#Protocol Optimization

Explore tagged Tumblr posts

Text

Protocol Optimization - Complete Guide with Filestack

Protocol optimization involves refining communication protocols to enhance efficiency and performance. This can include reducing overhead, minimizing latency, and improving data throughput. By optimizing protocols, systems can achieve faster data transfer, lower error rates, and better resource utilization, leading to enhanced overall performance and reliability in networked applications. Visit the Filestack blog post for more comprehensive information on Protocol optimization.

0 notes

Text

The Future of Lab Analyzers Interfacing: Trends and Innovations

In the realm of laboratory technology, Lab Analyzers Interfacing stands as a cornerstone of efficiency and productivity. As the demand for faster, more accurate results grows, so too does the need for seamless connectivity and integration within laboratory environments. In this article, we'll delve into the latest trends and innovations shaping the future of Lab Analyzers Interfacing, exploring concepts such as Connectivity, Integration, Cloud Interfaces, Protocol Optimization, and Remote Monitoring. Connectivity lies at the heart of modern laboratory operations. Gone are the days of isolated instruments operating in silos. Today, laboratories are embracing interconnected systems that allow for real-time data sharing and collaboration. Lab Analyzers Interfacing solutions enable instruments to communicate with each other, streamlining workflows and enhancing overall efficiency. Whether it's through Ethernet, Wi-Fi, or Bluetooth, the ability to seamlessly connect lab analyzers is revolutionizing the way experiments are conducted and results are analyzed.

Integration takes Lab Analyzers Interfacing a step further by incorporating disparate instruments and software into a unified ecosystem. By integrating lab analyzers with Laboratory Information Management Systems (LIMS) or Electronic Health Records (EHR) platforms, laboratories can centralize data management and streamline reporting processes. This not only reduces the risk of errors but also provides researchers and clinicians with a comprehensive view of their data, facilitating informed decision-making. The emergence of Cloud Interfaces has further expanded the possibilities of Lab Analyzers Interfacing. By leveraging cloud-based solutions, laboratories can access and analyze data from anywhere in the world, breaking down geographical barriers and fostering collaboration on a global scale. Cloud interfaces also offer scalability and flexibility, allowing laboratories to adapt to changing needs without the hassle of traditional IT infrastructure.

Protocol Optimization is another area where Lab Analyzers Interfacing is driving innovation. By optimizing communication protocols between instruments, laboratories can minimize data transfer times and maximize throughput. This not only improves the speed and efficiency of experiments but also reduces the risk of errors associated with manual data entry. Remote Monitoring is perhaps one of the most exciting developments in Lab Analyzers Interfacing. With remote monitoring capabilities, laboratories can monitor and control instruments from anywhere with an internet connection. This not only frees up valuable time for laboratory staff but also enables round-the-clock operation, maximizing instrument uptime and productivity. In conclusion, the future of Lab Analyzers Interfacing is one of connectivity, integration, and innovation. By embracing trends such as Connectivity, Integration, Cloud Interfaces, Protocol Optimization, and Remote Monitoring, laboratories can unlock new levels of efficiency and productivity, paving the way for groundbreaking discoveries and advancements in science and healthcare.

0 notes

Text

Unlocking Precision and Efficiency: The Benefits of Automated Slide-Staining Systems in Tumor Diagnosis

Introduction

In the realm of modern medicine, precision and efficiency are paramount, especially when it comes to diagnosing complex conditions like tumors. Traditional diagnostic methods, although effective, can be time-consuming and prone to human error. This is where automated slide-staining systems come into play. These advanced technologies have revolutionized tumor diagnosis, offering a host of benefits that enhance accuracy, streamline processes, and ultimately improve patient outcomes.

Enhanced Accuracy

One of the primary advantages of automated slide-staining systems in tumor diagnosis is their ability to provide consistent and accurate results. Human errors, such as variations in staining techniques or misinterpretation of slides, can lead to incorrect diagnoses. Automated systems, on the other hand, ensure uniform staining procedures and eliminate the risk of human error, leading to more reliable results.

Time Efficiency

Manual staining of slides for tumor diagnosis can be a labor-intensive and time-consuming process. Automated systems dramatically reduce the time required for staining, allowing for quicker turnaround times in pathology labs. This rapid processing not only expedites diagnosis but also facilitates timely treatment decisions, which can be critical in cancer cases.

Standardization of Processes

Consistency is key in pathology, and automated slide-staining systems excel in standardizing staining protocols. These systems can be programmed to follow precise staining procedures, ensuring that each slide is treated identically. This consistency minimizes inter-laboratory variability and enhances the reproducibility of results, which is essential for research studies and clinical trials.

Preservation of Sample Integrity

Preserving the integrity of tissue samples is crucial in tumor diagnosis. Manual staining techniques may subject samples to handling errors or contamination. Automated systems handle samples with care, reducing the risk of damage or contamination and preserving the sample's quality.

Cost-Efficiency

While automated slide-staining systems represent a significant initial investment, they often prove cost-effective in the long run. The reduced need for manual labor and the elimination of reagent waste due to precise, controlled staining contribute to cost savings over time. Additionally, the ability to process a higher volume of slides with fewer resources makes automated systems economically viable for high-throughput laboratories.

Improved Workflow

Streamlining the diagnostic process is a key benefit of automation. Automated slide-staining systems can be seamlessly integrated into laboratory workflows, reducing bottlenecks and optimizing resource allocation. This allows pathologists to focus more on interpretation and less on tedious, time-consuming tasks.

Flexibility and Customization

Modern automated systems offer a high degree of flexibility and customization. Laboratories can adapt staining protocols to suit specific diagnostic needs or accommodate different types of specimens. This adaptability ensures that the system can address a wide range of tumor diagnosis requirements.

Conclusion

The adoption of automated slide-staining systems like NanoVIP® has ushered in a new era of precision and efficiency in tumor diagnosis. By enhancing accuracy, reducing processing times, standardizing procedures, and preserving sample integrity, these systems contribute significantly to improved patient care and outcomes. As technology continues to advance, the benefits of automation in pathology will only become more pronounced, reinforcing the vital role that automated slide-staining systems play in the field of medicine.

#NanoVIP® 100 & 300#Automation#FISH#ISH#miRNA ISH#Reliable Results#Protocol Optimization#User-Friendly Software#Clinical Laboratories#Research Laboratories

0 notes

Photo

Kirill Sinyavin

Level Artist @ Gaijin Entertainment

artstation instagram steamcommunity youtube behance pinterest

More from «Artstation» here

#trims#Fan Art#lumen#color#Kirill Sinyavin#sci-fi artist#assets#artist#realism#level#room#Games and Real-Time 3D Environment Art#Sci-fi room#nanite mesh#drawing#Blockout#optimization#scifi#Protocol#atmospheric#mechanical decals#Level Design#memorable#Game-Ready#Unreal Engine 5#World Partition#lighting#Game Art#sinkir24#pipeline

4 notes

·

View notes

Text

"and even better, I know no one will ever read it." Uh huh yeah Sam. Just toss those super personal spooky answers into the void and the void TOTALLY won't answer back. for sure.

#loving the delusional optimism sam#this man wouldnt know caution if it stripped naked and shook its ass in his face#hes trying his best#his best just happens to look like reckless endangerment when looked at in certain uncharitable lights#not that id ever be uncharitable or suspicious#tmagp#the magnus protocol

19 notes

·

View notes

Text

last couple of weeks of fieldwork happened but were filled with chaos that included a crew of interns, hiring nonsense, permitting nonsense, and extreme weather including both a record-breaking heat wave and thunderstorms. we were bouncing up and down the east side of the sierra (at one point we crossed the CA/NV border, like, six times over the span of two days because the mountains we were in were very precisely bisected by it.) the epic highs & lows of fieldwork included:

sampling in Death Valley National Park during the heat wave. this was actually less bad than when we were sampling across the way from Death Valley, because 8000 feet vs. 5000 feet of elevation is a very noticeable difference when it's over ninety degrees out.

we had a team of interns who were remarkably good sports and helped tide us over when our crew was briefly down to just 2 people!

i later found out that the interns had been, uh, maybe misled about how much work they'd be doing, which went a long way to explaining why they had a chronically exhausted air about them. that's academia for you i guess

got to see the ancient bristlecone pine forest on our days off!

ditched some gear in the field at one point bc i didn't feel like carrying a long metal thingy through an Active Thunderstorm while we were a couple hundred feet off a mountain peak

ditched our camp overnight bc didn't feel like taking the car back up a muddy road following an Active Thunderstorm, since the tires had real bad traction on mud

got told by a motel manager the night that we ditched camp that i? smell like pine? which. was not the worst thing. and makes sense given my constant layer of pine sap residue. but sure was an interaction that happened

got to swim in alpine lakes on our days off!

stopped taking my lunch breaks because it was the only way to even slightly keep up once our crew was back up to 4 people

and by 'keep up' i mean i was still consistently finishing 30 minutes behind the other

i don't. recommend this

a couple nights in various spots, we heard coyote packs yipping somewhere around our camp, which is a haunting and unexpectedly lovely experience. genuinely highly recommend waking up to the sound of coyotes at three a.m.

#field notes#long post#workflow optimization is an important and underrated part of fieldwork organization and#boy howdy was there a failure of optimization this time around#the upside was it meant the rest of the crew was getting like. a normal amount of breaks for what was being asked of them?#given that my bit of the protocol was less physically intense#but it was still starting to wear on me by the end#i was happy to be doing some quiet intervention to let them have work days of reasonable length compared to the formal expectations#i just wish it had not been happening somewhat at the expense of my own sanity#since apart from the extra 30 minutes in the field i averaged 30 minutes - 1 hour over back at camp doing data management / plant pressing#anyway if anyone wants the full-length rant about the Numerous Labor Rights Issues we had this summer u know where to find me

6 notes

·

View notes

Text

portal the underground is so cool i want to talk abou it so much but everyone i know has no idea whagt it is jhasfbkavfjks

#portal the underground#portal#portal 2#optimism core#paranoia core#interview core#protocol core#my art

19 notes

·

View notes

Text

BRAIN BLAST (Update Assistant Edition)

#kismet talks#backfirewall_#OKAY SO#im on my 2nd run for achievement reasons#and. i had some more possible ideas for my eventual Update Assistant design#quite a few ppl react to your appearance with varying degrees of '🤨 you look....'#which gives me the impression that you Dont Look Like the others to some degree#+ OS9 saying you look like a punk#during the Update Protocol intros/vids. there's repetition of rectangles & the U icon#i wanna have at Least one of those aspects in my design somewhere#like i said before. i also wanna have the white - blue - black - gray colors that are Also seen on a lot of Update stuff#for the loading bar#it went from black bars to a Solid Blue Bar#that + OS10's appearance makes me wanna have a darker blue as a More Prominent color in the palette#(i wanna incorporate OS10 design aspects in general tbh)#i wanna go for that 'optimized minimalism to save system energy for a temp app/process' vibe#BUT#i also have a Lot of features that i wanna incorporate djgjsjfk#lots to ponder.

2 notes

·

View notes

Text

Stop Releasing Students to Welcome Dignitaries: Wike's Strong Warning to School Principals

#ceremonial protocols#educational standards#Federal Capital Territory#infrastructure improvement#Keywords for SEO Optimization: Nyesom Wike#school principals warning#student welfare

0 notes

Text

SECS/GEM on Canon MPA 600 Super Aligner Through the EIGEMBox

In the dynamic world of semiconductor manufacturing, ensuring that legacy equipment can keep up with modern communication standards is essential for maintaining productivity and efficiency. The Canon MPA 600 Super Aligner, a widely used piece of equipment in semiconductor fabs, often lacks the native SECS/GEM capabilities required for seamless integration into contemporary manufacturing systems. Enter EIGEMBox, a patented, plug-and-play solution that brings SECS/GEM compliance to legacy equipment without the need for extensive hardware or software installations.

In this blog, we will explore the benefits of using EIGEMBox to enable SECS/GEM on the Canon MPA 600 Super Aligner and how this can revolutionize your manufacturing process.

What is SECS/GEM?

SECS/GEM (SEMI Equipment Communications Standard/Generic Equipment Model) is a set of protocols developed by SEMI (Semiconductor Equipment and Materials International) to standardize communication between semiconductor manufacturing equipment and host systems. These protocols are critical for enabling automation, real-time data collection, and equipment control, which are essential for the efficiency and productivity of modern semiconductor fabs.

The Importance of SECS/GEM Compliance SECS/GEM compliance offers several significant benefits for semiconductor manufacturing: Automation: SECS/GEM protocols enable the automation of equipment operations, reducing the need for manual intervention and minimizing the risk of human error. This leads to higher throughput and more consistent production quality.

Data Collection and Analysis: SECS/GEM allows for real-time data collection from equipment, which can be analyzed to monitor performance, optimize processes, and predict maintenance needs. This data-driven approach helps in making informed decisions that improve overall efficiency.

Equipment Control: With SECS/GEM, equipment can be controlled remotely by the host system, allowing for better coordination and scheduling of manufacturing tasks. This ensures optimal utilization of resources and reduces downtime.

Interoperability: SECS/GEM provides a standardized communication framework, ensuring that equipment from different vendors can work together seamlessly. This interoperability is crucial for maintaining a cohesive and efficient manufacturing environment.

Challenges with Legacy Equipment

While SECS/GEM offers numerous advantages, many legacy equipment like the Canon MPA 600 Super Aligner lack native SECS/GEM capabilities. Upgrading these machines to meet modern standards can be a complex and costly process, often requiring significant hardware and software modifications. This is where EIGEMBox comes into play.

Introducing EIGEMBox

EIGEMBox is an innovative, patented solution designed to bring SECS/GEM capabilities to legacy equipment without the need for additional hardware or software installations. This plug-and-play device makes it easy to upgrade older machines, ensuring they can communicate effectively with modern control systems and integrate seamlessly into automated manufacturing environments.

Key Features of EIGEMBox

Plug-and-Play Convenience: EIGEMBox is designed for easy installation and operation. Simply connect the device to your legacy equipment, and it starts working immediately, without the need for extensive configuration or setup.

No Hardware or Software Installation Required: Unlike traditional SECS/GEM integration solutions that often require complex hardware and software installations, EIGEMBox eliminates these hassles. This makes it a cost-effective and time-saving solution for upgrading your equipment.

Patented Technology: EIGEMBox utilizes patented technology to ensure reliable and efficient communication between your legacy equipment and modern control systems. This guarantees seamless integration and improved operational efficiency.

Enhanced Data Exchange: With EIGEMBox, your legacy equipment can exchange data in real-time with control systems, enabling better monitoring, analysis, and optimization of manufacturing processes.

Benefits of Using EIGEMBox with Canon MPA 600 Super Aligner

Upgrading the Canon MPA 600 Super Aligner with EIGEMBox offers several significant benefits:

Extended Equipment Life: By enabling SECS/GEM compliance, EIGEMBox extends the operational life of the Canon MPA 600 Super Aligner, allowing you to maximize your investment in this equipment.

Improved Efficiency: Enhanced communication and control capabilities lead to better coordination of manufacturing tasks, increased throughput, and reduced downtime. This results in the overall improved efficiency of your manufacturing process.

Cost Savings: EIGEMBox eliminates the need for costly hardware and software upgrades, providing a more affordable solution for integrating SECS/GEM protocols into your manufacturing processes.

Seamless Integration: EIGEMBox ensures that your Canon MPA 600 Super Aligner can communicate effectively with modern control systems, enabling a smoother and more efficient manufacturing operation.

Case Study: Successful Integration of EIGEMBox with Canon MPA 600 Super Aligner

One of our clients, a leading semiconductor manufacturer, faced challenges in integrating SECS/GEM protocols into their Canon MPA 600 Super Aligner. After implementing EIGEMBox, they experienced a significant improvement in production efficiency. The plug-and-play nature of EIGEMBox allowed for a quick and hassle-free integration process, resulting in a 20% increase in equipment utilization and a 15% reduction in downtime. The client was able to extend the life of their existing equipment while achieving substantial cost savings. How to Get Started with EIGEMBox Ready to revolutionize your semiconductor manufacturing processes with EIGEMBox? Here’s how you can get started:

Contact Us: Reach out to our team for a consultation. We’ll assess your current equipment and provide tailored recommendations for integrating EIGEMBox into your manufacturing environment.

Easy Installation: Once you’ve decided to move forward, our team will guide you through the simple installation process. No need for extensive configuration or setup – just plug it in and start reaping the benefits.

Ongoing Support: Our commitment to your success doesn’t end with installation. We offer comprehensive support to ensure that your EIGEMBox operates seamlessly and delivers the desired improvements in efficiency and productivity.

Contact Us Today! Don’t let outdated equipment hold back your semiconductor manufacturing operations. With EIGEMBox, you can achieve modern communication and control capabilities without the need for costly hardware or software installations. Contact us today to learn more about how EIGEMBox can transform your Canon MPA 600 Super Aligner and drive your manufacturing processes forward.

#SECS/GEM integration#Canon MPA 600 Super Aligner#EIGEMBox#semiconductor manufacturing#legacy equipment upgrade#plug-and-play SECS/GEM#SECS/GEM compliance#semiconductor automation#factory automation#SECS/GEM protocol#SECS/GEM communication#equipment control systems#real-time data collection#manufacturing process optimization#cost-effective SECS/GEM solution#improve production efficiency#legacy equipment SECS/GEM#EIGEMBox installation#semiconductor industry standards#SECS/GEM host simulation#reduce equipment downtime

0 notes

Text

finally birthing male manipulator satoru with girl failure reader wwww

gojo satoru was used to getting what he wanted.

and he wanted you.

not in some deep, profound way—god, no. not at first. it started as a game. a challenge. a passing amusement that piqued his interest one random thursday morning when you stammered out an apology after bumping into his desk, cheeks flushed, eyes wide. he watched you trip over your own words, clutch your pen like a lifeline, and tuck your legs up onto the chair like you could shrink out of existence if you tried hard enough.

prime target. textbook girlfailure behavior. he could spot it from a mile away.

this was supposed to be easy.

he’d start small. nothing too intense. just a little white knight routine—softboy edition. give you just enough attention to get you spinning. love-bomb in casual doses. trauma-dump-lite over late-night fries. maybe let his voice go quiet and vulnerable one evening and say, “you remind me of someone i cared about.” glance away, bite his lip, look just the right amount of broken. play the victim just enough to make you feel like you had to fix him.

he’d make you think he saw you. that he understood you.

except you, with your messy hair and oversized hoodie sleeves pulled over twitchy fingers, dodged every single one of his perfectly curated attempts like your avoidant attachment style was running military-grade defense protocols.

“you okay, sweetheart?” he asked one afternoon, leaning a little too close to your desk, silver hair slightly tousled, reading glasses slipping down the bridge of his nose, his voice low and silky. lips curved into a smile that’d made stronger girls fold. “you looked a little sad today. i worry about you sometimes.”

you blinked up at him, lashes fluttering like you couldn’t believe he was talking to you. your throat worked around a half-swallowed gulp. then your face shifted. shutters slammed down. you forced a grin, lopsided and sharp around the edges.

“yeah, i’m just like this. it’s seasonal depression, but, y’know… year-round. i’m fine.”

you said it so matter-of-factly. like he was asking about the weather.

satoru froze, his hand briefly twitching near his glasses as he pushed them up slowly, searching for meaning in a world that had suddenly gone sideways.

what the actual hell.

okay. maybe you needed more.

he started sitting next to you in class. always coincidentally. elbows brushing, knees knocking. his thigh warm where it grazed yours. he sent you memes at 1:37 a.m. with captions like “us fr?” and “ur literally me,” despite you barely replying to half of them. he offered his jacket when the AC kicked on and watched the way you hesitated, blushed, and then said, “i run on spite, not warmth.”

and then, the pièce de résistance:

“i just feel like… you’re different,” he said one evening outside the library. the campus was quiet, sky the kind of inky navy that made everything feel more cinematic. he stood with hands stuffed into his hoodie pocket, a calculated slouch, glasses slightly askew, hair falling across his forehead. his voice dipped low, coaxing. “everyone else is so fake. but you? you’re real. you’ve got this… broken, beautiful thing going on.”

you tilted your head. stared. then squinted at him like he was a suspiciously priced antique. “did you get that line off tiktok?”

he flinched.

bro.

he ran a hand through his hair. a slow, dramatic drag of fingers. girls walking by giggled. he didn’t look up. he was malfunctioning.

he was trying. actually trying. not just running a script. not just playing games. he was pulling every page from the softboy manipulator playbook and rewriting it with style. the gaslight-gatekeep-girlboss starter pack, optimized for 2025.

and still. you met his carefully calculated charm with self-deprecating jokes, sarcasm, and the kind of deadpan delivery that made him question if he was losing it.

“you should save that line for someone without warranty issues,” you said, staring at him with a crooked little smile. “i come pre-broken.”

he left that encounter walking in slow motion, hoodie sleeves dragged over his hands, mouth set in a pout. if a sad indie movie montage started playing around him, he wouldn’t have questioned it.

here’s the thing, though: you liked him.

it was obvious.

he saw it in the way your gaze flickered to his mouth when he talked. the way your fingers curled tight around your notebook when he leaned in too close. the way your breath hitched just slightly when he used your name in a sentence. you were down bad.

but you were also your own worst enemy.

years of romantic misfires and silent yearning had turned you into a master of avoidance. you would rather make a joke about your emotional damage than let someone touch your heart. rather ghost your feelings than face them.

and it was frying his entire nervous system.

one night, 2:14 a.m., satoru lay on his bed staring at your latest post: a blurry picture of your cat with the caption “me.” it had two likes.

he stared at it longer than any man should. took a screenshot. set it as his lock screen for five minutes. unironically laughed.

then groaned and stuffed his face into his pillow.

“no,” he muttered. “no. she’s the one who canceled our group study session with ‘sorry i’m busy disappointing my ancestors.’”

and yet.

he kept thinking about the way your voice dropped to a whisper when you didn’t think anyone was listening. the way you fiddled with your sleeves when you were nervous. how you always sat at the edge of a group like you weren’t sure you belonged there.

you never clung to him. never fed into his savior complex. never let him be the one who "fixed" you.

and for some reason, that made him want to try harder.

not because it was a game anymore. because… well. because you were infuriating. weird. unpredictable. not like the others. god, maybe you were even kind of funny.

whatever. it wasn’t that deep.

gojo satoru: male manipulator dodged by the one girl who wanted him back… just enough to sabotage it.

and now he’s the one thinking way too hard about someone who won’t even sit next to him two days in a row.

he doesn’t like you.

he just… finds you interesting.

that’s all.

shut up.

#gojo satoru#gojo drabbles#gojo crack#gojo fluff#gojo x reader#gojo x female reader#gojo x reader crack#gojo x reader fluff#gojo satoru x reader#gojo satoru x y/n#gojo satoru x you#satoru gojo x reader#satoru gojo x you#satoru gojo x y/n#jjk fluff#jjk crack#jjk drabbles#jjk x reader

3K notes

·

View notes

Text

Integrating Lab Analyzers: Best Practices for Seamless Operations

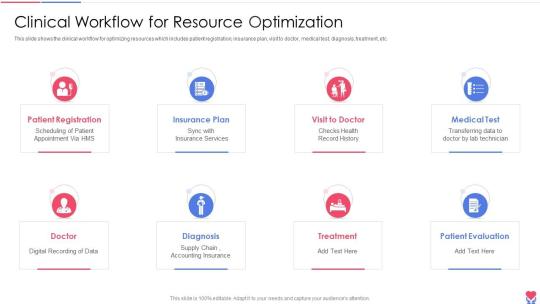

In the realm of laboratory operations, lab analyzers interfacing plays a crucial role in ensuring smooth and efficient workflows. Laboratories rely on interfacing solutions to seamlessly connect various analytical instruments and systems, enabling automated data transfer and streamlined processes. Let's delve into some best practices for integrating lab analyzers to optimize operations.

Automated transfer of data between lab analyzers and information systems is essential for reducing manual errors and enhancing efficiency. Leveraging interfacing solutions that support automated data exchange enables real-time transmission of test results, eliminating the need for manual data entry and reducing turnaround times. By automating data transfer, laboratories can improve accuracy, minimize delays, and enhance overall productivity.

Workflow optimization is another key aspect of integrating lab analyzers effectively. By designing workflows that leverage interfacing solutions to their full potential, laboratories can streamline sample processing, result reporting, and data management processes. This includes configuring automated workflows, setting up rule-based result validation, and implementing batch processing capabilities to maximize throughput and minimize bottlenecks.

Ensuring compatibility between lab analyzers and interfacing solutions is crucial for seamless integration. Before deploying interfacing solutions, laboratories must conduct thorough compatibility testing to verify that the software or middleware is compatible with the analytical instruments and information systems in use. This involves testing communication protocols, data formats, and connectivity options to ensure smooth and reliable operation.

Establishing robust integration protocols is essential for maintaining interoperability and data integrity across different systems and platforms. Standardizing communication protocols, data exchange formats, and error handling procedures facilitates seamless integration and ensures consistent performance across heterogeneous environments. By adhering to established integration protocols, laboratories can minimize compatibility issues and enhance system reliability.

In conclusion, integrating lab analyzers requires careful consideration of interfacing solutions, automated transfer, workflow optimization, compatibility testing, and integration protocols. By adopting best practices in these areas, laboratories can achieve seamless operations, improve efficiency, and deliver timely and accurate test results. Embracing innovative interfacing solutions and optimizing workflows are essential steps toward realizing the full potential of lab analyzer integration in modern laboratory settings

#Interfacing Solutions#Automated Transfer#Workflow Optimization#Compatibility Testing#Integration Protocols

0 notes

Text

Exploring the New Horizons of SQL Server 2022: MS-TDS 8.0 and TLS 1.3

Understanding Tabular Data Stream (TDS) in SQL Server – Introduction In the realm of Microsoft SQL Server, an essential component that ensures seamless communication between a database server and its clients is the Tabular Data Stream (TDS). TDS is a protocol, an application layer protocol, to be precise, that plays a pivotal role in the exchange of data between a client and a server. This blog…

View On WordPress

#MS-TDS 8.0 protocol#SQL Server 2022 TDS#SQL Server performance optimization#SQL Server security enhancements#TLS 1.3 encryption

0 notes

Text

Testosterone Boosting PROTOCOL through a Comprehensive Approach

Today, we delve into a pressing concern for those over 40—the decline in testosterone levels. As we age, our testosterone levels tend to plummet, with each passing year showing a disheartening trend. Read more...

Ladies and gentlemen, oh no, sorry, I mean gentlemen only! After an eight-month absence, during which I dedicated my time and energy to the research, design, and launch of my second flagship system, The PLUS+, I’m thrilled to be back with a renewed focus on sharing valuable insights through my YouTube videos / articles. Why do we need such a protocol? Today, we delve into a pressing concern…

View On WordPress

#aging and testosterone#balanced diet#best men&039;s lifestyle coach#Bodybuilding#coffee#creating#diet#fitness#free T#Health#hormone balance#masculinity#men&039;s health#over 50#over-40#protocol#resistance training#testosterone#testosterone optimization#testosterone testing kits#total t#training

0 notes

Text

I got home from the hospital after a knee incident to discover that apparently the wireless Internet had been specifically routing through my knee, which has actually sent me down this huge rabbit hole of how basically knees are the natural environment of electromagnetic waves due to the meniscusal resonance amplification but it wasn't until like 2014 that the first Verizon scientists were able to break people's knees open to figure out how to optimize this affinity for practical effect. These days obviously the Internet can resonate off of any human ligament but the knee internal protocol is still built into every system at the lower levels, which is why you get incidents like this even when all the rest of my wireless resonance chambers are fundamentally intact

1K notes

·

View notes

Text

The mattress store I work at gets transfers once a week. Stock comes in from the warehouse, a few beds on hand for pickup, frames, sheets, protectors. They also pick up stuff from us. Floor model beds that have been sold off mostly.

Today the transfer was picking up a boxspring that’s been languishing in the back room for over a year with a huge tag that says DO NOT SELL. I was elated when I found out what’s what they were taking.

Then the guys pulled it out and froze. Given the small space in the back room I was mostly trapped behind it waiting for them to pull it free.

They communicated rapidly in a language I didn’t speak then finally there was a tiny, “There’s a bug on it.”

“Oh. Gross. Want a paper towel?”

“No, it’s inside the bag.”

I paused in confusion and wiggled out from behind the box to regard where he pointed. A very desiccated dead beetle was clinging to the boxspring. I looked at the drivers. I looked back at the beetle.

“We can’t take it,” he said.

I frowned in confusion before the shoe finally dropped that it was a bed bug safety protocol. No bugs are allowed on any pickups because if we had bugs get into the warehouse it could be catastrophic.

“Oh. Can you send a picture?”

He took a picture and called the warehouse. The three of us regarded the dried up beetle husk.

There were several minutes of back and forth. Finally he turned back to me and said, “Can you get it out?”

“The beetle?” I asked, my voice hitting a shrill hilarity only perceivable by dogs. It was so clearly and evidently not a bedbug that the absurdity of this request was breaking me.

He nodded.

I went to get scissors. I poked the bug corpse down the plastic repeatedly until it reached the ground. I cut into the plastic and tried to flick it out. It went deeper.

Cursing I got on my knees, maneuvering the scissors to get the mummified insect free. It slid away from my hole. I hissed and cut a second hole, reaching hopefully in with the dull side of the scissors. It slid deeper once again.

I huffed and looked up at the guys in defeat, “It’s too far back.”

One of them took the scissors and gestured me away. The other hefted the box to try to slip and slide the bug body to one of the holes while the first guy dropped to his back on the floor like a boxspring mechanic, a frown of concentration on his face.

He and the guy holding it up maneuvered the poor boxspring between them back and forth trying to find an optimal beetle retrieval angle. Finally he managed to free the worse for wear beetle body.

It dropped anticlimactically to the ground at our feet, tiny and unassuming, a faded grey speck on the linoleum that had put all of us to so much trouble.

We cheered anyway.

The guys took the box and the beetle received last rites in the form of a paper towel.

764 notes

·

View notes