#ductility

Text

Balancing the seesaw: Simultaneously enhancing strength and elongation in metallic materials

Just as one side of a seesaw rises while the other falls, in the realm of metallic materials, "strength" and "elongation" typically conflict with each other. However, a collaborative team from POSTECH and Northwestern University has recently introduced a groundbreaking technology that enhances both properties.

A research team, consisting of Professor Hyoung Seop Kim from the Graduate Institute of Ferrous & Eco Materials Technology and the Department of Materials Science and Engineering, Professor Yoon–Uk Heo from the Graduate Institute of Ferrous & Eco Materials Technology, and Ph.D. candidate Hyojin Park from the Department of Materials Science and Engineering at POSTECH, collaborated with Dr. Farahnaz Haftlang from Northwestern University's Department of Materials Science & Engineering.

Together, they have tackled a long-standing issue in metals research: the tradeoff between strength and elongation. Their breakthrough involves designing an alloy that boasts both high strength and high elongation.

Read more.

#Materials Science#Science#Strength of materials#Ductility#Alloys#Phases#Phase transitions#Copper#Aluminum#Iron#High entropy alloys#High entropy materials

11 notes

·

View notes

Text

#metal#chemistry#solutions#sitar#violin#ductility#conductivity#malleability#sonorousness#science#strings

2 notes

·

View notes

Text

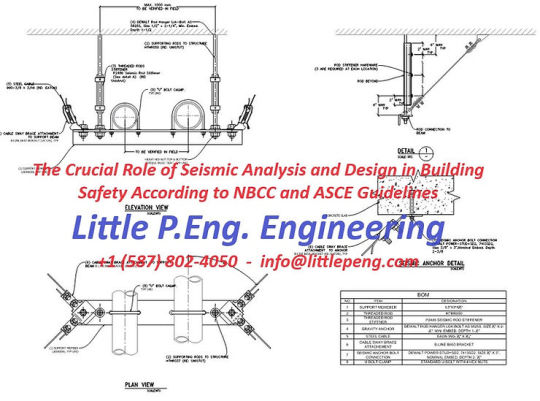

The Crucial Role of Seismic Analysis and Design in Building Safety According to NBCC and ASCE Guidelines

Seismic analysis and design are fundamental aspects of structural engineering that ensure buildings and their non-structural components can withstand the forces generated by earthquakes. These practices are not just essential for the safety and integrity of structures but are also mandated by comprehensive guidelines and codes such as the National Building Code of Canada (NBCC) and the American Society of Civil Engineers (ASCE). This article delves into the importance of seismic analysis and design for buildings and non-structural components, guided by the principles set forth in the NBCC and ASCE.

Understanding the Risks

Earthquakes pose a significant risk to life and property. The unpredictable nature of seismic events, combined with the potential for catastrophic damage, underscores the need for rigorous building standards. Seismic analysis and design aim to mitigate these risks by ensuring buildings can endure seismic forces without collapsing, thus safeguarding occupants and minimizing economic losses.

NBCC and ASCE Guidelines: A Benchmark for Safety

The NBCC and ASCE have established benchmarks for seismic safety in the construction industry. The NBCC, applicable in Canada, and the ASCE's standards, widely adopted in the United States and internationally, provide a framework for assessing seismic risks and implementing necessary design and construction practices.

Seismic Analysis

Seismic analysis involves evaluating how a structure responds to earthquake-induced forces. This process helps engineers understand potential stress points and the overall behavior of a building during seismic events. Both the NBCC and ASCE recommend detailed analysis methods, including linear dynamic analysis, nonlinear dynamic analysis, and modal response spectrum analysis, among others. These methodologies help in designing structures that are not only compliant with safety standards but also economically viable.

Design Considerations

The design phase is critical in integrating seismic resilience into buildings. The NBCC and ASCE guidelines emphasize the importance of ductility, redundancy, and energy dissipation in structural elements. Ductility allows parts of the structure to deform under seismic loads without failing, while redundancy ensures that if one part of the structure fails, others can take over the load-carrying responsibilities. Energy dissipation mechanisms are incorporated to reduce the energy transferred to the structure during an earthquake, thereby limiting damage.

Non-Structural Components

Seismic safety extends beyond the structural elements of a building. Non-structural components, including mechanical, electrical, and plumbing systems, as well as architectural elements like ceilings, partitions, and facades, play a crucial role in building functionality and occupant safety. The NBCC and ASCE guidelines require these components to be anchored and braced appropriately to prevent detachment or collapse, which could cause injury or block egress paths during an earthquake.

The Path Forward

In conclusion,

the seismic analysis and design of buildings and their non-structural components, as per the standards of the NBCC and ASCE, are indispensable in the pursuit of creating earthquake-resilient communities. These practices embody a proactive approach to disaster mitigation, emphasizing the critical importance of preparedness and the implementation of engineering solutions that protect both people and their environments.

Tags:

NBCC

ASCE

structural integrity

structural engineering

earthquake resilience

energy dissipation

building codes

seismic design

non-structural components

mechanical systems

disaster preparedness

plumbing systems

ductility

architectural elements

seismic safety standards

seismic risks

anchoring

bracing

electrical systems

redundancy

building safety

linear dynamic analysis

structural components

seismic analysis

modal response spectrum analysis

nonlinear dynamic analysis

earthquake mitigation

seismic guidelines

occupant safety

earthquake-induced forces

Seismic Bracing Experts

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#NBCC#ASCE#structural integrity#structural engineering#earthquake resilience#energy dissipation#building codes#seismic design#non-structural components#mechanical systems#disaster preparedness#plumbing systems#ductility#architectural elements#seismic safety standards#seismic risks#anchoring#bracing#electrical systems#redundancy#building safety#linear dynamic analysis#structural components#seismic analysis#modal response spectrum analysis#nonlinear dynamic analysis#earthquake mitigation#seismic guidelines#occupant safety#earthquake-induced forces

0 notes

Text

Poor Microstructure's Impact on Titanium Properties

Inconsistent and heterogeneous microstructure can significantly impact Titanium's properties and performance, resulting in reduced fatigue strength, fracture toughness, ductility, and biocompatibility.

For more information, you can connect with us at [email protected]

#KnowYourTitanium#Titanium#Microstructure#Properties#FatigueStrength#FractureToughness#Ductility#Biocompatibility#HorizonTitanium#StrongerTogether

0 notes

Text

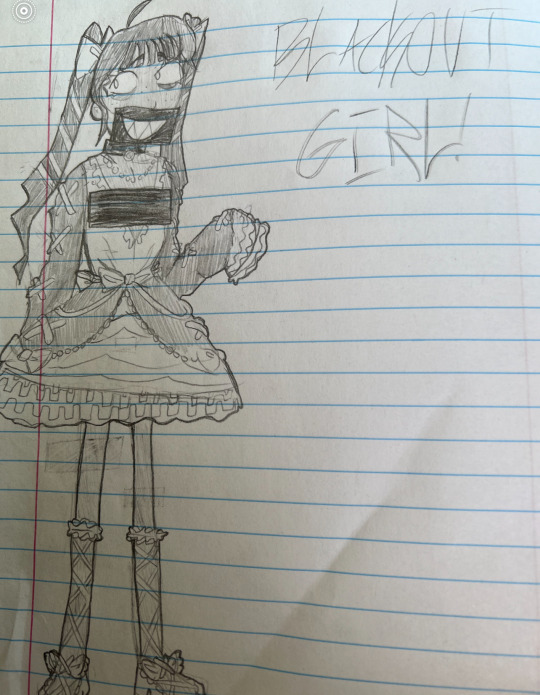

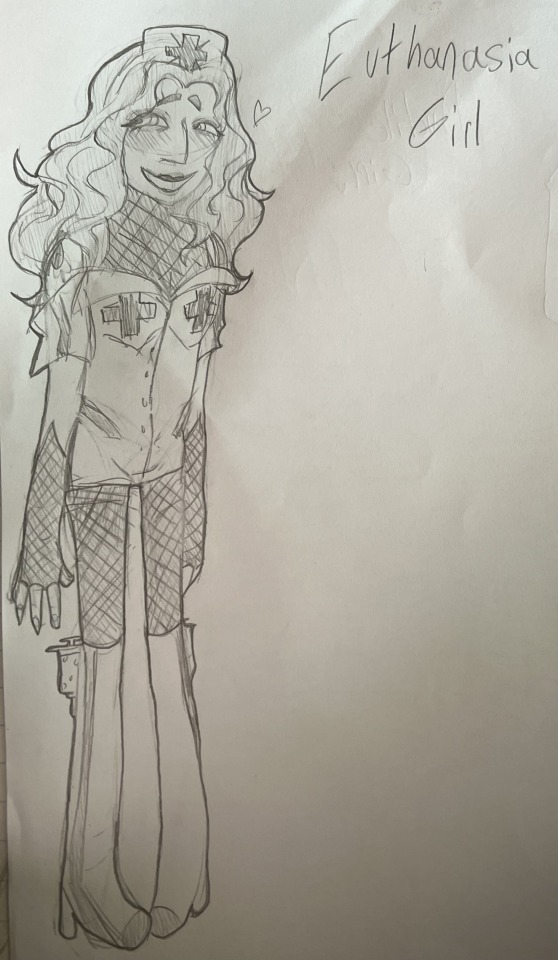

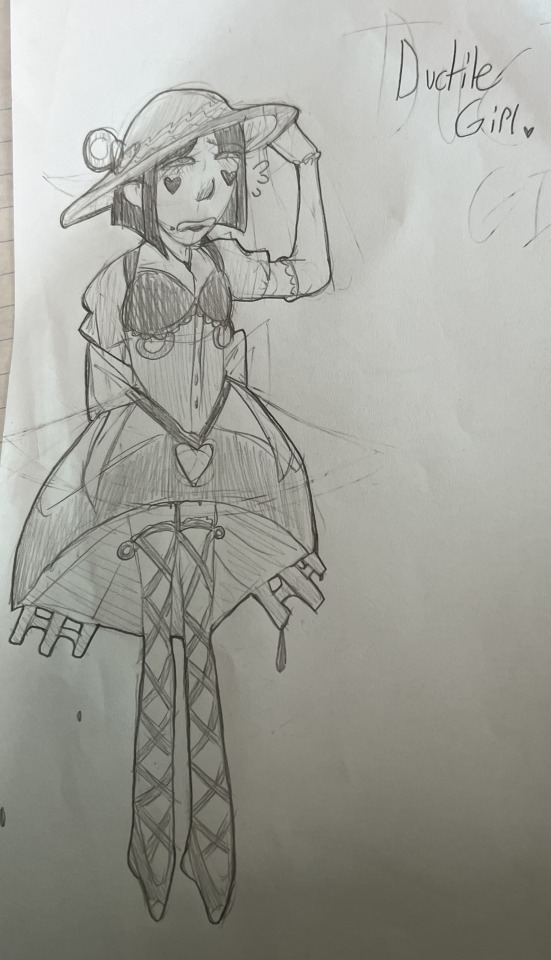

the silly symbols for my TPTM ocs <3 (song series by @weevildoing) feel free to predict what each girl is about if you wanna :]

each one separately (+ which girl they are undercut)

PROTOTYPE GIRL

COTARD GIRL

BLACKOUT GIRL

CORIOLIS-EFFECT GIRL

EUTHANASIA GIRL

DUCTILE GIRL

BOSSANOVA GIRL

#the post traumatic manifesto#tptm#tptm oc#weevildoing#prototype girl#cotard girl#blackout girl#coriolis-effect girl#euthanasia girl#ductile girl#bossanova girl

46 notes

·

View notes

Text

#Personal#Polls#Yay#Iron#Ductile iron#Cast iron#Carbon#Silicon#Sulfur#Phosphorus#Manganese#Nickel#Copper#Molybdenum#Titanium#Magnesium

43 notes

·

View notes

Text

"I'm your arch's nemesis"

Normal people: what? that doesn't sound right, don't you mean-

Architects: HAVE AT THEE, FUCKING BUTTRESS

#tumblr wants me to add tags#uuuh#architecture#here you go#I guess the actual nemesis of arches would be orthogonal horizontal pressure though?#since then an arch would (I presume) be less stable to that than a wall of similar length#that's just what I expect though I know literally nothing about architecture#At least if the arch doesn't support anything#If it does support something good luck felling it#I know that much#because obviously it's hard to push stuff out if there's stable weight on it#I wonder how that holds up to an architect's expertise#do architects do whole calculations of materials like how ductile they are and friction index and tensile strength and lots of stuff like#that so nothing bad happens#or do we have that stuff figured out and they just pull out a table with all the data and they just know by heart the important stuff#like 'don't use stucco as your foundation; it is brittle and sad'

4 notes

·

View notes

Text

Ductile to Brittle Transition Temperature

Of the two general types of fracture (ductile or brittle), not all materials fall neatly into one category or the other. Some materials experience what is known as the ductile to brittle transition temperature, or DBTT. Ferritic steels in particular, among other BCC metals, have two failure modes, switching from ductile failure at higher temperatures to brittle failure at lower ones. While the transition is perhaps more well known in metals, it can occur in other materials such as polymers and ceramics as well. Different forms of impact testing are used to determine the temperature.

Sources/Further Reading: (Image source - 2016 fracture mechanics book chapter) (YENA Engineering) (ASAMS) (nuclear-power.com) (UNSW) (2023 article) (Instron)

#Materials Science#Science#Ductility#Brittleness#Materials failure#Deformation mechanisms#Temperature#FailureFriday#2024Daily

9 notes

·

View notes

Text

there's a category of element called a "poor metal" which is just so fucking funny to me like

"oh these metals are just the worst they suck total shit"

#science humor#elements#they tend to be called ''post transition'' metals in modern literature#but while I know--i *know*--there's a joke there it's not coming straight to mind at the moment#i *think* they're called 'poor metals' because they don't exhibit the traits of transition metals as strongly as transition metals do?#like they tend to have less ductility or less electrical/thermal conductivity or whatever#maybe idk for 100% sure

4 notes

·

View notes

Text

“Jane was a willing tool whose personality it is more than kind to describe as ‘pliable.’” - Eric Ives

“Her conduct, first as a royal lady-in-waiting and later as a queen, indicates that she was more of a steel magnolia - a fragrant, seemingly fragile, ultra feminine exterior concealing a tensile core.” - Leslie Carroll

“Any woman setting out on the course Jane Seymour would follow over the next few months would have had to be possessed of both strength and resolution, as well as driving ambition and a flexible conscience." - Alison Weir

“Not much is known about Jane’s character, ['the mild and pliable’ Jane]. Most likely her meekness was exaggerated in the official documents in order to draw a strong distinction between this gentlewoman-queen and the other one, but certainly she was compliant enough to do just as she was told by her brother and his wife [...]” - Nicola Shulman

‘[This] characterization of ambition without flex of conscience [...] how far from the truth was that interpretation when one considers her double image and moral callousness?” - Pamela M. Gross

‘Jane Seymour was (apparently) more pliable than her mistress. Carew [and others] facilitated the courtship of Jane by offering lodgings [...]” - Tracy Borman

#i don't actually think these are too dissimilar.......?#pliable vs flexible vs tensile/ductile?#they are all very 90s but im not really taken in by many of the 2020s assessments#is it still true that no one else has done a full dissertation on jane seymour since pamela gross? man she did not hold back#@anne-the-quene really said 'show your work'...SO mother <3#eric ives#pamela gross

15 notes

·

View notes

Text

final exams are complete bullshit there's way too much to memorize and it can literally make or break your grade so literally everything relies on knowing every little detail of the fucking course

#this material science final is about to brutally massacre my b in the class#update no one asked for: got a 72!!!#missed like three questions in a row because i forgot what ductility meant but hey#i should end up with a b in the course so i will take it#ofc rn i have like a 200% because the ta accidentally put in the homework and activities as 100/#20

2 notes

·

View notes

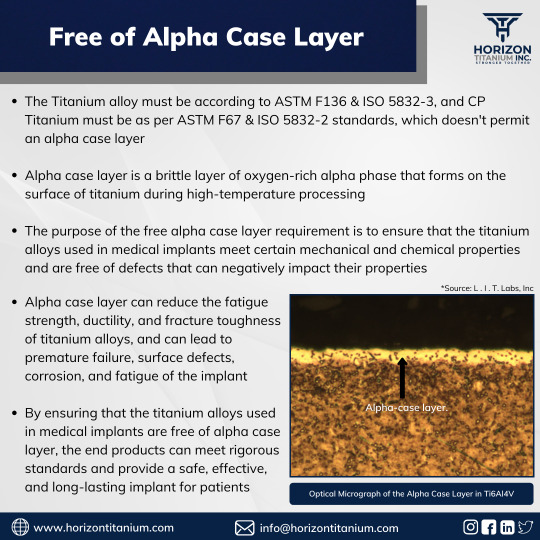

Photo

The alpha case forms when the Titanium surface reacts with oxygen at high temperatures, causing the Titanium surface to become brittle and susceptible to cracking and premature failure.

As a result, the alpha case layer is not permitted for medical applications according to ASTM F67, ISO 5832-2, ASTM F136, and ISO 5832-3.

For more information on Titanium for medical applications, you can write to us at [email protected]

#KnowYourTitanium#Titanium#AlphaCase#ASTM#ISO#Oxygen#Brittle#Mechanical#Metallurgy#Microstructure#FatigueStrength#Ductility#FractureToughness#Cracking#PrematureFailure#SurfaceDefects#CorrosionResistance#MedicalImplants#HighQuality#LongLastingImplants#OrthopaedicImplants#HorizonTitanium#StrongerTogether

0 notes

Text

what were your hands meant to do?

pray

Not necessarily to a god, but to hope. To family. In mud you see art. In shadows you see color. If the world fell apart around you, you would start gluing the pieces back together. Life tastes bitter but you like the bite. Those around you are inspired by your kindness, by your faith, by your hope. You might not speak often, but your words are the loudest in the room. You are rain and its ability to seep into every crack, the promise of new life.

Tagged by: @poeticphoenix (thank you!)

Tagging: @wingsdreamt, @breathofthearth, @hisalis, @alterfates, @calamitysshatteredson, and YOU!

#dash games#hc: kunsel#it fits. it fits Kunsel perfectly.#hope is gold - even crushed - even tarnished#hope - like gold - is conductive. conduit for energy. for change.#malleable and ductile and precious as anything.

5 notes

·

View notes

Text

Anybody knows which step of lost foam casting this video belongs to?

0 notes

Text

The Role of Ferro Silicon Magnesium Inoculants in Ductile Iron Production

The production of high-quality ductile iron is a critical process in contemporary foundries that necessitates the precise and meticulous management of metallurgical elements. The use of Ferro Silicon Magnesium as an inoculant is one of the most critical components in the production of superior ductile iron. This inoculant is indispensable in the refinement of the microstructure, the enhancement of mechanical properties, and the guarantee of the desired final product’s performance.

Comprehension of Ductile Iron

Ductile iron, also referred to as nodular iron or spheroidal graphite iron, is a form of cast iron that is distinguished by its extraordinary ductility, durability, and strength. Traditional cast iron is distinguished from ductile iron by its distinctive microstructure. This microstructure is accomplished by regulating the formation of graphite in the iron matrix, ensuring that it forms as nodules rather than particles, which are a defining feature of grey cast iron. The mechanical properties of ductile iron are considerably enhanced by the presence of nodular graphite, which increases its tensile strength and elongation. Consequently, it is well-suited for demanding industrial applications, including automotive components, pipelines, and apparatus parts.

Nevertheless, the addition of carbon to the molten iron is insufficient to achieve the desired microstructure. The formation of graphite nodules must be meticulously controlled, and this is where inoculants like Ferro Silicon Magnesium come into action.

The Function of Inoculants in Ductile Iron

Inoculant are added to molten iron to modify the solidification process, ensuring the formation of a desirable microstructure. In ductile iron, inoculation is a crucial stage because it directly influences the shape, size, and distribution of graphite nodules within the matrix. Without appropriate inoculation, the graphite may not form correctly, leading to inferior mechanical properties, reduced ductility, and increased brittleness.

Ferro Silicon Magnesium is one of the most effective inoculants used in the production of ductile iron. It is a combination of iron, silicon, and magnesium, with magnesium being the key element that promotes the formation of spheroidal (nodular) graphite. Silicon, on the other hand, functions as a deoxidizer and enhances the nucleation process, while iron serves as the base material.

How Ferro Silicon Magnesium Works as an Inoculant

Ferro Silicon Magnesium is typically added to the molten iron during the ladle treatment procedure, just before casting. The magnesium content in the inoculant reacts with the sulfur and oxygen present in the molten iron, forming magnesium sulfide and magnesium oxide. This reaction reduces the sulfur content and promotes the formation of graphite nodules instead of particles. By decreasing the sulfur levels, the inoculant prevents the formation of carbides, which can make the iron brittle and negatively impact its mechanical properties.

In addition to magnesium, the silicon content in Ferro Silicon Magnesium serves a vital function in stabilizing the structure. Silicon helps facilitate the nucleation of graphite, ensuring that the nodules are evenly distributed throughout the matrix. The balanced composition of the inoculant ensures that the molten iron solidifies with the desired microstructure, resulting in ductile iron with enhanced strength, ductility, and elongation.

Benefits of Using Ferro Silicon Magnesium Inoculant Enhanced Mechanical Properties: The principal benefit of using Ferro Silicon Magnesium as an inoculant is the enhancement in mechanical properties. The formation of spherical graphite nodules enhances the strength, ductility, and impact resistance of the ductile iron. This makes it suitable for applications that require both strength and ductility, such as in automotive components and heavy machinery.

Improved Castability: The use of Ferro Silicon Magnesium inoculant also enhances the castability of the iron, reducing defects such as contraction, porosity, and inclusions. This leads to higher-quality castings and minimizes the need for post-production refining or restorations.

Consistent Microstructure: Achieving a consistent and uniform microstructure is essential for the reliability of ductile iron components. Ferro Silicon Magnesium guarantees a more homogenous distribution of graphite nodules, leading to enhanced performance and durability in the final product.

Cost Efficiency: Proper inoculation with Ferro Silicon Magnesium helps optimize the production process by reducing waste and the likelihood of defects. This translates to cost reductions for foundries, as fewer defective castings mean less waste material and less need for revision.

Versatility in Applications: Ductile iron treated with Ferro Silicon Magnesium inoculants is highly versatile and suitable for a broad variety of industries, including automotive, construction, energy, and municipal infrastructure. Its enhanced mechanical properties make it an excellent choice for components like crankshafts, gearboxes, pipelines, and hydraulic components.

Challenges and Considerations

While the benefits of using Ferro Silicon Magnesium as an inoculant in ductile iron production are well-established, there are some challenges and considerations that foundries must bear in mind. The appropriate dosage of the inoculant is critical to attaining the desired microstructure. Too little magnesium can result in incomplete nodule formation, while too much can lead to excessive oxidation and the formation of defects such as slag inclusions. Foundries must carefully monitor and control the inoculation process to ensure optimal results.

In addition, the grade of the inoculant itself is a significant factor. The composition of Ferro Silicon Magnesium must be consistent and free from impurities to ensure reliable performance in the foundry. This is why many foundries prefer to work with trusted suppliers that provide high-quality, precisely formulated inoculants.

Conclusion

Ferro Silicon Magnesium inoculants serve a pivotal role in the production of high-quality ductile iron, ensuring the formation of nodular graphite that enhances the mechanical properties of the final product. By controlling the solidification process and fostering the formation of spheroidal graphite, Ferro Silicon Magnesium enhances the strength, flexibility, and durability of ductile iron, making it suitable for a wide range of industrial applications. As foundries continue to prioritize efficiency, quality, and performance, the use of advanced inoculants like Ferro Silicon Magnesium will remain essential in meeting the demands of modern manufacturing.

0 notes

Text

Some TPTM ocs !! @weevildoing

#the post traumatic manifesto#tptm#weevildoing#Prototype Girl#Cotard Girl#Blackout Girl#Euthanasia Girl#Ductile Girl#I’ll make full colored versions and their profiles soon#But I already made prototype girl’s#There is also Corliss Effect Girl and Bossanova Girl#But I haven’t made them yet#Btw if y’all want me to explain their issues uhhh feel free to ask lol

46 notes

·

View notes