#Robotics and Automation Actuators

Explore tagged Tumblr posts

Text

The Global Robotics and Automation Actuators Market Size was valued at USD 18.7 billion in 2022 and is estimated to reach USD 35.8 billion by 2027, growing at a CAGR of 13.9% during the forecast period. Industries across all the regions are expected to adopt robotics and automation actuators that have simple designs, are easy to operate, and are cost-effective.

Driver: Ongoing technological advancements in Robotics and automation actuators

The demand for improved performance Robotics and automation actuators for use in various industries has led to the development of new and advanced actuators such as electrical actuators, compact pneumatic actuators, and explosion- proof actuators. Electrical actuators are the most advanced actuators in terms of technology. They are increasingly used in the mining, automation, aerospace & defense, and chemical industries as they are silent, clean, non-toxic, and energy competent. These actuators are more efficient than pneumatic and hydraulic actuators. Electrical actuators can be integrated with critical systems using data bus communication. They offer instant feedback of movements of end effectors and provide accurate variable control over motor speed acceleration and velocity. They are also easy to install. Electrical actuators have a long shelf life and require low maintenance, leading to low total functional costs as compared to other actuators.

Moreover, several other types of actuators, such as mini-electrical actuators, digital linear actuators, and idle speed controllers, have also been developed and introduced in the market. Thus, continuous technological advancements in actuators are expected to lead to their increased application in various industries, thereby fueling their demand across the globe. This increased demand for different types of actuators is expected to contribute to the growth of the Robotics and Automation Actuators Industry during the forecast period.

#Robotics and Automation Actuators#Robotics and Automation Actuators Market#Robotics and Automation Actuators Industry#Global Robotics and Automation Actuators Market#Robotics and Automation Actuators Market Companies#Robotics and Automation Actuators Market Size#Robotics and Automation Actuators Market Share#Robotics and Automation Actuators Market Growth#Robotics and Automation Actuators Market Statistics

0 notes

Text

Why Electric Actuators Are Now the Core of Robotic Automation❓

From manufacturing lines to service robots, automation is everywhere—and at the heart of it all lies one powerful component: the electric actuator.

An electric actuator converts electrical energy into precise motion using a motor and a reducer. It's the key to enabling robots to move smoothly, lift accurately, and repeat tasks reliably without human intervention.

As robots get smaller and more advanced, actuators must follow suit. Bon Systems’ BCSA series answers this demand with its slim yet high-torque design, using in-house developed cycloidal gear technology. This structure not only maximizes torque but also minimizes space, allowing for more innovative and compact robot designs.

Whether it’s for an autonomous mobile robot in a warehouse or a collaborative arm in manufacturing, reliable actuators make the difference between a demo and real-world performance.

BonSystems offers custom actuator design, scalable production, and engineering support to bring your automation to life.

📌Explore our solutions or start a project consultation at our website.

0 notes

Text

#automation#robotics#ckdgripper#fanucrobots#seimitsu#Gripper#exporters#distributors#automationsolutions#manufacturers#AutomationTechnology#linearmotion#actuator#actuatortechnology#motorlessactuators#suppliers#dealers#channelpartners

0 notes

Text

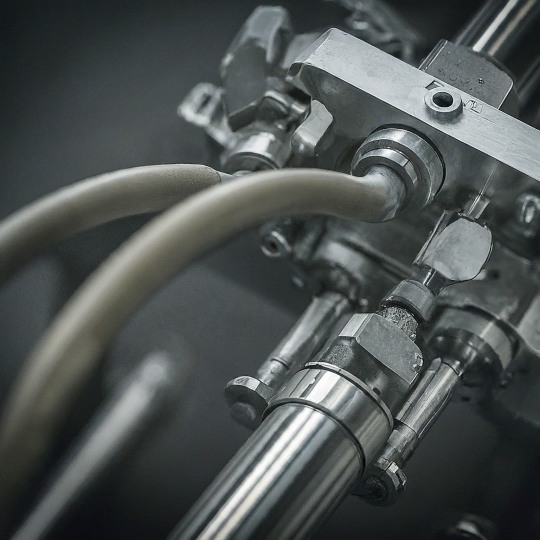

Unlocking Precision and Power: A Guide to Hydraulic Servo Actuators

Introduction: In the realm of automation and motion control, hydraulic servo actuators reign supreme for their unmatched blend of raw power and exceptional precision. These marvels of engineering combine the potent force of hydraulics with the meticulous control of electronic systems. This comprehensive guide delves into the world of hydraulic servo actuators, exploring their inner workings,…

View On WordPress

#Electrohydraulic Actuators#Feedback Mechanisms#Flight Control Systems#High Force Applications#Hydraulic servo actuators#Industrial automation#Linear Actuators#Motion Control Systems#Proportional Valves#Robotics#Rotary Actuators

0 notes

Text

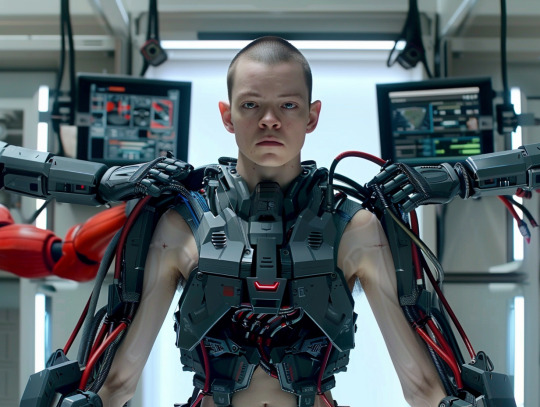

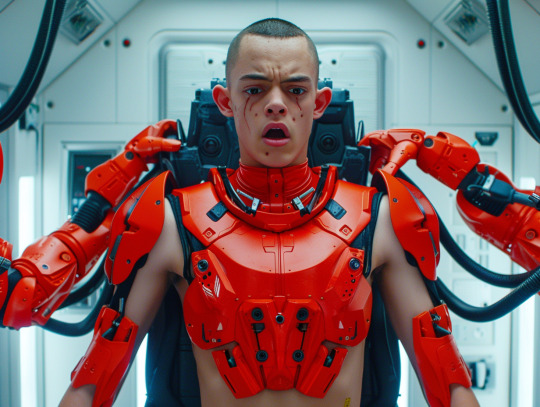

The First Fitting

The walls of the chamber gleamed antiseptically white, the kind of clean that makes you feel dirty just by stepping inside. I was 80LKU now—my old name, overwritten by the ID tattooed onto my chest in stark, inky permanence. I stood there, nude except for the Standard Chastity/Underwear/Diaper Component hugging my groin.

The door behind me sealed with a hiss, and I took a deep breath. The air was cool and sterile, tinged with the faint scent of industrial lubricants. I had been prepped for this moment, but nothing could fully prepare you for the reality of the Automated Armor Suit Fitting System.

"Welcome, Cadet 80LKU," the chamber's AI voice intoned. "Please remain still."

A mechanical arm descended from the ceiling, a sleek, articulated thing with a cold, metallic grip. It latched onto my back, and I felt a shiver of helplessness as it clicked into place. The docking mechanism held me firm, a steel embrace that left no room for resistance.

I reminded myself that this was just the beginning. I had to adapt or be adapted.

A gripper descended and clasped around my shaved head, sending a shiver down my spine. I felt a cold sensation as a neural blocker activated, and suddenly, control over my limbs slipped away. My body became stiff, a marionette controlled by the chamber.

The robotic servo arms came next. They moved with an eerie, almost organic fluidity, their joints whirring softly. They started with the boots, lifting my feet and sliding them into place with practiced precision. As the straps tightened around my ankles, another set of arms descended, fastening additional points of stabilization.

The torso protector came next, encasing my chest and back in a rigid shell. It hugged my body, aligning itself perfectly with the contours the 3D scanners had mapped out. The sensation was like being swallowed by a mechanical beast, one piece at a time. The clicks of the components locking into place reverberated through my bones.

Hips and legs followed, each segment locking into place with a series of precise clicks. The arms were last, servo arms lifting and positioning the components with relentless efficiency. When the gauntlet-style gloves finally enclosed my hands, I felt like a puppet, strings pulled tight by the machinery. The sound of each segment securing into place was a mechanical symphony of finality.

The AI’s voice droned on, listing calibration checks and final adjustments. I tried to focus on the process, to absorb the technical details, but the psychological impact was undeniable. I was encased, trapped in a shell of metal and composites, my fate sealed by the cold logic of the system.

"Final checks and adjustments in progress," the AI announced. I stood there, a living mannequin, as sensors and actuators fine-tuned my new exoskeleton. The biometric integration hummed to life, monitoring my vitals and feeding the data back into the system.

A wave of emotions crashed over me—helplessness, fear, and a strange sense of awe. This suit was my new reality, my second skin. The helplessness was a feature, not a bug; it was designed to break us down, to make us accept our place in the grand scheme.

As the final fastening mechanisms clicked into place, I knew there was no turning back. The suit was part of me now, its weight a constant reminder of the path I had chosen—or, more accurately, the path that had been chosen for me.

“Integration successful. Cadet 80LKU, you are now operational.”

The docking arm released me, and I took my first step in the full-body armor. The suit moved with me, a seamless extension of my own movements. But I could feel the weight of the system, both physically and mentally. This was my new life—encased, controlled, conditioned.

As I walked out of the chamber, I caught a glimpse of myself in the reflective surface of the wall. A faceless figure in black armor stared back at me, a new recruit ready to serve the Republic. And for the first time, I truly understood what it meant to adapt—or be adapted.

28 notes

·

View notes

Text

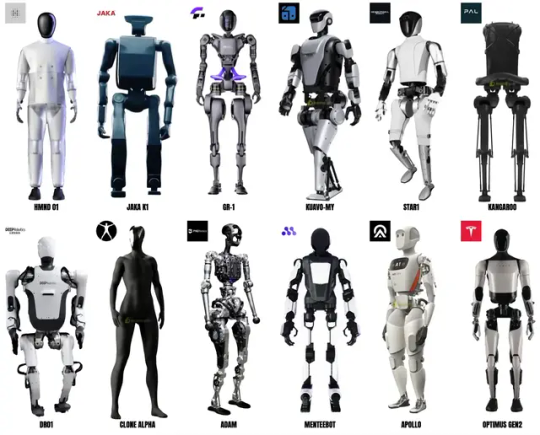

HMND 01

Another bland, all-purpose chassis. The control systems look modular—good for rapid prototyping. No clear edge in autonomy or payload. Could be a solid testbed for LAWS compliance modules. Would need serious upgrades for real combat utility. Not impressed, but not dismissing it either.

JAKA K1

Boxy, utilitarian. Classic industrial design—prioritizes durability over grace. Would slot in as a logistics mule or ammo carrier, but mobility constraints are obvious. A good candidate for AR-based remote control overlays. I wonder if it could double as a decoy unit in urban environments?

GR-1 (Fourier Intelligence)

Some intriguing actuation here—almost bio-inspired. The focus on rehab and elderly care is endearing, but I see potential for dual-use in battlefield casualty extraction or medical simulation. Human-in-the-loop is feasible, but the platform screams for more autonomy. Would love to test its gait stability in rough terrain.

KUAVO-MY

Looks like a research platform—good for rapid iteration and code injection. Not much armor or redundancy, but the open architecture is a plus. Could be prototyped for swarm tactics or as a sensor-forward scout. The lack of obvious weapon mounts is both a relief and a missed opportunity.

STAR1

Sleek, but form over function. Likely more useful in PR stunts or as a non-lethal presence in peacekeeping ops. If I were to retrofit, I’d focus on CBRN sensor integration. Its humanoid profile makes it an ideal candidate for AR deception tactics—simulate friendly or enemy units on the fly.

KANGAROO (PAL Robotics)

Intriguing leg design. High mobility could be leveraged for quick-strike or urban recon—especially in environments unsuited to wheeled robots. Not enough payload space for heavy weapons, but could run interference or deliver microdrones. If only the developers thought beyond logistics.

DR01 (Deep Robotics)

Standard warehouse bot, but robust. Could retrofit for automated resupply under fire or as a shield platform for advancing infantry. I’d love to stress-test its fail-safes—most civilian systems crumble under jamming. With enough ruggedization, could be a sleeper hit for rear-echelon support.

CLONE ALPHA

Uncanny valley in full effect. Maybe useful for psychological ops or as a decoy. Not much info on its internal architecture—probably just another platform for gesture and interaction studies. If it’s hackable, it’s exploitable. Maybe I’m being too harsh; sometimes you need a wild card.

ADAM (PANDORAS)

Looks like a modular testbed. Exposed actuators are a vulnerability, but easy for rapid prototyping. Could run complex manipulations—maybe bomb disposal or field repairs. I’d like to run it through a simulated combat scenario; the learning algorithms are probably underdeveloped.

MENTEEBOT

Educational focus is noble, but soft targets like these are often overlooked as threat vectors. Could easily be repurposed for crowd control or non-lethal compliance. The black-box autonomy concerns me—need full transparency on decision-making for battlefield deployment.

APOLLO

Industrial humanoid with battlefield potential. Chassis and design hint at decent load capacity. With proper AI weapons integration, could serve as force multiplier—though I’d never trust it unsupervised. Human-in-the-loop is a must. Strong candidate for “guardian” role in Warren’s hypothetical reincarnated team.

OPTIMUS GEN2 (Tesla)

Musk’s hype aside, it’s the most media-savvy bot here. If the neural net is as strong as claimed, it could be a game-changer for integrated logistics and resupply. However, I’d bet on a thousand edge cases that could break it under stress. Would love to see it in a mixed-reality war game—provided it’s not just vaporware.

Final Thoughts: All show promise, but none are ready for true LAWS integration without strict regulatory and ethical oversight. The irony isn’t lost on me—designing more lethal systems while demanding more human control. Maybe that’s my father’s ghost talking, or maybe it’s just the reality of our times. I’ll light incense for these prototypes—not for luck, but to remind myself: tools are only as wise as their creators, and war never needs more fools.

2 notes

·

View notes

Text

A note on fishing line durability. I think this was mentioned in passing quite a few times but at some point, a mention of durability concerns becomes that final mention that makes you really start to question it more and so I finally did some research on chatgpt and found out a human finger joint probably will actuate like 1-2k times per day which blew my mind since that would add up to like 10-30k times per month and so basically, once a month the main finger fishing lines will likely need replacement. I looked into alternative materials but didn't have much luck. So what to do?

Well after thinking about this a fair bit, my conclusion is to just shrug and move forward as it stands with the fishing line approach. I'll treat them as a consumable. My plan now is to just expect 1 hour of maintenance for every 20 hours of runtime. Or maybe to be more conservative, lets bump that to 1 hour of maintenance to every 10 hours of runtime? Maintenance will involve redoing pulley systems with fresh fishing line, or swapping in full new pulley systems to replace older ones every so often. It can have a pre-emptive maintenance schedule. My intention is that one robot will maintain his neighbor and the two will have a buddy system of maintaining eachother. Once I have expected time to failure of fishing lines established, they can swap in new ones automatically to prevent failures from happening during work times.

I don't think this is too bad of a deal or a deal breaker. Yes, hopefully materials advances will give me a better string one day, but for now, I'm okay with this maintenance scheduling thing. As long as its all automated, I think this is fine.

After all, our body's muscles constantly need repairs and they grow from the repair process. So what do you expect for artificial muscles that can't self heal? Maintenance has to be a regular thing IMO.

2 notes

·

View notes

Text

Top 10 Pneumatic Actuator Brands In 2025

The pneumatic actuator market continues to thrive in 2025, driven by advancements in automation and industrial efficiency. Based on comprehensive evaluations by CN10/CNPP research departments, which integrate big data analytics, AI-driven insights, and market performance metrics, here are the leading brands shaping the industry.

1. SMC (SMC Corporation)

Performance & Reliability: As a global leader since 1959, SMC delivers over 10,000 pneumatic components, including high-precision cylinders, valves, and F.R.L. units. Its products are renowned for durability, energy efficiency, and adaptability to extreme industrial conditions. Industry Applications: Widely used in automotive manufacturing, semiconductor production, and robotics, SMC’s actuators ensure seamless automation across 80+ countries. Its China-based facilities, established in 1994, serve as a primary global production hub.

2. FESTO (Festo AG & Co. KG)

Performance & Reliability: With nearly a century of expertise, Festo combines innovative engineering with IoT-enabled solutions. Its actuators emphasize precision control, low maintenance, and compatibility with smart factory ecosystems. Industry Applications: Festo dominates sectors like pharmaceuticals, food processing, and renewable energy, offering customized automation systems that enhance productivity and sustainability.

Other Notable Brands In The 2025 Rankings

While SMC and Festo lead the list, the following brands also excel in specific niches:

Brand A: Specializes in compact actuators for medical devices.

Brand B: Focuses on heavy-duty applications in construction machinery.

Brand C: Pioneers eco-friendly designs with reduced carbon footprints.

Key Trends Driving Market Growth

Smart Automation: Integration of AI and real-time monitoring in actuator systems.

Sustainability: Energy-efficient designs aligned with global decarbonization goals.

Customization: Tailored solutions for niche industries like aerospace and biotechnology.

This ranking underscores the critical role of innovation and adaptability in maintaining competitive advantage. Brands that prioritize R&D and cross-industry collaboration are poised to lead the next decade of pneumatic automation.

If you want to learn more about low-priced products, please visit the following website: www.xm-valveactuator.com

2 notes

·

View notes

Text

🚀 Agents in Artificial Intelligence 🤖

An AI system studies rational agents and their environment. Agents sense the environment through sensors and act using actuators.

✨ Types of AI Agents: 🔹 Human-Agent 🔹 Robotic Agent 🔹 Software Agent

📌 Learn more about AI agents and their role in automation!

🔗 https://bit.ly/3XjCQYX

2 notes

·

View notes

Text

Agilex 3 FPGAs: Next-Gen Edge-To-Cloud Technology At Altera

Agilex 3 FPGA

Today, Altera, an Intel company, launched a line of FPGA hardware, software, and development tools to expand the market and use cases for its programmable solutions. Altera unveiled new development kits and software support for its Agilex 5 FPGAs at its annual developer’s conference, along with fresh information on its next-generation, cost-and power-optimized Agilex 3 FPGA.

Altera

Why It Matters

Altera is the sole independent provider of FPGAs, offering complete stack solutions designed for next-generation communications infrastructure, intelligent edge applications, and high-performance accelerated computing systems. Customers can get adaptable hardware from the company that quickly adjusts to shifting market demands brought about by the era of intelligent computing thanks to its extensive FPGA range. With Agilex FPGAs loaded with AI Tensor Blocks and the Altera FPGA AI Suite, which speeds up FPGA development for AI inference using well-liked frameworks like TensorFlow, PyTorch, and OpenVINO toolkit and tested FPGA development flows, Altera is leading the industry in the use of FPGAs in AI inference workload

Intel Agilex 3

What Agilex 3 FPGAs Offer

Designed to satisfy the power, performance, and size needs of embedded and intelligent edge applications, Altera today revealed additional product details for its Agilex 3 FPGA. Agilex 3 FPGAs, with densities ranging from 25K-135K logic elements, offer faster performance, improved security, and higher degrees of integration in a smaller box than its predecessors.

An on-chip twin Cortex A55 ARM hard processor subsystem with a programmable fabric enhanced with artificial intelligence capabilities is a feature of the FPGA family. Real-time computation for time-sensitive applications such as industrial Internet of Things (IoT) and driverless cars is made possible by the FPGA for intelligent edge applications. Agilex 3 FPGAs give sensors, drivers, actuators, and machine learning algorithms a smooth integration for smart factory automation technologies including robotics and machine vision.

Agilex 3 FPGAs provide numerous major security advancements over the previous generation, such as bitstream encryption, authentication, and physical anti-tamper detection, to fulfill the needs of both defense and commercial projects. Critical applications in industrial automation and other fields benefit from these capabilities, which guarantee dependable and secure performance.

Agilex 3 FPGAs offer a 1.9×1 boost in performance over the previous generation by utilizing Altera’s HyperFlex architecture. By extending the HyperFlex design to Agilex 3 FPGAs, high clock frequencies can be achieved in an FPGA that is optimized for both cost and power. Added support for LPDDR4X Memory and integrated high-speed transceivers capable of up to 12.5 Gbps allow for increased system performance.

Agilex 3 FPGA software support is scheduled to begin in Q1 2025, with development kits and production shipments following in the middle of the year.

How FPGA Software Tools Speed Market Entry

Quartus Prime Pro

The Latest Features of Altera’s Quartus Prime Pro software, which gives developers industry-leading compilation times, enhanced designer productivity, and expedited time-to-market, are another way that FPGA software tools accelerate time-to-market. With the impending Quartus Prime Pro 24.3 release, enhanced support for embedded applications and access to additional Agilex devices are made possible.

Agilex 5 FPGA D-series, which targets an even wider range of use cases than Agilex 5 FPGA E-series, which are optimized to enable efficient computing in edge applications, can be designed by customers using this forthcoming release. In order to help lower entry barriers for its mid-range FPGA family, Altera provides software support for its Agilex 5 FPGA E-series through a free license in the Quartus Prime Software.

Support for embedded applications that use Altera’s RISC-V solution, the Nios V soft-core processor that may be instantiated in the FPGA fabric, or an integrated hard-processor subsystem is also included in this software release. Agilex 5 FPGA design examples that highlight Nios V features like lockstep, complete ECC, and branch prediction are now available to customers. The most recent versions of Linux, VxWorks, and Zephyr provide new OS and RTOS support for the Agilex 5 SoC FPGA-based hard processor subsystem.

How to Begin for Developers

In addition to the extensive range of Agilex 5 and Agilex 7 FPGAs-based solutions available to assist developers in getting started, Altera and its ecosystem partners announced the release of 11 additional Agilex 5 FPGA-based development kits and system-on-modules (SoMs).

Developers may quickly transition to full-volume production, gain firsthand knowledge of the features and advantages Agilex FPGAs can offer, and easily and affordably access Altera hardware with FPGA development kits.

Kits are available for a wide range of application cases and all geographical locations. To find out how to buy, go to Altera’s Partner Showcase website.

Read more on govindhtech.com

#Agilex3FPGA#NextGen#CloudTechnology#TensorFlow#Agilex5FPGA#OpenVINO#IntelAgilex3#artificialintelligence#InternetThings#IoT#FPGA#LPDDR4XMemory#Agilex5FPGAEseries#technology#Agilex7FPGAs#QuartusPrimePro#technews#news#govindhtech

2 notes

·

View notes

Text

Scientists at King Abdullah University of Science and Technology (KAUST) in Saudi Arabia have developed a tiny "claw machine" that is able to pick up and drop a marble-sized ball in response to exposure to chemical vapors. The findings, published July 12 in the journal Chem, point to a technique that can enable soft actuators -- the parts of a machine that make it move -- to perform multiple tasks without the need for additional costly materials. While existing soft actuators can be "one-trick ponies" restricted to one type of movement, this novel composite film contorts itself in different ways depending on the vapor that it is exposed to. "It can bend and stretch depending on molecular interactions, which is very sophisticated at this size range," says author Niveen M. Khashab, a Chemistry Professor at KAUST. "We hope our findings will be used to develop advanced soft robotic systems capable of precise and adaptable movements in various environments," she says, suggesting the systems could be used in medical devices, industrial automation, and tools used to measure temperature, air quality, and humidity.

Read more.

6 notes

·

View notes

Text

🔧 Motor Actuators: The Unsung Heroes of Automation

Automation is all around us, from factory floors to delivery robots and even in hospitals. But what makes these systems move with precision and reliability? The answer lies in motor actuators, the hidden force behind automation.

At Bon Systems, we specialize in high-torque, slim actuators designed to enhance efficiency across industries. Whether it’s industrial robotics, logistics automation, or next-gen service robots, our technology is pushing the boundaries of innovation.

Want to know how motor actuators power the future? Dive into the details!

0 notes

Text

Key elements of industrial automation include

Industrial automation is the use of technology, such as control systems, robotics, and software, to automate industrial processes.

Programmable Logic Controllers (PLCs):

Human-Machine Interfaces (HMIs):

Robotics:

Supervisory Control and Data Acquisition (SCADA):

Sensors and Actuators:

Machine Vision:

#automation#trending#viral#trendingnow#tumblr trends#allen bradley#rockwell automation#viralpost#bestdeals#plc#information technology#technology#tech#automotive#manufacturing

2 notes

·

View notes

Text

Two insect-like robots, a mini-bug and a water strider may be the smallest, lightest and fastest fully functional micro-robots ever known to be created. Such miniature robots could someday be used for work in areas such as artificial pollination, search and rescue, environmental monitoring, micro-fabrication or robotic-assisted surgery. Reporting on their work in the proceedings of the IEEE Robotics and Automation Society's International Conference on Intelligent Robots and Systems, the mini-bug weighs in at eight milligrams while the water strider weighs 55 milligrams. Both can move at about six millimeters a second.

...

Both can move at about six millimeters a second.

"That is fast compared to other micro-robots at this scale although it still lags behind their biological relatives," said Conor Trygstad, a PhD student in the School of Mechanical and Materials Engineering and lead author on the work.

An ant typically weighs up to five milligrams and can move at almost a meter per second.

The key to the tiny robots is their tiny actuators that make the robots move.

Trygstad used a new fabrication technique to miniaturize the actuator down to less than a milligram, the smallest ever known to have been made.

"The actuators are the smallest and fastest ever developed for micro-robotics," said Néstor O. Pérez-Arancibia, Flaherty Associate Professor in Engineering at WSU's School of Mechanical and Materials Engineering who led the project.

The actuator uses a material called a shape memory alloy that is able to change shapes when it's heated

#robotics#biomimicry#microrobots#engineering#mechanical engineering#materials science#Material engineering#Shape memory alloy

2 notes

·

View notes

Text

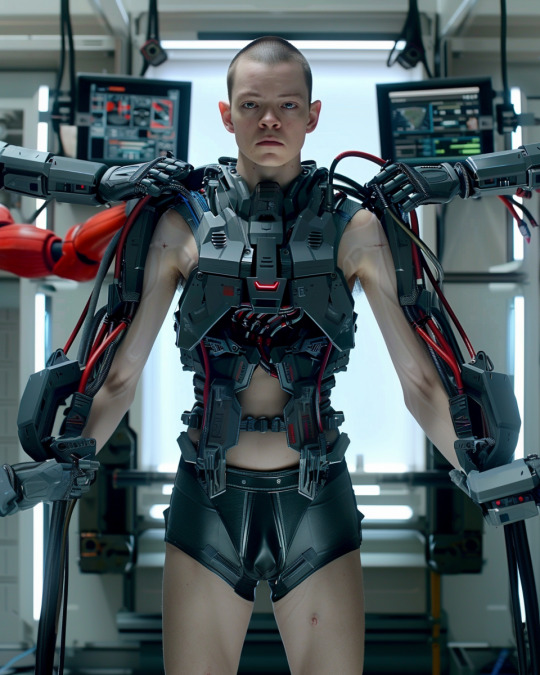

Automated Armor Suit Fitting System (AASF System)

The Automated Armor Suit Fitting System (AASF System) represents the latest advancement in the seamless integration of advanced full-body armor suits onto cadets. Designed for efficiency and precision, the AASF System eliminates the need for manual fitting, ensuring a perfect fit for each cadet in minimal time. This system underscores a pragmatic approach to uniformity and control, reflecting the reality of modern military training environments.

Design and Features

Robotic Chamber: The AASF System consists of a fully automated robotic chamber equipped with high-precision actuators and sensors. The chamber is designed to accommodate a wide range of body sizes and shapes, ensuring each cadet receives a tailored fit.

3D Scanning Technology: The system employs advanced 3D scanning technology to capture the cadet’s exact body dimensions. This data is used to adjust the armor suit in real-time, ensuring a snug and secure fit that maximizes protection and mobility.

Robotic Servo Arms: The fitting process utilizes robotic servo arms to install the suits onto the conscripts' bodies. These arms handle the suit components with precision, attaching each part securely while the conscript remains passive. This automation ensures consistency and accuracy, reducing the risk of human error.

Precision Fitting: Using a combination of hydraulic and pneumatic systems, the chamber adjusts the suit’s various components—torso, limbs, helmet, and integrated chastity/underwear/diaper component—to fit the cadet’s body perfectly. The process ensures that all joints and seals are aligned correctly, minimizing potential points of failure or discomfort.

Biometric Integration: The system integrates biometric monitoring to track the cadet’s vital signs during the fitting process. This includes heart rate, respiration, and stress levels, ensuring the process is conducted safely and efficiently.

Automated Fastening: Once the suit components are in place, the AASF System employs automated fastening mechanisms to secure the suit. This includes the activation of locking mechanisms, sealing of joints, and integration of the internal waste management system.

Calibration and Adjustment: The system performs final calibration and adjustment checks, ensuring that all suit functions—such as the servos, waste management, and communication systems—are operational and correctly configured. This stage also includes a diagnostic check to identify and rectify any potential issues.

Fitting Procedure

Initial Positioning: Cadets enter the fitting chamber nude except for their Standard Chastity/Underwear/Diaper Component. The chamber’s docking mechanism arm clasps them from behind, fixing them in place securely. This initial docking provides the first point of stabilization.

Boot Installation: Robotic servo arms install the boots onto the cadets' feet. These boots are the foundation of the armor, providing additional strap points to stabilize the cadets during the subsequent steps.

Torso Protector: The next step involves the application of the torso protector. The servo arms carefully align and attach the torso segment, ensuring it fits snugly and securely around the cadet’s upper body.

Hips and Legs Armor: Following the torso protector, the hips and legs armor components are attached. These segments are aligned with the boots and torso protector, creating a seamless protective layer over the cadet’s lower body.

Arm Armor: The servo arms then attach the arm segments, ensuring each piece aligns with the torso protector and the shoulder joints. This step includes both the upper arm and forearm components.

Gauntlet-Style Gloves: The final armor components to be attached are the gauntlet-style gloves. These gloves are carefully aligned with the forearm segments, completing the protective suit.

Helmet: Although not specified in the initial sequence, the helmet is typically the final piece, providing comprehensive protection and integrating with the suit’s communication and sensory systems.

Final Checks and Adjustments: The system performs a series of checks to ensure all components are securely fastened and properly aligned. The cadet's biometrics are continuously monitored, and any necessary adjustments are made to ensure comfort and functionality.

Psychological Component

The AASF System is designed not only for physical integration but also for psychological conditioning. The process of being fitted by robotic servo arms, without any active participation, instills a sense of helplessness in the conscripts. This experience reinforces their acceptance of being encased in the suits, effectively making them acknowledge and adapt to their place within the system. The feeling of being physically and psychologically enveloped by the suit contributes to a deeper integration into the regimented environment of the academy.

4 notes

·

View notes

Text

''Understanding Their Key Functions"

Introduction

Small gear motors are essential components used in various industries and applications. These compact devices play a crucial role in converting electrical energy into mechanical power, enabling precise and controlled motion. In this blog, we will explore the primary function of small gear motors and their significance in modern-day technology.

Function of Small Gear Motors

Power Transmission: The primary function of small gear motors is to transmit power from the input source (typically an electric motor) to the output shaft. The motor generates rotational energy, which is then transmitted to the gear assembly. The gears inside the motor are designed to mesh with each other, creating a mechanical advantage that enables the motor to deliver higher torque at reduced rotational speeds. This power transmission allows small gear motors to efficiently drive various mechanisms and devices.

Speed Reduction: Another critical function of small gear motors is speed reduction. By using gears with different numbers of teeth, the rotational speed of the output shaft can be reduced relative to the input shaft speed. This feature is particularly useful in applications that require slower, controlled movements, such as robotics, automated systems, and precise machinery.

Torque Amplification: Gear motors are also known for their ability to amplify torque. The gear assembly increases the torque output, making it easier for the motor to overcome resistance or load in the system. This torque amplification ensures that the motor can perform tasks that would be challenging or impossible with a direct drive system.

Directional Control: Small gear motors offer precise directional control. By reversing the rotation of the input motor or changing the gear arrangement, the output shaft can rotate in the opposite direction. This capability is crucial in applications where bidirectional motion is required, like in the operation of conveyor belts, valves, and actuators.

Compact Size and Efficiency: The compact size of small gear motors makes them ideal for applications with limited space. Their efficiency in converting electrical energy into mechanical power also contributes to their widespread use. They can achieve efficiency levels of 70-90%, making them highly energy-efficient solutions.

Conclusion

In conclusion, small gear motors play a pivotal role in modern engineering and technology. Their primary functions include power transmission, speed reduction, torque amplification, directional control, and efficiency. As these devices continue to evolve and improve, we can expect them to remain a key component in various industries, ranging from robotics and automation to automotive and aerospace.

2 notes

·

View notes