#commercial vehicles

Text

Mazda K360, 1959. A 3-wheeled micro-truck powered by a mid-mounted air-cooled V twin engine. The K360 remained in production for a decade during which time 280,000 were made

#Mazda#Mazda K360#micro-truck#3-wheeler#1959#mid-engine#V2#V-twin#air-cooled#commercial vehicles#utility vehicle#1960s

769 notes

·

View notes

Text

Introduced as „Schnell-Lastwagen“ in 1955: Mercedes-Benz L 319, probably a former fire truck and cute as an deep sea angler fish somehow. Or is it just me who sees similarities?

#mercedes benz#Mercedes Benz L 319#vintage mercedes#classic trucks#commercial vehicles#1950s#1960s#streetfightingcars#street fighting cars#autolandish#alfaromeole#vintage vans#vanlife#traveling

36 notes

·

View notes

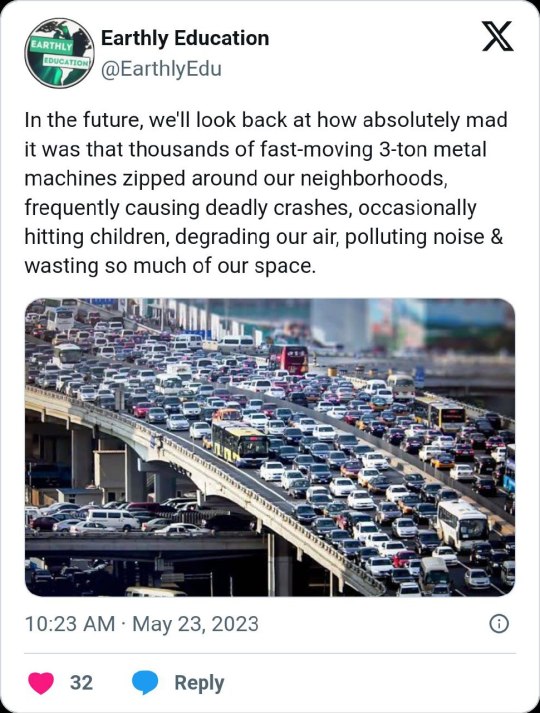

Text

#future#history#electric vehicles#unusual vehicles#vehicle transport#autonomous vehicles#commercial vehicles#vehicles#ausgov#politas#auspol#tasgov#taspol#australia#fuck neoliberals#neoliberal capitalism#anthony albanese#albanese government#roads#road#space#earth#ecology#pollution#pollutants#polluted water#polluted air#safety#health#occupational health and safety

17 notes

·

View notes

Text

1965 Ford Transit FK 1250

3 notes

·

View notes

Text

Electric Vehicles Market Global forecast 2031

2 notes

·

View notes

Text

We Specialized dedicated digital Marketing Support, Transportation solutions

We Specialized dedicated digital Marketing Support, Transportation solutions, Warehousing, any type of Vehicle, Food and catering services, Transportation management, freight brokerage, and truckload, Any type of Logistic Services.

We do this Business as Per your Budget.

2 notes

·

View notes

Text

Navigating Terrain: Off-Road Capabilities of Truck And Bus Radial (TBR) Tires

Truck and Bus Radial (TBR) tires are not only designed for highway use but also possess impressive off-road capabilities, making them versatile options for vehicles operating in various terrains.

Enhanced Traction and Grip

Truck And Bus Radial (TBR) Tires are engineered with tread patterns that offer enhanced traction and grip on off-road surfaces.

Their aggressive tread designs feature deep grooves and robust tread blocks, providing excellent grip on loose gravel, mud, sand, and other uneven terrains.

Resistance to Cuts and Punctures

Off-road environments pose unique challenges such as sharp rocks, branches, and debris that can cause cuts and punctures to tires.

TBR tires are built to withstand these challenges, with reinforced sidewalls and durable rubber compounds that resist cuts, punctures, and abrasions, ensuring reliable performance in rugged terrain.

Optimized Self-Cleaning Properties

Off-road driving often involves encountering mud, clay, and other sticky substances that can accumulate in tire treads, affecting traction and performance.

TBR tires are designed with self-cleaning tread patterns that prevent mud and debris buildup, ensuring continuous traction and stability even in the most challenging off-road conditions.

Get More Insights On This Topic: Truck and Bus Radial (TBR) tires

#Truck And Bus Radial Tire#TBR Tire#Commercial Vehicles#Heavy Duty Tires#Tire Safety#Transportation Industry#Tire Maintenance#Road Safety

0 notes

Text

Explore Tata Signa 2830.K TK SRT Tipper - Tata Motors

Discover the powerful Tata Signa 2830.K TK SRT Tipper designed for rugged performance. Learn about its features, specifications, and capabilities. Find out more at Tata Motors.

#trucks#commercial vehicles#tippers#Tata Motors#Tata Signa#heavy-duty trucks#construction vehicles#transportation#vehicle overview

0 notes

Text

Asia-Pacific Is Dominating Automotive V2X Industry

In 2023, the automotive V2X market yielded revenue of USD 633.8 million and is projected to experience a remarkable CAGR of 49.9% between 2024 and 2030, reaching a total of USD 10,225.5 million by 2030. This can be credited to the increasing need for enhanced technology concerning vehicle security, rising ecological anxieties, and cost aids.

Moreover, the need is growing for automatic cars,…

View On WordPress

0 notes

Text

Introduction to DOT Regulations for Commercial Vehicles

The Department of Transportation

The Department of Transportation (DOT) sets forth a myriad of regulations aimed at ensuring the safety and reliability of commercial vehicle operations within the United States. Among these, tire maintenance and repair standards are critical components, designed to prevent accidents and enhance road safety for both commercial drivers and the general public.

KEY POINTS

Understanding DOT's Role: The Department of Transportation (DOT) enforces safety regulations for commercial vehicles, including specific standards for tire maintenance and repair.

Importance of Compliance: Adhering to DOT tire regulations is essential for safety, preventing accidents, and avoiding penalties.

Proper Tire Inspection Protocols: DOT regulations require pre-trip inspections and regular maintenance checks to identify and address tire wear, damage, or inadequate pressure.

Acceptable Tire Repair Methods: DOT standards specify that repairs must ensure safety and durability, typically requiring a combination of patching and plugging for punctures.

Essential Tire Maintenance Tips: Regular pressure checks, balancing, alignment, and rotation are crucial for extending tire life and ensuring safety.

Record Keeping for DOT Compliance: Documenting tire maintenance and repair activities is essential for proving compliance during DOT inspections.

Understanding Out-of-Service Criteria: Tires must meet specific tread depth and condition standards; failing to do so can render a vehicle out of service.

Consequences of Non-Compliance: Violations can lead to fines, out-of-service orders, and negatively impact a company’s safety rating and insurance premiums.

Staying Up-to-Date with Regulations: Monitoring regulatory updates through FMCSA resources, industry associations, and legal experts is crucial for compliance.

Implementing Regulatory Changes: Updating policies, conducting training, and ensuring third-party vendors meet DOT standards are necessary steps for maintaining compliance.

Understanding DOT's Role in Commercial Vehicle Safety

The DOT, through its Federal Motor Carrier Safety Administration (FMCSA), enforces regulations that govern all aspects of commercial vehicle operations, from driver qualifications to vehicle maintenance. Tires, being pivotal to a vehicle's safety performance, receive considerable attention within these regulations.

Importance of Tire Maintenance and Repair Regulations

Tire-related issues are among the leading causes of commercial vehicle breakdowns and accidents. Recognizing this, DOT regulations meticulously outline the standards for tire condition, repair methods, and maintenance practices. Adherence to these regulations not only helps in avoiding costly penalties but also significantly reduces the risk of tire-related accidents on the road.

Overview of Compliance Benefits

Compliance with DOT tire repair and maintenance regulations brings numerous benefits beyond safety. It includes prolonging tire life, improving fuel efficiency, and ensuring that vehicles pass inspections without penalties, thereby avoiding unnecessary downtime. Moreover, compliance reflects a company's commitment to safety, potentially lowering insurance premiums and enhancing its reputation within the industry.

Key DOT Tire Repair Regulations

To ensure the safety and reliability of commercial transportation, the Department of Transportation (DOT) has established stringent tire repair and maintenance regulations. These regulations are designed to prevent tire failures that can lead to accidents, ensuring that all commercial vehicles operate safely on public roads. Here, we delve into the proper tire inspection protocols and the acceptable methods of tire repair as outlined by the DOT.

Proper Tire Inspection Protocols

Pre-Trip Inspection Requirements

Before any trip, drivers are required to conduct a thorough inspection of their vehicle's tires. This includes checking for adequate tread depth, signs of wear or damage, and ensuring that tires are inflated to the manufacturer's recommended pressure. The DOT mandates that these inspections are recorded and that any issues identified are addressed before the vehicle is operated.

Regular Maintenance Checks

In addition to pre-trip inspections, commercial vehicles must undergo regular maintenance checks as part of a comprehensive vehicle maintenance program. These checks should include detailed inspections of tire condition, tread depth measurements, and pressure adjustments. Regular maintenance not only helps in identifying potential issues before they become hazardous but also plays a critical role in ensuring compliance with DOT regulations.

Acceptable Tire Repair Methods

Patching vs. Plugging: What's DOT Approved?

When it comes to repairing tires, the DOT specifies acceptable methods to ensure that repairs are safe and durable. Patching, which involves applying a patch to the inside of the tire, is generally considered the most reliable form of repair for punctures in the tread area. Plugging, on the other hand, is not recommended as a standalone repair method by the DOT due to concerns about its durability and safety.

Importance of Professional Repairs

The DOT regulations emphasize the importance of having tires repaired by professionals who can assess damage and perform repairs that meet safety standards. This includes dismounting the tire to inspect for internal damage, which cannot be seen from the outside. Repairs should always be performed in accordance with the tire manufacturer's guidelines and DOT regulations to ensure the safety and reliability of the repair.

Tire Maintenance for Compliance

Maintaining tire integrity is not just a critical aspect of vehicle safety; it is also a regulatory requirement. The Department of Transportation (DOT) sets forth specific tire maintenance practices to ensure commercial vehicles operate safely and efficiently. This section explores essential tire maintenance tips and the importance of record-keeping for DOT compliance.

Essential Tire Maintenance Tips

Regular Pressure Checks and Balancing

One of the simplest yet most effective ways to maintain tire health is by regularly checking tire pressure and balancing. Proper tire pressure ensures optimal contact with the road, reducing wear and tear, and improving fuel efficiency. Tires should be checked at least once a month and before long trips. Balancing, on the other hand, helps in evenly distributing the weight around the tire, prolonging its lifespan and enhancing vehicle stability.

Alignment and Rotation for Extended Tire Life

Tire alignment and rotation are pivotal in preventing uneven wear. Misalignment can cause rapid and irregular tire wear, while rotation ensures that tires wear evenly, extending their usable life. Following the manufacturer's recommendations for alignment and rotation schedules can significantly contribute to tire longevity and safety.

Record Keeping for DOT Compliance

Documentation Best Practices

Accurate record-keeping is a cornerstone of DOT compliance. Operators should meticulously document all tire maintenance activities, including inspections, repairs, and replacements. Records should detail the date of service, nature of the maintenance performed, and the name of the person who carried out the service. This documentation is crucial during DOT inspections and audits, serving as proof of compliance with tire maintenance regulations.

How Records Ensure Compliance

Maintaining comprehensive records not only facilitates DOT compliance but also aids in monitoring the condition and performance of the tires over time. This historical data can be invaluable in identifying patterns of wear or recurring issues, allowing for preemptive maintenance and repairs. It also serves as a defense in the event of litigation by proving that the fleet has adhered to safety standards and regulations.

Understanding Out-of-Service Criteria for Tires

The Department of Transportation (DOT) stipulates clear criteria for when tires on commercial vehicles are considered out of service. These guidelines are crucial for preventing accidents caused by tire failures. This section will detail the wear and damage levels that render a tire unfit for the road and the consequences of operating vehicles with such tires.

Identifying Tire Wear and Damage Levels

When is a Tire Considered Unsafe?

A tire is deemed unsafe and subject to out-of-service criteria if it exhibits any of the following:

Tread depth less than 2/32 inch on steer tires or 1/32 inch on all other tires.

Visible fabric or cord through the tread or sidewall.

Bulges, bumps, or knots indicating separation within the tire.

Any cut or damage that exposes the reinforcing steel wires or fabric.

Tread or sidewall separation.

These conditions are considered hazardous and can significantly increase the risk of tire failure. It is the responsibility of the vehicle operator to ensure these criteria are checked regularly and addressed promptly to maintain safety and compliance.

Legal Tread Depth Minimums

The legal minimum tread depth is a critical measurement enforced by the DOT. For steer tires, the minimum tread depth is 4/32 inch, while for all other tires, it is 2/32 inch. These standards are in place to ensure that tires maintain adequate traction and performance in various driving conditions. Regular inspections and replacements of tires not meeting these standards are necessary to prevent out-of-service violations.

Consequences of Non-Compliance

Penalties and Fines

Operating a commercial vehicle with tires that fail to meet DOT standards can result in significant penalties and fines. The FMCSA enforces these regulations strictly, and violations can lead to out-of-service orders, where a vehicle is prohibited from operation until the issue is resolved. Fines can vary depending on the severity and frequency of the violations.

Impact on Safety Ratings and Insurance

Beyond immediate penalties, non-compliance with tire regulations can adversely affect a company’s safety rating. This rating is public information and can influence a company's reputation, insurance premiums, and even its ability to secure contracts. Ensuring tire compliance is not just a regulatory requirement but a critical component of a fleet’s operational integrity and financial health.

Staying Up-to-Date with DOT Regulations

The landscape of commercial vehicle regulations, particularly those pertaining to tire maintenance and repair, is subject to change as new safety data emerges and technologies evolve. Staying abreast of these changes is essential for fleet operators to ensure ongoing compliance and to safeguard their operations against potential penalties. Below, we discuss resources for accessing the latest information and strategies for effectively implementing regulatory updates.

Monitoring Regulatory Updates

Resources for Latest Information

The Federal Motor Carrier Safety Administration (FMCSA) website is a primary resource for the latest in commercial vehicle regulations. Subscribing to FMCSA updates, joining industry associations, and attending relevant workshops and seminars are proactive ways to stay informed. Additionally, consulting with legal experts specializing in transportation law can provide insights into complex regulatory changes and their implications for your operations.

Implementing Changes in Tire Repair Practices

Staying compliant requires not just awareness of regulatory changes but also their timely implementation into your fleet’s maintenance routines. This includes:

Training and Education: Regularly scheduled training sessions for maintenance staff and drivers on updated tire repair and maintenance practices are crucial. This ensures that everyone is aware of the latest standards and techniques approved by the DOT.

Policy Updates: Revise internal maintenance and operation policies to reflect the latest DOT regulations. This may involve updating repair procedures, inspection checklists, and compliance monitoring systems.

Vendor Compliance: Ensure that any third-party maintenance providers or tire repair services used by the fleet are also aware of and comply with the latest DOT regulations. Regular audits or compliance checks can help maintain this assurance.

The Importance of Proactivity

Adopting a proactive stance towards regulatory compliance not only minimizes the risk of penalties but also enhances overall fleet safety and efficiency. By fostering a culture of continuous improvement and compliance, operators can ensure their fleets remain safe, reliable, and profitable.

FAQs

What constitutes an acceptable tire repair under DOT regulations?

Acceptable tire repairs under DOT regulations typically involve the use of both a patch and a plug or a comparable commercial repair unit that seals the puncture from the inside of the tire. Repairs must be performed by removing the tire from the wheel to conduct an internal inspection, ensuring that hidden damages are identified and addressed.

How often should commercial vehicle tires be inspected to meet DOT standards?

Commercial vehicle tires should be inspected before each trip to ensure there are no visible defects, inadequate tread depth, or improper inflation that could lead to safety issues. Regular maintenance checks should also be scheduled based on the vehicle's mileage and usage to identify and address wear and potential issues proactively.

What are the penalties for not complying with DOT tire repair regulations?

Penalties for non-compliance can range from fines to out-of-service orders, where a vehicle is prohibited from operating until the issue is corrected. Repeated violations can lead to increased penalties and may negatively impact a company's safety rating and operational permissions.

Can a commercial vehicle be placed out of service for tire issues?

Yes, a commercial vehicle can be placed out of service for tire issues if inspections reveal conditions that meet the DOT's out-of-service criteria, such as tread depth below the minimum legal requirement, visible damage exposing the internal components, or other hazardous conditions.

How can fleet operators ensure their vehicles remain compliant with DOT tire regulations?

Fleet operators can ensure compliance by implementing a robust tire maintenance program, conducting regular inspections and maintenance, keeping detailed records of all tire-related activities, and staying informed about regulatory updates and best practices.

What resources are available for staying informed about changes in DOT regulations?

Resources include the FMCSA website, industry newsletters, transportation law seminars, and membership in professional associations. Engaging with a network of industry professionals and consulting with legal experts can also provide valuable insights into compliance strategies.

To learn more about tire maintenance, tire repairs, tire pressure monitoring system and how to reset them for your car, visit tpmsreset.com

0 notes

Text

Doubles And Triples Endorsement Test California

Prepare for success in the challenging Doubles and Triples Endorsement Test California. Our comprehensive guide navigates you through essential aspects of CDL doubles and triples proficiency, offering crucial insights for effective CDL training and confident handling of diverse commercial vehicles.

0 notes

Text

Citroën BX 16 S Break Entreprise, 1985. The BX has been designed by Marcello Gandini at Bertone but the long-roof conversion was done by French coachbuilders Heuliez who also made this commercial version that did away with rear seats. It was only offered for a year and very few were sold

#Citroën BX 16 S Break Entreprise#Citroën#Citroën BX#Citroën BX Enterprise#commercial vehicles#marcello gandini#Heuliez#1985#coachbuilt#long roof

205 notes

·

View notes

Text

Rivian Introduces R2, R3, and R3X Built on New Midsize Platform

LAGUNA BEACH, Calif. March 7, 2024 – Rivian today unveiled its new midsize platform which underpins R2 and R3 product lines.

R2 is Rivian’s all-new midsize SUV delivering a combination of performance, capability and utility in a five-seat package optimized for big adventures and everyday use. The silhouette and face of R2 are distinctly Rivian. The powered rear glass fully drops into the…

View On WordPress

#acceleration#adventure#Adventure Gear#affordability#all-new platform#automotive engineering#Automotive Technology#autonomous capabilities#autonomous driving#battery#capital efficiency#cash visibility#commercial vehicles#consumer services#cost savings#crossover#design innovation#design language#direct sales#drive unit#Durability#electric mobility#electric vehicles#emission reduction#energy density#environmental preservation#fast charging#feature growth#global transition#haptic controls

0 notes

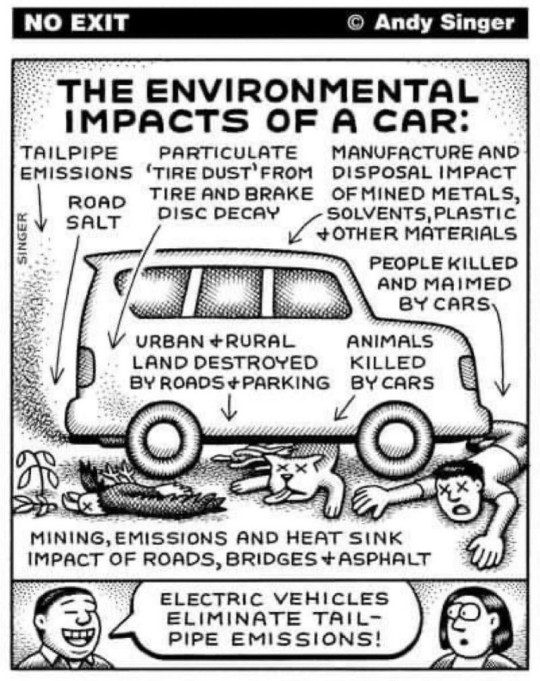

Text

#comics#comic#cartoons#cartoon#environmental impact#ecology#cars#car#vehicle#electric vehicles#unusual vehicles#vehicle manageent bd#vehicle service near me#commercial vehicles#vehicles#pollution#pollutants#polluted water#polluted air#polluters#private jet#jets#jet#airplane#aeroplane#fossil fuels#carbon dioxide#methane#co2 emissions#co2

10 notes

·

View notes

Text

Diamond Edge Limo provides a luxurious transportation in NJ, NY, TX, CA and PA. Elevate your travel experience with our luxurious fleet and professional chauffeurs. Our fleet includes Suv, Sedan, Sprinter limo, Strech limo and Limousine party bus.

visit at: https://diamondedgelimo.com

email at: [email protected]

call at: 1(888)568 9170

#limo rental#classic cars#airport limo service#limo service#sprinter van#electric vehicles#unusual vehicles#autonomous vehicles#commercial vehicles#vehicle service near me#cars#electric cars#fast cars#car show#suv#sedan#volvo#vehicle

1 note

·

View note

Text

Mini electric cars that can sell homemade ice cream popsicles and cold drinks, and 2.7-meter diameter umbrellas can be completed only when the logo is added.

1 note

·

View note