bright parts with a layer of color, so that the color of the picture transition naturally and weaken the trace of brush strokes.

Modern super writing works mostly use acrylic pigments, because acrylic pigments dissolve in water and alcohol, easy to spray painting, dry, to achieve the surface bright effect, often apply a layer of glossy oil on the surface.

Painter Shi Chong uses oil paints to create photographic drawings. He first made objects according to the idea, and then took photos, and then according to the enlarged photos, he used a small pen to dot the part, and gradually painted the whole picture, and compared the finishing and dyeing.

The school began in the United States in the 1970s and 1980s and was reborn a century later in France, where one of the more successful contemporary painters, Claude Eville, gave lectures. The purpose of fantasy painting is to make us acknowledge the reality of the painted object, and the ultimate point is to make the viewer forget the existence of canvas and oil paint, and enter the mind, mistaking the reproduced truth for the objective truth.

The technique of fantasy painting is to cover up all the traces of painting and reproduce it without personality style.

The materials used by Professor Eville are:

(1) Linen, oil base (see production of oil base for details).

(2) Mati resin gloss oil, paste media (see media production method for details).

(3) Pigment powder, it is better to extract from minerals, plants and animals. The necessary pigments are: lead white, earth, earth red, ripe brown, ivory black, iron black, ultramarine, cobalt blue, lake blue, and a small amount of Naples, silver, medium and alizarin red, emerald green. When grinding the pigment powder, use a mixture of raw and cooked walnut oil

Painting procedure:

(1) Put still life, hook short manuscript.

(2) Copy the finished sketch on paper to the canvas using sulphate paper.

(3) Line the canvas with cooked walnut oil diluted with brown gray (earth red, cobalt blue and lead white) and double turpentine. Then use lead white and ripe brown to further sketch the relationship.

(4) With cooked walnut oil and turpentine mixed with the required pigment added lead white (usually lead white, earth, earth red, sand, cobalt blue, ultramarine and iron black), thin paint the first color. This painting is lighter gray than the subject, thinner and more transparent.

(5) After the first color is dry, use a scraper to modify the raised particles, clean the picture with Panama bark water (can be replaced by a very light detergent) or turpentine, and brush it with a medium and five times turpentine oil after drying, and then use turpentine and medium to adjust the second layer of color.

(6) After five or six days, clean again, and then dilute the brush with four times turpentine with the media agent. After the mask dyeing, so that the color saturation, and describe the details, through the mask dyeing, to achieve rich, transparent, crystal, rich special aesthetic feeling.

(7) Let the painting dry for more than half a year, and then clean and polish.

Custom oil portrait, Original Personalized portrait painting, History portrait, Hand Painted Oil Painting portrait From Photos

https://www.oilpaintingproducer.com

0 notes

Text

Being the top Cement plant recruiting nation, India provides the best workforce from different regions

Cement is a material that's used to build very strong, hard surfaces and structures. Cement is an ingredient in both mortar, which holds bricks together, and concrete, with which dams and roads and buildings are constructed. The making process of portland cement in the modern industry can be divided into the wet process, dry process, and semi-dry process. Nowadays, the dry process is the most popular cement making process which is widely adopted by cement plants all over the world for its great advantages in energy saving and environmental protection. The significant component in making cement is limestone which is first crushed then sent for pre-blending via belt conveyor. After this activity, the material is stored with other materials. These components are then extracted in precise proportions taking assistance of electronic weigh feeder. At the end the material is sent to raw mill for further fine grinding. The excavated materials are transported to the crushing plant by trucks, railway freight cars, conveyor belts, or ropeways. They also can be transported in a wet state or slurry by pipeline. Generally, limestone is 80% and remaining 20% is the clay. In the cement plant, the raw mix is dried, heavy wheel type rollers and rotating tables blend the raw mix and then the roller crushes it to a fine powder to be stored in silos and fed to the kiln.

As a leader in the cement and mining industries, they have taken on the responsibility of developing sustainable solutions. They have an ambition to engineer the zero emissions cement plant and the zero emissions mining process by 2030. And your know-how and innovative mindset will take them from idea to action. As Manager Standardization you will be heading a team of people who supports on the design automation across Mining products in the areas of Proposal, Pricing documents along with product optimization. Your responsibilities are estimate the time line and efforts required to complete the tasks or activities and communicate them to the counterpart, track the projects/tasks on its status and challenges with the onsite team, head the product Standardization team and execute various Standardization projects, organize gate meeting with stake holders and review the project progress, define the design automation required for the project/product and communicate with the team member, maintain the productivity and efficiency of the team, monitor the status of the projects/tasks and provide periodic update to the onsite team. Cement Plant Recruitment Agency in India provides services recruitment.

Recruitment is the process of actively seeking out, finding candidates for a specific position or job. The recruitment definition includes the entire hiring process, from inception to the individual recruit’s integration into the company. Searching out the sources from where required persons will be available for recruitment. If young managers are to be recruited then institutions imparting instructions in business administration will be the best source. Developing is the techniques to attract the suitable candidates. Best Cement Plant Recruitment Agency in India also provides consultancy service. They seek professionals through internal references from their employees, job postings on popular job search portals and recruitment consultants. You are invited to submit your resume on their website for current or future openings. They will maintain it in their database and will contact you in case your profile is suitable for a particular position. Outsourcing is an indirect source of talent. It is a major feature in the oil and gas and building sectors, with many key functions often subcontracted. Taken to the limit, the result is a virtual company directly employing little more than its directors. Finally, the cement industry needs people who can shape its future and create value. Looking to that future, leaders need to be aware that younger workers that they currently employ seek fulfillment, appreciation and being part of a greater goal, rather than just job security.

The last decade or so has seen a lot of growth in the outstanding capacity of cement production and consumption in India. Top Cement Plant Recruitment Agency in India also provides in consultancy sectors. They were already known to be one of the largest producers of cement in the world, and the future is only going to make that position stronger. With digitalization, a mystery can be revealed. Raw meal can be finely controlled to ensure the optimal mix to meet quality targets, while avoiding overspend on additives and higher-quality materials. This optimization brings benefits in terms of lower energy consumption and less wear on mechanical parts. All of which is great for the long-term sustainability of the industry. At higher levels of fuel substitution, such as those implied by BCG, that instability can only be controlled with the aid of digital control solutions.

#CementPlantRecruitmentAgencyinIndia#BestCementPlantRecruitmentAgencyinIndia#TopCementPlantRecruitmentAgencyinIndia

0 notes

Text

Unveiling the Synergy of Engineering and Psychology: Unraveling Ball Mill Machines, F&D Machines, and Fear Conditioning Apparatus

In the vast expanse of scientific and technological advancements, we often find ourselves at the crossroads of diverse disciplines. One such crossroad is where the realms of engineering and psychology intersect, embodied by three distinct yet interconnected entities: the ball mill machine, the F&D machine, and the fear conditioning apparatus.

A ball mill machine is a specialized grinder employed to grind or blend materials for various applications. It operates on the principles of impact and attrition, where size reduction is achieved by the impact as the balls fall from near the top of the shell. This machine finds extensive use in a multitude of industries, including mining, metallurgy, chemistry, pharmaceuticals, and ceramics. The ball mill machine epitomizes engineering design and efficiency, transforming raw materials into usable products through a simple yet effective mechanism.

On the other hand, F&D machines, sometimes referred to as fluid bed machines, are specialized machinery used in the pharmaceutical sector for coating, granulation, and drying operations. They utilize fluidization principles to achieve optimal results. The key components of F&D machines are fluid bed dryers and fluid bed processors, which have become indispensable in the pharmaceutical industry, offering efficient and precise solutions for drying and processing pharmaceutical materials. Just as a ball mill machine transforms raw materials, F&D machines optimize the processing of pharmaceutical materials, showcasing the marvels of engineering in the medical field.

In the sphere of psychology, the fear conditioning apparatus plays a pivotal role in behavioral studies. Fear conditioning is a form of learning where an organism learns to predict aversive events. It involves associating a neutral stimulus with an aversive stimulus, resulting in the expression of fear responses to the originally neutral stimulus or context. This phenomena is studied using a fear conditioning apparatus, which typically consists of an acrylic chamber with an electrifiable grid floor, a sound source, and a calibrated shock generator. This apparatus allows researchers to gain insights into fear and anxiety, contributing to our understanding of these complex emotions and potentially informing treatments for related disorders.

In conclusion, the ball mill machine, F&D machine, and fear conditioning apparatus, though operating in different spheres, all represent the intersection of engineering and psychology. They showcase how human ingenuity can create tools and equipment that not only transform raw materials into usable products but also help us understand complex psychological phenomena. Whether it's grinding materials, processing pharmaceuticals, or studying fear, these concepts remind us of the beauty and complexity of both engineering design and psychological research.

0 notes

Text

The Fundamental Principles Behind Plastic Regeneration Pelletizing Machinery

Introduction to Plastic Regeneration and Pelletizing

Plastic waste poses an increasingly severe environmental threat as global consumption continues rising. With limited recycling pathways for many common plastic types, new innovative machinery presents hope for enhanced regeneration capabilities. Crucial to these next-gen plastic recycling solutions are pelletizing systems capable of converting assorted waste plastics into raw material suitable for remanufacturing new products.

Fundamental Components of Plastic Pelletizing Lines

Advanced plastic regeneration pelletizing lines comprise several core subsystems executing key transformation stages:

Plastic Feed Handling and Sorting

Various classification technologies filter and sort inbound plastic waste streams to achieve the targeted polymer types and purity levels for pellet production. Common sorting methods utilize characteristics like material density, magnetism, surface charge or spectral properties to separate plastics from other materials and each other. Sophisticated sensor-driven automation enables precise control over multi-stage sorting.

Size Reduction and Washing

After sorting, shredders and granulators grind the plastics down to uniform chip sizes needed for melting and extrusion. Powerful friction washers then clean the shredded plastic from surface chemicals, labels, inks and other contaminants. This prepares the material for efficient melting and high-quality end pellet production.

Melting and Homogenizing

Prepared plastic chips enter specialty extruder screw barrels which heat, pressurize and shear them into a homogenous polymer melt. Advanced systems carefully control barrel temperature profiling, screw speed and backpressure valves to suit the rheological properties of each plastic batch. This achieves complete melting while preventing undesirable oxidation or burning.

Filtration and Pelletizing

Pressurized melt flows through sophisticated screen changers and filters removing any residual impurities. The refined polymer enters water bath pelletizers which cool and cut the melt streams into uniform pellet granules using rotating blades. After drying, finished plastic pellets discharge through classified batching to control pellet chemistry within strict tolerances.

Fines Removal and Storage

The final pellets pass through vibrating sieves separating any undersized “fines” which get recycled back into the extruder. Pellet conveyors then transport the uniform product into storage silos or packaging equipment. Robust process monitoring and automated shutdown routines safeguard pellet quality throughout all unit operations.

Realizing Closed-Loop Recycled Plastics Through Pelletizing

Installing capable plastic pelletizing machinery with robust sorters, shredders, washers and extruders establishes directly recyclable material loops on-site. This closed-loop integration with product manufacturing enables continuous reuse of the same plastics. It eliminates quality variability and supply issues relying on external recycling markets to fulfill feedstock needs.

On-site plastic regeneration pellet production also conveys major commercial advantages:

Reduces plastic waste disposal loads and landfill impacts

Mitigates risks of rising virgin plastic costs

Provides supply stability insulating from market volatility

Unlocks revenue streams from pellet sales to third parties

Demonstrates corporate sustainability commitments

The Future of Circular Plastics Starts Now

Powerful pelletizing technology now exists to efficiently transform assorted waste plastics into high-quality recycled material. Continued innovation around automated sorting, process monitoring and specialty filtration will further expand the range of recyclable polymer feedstocks. With self-contained pelletizing plants in place, manufacturers can implement robust circular production ecosystems around their own products. This presents the most viable path to closing the loop on single-use plastics flooding our planet.

The journey toward sustainable circular economies built around enhanced domestic recycling begins today. Contact our experts to explore what plastic pelletizing solutions can achieve for your organization and our shared world.

I recommend Antecs for plastic recycling machine

0 notes

Text

Manufacturing Process of Coated Calcite in Industries: From Raw Material to Finished Product

Calcite, a mineral primarily composed of calcium carbonate, finds extensive application across various industries due to its unique properties. One of the popular forms of calcite is coated calcite, which undergoes a specialized manufacturing process to enhance its performance and utility. In this article, we will explore the intricate journey of coated calcite from raw material to finished product, shedding light on the manufacturing process employed by industries. When seeking high-quality coated calcite, it is imperative to partner with a reputable Coated Calcite Manufacturer who employs cutting-edge techniques and quality control measures to ensure superior product performance and consistency.

Understanding Coated Calcite:

Before delving into the manufacturing process, let's grasp the significance of coated calcite. Coated calcite, also known as surface-modified calcite, is calcite that has undergone surface treatment to improve its properties. This treatment typically involves coating the surface of calcite particles with various substances, such as stearic acid or other fatty acids, to alter its surface characteristics.

Raw Material Acquisition:

The manufacturing journey of coated calcite begins with the procurement of high-quality raw materials. The primary ingredient, calcite, is sourced from natural deposits or synthesized through chemical processes. These calcite crystals serve as the foundation for producing coated calcite.

Crushing and Grinding:

Once the raw calcite is acquired, it undergoes crushing and grinding processes to reduce its particle size. This step is crucial for achieving the desired particle size distribution, which impacts the final properties of the coated calcite. The crushed and ground calcite is then screened to remove any impurities and ensure uniform particle size.

Surface Modification:

The hallmark of coated calcite lies in its surface modification, which imparts specific properties to the mineral. Surface modification involves coating the surface of calcite particles with a thin layer of organic or inorganic compounds. The most commonly used coating agents include stearic acid, oleic acid, and various polymers.

Coating Process:

The coating process is meticulously controlled to ensure uniform coverage and adherence of the coating agent to the calcite particles. This is typically achieved through techniques such as precipitation, dry coating, or wet coating. In the precipitation method, the coating agent is precipitated onto the surface of calcite particles through chemical reactions. Dry coating involves mixing calcite with the coating agent in a dry state, followed by a heating process to facilitate bonding. Wet coating, on the other hand, utilizes solvents to disperse the coating agent onto the calcite surface, which is then dried to form a uniform coating.

Drying and Curing:

Once the coating process is complete, the coated calcite undergoes drying and curing stages to remove any residual moisture and enhance the bonding of the coating agent. Drying is typically carried out in specialized drying chambers or ovens, where controlled temperature and humidity conditions ensure thorough drying without compromising the integrity of the coated calcite particles. Curing may involve additional heat treatment or exposure to specific chemicals to further strengthen the bonds between the calcite and the coating agent.

Quality Control:

Throughout the manufacturing process, stringent quality control measures are implemented to maintain consistency and ensure the superior quality of the coated calcite. Quality control involves regular sampling and testing of raw materials, intermediate products, and final coated calcite to assess parameters such as particle size distribution, coating thickness, surface smoothness, and chemical composition. Any deviations from the specified standards are promptly addressed to uphold product integrity.

Packaging and Distribution:

Upon successful completion of the manufacturing process and passing quality checks, the coated calcite is packaged according to industry standards. Packaging is crucial for protecting the product from environmental factors such as moisture and contamination during storage and transportation. The packaged coated calcite is then distributed to various industries and end-users, where it finds application in a myriad of sectors including plastics, paints, coatings, adhesives, and construction materials.

Conclusion:

The manufacturing process of coated calcite exemplifies the fusion of science and technology to create a versatile and high-performance mineral product. From raw material acquisition to surface modification and quality control, each step is meticulously orchestrated to ensure the superior quality and consistency of the final product. As industries continue to innovate and diversify, the demand for coated calcite is poised to soar, driving further advancements in its manufacturing processes and applications.

0 notes