#microcontroller firmware

Explore tagged Tumblr posts

Text

youtube

NXP: FRDM Development Boards for Rapid Prototyping

https://www.futureelectronics.com/resources/featured-products/nxp-mcx-n-mcx-a-microcontrollers . FRDM development boards are a low-cost, scalable hardware platform supported by the MCUXpresso Developer Experience. Designed to promote creative freedom while developing for various end applications. https://youtu.be/YpHF9rL0oRQ

#Nxp#frdm#development board#rapid prototyping#software engineering#microcontroller firmware#microcontroller#FRDM#development boards#How to#future electronics#Youtube

1 note

·

View note

Text

youtube

NXP: FRDM Development Boards for Rapid Prototyping

https://www.futureelectronics.com/resources/featured-products/nxp-mcx-n-mcx-a-microcontrollers . FRDM development boards are a low-cost, scalable hardware platform supported by the MCUXpresso Developer Experience. Designed to promote creative freedom while developing for various end applications. https://youtu.be/YpHF9rL0oRQ

#Nxp#frdm#development board#rapid prototyping#software engineering#microcontroller firmware#microcontroller#FRDM#development boards#How to#future electronics#Youtube

0 notes

Text

TLV320DAC3100 first bops 🔊🎶💃🕺

OK, after many hours spent with Claude on writing a driver for the TLV320DAC3100 (https://www.digikey.com/en/products/detail/texas-instruments/TLV320DAC3100IRHBR/2260591), we finally have it configured using our driver, and playing an MP3 stream on this ESP32. This I2S DAC has a particularly complex PLL and audio-routing system, so it's not one where you can just pipe in I2S data and have it magically play. One nice thing we got working on is the MCLK, which is generated from the BCLK, so it'll work great with anything from an Arduino-compatible to a single-board computer like Raspberry Pi. We're hoping to get the headphone detection working next so that we can turn off the amp when the headphone is plugged in. Also, it should be able to control the volume from the headset buttons. Also, we want to get the internal beep generator going so we can make tones separate from the audio stream for UI notifications.

#tlv320dac3100#dac#esp32#i2s#audioengineering#opensource#mp3streaming#embeddedhardware#hardwarehacking#arduino#raspberrypi#microcontrollers#firmware#coding#electronics#headphones#pll#audioprocessing#dsp#mclk#bclk#headphonemod#techinnovation#audiophile#sounddesign#makercommunity#opensourcehardware#iot#embeddeddev#beepgenerator

36 notes

·

View notes

Text

Embedded Computing Marled is Anticipated to Witness High Growth Owing to Wide Adoption Across End-use Industries

Embedded computing refers to a computer system that is part of a larger mechanical or electrical system designed to perform a dedicated function. Embedded systems are designed for specific control functions within embedded products and machines and operate under the direct control of an embedded program. Some key features of embedded systems include rugged construction, low power usage, real-time operating capabilities and compact size. Embedded devices are commonly found in industrial equipment, automobiles, consumer electronics, home appliances and medical devices to control electronic systems. Their key advantage is the ability to control electronic processes in a precise, flexible and cost-effective manner.

The global embedded computing market is estimated to be valued at US$ 112.45 Bn in 2024 and is expected to reach US$ 174.38 Bn by 2031, exhibiting a compound annual growth rate (CAGR) of 6.5% from 2024 to 2031.

Wide adoption across industries such as industrial automation, transportation, healthcare, telecommunication and consumer electronics is fueling market growth. Embedded systems allow streamlining of electronic processes, reducing downtimes and operation costs for end-use industries. Key Takeaways Key players operating in the embedded computing market are Advanced Micro Devices (AMD), Inc., Advantech Co., Ltd., Avalue Technology Inc., Curtiss-Wright Corporation, Dell Technologies Inc., Emerson Electric Co., Fujitsu Limited, General Electric Company, Hewlett Packard Enterprise Company, Honeywell International Inc., Intel Corporation, Kontron ST AG, Mitsubishi Electric Corporation, Rockwell Automation, Inc., and Texas Instruments Incorporated. The Embedded Computing Market Demand offers significant opportunities for system integrators and solution providers through new product development and capability expansion. Growing digitization trends across industry verticals will continue to generate strong demand for embedded systems with advanced computing and connectivity features. Leading embedded computing companies are focusing on global expansion strategies through partnerships, joint ventures and acquisitions to solidify their presence in emerging economies of Asia Pacific, Latin America, Middle East and Africa. These regions offer high growth potential driven by ongoing modernization of infrastructure and growing electronics manufacturing activities. Market Drivers Wide adoption across industrial automation applications is a key driver for the embedded computing market. Use of embedded systems allows streamlining of electronic processes, reducing downtimes and operation costs for industrial equipment manufacturers. Growing connectivity trends through Industrial Internet of Things (IIoT) will further propel demand. Rising electronics content in automobiles is positively impacting the market. Advanced driver assistance systems, infotainment systems and vehicle networking require powerful embedded computing solutions. Strict fuel efficiency and vehicle emissions norms will accelerate integration of embedded computing hardware. Market Restrain Design complexity of developing embedded system on a chip (SoC) poses challenges, especially for integrating advanced Embedded Computing Companies capabilities with low power requirements. This increases new product development timelines and costs. Limited standardization across various embedded system platforms inhibits seamless interoperability, data exchange and application portability. This poses difficulties for globally distributed product development activities.

Segment Analysis Automotive industrial and transportation is dominating the embedded computing market due to increasing implementation of advanced driver-assistance systems, connected vehicles solutions, electric vehicles, and autonomous vehicles. According to recent surveys over 65% of all new light vehicles shipped will have features like adaptive cruise control, automatic emergency braking, and blind spot monitoring by 2030. All these emerging technologies are driving the growth of embedded systems in automotive applications. Security and defense is another major sub segment in the embedded computing market owing to rising implementation of thermal weapon sights, combat management systems, imaging payloads and guidance systems in warships, aircraft carriers and fighter jets. Real-time information, enhanced situational awareness and integrated mission capabilities are some key priorities for embedded systems in defense applications. Various nations are also focusing on developing autonomous weapons which will further augment demand in coming years. Global Analysis North America dominates the global embedded computing market with a share of over 35% due to substantial research funding and presence of major OEMs in the region. US and Canada are hub for embedded technology development owing to advancement in networking infrastructure, IoT penetration and adoption of Industry 4.0 concepts. Asia Pacific shows fastest growth momentum led by China, India, Japan and South Korea. Low manufacturing cost and government initiatives to digitize industries are driving Asia Pacific market. Intensifying Sino-US trade war may impact supply chain dynamics in long run. Europe captures around 25% market share led by Germany, United Kingdom and France.

Get more insights on Embedded Computing Market

About Author:

Money Singh is a seasoned content writer with over four years of experience in the market research sector. Her expertise spans various industries, including food and beverages, biotechnology, chemical and materials, defense and aerospace, consumer goods, etc. (https://www.linkedin.com/in/money-singh-590844163)

#Coherent market insights#Embedded Computing Market#Embedded Computing#Microcontrollers#IoT#Firmware#Real-Time Operating Systems#Hardware Design#Software Development#Sensor Integration#Embedded Software

1 note

·

View note

Text

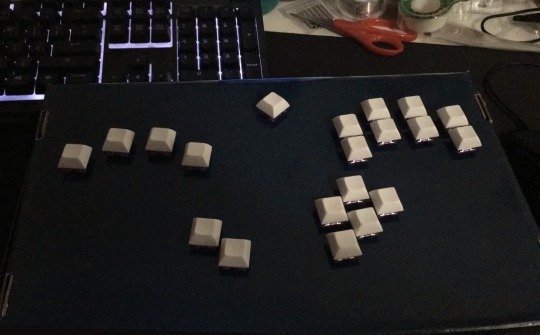

let’s dispel once and for all the fiction that mechanical keyswitches are good. They aren’t that much better than the alternatives.

More earnestly: the number one benefit of mechanical keyswitches is that they grant a designer an extraordinary degree of latitude when it comes to the structure and design of a keyboard. Unless you really highly value clickiness the majority of their features can be matched by high quality rubber domes from any decent keyboard manufacturer.

Their real strength is that you can pick consistent, reliable switches and put them anywhere you want in 3D space and just run wires to them to make a unique 1 of 1 keyboard that perfectly fits you, and you can easily stick a microcontroller with custom firmware in there to implement whatever features you want.

I got a Logitech ergo rubber dome today and it feels great, the biggest issue is that I wish it didn’t have a numpad and I wish it had more thumb buttons so that they could do more work. And of course I would! That’s what my homemade custom mechanical split keyboard looks like! I could make that to exact specs with some wood tools and a laser cut sheet of brass for the switchplate, whereas this Logitech is a miracle made of over a dozen unique injection moulded parts with an overall mould cost probably exceeding USD 50k!

I would love to have exactly the perfect high end rubber dome mass-produced keyboard of my dreams, but no one makes it, and that’s, reasonable, I have very specific dreams, but I have never understood bog standard layout mechanicals. You could be having a much better time with something with nicer switches!

Sorely tempted to figure out if I can physically hack off the numpad here and sneakily hot-glue some kailh choc switches to the wristrest as thumb keys. At the moment I'm just putting my trackball square on top of the numpad which works fine. I'll print a cap for it later. This is going to end up at Gainful Employment Location not home. At the very least I want to see if there's a way to distinguish the two spacebars in software and use some clever hacks to make them behave as enter/backspace/both.

ISO enter keys were sent by the devil but I don't really have a lot of good options unless I want to import ANSI keyboards.

15 notes

·

View notes

Text

For future reference (my own and others), if your TI SilverLink USB cable stops working and starts showing up as "TUSB3410 Boot Device" or similar under device manager (AKA this issue on TI's help page), this is how you can fix it:

Download the TUSB3x10 EEPROM Burner. This is a Windows-only program, but to my knowledge will work on basically any windows machine from XP on -- so long as it's got USB ports. No clue if it'll work in a VM. (You might want to consult this user's manual.)

Download the SilverLink firmware. I got it from here, and compiled it from their de-compilation. It's just a standard 'make' to build. The output file you're looking for is called "ti_graph_link_silver.eep".

Rename "ti_graph_link_silver.eep" to "ti_graph_link_silver.bin".

Open the TUSB3x10 EEPROM Burner, click on the options dropdown and click "Show the 'Program Full Binary Image' button". (page 7 of the manual).

Select the entry under "Computer" labeled "TUSB3410 EEPROM Burner Instance (1.00)".

Set EEPROM size to "64Kb".

Set "File Path" to point to "ti_graph_link_silver.bin". (The renamed .eep, not the original .bin)

I don't know if the VID, PID, Manufacturer string, Product string and Serial # need to be set manually or not with a 'Full Binary Image' burn. Just to be safe, I set VID to 0451, PID to e001, Manufacturer to "Texas Instruments", Product to "TI-GRAPH LINK USB", and checked "Not Serialized"*.

Click the "Program Full Binary Image" button (yellow triangle with the exclamation point), and proceed with the write.

Unplug and re-plug your cable, and it should show up as a SilverLink again!

Additional notes:

The reason that this happens is because the SilverLink cable (revision b, at least) is based on the TUSB3410 microcontroller. That microcontroller's boot process involves checking for an I2C EEPROM containing program code. If it finds that EEPROM and its contents are properly formatted, it'll copy that code into internal RAM and start executing it. If it can't find the EEPROM, or its contents aren't properly formatted, it'll fall back to looking for boot code over USB. Thus: "TUSB3410 Boot Device". Your cable has, in essence, forgotten who it is and and is begging for you to give it a purpose.

The default page-write buffer size (32 bytes) and I2C bus speed (400 KHz) in the burner app are already correct, so no need to change them.

*I don't remember exactly what the Manufacturer string, Product string, or serial number fields were set to pre-corruption. Likewise, no idea about the advanced descriptor options. If someone wants to send the output of lsusb -v -s [whatever their silverlink's bus/id numbers are], I'd really appreciate it!

You might be able to skip the header rigamarole by taking the ti_graph_link_silver.bin file directly ("directly coming from the compiler") -- but I again I don't know exactly what information is in the .eep file and what isn't. Are the PID and VID encoded somewhere in there? I peeked with a hex editor but have no clue. If someone has hardware lying around they're willing to experiment with/potentially brick, I'd love to hear your results!

If you mess up and accidentally forget to do a "Full Binary Image" write, or otherwise brick the firmware, you can force the TUSB3410 to fall back to USB boot mode by opening the plastic shell around the PCB (one Torx screw under the sticker, then just normal plastic tabs) and shorting the right-bottom (Vss) and right-top (SDA), or right-bottom (Vss) and center right-top (SCL) pins of the EEPROM (the chip labeled "24LC64") as you plug it into the USB port. You may need multiple attempts. This works because it temporarily convinces the TUSB3410 that the EEPROM is missing/corrupt, and thus it decides to fall back into USB boot mode -- until you reset it. It might be better to do this with a ~1k resistor instead of a jumper wire, but IDK I'm not an electrical engineer. All I know is that shorting Vss and SDA worked for me. Again, would love feedback.

No clue what causes the corruption in the first place, or how long this fix will last. It might be because the EEPROM's write protect pin is set to "write enable"? It could also just be degrading hardware, for all I know, so no idea how long the fix will last. All I do know is that everything seems nominal right now (immediately after performing this procedure).

10 notes

·

View notes

Text

Essential Skills Every Electronics Engineer Should Master

Electronics engineering is an exciting and constantly evolving field. With new technologies emerging every day, the need for skilled professionals has never been greater. If you're pursuing a B Tech in Electrical and Electronics Engineering or exploring options at B Tech colleges for Electrical and Electronics, it's crucial to know which skills can set you apart in this competitive domain.

Let’s dive into the essential skills every aspiring electronics engineer should master.

Strong Foundation in Circuit Design

Circuit design is at the heart of electronics engineering. Understanding how to create, analyze, and optimize circuits is a must-have skill. Whether you’re designing a simple resistor network or a complex integrated circuit, mastering tools like SPICE and PCB design software can make your designs efficient and innovative.

Programming Proficiency

Electronics and programming often go hand in hand. Languages like Python, C, and MATLAB are widely used to simulate electronic systems, automate processes, and even build firmware for devices. Engineers proficient in programming can troubleshoot problems effectively and add versatility to their skill set.

Knowledge of Embedded Systems

Embedded systems are everywhere—from your smartphone to your washing machine. As an electronics engineer, understanding microcontrollers, sensors, and actuators is crucial for creating devices that work seamlessly in our daily lives. Hands-on experience with platforms like Arduino and Raspberry Pi can be a great way to start.

Problem-Solving and Analytical Thinking

Electronics engineers often face unique challenges, such as debugging faulty circuits or improving system performance. Strong problem-solving and analytical thinking skills help them identify issues quickly and find effective solutions. To cultivate these skills, tackle real-world projects during your coursework or internships.

Familiarity with Power Systems

As the world moves toward renewable energy and smart grids, knowledge of power systems is becoming increasingly important. Engineers in this field should understand how electrical power is generated, transmitted, and distributed and how to design energy-efficient systems.

Effective Communication Skills

Electronics engineering often involves working in teams with other engineers, designers, or clients. Communicating your ideas clearly—whether through reports, presentations, or technical drawings—is just as important as your technical skills. Strong communication ensures that your brilliant ideas come to life effectively.

Adaptability to New Technologies

Technology evolves rapidly, and staying updated is essential for electronics engineers. Whether you’re learning about IoT (Internet of Things), AI integration, or 5G communication, an adaptable mindset will ensure you remain relevant and capable of tackling emerging challenges.

Hands-On Experience

While theoretical knowledge is important, nothing beats practical experience. Participating in labs, internships, or personal projects gives you the opportunity to apply what you’ve learned and develop confidence in your skills. Employers often value hands-on experience as much as your academic achievements.

Preparing for Success in Electronics Engineering

Pursuing a B Tech in Electrical and Electronics Engineering is the first step toward mastering these skills. The best B Tech colleges for Electrical and Electronics not only provide a strong academic foundation but also opportunities for practical learning and industry exposure. By focusing on the skills mentioned above, you can position yourself as a competent and innovative engineer ready to tackle real-world challenges.

4 notes

·

View notes

Note

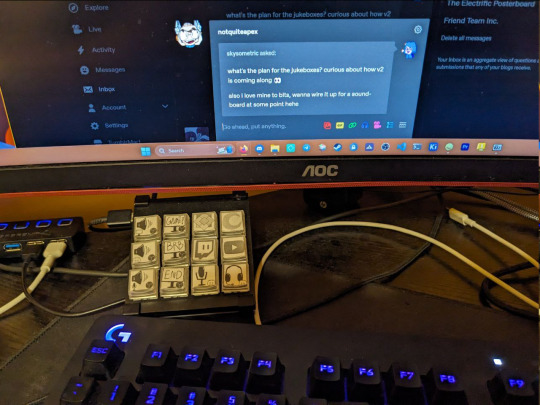

what's the plan for the jukeboxes? curious about how v2 is coming along 👀

also i love mine to bits, wanna wire it up for a soundboard at some point hehe

OH BOY I GET TO TALK ABOUT MY OTHER WEIRD PROJECTS!

Jukebox development has been on hold for a while now! Between the work on the next version (which would've been v4, btw, not v2. (I've been working on this for fuckin ever dude good god) Fun fact, you and some others got a v3!) and life just kind of happening to me, I haven't made much progress. Part of that life bit was also because I'm actually going to be doing an independent study with a prof at my university to develop the (hopefully last) version of the Jukebox.

The plan is to use a cheaper microcontroller (v4 had one that cost $2.50 to $4 per chip, v5 will be using one that's only $1 with a $0.25 memory chip) but keep pretty much everything else the same from the previous version. That means USB-C, Cherry MX and Kailh Choc key switch support, and open source everything. It would also have another 4 keys for the "modifier" (ctrl, alt, shift, super) keys for even more hotkey-ability.

I actually have a bunch of v4's built, and have been meaning to give them away to local friends or swap them with existing Jukeboxes I have given/sold to people. I also use a v4 with some "relegendable" key caps.

Ideally, the final version of the Jukebox would be sold with these (or similar) key caps, with a fun sticker sheet or something. The current "stickers" are made of printer paper, held in by the top and bottom halves of the keycap. I regularly use this while streaming and when I'm in Discord calls. It's great!

A big part of the reason the Jukebox still isn't finished, even with the whole independent study thing, is that I want it to be basically "finished" when I release it. Nothing new should need to be done with it once its out in the world. No firmware revisions, no bloated desktop applications. I want it to be something you can buy once and be happy with for the rest of your computing days, because lord knows we already have enough e-waste in the world. Designing products that last and that people want to use can be hard, especially when you're self funded and solo!

But I still have more plans for this thing, like this screen add-on for monitoring PC performance for weird PC building nerds like myself (or just anything, because it's a screen), and hopefully by next May it'll be ready for order proper. (Also ideally any old jukeboxes out there would just get a simple swap with the new ones. I'm already super in-the-red in terms of profit off these things, going in further wouldn't be so bad if it meant I got some of my old equipment and stuff back so I can use it for other things :D)

7 notes

·

View notes

Text

The PicKit 2 is a USB PIC programmer tool that can utilize Windows Platform with MPLAB Integrated Development Environment (IDE) to program or debug PIC Microcontrollers that support In-Circuit Serial Programming (ICSP). Meaning the PIC can be programmed with only 2-wires (2-pins) PGD and PGC excluding the power pins. It's great for beginners who wish to program or flash their PIC Microcontrollers which supports ICSP or for any firmware update. ICSP ensures that the microcontroller can be programmed without removing it from the circuit. This makes the debugging of the circuit easier and more convenient.

3 notes

·

View notes

Text

so excited to wire my diy boxx 2morrow <3

kind of anxious about measuring the red wires and whether or not i should tape the microcontroller to the box or let it just hang there so that vibrations and jostling don't mess w the chip as much. wires should be fine though since i bought stranded ones.

this is what it looks like outside. ive made myself a little guide to make it easier soldering each button to the default pinhole set in the firmware, but again anxious about that part. i'll defo (probably) have it in the center to save on wire. the ground though, that part i found pretty fun on my stream deck.

thing im most anxious abt is the usb wire. im hoping i can find one lying around that i can leave inside to have a dedicated wire since i dont have a breakout. but if it comes to it, i can share the one i use for my drawing tablet. unplugging its gonna be a bitch though.

hope in the future i can also wire a gamecube usb, so i can play on my wii or at locals that use gamecubes.

#smash bros#ssb melee#ssbm#hitbox#boxx#frame1#diy#diy controller#arcade stick#fightstick#fighting games#fgc#fighting game community#196#fanter#rasberry pi#rasberry pi pico

7 notes

·

View notes

Text

Custom Firmware Services for IoT & Embedded Systems

Get robust and tailored firmware that powers your embedded systems. We offer full-cycle firmware development for microcontrollers, sensors, and connected devices. Whether it's real-time control or secure connectivity, we turn your hardware into intelligent, feature-rich products with minimal time to market.

0 notes

Text

How Do Power, Motor & Robotics Development Tools Drive Innovation in Automation?

Introduction to Modern Development Ecosystems

As the era of intelligent machines, automation, and smart manufacturing continues to advance, Power, Motor & Robotics Development Tools have emerged as essential components in transforming ideas into functioning prototypes and commercial solutions. These tools serve as the backbone for developing precise and reliable control systems used in a wide variety of sectors—from industrial robotics to electric mobility.

With the increasing integration of microcontrollers, sensors, thermal management components, and electronic controllers, development tools offer a modular and practical approach to building sophisticated electronic and electromechanical systems.

What Are Power, Motor & Robotics Development Tools?

Power, Motor & Robotics Development Tools consist of hardware kits, interface boards, and control modules designed to help developers and engineers test, prototype, and deploy automated systems with precision and speed. These tools make it possible to manage current, voltage, mechanical motion, and real-time decision-making in a structured and scalable manner.

By combining essential components such as capacitors, fuses, grips, cables, connectors, and switches, these kits simplify complex engineering challenges, allowing smooth integration with controllers, microprocessors, and sensors.

Exploring the Primary Toolsets in the Field

Power Management Development Tools

Efficient energy management is crucial for ensuring stability and performance in any robotic or motor-driven system.

Development boards supporting AC/DC and DC/DC conversion

Voltage regulators and surge protection circuits for safe energy flow

Thermal sensors and oils to maintain system temperature

Battery management ICs to control charge-discharge cycles

High-efficiency transformers and current monitors

Motor Control Development Tools

Motor control kits are built to manage torque, direction, and speed across a range of motor types.

H-bridge motor drivers for bidirectional motor control

Stepper motor controllers with high-precision movement

Brushless DC motor driver modules with thermal protection

Feedback systems using encoders and optical sensors

PWM-based modules for real-time torque adjustment

Robotics Development Tools

Robotics kits merge both mechanical and electronic domains to simulate and deploy automation.

Preassembled robotic arm platforms with programmable joints

Sensor integration boards for object detection, motion sensing, and environmental monitoring

Wireless modules for IoT connectivity using BLE, Wi-Fi, or RF

Microcontroller development platforms for logic execution

Mounting hardware and cable grips for secure installations

Benefits of Using Professional Development Tools

Advanced development kits offer more than just experimentation—they serve as stepping stones to commercial production. These tools minimize development time and maximize productivity.

Enhance system performance with modular plug-and-play designs

Enable easy integration with laptops, diagnostic tools, and controllers

Reduce design errors through pre-tested circuitry and embedded protection

Facilitate rapid software and firmware updates with compatible microcontrollers

Support debugging with LED indicators, thermal pads, and status feedback

Key Applications Across Industries

The adaptability of Power, Motor & Robotics Development Tools makes them suitable for countless industries and applications where intelligent movement and power efficiency are essential.

Industrial robotics and pick-and-place systems for manufacturing automation

Smart agriculture solutions including automated irrigation and drone control

Automotive design for electric vehicle propulsion and battery systems

Aerospace applications for lightweight, compact control mechanisms

Educational platforms promoting STEM learning with hands-on robotics kits

Essential Components that Enhance Development Kits

While the kits come equipped with core tools, several other components are often required to expand capabilities or tailor the kits to specific use cases.

Sensors: From temperature and light to current and magnetic field detection

Connectors and plugs: For flexible integration of external modules

Switches and contactors: For manual or automatic control

Thermal pads and heatsinks: For preventing overheating during operation

Fuses and circuit protection devices: For safeguarding sensitive electronics

LED displays and character LCD modules: For real-time data visualization

How to Choose the Right Tool for Your Project

With a vast array of kits and tools on the market, selecting the right one depends on your application and environment.

Identify whether your project focuses more on power management, motor control, or full robotic systems

Consider compatibility with popular development environments such as Arduino, STM32, or Raspberry Pi

Check the current and voltage ratings to match your load and motor specifications

Evaluate add-on support for wireless communication and real-time data processing

Ensure the tool includes comprehensive documentation and driver libraries for smooth integration

Why Development Tools Are Crucial for Innovation

At the heart of every advanced automation solution is a well-structured foundation built with accurate control and reliable hardware. Development tools help bridge the gap between conceptualization and realization, giving engineers and makers the freedom to innovate and iterate.

Encourage experimentation with minimal risk

Shorten product development cycles significantly

Simplify complex circuit designs through preconfigured modules

Offer scalability for both low-power and high-power applications

Future Scope and Emerging Trends

The future of development tools is headed toward more AI-integrated, real-time adaptive systems capable of learning and adjusting to their environment. Tools that support machine vision, edge computing, and predictive analytics are gaining traction.

AI-powered motion control for robotics

Integration with cloud platforms for remote diagnostics

Advanced motor drivers with feedback-based optimization

Miniaturized power modules for wearable and mobile robotics

Conclusion: Is It Time to Upgrade Your Engineering Toolkit?

If you're aiming to build smarter, faster, and more energy-efficient systems, Power, Motor & Robotics Development Tools are not optional—they’re essential. These kits support you from idea to implementation, offering the flexibility and performance needed in modern-day innovation.

Whether you're developing a prototype for a high-speed robotic arm or integrating power regulation into a smart grid solution, the right development tools empower you to transform challenges into achievements. Take the leap into next-gen automation and electronics by investing in the tools that make engineering smarter, safer, and more efficient.

#Power Motor & Robotics Development Tools#electronic components#technology#electricalparts#halltronics

0 notes

Text

Solenoids go clicky-clacky 🔩🔊🤖

We're testing out an I2C-to-solenoid driver today. It uses an MCP23017 expander. We like this particular chip for this usage because it has push-pull outputs, making it ideal for driving our N-channel FETs and flyback diodes. The A port connects to the 8 drivers, while the B port remains available for other GPIO purposes. For this demo, whenever we 'touch' a pin on port B to ground, the corresponding solenoid triggers provide an easy way to check speed and power usage.

#solenoid#electronics#i2c#mcp23017#hardwarehacking#maker#embedded#engineering#robotics#automation#circuitdesign#pcb#microcontroller#tech#hardware#diyelectronics#electricalengineering#firmware#innovation#prototype#electromechanical#diy#electronicsproject#smarthardware#tinkering#gpio#fet#flybackdiode#programming#linux

44 notes

·

View notes

Text

Best Embedded system Coaching Center in Chennai

Chennai is a major educational and technological hub that hosts some of the best embedded system coaching centers catering to the growing demand for skilled embedded systems professionals. The best embedded system coaching center in Chennai offers a comprehensive curriculum that covers fundamental to advanced topics such as microcontroller programming, embedded C, RTOS (Real-Time Operating Systems), firmware development, and hardware interfacing.

0 notes

Text

Understanding Load Cells: Precision Force Measurement with Star EMBSYS Technology

A load cell is a highly precise transducer that converts force or weight into an electrical signal. It plays a crucial role in modern industries where accurate weight measurement is essential—ranging from manufacturing and automation to medical and agricultural applications. One company at the forefront of delivering reliable load cell solutions is Star EMBSYS, renowned for its commitment to innovation and quality in embedded system technologies.

Load cells work primarily based on strain gauge technology, where mechanical force causes minute deformation in the strain gauges, resulting in a change in electrical resistance. This change is measured and converted into a readable digital signal, allowing for highly accurate force or weight measurements. Depending on the application, load cells come in various forms such as compression, tension, shear beam, and single-point load cells.

Star EMBSYS specializes in integrating these load cell technologies into smart, embedded systems. Their custom solutions support both analog and digital output types, enabling seamless integration with microcontrollers, industrial PLCs, and IoT devices. The company’s expertise in embedded hardware and firmware development ensures that their load cell systems offer robust signal conditioning, temperature compensation, and high sensitivity, even in challenging environments.

A standout feature of Star EMBSYS’s load cell solutions is their adaptability. Whether it's for a smart weighing scale, an industrial automation unit, or a robotic arm that requires real-time force feedback, Star EMBSYS provides tailored embedded systems that meet diverse technical and environmental demands. Their R&D team also works closely with clients to design load cell circuits optimized for performance, longevity, and minimal noise interference.

Moreover, Star EMBSYS places a strong emphasis on calibration and accuracy. Their systems support both factory and field calibration methods, ensuring reliability across the entire product lifecycle. Advanced signal processing algorithms embedded within their microcontroller units help maintain precision and stability, making their load cell systems ideal for high-stakes applications such as aerospace, healthcare, and precision agriculture.

In conclusion, load cells are a vital part of modern measurement systems, and Star EMBSYS’s contribution to this field is significant. By combining advanced electronics with mechanical precision, they deliver cutting-edge solutions that enhance accuracy, efficiency, and performance. For industries requiring dependable force measurement systems, Star EMBSYS stands out as a trusted technology partner.

Visit:- https://www.starembsys.com/master-load-cell.html

0 notes

Text

goddammit.

My SilverLink cable is dead -- somehow either the firmware was lost or corrupted, and it's just showing up as a generic microcontroller to lsusb. Doesn't seem like there's a way to flash it, though I am still looking.

So much for going back to calculator programming tonight.

#maybe ill get a black link cable and a usb to serial adapter#that wouldnt be susceptible to this problem#though itd require more effort to bitbash#my thoughts#calculators#programming

6 notes

·

View notes