#voltage sensor

Explore tagged Tumblr posts

Text

The Omron SDV-FH2 Voltage Sensor 24VDC is a reliable and efficient solution for monitoring voltage in industrial and automation systems. Designed for precision and durability, this sensor ensures accurate voltage detection, enhancing system performance and safety. Ideal for various applications, it operates seamlessly in demanding environments, providing consistent results. Its compact design allows easy integration into existing systems, while the 24VDC compatibility ensures energy efficiency. Perfect for use in control panels, power distribution systems, and automation processes, the Omron SDV-FH2 is a trusted choice for professionals. Explore high-quality voltage sensors like this at Auto2mation for dependable performance.

#marine spare parts#industrial and marine automation#industrial spare parts#auto2mation#marine automation#industrial automation#industrial equipment#industrial and marine automation equipment#industrial automation equipment#automation#sensor#voltage sensor

0 notes

Text

The Omron SDV-FH2 Voltage Sensor (24VDC) is a high-performance voltage detection sensor designed for use in industrial and automation applications. Operating with a 24V DC power supply, this sensor provides precise monitoring of voltage levels within electrical systems to ensure safe and efficient operations. The SDV-FH2 sensor is typically used to detect voltage variations, over-voltage, or under-voltage conditions, providing real-time feedback for protective actions or system adjustments.

0 notes

Text

The Omron SDV-FH2T Voltage Sensor 24 VDC ESWB.0109.010 is a reliable and precise device designed for monitoring and measuring voltage levels in various industrial applications. Operating at 24 VDC, this sensor ensures accurate detection and response to voltage fluctuations, enhancing system stability and safety. Its compact design and robust construction make it suitable for integration into diverse environments, offering consistent performance and long-term durability. Ideal for automation and control systems, the Omron SDV-FH2T is a dependable solution for voltage monitoring needs.

0 notes

Text

youtube

#AC voltage measurment#arduino nano#voltage sensor#ZMPT101B#TM1637 4 Digit Seven Segment Display Module#TM1637#buzzer module#arduino IDE#IOT#smart city#smart home#internet of things#Youtube

1 note

·

View note

Text

Medium voltage support insulator manufacturers in India | radiantenterprises

Elevate your electrical solutions with Radiant Enterprises, a top name among customised insulator manufacturers in India. Specializing in high-quality epoxy insulators, we cater to the specific needs of your projects with precision and expertise. As leading medium voltage support insulator manufacturers in India, we provide durable and reliable products that meet the highest industry standards.

Trust Radiant Enterprises for innovative and customized insulator solutions designed to enhance the performance and safety of your electrical systems.

#Epoxy insulator#Customised insulator manufacturers in India#Medium voltage support insulator manufacturers in India#epoxy bushing#epoxy insulator#epoxy resin#electrical company#electrical engineering#electrical industry#fuse cutouts#smart grid sensor#rail insulator#railway technology companies#train operating companies#locomotive#tramways#metro systems#traffic infrastructure#third rail#cable connector#innovative insulators#export quality

4 notes

·

View notes

Text

never give a neurobiologist the tv remote... they'll always put on the potassium channel

#melonposting#spoof#augh ions and action potentials and voltage sensors!!!! ...neurobio is driving me crazy#world's most insane sci class. you're given a full-length scientific paper and like two days later you have to present on it to the class#anyway i know way too much about voltage-gated potassium ion channels now. so there's that

4 notes

·

View notes

Text

Voltage Detection Sensor Module - Arduino, ARM and other MCU – TOMSON ELECTRONICS

Enhance your electronic designs with the top-of-the-line Voltage Detection Sensor Module. Ideal for Arduino, ARM, and MCU projects. Source wholesale Electronic Components for cost-effective solutions.

0 notes

Text

Distribution Feeder Automation Market Business Research, Types and Applications, Demand by 2032

Market Overview: The Distribution Feeder Automation Market refers to the market for advanced technologies and systems that automate the monitoring, control, and management of distribution feeders within an electrical distribution network. Distribution feeder automation improves the efficiency, reliability, and resiliency of power distribution by utilizing sensors, communication networks, and automation software to monitor and control power flows, fault detection, and restoration. These solutions enhance the performance of distribution feeders and enable utilities to deliver electricity more effectively.

Feeder Automation Market is projected to be worth USD 7.85 Billion by 2030, registering a CAGR of 8.2% during the forecast period (2022 - 2030)

Demand: The demand for distribution feeder automation is driven by several factors, including:

Distribution feeder automation solutions help utilities improve the reliability and resiliency of their distribution networks. By automating fault detection, isolation, and restoration, these systems minimize outage durations and enhance the overall performance of the grid, ensuring a more reliable power supply for customers.

Distribution feeder automation systems streamline operations by reducing manual interventions, optimizing power flow, and enhancing network monitoring capabilities. These solutions enable utilities to manage distribution feeders more efficiently, reduce costs, and improve the overall operational performance of their networks.

The increasing integration of renewable energy sources, such as solar and wind power, into the distribution grid presents operational challenges. Distribution feeder automation helps utilities manage the intermittent nature of renewables, optimize power flow, and ensure grid stability, facilitating the integration of clean energy sources.

Latest technological developments, key factors, and challenges in the Distribution Feeder Automation Market:

Latest Technological Developments:

Intelligent Sensors and IoT Integration: Distribution feeder automation is leveraging intelligent sensors and Internet of Things (IoT) integration to monitor real-time data from various points along the distribution feeders. These sensors provide insights into voltage levels, current flow, fault detection, and other parameters, enabling quicker fault localization and resolution.

Advanced Communication Protocols: Modern distribution feeder automation systems are adopting advanced communication protocols like for seamless data exchange between field devices and control centers. This facilitates real-time monitoring, remote control, and efficient data transmission.

Decentralized Control and Edge Computing: Distribution feeder automation systems are moving toward decentralized control and edge computing. This allows decision-making and control to occur closer to field devices, reducing latency and enhancing responsiveness.

Distributed Energy Resource (DER) Management: With the integration of distributed energy resources like solar panels, wind turbines, and energy storage systems, feeder automation systems are being developed to manage these resources effectively, ensuring grid stability and optimal energy distribution.

Advanced Analytics and AI: Distribution feeder automation is incorporating advanced analytics and artificial intelligence to analyze data from various sources. AI algorithms can predict and prevent potential faults, optimize energy flows, and enhance overall feeder performance.

Key Factors:

Reliability Enhancement: Distribution feeder automation improves the reliability of electricity distribution by enabling quicker fault detection, isolation, and restoration. This minimizes outage durations and enhances overall grid reliability.

Efficient Grid Management: Feeder automation allows utilities to manage the distribution grid more efficiently. Load balancing, voltage regulation, and fault management can be automated, leading to optimized energy delivery.

Integration of Renewable Energy: As the penetration of renewable energy sources increases, distribution feeder automation becomes crucial for managing the intermittent nature of these resources and maintaining grid stability.

Grid Resilience and Outage Management: Feeder automation systems enhance grid resilience by providing real-time data on grid conditions and faults. This facilitates faster response and restoration during outages, minimizing customer impact.

Challenges:

Interoperability: Integrating various devices and protocols into a cohesive feeder automation system can be challenging due to the need for interoperability between different vendors and technologies.

Cybersecurity: With increased connectivity and data exchange, distribution feeder automation systems face cybersecurity threats. Ensuring the security of these systems is paramount to prevent unauthorized access and data breaches.

Cost and Infrastructure: Implementing distribution feeder automation can involve significant upfront costs, including hardware, software, and training. Retrofitting existing infrastructure for automation may also pose challenges.

Complexity of Data Management: Feeder automation generates vast amounts of data that need to be effectively managed, analyzed, and acted upon. Handling this complexity can be demanding.

Change Management: Transitioning from manual to automated processes requires change management efforts to train personnel, address resistance, and ensure smooth integration.

Maintenance and Upgrades: Ensuring the proper functioning of feeder automation systems over time requires regular maintenance and potential upgrades to keep up with technology advancements.

Distribution feeder automation is at the forefront of modernizing electricity distribution networks. While it offers significant benefits in terms of reliability, efficiency, and resilience, addressing technical challenges and ensuring a smooth transition is crucial for successful implementation.

By visiting our website or contacting us directly, you can explore the availability of specific reports related to this market. These reports often require a purchase or subscription, but we provide comprehensive and in-depth information that can be valuable for businesses, investors, and individuals interested in this market.

“Remember to look for recent reports to ensure you have the most current and relevant information.”

Click Here, To Get Free Sample Report: https://stringentdatalytics.com/sample-request/distribution-automation-solutions-market/10965/

Market Segmentations:

Global Distribution Feeder Automation Market: By Company

• ABB

• Eaton

• Grid Solutions

• Schneider Electric

• Siemens

• Advanced Control Systems

• Atlantic City Electric

• CG

• G&W Electric

• Kalkitech

• Kyland Technology

• Moxa

• S&C Electric Company

• Schweitzer Engineering Laboratories (SEL)

Global Distribution Feeder Automation Market: By Type

• Fault Location

• Isolation

• Service Restoration

• Automatic Transfer Scheme

Global Distribution Feeder Automation Market: By Application

• Industrial

• Commercial

• Residential

Global Distribution Feeder Automation Market: Regional Analysis

The regional analysis of the global Distribution Feeder Automation market provides insights into the market's performance across different regions of the world. The analysis is based on recent and future trends and includes market forecast for the prediction period. The countries covered in the regional analysis of the Distribution Feeder Automation market report are as follows:

North America: The North America region includes the U.S., Canada, and Mexico. The U.S. is the largest market for Distribution Feeder Automation in this region, followed by Canada and Mexico. The market growth in this region is primarily driven by the presence of key market players and the increasing demand for the product.

Europe: The Europe region includes Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe. Germany is the largest market for Distribution Feeder Automation in this region, followed by the U.K. and France. The market growth in this region is driven by the increasing demand for the product in the automotive and aerospace sectors.

Asia-Pacific: The Asia-Pacific region includes Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, and Rest of Asia-Pacific. China is the largest market for Distribution Feeder Automation in this region, followed by Japan and India. The market growth in this region is driven by the increasing adoption of the product in various end-use industries, such as automotive, aerospace, and construction.

Middle East and Africa: The Middle East and Africa region includes Saudi Arabia, U.A.E, South Africa, Egypt, Israel, and Rest of Middle East and Africa. The market growth in this region is driven by the increasing demand for the product in the aerospace and defense sectors.

South America: The South America region includes Argentina, Brazil, and Rest of South America. Brazil is the largest market for Distribution Feeder Automation in this region, followed by Argentina. The market growth in this region is primarily driven by the increasing demand for the product in the automotive sector.

Click Here, To Buy Report: https://stringentdatalytics.com/purchase/distribution-feeder-automation-market/10966/?license=single

Reasons to Purchase Distribution Feeder Automation Market Report:

Comprehensive Market Insights: Global research market reports provide a thorough and in-depth analysis of a specific market or industry. They offer valuable insights into market size, growth potential, trends, challenges, and opportunities, helping businesses make informed decisions and formulate effective strategies.

Market Analysis and Forecasts: These reports provide detailed analysis and forecasts of market trends, growth rates, and future market scenarios. They help businesses understand the current market landscape and anticipate future market developments, enabling them to plan and allocate resources accordingly.

Competitive Intelligence: Global research market reports provide a competitive landscape analysis, including information about key market players, their market share, strategies, and product portfolios. This information helps businesses understand their competitors' strengths and weaknesses, identify market gaps, and develop strategies to gain a competitive advantage.

Industry Trends and Insights: These reports offer insights into industry-specific trends, emerging technologies, and regulatory frameworks. Understanding industry dynamics and staying updated on the latest trends can help businesses identify growth opportunities and stay ahead in a competitive market.

Investment and Expansion Opportunities: Global research market reports provide information about investment opportunities, potential markets for expansion, and emerging growth areas. These reports help businesses identify untapped markets, assess the feasibility of investments, and make informed decisions regarding expansion strategies.

Risk Mitigation: Market reports provide risk assessment and mitigation strategies. By analyzing market dynamics, potential challenges, and regulatory frameworks, businesses can proactively identify risks and develop strategies to mitigate them, ensuring better risk management and decision-making.

Cost and Time Efficiency: Conducting comprehensive market research independently can be time-consuming and expensive. Purchasing a global research market report provides a cost-effective and time-efficient solution, saving businesses valuable resources while still gaining access to reliable and detailed market information.

Decision-Making Support: Global research market reports serve as decision-making tools by providing data-driven insights and analysis. Businesses can rely on these reports to support their decision-making process, validate assumptions, and evaluate the potential outcomes of different strategies.

In general, market research studies offer companies and organisations useful data that can aid in making decisions and maintaining competitiveness in their industry. They can offer a strong basis for decision-making, strategy formulation, and company planning.

About US:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs

Contact US:

Stringent Datalytics

Contact No - +1 346 666 6655

Email Id - [email protected]

Web - https://stringentdatalytics.com/

#Distribution Feeder Automation#Smart Grid Technology#Intelligent Sensors#IoT Integration#Edge Computing#Advanced Analytics#AI in Grid Management#Microgrid Integration#Fault Detection#Voltage Regulation#Load Balancing#Power Distribution Optimization#Grid Resilience#Outage Management#Renewable Energy Integration#Distribution System Efficiency#Energy Management Solutions.

0 notes

Text

#semiconductor#electronics#engineering#technology#transistor#electronicsolution#circuitdesign#electricalengineering#electronicsengineering#electrical#voltage#sensor#mechatronics#engineers#robot#arduinolove#ohms#electronicsolvers#arduinofun#wires#electronicsproject#electronique#vlsi#digital#electricalengineers#electricals#electronicsprojects#electroniccomponents#electronspark#electronicshop

0 notes

Text

Cybersecurity in Power Systems: Safeguarding Transmission and Distribution Infrastructure

Introduction:

In an era dominated by technology, the power industry is undergoing a transformation, with the integration of smart grids and digital solutions becoming increasingly prevalent. However, this digital evolution brings with it a new set of challenges, particularly in the realm of cybersecurity. Power systems, including transmission and distribution infrastructure, are critical components of our modern society, making them prime targets for cyber threats. In this blog post, we will delve into the importance of cybersecurity in power systems and explore measures to safeguard transmission and distribution infrastructure.

Understanding the Landscape:

Power systems, encompassing transmission and distribution, are the backbone of any nation's infrastructure. As these systems become more interconnected and reliant on digital technologies, the vulnerability to cyber threats escalates. Transmission and distribution manufacturers in India are at the forefront of adopting innovative solutions to enhance the efficiency of power systems. However, with this increased connectivity comes the imperative need to fortify these systems against cyber attacks.

The Role of Cybersecurity in Power Systems:

Protecting Critical Infrastructure:

Cybersecurity plays a pivotal role in protecting critical infrastructure, especially in the power sector. Transmission and distribution manufacturers in India are recognizing the significance of robust cybersecurity measures to safeguard their equipment and networks.

Securing Outdoor Support Insulators:

Outdoor support insulators are crucial components in power systems, providing structural support and insulation. Cyber threats targeting these insulators could compromise the integrity of the entire power grid. Implementing cybersecurity protocols ensures the resilience of these components against potential attacks.

High Voltage Primary Bushing Outdoor Manufacturers in India:

Manufacturers producing high voltage primary bushings outdoors are well-aware of the challenges posed by cyber threats. Implementing stringent cybersecurity measures is imperative to prevent unauthorized access and manipulation of these critical components.

Addressing Vulnerabilities in Fuse Cutouts:

Fuse cutouts are essential for protecting power distribution systems from overcurrents. However, these components are susceptible to cyber threats that could disrupt their functionality. Cybersecurity measures are crucial in identifying and addressing vulnerabilities in fuse cutouts.

Cyber Threats in Power Systems:

Malware and Ransomware Attacks:

Malicious software and ransomware attacks pose a significant threat to power systems. These attacks can disrupt operations, compromise sensitive data, and demand ransom payments. Implementing robust cybersecurity measures is essential to mitigate the risk of malware and ransomware infiltrations.

Phishing and Social Engineering:

Phishing attacks and social engineering tactics target human vulnerabilities within organizations. Employees in transmission and distribution manufacturers in India must be educated on recognizing and avoiding these cyber threats to prevent unauthorized access to critical systems.

Insider Threats:

Insider threats, whether intentional or unintentional, can pose a severe risk to power systems. Establishing comprehensive access controls, monitoring systems, and conducting regular employee training can help mitigate the potential impact of insider threats.

Safeguarding Strategies:

Network Segmentation:

Implementing network segmentation is crucial to isolate and contain cyber threats. This strategy ensures that even if one part of the network is compromised, the entire system remains secure.

Regular Security Audits:

Conducting regular security audits is essential for identifying vulnerabilities and weaknesses in power systems. Transmission and distribution manufacturers in India should prioritize periodic assessments to stay ahead of evolving cyber threats.

Employee Training Programs:

Employees play a crucial role in cybersecurity. Training programs should focus on raising awareness about potential threats, recognizing phishing attempts, and promoting a security-conscious culture within the organization.

Advanced Authentication Protocols:

Implementing advanced authentication protocols, such as multi-factor authentication, adds an extra layer of security to prevent unauthorized access to critical systems.

Conclusion:

As power systems evolve with technological advancements, the need for robust cybersecurity measures becomes paramount. Transmission and distribution manufacturers in India must prioritize safeguarding their infrastructure against cyber threats to ensure the continuous and reliable delivery of power. From outdoor support insulators to high voltage primary bushings outdoors and fuse cutouts, every component plays a critical role in the functioning of power systems and requires protection from potential cyber attacks.

In the face of evolving cyber threats, a proactive approach to cybersecurity is the key to resilience. By adopting advanced cybersecurity measures and staying abreast of the latest developments in the field, Radiant Enterprises and other stakeholders in the power industry can fortify their transmission and distribution infrastructure, contributing to a secure and sustainable energy future.

#Transmission and Distribution Manufacturers in India#Outdoor Support Insulator#High Voltage Primary Bushing Outdoor Manufacturers in India#Fuse Cutouts#epoxy insulator#epoxy bushing#electricity#fuse cutouts#smart grid sensor#railway technology companies#train operating companies#locomotive#tramways#metro systems#traffic infrastructure

6 notes

·

View notes

Text

Athletes Go for the Gold with NASA Spinoffs

NASA technology tends to find its way into the sporting world more often than you’d expect. Fitness is important to the space program because astronauts must undergo the extreme g-forces of getting into space and endure the long-term effects of weightlessness on the human body. The agency’s engineering expertise also means that items like shoes and swimsuits can be improved with NASA know-how.

As the 2024 Olympics are in full swing in Paris, here are some of the many NASA-derived technologies that have helped competitive athletes train for the games and made sure they’re properly equipped to win.

The LZR Racer reduces skin friction drag by covering more skin than traditional swimsuits. Multiple pieces of the water-resistant and extremely lightweight LZR Pulse fabric connect at ultrasonically welded seams and incorporate extremely low-profile zippers to keep viscous drag to a minimum.

Swimsuits That Don’t Drag

When the swimsuit manufacturer Speedo wanted its LZR Racer suit to have as little drag as possible, the company turned to the experts at Langley Research Center to test its materials and design. The end result was that the new suit reduced drag by 24 percent compared to the prior generation of Speedo racing suit and broke 13 world records in 2008. While the original LZR Racer is no longer used in competition due to the advantage it gave wearers, its legacy lives on in derivatives still produced to this day.

Trilion Quality Systems worked with NASA’s Glenn Research Center to adapt existing stereo photogrammetry software to work with high-speed cameras. Now the company sells the package widely, and it is used to analyze stress and strain in everything from knee implants to running shoes and more.

High-Speed Cameras for High-Speed Shoes

After space shuttle Columbia, investigators needed to see how materials reacted during recreation tests with high-speed cameras, which involved working with industry to create a system that could analyze footage filmed at 30,000 frames per second. Engineers at Adidas used this system to analyze the behavior of Olympic marathoners' feet as they hit the ground and adjusted the design of the company’s high-performance footwear based on these observations.

Martial artist Barry French holds an Impax Body Shield while former European middle-weight kickboxing champion Daryl Tyler delivers an explosive jump side kick; the force of the impact is registered precisely and shown on the display panel of the electronic box French is wearing on his belt.

One-Thousandth-of-an-Inch Punch

In the 1980s, Olympic martial artists needed a way to measure the impact of their strikes to improve training for competition. Impulse Technology reached out to Glenn Research Center to create the Impax sensor, an ultra-thin film sensor which creates a small amount of voltage when struck. The more force applied, the more voltage it generates, enabling a computerized display to show how powerful a punch or kick was.

Astronaut Sunita Williams poses while using the Interim Resistive Exercise Device on the ISS. The cylinders at the base of each side house the SpiraFlex FlexPacks that inventor Paul Francis honed under NASA contracts. They would go on to power the Bowflex Revolution and other commercial exercise equipment.

Weight Training Without the Weight

Astronauts spending long periods of time in space needed a way to maintain muscle mass without the effect of gravity, but lifting free weights doesn’t work when you’re practically weightless. An exercise machine that uses elastic resistance to provide the same benefits as weightlifting went to the space station in the year 2000. That resistance technology was commercialized into the Bowflex Revolution home exercise equipment shortly afterwards.

Want to learn more about technologies made for space and used on Earth? Check out NASA Spinoff to find products and services that wouldn’t exist without space exploration.

Make sure to follow us on Tumblr for your regular dose of space!

2K notes

·

View notes

Note

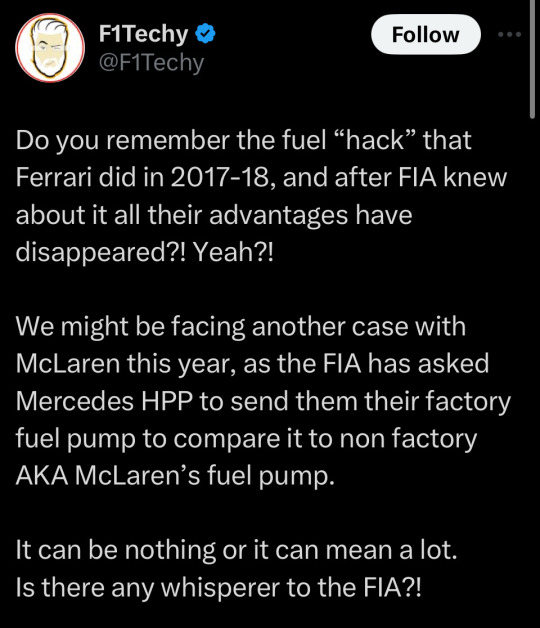

https://x.com/F1Techy/status/1797338007860662614

is this real?

Nope, whoever this person is, they are way off and they have no sources so don’t believe a word they say

In fact Mercedes don’t make their own fuel pumps, let alone McLaren’s. No team has made their own fuel pumps since 2021.

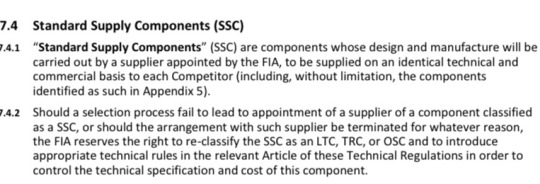

Fuel pumps are categorised as a Standard Supply Component which means that they are designed and manufactured by a third party designated by the FIA.

This means that the same company makes all of the fuel pumps for all of the teams on the grid, so if there was anything going on with a fuel pump they would be going back to this third party not Mercedes.

Just because someone has a blue tick, doesn’t mean that they know what they are saying.

Full list of SSC parts below (from FIA regulations)

Wheel covers

• Clutch shaft torque

• Wheel rims

• Tyre pressure sensor (TPMS)

• Tyres

• Fuel system primer pumps, and flexible pipes and hoses

• Power unit energy store current/voltage sensor

• Fuel flow meter

• Power unit pressure and temperature sensors

• High-pressure fuel pump

• Car to team telemetry

• Driver radio

• Accident data recorder (ADR)

• High-speed camera

• In-ear accelerometer

• Biometric gloves

• Marshalling system

• Timing transponders

• TV cameras

• Wheel display panel

• Standard ECU

• Standard ECU FIA applications

• Rear lights

69 notes

·

View notes

Text

Quick sketch for Piers’ bionic arm.

Design Features

•Aesthetics: Streamlined, ergonomic design with a minimalist look, often featuring a matte or metallic finish.

•Materials: Lightweight composites like carbon fiber and titanium, providing durability without sacrificing mobility.

•Color Options: Customizable colors or finishes, including options for skin-like textures or futuristic metallics.

Technology

•Actuation: Advanced motors and actuators that enable precise, fluid movement mimicking natural limb motion.

•Sensors: Integrated sensors (e.g., myoelectric sensors) to detect muscle signals for intuitive control and movement.

•Feedback Systems: Haptic feedback mechanisms to provide users with sensory information about grip strength and object texture.

Safety and Durability

•Water and Dust Resistance: High IP ratings to protect against environmental factors.

•Emergency Features: Manual override systems or fail-safes in case of technology malfunction.

Advanced Technological Interface

•Integrated Biosensors: Built-in biosensors that can analyze blood or interstitial fluid samples to measure viral load in real time.

•Data Analytics: Utilizes algorithms to process biosensor data, providing insights on viral dynamics and trends.

•Alerts and Notifications: Real-time alerts sent to the user or healthcare provider when viral load exceeds predetermined thresholds.

•Communication System: Integrated with a communicator on the wrist, the arm serves as a reliable device for maintaining contact with his team. This system includes encrypted channels for secure communication during high-stakes operations.

•Objective Management Display: The arm features a holographic display that provides a detailed version of the communicator’s data, allowing Piers to view mission objectives and tactical data in real-time. This feature minimizes the need for external devices and keeps critical information accessible.

Augmented Reality (AR) Compatibility

•Enhanced Visualization: The arm’s display projects augmented reality overlays, allowing Piers to see additional information, such as enemy positions, weapon stats, or tactical directions, directly in his line of sight.

•Environmental Scanning: The arm can analyze the surroundings for potential threats, detect biological or chemical hazards, and provide alerts for safer navigation through hostile environments.

Electricity Conduction and Control

•Energy Conduit Design: The bionic arm acts as a conductor for the constant electrical energy generated by Piers’ mutation. It includes specialized channels and circuits designed to manage this energy flow, allowing Piers to use his mutation’s electrical pulse without it spiraling out of control.

•Dielectric Structures: The arm’s design incorporates materials that mimic the dielectric properties of his mutated tissue, particularly in the finger joints and bones. These dielectric components help regulate and contain the high voltage his body produces, diffusing excess energy safely throughout the arm.

•Controlled Release Mechanism: To avoid overload, the arm features a controlled release system that allows Piers to release pulses of energy strategically, whether in combat or to alleviate the internal buildup. This system prevents the arm from overheating or sustaining damage from prolonged electrical activity.

Containment and Compression of the Mutation

•Compression Framework: The prosthetic was specially designed by UMBRELLA engineers to act as a containment “net” around his mutation. It includes a flexible, reinforced framework that compresses the mutated tissue, keeping it in check and preventing further growth or erratic shifts in form.

•Adaptive Pressure System: As the mutation strains against the arm, sensors detect any changes in size or energy output, triggering adaptive responses. The arm tightens or loosens as necessary to hold the mutation back, functioning almost like a high-tech brace that adjusts in real-time to maintain Piers’ arm in a stable form.

•Automatic Safety Lock: In the event of a significant spike in mutation activity or electrical output, the arm engages an emergency lock to keep the mutation from expanding. This feature is a safeguard against sudden bursts of energy that could cause the arm to revert to its mutated state.

Dependency and Risks of Removal

•Rapid Mutation Onset: Without the prosthetic in place, Piers’ arm begins to mutate almost immediately, returning to its original, unstable form. The electrical pulse that his body generates becomes unrestrained, emitting a continuous, breath-like rhythm that is both painful and dangerous, with energy leaking through protruding bones and exposed tissue.

•Uncontrollable Pulse: When uncontained, the electrical pulse from his mutation surges in intensity, lacking any natural “closure” or stopping point. This pulse causes rapid fluctuations in his vital signs and risks systemic overload, leading to loss of control over his mutation and putting him at severe physical risk.

Miscellaneous Details

•The arm has a unique serial code engraved on an inner plate, serving as an identifier for UMBRELLA technicians. This code also links to Piers’ personal health records, mutation data, and arm specifications for quick access during maintenance or in emergencies.

•Due to the intense electrical pulses generated by his mutation, the arm is equipped with an internal cooling system. Micro-fans and heat-dissipating channels prevent overheating during extended use, keeping the arm at a safe, comfortable temperature. If the arm overheats, an internal alarm alerts Piers to prevent any potential damage.

•The outer layer is treated with a UV-resistant coating to protect it from environmental damage and exposure. This ensures that prolonged exposure to sunlight or harsh conditions doesn’t wear down the arm’s exterior, making it more durable in diverse climates and situations.

•Designed for various operational environments, the arm is fully waterproof and corrosion-resistant. It functions normally underwater, which is crucial for aquatic missions or when exposed to rain, mud, or corrosive substances.

•The holographic display can be customized to show additional details, such as weather, GPS navigation, or tactical maps. Piers can also set personal preferences, like color schemes or alert tones, for a more intuitive user experience. This flexibility lets him prioritize the information he finds most critical during missions.

•The communicator has an onboard language translator, enabling Piers to communicate with individuals across different languages. The arm’s display shows translated text, and a subtle earpiece can even relay audio translations, making it easier for him to gather intel and negotiate in multilingual environments.

#𝐒𝐮𝐛𝐣𝐞𝐜𝐭 𝟏𝟑#𝐌𝐮𝐬𝐞; 𝐏𝐢𝐞𝐫𝐬 𝐍𝐢𝐯𝐚𝐧𝐬#I think I very severely fucked up my lefts and rights Ngl but oh well#resident evil#resident evil 6#piers nivans#long post

44 notes

·

View notes

Text

One time someone brought a salvaged Seraph (god knows how they got it) with a VDNI setup in it, and wanted us to repair the mech and replace the interface cockpit with a customer supplied standard cockpit from a Victor. For those of you who have not interacted with a Direct Neural Interface setup -- which I would assume is most y'all for obvious reasons -- the system actually runs all throughout the entire mech structure. Upon informing the customer that removing said equipment would entail:

• Basically stripping down all of the myomer and rewiring the whole musculature with standard wiring

• Reformatting all of the integrity sensors in the structure

• Reprogramming the gyro to talk to a neurohelmet (big job on its own)

• Reprogramming the entire targetting system

The customer asked if we could "just put the Victor cockpit in and piggyback the outputs into its consoles". The Victor cockpit would not fit at all either, since the Celestials seem to only have enough space for a cockpit the size of a bar fridge for some reason.

We eventually got a cockpit setup that would fit, at which point we had also figured out that the NONE of the modules would talk to any of our diagnostics equipment, let alone output anything readable to the cockpit displays. So we had to build a custom harness for whole thing, which involves manually tracing the entire mech's wiring from top to bottom, to figure out which wires going into the cockpit were connected to what components and sensors.

The entire mech runs on 3 different voltage systems, none of them are the same as standard Inner Sphere or even Clan systems, and so many of those god damn wires are duplexed BUS cables.

By the third month we were about ready to dump the thing out in the middle of nowhere and tipping Comstar off to its location, and telling the customer it got stolen.

Oh! And while we were trying to figure this absolute headfuck of a mech out, it was taking up one of our bays and we still had to keep up our standard amount of work output using only the other 3 bays, because this customer was a friend of the shop's owner so we were doing this as a "favour" to the guy.

Long story short if someone ever brings you a Blake mech and asks you to make it work, tell them to take it to a Comstar shop cause you really do not want to, I promise you it will make you want to die. What are you gonna do with it? Do you have ANY other mechs with a C3i computer that it will even be able to connect with? No you don't! Don't lie!

23 notes

·

View notes

Text

Eternal LMK Au (Part 17) Interactive Story

Chang'e arrives~

The rules are simple.: I will give the written passage, and then at the bottom there will be a vote on how the characters act next!

Story; Eternal Au

Ship; ShadowPeach

Wukong's battle-ready stance immediately dissolved into pure delight. His eyes widened, sparkling with childlike wonder as the robotic bunny approached. "OH MY GOODNESS!" he squealed, bouncing on his toes. "LOOK HOW CUTE YOU ARE!"

---------

If he could see Mihou... he had a feeling he would be smacking his forehead right now.

The robotic bunny, clearly designed for surveillance and defense, seemed momentarily confused by Wukong's enthusiastic response. Its mechanical ears twitched, sensors scanning the unexpected visitor. It had come out here with the intention of tracking the unwanted visitor. Typically to scare them off… not get fawned over.

Wukong was practically vibrating with excitement, his previous tension completely forgotten. "Aren't you just the most adorable little thing?!" he cooed, taking a step forward with outstretched hands.

The robotic bunny's metallic ears pivoted, tracking Wukong's movement. Its glowing eyes flickered between scanning modes, assessing whether this strange monkey was a potential threat.

A synthesized voice emerged, crisp and precise. "Unidentified entity detected. State your purpose." as it scanned it, it reached into his memory to recall why this man seemed familiar. As Wukong swayed a little, it was quick to realize.

Target identified as: Sun Wukong, the Monkey King. Threat level: RED.

The robotic bunny's demeanor shifted instantly. Where moments ago it had been a cute, potentially friendly surveillance unit, now it transformed into a defensive mechanism. Its metallic ears hardened like blades, and its cute exterior seemed to ripple and reshape, revealing intricate defense systems.

"Threat detected," the synthesized voice announced, now cold and clinical. "Sun Wukong: Known disruptor. Initiating defensive protocols. Commencing capture."

Wukong, who had been mid-squeal about how adorable the bunny was, suddenly froze. His excited expression morphed into a bewilderment. “Oh-” He blinked rapidly, gagging a moment later when the Robot pounced on him, "WHOA-!" Wukong yelped as the robotic bunny launched itself at him with surprising agility. Its metallic limbs unfolded, revealing an array of restraining mechanisms and defensive weaponry. "Hey now, let's talk about this-!"

The robot's synthesized voice remained emotionless. "Capture protocol activated. Subject: neutralization required."

With it’s arm around Wukong, a sudden controlled shock, similar to a high voltage razor, sprung from it’s fingertips. Wukong yelped as his fur puffed, vision going fuzzy for a moment. He had been hit by far worse, but it certainly caught him off guard.

The shock jolted through Wukong's body, causing his fur to stand on end and his muscles to seize momentarily. "Okay, that's not cute anymore!" Wukong shouted, eyes like swirls. If he could hear Mihou right now, he probably would have been screaming that he was an idiot. Probably had been warning him to take this all serious for a while now, actually.

Wukong's initial shock quickly transformed into irritation. These robotic contraptions were always so dramatic. He twisted in the bunny's grip, "Listen, little bunny," he attempted to reason, "You are super cute, but I don’t appreciate being shocked. I'm not here to cause trouble.”

The robotic bunny's sensors flashed red. "Threat level increasing. Initiating full restraint protocol."

Binding rings of light seemed to form from the bunny’s hands, wrapping around Wukong’s torso to pin his arms to his side. Wukong struggled against the robotic bunny's restraints, his initial delight transforming into mild annoyance. "Hey! This is NOT how you treat guests!" he shouted, writhing against the light-based bindings.

The robotic bunny remained impassive, its mechanical voice cutting through the lunar silence. "Sun Wukong: Recognized threat. Containment mandatory." grasping the back of his shirt, it turned, dragging him back the way it came.

“Heyyy~!” Wukong kicked and pouted. Clearly captured…

Though, if he was honest, it wasn’t exactly like he was trying to escape or avoid this. Could easily change shape to get out of this- or brute force it open. But, breaking Chang’e’ things was the last thing he needed going for him right now. After all, his goal was to convince her to listen to him, so best to come in by playing by her terms.

Either way, it got him back towards the little Moon town, which is where he was going anyway. He just wished he didn’t have to deal with the judging sensation in the air.

Mihou definitely wasn’t happy…

He laughed nervously, “T-This is one way to make an entrance,” he joked to the open air. He half expected a cricket to sound back in return.

Dragged into the little domain, he was tossed into the open court yard, his face smacking into the dirt. He grumbled, peeling his face off the cement to look up.

The courtyard was immaculate, perfectly manicured gardens surrounding pristine white marble pathways. Elegant lunar architecture rose around him, with delicate archways and crystalline structures that seemed to shimmer with an ethereal light - Chang'e's celestial residence. All at full alarm.

Seemed the bunny had notified the entire domain and put everything into lock down. Expected, he understood, but a tad loud.

"Wonderful," he muttered, spitting out a bit of dust. "Just wonderful."

The robotic bunny stood guard, its mechanical ears twitching as it monitored his movements. Wukong slowly picked himself up, shacking off his fur and trying to maintain some semblance of dignity as he sat on his knees.

A series of soft, melodic footsteps approached, and Wukong looked up to see a figure emerging from the pristine archways. Chang'e herself, resplendent in flowing lunar robes that seemed woven from moonlight itself, stepped forward. Her expression was a complex mixture of curiosity, wariness, and a hint of something deeper - perhaps pain-hurt… fear.

"Sun Wukong," she said, her voice cool and measured, clear she was keeping her distance, "I did not expect to see you here." normally she was so peppy and upbeat. Her expression solemn, very aware that bring across Wukong's chest was not something that would hold the person before her. "Why are you here?"

Wukong hesitated at the sight of her lingering a distance. Beyond her, he could sense more of her robots on guard. As well as another presence. Powerful, familiar- and seething...

It seems Princess Iron Fan had arrived just in time for him to be dragged in too. She wasn't revealing herself yet, perhaps waiting to see what he would do?

This was the first time he had seen either since what happened with Mihou. As the only person who could communicate with them on his mate’s behalf, and desperately needing their help, he felt he needed to consider his first words carefully. He would turn on his gold vision to ask for help from Mihou, if doing so wouldn’t put everyone on more edge than they already were.

So that left himself to figure this out until he could explain.

Previous

next

44 notes

·

View notes