#Batching & Pre-Mixing System

Explore tagged Tumblr posts

Text

Batching & Pre-Mixing System from DhimanGroup

Batching & Pre-Mixing System from DhimanGroup simplifies bulk batching, mixing, and dissolving, allowing you to create pre-blended syrups with customizable ingredient proportions. This system ensures efficient and precise preparation, making it ideal for large-scale production with varying ingredient requirements.

For more information, visit: www.DhimanGroup.com or contact us at [email protected] or +91 98880 89018.

0 notes

Note

The more I learn about your comic... The more I fall in love with it. Especially your bugs! Like can you explain more about them? I'm really curious about them (from the full bugs to the hybrids and anything else that comes to mind).

Anyway your art is wonderful and I adore seeing it on my dash. And you can info-dump too. If you want ofc.

Thank you!

The worldbuilding is a work in progress (as it always is, but the first chunk of the comic itself is pretty self-contained so we've been slowly tinkering at the rest of the world and creatures as we go without affecting it much), so we mostly have loose rules and ideas for the bugs as a species. Or anything in between for that matter.

For all intended purposes, bug people are all the same species and can usually cross-breed within mechanical constraints, as well as mix with the elves we threw into the mix. Genetics? Don't know her. We operate on Sims logic here.

A full bug has roughly a human lifespan, with some variation depending on the type of bug it's closer to and some type-specific quirks. The one we've explorer the most, as it pertains to Ashton and the latest batch out of the oven, is the ability that some types might have to undergo metamorphosis, usually at the expense of lifespan. This is Ashton btw

And this is Ashton pre-metamorphosis:

Something like this isn't super common tho! So despite me drawing a bunch of butterfly or moth people they generally don't get to that point and stay looking more like funky lizards with many arms

Bugs can have many arms or legs or eyes, funky colours, exoskeletal bits, antennae, or look pretty close to your average human/elf with hidden bug features. Dahlia for instance is a vaguely spidery bug but can easily hide a bunch of her eyes and secretes venom thru hidden glandes so you could mistake her for an elf

Meanwhile it'd be very hard to mistake someone like this guy for anything other than a horned bug

If u catch my drift.

Some bugs are small! Some are huge. Some are out there committing atrocities

Some dont look like bugs at all

They're generally not as physically strong as the average elf but more resilient in a cockroach kinda way. They can have a chaotic range of circulatory systems and internal organs that sometimes just make them really hard to kill and its also pretty hard to keep track of every variation of the species and their quirks.

That being said in a lot of places they're super common and coexist with elves just fine, mix up and it's also not super uncommon to have half breeds like our man Staeve (the ThUG edition). The closer you get to elf the longer you live and less "non human" traits you have. There's also a bunch of different types of regular ass elf and it all falls under the elf category unless we decide to name them something else down the line.

Then you've got a smaller category of super elves that have been isolated for so long they never blended with anything else, are more attuned to magic and in general have a sort of mythical status amongst everyone else. They also have the longest lifespan at around 250 ish years.

That's sort of the TL;DR for now! Ollie and I have started to put all the info we've got into a single repository and do want to start sharing it (probably as patreon posts for now) because comics are slow and the scope might not encompass that much of what we want to explore of this world. And the chaotic idea machine never stops

Here's a metamorphosis meme for ya

392 notes

·

View notes

Text

Grocery Store Fire Cider

I try to always have fire cider on hand during the colder months. Fire cider is vinegar infused with warming, expectorant (mucus-clearing) herbs to help clear out gunk from our respiratory system. It's great for clearing up congestion and helping with wet coughs. Since pretty much everyone in my house tends towards wet cold symptoms (congestion/runny nose, coughing up mucus, etc.), we go through a lot of this stuff every cold and flu season.

I take a shot of fire cider as soon as I feel congestion or a wet cough coming on, or if I've been around someone I know is sick. While it doesn't always keep me from getting sick, I do think it helps speed up my recovery and keep my symptoms less severe.

A lot of fire cider recipes online and in herbalism books call for less common herbs that need to be purchased online or from a speciality herb shop. This year, I decided to make a batch with only herbs you can buy cheaply at most grocery stores. Here's the recipe for my fellow herbalists on a budget!

You will need:

A quart mason jar

1 whole head of fresh garlic, peeled and roughly chopped, OR 3 spoonfuls of pre-minced jarred garlic

3 knobs of fresh ginger about the size of your thumb, roughly chopped, OR 3 spoonfuls of store-bought ginger paste

1 package fresh thyme OR 2 tablespoons dried thyme

1 package fresh sage OR 2 tablespoons dried sage

1 quart apple cider vinegar

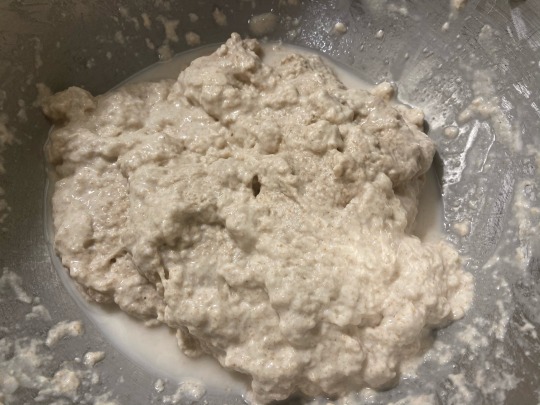

There are two methods I've used to make this cider. The traditional method is a slow infusion that takes 2+ weeks, but I've also developed a fast infusion method for when I feel a cold coming on and need a batch of fire cider ASAP.

Traditional Method:

Add your herbs to a clean mason jar. Pour the vinegar over the herbs and fill the jar to the top. Put a lid on the jar. (Vinegar will corrode metal lids, so either use a plastic lid or place a square of parchment paper between your jar and the metal lid.)

Place the jar in a cool, dark place and allow it to infuse for at least 2 weeks and up to 1 month. You can strain the herbs out to store at room temperature, or you can do what I do and store the whole thing in the fridge, herbs and all.

If you leave the herbs in, you can keep this batch of fire cider going all winter by topping the jar up with more vinegar every time it gets below halfway full.

Fast Infusion Method:

Add the herbs to the mason jar like you would for the traditional method. Instead of adding vinegar, fill the jar halfway with boiling water. Let sit for 2-3 hours.

Once the water has cooled down to room temperature, fill the jar the rest of the way with vinegar. Let it sit overnight and then either strain the herbs out or store the whole thing in the fridge.

To use the fire cider, take a shot glassful whenever you feel cold symptoms coming on. If you made your cider with the traditional method, you can dilute it with water if your stomach doesn't handle acid well. You can also mix in some honey to improve the taste.

Please note that fire cider and other folk remedies are not a replacement for medical care. I highly recommend staying up to date on your flu and COVID-19 vaccines in addition to using remedies like this.

#fire cider#herbal remedy#herbalism#traditional western herbalism#kitchen witch#kitchen witchery#kitchen witchcraft#green witch#green witchcraft#green witchery#budget herbalism#budget witchcraft#witchblr#mine#recipes

605 notes

·

View notes

Text

Mindset Shift #3: You Need to Learn How to Plan and Cook Your Meals—There’s No Way Around It!

Did You Know?

Studies show that for the same number of calories consumed, people eating processed foods are more likely to experience weight gain compared to those eating whole foods.

Here’s why this happens:

Thermic Effect of Food (TEF):

• Whole foods like lean proteins, fruits, and vegetables require more energy to digest, absorb, and metabolize.

• Processed foods are often pre-digested (e.g., refined carbs), meaning your body spends less energy breaking them down, storing more as fat.

• A study published in Food & Nutrition Research (2010) found that a meal of whole foods increased energy expenditure by 50% compared to a meal of processed foods of the same calorie count.

Satiety and Nutrient Density:

• Whole foods are richer in fiber, protein, and water, which keep you fuller longer.

• Processed foods are often calorie-dense but nutrient-poor, leading to overeating.

Blood Sugar Spikes:

• Processed foods often cause quick spikes and crashes in blood sugar, triggering hunger and cravings sooner than whole foods would.

Learning to Cook Can Be Daunting, But Here’s How to Start:

Start Small: Focus on mastering 2–3 simple recipes you enjoy. Build confidence by perfecting these before moving on to more.

Meal Prep Basics: Plan meals for the week, batch-cook staples like grilled chicken or roasted veggies, and keep your pantry stocked with essentials like spices, whole grains, and healthy fats.

Keep It Simple: Use minimal ingredients and techniques at first. For example, a stir-fry with fresh veggies, protein, and a simple sauce can be quick and nutritious.

Get Curious About Food:

To make better food choices, it’s important to read labels and understand nutritional information. Here’s how:

Start with Ingredients: The fewer the ingredients, the better. Avoid items with a long list of unrecognizable additives.

Watch for Hidden Sugar and Sodium: Processed foods often sneak in sugar under names like maltose or high-fructose corn syrup. Check for sodium content, especially in packaged meals.

Focus on Nutrient Density: Look for foods high in protein, fiber, and healthy fats while being lower in refined carbs.

Be Wary of “Low Calorie/Low Sugar/Low Fat” Options:

Many “low” options can have unintended consequences:

1. Increased Hunger:

• Artificial sweeteners or fat replacements often leave you unsatisfied, leading to overeating.

• A study in Obesity Reviews (2010) showed that artificial sweeteners might increase appetite in some individuals.

2. Insulin Imbalance: Sugar substitutes can trigger insulin release even without calories, causing blood sugar instability.

3. Hidden Additives: Low-calorie or low-fat foods often replace natural fats or sugars with artificial additives that don’t support your health.

Reframe your mindset about cooking: it’s not a chore—it can be a fun meditative self-care experience.

Cooking engages all five senses, requiring focus on the present moment, which can have a calming effect on your nervous system. Here’s why:

1. Sensory Stimulation:

• The aroma of spices, the sound of sizzling pans, the texture of fresh ingredients, the sight of vibrant colors, and the taste of the final dish all ground you in the moment.

• Sensory activities like these can activate the parasympathetic nervous system, which promotes relaxation and reduces stress.

2. Mindfulness in Action:

• Cooking requires concentration on specific steps—chopping, measuring, mixing—which can act as a form of mindfulness, quieting racing thoughts.

• A study in Frontiers in Psychology (2014) found that mindfulness-based activities, even in small doses, improve mood and reduce anxiety.

3. Creative Outlet: Experimenting with flavors and presentation can turn cooking into a form of self-expression, which enhances mental well-being.

4. Sense of Accomplishment: Completing a meal, especially one you’ve planned and cooked yourself, fosters a sense of pride and satisfaction, boosting confidence.

All of this to say, making time for cooking and learning how to do it is not an option to lead a healthy lifestyle. Find cooking influencers who inspire you to try new recipes and offer advice for beginners. Get a beginner friendly cooking book with recipes you like and make it a journey to complete as many recipes during the year. You’ll soon recognize the common patterns in cooking and will be able to trust your abilities to nourish yourself in no time!

#2025#health and wellness#wellbeing#fitness#glow up#weight loss#fitblr#it girl#that girl#wellnessjourney#cooking#learning#learning to cook#how to cook#whole foods#eating healthy#eating well#healthy recipes#healthylifestyle#healthyliving#becoming that woman#becoming the best version of yourself#becoming her#becoming that girl#fitforsummer#fitfam#fitspo#fitspiration#health & fitness#kitchen

65 notes

·

View notes

Text

[ID: A plate of light brown bumpy flatbread with blackened spots, surrounded by za'tar and green olives. End ID]

خبز طابون / Khobz taboon (Palestinian flatbread)

Khobz taboon ("taboon bread") is a soft, chewy Palestinian flatbread. It may be eaten with olive oil and za'tar, but it is best known as the base of مسخن (musakhkhan), where it is topped with spiced aromatics and perhaps chicken.

Khobz taboon gets its name from the vessel it is traditionally cooked in—an outdoor, shallow conical oven with an opening at the top and a clay or metal cover to trap heat. Taboons may also have an opening at the side through which the fire can be stoked, especially in the east of Palestine. These ovens were historically made from a mixture of local clay and hay, but have more recently also been constructed from clay treated to be sturdier, or from metal.

A taboon is used by packing flammable material, such as hay, fabric, animal dung, wood, and charcoal, around the outside of the oven and letting it burn overnight; the fire transfers thermal energy to the clay, and to the river stones, sand, glass, or flint stones (صوان, "ṣawwān") that form the base of the oven. The ash is then brushed away, and the flattened dough is placed on the stones or stuck to the walls of the oven to cook. The clay and stones will continue to release thermal energy and cook things throughout the day. The clay and ash give a distinctive flavor to anything cooked inside the taboon, making this method a source of nostalgia for many people who have transitioned to cooking in indoor ovens.

Khobz taboon was traditionally made with whole wheat flour. Most people today use a blend of around two parts white flour to one part whole wheat, or else all white flour; they may even add milk or milk powder to ensure a very soft dough. This recipe uses a blend of flours to combine the nutty flavor of whole wheat dough with the pliancy of white dough. It also begins with an optional pre-ferment to mimic the traditional Palestinian method of including a piece of dough from the previous day's bread into each new batch (like a pâte fermentée) giving a rich and slightly sour flavor to the final bread. It calls for the use of rocks to imitate the bottom of a taboon; the rocks give the khobz its distinctive dimpled texture, and ensure that no interior pocket forms in the bread.

In the years following 2007, the siege Israel had imposed on Gaza caused a shortage of cooking gas that led to a resurgence in the use of taboons. The ovens were used to bake bread and to grill sweet potatoes during the time of their winter harvest. Meanwhile, in the West Bank, Israeli military forces repeatedly destroyed taboon ovens and assaulted villagers who tried to defend them, as Israeli settlers from nearby villages complained about the smoke that the ovens produced. Some of these ovens had been used to bake bread for entire families of 40 or more people. Palestinians continue to build, use, and defend these ovens, despite the fact that Israeli law de facto forbids Palestinians in the West Bank to build anything.

Today, Israel is deliberately targeting and destroying bakeries in refugee camps that had been supplying bread to tens of thousands of people in Gaza, continuing a long campaign of starvation of the Palestinian people.

Support Palestinian resistance by calling Elbit System's (Israel's primary weapons manufacturer) landlord; and donating to Palestine Action's bail fund.

Equipment:

A large, shallow mixing bowl, like a Moroccan qus'a

A large (12"), shallow clay cooking vessel, such as the bottom of a Moroccan tajine (one that is rated for very high temperatures), or a large baking tray

Assorted smooth river rocks of varying sizes, from 1 to 3" in diameter.

Make sure that your rocks have been thoroughly cleaned, and that they do not contain any fissures, cracks, or veins that could contain water (this water, once heated in the oven, could cause the rocks to crack open). Instead of river rocks, I used lava rocks designed for use in a clay tanoor. You just need something to provide thermal mass and give a bumpy texture.

Ingredients:

Makes 3 large breads.

For the pre-ferment:

140g whole wheat flour

1/2 tsp active dry yeast

140g water

You may also use a pâte fermentée that you already have (just adjust the ratio of white to whole wheat flour added later accordingly), or a sourdough starter. The hydration of the starter doesn't matter, since you will be adding water by eye later.

For the bread:

330g bread flour or all-purpose flour

30g whole wheat flour

5g salt

Water

If you skipped the pâte fermentée step, add 170g (rather than 30g) of wheat flour at this stage, as well as 1/2 Tbsp of active dry yeast. I have not tested the recipe this way.

Instructions:

For the pâte fermentée:

1. Mix flour and yeast in a small mixing bowl. Add water and stir to combine. Cover and leave out at room temperature for a day, or in the refrigerator for up to three days. At the end of the rising time, it should be about one and a half times its original size.

For the bread:

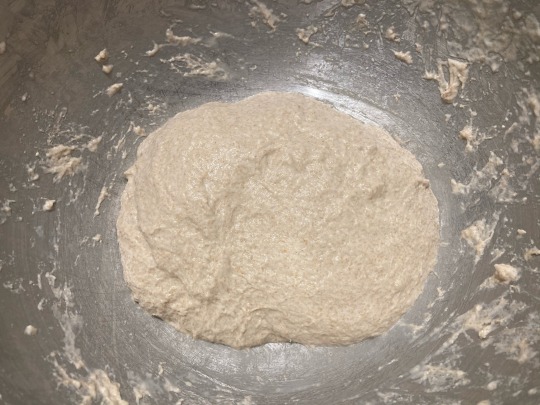

This recipe makes a high hydration dough that will need techniques such as slapping and folding to knead effectively.

1. Mix flours and salt in a very large, shallow mixing bowl. Add your pâte fermentée and mix to combine.

2. Add water until the flour comes together into a soft, sticky dough and continue keading. Have a bowl of water on your workstation. Every time the dough starts to stick to your hands or the sides of the bowl, wet your hands and rinse down the side of the bowl with some water. This will gradually add water to the dough.

3. You will notice the dough growing smoother and laxer. At this point, start kneading by repeatedly folding the edges of the dough in towards the center. Do this by occasionally wetting your hands, then running a hand along the side of the bowl and under the edge of the dough to unstick it from the bowl; then fold. You will get stuck less often if you try to touch the dough as lightly and briefly as possible. Every few folds, dimple the surface of the dough all over with your fingertips. You will have been kneading for about 10 minutes at this point.

The dough should become more smooth and less bumpy—you will notice it holding its shape and becoming more stretchy as gluten forms. It should form into a ball when you fold the corners in and hold its shape for a minute, but then gradually expand to take the shape of the bowl. I added about 2 1/2 cups of water total (in dry conditions) during steps 2 and 3.

4. At this point, the dough is wet enough that the slap and fold method is the best way to knead. Wet your hands and again unstick the dough from the sides of the bowl. Hook your hands under the dough and quickly pull it all up into the air; fold the hanging bottom part of the dough under, and plop the dough back down, folding it on top of the part you plopped down earlier. Give the bowl a quarter turn and repeat. Do this continually for another few minutes.

5. When the dough is very smooth and lax, smear some olive oil on the sides of the bowl and under the dough, and pat some oil on top.

6. Cover the bowl and bulk ferment the dough at room temperature for 8 hours, or for 16-24 hours in the fridge. At the end of the rising time, you should see bubbles beginning to form on the surface of the dough.

To shape and bake:

1. Place a layer of rocks at the bottom of a clay cooking vessel or baking sheet. Put the sheet in the top third of the oven and preheat your oven to 550 °F (290 °C), or as hot as it will go.

2. Meanwhile, fold the edges of the risen dough over into the middle a few more times with damp hands. Pinch off a large piece of dough (about the size of two fists), and fold the sides over into the middle to make a neat packet.

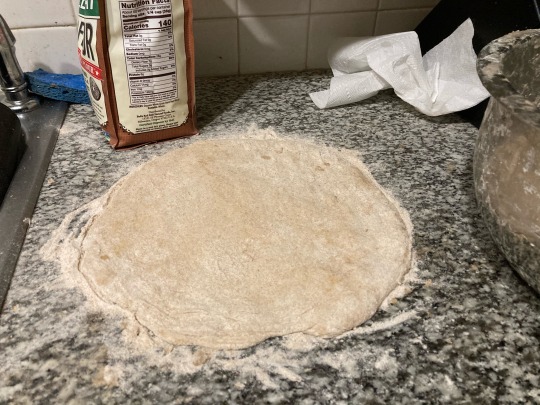

3. Drop the packet of dough onto a heavily floured surface, and flip to flour both sides. Pat the dough flat, then throw it back and forth between your hands, catching the edge each time as you spin it through the air, like a pizza crust, to stretch it into a circle about 1/4" (1/2cm) thick with a diameter of about 10" (25cm).

You may also stretch and pat the dough out on a flat surface.

4. Remove the tray from the oven. Flip the dough circle over the back of your hand to transfer it and lay it down over the hot rocks. Re-stretch it into a circle, if necessary.

5. Place the tray back in the oven and cook for 5-7 minutes, until the top of the bread has golden brown spots. Repeat with each piece of dough, leaving the rocks in the oven for a few minutes between each one to allow them to come back up to temperature.

6. (Optional): Hold each flatbread directly over a gas flame for a minute or two to blacken a few spots and mimic the flavor that a wood-fired oven would give to your khobz.

You may also use a method similar to the dhungar technique to smoke your bread. Place each piece of bread one at a time into a large vessel with a closely fitting lid, alongside a small bowl. Light a piece of wood on fire and drop it into the bowl; then cover the vessel with the lid as you allow the wood to smoke for a minute or two.

#note that I do not recommend this recipe to anyone who is not experienced with making bread#I'll have another Palestinian flatbread recipe up soon which will be more beginner-friendly#Palestinian#bread#khobz#flatbread

349 notes

·

View notes

Text

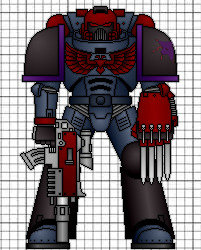

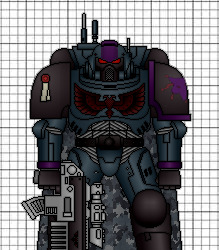

WH40K Homebrew Space Marine Chapter: Stormwolves

I've posted about them before, but with the April 2024 Field Manual Points List v1.8 recently dropping, I'd gone back to make sure my army list for my Homebrew Chapter was still in compliance, or as close to it as I can get seeing as much of it is from Legends due to the nature of my Chapter's Backstory, and it felt like a good time to consolidate the Lore as well.

(Keep in mind I don't actually play this army, the last time I played 40k was when Clinton was in office, it's just an exercise in seeing how well I can apply the army building rules to my Homebrew's fluff.)

Stormwolves Lore

The story of my Homebrew Marine Chapter, the Stormwolves, starts with an Ordo Sicarius Inquisitor who had been embedded as a deep-cover operative in the Vanus Temple Assassin of the Officio Assassinorum -- Real name undisclosed, known only by her Inquisitorial Authorization Code for her Mission: 𝜮 — Niner . Septagraph \ Halley | ℚ [Rational] • Soul : Zed <𝑖> ∞ = Foxtrot ^ V̿ (This is often shortened to "Sigma Stroke Niner", and in rare cases to just Halley)

The combination of Inquisitorial zeal and the Data Gathering & Manipulation skills of an Unbound Infocyte is a potent mix, and Sigma Stroke Niner was able to deduce the existence of Cawl's Primaris project prior to it's official unveiling, including the initial reports (later proven wrong) that these new marines would be near-immune to the various chapters' gene-seed flaws.

She brought this finding back to her compartmentalized Inquisitorial Conclave, who decided that it warranted further investigation in the utmost secret. They also came to the verdict that if there were going to be a next generation of Marines, it was ill-advised to let them all be under the sole control of a lone member of the Mechanicus, no matter how intelligent and skilled. The Inquisitor Infocyte was authorized for a new assignment, to divert one of Cawl's secret remote caches of Primaris for study by an independent Mechanicus Arch-Genetor. This diverted batch of Primaris would also secretly serve as a fail-safe contingency for the eventuality of Cawl's project posing a threat to the Imperium, giving the Inquisition an independent stock of Primaris from which a counter-force could eventually be raised from.

A Vogelist Arch-Genetor, Kristiana Rozza, was chosen and allowed to review the collected research intercepted from Cawl. She hypothesized that the supposed flaw resistance may be possible to be backported to Firstborn Marines, especially if aspirants were screened for favorable genomes. A Rogue Trader, Jareth Keldon XXIV, was secretly commissioned to locate an obscure world to conduct experiments with this new "Marine Chapter", his payment being a full company's worth of these new marines being seconded to his flagship to assist with his explorations.

The planet that the Rogue Trader was able to locate for the project, Etherion IV, was a pre-Imperium Dark Age of Technology -Remnant human colony Industrial-Hive not on standard navigational charts due to surrounding warp-storms (these warp-storms would result in several temporal anomalies and the planetary system having an asteroid belt littered with Space Hulk wreckage from the past and even future).

Etherion IV's planetary culture consists of a Capitalist Corporate Oligarchy with proxy wars of genegineered Abhuman Hive-Gangs, called "Splicer Gangs". The wide variety of genegineering among segments of the native population gave Arch-Genetor Rozza a broad canvas of potential aspirants for her various experiments in Astartes creation.

In addition to the stasis Primaris extracted from Cawl's secret cache, a small amount of Astartes genetic tithings were diverted so that Firstborn Marines could also be made. The primary source was the Space Wolves, but some Blood Angels Progenoids were also in the mix of what could be illicitly redirected. While carrying the Geneseed mutations of these parent Chapters, the Marines created from this supply were entirely divorced from the homeworlds of Fenris and Baal, carrying no cultural context for any Chapter-specific flaws that develop.

The Stormwolves are not a full strength Chapter, and lack much of the heavier hardware. What vehicles and aircraft they do have are often archived museum pieces whose storage records were "misfiled" or unused prototype schematic designs pulled from mothballs at various Forge Worlds to then be manufactured locally on Etherion IV.

Due to their covert "founding", the Stormwolves are also at risk of being misidentified as a Renegade Chapter or even surviving Heresy-era Blackshields. Or they would be, if they hadn't been trapped by a severe time-distorting Warp Storm keeping them isolated while time ran at widely disparate rates inside and outside of the storm. This Storm lasted several centuries and did not fully dissipate until the middle of the Indomitus Crusade.

Due to the research-based charter that was their unofficial founding, the Stormwolves have a non-Codex structure.

Chapter Leadership is referred to as "Control" and consists of Firstborn Marines that have not been experimented on. They assist the Arch-Genetor with her experiments, and also lean hard into the monastic side of being an Astartes. Their unique power armor color scheme is often not fully visible due to cloaks, robes, tabards, capes, and hoods in black, red, and royal purple. Control also almost exclusively carries high-powered relic combi-weapons.

Then come the Bloodstorm Squadrons which are batches of Firstborn who have had their Geneseed experimented on. Their armor scheme is a variation of Control's colors, with more red. Conscripts from the Abhuman Splicer Gangs are also assigned to Bloodstorm as they wait to see if they get chosen for Marine implants.

Both these Firstborn sections are outnumbered by the Primaris Marines of the Stygian Wolves Division. Sporting a much darker paint scheme, the Stygian Wolves are a mostly Phobos-armored Vanguard Force and are typically grouped into 5 Marine squads, one of which is always a Helix Adept. These squads are either designated as Obscuratus Pack if they are equipped with Omni-Scramblers and Comms Arrays, or as Phantom Pack if they eschew this extra equipment in favor of mobility. The Helix Adepts in both types of Pack are charged with monitoring the genetic health of the rest of their squad in addition to all their other normal Helix Adept duties. Both Obscuratus and Phantom Packs wield the locally produced Etherion-Pattern Marksman Bolt Carbine, a design that takes cues from both the Instigator Bolt Carbine and the Stalker Pattern Bolter. Occasionaly, smaller fire teams armed with either Bolt Sniper Rifles or Las-Fusils are also employed.

Uncommonly, the Stygian Wolves also use Tacticus Configuration of Mk. X Power Armor, frequently in combination with Plasma Incinerators in a Hellblaster-style loadout, in squad formations lead by an Apothecary and known as Sterilization Detail. Very rarely will the Intercessor-syle loadout with the Cawl Pattern Bolt Rifle be used; this equipment profile is typically reserved for in boarding actions. Rarest of all are the Gravis-armored Multi-Melta wielders of the Extermination Crew.

The devotion to monitoring their own genetics in the pursuit of constant improvement is not just limited to the Stygian Wolves Division, as Control is also very Apothecary heavy, with many Apothecaries assigned to a leadership role by the title of Helix Keeper. Helix Keepers also frequently assume the command position over Bloodstorm Squads. The Helix Keepers, Apothecaries, and Helix Adepts of the Chapter take the place of Chaplins, as the Stormwolves have no Chapter Cult of their own, their worship is directed solely towards genetic experimentation. The quest for purity also has weeded out most all forms of random mutation, including the Psyker genes, so the Chapter also lacks Librarians. (The deliberate genengineering of potential aspirants is an exception to the purity mandate.)

The Stormwolves often fight alongside Auxiliaries draw from the troops assigned to Rogue trader Keldon's fleet. Keldon's Elite Personal Guard, the 1st Selene Contingent, is the most powerful of these. They provide an additional avenue for Arch-Genetor Rozza to experiment on enhancements that fall outside of the Inquisitorial charter to research Space Marine genetics and the Primaris Project. The true nature of these side experiments by the Arch-Genetor are shrouded in secrecy for unknown reasons. While there is always the possibility that the sub-project could be something considered to be Heretical by either the Mechanicus or the Imperium, Sigma Stroke Niner is aware of the details, and permits the work to continue. It is of note that the 1st Selene Contingent is an all-female unit.

#wh40k#Warhammer 40k#Warhammer 40000#Space Marines#Homebrew Space Marine Chapter#Stormwolves#Adeptus Astartes#Games Workshop#Hero Forge

21 notes

·

View notes

Note

i see you got a mspp sooo what do you think of the new nostalgic pets?

Oh yeah, I splurged a touch. Had some leftover NC from the pumpkin spice gacha LOL. BUT I'm uh, not.. not great with gacha systems and the fact that they not only made it a gacha but also FOMO is rlly bad for people like me who are susceptible to gambling/addiction disorders. I had to get the for-sure deluxe one because I know I'd spend thrice the amount of the significantly cheaper one if my luck turned sour. I have to limit myself to one event a year (usukicon) or I'll hurt my finances (looks at pumpkin spice gacha not me spending unhealthy $$$)

MSPP was one of the pets that REALLY suffered from conversion so I'm pleased it was part of the first batch! Same with Usuki!

overall it's a net positive. I don't engage with the neo community and i have been avoiding pound chat (and forums) since the 2010s but I hear that it's kind of imploding right now. While I empathize with lost time spent trading and negotiating for pets that no longer hold value.. its worth remembering that value had a rly ugly black market and it was an aspect worth nipping in the butt. Hopefully trading will go back to pre-2010 where people actually traded for pets. But who knows.

The art... Its.. mixed feelings. The art is an improvement for sure, but idk if that improvement was a good thing. (pets like kiko lost some charm for sure.) cause a lot of what made old neo really charming was that it was kind of ugly? I've been staunchly against the softer shading style for a long time so it's refreshing to see & know that the old style of art is still possible.

So while overall I think its a good thing, what worries me most is that.... Well, I think it might be setting a... bad precedent for future ways of handling the site & it's monetization. I actually haven't seen a lot of people discussing it BUT... unlike a game like Fortnite or smth where skins don't affect gameplay- coloring your pet is a gameplay element of Neo! Being able to buy colors- be it UC (nostalgic now I guess?) or some of the body paints (I think they had like.. a cherry blossom one?) Is not.. not good. Buying paint brush colors should NOT be done with REAL WORLD MONEY, and I think the success of the Nostalgic pets is going to give World of Neopets a green light to keep doing that. (Heck, I don't even thing color-changing ITEMS for PETS should be allowed. Paint brushes are a core element of the site and its not like single-species colors aren't a thing.)

But maybe im being paranoid, it's not like Neopets has been a site for me for a long time. It feels like a glorified gachapon doll site these days and.. it's not the weird and kinda messed up site it used to be. I know they have a lot to do involving code but It's.. it's not.. going fast enough. Not when I see them doing shit like popping up stalls at cons.. you know how expensive that stuff is? a stall at comicon? Take that several thousand grand and hire a code engineer.

tldr: Nostalgics are a step in the correct direction, and it's SO good to see non-fisted pets!! but their implementation & monetization worries me.

3 notes

·

View notes

Note

hey I have messaged you before because we both have boneitus but I wanted to ask - how severe has the immune compromise from humera and biologics been for you? My joint pain is just on the inside of manageable and I'm concerned that, going to uni and generally being outdoorsy, I'm putting my health more at risk by starting it then by seeking other methods of management? right now inflammation and pain are the only concerns, not more severe health risks.

[2nd message: obviously you can't give medical advice etc I'm just hoping to hear your perspective and experience. my mother is less severely impacted and also doesn't seem to be too compromised but I think she's a bit casual about health risks sometimes]

tbh I haven't felt like the immune compromise has been too bad even though I started taking biologics during the height of covid... now that I'm thinking about it I remember I was supposed to start my first humira shot before the covid vaccine was widely available, literally had the shot sitting on the counter to thaw, but then the pharmacy rang me up to say they got a batch of vaccines in and I postponed my humira shot a few days so I could go get a different shot first lol. other than getting Actual Covid about a year ago (which sucked ass but obviously didn't kill me, I think my partner who's normally in great health got hit harder by it than I did) I actually think I've gotten sick way less often in the past few years than I ever did pre-biologics/pre-covid. knock on fucking wood obviously. and I was aaaallllwaaaays getting sick with random shit pre-2020. not sure whether that's a testament to how well proper masking works or a testament to how treating my fucked-up immune system actually made me less susceptible to random viral infections but either way there's some anecdata for you.

but full disclosure that I'm a homebody in general, and then the combo of covid and my Problems means I haven't been traveled out of state more than once or twice, I still mask up in public 95% of the time, my only roommate is my partner who also masks up in public 95% of the time, we live in a private residence with our own bathroom/laundry facilities, etc. granted I do still Go Out and have potential avenues of exposure to whatever random shit is brewing, particularly in restaurants, but I don't wanna generalize my experience too too much if you're a student and might be living in a dorm, travelling a lot, etc.

although with that said I think (and don't quote me on this?) the main concerns with biologics are less about your average cold/flu/covid situation than with more serious stuff like TB or hospital acquired infections or whatever. I definitely had to get a TB test before I could start humira. and I have admittedly had some chronic but very mild skin infections thanks to being immunocompromised, but they've all been treatable, and it's hard to say whether they were caused by the biologics themselves or the combo of biologics + intermittent steroid use + preexisting eczema + recently adding methotrexate into the mix. and generally having the constitution of a sickly orphan boy lol. which is all to say that unless you're being exposed to really freaky shit on the regular I don't think going on biologics will be the difference between you staying healthy and you getting struck down by Icky Space Virus, especially since biologics are a targeted immunosuppressant in a way that (e.g.) prednisone isn't. a good N95 or KN95 mask goes a long way, too.

it's ultimately up to you and your comfort level, especially if you said you're managing the joint pain okay right now—but I've also been there and I know that "managing" pain still is not a fun place to be at all. I also don't know if you have a flavor of boneitis that turns into degrative damage over time, so that's another consideration; I was honestly pretty scared about the (depending on who you ask, minor) cancer risk of taking TNF inhibitors, but I kind of rationalized it as like, okay, if I go on these drugs and get cancer, there's a solid chance of surviving cancer, but if I don't go on these drugs and my spine fuses permanently then my spine will be fused forever and ever and I can never fix it. there's also the fact that untreated inflammation is a major cancer trigger in itself, so on the crohn's side of things I have a way higher chance of getting cancer from untreated crohn's than I do of getting cancer from crohn's treatment.

don't take it as medical advice but here's my two cents: if your doctor thinks it's safe, and if you would benefit significantly from treatment, I think it's worth trying. soooooo many people take these drugs and the majority don't have life-altering side effects. with the immune suppression specifically, or even other minor side effects, I see it as a question of whether those risks/side effects are outweighed by the symptoms you're dealing with on a daily basis. I tend to approach that with a rough formula of severity x probability on both sides, which means unless the side effects are really bad AND really likely to happen, or unless the symptoms are relatively minor, I usually gravitate towards taking the drug. "symptom I already have that fucking sucks" usually comes out on top as the greater evil. but that's just me!

tangentially related point you might find interesting: I mentioned the other day about getting a consultation from a cosmetic surgeon who I later found out was related to the lead singer of imagine dragons, but the way I found that out was because I asked the surgeon if it was okay to get operated on while taking humira, and he said that not only was it fine, but also that he takes humira for the same arthritis + IBD combo that I have. and then later I heard an imagine dragons song on the radio, which reminded me how the lead singer is my nemesis because he's the most famous person alive with spondylitis but makes shitty music, and then I thought about how he's from vegas, and then how he's mormon, and then how the surgeon I saw is also mormon (BYU diploma spotted in his office lol. despite his main specialty being top surgery. #respect), and then how the surgeon told me he has like eight brothers and they all have IBD too, and then I was like "there can't be that many mormon families in las vegas with the same genetic autoimmune issues, right...?" and looked up the lead singer's last name and it was the same as the surgeon's...

so anyway just know that active practicing surgeons take biologics and seem to be doing alright! and also that someone out there has a family with a million sons who all have Shitting Constantly disease. the toilet paper bill when those kids were growing up must have been totally insane

6 notes

·

View notes

Text

Analysis of NPK blending fertilizer production line process characteristics

NPK blended fertilizer is a compound fertilizer made by physically mixing nitrogen (N), phosphorus (P), potassium (K), and other base fertilizers. NPK blending fertilizer production line process offers features like flexible formulation, low investment, and strong adaptability, allowing it to meet the nutrient needs of different crops and soil types.

1.Raw Material Pre-treatment

Raw Material Selection: Base fertilizers like urea, monoammonium phosphate (MAP), potassium chloride (MOP), and potassium sulfate (SOP) must meet particle size standards (1-4mm) to ensure even mixing.

Crushing and Screening: Large particles need processing by a chain crusher and grading via a vibrating screen to prevent clumping, which affects mixing effectiveness.

2.Automatic Batching and Mixing

Computer-Controlled Weighing: A PLC automatic batching system precisely adjusts the N, P, K ratios with an error ≤1%.

Double Axis Paddle Mixing: A high-efficiency mixer achieves a uniformity ≥95% in just 3-5 minutes, preventing nutrient segregation.

3.Finished Product Handling

Anti-Caking Treatment: Coating oil or anti-caking agents are added to improve storage stability.

Automatic Packaging: Quantitative packing scales + sewing machines support different bag sizes (5-50kg) to meet diverse market demands.

Outstanding Features of NPK Blending Process:

1.Flexible Adaptation: Formulas can be quickly adjusted to produce specialized fertilizers with different NPK ratios (like 15-15-15, 20-10-10).

2.Low Investment, Quick Returns: Compared to chemically synthesized compound fertilizers, equipment investment is reduced by over 50%, making it suitable for small and medium-sized enterprises.

3.Energy Efficient and Eco-Friendly: No high-temperature chemical reactions mean lower energy consumption and no wastewater or exhaust gas emissions.

4.High Adaptability: Medium or trace elements (calcium, magnesium, sulfur) or organic matter can be added to meet the needs of specialty fertilizers.

With advantages like simple processing, flexible formulation, and controllable costs, NPK blending fertilizer production lines have become a key choice in the compound fertilizer market.

0 notes

Text

How to Safely Load and Unload Cement from Silos: A Guide for Site Operators

Cement silos are essential storage units used on construction sites to store bulk cement and fly ash efficiently. Ensuring safety during the loading and unloading process is vital for maintaining worksite productivity, preventing accidents, and preserving material quality. This guide provides site operators with practical knowledge on handling cement silos while following the latest safety standards used by industry leaders in road construction and material handling equipment.

What is a Cement Silo?

A cement silo is a specialized container used for storing dry bulk materials like cement and fly ash. These silos come in various types, including vertical silos, horizontal silos, and mobile silos. They are commonly used in infrastructure projects, ready-mix concrete plants, and road construction sites. Silo manufacturing companies in India design these units to handle large volumes efficiently and safely, often aligning with IS code standards and CPCB dust control norms. Operators should confirm whether the silo complies with IS 4925:2004 to ensure safe batching practices.

Why Proper Handling of Cement Silos is Crucial?

Proper handling of cement silos is essential to avoid material spillage, equipment damage, and safety risks. Incorrect procedures can lead to clogged discharge systems, dust pollution, and even structural damage to the silo. Following safe loading and unloading methods ensures that operations run smoothly and reduces downtime, especially when working with fly ash silo systems. Some advanced silos are designed with user-friendly safety features like digital level indicators and automatic venting systems that minimize human error.

Cement Loading Process: Step-by-Step Guide

The loading process involves transferring bulk cement into the silo from a tanker or bulk carrier. Here's how to do it safely:

Check all connections and pressure levels before starting.

Use appropriate conveyors or blowers as recommended by the equipment manufacturer.

Monitor the silo’s level indicator to avoid overfilling.

Ensure the dust collector is operational to prevent airborne particles. Skipping these steps can lead to material loss and air contamination.

Pro Tip: In one project involving high-output cement batching, an operator avoided a costly system shutdown by double-checking the pressure settings against the values in the manufacturer’s manual before initiating loading. Always confirm tanker pressure settings to prevent structural stress on the silo.

Cement Unloading Process: Best Practices

Unloading cement from silos should be done systematically:

Open discharge valves slowly to control material flow.

Use gravity or pneumatic systems as per equipment specifications.

Maintain silo pressure balance by using a functional air vent.

Clean the discharge line regularly to avoid clogging. Leading manufacturers often recommend scheduled maintenance and some provide digital alerts on silo health via SCADA systems, especially on high-volume projects.

Safety Measures to Follow During Loading and Unloading

Safety should always come first during cement handling. Key measures include:

Wearing personal protective equipment (PPE) such as helmets, goggles, and dust masks.

Implementing lockout/tagout systems to prevent accidental starts.

Installing emergency stop buttons near the control panel.

Using dust suppression equipment to reduce inhalation risks. Many construction equipment suppliers now integrate dust filters and pressure relief systems that comply with national safety standards.

Real-World Note: During a recent highway expansion project, one site team reduced handling-related delays by 30% by conducting pre-shift safety inspections and using silo systems with automatic dust control features.

Maintenance Tips for Cement Silos

Routine maintenance extends the life of a cement silo and enhances safety:

Inspect structural components for cracks or corrosion.

Clean filters and pressure relief valves.

Lubricate moving parts such as screw conveyors.

Keep a logbook of inspections and repairs. Several Indian silo manufacturers now provide maintenance kits and digital maintenance reminders for efficient site management.

How Modern Cement Silos Improve Safety and Efficiency

Advanced cement silos come equipped with automation and smart features:

Digital level indicators reduce manual checks.

PLC and SCADA systems allow real-time monitoring.

Better insulation and ventilation improve material preservation.

Adopting modern silo technology improves project timelines and supports remote monitoring features particularly useful in large-scale highway and infrastructure projects.

To Conclude

Handling cement silos properly is a key part of safe and efficient construction site operations. Following best practices for loading, unloading, and maintenance helps prevent accidents and material wastage. By choosing reliable equipment and adhering to safety protocols, site operators can ensure a smooth and secure workflow across construction and infrastructure projects.

FAQs

1. What is the purpose of a fly ash silo in construction?Ans: Fly ash silos store fly ash, a byproduct of coal combustion used in cement and concrete mixes to improve strength and durability. These silos help keep the material dry and uncontaminated. For projects in humid areas, look for silos with moisture control systems.

2. How often should cement silos be inspected?Ans: At a minimum, silos should be inspected once a month. For high-use sites, bi-weekly checks are recommended. Focus on structural integrity, discharge lines, and dust filtration systems. Sites that use SCADA-enabled systems can automate this process with real-time alerts.

3. Can one cement silo be used for different materials?Ans: Technically yes, but not advisable. Using the same silo for both cement and fly ash can lead to contamination and inconsistent mixing quality. Best practice is to use dedicated silos for each material.

4. What are the common causes of blockages in cement silos?Ans: Moisture infiltration, lack of routine discharge cleaning, and irregular maintenance schedules are major causes. Using anti-bridging devices, air dryer systems, and regular vent cleaning helps prevent buildup.

5. Are mobile silos a better option for remote projects?Ans: Yes. Mobile silos are particularly useful for projects in remote or temporary locations. They offer quick setup and disassembly, and reduce transportation costs by eliminating the need to haul cement daily from fixed storage units.

0 notes

Text

What Is a Mixed Bill Counter and How Does It Work?

In today's fast-paced business environment, efficiency and accuracy are key components of success. Whether you're managing a retail store, a bank, a casino, or any other cash-heavy operation, handling money manually can be time-consuming and error-prone. This is where a mixed bill counter comes in — an innovative piece of technology designed to streamline the cash handling process while reducing human error.

In this article, we’ll explore what a mixed bill counter is, how it works, and why investing in the best mixed bill counter is a smart decision for any business. We'll also spotlight a trusted brand in the industry: Cassida USA.

What Is a Mixed Bill Counter?

A mixed bill counter is a type of money counting machine that can recognize and count different denominations of banknotes in a single pass. Unlike traditional bill counters, which require all bills to be sorted by denomination before being fed into the machine, a mixed bill counter can handle unsorted stacks of currency. It uses advanced recognition technologies to detect the value of each note and provides a total count and value instantly.

This innovation not only saves time but also greatly reduces the chances of human error, making it an essential tool for businesses dealing with high volumes of cash.

How Does a Mixed Bill Counter Work?

Mixed bill counters are equipped with several technologies that work in tandem to identify and count currency accurately:

1. Currency Recognition Technology

At the heart of every mixed bill counter is a system that uses optical sensors and image recognition to identify the denomination of each bill. These sensors scan both sides of each note to detect unique features such as:

Size and dimensions

Colors and patterns

Security features like watermarks, micro-printing, and holograms

The machine then cross-references this data with pre-programmed templates for each denomination, enabling it to differentiate between $1, $5, $10, $20, $50, and $100 bills automatically.

2. Magnetic and Ultraviolet (UV) Detection

To prevent counterfeit currency from slipping through, most high-end mixed bill counters incorporate counterfeit detection technologies. Magnetic sensors detect magnetic ink used in legitimate notes, while UV sensors check for fluorescent symbols and threads embedded in genuine currency.

3. Infrared (IR) Detection

IR sensors further enhance the machine’s ability to verify the authenticity of each bill by checking for IR ink patterns that are invisible to the naked eye.

4. Batching and Sorting Features

Many of the best mixed bill counters also offer batching and sorting features. For example, you can set the machine to count a certain number of bills at a time, or to sort out specific denominations or suspect bills for further review.

Benefits of Using a Mixed Bill Counter

1. Time-Saving

One of the primary advantages of using a mixed bill counter is the time it saves. Counting cash manually can take hours, especially if the bills are not sorted. A mixed bill counter can process hundreds, even thousands, of notes in minutes.

2. Improved Accuracy

Even the most diligent employee can make mistakes when counting large amounts of cash. A mixed bill counter minimizes the chance of error and ensures every cent is accounted for.

3. Counterfeit Detection

With counterfeit detection features, you can rest assured that every bill that passes through the machine is thoroughly examined for authenticity.

4. Convenience

Mixed bill counters eliminate the need to sort money beforehand, allowing staff to focus on other tasks. They also produce printed reports and summaries for easy record-keeping and audits.

5. Professional Image

Using advanced cash handling equipment conveys a sense of professionalism and reliability to customers and business partners.

Who Needs a Mixed Bill Counter?

Mixed bill counters are ideal for a variety of industries, including:

Retail Stores: Daily cash register reconciliation becomes faster and more accurate.

Banks and Credit Unions: Large volumes of deposits and withdrawals can be processed with ease.

Casinos and Gaming Centers: Handle significant amounts of cash quickly and securely.

Restaurants and Cafés: Manage cash from multiple tills effortlessly.

Churches and Charities: Accurately count donations made in various denominations.

Choosing the Best Mixed Bill Counter

When selecting a mixed bill counter, it's important to consider several key features:

Counting Speed: Look for machines that offer fast throughput (at least 1,000 notes per minute).

Multi-Currency Support: If your business deals with international cash, choose a model that can handle multiple currencies.

Ease of Use: User-friendly interfaces, clear displays, and intuitive operation are essential.

Counterfeit Detection: Make sure the machine includes magnetic, UV, and IR detection.

Durability and Warranty: A reliable build and good manufacturer support will save you from headaches down the line.

One of the top providers of cash handling equipment is Cassida USA, a brand known for quality, precision, and innovation in the industry.

Why Choose Cassida USA?

Cassida USA has established itself as a trusted name in currency handling solutions. Their mixed bill counters combine high-speed performance with state-of-the-art detection features, all housed in sleek, user-friendly designs.

Popular models like the Cassida Zeus or Cassida Quattro are known for:

Superior counterfeit detection

High counting speeds

Reliable performance under heavy usage

Touchscreen displays for ease of use

Compatibility with both U.S. and international currency

With a commitment to customer satisfaction and cutting-edge technology, Cassida USA consistently delivers some of the best mixed bill counters on the market.

Explore their full range of mixed bill counters here: https://cassidausa.com/collections/mix-bill-counters

Conclusion

In a world where time is money, a mixed bill counter offers an efficient, accurate, and secure way to manage your cash flow. Whether you run a small business or oversee operations for a large financial institution, investing in a reliable machine from a reputable brand like Cassida USA can save you both time and money.

From rapid currency recognition to advanced counterfeit detection, the best mixed bill counters are more than just counting machines — they’re essential tools for modern money management.

Make the smart move. Automate your cash counting process and experience the difference a professional-grade mixed bill counter can make.

1 note

·

View note

Text

Ready-Mix Concrete Market Growth Driven By Urban Infrastructure Expansion

The Ready-Mix Concrete Market is experiencing accelerated growth, largely fueled by the rapid expansion of urban infrastructure across the globe. As metropolitan areas evolve to accommodate population booms and economic progress, demand for construction materials that deliver speed, strength, and scalability—like ready-mix concrete (RMC)—has intensified significantly.

Urbanization Sparks Strong Demand

With global urban populations growing at unprecedented rates, cities face pressure to enhance housing, mobility, and essential utilities. Ready-mix concrete, known for its quality consistency and efficiency, is increasingly favored in the construction of roads, metro systems, tunnels, bridges, and large residential and commercial projects.

In regions such as Southeast Asia, Sub-Saharan Africa, and parts of Latin America, new city zones and urban extensions are being built from the ground up. These megaprojects rely on high-volume, precise delivery—features that RMC suppliers are uniquely equipped to provide.

Public Infrastructure Projects Drive Consumption

Governments around the world are scaling up infrastructure budgets, seeing public works as economic catalysts. In India, the Smart Cities Mission has driven large-scale RMC usage in rapid transit, stormwater systems, and energy-efficient buildings. In the U.S., the Infrastructure Investment and Jobs Act is earmarking over $1 trillion for highways, ports, and broadband, all requiring concrete in massive quantities.

Emerging economies are likewise directing funds into roads, water systems, and urban housing. Ready-mix concrete, with its time-saving batch mixing process and regulated quality control, is vital in these cost-conscious yet high-speed initiatives.

Superior Efficiency and Quality Assurance

Urban construction projects face several challenges: limited space, tight timelines, and labor shortages. RMC addresses these pain points by offering:

Factory-controlled quality: Batching plants monitor mix ratios to deliver consistent results.

Reduced on-site labor: Fewer workers are needed for mixing, lowering costs and safety risks.

Faster completion: Concrete is delivered ready to pour, minimizing construction delays.

Additionally, batching plants are often strategically located near high-demand zones, reducing delivery times and ensuring uninterrupted project flow.

Technological Enhancements Aid Urban Construction

Urban developers are also leveraging new technologies in concrete mix design. Today’s RMC includes self-compacting, fiber-reinforced, and temperature-controlled variants. These innovations improve workability in constrained sites and enhance load-bearing capacity for large-scale structures.

Digital integration is another growth catalyst. Contractors use real-time delivery tracking, sensor-based slump measurement, and automated plant controls to ensure consistency. These features are particularly critical in urban environments where construction timelines are often non-negotiable.

Regulatory Pressures and Environmental Goals

As cities adopt sustainability frameworks, the construction sector is under increasing scrutiny for its environmental footprint. RMC producers are responding by adopting:

Low-carbon cement blends

Recycled water use

Waste management systems at batching plants

Urban building codes now often require LEED or BREEAM-certified construction. RMC plays a central role in meeting such criteria by offering pre-tested, specification-compliant mixes that reduce overall site emissions.

Urban Resilience and Climate Readiness

Climate-resilient infrastructure is a growing priority for urban planners. RMC is vital in constructing flood-resistant buildings, sea walls, and drainage systems. In coastal cities, special formulations of ready-mix concrete are being used for salinity resistance and long-term durability.

As extreme weather events increase, RMC’s flexibility in composition enables builders to tailor solutions that stand the test of time while still meeting fast-paced project schedules.

Future Outlook: Expansion with Strategy

The ready-mix concrete industry is responding to urban growth by investing in regional batching capacity, fleet upgrades, and process digitization. Leading players are forming partnerships with public agencies, real estate developers, and transit authorities to secure long-term supply contracts.

Markets like China, Indonesia, Brazil, and Egypt are forecast to experience double-digit RMC growth in the next five years as megacities emerge and peri-urban zones expand.

Conclusion

Urban infrastructure expansion is transforming the landscape of the Ready-Mix Concrete Market. With high-performance requirements, sustainable building standards, and rising urban density, RMC is emerging not just as a preferred material but as an urban construction essential. As infrastructure evolves, so will the role of RMC—cementing its position in building the cities of tomorrow.

#urbaninfrastructure#readymixconcrete#constructiontrends#cementindustry#smartcities#sustainablebuilding#civilengineering#concreteinnovation#infrastructuredevelopment#urbanplanning

0 notes

Text

Auger Filling Machine: The Ultimate Guide for Precision Powder Packaging

What is an Auger Filling Machine?

An auger filling machine is a specialized device used to fill powdered or granular products into containers such as pouches, bottles, jars, or cans. It uses a rotating screw-like device (auger) to control and dispense a specific quantity of product into packaging with exceptional accuracy.

Whether for fine powders like talcum or coarse materials like detergent granules, auger fillers ensure uniform dosing and minimal product wastage.

How Does an Auger Filler Work?

The machine operates by rotating an auger screw housed within a funnel-like hopper. As the auger turns, it displaces product down into the container. The amount of product dispensed is controlled by:

The auger screw’s pitch

Speed of rotation

Number of rotations per cycle

Auger fillers can operate in volumetric mode (pre-set volume) or gravimetric mode (based on weight, with load cell integration).

Types of Auger Filling Machines

1. Semi-Automatic Auger Filler

Ideal for low-volume production, small businesses, or startups. Operators place the container manually under the nozzle. A foot pedal or button initiates the fill.

2. Automatic Auger Filler

Integrated into full packaging lines with conveyor systems. The process—from container feeding to filling—is completely automated.

3. Vertical Form Fill Seal (VFFS) with Auger

Combines film-forming and pouch sealing with auger filling in a vertical format. Common in snacks, spices, and dairy creamer packaging.

4. Rotary Auger Fillers

Used in high-speed applications where bottles or jars move in a rotary carousel under the filling heads.

Applications of Auger Filling Machines

Food Industry

Spices (turmeric, chili, cumin, garam masala)

Flour and baking mixes

Protein powders

Instant drink powders

Coffee, tea, sugar

Pharmaceuticals & Nutraceuticals

Antibiotic powders

Oral rehydration salts (ORS)

Ayurvedic powders

Nutritional supplements

Cosmetics

Face powders

Dry shampoos

Clay masks

Chemical & Agro Industries

Fertilizer powders

Detergents

Laboratory reagents

Key Features of Modern Auger Filling Machines

1. Servo Motor Drive

Enables precise control of the auger screw, enhancing fill accuracy and repeatability.

2. Touchscreen HMI & PLC Control

User-friendly interface for recipe settings, diagnostics, and batch counting.

3. Dust Extraction System

Protects both operator health and product integrity by removing airborne particles.

4. Tool-Free Changeover

Fast cleaning and auger replacement for different product types or weights.

5. Level Sensor Integration

Automatically controls hopper refilling to avoid overflows or underfills.

Advantages of Auger Filling Machines

High Accuracy: ±1–2% fill tolerance depending on product.

Hygienic and GMP Compliant: Stainless steel contact parts (SS304 or SS316).

Versatile: Works with both free-flowing and non-free-flowing powders.

Scalable: From manual operations to fully automated high-speed lines.

Low Maintenance: Rugged design with minimal wear and tear.

0 notes

Text

Revolutionizing Sauce Production with a Food Grade Mayonnaise Processing Machine

In the modern food industry, the food grade mayonnaise processing machine has become an essential tool for large-scale condiment manufacturers. These machines ensure consistent texture, superior hygiene standards, and optimal productivity in producing mayonnaise. From small commercial setups to large-scale food factories, the demand for highly efficient and automated equipment has grown tremendously. With changing consumer expectations for taste, quality, and food safety, these machines have emerged as the gold standard in mayonnaise production. A well-engineered food grade mayonnaise processing machine not only streamlines mixing and emulsification but also maintains perfect balance in viscosity and flavor, which is vital for brands striving for excellence.

A critical advantage of using a food grade mayonnaise processing machine lies in its compatibility with automatic mayonnaise making machines that support continuous production. These machines are designed to handle precise mixing cycles and ingredient proportions with minimal human interference. The integration of commercial mayonnaise processing equipment enables businesses to meet large-scale market demands without compromising on hygiene or efficiency. In contrast to manual methods, which often introduce inconsistency and risk of contamination, these automated systems maintain a controlled environment. This ensures that every batch of mayonnaise maintains the same high quality, taste, and shelf life — making the food grade mayonnaise processing machine a must-have for any serious food manufacturer.

Another compelling aspect of the food grade mayonnaise processing machine is the robust build and hygienic design, typically made with stainless steel mayonnaise mixers that are corrosion-resistant and easy to clean. Stainless steel construction is crucial for maintaining cleanliness, preventing bacterial growth, and ensuring food-grade compliance. These mixers are also designed for easy disassembly and sanitation, making daily cleaning routines quick and effective. Furthermore, these machines often come with programmable logic controllers (PLCs) that allow operators to monitor and fine-tune parameters like mixing speed, temperature, and emulsion duration. This versatility and precision underline why investing in a food grade mayonnaise processing machine can lead to higher operational efficiency and long-term savings in maintenance and labor.

As global demand continues to rise for packaged and processed foods, industries are increasingly turning to complete industrial mayonnaise production lines powered by advanced food grade mayonnaise processing machine. These lines typically include pre-mixing units, high-shear emulsifiers, holding tanks, and filling stations, all of which work in unison to deliver seamless production. The scalability of these systems allows manufacturers to adapt to changing production volumes without overhauling the entire infrastructure. Moreover, with enhanced automation, smart diagnostics, and energy efficiency, a food grade mayonnaise processing machine not only enhances product consistency but also aligns with sustainable manufacturing practices. Ultimately, these machines are reshaping the way modern food businesses operate, providing them with the technology and assurance needed to thrive in a competitive market. Tags: automatic mayonnaise making machine commercial mayonnaise processing equipment stainless steel mayonnaise mixer industrial mayonnaise production line

0 notes

Text

Green Construction with Ready Mix Concrete in Pakistan

In recent years, the construction industry in Pakistan has undergone a transformation, embracing innovation, sustainability, and modern building practices. One of the most significant developments in this shift is the widespread adoption of Ready Mix Concrete in Pakistan. As environmental concerns grow and green building standards become more critical, construction professionals are turning to ready mix concrete (RMC) as a sustainable, efficient, and eco-conscious choice. This article explores how Allied Materials, a leading construction material supplier, is helping Pakistan build a greener future with ready mix concrete — while meeting the demands of modern infrastructure and development.

Understanding the Need for Green Construction in Pakistan

Pakistan is facing a variety of environmental challenges, from air pollution and water shortages to rapid urbanization and deforestation. As urban areas expand, the construction industry is under increasing pressure to adopt sustainable practices that:

Reduce carbon emissions

Minimize resource consumption

Improve energy efficiency

Protect the natural environment

Green construction — also known as sustainable or environmentally responsible building — focuses on minimizing the negative environmental impacts of construction processes and materials. It also enhances long-term building performance, reduces operational costs, and improves the health of occupants.

In this context, Ready Mix Concrete in Pakistan is proving to be an essential ally in promoting greener construction.

What Is Ready Mix Concrete?

Ready mix concrete is a pre-mixed formulation of cement, aggregates, water, and sometimes admixtures. It is produced in a controlled environment at a batching plant and then transported to the construction site in specially designed transit mixers.

Unlike traditional on-site mixing, which often leads to inconsistencies and waste, RMC ensures:

Precise proportions

Consistent quality

Faster delivery and application

Enhanced durability

Why Ready Mix Concrete Supports Green Building

1. Reduces Material Waste

On-site mixing can lead to over-ordering, spillage, or incorrect mix ratios. With RMC, batching is done in a controlled plant, which means exact quantities are produced based on project requirements, minimizing excess and reducing waste.

2. Energy Efficiency

Producing concrete at a centralized location is significantly more energy-efficient than mixing it on multiple job sites. It reduces redundant processes and allows manufacturers like Allied Materials to implement energy-saving technologies during production.

3. Lower Carbon Footprint

One of the major contributors to greenhouse gas emissions in construction is the inefficient use of cement. RMC plants can optimize cement content while maintaining strength, reducing the embodied carbon in each cubic meter of concrete.

4. Reduced Site Pollution

Traditional mixing methods can create dust, noise, and water pollution. Ready mix concrete minimizes these effects by eliminating on-site mixing. Allied Materials also uses closed systems and dust collection technologies to limit emissions at their batching plants.

5. Recyclable and Reusable Materials

Modern RMC practices include the recycling of wash water, aggregates, and returned concrete, ensuring that even leftovers are put to productive use instead of being discarded.

Leading the Green Revolution in Pakistan’s Construction Sector

As a top-tier supplier of Ready Mix Concrete in Pakistan, Allied Materials stands at the forefront of sustainable construction innovation. With a focus on quality, environmental responsibility, and client satisfaction, Allied is transforming how construction materials are produced and used in Pakistan.

Key Green Initiatives by Allied Materials:

Modern Batching Plants

Allied Materials operates advanced batching facilities equipped with automated systems to minimize material loss and energy use. These plants are strategically located to reduce transport distances and emissions.

Eco-Friendly Admixtures

By using chemical admixtures that enhance performance, Allied can produce high-strength concrete with less cement, further reducing carbon emissions.

Water Recycling Systems

Allied’s plants are equipped with recycling systems that reuse wash water, helping conserve Pakistan’s precious water resources.

Sustainable Supply Chain

From sourcing raw materials to delivering concrete, Allied Materials emphasizes local procurement and efficient logistics, which cuts down on fuel consumption and supports the local economy.

Green Certifications

Allied is actively working with clients on LEED (Leadership in Energy and Environmental Design) and other green-certified projects, offering concrete mixes that meet rigorous sustainability criteria.

Applications of Ready Mix Concrete in Sustainable Development

RMC isn’t just for large commercial projects. Its flexibility, efficiency, and sustainability benefits make it suitable for a wide range of eco-friendly developments across Pakistan:

Residential Construction

New housing societies in cities like Lahore, Islamabad, and Karachi are opting for ready mix concrete to ensure stronger, longer-lasting, and environmentally responsible homes.

Green Commercial Buildings

From LEED-certified office towers to malls and hospitals, RMC helps achieve energy and sustainability targets through efficient material usage and consistent quality.

Infrastructure Projects

Bridges, highways, and flyovers benefit from RMC’s speed of application, reduced material wastage, and superior strength, reducing future maintenance and carbon emissions.

Agricultural & Water Projects

Irrigation channels, dams, and water tanks made with eco-conscious RMC solutions offer better leak prevention and durability, essential for managing Pakistan’s scarce water resources.

The Economic Advantages of Green Construction with RMC

While sustainable materials like ready mix concrete may seem costlier initially, they provide significant long-term savings through:

Reduced maintenance costs

Fewer construction delays

Lower energy usage in buildings

Increased property value

Eligibility for government incentives or tax benefits on green projects

For contractors, developers, and property owners alike, the return on investment from using high-quality RMC in green projects is both tangible and enduring.

Government and Industry Support for Sustainable Materials

Pakistan’s government is showing increasing support for green construction. Initiatives such as:

Green Building Guidelines by the Pakistan Green Building Council (PGBC)

Incentives for renewable energy and sustainable housing

Encouragement for local production of eco-friendly materials

These are fostering a more environmentally responsible construction landscape — and Ready Mix Concrete in Pakistan is a key enabler of this shift.

Where Is Green RMC Headed in Pakistan?

Smart Concrete Technologies

Research is ongoing into “smart concrete” that can heal itself, resist pollutants, and store energy. Allied Materials is keen to adopt such innovations as they become commercially viable.

Modular and Prefab Construction

RMC pairs well with prefabricated structures, which are growing in popularity for their speed, cost-efficiency, and sustainability.

IoT and Automation in Concrete Delivery

Smart sensors and AI are being used to optimize mix design, monitor curing times, and ensure precise quality control, reducing waste and increasing efficiency.

Why Choose Allied Materials for Ready Mix Concrete in Pakistan?

When it comes to eco-friendly and performance-driven RMC, Allied Materials is a name you can trust.

Reliable Delivery

A fleet of modern transit mixers ensures on-time, on-site delivery across major urban centers and remote project sites.

Custom Mix Designs

Every project is different. Allied offers tailored mix designs to meet specific strength, workability, and sustainability goals.

Strong Customer Support

From technical consultations to on-site troubleshooting, Allied provides end-to-end assistance to contractors, engineers, and developers.

Competitive Pricing

High quality doesn’t mean high cost. Allied offers competitive rates for RMC without compromising environmental responsibility.

Conclusion

Pakistan’s journey toward sustainable construction is gaining momentum, and Ready Mix Concrete in Pakistan is playing a vital role in this transformation. From reducing waste and emissions to boosting efficiency and long-term building performance, RMC offers a greener alternative to traditional concrete methods. With leaders like Allied Materials at the forefront, the future of green construction in Pakistan looks stronger, smarter, and more sustainable. Whether you're building a housing project, industrial plant, or urban infrastructure, ready mix concrete is the foundation of a better tomorrow.

0 notes

Text

Everything You Should Know Before Mixing Salt Nic with Regular E-Juice