#refinery engineering services

Text

Expert Refinery Engineering Solutions by Little P.Eng.

In the dynamic and complex world of refinery operations, the demand for cutting-edge, reliable engineering solutions is more critical than ever. Little P.Eng. Engineering Services emerges as a beacon of excellence, offering bespoke engineering solutions tailored to the unique needs of refineries. With a deep understanding of the challenges and intricacies of refinery engineering, Little P.Eng. stands out as a premier choice for operators aiming to enhance efficiency, safety, and profitability.

Unmatched Expertise in Refinery Engineering

At the core of Little P.Eng.'s services lies a team of highly skilled and experienced engineers specializing in refinery operations. Our professionals are adept at navigating the latest industry standards, ensuring that all projects not only meet but exceed expectations. From process engineering to safety management systems, Little P.Eng. offers a comprehensive suite of services designed to address every aspect of refinery engineering.

Process Optimization for Enhanced Efficiency

Understanding the critical importance of process efficiency, Little P.Eng. employs state-of-the-art techniques and technologies to optimize refinery operations. Our approach focuses on minimizing energy consumption, reducing waste, and maximizing product yield, thereby significantly enhancing overall operational efficiency. Through detailed analysis and innovative solutions, we help our clients achieve their goals of cost reduction and improved productivity.

Safety and Compliance: A Top Priority

In the refinery industry, safety cannot be overstated. Little P.Eng. places paramount importance on ensuring that all engineering projects adhere to the strictest safety standards and regulatory compliance. Our safety management systems are designed to identify potential hazards, mitigate risks, and create a safe working environment for all employees. By staying ahead of regulatory changes, we ensure that our clients' operations are not only safe but also future-proofed against evolving industry requirements.

Customized Solutions for Every Challenge

Expert Refinery Engineering Solutions by Little P.Eng.

Partnering with Little P.Eng. for Your Refinery Needs

Choosing Little P.Eng. for your refinery engineering services means partnering with a leader in the field. Our commitment to excellence, combined with a client-centric approach, sets us apart in the industry. We invite you to discover how our expertise can transform your refinery operations, driving them towards unparalleled efficiency, safety, and success.

With Little P.Eng., your refinery is in expert hands. Contact us today to explore how we can support your engineering needs and propel your operations to new heights.

Tags:

Little P.Eng.

operational efficiency

engineering consulting

industry standards

regulatory compliance

process optimization

engineering solutions

refinery project management

process engineering

refinery engineering services

productivity improvement

energy consumption reduction

refinery optimization

engineering analysis

project efficiency

safety management systems

refinery technology

safety hazard mitigation

innovative engineering

efficiency enhancement

waste reduction

refinery design

refinery management solutions

refinery safety standards

bespoke engineering

tailored engineering services

safety and compliance

custom engineering solutions

engineering expertise

refinery operations

Engineering Services

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#•#Little P.Eng.#operational efficiency#engineering consulting#industry standards#regulatory compliance#process optimization#engineering solutions#refinery project management#process engineering#refinery engineering services#productivity improvement#energy consumption reduction#refinery optimization#engineering analysis#project efficiency#safety management systems#refinery technology#safety hazard mitigation#innovative engineering#efficiency enhancement#waste reduction#refinery design#refinery management solutions#refinery safety standards#bespoke engineering#tailored engineering services#safety and compliance#custom engineering solutions#engineering expertise

0 notes

Text

Backflip

STAR WARS EPISODE I: The Phantom Menace 01:52:38

You can clearly see this is Ewan McGregor's stunt double, Andreas Petrides, in this scene.

#Star Wars#Episode I#The Phantom Menace#Naboo#Theed#Battle of Theed#Battle of Naboo#Plasma Refinery Complex#Duel of the Fates#Qui-Gon Jinn#Qui-Gon Jinn's lightsaber#Obi-Wan Kenobi#Obi-Wan Kenobi's lightsaber#Darth Maul#Darth Maul's lightsaber#service catwalk#plasma acceleration shaft#thermal carbon membrane#remote engineering console

4 notes

·

View notes

Text

We provide mechanical engineering & machining services for conventional & subsea bolt tensioning, bolt torquing, pipe cutting & beveling, flange facing, milling, drilling & tapping, line boring, & leak sealing operations to a vast range of industries.

3 notes

·

View notes

Text

Exploring the Role of Oil and Gas EPC Companies in Energy Projects

Oil and gas exploration, production, and refining projects require specialized expertise and seamless coordination to ensure successful execution. This is where Oil and Gas EPC (Engineering, Procurement, and Construction) companies play a pivotal role. In this blog, we will delve into the significance of Oil and Gas EPC companies and how they contribute to the energy sector.

Integrated Solutions: Oil and Gas EPC companies provide integrated solutions for energy projects, starting from the initial engineering and design phase. They bring together a diverse range of professionals, including engineers, project managers, and procurement specialists, to develop comprehensive project plans that align with client objectives.

Engineering Expertise: EPC companies possess extensive engineering capabilities specific to the oil and gas industry. They conduct detailed feasibility studies, design equipment layouts, and plan for efficient resource utilization, ensuring compliance with industry standards and regulations.

Procurement and Supply Chain Management: Procurement plays a crucial role in oil and gas projects. EPC companies leverage their global networks and expertise to procure high-quality equipment, materials, and services at competitive prices. They establish robust supply chain management systems to ensure timely delivery and cost efficiency.

Construction and Project Management: EPC companies oversee the construction phase, managing subcontractors, coordinating activities, and ensuring adherence to project timelines and safety standards. They employ advanced project management tools and techniques to monitor progress, mitigate risks, and deliver projects within budget.

Health, Safety, and Environmental Compliance: Oil and gas projects require strict adherence to health, safety, and environmental regulations. EPC companies prioritize safety protocols, implement environmental management systems, and conduct regular inspections to ensure compliance and mitigate risks.

Commissioning and Start-Up Support: Once construction is complete, EPC companies provide commissioning and start-up support, assisting with the testing, verification, and integration of equipment and systems. They ensure a smooth transition from construction to operational phase, minimizing downtime and optimizing project performance.

Maintenance and Asset Management: EPC companies often offer maintenance and asset management services, ensuring the longevity and efficiency of oil and gas infrastructure. They conduct routine inspections, perform preventive maintenance, and manage repairs, maximizing asset lifespan and minimizing operational disruptions.

Conclusion: Oil and Gas EPC companies play a critical role in the successful execution of energy projects. With their expertise in engineering, procurement, construction, and project management, they provide integrated solutions that drive efficiency, safety, and sustainability in the oil and gas industry. Their contributions help meet the growing energy demands while adhering to industry standards and environmental considerations, ensuring a reliable and sustainable energy future.

#Engineering Consulting#Engineering Consulting Firm#EPC Companies India#EPC Consultants in India#EPC Contracting Company#EPC Contractors in India#Engineering Consultancy for Petrochemicals Projects#Engineering Consultancy for Refinery Projects#Engineering Consultancy Services#Engineering Consultancy Services India#Engineering Consulting Firms in India#Engineering Services for Infrastructure Projects#EPC in Oil and Gas Industry#EPCM Services for Oil and Gas#Multinational Epc Company#Oil and Gas EPC Companies#Oil and Gas EPC Companies in India#Oil and Gas EPC Contractors in India#Project Management Consultancy Services for Refinery#Top EPC Companies in India

0 notes

Text

CMM Inspection Services in Gujarat | The SUNCAD Training & Designers

Suncad leading CMM Inspection Services in Gujarat. We Infinity Automation Provide Outdoor as well as indoor CMM inspection services to our valuable customers. CMMs offer a reliable alternative to handheld inspection tools. They monitor the quality of manufactured items to ensure that they match original design plans within the customer’s preferred tolerance levels. CMMs can measure objects at different stages of production to quickly catch issues before the project is finished or before large-volume runs are completed, keeping the production process fast and efficient with less material waste. Under the efficient supervision of our skilled professionals, we have been able to render premium quality gamut of Faro CMM Inspection Service.

The Suncad Training & Designers provides the best CMM Inspection Services in Gujarat. For more information visit on : https://suncad.in/product/cmm-inspection/ or call us on : 9925023229

#BIM modeling and scanning service in Gujarat#3D Scanning in Gujarat#Leica RTC 360 Scanning Service Provider in Gujarat#Heritage scanning services in Gujarat#Faro Scanner Service Provider in Gujarat#3D Plant / refinery scanning service in Gujarat#D Lidar scanning / 3d Terrestrial scanning services in Gujarat#Laser tracker service in Gujarat#Reverse Engineering in Gujarat#3D Inspection services in Gujarat#CMM inspection services in Gujarat#CNC / VMC Machine operating in Gujarat#3D printing Services in Gujarat#Solid Edge training in Gujarat#SolidWorks Training in Gujarat

0 notes

Text

Rodimus' Prime Boobs

summary: Rodimus invites you to indulge in his refineries and have a drink.

pairing: Rodimus/Reader

fandom: Transformers

rating: Explicit

warnings: None

tags: Robot Boobs, Lactation, Coitus Interruptus.

Ao3 link is HERE.

“So, what’d you think?”

Rodimus asked, proudly showing off his refineries. They weren’t huge, but they weren’t small, either. About the size of your servos. They were perky, the nozzles slowly hardening in the slightly cool air of his habsuite. The protoform flesh was soft, light grey coloured, his nozzles a faint red. There was a faint glow from his spark beneath the flesh, almost entirely hidden away.

“They’re cute.”

“Eh? Cute?”

Rodimus looked at you with a slight frown. You bit back a small grin as his spoiler drooped, no doubt from disappointment.

“Come on! They’re sexy! Look how perky they are! Look at the way they lightly bounce every time I move!”

And he was right- as he gestured and pointed to them, there was a slight bounce from them. You smiled. Gulping, you bashfully looked at Rodimus and asked the burning question.

“Am I allowed to-”

“Hell yes you are! I’ve been waiting for you to grab ‘em!”

Rodimus leaned forward, pushing his open chestplate towards you with an eager grin. Shuffling forward on the berth, you gently cupped one of his refineries. He made a small noise, not quite a moan, more like a squeak.

“C-careful, they’re- they’re sensitive…”

“I’ll be gentle, Roddy. Tell me if I hurt you.”

The refinery was as soft as it looked. It filled your servo quite nicely, and it felt light. Rodimus bit his derma to stifle another noise as your thumb grazed over the nozzle.

“I’m surprised you didn’t try getting these pierced.”

“I wanted to!” Rodimus said, indignation laced his words as he rolled his optics. You chuckled at the young captain as he continued, “Ratchet said it might cause damage. And that it’d look foolish.”

“I dunno…” Trailing off, you looked back down at the nozzle, once again lightly rubbing your thumb over it. You hummed in appreciation as it hardened at your touch, in your processor you could picture a straight barbell piercing. “I bet you could rock the look, and I imagine it’d be nice to pinch them when they’re pierced.”

“They’re nice to pinch now.”

A loud rev was heard from him as he finished speaking. Looking at Rodimus, you could see a light blue luminescent blush on his faceplate, his optics were dark with need.

“Oh, I bet they are.”

You purred out, grinning. Rodimus shuffled closer to you, smirking at you..

“Well? Go on…”

Rodimus urged you softly, once again jutting out his refineries towards you. They were certainly inviting. Gently, almost unsure of yourself, you lightly pinched the nozzle, tugging it. Rodimus sighed.

“That’s nice… You can pinch harder though, they’re not fragile. They, uh, they leak energon if you do.”

You looked at Rodimus with a quirked browplate and a silent question on your glossa. Rodimus picked up on it, and answered without needing you to ask it.

“It’s a Prime thing.”

Rodimus shrugged, grinning. You nodded, accepting the somewhat lame answer. But it also made sense, somewhat. Just another Prime thing.

“I see.”

Looking back at his chest, you tugged at his nozzles again, this time more firmer. Rodimus’ engine was actively purring now, his spoiler twitching. You brought your other servo up and fondled the other refinery, humming in delight.

“These are nice. Wish my frame had these, they look nice to play with while self servicing.”

“They- they are.”

Rodimus breathed out, his glossa darting out to wet his derma. You weren’t surprised that Rodimus knew- honestly, it’d be surprising if he didn’t know since he was so adventurous. Rolling his nozzles between your thumb and digits, you tugged once more- and a drizzle of energon leaked out.

“Oh wow.”

The sight did something to you- seeing the bright pink liquid contrast with the light grey colouring of his protoform flesh and red nozzles caused your fans to click on the lowest setting.

“Like what you see?”

Rodimus’ tone was smug as he arched his back further into your touch. Gulping, you nodded.

“Y-yeah. Primus, yeah.”

“You can, you know. I’ve been told my energon is the best tasting ever.”

By Drift, no doubt.

You thought to yourself. Now it was your turn to wet your derma with glossa, suddenly finding yourself with a dry intake. The offer was tempting as you watched the small leak drip down your servo.

“I’d love to.” You croaked out, feeling both excited and nervous. Sensing your nervousness, Rodimus shuffled closer, climbing onto your lap and all but shoving the refineries into your face, the nozzles catching onto your derma. You placed your servos on his hips and held onto him tightly.

“Come on, drink up.”

Who were you to deny your Captain? Greedily, you latched onto his nozzles and gave a soft, experimental suckle. A small burst of energon met your glossa, the taste shocking you. Lapping at the leaking nozzle, you pulled away and looked up at Rodimus, wide optics staring at the young prime.

“That’s- you weren’t kidding. This is… the best energon I’ve ever drank. Wow!”

You latched back onto the nozzle, sucking harder. One servo left his hip to fondle the other, lightly pinching the ignored nozzle. Rodimus moaned lowly, his fans now turning on to a low setting. The quiet combined whirr of both of your fans filled the room, along with the quiet gasps and moans of Rodimus and your soft suckling noises.

“Primus, yes…”

Rodimus gripped your helm, keeping you from moving away from his chest- not like you wanted to. Sucking and lapping at his nozzle continuously, you drank the energon like you were starving and the noises Rodimus was making was egging you on, almost making you delirious.

“Fr-frag, you- I think the one’s empty.”

Rodimus' voice was strained, breathless. Pulling away, you looked up and grinned- Rodimus’ faceplate was flushed blue, optics unfocused and watery, his derma parted and his spoiler was quivering behind him- all clear indications of what you were doing to him. Of what you were making him feel.

Primus above and Pits below, he looked gorgeous.

Quickly, you dipped your back helm down and grabbed onto the other refinery, sucking on the nozzle long and hard. Rodimus threw his helm back, choking out a moan. He began to grind his hips against you, your modesty panels bumping against each other. You began to nibble on the nozzle lightly.

“Oh fuck- yes! Yes, keep doing that!”

I’m barely doing anything- they have got to be really sensitive…

You thought to yourself with a grin as you swallowed another mouthful of energon. Rodimus mewled at your suckling, at how your servo fondled his refinery, tugging at the nozzle. You sucked again, Rodimus’ moaning getting louder-

The door opened.

You jumped at the sudden sound of the habsuite door opening. Rodimus’ nozzle left your derma as you turned your helm and looked at the unannounced visitor- Megatron. You were suddenly filled with dread as you realised that your captain, your boss, had walked in on your fraternising with your other boss. You still had a dribble of energon down your chin as you choked out your word.

“C-Captain.”

“Oh, uh- hey Megs.”

Megatron said nothing, at first- only looking at you, then Rodimus with a frown and a disapproving glare.

“You’re late for the meeting, Captain Rodimus.”

“Oh! Oh, that meeting- That’s today? Wow! Um-”

“You got five kliks.”

With that, the door closed shut, leaving both you and Rodimus alone. Rodimus coughed into his servo, blushing- now out of embarrassment, rather than arousal. You cleared your own intake. Rodimus was the first to talk.

“S-so, uh- you free tonight?”

“Yeah- yeah, I am. Uh, drink at Swerve’s or- or back here? Or mine?”

Rodimus grinned. He shuffled away from your lap and closed his chestplate, putting his refineries away from view.

“Swerve’s sounds good, would love to share a drink.”

“You already did.”

You glanced at his chestplate with knowing optics. Rodimus smirked.

“You perv.”

#fanfiction#transformers#valveplug#Rodimus/Reader#RodimusxReader#Rodimus x Reader#Reader Fic#writing#transformers fanfic#fanfic

76 notes

·

View notes

Text

Shout out to @frogs4frogs for finding these picrews for spidersonas for shawties that can't draw! I didn't want to hop on her post with her Sona and rambles for jt, So! I made my own to ramble on lol.

This is Etta Hampton (Ezy) aka The Recluse the one and only Spiderwoman of New Tulsa on earth 9539

Etta is 17 and lives with her Uncle Barney who owns the Urban Stables that most people in North use for boarding. Etta's lived with her Uncle Barney since she was seven after the death of her parents in a mysterious OzCorp Refinery explosion. She has an army of aunties and cousins that live on the East Coast in Old York or DC.

Etta is incredibly smart, soft spoken and caring. She loves ATV or horse trail riding, welding, pottery, and botany. To the point she plans on triple majoring civil engineering, mechanical engineering and sculpture after she graduates from the Parker's Gifted Academy. Her uncle is her biggest supporter for her education and hobby pursuits and gave her her own garage/studio to work in.

Etta is best friends with the fire chief's son Bart Brown (9539's Hobie), the Bugle Radio's owner's daughter Merry Jameson ( 9539's MJ) and Harry O. (9539's green goblin who just causes more chaos over harm, absolutely hate his father) who the world fattest crush on her and she is 100% oblivious to it.

When Etta was 14 she stormed off after an argument with various of her visiting aunties about her "manish" pursuits she took her four-wheeler and went off trail to a forbidden zone that was the contamination and closed of remains of the OzCorp Refinery. While exploring the remains, Etta was bitten by a radioactive Brown Recluse when security guards had cornered her and she was forced to hide in one of the old R&D offices.

She has the usual power set for a spider person: Spidey sense, the ability to stick to walls, super strength and super agility. Along with long sharp nails that are extremely durable and sharpened canines that have a paralytic and necrotic venom. Etta has two specialty abilities: one is to produce different kinds of acid from her hands and apply it to her organic webs to create different kinds of traps or help her to escape. The other is an ability to control her temperature to the point she can send heat waves of energy off her body or stun/shock others with a fridged touch.

As the Recluse her biggest foes are Cyclone Sandman, Cotton Mouth, and King Scorpion. She has a half allyship with the for hire thief/ spy Prowler (Miles M. Davis) and Green Goblin (she usually just catches and releases with his antics) the fire chief and sheriff work well with her. In school as her regular persona her academic rival is Miles.

Etta tricked out an ATV to fit her theme and made it hover/wall fly so she can still get to places that don't have the highrises that need her help. She controls it remotely sometimes to help rescue people or lead the emergency services to a location/criminals she's taken care of. This causes her Uncle Barney to think she is a close friend of Recluse and works on her tech. He likes Recluse but is highly worried for 'both' their safeties.

The only "Canon Events" she has gone through is the death of her parents and giving up being Spiderwoman for a while after she failed to save a little boy's parents during a train derailment caused by Sandman.

Miguel sent Jess and Ben to recruit her for the Spider Society after she dealt with a Vulture variant and he worried over the fact that her Gwen Stacy event hadn't occurred yet (death of Harry in her case, his spine snaps as he is GG when she tired to stop him from plummeting after a mid-air battle) they haven't explained this to her yet. Etta tries to stay in her world but really likes collaborating on inventions with other spider-peoples and usually sticks to the R&D or repair department over missions.

Is works besties with Margo but highly distrusts Lyla. She partial mentors under Jess and let's Gwen stay in her dimension sometimes when Hobie's world is overwhelming.

Loves blooming onions and other savory snacks, it's not unusual to see her as Recluse snacking on jerky or street corn. Tamale ladies love her. Often wears overalls or jeans jackets over her spider suit. Has hella Spotify followers because her playlists are absolutely fire (even Miles admits this)

And that's kinda it! I have hella backstory about my girl, please ask about her😁💛

#spiderman into the spiderverse#spiderman across the verse#spidersona#original character#Hobie Brown#miles morales#some midwesten hero love

41 notes

·

View notes

Text

January 27th 1974 the Greek sugar-carrying merchant navy ship Captayannis dragged it’s anchor and capsized on the Firth of Clyde between Greenock and Helensburgh.

The 4,567-ton 'sugar boat’ got into trouble on the night of January 27, when a fierce storm hit.

The vessel had dropped anchor at the Tail of the Bank, with a cargo of sugar from Lourenco Marques in Portuguese East Africa, and waited for high tide to offload it at the James Watt Dock sugar terminal for processing at Tate & Lyle’s Westburn Refinery.

However, a severe gale hit the west coast, with winds of more than 60mph, and the Captayannis began to drag anchor.

Captain Theodorakis Ionnis ordered the engine to be started, intending to make for the more sheltered waters of the Gare Loch.

Also anchored at the Tail of the Bank, however, was the 36,754 ton BP tanker British Light, recently arrived from Elderslie dry dock.

Before the Captayannis could power-up, the gale blew her towards the tanker, and, although the two vessels didn’t touch, the tanker’s anchor chain ripped through the passing Captayannis’ hull.

Seawater immediately started pouring in, and the pumps couldn’t cope.

The captain made for the sandbank to try to ground his ship, but, when he reached it, the profile of the hull meant the vessel wasn’t stable and began to heel over to port.

This resulted in all power being lost, and the Captayannis eventually settled port side down on the sandbank.

The crew were rescued, without injury, by the tug Labrador and the MV Rover of Clyde Marine Services.

By 10am on January 28, wreckage from the ship had already been washed ashore at Helensburgh.

The vessel has lain in the same spot since the sinking and is not considered a hazard to navigation.

She remains unable to be removed due to a wrangle between her owners and insurers, and plans to have her blown up were shelved due to fears over damage to the nearby Ardmore Point bird sanctuary.

The locals don't seem to mind the wreck lying there as it became a popular attraction for young fishermen and even tourists, a Bistro on Colquhoun Square, Helensburgh even bears the name Sugarboat. Through time Captayannis has become 'home' to marine life and birds, the wreck is even visible on satellite and is tagged on Google Earth.

Clyde Charters are running trips from James Watt Dock Marina to MV Captayannis to mark 50 years since the ship. It's a small boat carrying 12 passengers and the trip, which lasts an hour costs £17.95 for adults and £12.95 for children.

8 notes

·

View notes

Text

Good morning TUMBLR - March 7th - 2024

''Mr. Plant has owed me a shoe since July 5, 1971."

Ch. VIII - 1985- 1989 - Bahrain - Part 1

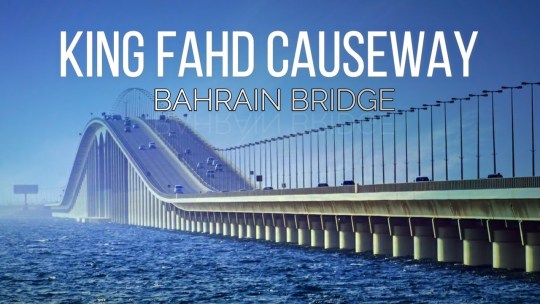

The 25 km King Fahd causeway that links Saudi Arabia to Bahrain.

Manama, the modern capital of Bahrain.

Bahrain desert - the Tree of Life

Bahrain life

GPIC - Gulf Petrochemical Complex - Sitra Island, Bahrain

The winter between December 1984 and January 1985 was particularly harsh in Italy, characterized by increasingly lower temperatures. Between 13 and 17 January 1985, a depression centered on the Corsican Sea caused what is still remembered in Milan today as the snowfall of the century or the snowfall of '85, constituting the heaviest snowfall recorded in Milan in the 20th century. The snowfall caused serious damage. After four days of real storm, January 17th 1985 the Sports Hall collapsed in Milan due to the excessive weight of the snow that had accumulated on the roof.

In this certainly not festive atmosphere, I received a call from an engineering company in Milan, INTECH, an already a supplier of services to SNAMPROGETTI, with whom I soon agreed to leave for Bahrain.

From the SNAMPROGETTI office in San Donato, the Head of HR office Mr. Cincotta reassured me:

''It's a temporary destination, just a few months, waiting that construction of new Agadir International Airport will start … don't worry…''

I stayed there for 4 years…….

Mind you, not that I minded: Bahrain was a liveable place (drinkable, in the language of shipbuilders) especially because it also allowed families to reach the employees involved in the project.

I then left at the beginning of March 1984, with a flight via Kuwait.

I arrived at Manama airport and believe it or not there was someone waiting for me! A local guy holding a board with my name written on it almost correctly: Brino Sirino….

Bahrain is a small Emirate in the Persian Gulf (Kaleejj el Arabi) made up of a main island and a myriad of uninhabited islets. It is the ''poorest'' Gulf state, relative to its surrounding neighbors. Above all, Saudi Arabia provides the Emirate with considerable economic aid as the ruling house of Bahrain, like the Al Saud, is of the Sunni faith, in spite to a majority Shiite population

The Saudis would never allow a Shiite regime to be established 25 km from the Saudi coast with the approval of the ''Great Enemy'' Iran. And then Bahrain was a sort of ''playground'' for Saudis looking for entertainment just outside their front door. This therefore explains the reason for the economic support to Bahrain by the Saudis. For instance, one of the largest oil well in Saudi waters has always been exploited for free by the Bahraini oil industry. The construction of the 23 km long bridge that connects Saudi Arabia to the island of Bahrain was financed by the Saudis. The free sale of alcohol in Manama by shops managed by a company belonging to the ruling Bahraini family is another concession aimed at helping the Emir Al Khalifa's coffers. In 1986, shortly before the opening of the Dahran – Manama bridge to traffic, King Fahad proposed to the Emir Sheik Eissa the prohibition of alcohol sale, promising to compensate the Emir for the lost earnings: an offer returned to the sender.

On top of all this, about 50% of the Southern territory of the island of Bahrain is off limits, due to the largest naval base leased to the US in the Gulf. However, Manama has since then been a modern city, full of skyscrapers, luxury hotels and shopping centres.

AWALI

I was housed in Awali, a village of wooden houses built by the Americans of Caltex in 1939, when the first refinery in Bahrain (and the entire Persian Gulf) was built. Someone later told me that around 1942 some Italian planes departing from a base in Egypt tried to bomb the refinery, which produced fuel for the English army. Not having enough fuel to guarantee the return, the planes dropped their bombs into the sea just before the island of Bahrain, and aborted the mission.

The village of Awali is located almost in the center of the main island of Bahrain, and its wooden houses are reminiscent of those from the Lassie TV series in every way, including anti-mosquito doors. The houses are 2 and 4 bedrooms, with a large living-dining room, kitchen and two bathrooms. I was assigned to a small 4 bedroom house, but when I got there I was the only occupant. The village also had a club with a partially covered swimming pool (to prevent the summer sun from making the water too hot) and tennis courts, to which we had free access.

RONCI ATHOS

A few days after my arrival, around 3.00 AM, I heard some noises: the sound of a car stopping, doors slamming, and than someone throwing something (I than saw that it was suitcases…) inside the house. , on the wooden floor. Then the door of my room suddenly open, and someone said:

Are you asleep?

Before you arrived I was asleep…….

However...... - says the guy - I'm not going to stay here…….tomorrow I'll talk to the HR and then I'll see .....

Okay…. I say…. do as you like but let me sleep now….

For the record, Mr. Ronci Athos – Umbrian from Narni – was still there in 1993, in the place that 8 years earlier he had said he would leave as soon as possible….

THE PROJECT

Our client was called GPIC - Gulf Petrochemical Industries Company - a mixed Bahraini, Saudi and Kuwaiti capital company - and was part of the economic aid package from the rich Gulf countries to the ''poor'' relative of Bahrain.

Later, at the time of the commissioning and start up of the plants - we would have transformed the acronym into Gruppo Pensionati Italiani Comerint, given the average age of the people that the then company 'ENI had sent to proceed with the commissioning of the plants.

The project was in its final phase, and was directed by none other than the P.I. Manoli Benito Italo. Bahrain would be his last construction site personally managing, before becoming Director of the CSO Service of SNAMPROGETTI. The works were even ahead of schedule, so SNAMPROGETTI enjoyed a lot of credit with the Client. Upon delivery of the plant, the Client gifted an extra bonus of 4 million dollars to SNAMPROGETTI for its performance.

The credit was than canceled in 1990, during the first Gulf War. GPIC invited SNAMPROGETTI, BECHTEL and UHUDE to provide an initial feasibility study for a urea plant to be built alongside the existing ammonia and methanol plants. BECHTEL replied that she was not interested, SNAMPROGETTI sent a fax requesting an advance of 11,000 USD for the preliminary study. The Germans from HUDE, sensing the deal, in the midst of the Gulf War, sent a representative to Bahrain to discuss the possibility of building the urea plant. In 1992 the belated SANMPROGETTI envoy to Manama was detained at the entrance gate of the plant for a couple of hours, only to be informed that GPIC had officially commissioned UHUDE with the preliminary study.

COMMISSIONING & START UP

The long phase of pre-commissioning, commissioning and start-up of the plants soon began. Which were built on a so-called reclaimed land (an artificial island) created by dredging the shallow seabed, characteristic of the Bahraini island. The artificial island - equipped for safety reasons with an outer gate and an inner gate - was connected to the mainland by a causeaway approximately 3 kilometers long, and a second causeaway joined the island to the loading arms of the products, 10 kilometers further into the sea. This is to allow ships to carry out loading operations in complete safety, without the risk of running aground in the shallow seabed. There were many wrecks of ships stranded along the channel dug by the open sea up to the port of Manama - this much to the happiness of the divers, given that the wrecks had been transformed into sanctuaries of Persian Gulf tropical fish.

However, I must say a word to describe the characters who are part of the commissioning – start up. These particular people, who believe they are a sort of ''NASA scientists'' intent on launching the SPACE SHUTTLE into space. As soon as they arrived at site their aim was: ''Okay, get rid of Construction people, we're here now''.

The fact is that, apart from 3 or 4 of them who really knew what they were doing and were experts in the difficult process of putting the plants into operation (very dangerous indeed) all the others followed suit: ''they claimed to know'' and the less they knew, the more they pretended they were knewing. I met someone who, as soon as they heard someone approaching, started to talk about chemical formulas, operating pressures, and so on, just to put on airs.

In any case, within 3 months the start up team had managed to get the two plants up and running, even if the (rhetorical) question that was circulating was - Did you make the methanol?'' ''no…I didn't…So who did it?? No one knows.... ''

Tawfeeq Mohammed Rasul Almansoor - GPIC President

The President of GPIC, however, did not seem entirely satisfied, and he demonstrated it with a series of actions that were surprising to say the least.

One day Mr. Tawfiq arrived at high speed at the outer gate driving his metallic blue Rolls Royce. The presence of smat guy on the guard post prevented him from ending up against the bars at the outer check point.

Mr Tawfiq continued on the causeway at full speed and the inner gate guard, warned by radio by his colleague at the outer gate, promptly raised the bars. The President's Rolls entered the area of the Administrative offices, where he finally stopped. Tawfiq got out of the car in a rage, and ordered the Security Chief who met him to organize a meeting within 15 minutes. Participants in addition to him were the Security Chef, the Director of COMERINT and the Security Advisor.

We mortals later learned that the Security Chef – an British guy, former officer in Hes Majesty's army, had been fired on the spot – Reason given by Mr. Tawifiq:

''Two gates were opened for me and I was able to drive my car into the plant – and this was because at the sight of my Rolls Royce the guards thought I was driving the car. What if he was a terrorist? What if I suddenly went crazy and wanted to attack the plant? What if I had been kidnapped by terrorists who were hiding in the car filled with explosives??'' (I remember that the Rolls Royce was equipped with tinted mirror windows which did not allow anyone to see who was driving the car.)

A few days later, a second episode, again with Mr. Tawifiq as absolute protagonist. He had gone between the Main Control Room and Plant Laboratory, in a fairly hidden corner of the plant, and had broken the glass of one of the fire alarms that send a signal to the Fire Department control room. He than set off the stopwatch on his Rolex Platinum Diamond Pearlmaster to see how long it would take for the firefighters to arrive. After 11 interminable minutes - I would like to point out that the Fire Station was about 700 meters from the place where Mr. Tawfiq was stationed - the firefighters arrived to find that it was a false alarm. Again an urgent meeting was called, where this time the HSE manager lost his job. The reason for such a delay – which according to Tawfiq could have led to a disaster in the event of a real fire – was that on the synoptic panel of the fire brigade control room it was not possible to identify precisely where the alarm had went off.

Just a week after the episode of the false fire, the start-up of the plants had been successfuly done. The plant was even proding more ammonia and methanol than expected, around 1,200 tons per day per product, instead of the 1,000 tons expected. But many of the ''COMERINT Pensioners'' who had participated in the commissioning were still circulating in the plant. As they say in Southern Italy, ''they were mugging''.

Obviously COMERINT was looking for all the plausible excuses to keep them in service, given the daily rates with which they were invoiced to the Customer. (an average of $1,200/day per person). The situation between COMERINT and GPIC had become very tense, with daily requests from the latter to demobilize the technicians.

One day Tawfiq lost patience, and went to the Main Control Room - still dressed in the traditional white disdasha, ghutra on his head, he surprised a swarm of Italians having coffee, talking about football, playing on the computer. Tawfiq, who had been taken like an ordinary local, turned to the bystanders waving his arms in the Arab manner and said:

''What is this? Coffee shop''?

The shift manager, at that moment sitting on the desk with a cup of coffee in his hand and his legs dangling, stood up and in a benevolent manner, took Tawfiq by the arm (a very serious mistake as per Arab habits) pointed to a door at the end of the corridor and told him :

Shouff (look) coffee shop for Arab is there, at the end of corridor – accompanying it all with a laugh.

Tawifiq, according to bystanders, didn't show any sign of upset - he left the Control Room, called the Italian Director on the phone. Mr Fiorentino, COMERINT top manager. Mr Tawfiq ordered that all those present at the unfortunate episode were boarded on the first plane to Italy. The offices in the North wing of the Control Room were closed until further notice.

But where the President of GPIC gave his best was at the final meeting with Construction Director Benito Italo Manoli and the entire SAMPROGETTI staff present. During the meeting, numbers of questions were raised which mainly concerned the safety of the systems. At a certain point Mr. Tawfiq turned directly to the Italian Doctor Mr. Busonero asking :

Doctor, in case of explosion of one or more tanks of ammonia or methanol, either due to a terrorist attack, or due to an accident, what could be the consequences?

Dead silence in the meeting room… gazes of all those present frantically crossing each other… Mr. Manoli trying to communicate via brain waves with Doct. Busonero, while coughs and noises of chairs moving rang out in the room…. ..and finally the Doctor, red in the face and with drops of sweat running down his forehead (despite the air conditioning being set to 19 degrees C – Tawfiq's favorite temperature) Doct. Busonero replied:

- Well…Mr. Tawifiq…with a prevailing wind from the South-East to the North-West, the inhabitants of Manama would have from 7 to 10 minutes to recommend each one's soul to God…''

It was freezing in the meeting room, no one said a word, everyone was waiting for the President's counter-reply. Tawfiq stood up and nodded to Mr. Manoli who followed him into President's private office.

The next day there was no trace of Doct. Busonero. We learned that he had been put on a plane to Rome before midnight, the deadline that Tawfiq had indicated to Mr. Manoli. Contrary, Doct. Busonero would have been arrested for telling the truth.

5 notes

·

View notes

Photo

Frans Geffels - Dinner Party on a Terrace - 1660s

oil on canvas, 85.1 x 102.5 cm

Philadelphia Museum of Art, Pennsylvania, USA

Frans Geffels, known in Italy as Francesco Geffels (25 August 1624 – 18 February 1694) was a Flemish painter, printmaker, architect, stage designer and designer of ephemeral structures for solemn and festive occasions. After training in his native Antwerp, he was mainly active in Mantua, where he was prefetto delle fabbriche to the Duke, a role that gave him the direction of the artistic and construction activities undertaken by the Ducal court. He worked also on projects for the local aristocratic class of Mantua. In addition, he completed projects for the Liechtenstein princes and for the imperial court in Vienna.

He was both a canvas and fresco painter. He created portraits, history subjects, military scenes, architectural scenes and genre art, in particular merry companies. Geffels is mainly remembered as the designer of some of the key examples of Baroque architecture in Mantua.

He was born in Antwerp as the son of a laborer in a sugar refinery and a mother who operated a cheese shop. He trained in the guild year 1635/36 with Daniel Middeleer (also called Daniel Middeler and Daniël de Middelaer). Middeleer was a painter, printmaker and publisher. Geffels became a master in the local Guild of St. Luke some time between 18 September 1645 and 18 September 1646. By 1653 he was already abroad for some time.

He was likely recruited to work in Mantua in 1659, by his fellow Flemish painter and architect Daniel van den Dyck. Van den Dyck had been appointed by duke Carlo II Gonzaga, Duke of Mantua as the prefetto delle fabbriche ('Prefect of the Buildings'), a position which combined the duties of official court painter, architect, surveyor of the Ducal construction program and engineer for theatrical stage design.[8] Geffels was working as an architect at the court.

Geffens spent some time in Vienna in 1660-1661 where he worked for the Imperial Court. He returned to Mantua where he became, like van den Dyck before him, prefetto delle fabbriche of the duke of Mantua in 1663. He took the place of his compatriot van den Dyck had died in the previous year. In 1664 Geffens was granted citizenship of Mantua. He was described in official records as an artist who was skilled in creating devices for the theatre.

Geffels remained in the service of the Dukes of Mantua for 30 years. He worked in 1667 in Vienna on commissions for Karl Eusebius, Prince of Liechtenstein. There existed a close relationship between the Viennese court and the dukes of Mantua through marital links. The Empress Dowager Eleonora Gonzaga (1630–1686) was the third wife of Emperor Ferdinand III and the sister of Charles II Gonzaga, Duke of Nevers. He also participated on a book containing the libretto by Francesco Sbarra for the opera Il pomo d'oro scored by Antonio Cesti, which was staged twice in July 1668 on the occasion of the marriage of Emperor Leopold I and Margaret Theresa of Spain. The book was illustrated with prints depicting the various sets used during the staging of the opera. The folio de luxe edition of the book holds a print designed and etched by Geffels showing the opera's performance with Emperor Leopold I and his bride in attendance. The theatre in which the opera was staged had been purpose-built on the occasion of the couple's wedding after a design by Ludovico Ottavio Burnacini. The theatre was destroyed during the Turkish siege of Vienna in 1683 and Geffens' print now serves as the sole evidence of the interior layout of the theatre. In the print, the imperial family is shown sitting at the front. In the foreground there is a row of soldiers. Geffels had himself worked on the illusionist ceiling paintings for the court theatre, which are also shown in the print.

Even after his return to Mantua later in 1668, Geffels maintained contact with the Viennese court, as evidenced by his collaboration on the three-volume book by Gualdo Priorato with the title Historia di Leopoldo Cesare and also by his paintings depicting the Relief of Vienna in 1683 (Wien Museum Karlsplatz) and the Retaking of Buda in 1686 (Hungarian National Museum).

Geffens' official duties at the Mantua court included the design and execution of ephemeral objects and structures used on the occasion of important court-related events. In January 1666 he collaborated with Andrea Seghizzi on the decorations and objects made for the funeral of Duke Charles II Gonzaga, Duke of Nevers in the Basilica palatina di Santa Barbara in Mantua. When in 1776 Empress Claudia Felicitas of Austria died in Vienna not long after giving birth, her aunt Isabella Clara of Austria, Duchess of Mantua, had a funeral mass performed in the church of the Mothers of St. Ursula of Mantua, where the Duchess had become a Poor Clare nun. Frans Geffels was commissioned to design and construct a funeral monument that was set up in the middle of the church during the mass. It was mounted on four large marble-coloured pedestals, adorned on the top front with imperial eagles in low-relief. A print of the design was included in the book by Antonio Gobio and Geffels entitled Le essequie celebratesi nella chiesa delle MM. RR. Madri di S. Orsola di Mantoua: d'ordine della serenissima signora arciduchessa Isabella Clara d' Austria, duchessa di Mantoua, Monferrato, &c., per la morte dell' imperatrice augustissima Claudia Felice lei nipote published in Mantua in 1676 by Francesco Osanna, printer to the Duke.

As a court painter and architect, Geffels was not prohibited from taking on private commissions. An important private commission was the redesigning of the Sordi Palace for Benedetto Sordi. He created frescoes in the palace and had the sculptor Gian Battista Barberini provide sculptured decoration of the façade and interior of the palace.

He remained in office until his death in Mantua on 18 February 1694. He was buried in the Church of San Martino which he had himself redesigned. He was the last prefetto delle fabbriche of the duke of Mantua as the role was split over multiple persons after his death.

13 notes

·

View notes

Text

Process Engineering in the Oil and Gas Sector: Challenges and Innovations

The oil and gas industry has long been a cyclical industry influenced by global hydrocarbon prices. However, even by industry standards, the volatility of the past few years has been unprecedented. Cycle times between highs and lows have compressed, and the transition to lower-carbon energy and fuels has added another layer of complexity to the oil and gas industry. Buckle up! However, it's important to note that while oil and gas have undoubtedly seen advancements in process engineering services, there are also numerous environmental and sustainability challenges associated with these industries. For example, the extraction and refining processes not only contribute to air and water pollution but also exacerbate climate change through the release of greenhouse gases.

What's Oil and Gas Process Engineering, Anyway?

Imagine a giant puzzle. The oil and gas industry is like that puzzle, and process engineers are the master puzzlers. Their job? To figure out how to extract, refine, and deliver oil and gas to our homes and industries. It’s a big deal because, well, our world kind of runs on these energy sources!

Challenges: The Rocky Road

Complexity Overload: Oil and gas processing is as complex as rocket science. Well, almost! Engineers deal with intricate processes, ensuring everything runs smoothly from drilling to refining. One hiccup can cause major problems.

Environmental Hurdles: Mother Earth isn’t always happy with how we extract oil and gas. Engineers face the challenge of making processes eco-friendly, ensuring they don’t harm our planet.

Cost Conundrum: Extracting and refining oil and gas can be expensive. Engineers need to find innovative ways to cut costs without compromising safety and quality.

Safety First: Working in oil and gas can be risky. Ensuring the safety of both workers and the environment is a constant challenge that engineers tackle.

Innovations: Riding the Technological Wave

Smart Sensors and AI: Imagine sensors that can predict when a machine might break down. With the power of Artificial Intelligence, engineers can now foresee issues and fix them before they escalate.

3D Printing Magic: Need a specific tool on the spot? 3D printing allows engineers to create custom parts quickly and efficiently, saving time and resources.

Cleaner, Greener Tech: Engineers are investing in renewable energy sources, making the shift from fossil fuels to cleaner alternatives like solar and wind power.

Digital Twins: Picture this: a virtual copy of an entire oil rig or refinery. Digital twins help engineers simulate processes, identify problems, and test solutions without any real-world consequences.

Conclusion: The Future Shines Bright

In the ever-evolving world of oil and gas process engineering, challenges are met with incredible innovations. With smart technology, eco-friendly solutions, and a commitment to safety, engineers are shaping a brighter, cleaner future for us all.

So, there you have it, folks! Oil and gas process engineering might have its challenges, but with innovation at its core, the industry is not just keeping up; it’s racing into a future where energy is efficient, safe, and sustainable. Until next time, stay curious and keep exploring the wonders of our world!

How can Cambay Engineering help you?

In the challenging landscape of oil & gas process engineering, Cambay Engineering shines as a trusted partner. Specializing in tailored solutions, they offer innovative approaches to industry complexities. Their expertise, commitment to excellence, and focus on sustainability make them pioneers in the field. By collaborating with Cambay Engineering, companies gain access to cutting-edge technologies and sustainable practices, ensuring a greener and more efficient future for all.

3 notes

·

View notes

Text

M.S.D Pyrite - A Solar Cargo Ship of a Used Future

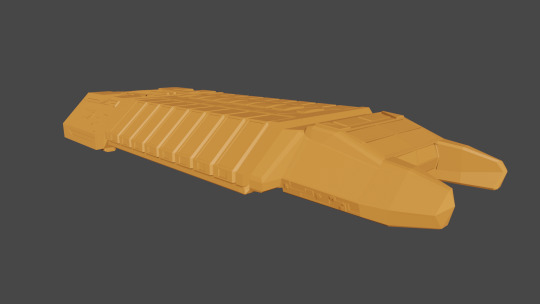

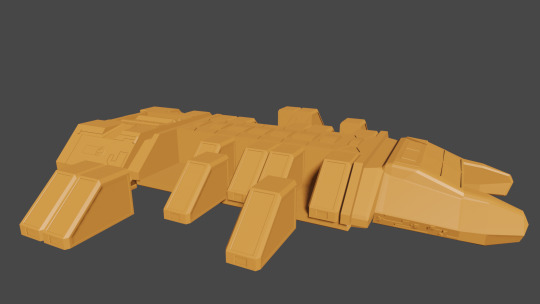

I keep poking at this model, but it's not getting better without a complete rebuild I think. So, I might as well introduce the Pyrite.

The 'small' transport class of the solar system, it fills the role a semi-truck does today. Large enough to make moving cargo worth the time and money, small enough that it can get into all sorts of places that a much larger ship, equivalent in function to a Super-Tanker, wouldn't be able to. It can go the distance, capable of operating between planets, while also easily docking with small stations as much as large habitats.

With the engines and fusion plant in the aft, the command deck and recreation areas in the fore, the bulk of the ships accessible mass is devoted to locking points for cargo containers.

The Containers docked to the ship directly (with a box representing a 6' tall person and a 40' x 8' x 8.5' Semi Container for scale) are plugged into the power plant, able to generate their own bubbles of minimal heat and even atmosphere if specially pods are swapped out for, to allow the transport of perishable goods across the void.

Perishable goods are often smaller than raw goods like minerals so a fair amount can be fit in the 16 pods, but that is not all this class of vessel is capable of hauling.

On the underside is what is often colloquially known as the 'Docking Bump'. While meant to allow docking arms to grab hard onto a solid bit of the ship, a bit like jack points on a car, they also allow additional cargo to be clamped onto the ship, riding on the belly like a young marsupial on it's mother. While capable of attaching far greater amounts of cargo, it's also a lot more limited in what it can move.

Nothing that would be overly bothered by high amounts of radiation, horrific swings between hot and cold, a airless environment. Standalone self powering containers do exist, but they are both expensive and not that common.

Finally, carrying "Belly Cargo" also changes the logistics of being on the move. More mass means a longer travel time, slower acceleration and deceleration. It can mean more time waiting at the other end as, to big now to fit in a berth, you have to wait for more manual unloading. More does not always equal more profit and it takes a canny Quartermaster to find that line.

So, the Pyrite is a cargo ship, nothing glamorous, the invisible workhorse of the solar system. But there's more to it than that. While this basic un-textured model doesn't show it, the Pyrite is old, and worn. The M.S.D (Mercury Service Designation) reveals how far this ship came to end up rotting in a berth on Io. The scuffs, stains, oil, and patches show just how long it's been in service.

More than that is the name, Pyrite, who would name a trading ship that they were staking their livelihood that. Pyrite, Fools Gold, what does that say about your prospects?

I will likely never get to make Io, but I'd like to. I'd like to make a game in a cool setting where the stakes are still very personal. Where both the player and the character they inhabit take a small boon revived out of the blue and take a chance on not a momentary distraction but a better tomorrow, on fulfilling a lifelong dream.

The Pyrite is old, it's under-serviced, and it's clearly had a history of bad luck. Everyone who isn't similarly at the bottom will look at all the effort gone to to scrape together enough cash for the ship, a cargo, and crew, and deride it as utterly foolish.

But Pyrite has another meaning, beyond Fools Gold. That of fire, for the sparks it produces when struck, a fact largely forgotten nowadays. Yes, working your way from bottom of the barrel refinery work to ship owner is not likely, it is not a safe use of a unexpected windfall. But within the confines of fiction, it's totally possible

Hey, if you read this far for some reason, thanks! Io is one of those projects I'd love to make but, unfortunately, my skills deficient in so many ways. I'm best at worldbuilding, writing and I've been learning how do basic models, but I have no ability to code, getting my head around even basic engine stuff makes it spin, and such things as music and textures are beyond me.

But I keep plugging away at little things.

Speaking of that actually, wish I knew how much it would cost to get a texture made for this ship?

2 notes

·

View notes

Text

Into the Refinery Complex

STAR WARS EPISODE I: The Phantom Menace 01:52:19

#Star Wars#Episode I#The Phantom Menace#Naboo#Theed#Battle of Theed#Battle of Naboo#Theed Hangar#Duel of the Fates#Qui-Gon Jinn's lightsaber#Darth Maul#Darth Maul's lightsaber#plasma acceleration shaft#plasma refinery complex#thermal carbon membrain#plasma#remote engineering console#service catwalk

2 notes

·

View notes

Text

Our equipment can perform any kind of bevels; modified bevels and J-Bevels for various weld preparations and delivers an outstanding performance when cutting and beveling large pipe diameters.

If you would like to find out more, please ask us today. Drop us an email at [email protected] | Visit us at petracarbon.com

2 notes

·

View notes

Text

Sunflower oil refinery plant supplier

Sunflower oil processing involves several steps, including cleaning and de-hulling the seeds, pressing and extraction of the oil from the seeds, refining the oil, and packaging the oil for sale. The first step in the process is cleaning the seeds, which involves removing any debris or foreign material that may be present in the seeds. After the seeds are cleaned, they are de-hulled to prepare them for pressing and extraction. Once the seeds have been de-hulled, they are pressed and the oil is extracted from the seeds. The extracted oil is then processed to remove any impurities and is usually then refined and blended with other oils to improve its flavour, colour, and stability. Finally, the oil is packaged and is ready for sale.

Sunflower oil refinery plant suppliers provide the necessary equipment services, and expertise to help process sunflower oil. DVC Process Technologists provide complete turnkey solutions for sunflower oil processing plant, including engineering, design, manufacturing, installation, and commissioning. Additionally, suppliers can provide spare parts, maintenance, and training to ensure the refinery is operational and efficient. We are one of the leading suppliers of sunflower oil refinery plants

Some of the best features of sunflower oil processing plants supplied by DVC Process Technologists include:

1 High efficiency and productivity,

2 Significantly reduced energy consumption,

3 Capability to produce oil of a consistent quality.

High efficiency and productivity help to reduce costs and increase profits, while the reduced energy consumption helps to keep emissions low. Additionally, sunflower oil processing plants are able to produce oil of a consistent quality to meet the demands of consumers.

To Know more About DVC - https://dvcprocesstech.com/

For Latest updates follow us - https://www.linkedin.com/company/dvc-process-technologists/?viewAsMember=true

Connect with us -

Facebook

Twitter

YouTube

#Sunflower oil processing plant#Sunflower oil processing plant supplier Sunflower oil processing plant manufacturer

2 notes

·

View notes

Text

Laser Tracker Service in Gujarat | The SUNCAD Training & Designers

Suncad provides the best Laser Tracker Service in Gujarat. We offer our clients an unmatched range of measurement using laser tracker. Laser trackers are instruments that accurately measure large objects by determining the positions of optical targets held against those objects. The components that make up a laser tracker are generally divided into four parts. A PC to run laser tracker operation software, a camera body that integrates a light emitting unit and a light receiving unit, a tripod that supports it, a retroreflector (SMR) that contacts the object to be measured.

The Suncad Training & Designers offers the best Laser Tracker Service in Gujarat. For more information visit on : https://suncad.in/lieca-3d-laser-tracker-services/ or call us on : 9925023229

#BIM modeling and scanning service in Gujarat#3D Scanning in Gujarat#Leica RTC 360 Scanning Service Provider in Gujarat#Heritage scanning services in Gujarat#Faro Scanner Service Provider in Gujarat#3D Plant / refinery scanning service in Gujarat#3D Lidar scanning / 3d Terrestrial scanning services in Gujarat#Laser tracker service in Gujarat#Reverse Engineering in Gujarat#3D Inspection services in Gujarat#CMM inspection services in Gujarat#CNC / VMC Machine operating in Gujarat#3D printing Services in Gujarat#Solid Edge training in Gujarat#SolidWorks Training in Gujarat

0 notes