#Material Science Engineering

Explore tagged Tumblr posts

Text

For 200 years, scientists have failed to grow a common mineral in the laboratory under the conditions believed to have formed it naturally. Now, a team of researchers from the University of Michigan and Hokkaido University in Sapporo, Japan have finally succeeded, thanks to a new theory developed from atomic simulations. Their success resolves a long-standing geology mystery called the "Dolomite Problem." Dolomite—a key mineral in the Dolomite mountains in Italy, Niagara Falls, the White Cliffs of Dover and Utah's Hoodoos—is very abundant in rocks older than 100 million years, but nearly absent in younger formations. "If we understand how dolomite grows in nature, we might learn new strategies to promote the crystal growth of modern technological materials," said Wenhao Sun, the Dow Early Career Professor of Materials Science and Engineering at U-M and the corresponding author of the paper published today in Science. The secret to finally growing dolomite in the lab was removing defects in the mineral structure as it grows. When minerals form in water, atoms usually deposit neatly onto an edge of the growing crystal surface. However, the growth edge of dolomite consists of alternating rows of calcium and magnesium.

Continue Reading.

1K notes

·

View notes

Text

On the Mechanics of Wet Sand

Sand is a critical component of many built environments. As most of us learn (via sand castle), adding just the right amount of water allows sand to be quite strong. But with too little water -- or too much -- sand is prone to collapse. (Video and image credit: Practical Engineering) Read the full article

70 notes

·

View notes

Text

For a different project I was reading about developments in induction heating technologies and realized I had a small misunderstanding about how induction stoves work.

So, the classic misunderstanding is in why steel works on an induction hob but aluminium doesn't. Most people assume this is because you need a magnetic material in order to induce a current, but if you know your physics you know this isn't true. You can induce a current in any conductor, and indeed inducing currents in aluminium is something that happens in industry all the time.

So then you get to my understanding of why you can't use aluminium and copper, which is that they're too good at conducting electricity. Induction generates a voltage that pushes a current through the material. Aluminium and copper are much better conductors than steel, so the generated potential is lower and the overall current is lower as a result of material interactions with the field, so you don't get nearly as much heat out of induction on aluminium as on steel. This was what I thought. This is also wrong, although it's closer.

The actual answer is one step deeper. Induction hobs have to operate at pretty high frequencies, usually 24-ish kHz, both for audible noise reasons and, crucially, because they rely heavily on the skin effect. Interestingly this makes that first wrong explanation kind of more correct, I'll get to that in a moment.

The skin effect is a thing that happens when you have an alternating current in a bulk material; the AC signal sets up magnetic fields that force current to flow in a thin layer closer to the surface of the solid rather than flowing evenly throughout the material. This increases the effective resistance of the material, since you end up with a reduced effective surface area through which current can flow. The skin effect gets more pronounced at higher frequencies, and it's part of why you'll see bundles of smaller cables used to conduct high power AC: each cable has its own skin that can carry more current than the same quantity of material in one bulk cable.

In the right kinds of steel and iron, 24kHz is enough to generate a current carrying skin only a few tenths of a millimeter thick, which has a high enough resistance to generate the heat needed for cooking. Ferromagnetic materials have very high magnetic permeability, which causes them to experience much stronger skin effects. Copper and aluminium, between their high conductivity and lower magnetic permeability, have much weaker skin effects, their skins at 24kHz are much thicker, and so you just can't kick up enough resistance to the current to generate heat, it just spins around in there getting kind of warm but you'd have a hard time actually cooking with it. Indeed, non-magnetic stainless steel also won't work on induction hobs, because it also has a much thicker skin effect.

So you have the "real answer" being a fun hybrid of the two incorrect explanations.

The main side effects I take away from this are twofold.

1) you can absolutely make an induction hob that will heat copper and aluminum and non-magnetic stainless steels, you just need a high enough frequency to generate a strong enough skin effect to generate heat. Panasonic makes one that uses 60+kHz induction under the brand "Met-all".

2) if you physically constrain the current by having a really thin piece of metal, you can induction heat it anyway. When I read this, I stopped, took out a piece of aluminium foil, and stuck it on my induction cooktop. It almost immediately got incredibly hot and I pulled it away before anything bad happened. Turns out you could definitely melt and maybe even vaporize aluminium this way. So don't do that. Apparently people do this with lightweight titanium cookware too, which would not be able to sustain the necessary currents in a large bulk solid but can if you thin the base of the pan out enough.

779 notes

·

View notes

Text

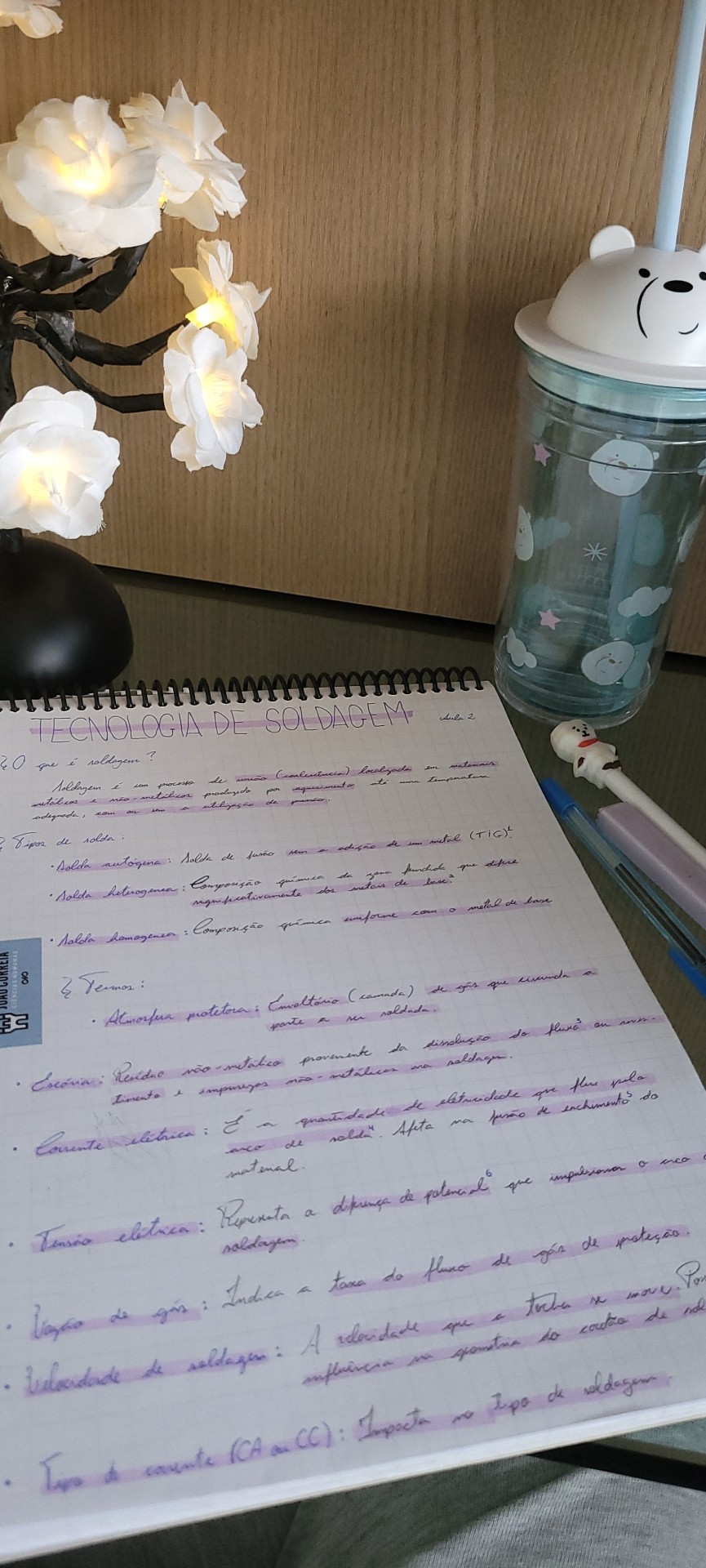

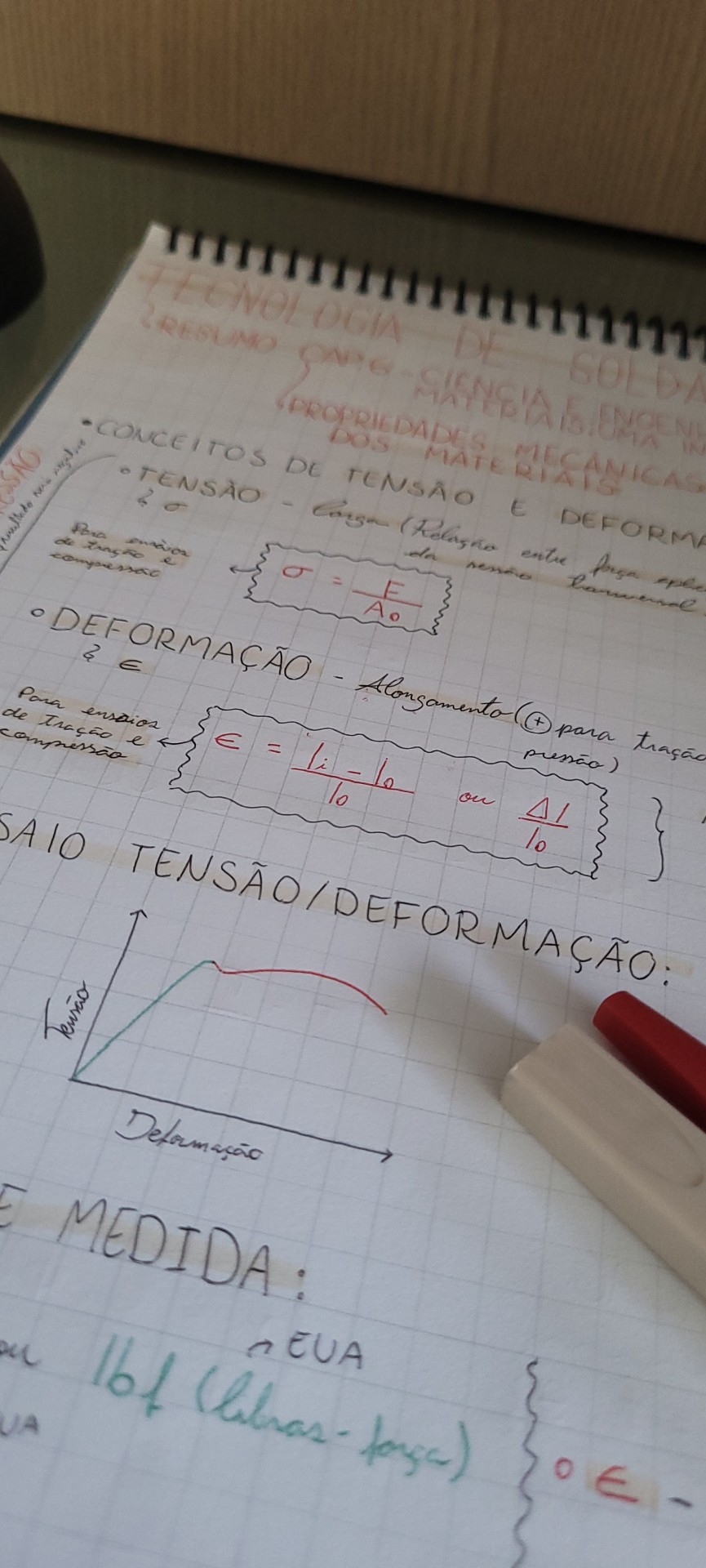

20/08/24

I forgot to post this yesterday 'cause I got home so late from uni 😭

Yesterday was a pretty tiring, but worth it, day of studying since I missed an entire week of class and had to study all of the content from last week's welding technology class + study from a texbook on science and engineering of materials.

Content studied yesterday:

> Stress-Strain of metals under tension, compression, sheer and torsion tests ;

> Stress-Strain graph (elastic and plastic strain, recognition of ductile and brittle materials, points of elastic limit, yielding, ultimate strength and rupture) ;

> General types of welding ;

> Concepts of welding technology .

My welding technology class went great and I was relieved when I found myself following the explanations with ease and being able to participate because of successful studying and absorption of the last class' content through photos of the board that my classmate sent me. I was really scared I would fall behind but I feel pretty confident and intrigued by the subject and engineering in general... I think I'm finally falling in love with it!

#mechanical engineering#college studyblr#engineering#studyblr#study blog#academic validation#college student#stem academia#study motivation#stem student#materials science#materials engineering#student life#stem#study#student#welding#welding technology#engineering studyblr#engineering major#mechanical engineer#engineer#university student#uni life#Spotify

69 notes

·

View notes

Text

A bioreactor that mimics a circulatory system can deliver nutrients and oxygen to artificial tissue, enabling the production of over 10 grams of chicken muscle for cultured meat applications. These results are publishing in the Cell Press journal Trends in Biotechnology on April 16. "Our study presents a scalable, top-down strategy for producing whole-cut cultured meat using a perfusable hollow fiber bioreactor," says senior author Shoji Takeuchi of The University of Tokyo. "This system enables cell distribution, alignment, contractility, and improved food-related properties. It offers a practical alternative to vascular-based methods and may impact not only food production but also regenerative medicine, drug testing, and biohybrid robotics."

Read more.

22 notes

·

View notes

Text

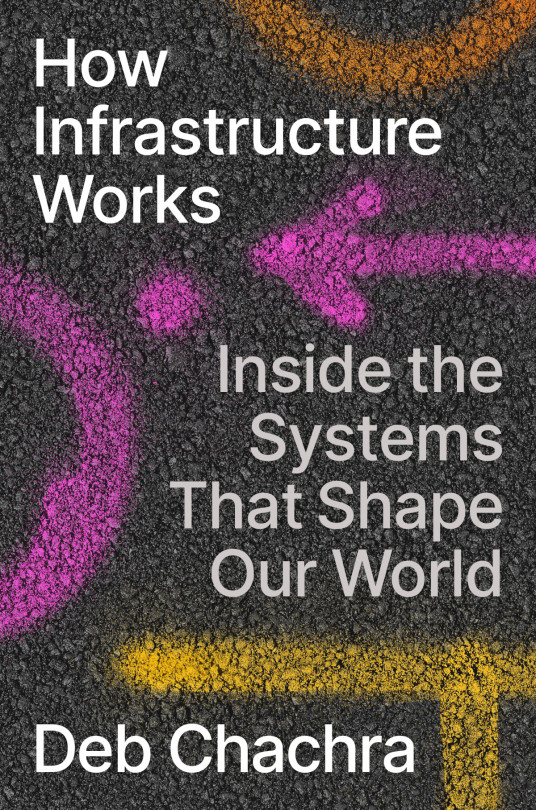

Deb Chachra's "How Infrastructure Works": Mutual aid, the built environment, the climate, and a future of comfort and abundance

This Thursday (Oct 19), I'm in Charleston, WV to give the 41st annual McCreight Lecture in the Humanities. And on Friday (Oct 20), I'm at Charleston's Taylor Books from 12h-14h.

Engineering professor and materials scientist Deb Chachra's new book How Infrastructure Works is a hopeful, lyrical – even beautiful – hymn to the systems of mutual aid we embed in our material world, from sewers to roads to the power grid. It's a book that will make you see the world in a different way – forever:

https://www.penguinrandomhouse.com/books/612711/how-infrastructure-works-by-deb-chachra/

Chachra structures the book as a kind of travelogue, in which she visits power plants, sewers, water treatment plants and other "charismatic megaprojects," connecting these to science, history, and her own memoir. In so doing, she doesn't merely surface the normally invisible stuff that sustains us all, but also surfaces its normally invisible meaning.

Infrastructure isn't merely a way to deliver life's necessities – mobility, energy, sanitation, water, and so on – it's a shared way of delivering those necessities. It's not just that economies of scale and network effects don't merely make it more efficient and cheaper to provide these necessities to whole populations. It's also that the lack of these network and scale effects make it unimaginable that these necessities could be provided to all of us without being part of a collective, public project.

Think of the automobile versus public transit: if you want to live in a big, built up city, you need public transit. Once a city gets big enough, putting everyone who needs to go everywhere in a car becomes a Red Queen's Race. With that many cars on the road, you need more roads. More roads push everything farther apart. Once everything is farther apart, you need more cars.

Geometry hates cars. You can't bargain with geometry. You can't tunnel your way out of this. You can't solve it with VTOL sky-taxis. You can't fix it with self-driving cars whose car-to-car comms let them shave down their following distances. You need buses, subways and trams. You need transit. There's a reason that every plan to "disrupt" transportation ends up reinventing the bus:

https://stanforddaily.com/2018/04/09/when-silicon-valley-accidentally-reinvents-the-city-bus/

Even the cities we think of as motorists' paradises – such as LA – have vast, extensive transit systems. They suck – because they are designed for poor people – but without them, the city would go from traffic-blighted to traffic-destroyed.

The dream of declaring independence from society, of going "off-grid," of rejecting any system of mutual obligation and reliance isn't merely an infantile fantasy – it also doesn't scale, which is ironic, given how scale-obsessed its foremost proponents are in their other passions. Replicating sanitation, water, rubbish disposal, etc to create individual systems is wildly inefficient. Creating per-person communications systems makes no sense – by definition, communications involves at least two people.

So infrastructure, Chachra reminds us, is a form of mutual aid. It's a gift we give to ourselves, to each other, and to the people who come after us. Any rugged individualism is but a thin raft, floating on an ocean of mutual obligation, mutual aid, care and maintenance.

Infrastructure is vital and difficult. Its amortization schedule is so long that in most cases, it won't pay for itself until long after the politicians who shepherded it into being are out of office (or dead). Its duty cycle is so long that it can be easy to forget it even exists – especially since the only time most of us notice infrastructure is when it stops working.

This makes infrastructure precarious even at the best of times – hard to commit to, easy to neglect. But throw in the climate emergency and it all gets pretty gnarly. Whatever operating parameters we've designed into our infra, whatever maintenance regimes we've committed to for it, it's totally inadequate. We're living through a period where abnormal is normal, where hundred year storms come every six months, where the heat and cold and wet and dry are all off the charts.

It's not just that the climate emergency is straining our existing infrastructure – Chachra makes the obvious and important point that any answer to the climate emergency means building a lot of new infrastructure. We're going to need new systems for power, transportation, telecoms, water delivery, sanitation, health delivery, and emergency response. Lots of emergency response.

Chachra points out here that the history of big, transformative infra projects is…complicated. Yes, Bazalgette's London sewers were a breathtaking achievement (though they could have done a better job separating sewage from storm runoff), but the money to build them, and all the other megaprojects of Victorian England, came from looting India. Chachra's family is from India, though she was raised in my hometown of Toronto, and spent a lot of her childhood traveling to see family in Bhopal, and she has a keen appreciation of the way that those old timey Victorian engineers externalized their costs on brown people half a world away.

But if we can figure out how to deliver climate-ready infra, the possibilities are wild – and beautiful. Take energy: we've all heard that Americans use far more energy than most of their foreign cousins (Canadians and Norwegians are even more energy-hungry, thanks to their heating bills).

The idea of providing every person on Earth with the energy abundance of an average Canadian is a horrifying prospect – provided that your energy generation is coupled to your carbon emissions. But there are lots of renewable sources of energy. For every single person on Earth to enjoy the same energy diet as a Canadian, we would have to capture a whopping four tenths of a percent of the solar radiation that reaches the Earth. Four tenths of a percent!

Of course, making solar – and wind, tidal, and geothermal – work will require a lot of stuff. We'll need panels and windmills and turbines to catch the energy, batteries to store it, and wires to transmit it. The material bill for all of this is astounding, and if all that material is to come out of the ground, it'll mean despoiling the environments and destroying the lives of the people who live near those extraction sites. Those are, of course and inevitably, poor and/or brown people.

But all those materials? They're also infra problems. We've spent millennia treating energy as scarce, despite the fact that fresh supplies of it arrive on Earth with every sunrise and every moonrise. Moreover, we've spent that same period treating materials as infinite despite the fact that we've got precisely one Earth's worth of stuff, and fresh supplies arrive sporadically, unpredictably, and in tiny quantities that usually burn up before they reach the ground.

Chachra proposes that we could – we must – treat material as scarce, and that one way to do this is to recognize that energy is not. We can trade energy for material, opting for more energy intensive manufacturing processes that make materials easier to recover when the good reaches its end of life. We can also opt for energy intensive material recovery processes. If we put our focus on designing objects that decompose gracefully back into the material stream, we can build the energy infrastructure to make energy truly abundant and truly clean.

This is a bold engineering vision, one that fuses Chachra's material science background, her work as an engineering educator, her activism as an anti-colonialist and feminist. The way she lays it out is just…breathtaking. Here, read an essay of hers that prefigures this book:

https://tinyletter.com/metafoundry/letters/metafoundry-75-resilience-abundance-decentralization

How Infrastructure Works is a worthy addition to the popular engineering books that have grappled with the climate emergency. The granddaddy of these is the late David MacKay's open access, brilliant, essential, Sustainable Energy Without the Hot Air, a book that will forever change the way you think about energy:

https://memex.craphound.com/2009/04/08/sustainable-energy-without-the-hot-air-the-freakonomics-of-conservation-climate-and-energy/

The whole "Without the Hot Air" series is totally radical, brilliant, and beautiful. Start with the Sustainable Materials companion volume to understand why everything can be explained by studying, thinking about and changing the way we use concrete and aluminum:

https://memex.craphound.com/2011/11/17/sustainable-materials-indispensable-impartial-popular-engineering-book-on-the-future-of-our-built-and-made-world/

And then get much closer to home – your kitchen, to be precise – with the Food and Climate Change volume:

https://pluralistic.net/2021/01/06/methane-diet/#3kg-per-day

Reading Chachra's book, I kept thinking about Saul Griffith's amazing Electrify, a shovel-ready book about how we can effect the transition to a fully electrified America:

https://pluralistic.net/2021/12/09/practical-visionary/#popular-engineering

Chachra's How Infrastructure Works makes a great companion volume to Electrify, a kind of inspirational march to play accompaniment on Griffith's nuts-and-bolts journey. It's a lyrical, visionary book, charting a bold course through the climate emergency, to a world of care, maintenance, comfort and abundance.

If you'd like an essay-formatted version of this post to read or share, here's a link to it on pluralistic.net, my surveillance-free, ad-free, tracker-free blog:

https://pluralistic.net/2023/10/17/care-work/#charismatic-megaprojects

My next novel is The Lost Cause, a hopeful novel of the climate emergency. Amazon won't sell the audiobook, so I made my own and I'm pre-selling it on Kickstarter!

#pluralistic#books#reviews#deb chachra#debcha#engineering#infrastructure#free energy#material science#abundance#scarcity#mutual aid#maintenance#99 percent invisible#colonialism#gift guide

262 notes

·

View notes

Text

An SEM image of a guitar string held down with carbon tape to a sample mount.

24 notes

·

View notes

Text

What is the difference between welding, brazing, and soldering?

A summary of the main points of difference between welding, brazing, and soldering are:

1. Temperature Range:

Welding: Above 1,200°C.

Brazing: From 450°C to 1,100°C.

Soldering: Below 450°C.

2. Strength of Joints:

Welding: Highest.

Brazing: Moderate.

Soldering: Lowest.

3. Applications:

Welding: Heavy-duty construction, automotive, aerospace.

Brazing: HVAC, electrical, automotive.

Soldering: Electronics, plumbing, jewelry.

4. Process complexity:

Welding: Requires high skill and complex equipment.

Brazing: Moderate skill and equipment.

Soldering: Low skill and simple equipment.

#science#materials science#engineering#materials science and engineering#materials#metals#alloys#welding#soldering#brazing#differences

63 notes

·

View notes

Text

Minecraft-style mushroom houses when? 🍄

#fungus among us#science#news#good news#environment#climate crisis#climate change#architecture#engineering#biology#fungi#fungus#materials science#neat stuff

12 notes

·

View notes

Text

Julia Weertman

Materials scientist Julia Weertman was born in 1926 in Mount Lebanon, Pennsylvania. Weertman made significant contributions to the study of basic deformation processes and failure mechanisms in a variety of materials. She used small-angle neutron scattering to study damage and cavitation in metal deformation. This innovative approach resulted in a new view of cavitation, offering a non-destructive technique for gathering information on micrometer-sized cavities. Weertman taught at Northwestern University for 45 years. In 1987, she was appointed Chair of the Department of Materials Science and Engineering, and remained in this role until 1992. In 2003, Weertman won the Von Hippel Award, the Materials Research Society's highest honor. She won the ASM Gold Medal two years later. In 2014, Weertman was honored with the John Fritz Medal from the American Association of Engineering Societies.

Julia Weertman died in 2018 at the age of 92.

15 notes

·

View notes

Text

Mechanics of Materials Professor: "If I heated the room to 300 degrees Fahrenheit...we would not be in here, we would be out."

#college#university#quote blog#student#student life#dialogue#quotes#college quotes#university quotes#school#science#mechanics of materials#mechanical engineering

10 notes

·

View notes

Text

Concrete is an excellent and versatile material, but it's not without its limitations. One of the biggest problems materials scientists are keen to find a workaround for is its brittleness. Concrete doesn't have very high tensile strength at all, which means it's prone to cracking under stress. One way of resolving this issue would be to develop concrete that can fill in its own cracks, and a new method could be that panacea. A team led by mechanical engineer Congrui Grace Jin of Texas A&M University has developed concrete that can heal itself by harnessing the power of synthetic lichen.

Continue Reading.

83 notes

·

View notes

Text

Running Out of Sand?

Headlines over the past few years have suggested that the world is running out of sand -- specifically, that we're running out of the angular sand grains preferred for concrete. Grady breaks down this idea in this Practical Engineering video, showing that the issue is more complicated than the shape of a sand grain. (Video and image credit: Practical Engineering) Read the full article

96 notes

·

View notes

Text

youtube

hell yes

38 notes

·

View notes

Text

The papers in this volume give the reader focused information on the important extractive metallurgy unit operations of drying, roasting, and calcining

#metallurgy#calcination#metals#minerals#science#materials science#engineering#book cover#cover design

5 notes

·

View notes

Text

New hydrogel semiconductor could lead to better tissue-interfaced bioelectronics

The ideal material for interfacing electronics with living tissue is soft, stretchable, and just as water-loving as the tissue itself—in short, a hydrogel. Semiconductors, the key materials for bioelectronics such as pacemakers, biosensors, and drug delivery devices, on the other hand, are rigid, brittle, and water-hating, impossible to dissolve in the way hydrogels have traditionally been built. A paper published today in Science from the UChicago Pritzker School of Molecular Engineering (PME) has solved this challenge that has long stymied researchers, reimagining the process of creating hydrogels to build a powerful semiconductor in hydrogel form. Led by Asst. Prof. Sihong Wang's research group, the result is a bluish gel that flutters like a sea jelly in water but retains the immense semiconductive ability needed to transmit information between living tissue and machine. The material demonstrated tissue-level moduli as soft as 81 kPa, stretchability of 150% strain, and charge-carrier mobility up to 1.4 cm2 V-1 s-1. This means their material—both semiconductor and hydrogel at the same time—ticks all the boxes for an ideal bioelectronic interface.

Read more.

#Materials Science#Science#Hydrogels#Semiconductors#Biomaterials#Tissue engineering#Electronics#University of Chicago

35 notes

·

View notes