#PCB Material Management

Explore tagged Tumblr posts

Text

The Evolution of PCB Manufacturing: From Basics to High-Performance Boards

PCB manufacturing has evolved from single-layer boards to high-performance, multi-layered designs, enabling innovation in automotive, healthcare, telecommunications, and aerospace. Learn how cutting-edge PCB technologies support modern electronics and drive UK industries forward. Explore advanced PCB solutions for your business today.

#PCB manufacturing evolution#high-performance PCBs#multi-layer PCB design#PCB for 5G networks#advanced PCB technology#UK PCB industry#flexible PCBs#PCB signal integrity#automotive PCB solutions#medical device PCBs#aerospace PCB manufacturing#PCB miniaturisation#HDI PCBs#thermal management in PCBs#next-gen PCB solutions#A-Gas Electronic Materials

0 notes

Note

thank you for the reply and the information! I was curious how the other fox would fit in with PCB Extra's metatextual mention of Three Lands, but I hadn't even considered it might be three worlds and not three countries. this is neat

(Original post for context)

I forgot I left the response to this in my drafts, sorry. Luckily, this means I could update it with recently acquired knowledge when I found it again. Truth to be told, my point is less that the other fox is a better match, and more that Ran being Tamamo no Mae is one of these things which make sense at first glance, but the deeper you look into it, the less coherent it becomes.

This got much longer than I planned, so for organizational purposes let's refer to this post as Revenge of the "graveyard god", or why I don't think Ran is Tamamo no Mae. More under the cut.

The early Tamamo no Mae

The main point of connection between Tamamo no Mae and Ran are the nine tails, but that’s not even really a consistent part of the former's background. The oldest version of the story - which is really fun, the seduction section is pages upon pages of Tamamo and emperor Toba discussing esoteric Buddhism - states that she was “an 800-year-old two-tailed fox from the Nasuno Plain in Shimotsuke Province”. Early depictions of her true form follow this pretty closely:

Nezu Museum of Art, via Monsters, Animals, and Other Worlds. A Collection of Short Medieval Japanese Tales

Kyoto University Rare Materials Digital Library

Suntory Museum of Art

As far as I am aware, the two tails are actually unique to her. Other foxes of note have either one tail or nine. While it does seem the belief in the number of tails growing with age is genuine rather than a modern misconception, it’s hardly central to fox folklore (I’ve seen the portmoneu “foxlore” at least once btw, it’s very funny). And, as I will outline later, it doesn’t even seem to be behind the idea of nine-tailed foxes in the first place. Anyway, the oldest version does provide Tamamo with more backstory, but it’s closer to presenting Shuten Dōji as a manifestation of Mara than to a straightforward “Tamamo is x under a pseudonym” popular today. As we learn, the two-tailed fox is in fact a reincarnation of a “graveyard god” (塚の神, Tsuka no Kami) from India, described in the apocryphal Humane Kings Sutra (it gets namedropped directly), likely originally composed in China.

How come? It all started when Kalmashapada, a prince of Devala in India, wanted to offer 1000 skulls of virtuous rulers to this deity because a suspicious “heretical” preacher convinced him it’s a good idea. After defeating and imprisoning 999 such kings, he encountered Shrutasoma, one of the previous incarnations of the historical Buddha, who managed to show him the error of his ways. All of the kings were released, and Kalmashapada was redeemed. The “graveyard god” was less than thrilled, and swore to keep reincarnating as a fox in kingdoms where Buddhism flourished to destroy it. We are told that happened many times, but only one past identity, that of Bao Si (Hōji), comes up. Obviously, eighth century BCE China was not exactly an area famous for Buddhist devotion, but that’s irrelevant here. We are told the endgame is not just to overthrow a righteous ruler, but also to become his replacement. Alas, Tamamo no Mae obviously fails at both of these goals. Still, points for trying.

The story does not provide the deity with a specific identity. However, Nobumi Iyanaga notes that in the referenced sutra he’s Mahakala (the original Makakaraten version, not the joyful Daikokuten). In East Asian Buddhism he is described as dwelling in the graveyards due to acting as both the chief of dakinis and their subduer. At the same time, Iyanaga argues in the context of the Tamamo no Mae story it can be argued he is either implicitly replaced by the dakini par excellence, Dakiniten (closely associated with foxes), or that the deity has no identity other than the fox one.

Later Tamamo developments

Two elements which are mainstays of modern retellings are missing from the oldest version, as you might have noticed. It doesn’t feature the Sesshōseki, which was only added later, seemingly as a way to promote Zen Buddhism, since this extension of the story casts a member of this school as the new protagonist. In the early variants Tamamo’s corpse was brought to the imperial treasury, the same one which shows up in a similar context in the tale of Shuten Dōji, and there is no indication she came back as a vengeful ghost, let alone that she repented and accepted Buddhism, as she does in some of the Sesshōseki variants.

The other difference is, as I already pointed out, the tails. The oldest depiction of a nine-tailed Tamamo no Mae I am aware of is Sekien’s. Based on a few papers I read it would appear textual variants of the story giving her nine tails might have been in circulation earlier, but that’s not reflected in any of the illustrated scrolls shown above.

Sekien's nine-tailed Tamamo (wikimedia commons)

Sekien claims that Tamamo no Mae is one and the same as Daji (I’ll get back to her later), and specifies the latter was a nine-tailed fox. He cites Zhang Dingsi’s Langye Dai Zui Bian (浪挪代醉編, “Langye’s Substitute for Drunkenness: A Compilation”) as his source for this tidbit, but does not explain where does the conflation of the two foxes come from. In contrast with the elaborate reincarnation scheme from the older version, he states Daji simply flew across the sea to reach Japan, without reincarnating.

What is now essentially treated as the “definitive” version of the Tamamo no Mae story, and what cemented her image as a nine-tailed fox, only dates back to 1805. That’s when Ehon Sangoku Yōfuden (絵本三国妖婦伝; “Tales of Enchantresses in the Three Kingdoms”) finished publication. The author, Ranzan Takai (高井蘭山), was an enthusiast of neo-confucian thought, and he wanted to write a story highlighting the time honored confucian belief that dynasties are brought down by suspicious concubines. The real goal was somewhat broader, though -the story of Tamamo no Mae was essentially repurposed as a critique of the concept of women playing an important role in public life.

It needs to be noted here that it is not impossible that the original was already part of a political polemic. Arguments have been made that Tamamo is a fictional representation of Bifukomon-in, for instance. They are certainly linked to the same emperor, Toba.

Bifukomon-in (wikimedia commons)

However, while I would not rule this out altogether, it’s hard to deny the typical medieval penchant for reinterpreting Buddhist material feels more central to the story. It is ultimately a very elaborate twist on the Humane Kings Sutra first and foremost. It belongs to the same world as other fabulous tales about figures from distant Buddhist lands arriving in Japan, alongside the likes of the legend of emperor Suwa of Hadai or the medieval Amaterasu narrative involving Mara (stay tuned for my post about that one).

Ideological motivations aside, in Ranzan’s version an anonymous nine-tailed fox appears as Daji in China, Kayō in India (seemingly a leftover of the original “graveyard god” story; here the prince is convinced to carry out his evil plans by his concubine instead though), and finally Tamamo no Mae in Japan. He also gives a unique account of Tamamo’s arrival in Japan, as far as I am aware: in his novel, she was brought there by Kibi no Makibi, a famous historical envoy to China. This was not his first time as a literary character, a much earlier picture scroll about his adventures is pretty funny (I have Touhou ocs based on it), but I’ll save this discussion for another time.

Not quite Tamamo: the influence of Daji

Daji, as depicted by Hokusai (wikimedia commons)

Daji requires some further discussion. She was initially regarded simply as a non-supernatural wicked concubine, but came to be treated as a fox posing as a human by the Song period. According to Xiaofei Kang the oldest evidence for that comes from 1101, from a Japanese text presumably reflecting an already extant Chinese belief. By the Yuan period it became a commonly accepted view, with Quanxiang Pinghua (全相平話) specifically stating Daji had nine tails. Her fox-like image was finally cemented fully by popular novels in the Ming and Qing periods.

Since there was a preexisting tradition in which Daji was a human woman, a remedy was developed: the “real” Daji was possessed by a fox, who took her name and identity. Curiously, the fox component of her story is otherwise not very important, and some modern authors basically characterize it as “tacked on”: she is the quintessential evil concubine bringing kingdoms to ruin out of a sense of cruelty who just happens to be a fox, and her story doesn’t really depend on preexisting fox-related motifs.

There are multiple accounts of Daji’s deeds, but the most famous one, and at the same time the most likely influence on Razan’s portrayal of her (and thus Tamamo), is Investiture of the Gods. However, he skips the origin attributed to her here: in the Chinese original, Daji is an agent of the goddess Nuwa, though she eventually overdoes it and is rebuked by her former boss for excessive cruelty. This doesn’t really fit well with Tamamo’s backstory, obviously; making her and Daji interchangeable was detrimental to both characters, I feel. A Chinese story dealing with Daji reincarnating does exist, but it’s not exactly similar. In the Ming novel Zhaoyang Qushi (昭陽趣事) she reincarnated as Zhao Hede, a concubine of emperor Cheng of Han. What happens next has been described as “pornographic entertainment enlivened by supernatural and historical costumes”. For more details, check out Rania Huntington’s book from the bibliography below.

Curiously, it is possible Daji was simultaneously an object of active cult, since there is a Song imperial edict outlawing the shrines dedicated to her, Wutong (a southern Chinese spirit who was believed to bring wealth and bewitch people, compared with foxes in the north) and “General Shi” (no clue who that might be, I’d hazard a guess one of the popular pacified vengeful spirit cults but don’t quote me on that). However, another contemporary source instead mentions the outlawing of temples of “fox kings”, so it might also mean that the name of Daji was applied by officials to an unrelated popular fox cult (“fox king” is a reasonably common appellation for supernatural foxes). Both regular and nine-tailed foxes are attested in such a context across history.

Early nine-tailed foxes

An early Chinese depiction of a nine-tailed fox (wikimedia commons)

The early portrayals of nine-tailed foxes are something I started looking into recently because of Ran’s freshly revealed connection to Yuuma: I figured it makes sense that she’d be in origin someone who belongs to the same world as the taotie.

Looking at the earliest Chinese sources, multiple nine-tailed foxes appear in legends about virtuous rulers like Tang, Wen or Yu the Great, essentially as generic good omens, without much fanfare. According to confucian commentaries from the Later Han period, the nine tails were understood as a sign a given emperor will have many descendants. The exception from this generally positive tendency is the Classic of Mountains and Seas, where the nine-tailed fox is described as “man-eating” (something very uncommon in Chinese fox literature). However, it also doesn’t exactly get more spotlight than the other creatures. It’s also treated as a separate animal from regular foxes, not as a particularly old fox. You could say it is to the fox what a bai ze is to an ox, I think. Visual arts add further specimens: the source of this discussion, the nine-tailed fox attendant of Xi Wangmu, later seemingly “decanonized”, and another belonging to the entourage of Zhong Kui. Both of these are hardly eminent and seem to fit the mold of auspicious omens. In Zhong Kui’s case the fox is in one case listed alongside the bai ze which only strengthens this impression. However, it also makes sense that its inclusion would reflect Zhong Kui’s role as a demon queller: he is often portrayed with conquered demons as servants, after all.

Conclusions

To sum up: ultimately it just doesn’t seem nine-tailed foxes are quite as big of a deal as popculture makes them seem, and nine tails are neither exclusive nor innate to Tamamo no Mae. Since that’s the only real point of connection between her and Ran save for a throwaway PCB line which leads to no further references, I maintain there’s no strong case for identifying them with each other, especially since there is no shortage of other candidates.

There’s also the fact that, Daji aside, most other nine-tailed foxes are largely blank slates you can do anything with, while Tamamo has many fairly unique characteristics which would be wasted by randomly slapping her name on Ran, in my opinion. To be fair, ZUN does occasionally make similar mistakes - Yoshika is the main example (remember, the actual legend about Yoshika’s immortality claims he decided to pursue eternal life after having a thrilling affair and has him call himself “strongest madman under heaven”).

I would personally argue ZUN himself probably did not feel strongly about who Ran is supposed to actually be when he originally came up with her, though. None of her spellcards reference Tamamo no Mae. Or any other fox identified with her, for that matter. They do have a more or less consistent theme, but that theme is, broadly speaking, “magic arts”, from onmyodo (Shikigami "Banquet of the Twelve General Gods"), through shugendo (Illusion God "Descent of Izuna-Gongen", Shikigami "The Protection of Zenki and Goki", Superhuman "Soaring En no Ozunu") and esoteric Buddhism (Shikigami "Channeling Dakiniten", Esoteric Sign "Odaishi-sama's Secret Key"), to contemporary stage magic (Shiki Brilliance "Princess Tenko -Illusion-"). In other words, I do not think canon actually strongly supports any specific option.

I will admit I’m biased but personally I think picking a different fox makes it much easier to accommodate Yuuma and their shared animal realm past, the most thrilling Ran development in ages. As for Tamamo, I do think she would be fun to see in Touhou, but preferably as her own character - with two tails, if possible.

Bibliography

Bernard Faure, The Power of Denial. Buddhism, Purity, and Gender

Rania Huntington, Alien Kind. Foxes and Late Imperial Chinese Narrative

Nobumi Iyanaga, Under the Shadow of the Great Śiva: Tantric Buddhism and its Influence on Japanese Mediaeval Culture

Idem, Dākinī in: Brill's Encyclopedia of Buddhism (vol. 2)

Xiaofei Kang, The Cult of the Fox: Power, Gender, and Popular Religion in Late Imperial and Modern China

Laura K. Nüffer, Lady Tamamo in: Keller Kimbrough and Haruo Shirane (eds.), Monsters, Animals, and Other Worlds. A Collection of Short Medieval Japanese Tales

Sumiko Sekiguchi, Gender in the Meiji Renovation: Confucian 'Lessons for Women' and the Making of Modern Japan

Chun-Yi Joyce Tsai, Imagining the Supernatural Grotesque: Paintings of Zhong Kui and Demons in the Late Southern Song (1127-1279) and Yuan (1271-1368) Dynasties

43 notes

·

View notes

Text

“J K Enterprises” is a reputed Sole Proprietorship (Individual) firm, registered in the year 2015. We are engaged in Manufacturing a diverse range of REFRESH PCB Board, Laptop Charger, Mobile Chargers, USB Chargers, Mobile Adapter, Data Cable etc. These products are manufactured in our high-tech manufacturing unit using supreme grade raw material. With the core values of transparency and uprightness, we are building a collaborative platform for ourselves in the market. Our company is facilitated with all kinds of requisites for qualitative production.

Under the proficient management of our mentor, Mr. JUNAID KHAN, we have earned an unrivaled position in the market and gained massive acceptance of our esteemed customers. Our company is based on the grounds of moral values, principles, and ethics which are led by our mentor.

2 notes

·

View notes

Text

Good News - April 22-28

Like these weekly compilations? Support me on Ko-fi! Also, if you tip me on here or Ko-fi, at the end of the month I'll send you a link to all of the articles I found but didn't use each week - almost double the content! (I'm new to taking tips on here; if it doesn't show me your username or if you have DM's turned off, please send me a screenshot of your payment)

1. Millions Of Maggots Donated To Charity In Honour Of The Maggot King

“[Blizzard Entertainment] donated millions of maggots to Tiggywinkles UK, a leading wildlife hospital, […] in honor of Duriel, the Maggot King, a notorious character in the Diablo series. […] This significant contribution is expected to feed the patients at Tiggywinkles for two years.”

2. New circuit boards can be repeatedly recycled

“A team led by researchers at the University of Washington developed a new PCB that performs on par with traditional materials and can be recycled repeatedly with negligible material loss. Researchers used a solvent that transforms a type of vitrimer—a cutting-edge class of sustainable polymers—to a jelly-like substance without damaging it, allowing the solid components to be plucked out for reuse or recycling.”

3. How a Cloned Ferret Inspired a DNA Bank for Endangered Species

“This black-footed ferret (Mustela nigripes) [is] the first endangered species in the U.S. to ever be successfully cloned […] from [a] cryogenically preserved cell line, obtained from a ferret named Willa, who lived in Wyoming in the 1980s. [… T]he FWS [is now] on a major project to cryogenically store tissue from every endangered species in the U.S., [… as] “an insurance policy against future loss of biodiversity in the wild.””

4. Maine Signs Trans And Abortion Sanctuary Bill Into Law, Despite Violent Threats

“[The new law] states that criminal and civil actions against providers and patients are not enforceable if the provision or access to that care occurred within Maine’s borders, asserting jurisdiction over those matters. It bars cooperation with out-of-state subpoenas and arrest warrants for gender-affirming care and abortion that happen within the state.”

5. $70M for Fish Passage Projects Address Climate Resilience, Strengthen Local Economies

“The Department of the Interior today announced more than $70 million […] that will improve fish passage around […] barriers fragmenting the nation’s rivers and streams [… as an] “investment to restore our nation’s rivers and streams, safeguard endangered fish species, protect Indigenous subsistence practices and provide communities with increased opportunities for outdoor recreation and economic growth,” said Secretary Deb Haaland.”

6. A Golden Age of Renewables Is Beginning, and California Is Leading the Way

“California—the fifth-largest economy in the world—has experienced a record-breaking string of days in which the combined generation of wind, geothermal, hydroelectric and solar electricity has exceeded demand on the main electricity grid for anywhere from 15 minutes to 9.25 hours per day.”

7. Collaborative conservation efforts keep lake sturgeon off the endangered species list

“The Service’s 12-month finding [that these sturgeon are not endangered] shows ongoing management efforts, such as fish stocking, have contributed to the conservation and resiliency of the species. “Today’s announcement shows the power of collaborative conservation and the impact it can have for species like the lake sturgeon,” said Midwest Regional Director Will Meeks.”

8. French municipalities bordering Luxembourg to offer free transport to commuters

“Luxembourg is the only country in the world to offer entirely free public transport. […S]ix French communities located near the border and many of whose residents work in Luxembourg have decided to band together and also offer a free shuttle for daily workers. […] Last year, governments in the two countries said they would work to increase train services to run every 10 minutes between Metz and Luxembourg City by 2030. There’s also a plan to extend Luxembourg City’s tram service to reach all the way to the border – a trip that would take only 30 minutes when ready.”

9. Solar is about to get a lot more affordable for low-income households

“The EPA granted 49 state and territory awards totaling $5.5 billion, six tribal awards worth more than $500 million, and five multistate awards amounting to $1 billion. Together, the awards cover all 50 states, Puerto Rico, and the District of Columbia. All of the funding is dedicated to low-income and disadvantaged households.”

10. Amsterdam will cover cost of changing one's gender on documents

“[T]he city’s residents will be able to change the gender on their birth certificate and Basic Registration of Persons (BRP) free of charge. [… T]he local government will also reimburse (part of) the costs of a new passport, identity card or driver's license.”

April 15-21 news here | (all credit for images and written material can be found at the source linked; I don’t claim credit for anything but curating.)

#good news#hopepunk#bugs#tw bugs#diablo#wildlife#technology#recycling#ferret#cloning#dna#endangered species#trans#abortion rights#abortion#law#transgender#fish#renewableenergy#solar#geothermal#electricity#sturgeon#conservation#nature#france#public transit#low income#lgbtq#lgbtqia

6 notes

·

View notes

Text

Understanding Circuit Board Electronic Components: A Comprehensive Guide

In today's digital world, electronic devices have become an essential part of our daily lives. But what makes these devices tick? At the heart of every electronic device lies a circuit board—a masterpiece of tiny electronic components working together to perform complex tasks. In this article, we’ll dive deep into the fascinating world of circuit board electronic components, exploring each element’s role and how they contribute to the overall functionality of the device.

What is a Circuit Board?

A circuit board, often referred to as a PCB (Printed Circuit Board), is a flat board used to mechanically support and electrically connect various electronic components. These components work in unison to perform a specific task. Think of the circuit board as the skeleton and nervous system of an electronic device—it holds everything together and allows communication between parts.

Types of Circuit Boards

Single-sided PCB: Has one layer of conducting material.

Double-sided PCB: Contains two layers for components and connections.

Multi-layer PCB: Complex boards with multiple layers for advanced applications.

The Role of Electronic Components on a Circuit Board

Every electronic device you interact with is powered by a carefully designed circuit board filled with various components. These components might be tiny, but each one has a critical role in the operation of the device. Here's a breakdown of the most important electronic components you’ll find on a typical circuit board.

1. Resistors

Resistors are fundamental components that control the flow of electrical current. They resist the flow of electrons, hence the name "resistor." Their primary function is to reduce current flow, adjust signal levels, and divide voltages in a circuit. Without resistors, circuits would allow too much current to flow, potentially damaging other components.

Types of Resistors

Fixed resistors: Have a set resistance value.

Variable resistors: Allow adjustment of the resistance.

2. Capacitors

Capacitors store and release electrical energy in a circuit. They are often compared to small rechargeable batteries that quickly charge and discharge. Capacitors help smooth out fluctuations in voltage, filter noise, and store energy for future use.

Common Uses of Capacitors

Energy storage

Signal filtering

Voltage stabilization

3. Inductors

Inductors are components that store energy in a magnetic field when electrical current flows through them. They resist changes in current and are typically used in circuits to filter signals, manage power, and store energy.

Applications of Inductors

Power supplies

Radio frequency circuits

Noise suppression in circuits

4. Diodes

A diode is like a one-way valve for electricity, allowing current to flow in only one direction. They are vital in circuits to prevent reverse currents, which can damage components.

Types of Diodes

Light-emitting diodes (LEDs): Produce light when current flows through.

Zener diodes: Regulate voltage within a circuit.

5. Transistors

The transistor is a versatile component used to amplify or switch electronic signals. In essence, transistors are like tiny switches that turn signals on and off rapidly, making them essential in modern electronics.

Types of Transistors

NPN transistors: Allow current flow when a small voltage is applied to the base.

PNP transistors: Conduct when the base is negatively charged.

How Circuit Board Components Work Together

In a circuit, each component has a specific role, and together they form a cohesive system. For example:

Capacitors and resistors may work together to filter signals or smooth out voltage fluctuations.

Transistors and diodes ensure that signals are amplified or directed properly.

Integrated circuits handle the complex tasks, processing data, and controlling the overall system.

Choosing the Right Components for Your Circuit Board

When designing or repairing a circuit board, choosing the correct components is crucial. Some factors to consider include:

Voltage requirements

Power consumption

Signal type and frequency

Physical size and compatibility

Conclusion

Circuit boards are an integral part of any electronic device. The various components on the board each play a specific role in ensuring the device functions as intended. Understanding these components, from resistors to integrated circuits, is essential for anyone working with electronics, whether you're designing a new system or troubleshooting an existing one.

2 notes

·

View notes

Text

Printed Circuit Board Basics

Most of us are using Printed Circuit Board in our daily life. Printed Circuit Boards are used in almost all the Electronic products, from consumer gadgets such as PCs, tablets, smartphones, and gaming consoles to industrial and even high tech products in strategic and medical electronics domains.

Here, we have some statistics for you that shows how many electronic devices connect worldwide from 2015 to 2025. This statistic shows an increase in the use of a number of PCB in people daily life. Hence, CircuitWala took this opportunity to provide a basic knowledge about PCB via this article.

There are so many books available online which teach about Printed Circuit Board design and hardware part. There are few links available online which shows only a few basic fundamentals of PCB and few are there for Basics of Printed Circuit Board (PCB) Design. Few which gives good know knowledge on Printed Circuit Board terminology. But in the end for the hobbyist, there is no such material available which make their work easy.

Now days there few online designing websites available which allow hobbyist and students to create their design and Printed Circuit Board fabrication part. These websites provide limited features and charge high for the full edition. We, @CircuitWala are in try to provide one platform which provides plenty of Printed Circuit Board knowledge digitally to make your work simple and easy.

Alternatives of PCB include wire wrap and point-to-point construction. Creating a layout of PCB is a little bit time-consuming method as compared to its alternative solution but manufacturing of PCB is cheaper and faster then other wiring methods as electronic components are mounted and wired with one single part.

Let’s start with some basics of Printed Circuit Board with this article. Here in this article we will discuss about history of PCB to understand the emerge of PCB, Types of PCB to make your complex PCB a very simple using different types, Usage of PCB to provide you an idea to create more Printed Circuit Board projects, Advantages and Disadvantages, Possible Future to know about new technological change in Printed Circuit Board manufacturing and also about how to destroy and manage your PCB’s e-waste? We know you are eager to know all the stuff in details but before that let’s make a simple definition of Printed Circuit Board.

What is Printed Circuit Board?Printed Circuit Board is an electronic device made of conductive material(FR-4) like copper which connects components mounted on it to to get desired output by providing an input on another end.

When the board has not mounted with any of the components is called as Printed Circuit Board or Printed Wired Board. Mounting of an electronic component on Printed Circuit Board is called as PCB assembly.

History of Printed Circuit BoardThe invention of Printed Circuit Board was by Austrian engineer Paul Eisler as part of a radio set while working in England around 1936.

In early days before Printed Circuit Board became common in use, Point-to-Point construction was used. This meant some bulky and unreliable design that required plenty of sockets and regular replacement of it. Most of this issue directly address when PCB went into regular production.

Originally, every electronic component had wire leads, and the PCB had holes drilled for each wire of each component. The components’ leads were then passed through the holes and soldered to the PCB trace. This method of assembly is called Through-Hole construction. There is one other method to mount component is called as Surface Mount.

Type of Printed Circuit BoardPCBs are produced from the different types of material and on the basis of that material PCBs are divided mainly into two parts: Rigid PCB and Flexible PCB. Nowadays, a combination of Rigid and flexible PCB is also possible and that is called as Flexi-Rigid PCBs.

Most of the PCBs are built in layers. The inner layer is the base material called as a substrate. Rigid PCBs are mainly made of material like epoxy materials and Flexible PCBs are made of plastic material that can withstand high temperatures.

Rigid PCBs are generally, hard materials that hold the component in a better way. The motherboard in the tower of a computer is the best example of Rigid PCBs. Flexible PCBs fundamental material allows PCB to fit into forms that Rigid PCBs can not. Flexible PCBs can turn round without harmful the circuit on PCB.

All Rigid and Flexible PCBs can come in three formats by layers: Single Layer, Double Layer, and Multi-Layer.

1. Single Layer PCBSingle Layer PCBs have been around since the late 1950s and still dominate the world market in sheer piece volume. Single Sided PCBs contain only one layer of conductive material and are best suited for low-density designs. Single-sided PCBs are easy to design and quick to manufacture. They serve as the most lucrative platform in the industry.

2. Double Layer PCBDouble Layered printed circuit board technology is conceivably the most popular type of PCB in the industry. Double Sided PCB (also known as Double-Sided Plated Thru or DSPT) circuits are the gateway to advanced technology applications. They allow for a closer (and perhaps more) routing traces by alternating between top and bottom layers using vias.

3. Multi Layer PCB

Multilayer PCB is a circuit board that has more than two layers. Unlike a Double-Sided PCB which only has two conductive layers of material, all multilayer PCBs must have at least three layers of conductive material which are buried in the center of the material.

Usage of Printed Circuit BoardBy reading this article till this point, we hope that you are now able to get about printed circuit boards. Now, we will make you understand about different applications of printed Circuit Board.

In this digital world, Printed Circuit Board is in almost all our daily life electronic devices and in our industrial electronics as well. Below are the industries where PCBs are used:

Possible FutureNowadays, most of the circuits are replaced to produce Printed Circuit Board from the old methods. Revolution in technology made many of the processes automated and hence it is easy to manufacture PCB. But still, these processes are a bit expensive to hire, involve toxic waste and use high temperatures and acids. With technological advances we have seen in the past years, it is not hard to imagine PCB will soon be revolutionized. Not only that but research institutes predict a more ‘green’ future for PCBs; PCBs being made of paper.

Electronic Waste (e-waste)Electronic Waste or e-waste is described as discarded electrical or electronic devices. Informal processing of e-waste in developing countries can lead to adverse human health effects and environmental pollution.

Electronic scrap components contain a hazardous substance such as lead, cadmium, beryllium, or brominated flame retardants. Recycling and disposal of e-waste may involve significant risk to health of workers and communities in developed countries and great care must be taken to avoid unsafe exposure in recycling operations

Nowadays, developing countries are encouraging electronic users to take care while recycling the e-waste or submit them to the organization who are involved in such activities.

SummaryIn this blog, we have learned the basics of Printed Circuit Board. CircuitWala is planning to write as many blogs to provide more and more knowledge of Printed Circuit Board. Either it is basics or manufacturing or usages or advantages and disadvantages of PCBs. We will also try to make our users/customers up to date for the new technology innovations, including past histories and revolution of the PCB industries.

In the next blog, we will look at more briefly about the different types of Printed Circuit Board. We also understand the process to make it and different usage and application for the same.

#electronic circuit design company#pcb circuit manufacturer in ahmedabad#pcb design & manufacturing services#printed circuit board companies#printed circuit board order online#PCB manufacturer#Printed Circuited Board#double layer PCB#PCB Quality Control

2 notes

·

View notes

Text

4 Crucial Things to Consider While Choosing LED PCB Manufacturer

LEDs have revolutionized lighting. At the heart of their brilliance, is the PCB assembly. Electing the right LED PCB assembly manufacturer can make or break your project. This ensures quality, performance, and ultimately, success. So, before you dive into the luminous world of LED PCBs, this article sheds some light on the key factors to consider when making your purchase:

1. Experience Matters: You should choose a manufacturer with proven expertise in LED PCB assembly. The company you choose should have a track record of successful projects similar to yours. Experience means they will understand your specific needs and deliver assemblies that meet or exceed your expectations.

2. Material Matters: The heart of your PCB is its materials. Go for manufacturers

who ensure high-quality FR4 or metal-core PCBs for optimal thermal management and longevity. They must adhere to industry standards for materials and components to guarantee reliability and safety.

3. Thermal Management: LEDs are designed to generate heat, so proper thermal management plays a crucial role. Look for manufacturers who offer solutions like aluminium heat sinks. Their expertise in thermal management can extend the lifespan of your LED PCB and prevent overheating issues.

4. Price is Not Everything: Though cost is important, its priority is not over quality.

The cheapest option might have hidden costs in the long run. Choose a manufacturer who offers budget-friendly pricing while maintaining high-quality standards and reliable service.

If you are looking for an LED PCB manufacturer near you you can count on Hitech Circuits Co., Limited. They have more than 20 years of experience in the electronics manufacturing industry. They have a talented design team who follow advanced manufacturing techniques.

These guidelines help you illuminate your path to finding the perfect LED PCB assembly manufacturer. Your choice has a direct impact on the performance, lifespan, and success of your project.

2 notes

·

View notes

Text

On Autonomy in the IT Industry

What's kinda frustrating for a disabled hardware geek like me is that a lot of my peers don't really see how common maintenance tasks are day-long planning and execution rigamaroles for me. Those tiny M.2 screws? They're a bitch to wrangle if your hind brain is so convinced you'll drop it in the frame that your limbs are overtaken by tremors so strong that the entire case shakes.

At the Old Place, my former boss used to give me an amused look. "Relax, Grem! It's just a single screw; you can't mess this up!" she'd say.

The fact is, I could - and I knew it. I've scratched material off of PCBs, shorted boards, lost screws, broke posts and scrapped hardware all because my motor controls never got the message that I know how to handle a PC case in multiple formats. The old boss never understood why I needed to force myself into borderline monastic levels of focus to switch M.2 drives out of a system, or why I demanded near-absolute quiet when my colleagues could shoot the shit while handling a laptop's stumpy little external screws.

Walt and Sarah, however, understand this all too well. I updated my Steam Deck's SSD last night, and both of them treated this like I were a heart surgeon performing a triple bypass. Others might've laughed, but I was actually given the space I needed, for a change. The same went for the Palpatine server - the more crucial operations always came with a ramping-down of Walt's phone calls.

What they also understand is that pushing past my disability and succeeding feels insanely good. I walked out of mine and Walt's room with a big-ass grin and a functional 1 TB Steam Deck in hand with no stripped screws or broken screw posts, and I was proud of myself. Sarah gave me a wolf whistle and Walt added a golf clap in equal parts supportive and teasing measures.

I doubt many able-bodied techs get that feeling; this "I did something! Me, on my own, without ever asking for help! Yes!" type of euphoria that I've only ever seen out of cripples like me when we both manage to pull ourselves by our bootstraps and materially succeed in what we'd envisioned. Able-bodied people tend to downplay most of what they do, but even switching RAM sticks without missing the slots at least four or five times still feels like a big thing for me - and I've been building PCs for about twenty years, now. Plus, the older I get, the more demanding some operations become. It makes successes all the more precious - and increasingly less banal.

#disability#IT post#self-reliance#autonomy#adulting#pride#an actual sense of accomplishment#yay i screwed in this tiny screw and didn't strip everything i'm the best#something able-bodied techs always look a little flummoxed by#it's not that I feel like I'm five it's that it's hard

2 notes

·

View notes

Text

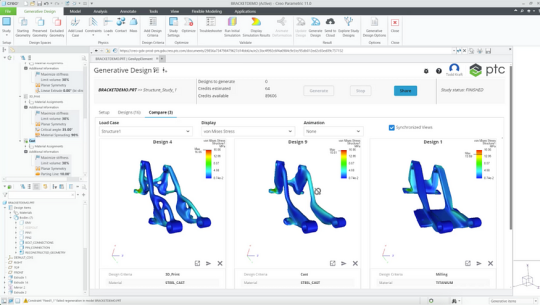

PTC Creo 12: New Tools for Smarter, Faster 3D Design

Discover what’s new in PTC Creo 12 — enhanced simulation, AI-driven design, MBD, and manufacturing tools. Upgrade now with ANH, the trusted PTC Creo reseller in the Delhi NCR region.

Top New Features in Creo 12

1. AI-Driven Design Guidance

Creo 12 takes intelligent design to the next level with built-in AI tools that offer real-time suggestions and improvements.

Get feedback during modeling

Reduce trial-and-error

Improve efficiency with every click

2. Enhanced Model-Based Definition (MBD)

Creo 12 makes MBD more practical and powerful, eliminating the need for traditional 2D drawings.

Improved PMI (Product Manufacturing Information)

Better GD&T annotation support

Clearer data for downstream users

3. Performance & Usability Upgrades

PTC has improved the overall speed, responsiveness, and ease of use:

Faster model regeneration

Smart mini toolbars

Enhanced model tree filters

Customizable dashboards for quick access

4. Creo Simulation Live — More Powerful Than Ever

Simulation Live has been expanded to cover:

Structural & thermal simulations

Better support for nonlinear materials

Real-time design feedback

5. Advanced Multi-Body Design

Creo 12 makes it easier to work with complex parts and assemblies:

Better control over multiple bodies in a single part

New body operations and organization tools

Improved part-to-part interactions

It’s ideal for high-detail engineering and intricate product development.

6. Additive and Subtractive Manufacturing Enhancements

Manufacturing has never been smoother in Creo:

More control over lattice structures

Enhanced 5-axis CAM functionality

New machine support and output formats

Whether you’re 3D printing or using CNC, Creo 12 has you covered.

7. Improved ECAD–MCAD Collaboration

With electronics becoming a bigger part of mechanical products, Creo 12 improves:

PCB visualization

Layer management

Synchronization between electrical and mechanical teams

This helps avoid costly errors during development.

Why Creo 12 is a Must-Have Upgrade

PTC Creo 12 isn’t just for big enterprises — it’s built for everyone who values smart, high-quality design. Whether you’re a design engineer, manager, or product innovator, Creo 12:

Saves time

Reduces errors

Encourages innovation

Supports industry 4.0 goals

Get Creo 12 from Delhi NCR’s Trusted PTC Reseller — ANH

Looking to upgrade your CAD tools or switch to Creo 12? ANH is a leading authorized PTC reseller in the Delhi NCR region. From licensing to training, we help businesses unlock the full potential of Creo.

Contact ANH today to get started with Creo 12!

✅ Conclusion: Welcome to the Future of Design

PTC Creo 12 is more than just an upgrade — it’s a gateway to smarter design, quicker development, and stronger innovation. With new AI tools, advanced simulations, and seamless usability, it’s built to give your team a competitive edge.

Design faster. Design smarter with Creo 12.

0 notes

Text

PCBA: The Silent Backbone of Electronic Devices

Printed Circuit Board Assembly (PCBA) serves as the critical foundation for nearly every electronic device in our modern world. From smartphones and laptops to industrial automation systems and aerospace equipment, PCBA ensures that the various electronic components within a device function smoothly and cohesively. Its precision and reliability are not just technical necessities but vital to sustaining innovation in the global tech economy.Get more news about PCBA manufacturer,you can vist our website!

Understanding PCBA

At its core, PCBA refers to the process of soldering electronic components onto a printed circuit board (PCB). While a PCB is simply the board with copper traces that connect components electrically, the assembly process transforms it into a fully functional circuit. This involves mounting integrated circuits (ICs), resistors, capacitors, diodes, and other components using either Surface Mount Technology (SMT), Through-Hole Technology (THT), or a hybrid of both, depending on the design and purpose of the device.

The PCBA Process

The process typically begins with solder paste application, where a stencil is used to apply the paste on predefined areas of the PCB. Automated pick-and-place machines then accurately position the tiny components onto the board. This is followed by reflow soldering, where the board is passed through a controlled oven to melt the solder and secure the components.

For boards requiring through-hole components, manual or wave soldering is used. Once soldered, the board undergoes inspection and testing—ranging from Automated Optical Inspection (AOI) to X-ray analysis and functional testing—to ensure quality and performance. Advanced PCBA plants employ high levels of automation, drastically reducing human error and improving output consistency.

Applications Across Industries

PCBA's influence stretches far beyond consumer electronics. In the automotive sector, it powers systems ranging from infotainment units to electric vehicle battery management. In healthcare, PCBA-based medical devices like ECG machines and portable monitors are critical to patient diagnostics and care. Aerospace and military applications demand high-reliability PCBA to function under extreme environments—an area where rigid quality controls and testing standards become indispensable.

Trends and Innovations

The PCBA landscape continues to evolve rapidly with advances in miniaturization, multi-layer boards, and flexible circuits. With the rise of the Internet of Things (IoT), demand for compact, power-efficient, and wireless-capable assemblies has exploded. Manufacturers are investing in smart factories, using AI-driven inspection and robotics to further optimize production.

Meanwhile, environmental considerations are pushing green manufacturing methods, such as lead-free solder and recyclable board materials. Companies are also embracing design-for-manufacturing (DFM) principles to streamline assembly and minimize waste.

Conclusion

Though rarely visible to end-users, PCBA is the invisible force driving the electronics revolution. Its blend of engineering precision, automation, and innovation enables the digital tools and systems we rely on daily. As global technology continues to push boundaries, PCBA will remain the structural and functional heart of that progress—quietly pulsing behind every screen, circuit, and sensor.

0 notes

Text

Electronic Spacer Market Report: Forecasting Growth to USD 1.13 Bn by 2025–2032

MARKET INSIGHTS

The global Electronic Spacer Market size was valued at US$ 743.8 million in 2024 and is projected to reach US$ 1.13 billion by 2032, at a CAGR of 6.2% during the forecast period 2025-2032.

Electronic spacers are precision components used to maintain proper spacing and alignment between electronic parts in various applications. These spacers come in multiple forms including hexagon swage spacers, round spacers, and metric spacers, each designed for specific mechanical and electrical requirements. They play a crucial role in ensuring structural integrity and electrical insulation in assemblies.

The market growth is driven by increasing demand from consumer electronics and automotive sectors, where miniaturization and reliable component spacing are critical. While the U.S. leads in market size currently, China’s rapid electronics manufacturing expansion is creating new growth opportunities. Key players like Wyandotte Industries and Keystone Electronics are expanding their product portfolios to cater to evolving industry needs, particularly in high-density PCB applications.

MARKET DYNAMICS

MARKET DRIVERS

Expansion of Consumer Electronics Manufacturing to Accelerate Market Demand

The global electronic spacer market is experiencing robust growth driven by the rapid expansion of consumer electronics manufacturing. With smartphone production exceeding 1.4 billion units annually and tablet production reaching nearly 200 million units, the demand for precision components like electronic spacers continues to surge. Electronic spacers play a critical role in PCB assemblies and device housings, ensuring proper component alignment and thermal management in increasingly compact electronic designs. Major electronics manufacturers are adopting automated production lines that require standardized spacer components, creating a stable demand pipeline for market players.

Automotive Electronics Revolution to Spur Technological Advancements

The automotive sector’s shift toward electric vehicles and advanced driver assistance systems is generating significant demand for specialized electronic spacers. Modern vehicles now contain over 3,000 electronic components requiring precision spacing solutions that can withstand vibration, temperature fluctuations, and electromagnetic interference. Automotive-grade spacers must meet stringent quality certifications, driving innovation in materials and manufacturing processes. The growing adoption of vehicle electrification, with projections indicating electric vehicles will comprise over 30% of new car sales by 2030, positions electronic spacers as critical components in next-generation automotive architectures.

MARKET CHALLENGES

Raw Material Price Volatility Creates Margin Pressure

While the electronic spacer market shows strong growth potential, manufacturers face persistent challenges from raw material price fluctuations. Stainless steel, aluminum, and specialty polymers – which account for approximately 60-65% of production costs – have experienced significant price volatility in recent years. This instability makes cost management difficult, particularly for manufacturers serving price-sensitive market segments. Smaller manufacturers with limited purchasing power find it especially challenging to maintain profitability while competing with larger firms that benefit from economies of scale.

Other Challenges

Supply Chain Disruptions Recent global supply chain disruptions have highlighted vulnerabilities in the spacer manufacturing ecosystem. Many producers rely on specialized metal alloys and polymers sourced from limited suppliers, creating bottlenecks during periods of high demand or logistical challenges.

Inventory Management Pressures The need to maintain extensive inventories of spacer variants for diverse applications increases working capital requirements and storage costs, presenting ongoing operational challenges for market participants.

MARKET RESTRAINTS

Miniaturization Trend Challenges Traditional Spacer Designs

The electronics industry’s relentless push toward miniaturization is forcing spacer manufacturers to radically redesign their products. Conventional spacer designs struggle to meet the dimensional precision requirements of modern microelectronics, where component spacing tolerances are now measured in micrometers rather than millimeters. This technical challenge is compounded by the aerospace and medical device sectors adopting similarly stringent requirements for their electronic assemblies. Manufacturers must invest heavily in precision tooling and quality control systems to remain competitive, creating barriers to entry for smaller players.

MARKET OPPORTUNITIES

Emerging Applications in Renewable Energy Systems

The rapid growth of renewable energy infrastructure presents significant opportunities for electronic spacer manufacturers. Solar inverters, wind turbine control systems, and energy storage installations all require robust spacing solutions capable of withstanding harsh environmental conditions. With global renewable energy capacity projected to increase by over 60% in the next five years, specialized spacers designed for outdoor electrical applications represent a high-growth market segment. Manufacturers developing corrosion-resistant, UV-stable spacer solutions stand to benefit substantially from this trend.

Additive Manufacturing Opens New Design Possibilities

Advances in 3D printing technologies are enabling the production of complex spacer geometries that were previously impossible or cost-prohibitive to manufacture. This technological leap allows for spacers with integrated features like conductive traces, thermal management channels, or customized mounting points. Early adopters of metal and polymer additive manufacturing are gaining competitive advantages through reduced prototyping costs, shorter lead times, and the ability to offer highly customized solutions. As additive systems become more affordable and material options expand, this production method is expected to transform spacer manufacturing paradigms across multiple industries.

ELECTRONIC SPACER MARKET TRENDS

Miniaturization in Electronics Driving Demand for Precision Spacer Solutions

The rapid advancement of miniaturization in electronics has created a significant demand for high-precision electronic spacers across industries. As consumer electronics and automotive components shrink in size while increasing in complexity, the need for reliable spacing solutions that maintain structural integrity and thermal management has grown substantially. Hexagon swage spacers, known for their durability and secure fastening, currently dominate the market with an estimated 32% revenue share in 2024. The shift toward 5G infrastructure and IoT devices has particularly accelerated adoption, with metric spacers witnessing 8.7% year-over-year growth in telecommunications applications. Furthermore, material innovations including high-temperature plastics and conductive alloys are expanding spacer functionality beyond mechanical separation into thermal dissipation roles.

Other Trends

Automotive Electrification Spurs New Spacer Requirements

The global push toward electric vehicles has introduced stringent new requirements for electronic spacers in battery management systems and power electronics. Where traditional applications required basic isolation, EV applications now demand materials with dielectric strength exceeding 5kV/mm while maintaining thermal conductivity above 3 W/mK. This has led to increased R&D investment in hybrid polymer-metallic spacer solutions, with leading manufacturers launching over 15 new specialized products in 2023 alone. The automotive segment is projected to grow at 9.2% CAGR through 2030, outpacing overall market growth as EV production scales globally.

Supply Chain Localization Reshaping Manufacturing Landscapes

Geopolitical tensions and logistics disruptions have accelerated the trend toward localized spacer production, with North American and European manufacturers investing over $120 million in new production facilities since 2022. While China remains the dominant production hub with 44% of global capacity, regional demand is increasingly met by domestic suppliers – particularly for defense and medical applications requiring certified supply chains. This shift has created opportunities for mid-sized manufacturers with fast prototyping capabilities, as OEMs prioritize vendors who can rapidly adapt to design changes while meeting regional content requirements. The trend is most pronounced in the aerospace sector, where lead times have decreased by 18% through localized spacer sourcing strategies.

Smart Manufacturing Technologies Enhancing Production Efficiency

Industry 4.0 adoption is transforming electronic spacer manufacturing through AI-driven quality control and predictive maintenance systems. Leading producers report 27% reduction in material waste and 15% improvement in production throughput after implementing machine vision inspection systems. Automated inventory management using RFID-tagged spacer bins has reduced stockouts by 40% in high-volume applications. These efficiency gains are critical as manufacturers balance the need for mass production of standard spacers with growing demand for customized solutions – a segment that now represents 22% of total market value and commands 35-50% price premiums over standard products.

COMPETITIVE LANDSCAPE

Key Industry Players

Innovation and Strategic Partnerships Drive Competition in the Electronic Spacer Market

The global electronic spacer market features a dynamic competitive landscape, characterized by both established manufacturers and emerging players striving to capture market share. Wyandotte Industries, Inc. and Keystone Electronics Corp. have emerged as leading players, leveraging their extensive product portfolios and robust distribution networks across North America and Europe. These companies collectively held approximately 35% market share in 2024, with their dominance rooted in precision manufacturing capabilities and rapid response to industry demands.

While the U.S. remains the largest regional market for electronic spacers, Boker’s, Inc. and PennEngineering have been increasingly focusing on expansion in Asia-Pacific, particularly in China and Japan, where demand is projected to grow at a CAGR of 7.2% through 2032. These players are investing heavily in automated production technologies to enhance efficiency and reduce lead times, addressing the needs of fast-growing applications in consumer electronics and automotive sectors.

Mid-size competitors like MBK Tape Solutions and Fabri-Tech Components, Inc. are differentiating themselves through specialized solutions, particularly in the hexagon swage spacers segment, which is expected to reach $85 million by 2032. Their strategy focuses on customized spacer solutions for niche applications, allowing them to compete effectively against larger industry players.

The market also sees active participation from component specialists such as Nyltite Corp. and XTO, Inc., who are strengthening their positions through strategic acquisitions and partnerships. Recent developments include expansion of high-temperature resistant spacer lines to serve the growing electric vehicle market, reflecting the industry’s response to evolving technological requirements.

List of Key Electronic Spacer Companies Profiled

Wyandotte Industries, Inc. (U.S.)

Boker’s, Inc. (U.S.)

MBK Tape Solutions (U.S.)

Fabri-Tech Components, Inc. (U.S.)

XTO, Inc. (U.S.)

Nyltite Corp. (U.S.)

Keystone Electronics Corp. (U.S.)

Miller Gasket Co. (U.S.)

PennEngineering (U.S.)

Segment Analysis:

By Type

Hexagon Swage Spacers Segment Leads Due to High Demand in Precision Engineering Applications

The market is segmented based on type into:

Hexagon Swage Spacers

Round Spacers

Metric Spacers

Others

By Application

Consumer Electronics Segment Dominates Due to Increasing Demand for Compact Electronic Devices

The market is segmented based on application into:

Consumer Electronics

Automotive

Industrial Equipment

Aerospace

Others

By Material

Plastic Spacers Gain Preference Due to Lightweight and Insulating Properties

The market is segmented based on material into:

Metal

Plastic

Rubber

Others

Regional Analysis: Electronic Spacer Market

North America The North American electronic spacer market is anticipated to exhibit steady growth, driven by high demand from the consumer electronics and automotive sectors. The presence of key manufacturers such as PennEngineering and Keystone Electronics Corp. supports regional supply chains, while stringent regulatory standards for precision components in electronics bolster quality requirements. The U.S., accounting for the largest market share in the region, benefits from advancements in smart devices, aerospace, and automotive assembly technologies. However, rising material costs and supply chain disruptions pose challenges to cost-sensitive applications.

Europe Europe’s market is characterized by demand for high-precision spacers, particularly in Germany and the U.K., where the automotive and industrial electronics segments dominate. Compliance with EU regulations on material safety and sustainability drives innovation in spacer materials, such as recyclable polymers and corrosion-resistant alloys. While the region maintains a strong foothold in precision manufacturing, competition from Asia-Pacific suppliers has led to pricing pressures. Nevertheless, collaborations between research institutions and manufacturers continue to foster technological advancements in spacer design.

Asia-Pacific Asia-Pacific leads global market growth, propelled by China’s massive electronics production and India’s expanding automotive industries. With cost efficiency being a key driver, manufacturers like Nyltite Corp. leverage regional supply chains to produce hexagon swage and metric spacers at competitive prices. However, despite high-volume production, the market faces challenges in quality standardization. Japan and South Korea remain pivotal for advanced spacer applications in semiconductors and robotics, emphasizing precision and durability in their manufacturing ecosystems.

South America South America presents modest growth opportunities, largely tied to Brazil’s automotive sector and Argentina’s electronics assembly market. While demand for spacers in industrial applications is rising, economic instability and inconsistent infrastructure investment limit large-scale adoption. Local manufacturers often rely on imported materials, making production costs volatile. Despite these hurdles, niche applications in renewable energy and telecommunications are emerging, indicating long-term potential.

Middle East & Africa This region remains a developing market, with growth primarily concentrated in the UAE, Saudi Arabia, and South Africa. Demand stems from infrastructure projects and telecommunications expansion, though the lack of local production capabilities results in heavy reliance on imports. While the adoption of electronic spacers in oil & gas equipment and consumer electronics shows promise, limited industrialization and financing constraints slow market penetration. Strategic partnerships with global suppliers could unlock opportunities in the coming years.

Report Scope

This market research report provides a comprehensive analysis of the Global Electronic Spacer Market, covering the forecast period 2025–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include:

Market Size & Forecast: Historical data and future projections for revenue, unit shipments, and market value across major regions and segments. The Global Electronic Spacer market was valued at USD million in 2024 and is projected to reach USD million by 2032, growing at a CAGR of % during the forecast period.

Segmentation Analysis: Detailed breakdown by product type (Hexagon Swage Spacers, Round Spacers, Metric Spacers, Others), application (Consumer Electronics, Automotive, Others), and end-user industry to identify high-growth segments and investment opportunities.

Regional Outlook: Insights into market performance across North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa, including country-level analysis. The U.S. market size is estimated at USD million in 2024, while China is projected to reach USD million.

Competitive Landscape: Profiles of leading market participants including Wyandotte Industries, Inc., Boker’s, Inc., MBK Tape Solutions, Fabri-Tech Components, Inc., and others, covering their product offerings, market share, and recent developments.

Technology Trends & Innovation: Assessment of emerging manufacturing techniques, material advancements, and evolving industry standards in electronic spacer production.

Market Drivers & Restraints: Evaluation of factors driving market growth such as increasing demand from electronics manufacturing, along with challenges like raw material price volatility.

Stakeholder Analysis: Insights for component suppliers, OEMs, system integrators, investors, and policymakers regarding the evolving ecosystem and strategic opportunities.

Related Reports:https://semiconductorblogs21.blogspot.com/2025/06/fieldbus-distributors-market-size-and.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/consumer-electronics-printed-circuit.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/metal-alloy-current-sensing-resistor.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/modular-hall-effect-sensors-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/integrated-optic-chip-for-gyroscope.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/industrial-pulsed-fiber-laser-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/unipolar-transistor-market-strategic.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/zener-barrier-market-industry-growth.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/led-shunt-surge-protection-device.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/type-tested-assembly-tta-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/traffic-automatic-identification.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/one-time-fuse-market-how-industry.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/pbga-substrate-market-size-share-and.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/nfc-tag-chip-market-growth-potential-of.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/silver-nanosheets-market-objectives-and.html

0 notes

Text

Cost-Effective Strategies for Efficient PCB Production by A-Gas Electronic Materials

Learn how to optimise PCB production with cost-effective strategies, including design for manufacturability, efficient production techniques, and energy efficiency. Improve quality and reduce costs. Contact A-Gas Electronic Materials for expert guidance and tailored solutions.

#PCB production#cost-effective PCB manufacturing#design for manufacturability#PCB materials#efficient PCB production#supplier collaboration#PCB inventory management#PCB energy efficiency#automated assembly#A-Gas Electronic Materials#UK#PCB production strategies#PCB quality improvement

0 notes

Text

Marck Industries: Trusted Manufacturer of Premium Elevator Spare Parts

Why Reliable Spare Parts Matter in Elevator Systems

Elevators are essential in modern buildings—transporting people and goods swiftly and safely. Downtime due to broken or worn-out parts isn’t just inconvenient—it can impact safety, building efficiency, and tenant satisfaction. That’s why having a dependable source of high-quality spare parts is vital.

What Sets Marck Industries Apart

1. Decades of Expertise

With years of experience in manufacturing elevator components, Marck Industries understands the stringent requirements of vertical transportation—ensuring every part is engineered for precision, durability, and compliance with international safety standards.

2. Comprehensive Product Portfolio

From mechanical to electrical systems, we supply a full range of elevator parts, including:

Controller boards & PCBs

Inverter and VFD units

Proximity switches & sensors

Door lock and safety gear

Brake assemblies & drums

Buffers, rollers, and pulleys

Cabin fixtures: buttons, display panels, handrails

3. Precision Manufacturing

Utilizing CNC machining, injection molding, and automated PCB assembly, each component is produced to exact tolerances—ensuring fit and function with OEM performance or better. Strict quality checks, including EN 81, ASME A17.1, and ISO audits, guarantee consistency.

4. Certified Quality & Safety

Marck operates with certifications to:

ISO 9001 Quality Management

CE marking and compliance

Adherence to EN (Europe) and ASME (North America) elevator safety codes

These credentials ensure safe, global-grade parts.

5. Custom Solutions & Adaptability

Recognizing that every elevator system is unique, Marck Industries excels in custom engineering—from tailored connectors and cables to complete PCB re-engineering—while maintaining cost and lead-time efficiency.

Benefits of Partnering with Marck Industries

Advantage

Impact

High Uptime & Quick Delivery

Minimize downtime with rapid part replacement and fast shipping

Competitive Pricing

Optimized production lowers costs without compromising quality

Global Support Infrastructure

Sales and technical teams available round-the-clock across regions

Extended Product Warranty

Confidence via long-term warranty and support packages

Serving Diverse Market Segments

Residential Buildings: Reliable replacements for passenger-lift maintenance.

Commercial Complexes: Durable components suited for high-traffic usage.

Industrial Facilities: Heavy-duty parts designed for freight and goods lifts.

OEM Collaborations: Contract manufacturing aligned with global elevator brands.

Quality Control & Testing Procedures

Each batch undergoes:

Incoming Material Inspection (IQC)

In-Process Monitoring (IPC)

Performance Testing: Load, endurance, vibration, and electrical tests

Final Audits & Certification

Partnering with Marck: How It Works

Initial Consultation Understand your system specs, OEM models, and usage patterns.

Quotation & Sample Approval We provide detailed proposals and offer test samples for validation.

Order & Production Ranging from small spare lots to mass production, with regular updates.

Technical & After-Sales Support Including troubleshooting, field assistance, and prompt RMA processes.

Ongoing Relationship We offer lifecycle support—even for legacy elevators requiring obsolete part replacements.

Elevate Your Operations with Marck Industries

Your elevator fleet deserves nothing less than reliable, certified parts that stand the test of time. Choose Marck Industries for precision, safety, and peace of mind—backed by technical excellence and global service reach.

Ready to discuss your parts needs? Contact our sales team or request a quote through the Marck Industries website today.

0 notes

Text

Understanding CEM in Modern Electronics: A Practical Insight

Understanding CEM in Modern Electronics: A Practical Insight

In today’s complex electronics landscape, product innovation and efficient manufacturing go hand in hand. For engineers, designers, and procurement professionals, choosing the right electronics partner is no longer a matter of convenience—it’s essential to product success. At Arrival Electronics Limited, a company based in Arundel, West Sussex, clients find an experienced and well-established resource for navigating the ever-changing world of electronic components and contract manufacturing.

Whether you are developing a product prototype or managing large-scale production, understanding the value and structure of CEM—Contract Electronics Manufacturing—is key to maintaining consistency, reliability, and supply chain strength. This article breaks down the concept of contract electronics manufacturing in practical terms, why it matters, and what to consider when selecting the right partner for your business.

CEM Explained: How Outsourced Electronics Manufacturing Supports Product Success

CEM refers to the process where a company outsources some or all of its electronic manufacturing responsibilities to a third-party provider. These services can include the assembly of printed circuit boards (PCBs), box builds, cable assemblies, and even full system integration. For many businesses, this arrangement helps bridge the gap between concept and market delivery without investing in internal production facilities.

But the advantages of outsourcing electronic manufacturing are not limited to infrastructure savings. A seasoned provider brings value through quality control, compliance assurance, procurement efficiency, and reduced lead times. The focus is not just on manufacturing but on delivering consistent results across the entire product lifecycle.

The Role of Contract Manufacturing in Product Development

In the early stages of product development, design and testing cycles can be both time-intensive and cost-sensitive. Working with an experienced manufacturing partner during this phase ensures that designs are ready for production, not just in theory but in practice. This includes:

Design for Manufacture (DfM) input: Ensuring that designs can be replicated reliably at scale.

Component sourcing guidance: Helping identify component availability, pricing trends, and lifecycle risks.

Rapid prototyping: Allowing for multiple iterations and validation cycles before full production.

The value of this support is particularly noticeable in industries with tight regulatory requirements or highly customized designs. Knowing that your product is being assembled by a team familiar with these challenges adds a layer of assurance often missed when production is fragmented or uncoordinated.

Quality Control and Compliance in Electronics Manufacturing

Consistency is everything when it comes to electronics. A single deviation in assembly quality or component specification can compromise an entire batch of products. Reputable manufacturers implement rigorous quality control standards—often including ISO certifications and IPC-A-610 class ratings—to ensure production meets both industry standards and client expectations.

In addition, experienced production partners are frequently tasked with managing regulatory documentation. For sectors like medical, automotive, aerospace, and defence, regulatory compliance is not just about paperwork—it’s a vital part of risk management and long-term reliability.

With experienced providers, clients benefit from:

Traceability systems to track component origins and manufacturing data

Test procedures tailored to the client’s performance standards

Material compliance such as RoHS, REACH, and conflict mineral regulations

This commitment to precision manufacturing and documentation forms the foundation of long-term supply stability.

Supply Chain Management and Procurement

One of the most significant advantages of working with an experienced electronics manufacturing partner is procurement efficiency. The global electronics supply chain can be unpredictable—affected by material shortages, geopolitical issues, and currency fluctuations. A reliable provider has both the scale and supplier relationships to manage these challenges on your behalf.

By centralizing procurement and inventory management, the risk of component obsolescence, stockouts, and delivery delays is greatly reduced. Strategic sourcing, long-term supplier contracts, and access to authorized distribution channels allow clients to focus on core design and development tasks.

In many cases, these providers also help negotiate better pricing through consolidated purchasing volumes, improving overall cost-effectiveness without compromising on quality.

Customization and Flexibility in Electronics Manufacturing

Different companies have different requirements. Some need full assembly and testing; others only need PCB population or logistics support. A flexible production model is one that adapts to these varying levels of engagement.

For example, some clients may request:

Box build and enclosure integration

Cable and wire harness manufacturing

Programming and firmware upload

Functional testing and diagnostics

A well-structured manufacturing relationship allows businesses to adjust their production effort (either up or down) based on demand, without renegotiating contracts or reorganizing supply infrastructure. This adaptability is particularly important for startups, R&D teams, and businesses with seasonal product cycles.

The Importance of Local Manufacturing Support

While many companies consider offshore production due to lower costs, working with a local manufacturing partner still provides key advantages in terms of quality and communication. UK-based providers offer accessible collaboration, faster turnaround times, and streamlined logistics—all important factors in today’s competitive electronics environment.

Local manufacturing also contributes to:

Greater visibility during production runs

Faster issue resolution if engineering changes are required

Reduced transportation risks, especially for fragile or sensitive components

Working with a local partner ensures better control, particularly when dealing with niche products, custom builds, or compliance-heavy applications.

Trends in Electronics Manufacturing for 2025 and Beyond

As the demand for smarter, more integrated electronics continues to grow, so do the expectations placed on modern manufacturing services. Emerging technologies such as IoT-enabled devices, wearable electronics, and electric vehicle systems require a more advanced and flexible approach to assembly and testing.

In response, many manufacturing specialists are expanding their capabilities to include:

Microelectronics assembly

High-frequency RF product support

Environmentally controlled production environments

Long-term product lifecycle support

These advancements are not confined to high-volume production. Niche developers and innovators also benefit from working with partners that understand how to manage intricate designs and deliver dependable, high-quality builds.

Choosing the Right Manufacturing Partner

With so many electronics manufacturing options available, how do you decide which one is right for your project?

Here are five practical factors to consider:

Experience: Look for a provider with a strong track record in your specific industry. Practical experience brings valuable insight, especially when navigating technical designs and regulatory requirements.