#biodegradable plastics

Text

0 notes

Text

instagram

#biodegradable plastics#those lying fuckers#united nations treaty on plastics#fossil fuel companies#yeah that’s to be expected with these companies#Instagram

1 note

·

View note

Text

Finding nature-inspired alternatives to plastics focus of new center - Technology Org

New Post has been published on https://thedigitalinsider.com/finding-nature-inspired-alternatives-to-plastics-focus-of-new-center-technology-org/

Finding nature-inspired alternatives to plastics focus of new center - Technology Org

Despite efforts to reduce the use of plastic or recycle it, most plastic produced in the world ends up in landfills, the oceans, or is dumped, causing catastrophic effects on the environment, the ecosystem, and the economy.

The mission of the Synthetic Biology Manufacturing of Advanced Materials Research Center is to push the frontiers of knowledge through convergent research; develop pathways to train a manufacturing workforce; leverage an environment of diversity; and enhance innovation in the manufacturing of synthetic biological materials. Image credit: Aimee Felter/McKelvey School of Engineering

To address this, a team of researchers in the McKelvey School of Engineering at Washington University in St. Louis has established the Synthetic Biology Manufacturing of Advanced Materials Research Center (SMARC) to create an integrated education, research and innovation ecosystem enabled by the convergence across multiple disciplines and research areas.

Its mission is to push the frontiers of knowledge through convergent research; develop pathways to train a manufacturing workforce that can harness artificial intelligence and the biological transformation in manufacturing; leverage an environment of diversity and inclusion to maximize human capital; and enhance innovation in the manufacturing of synthetic biological materials by understanding and overcoming barriers to technology adoption in partnership with industry.

Marcus Foston, an associate professor of energy, environmental and chemical engineering, will co-lead the center with Fuzhong Zhang, a professor of energy, environmental and chemical engineering and co-director of the center, which is funded in part by a five-year $3.6 million Growing Convergence Research grant from the National Science Foundation. With this funding, the team plans to develop a new class of biologically synthesized, protein-based and biodegradable materials that harness themes from nature to replace traditional petroleum-derived plastics.

“Our vision is a future in which advances in synthetic biology, biotechnology and biomanufacturing, machine learning, social sciences, materials science and mechanics converge to transition the world toward wide-spread use of bio-derived and biodegradable plastics from renewable feedstocks,” Foston said.

[embedded content]

Also on the Washington University leadership team are Guy Genin, the Harold and Kathleen Faught Professor of Mechanical Engineering, and Roman Garnett, an associate professor of computer science and engineering. Researchers from Northwestern University, Iowa State University and the University of South Florida bring together a convergence of cross-disciplinary expertise to evolve the plastics economy by developing a platform for the discovery of synthetic biological materials with desired properties.

Foston and Zhang will lead a team that includes experts in synthetic biology, machine learning, polymer science, material mechanics and computational materials simulation. They will use machine learning aided with material screening and simulation approaches to accelerate the process of finding promising protein sequences that can be used to make biodegradable materials with targeted properties to replace plastics in both high- and low-value applications. In addition, they will develop synthetic biological methods and genetically engineered microbes to produce protein-based materials sustainably and economically.

While much of the biomanufacturing industry has focused on medicines and biotherapeutics, this center will focus on fundamental scientific and engineering problems that occur during the design, development and manufacturing stages of synthetic biological materials, with the goal of leading a large-scale transition to an economy based upon sustainable and biodegradable plastics. This transition will begin with high-performance polymers.

“Synthetic biology has the potential to deliver the next generation of advanced materials with new functional properties to address a wide range of unmet needs,” Genin said. “With examples such as spider silk, elastin and resilin, synthetic biology also has the potential to leverage nature to provide access to affordable and sustainable production of novel macromolecular materials.”

Along with research, the center will include an education component.

“We will develop unique graduate educational frameworks for cross-disciplinary innovation at WashU, while simultaneously working to develop a pipeline of future innovators in the St. Louis community,” said Zhang, the center’s director of education and outreach. “This is a unique opportunity to impact our community and our world.”

[embedded content]

The center will open with a major international symposium April 18-19. Until then, Foston said, their work is cut out for them.

“This is a once-in-a-lifetime opportunity for major impact in the region and world,” he said. “We are all thrilled to have these resources to bring together the particular strengths of WashU and St. Louis to solve a pressing global challenge.”

Source: Washington University in St. Louis

You can offer your link to a page which is relevant to the topic of this post.

#A.I. & Neural Networks news#advanced materials#applications#artificial#Artificial Intelligence#artificial intelligence (AI)#biodegradable#biodegradable materials#Biodegradable plastics#Biology#biotechnology#challenge#chemical#Chemical engineering#Community#computer#Computer Science#Design#development#diversity#Diversity and Inclusion#economy#education#effects#energy#engineering#Environment#Environmental#Foundation#Fundamental

0 notes

Text

#BIODEGRADABLE PLASTIC BAGS#BIODEGRADABLE PLASTICS#ENVIRONMENT SAFE PLASTICS#MICROWAVING FRIENDLY PLASTICS#START BIODEGRADABLE PLASTICS

0 notes

Text

The Transformative Journey of the Bioplastic Packaging Industry

The global bioplastic packaging market size is expected to reach USD 50.57 billion by 2030. The growth of the global plastics packaging industry is likely to be driven by the increasing consumption of plastics in packaging food, beverages, cosmetics, personal care, and consumer goods.

Gain deeper insights on the market and receive your free copy with TOC now @: Bioplastic Packaging Market Report

Bioplastics are plastics that are made from renewable sources such as corn, sugarcane, potato, wheat, rice, vegetable oil, or cellulose. There are two types of bioplastics, namely biodegradable plastics and non-biodegradable plastics. Biodegradable plastics include polylactic acid, starch blends, PBAT, and PBS, while non-biodegradable plastics include polyethylene, polyethylene terephthalate, polyamide, and polytrimethylene terephthalate.

Bioplastic packaging is considered to be an environment-friendly solution and helps enhance the final product’s appearance. Growing usage of bioplastics in flexible packaging is expected to fuel market growth. The growing demand for food, due to the rising global population, is a key factor driving the demand for flexible packaging. Moreover, the packaged food industry in the U.S. and Europe has grown tremendously in recent years. Furthermore, increasing concerns regarding toxins in petrochemicals, along with depleting crude oil reserves, are driving the development of bio-based polymers.

Regulations by most governments restricting the consumption of petroleum-based plastics in certain applications such as food packaging and medical devices are expected to further incentivize bioplastic production in the plastics industry. However, the high cost as compared to conventional plastics is a major factor restraining the market growth. Currently, low prices of conventional plastics are making it difficult for bioplastics to achieve competitive pricing.

#Bioplastic Packaging#Sustainable Packaging#EcoFriendly Materials#Green Packaging#Biodegradable Plastics#Plant Based Packaging#Circular Economy#Packaging Innovation#Reducing Plastic Waste#BioMaterials#Plastic Free Packaging#Environmentally Friendly#Packaging Solutions#Bioplastics#Compostable Packaging#Renewable Materials#Packaging Design#Responsible Consumption#Sustainable Choices#Future Of Packaging

1 note

·

View note

Text

Welcome to my Tuesday morning PSA about plastics!

So--I was walking along the Bolstadt beach approach sidewalk here in Long Beach, WA yesterday afternoon, and I started seeing these little orange pellets on the ground that looked a little bit like salmon roe (but probably weren't). So I picked one up, and it was most definitely rubber. I went around picking up every one I could find, and while I didn't keep exact count I probably amassed 50-60 of them. I took this picture before depositing them in the nearest trash can.

These are airsoft gun pellets, and you can buy them in big jars containing thousands of them. That means that someone who decided that the beach was a great place to shoot their airsoft guns could easily litter the place with countless little bits of plastic rubber in less than an hour. We already have a huge problem here with people leaving trash, including tiny bits of plastic, all over the beach (you should see the gigantic mess after 4th of July fireworks when thousands of people come in from out of town, blow things up, and then leave again without picking up after themselves.)

But these airsoft pellets have a particularly nasty side effect. You know how my first thought was "wow, those look kind of like salmon roe?" Well, we have a number of opportunistic omnivore birds like crows, ravens, and several species of gull that commonly scavenge on the beach, especially along the approaches because people often feed them there. If I can catch the resemblance of an orange airsoft pellet to a fish egg, then chances are there are wildlife that will assume they're edible.

Since birds don't chew their food, they probably won't notice that the taste or texture is wrong--it'll just go down the hatch. And since they can't digest the pellets, there's a good chance they might just build up in the bird's digestive system, especially if the bird eats a large number of them--say, fifty or sixty of them dropped on the ground along the same fifty foot stretch of sidewalk. The bird might die of starvation if there's not enough capacity for food in their stomach--or they might just die painfully of an impacted gut, and no way to get help for it. If the pellets end up washed into the ocean, you get the same issue with fish and other marine wildlife eating them, and then of course the pellets eventually breaking up into microplastic particles.

You can get biodegradable airsoft pellets; they appear to mainly be gray or white in color rather than bright screaming orange and green. But "biodegradable" doesn't mean "instantly dissolves the next time it rains." An Amazon listing for Aim Green biodegradable airsoft pellets advertise them as "Our biodegradable BBs are engineered to degrade only with long-term exposure to water and sun and will degrade 180 days after being used." That's half a year for them to be eaten by wildlife.

I don't know, y'all. That handful of carelessly dropped rubber pellets just encapsulates how much people don't factor in the rest of nature when making decisions, even on something that is purely for entertainment like an airsoft gun. We could have had a lot of the same technological advances we have today, but with much less environmental impact, if we had considered the long-term effects on both other people and other living beings, as well as our habitats. We could have found ways from the beginning to make these things in ways that benefited us but also mitigated any harm as much as possible. Instead we're now having to reverse-engineer things we've been using for decades, and sometimes--like the "biodegradable" airsoft pellets--they still have a significant negative impact.

But--at least there are people trying to do things better, thinking ahead instead of just on immediate profit. We're stuck in a heck of a mess here, figuratively and literally, and changing an entire system can't be done in a day. Maybe we can at least keep pushing for a cultural shift that emphasizes planning far into the future--if not the often-cited "seven generations ahead", then at least throughout the potential lifespan of a given product.

#plastics#microplastics#environment#environmentalism#conservation#nature#pollution#litter#birds#tw animal death#animal welfare#ecology#science#wildlife#animals#scicomm#pnw#airsoft#biodegradable#solarpunk

4K notes

·

View notes

Text

MAIRE Tecnimont Acquires Conser to Strengthen Energy Transition Portfolio

MAIRE Tecnimont S.p.A., a leading player in the engineering and construction of plants in the energy, infrastructure, and petrochemical sectors, announced the completion of the acquisition of an 83.5% stake in Conser.

(more…) “”

View On WordPress

0 notes

Text

Innovation prize for Limburg-based company that combats plastic soup

The producer of bioplastics B4Plastics has won the Limburg Innovation Award from Voka Limburg.

Every year since 2008, employers' organisation Voka[1] Limburg has awarded a prize to a Limburg company that has launched an innovative product or service. The Innovation Award, which is organized in collaboration with the Flemish Agency for Innovation and Entrepreneurship, goes this year to B4Plastics in Dilsen-Stokkem[2], a company that develops and produces bioplastics.

Innovative and sustainable

B4Plastics[3] succeeds brick maker Vandersanden[4] and drone specialist DroneMatrix[5], who were the previous winners. B4Plastics eventually beat the companies Luminex[6] and Netalux[7]. “By extracting building blocks from nature and producing them on an industrial scale, B4Plastics shows that innovative and sustainable entrepreneurship go hand in hand,” say Johann Leten and Cathérine Dreesen, respectively managing director and innovation director at Voka Limburg.

CEO Stefaan De Wildeman of B4Plastics was particularly delighted with the award presented by Governor of Limburg Jos Lantmeeters. “This award not only recognizes our work, but also highlights the growing importance of the bioeconomy in our society.”

Stefaan De Wildeman from West Flanders founded B4Plastics in 2014 and started producing ecological plastics based on organic raw materials in 2018. Over the past five years, the company has received more than 2.3 million euros in support from VLAIO (Agency for Innovation and Enterprineurship in Flanders) for this purpose.

Plastic in food

"Plastics are an indispensable part of our lives, but they also have major disadvantages," says Stefaan De Wildeman. “For example, today’s plastic is mainly produced from fossil oil. After use, we often do not know what to do with it, so plastics end up in incinerators or, even worse, in our forests, roadsides and waterways. Think of the so-called plastic soup in the oceans. Moreover, plastic is hardly biodegradable. In the worst case, it ends up in the food chain in the form of microplastics.”

With B4Plastics, Stefaan De Wildeman has been looking for biological alternatives to plastic since 2018. “The way plastics are produced and the way we use them are outdated. We need to move towards more sustainability.”

Ambition

At B4Plastics, about twenty people are currently working on plastics based on, among other things, biological waste from agriculture and residual flows from the food industry. This results in bio-based and degradable products. For example, a sustainable alternative was developed for the classic rubber shoe sole, in which the worn rubber is degradable and does not float around in the form of granules. Another innovation is the development of animal-free leather based on biomass. As a result, the company enjoys the interest of potential customers from all over the world.

The business has an enormous potential, at a global level. No one doubts that the milestone of 1 million euros in turnover will be pulverized repeatedly in the coming years. B4Plastics has concrete plans to build a new production plant next door, where large volumes of basic material will provide an impactful revolution in terms of environmental friendliness. In the meantime, the team has been considerably expanded with specialists, such as very recently Leen Thys, who will professionalise communication and marketing. The company was awarded the prestigious Food Planet Prize for the development of biodegradable fishing nets.

Source

Guido Cloostermans, Innovatieprijs voor Limburgers die plastic soep bestrijden, in: De Standaard, 8-03-2023, https://www.standaard.be/cnt/dmf20230307_98213819

[1] Voka, network of companies in Flanders is an employers' organisation. As a network of companies, it claims to represent more than 18,000 companies and thus 65% of the added value in Flanders and 66% of private employment. In total, this would concern more than 910,000 employees. As one of the seven represented social partners in the Social and Economic Council of Flanders (SERV), Voka has a say in the policy of the Flemish government. Voka stands for Entrepreneurs Chambers Alliance of Flanders.

[2] Dilsen-Stokkem is a city and municipality located in the Belgian province of Limburg. On January 1, 2018, Dilsen-Stokkem had a total population of 20,454. The total area is 65.61 km² which gives a population density of 312 inhabitants per km².

[3] B4Plastics is a Polymer Architecture company, catalysing the introduction of novel biomaterials, and growing them from niche to bulk applications. https://b4plastics.com/about/

[4] Vandersanden is a family company established in 1925. Based on a rich experience and knowledge in innovation Vandersanden profiles itself as the Belgian market leader in handformed facing bricks. Vandersanden develops and sells worldwide hand-formed, waterstruck and wire cut facing bricks, pavers for public spaces and gardens, joint-free brickwork (Zero®), insulated brick solutions (E-Board®) and creative façade systems (Signa®). Vandersanden offers facing bricks and pavers in different colours, shapes and textures to obtain a unique esthetic result for every project, house, public space, garden and building. There is a continuous improvement and prevention of energy use. Vandersanden is positioning itself as a real force for sustainable development and demonstrating its active concern for the environment. https://www.vandersanden.com/nl-be

[5] Founded in 2015 by the Vanwelkenhuyzen family and based in Belgium, grown from the RiskMatrix group and since 2022 together with investing shareholder Nordic Unmanned, global leader of high-end products and services related to drones and data capture. https://www.dronematrix.eu/company

[6] Luminex Network Intelligence is a Belgium-based manufacturer of data distribution equipment for professional lighting, audio, and video applications in the entertainment industry. We offer a complete range of network switches, DMX–converters –nodes, and –splitters. Offering easy to deploy and cutting-edge technology for AV designers and technicians to build complete data distribution systems for events and venues of any size. https://www.luminex.be/company-2-2/

[7] Netalux specializes in laser cleaning technology and is unique in its position as a service provider and manufacturer. As a company, we have first-line experience with the technology and can therefore develop the best possible machines, built for users by users. This approach has earned our product Needle a Red Dot Industrial Design Award. 5 Good reasons to use laser cleaning: 1) Not dirty and non-toxic 2) Laser makes cleaning easier 3) Less preparation, less logistical burden 4) Cleaning of corners and edges 5) Super clean result without damage. https://www.netalux.com/?utm_term=netalux&utm_campaign=BENL&utm_source=adwords&utm_medium=ppc&hsa_acc=6455356997&hsa_cam=623451254&hsa_grp=25857746207&hsa_ad=573287201645&hsa_src=g&hsa_tgt=kwd-1641244654302&hsa_kw=netalux&hsa_mt=p&hsa_net=adwords&hsa_ver=3&gclid=Cj0KCQiAgaGgBhC8ARIsAAAyLfHrcQJDnDbBafND2gIRcJfuVlqasAUPngE9vIpjvZ_ZY4KjIVvuc4kaAhKQEALw_wcB

0 notes

Text

Horticulture Bioplastic Market – Current Trends and Growth Drivers Along with Key Industry Players 2029

Better production, enhanced mechanization, and easier logistics are some of the key contributors to the higher usage of plastics in the horticulture industry. They have quickly replaced heavy and brittle clay pots as they are not as lightweight and durable as plastics. As globalisation gains momentum, the demand for exotic plants has increased. To this end, many greenhouses, growers, and nurseries are investing in larger, more efficient, and profitable logistical mediums and packaging, which is plastic. Although, as the environmental impact of plastics attracts higher scrutiny, bioplastics have grown in demand. Bioplastics are made up of sustainable materials such as vegetable oils and fats, soybean flour, and cornstarch. This is setting the stage for the growth of the global horticulture bioplastic market. In the coming years, favourable government initiatives and paced urbanisation is expected to lead the market to sound maturity.

For More Industry Insights Read: https://www.fairfieldmarketresearch.com/report/horticulture-bioplastic-market

Favourable Government Norms to Sustain Market Growth

In the recent past, worsening plastic pollution trends have paved the way for several changes. Many government initiatives are also being proposed to encourage horticultural experts and players to adopt more eco-friendly and sustainable practices. Landfills have a notable environmental impact, creating an incentive to imbue bioplastics into horticultural techniques. Many greenhouse owners and gardeners are also making considerable efforts to adopt more ecological processes by using biodegradable plastics. Moreover, paced urbanisation is also contributing to landfills, creating a need for better usage of water resources and urban lifestyle conditions. These factors are propelling the global horticulture bioplastic market to greater heights.

Paced Demand for Polyesters to Open New Avenues of Growth

As bioplastic materials continue to improve in terms of quality and durability, the demand for polyesters is expected to exhibit an explosive increase. The demand for polyesters is growing amidst growing carpets, rugs, and other industrial product sales. Moreover, a mattress made of polyester is being employed in both residential and commercial floor settings. Moreover, several end-use industries including healthcare, automobiles, home, and electronics & construction are also contributing to positive market trends. Such a prolific demand for polyesters is expected to bode well for the global horticulture bioplastic market in the forecast period. Of late, high-end polyesters with greater durability, drying speed, and ease of clearing are also gaining traction.

North America to Dominate Horticulture Bioplastic Market Amidst Growing Environmental Awareness

A high concentration of key market entities, a fast-maturing consumer base, and higher environmental consciousness is expected to sustain North America’s dominance in the horticulture bioplastic market. Moreover, the presence of supportive government initiatives and support for sustainable industries is furthering the regional market growth prospects. Bioplastics are quickly replacing single-use plastics through stringent rules and regulations is also creating positive trends for bioplastics. In addition, growing technical breakthroughs in horticulture bioplastic technology are expected to stimulate further growth in major economies in North America.

Major Market Players

Some of the most notable players in the global horticulture bioplastic market players include Novomant SPA, Metabolix, Inc., Green Dot Bioplastics, Corbion Purac, Braskem, Cardia Bioplastics, Biome Technologies Plc, BASF S.A., Natureworks LLC, FKuR Kunststoff GmbH, and Innovia Films.

For More Information Visit: https://www.fairfieldmarketresearch.com/report/horticulture-bioplastic-market

About Us

Fairfield Market Research is a UK-based market research provider. Fairfield offers a wide spectrum of services, ranging from customized reports to consulting solutions. With a strong European footprint, Fairfield operates globally and helps businesses navigate through business cycles, with quick responses and multi-pronged approaches. The company values an eye for insightful take on global matters, ably backed by a team of exceptionally experienced researchers. With a strong repository of syndicated market research reports that are continuously published & updated to ensure the ever-changing needs of customers are met with absolute promptness.

#fairfield market research#biodegradable plastics#polyethylene bioplastic#horticultural#bioplastic for horticulture#bioplastic#horticulture#horticulture bioplastic#horticulture bioplastic market#horticulture bioplastic market size#horticulture bioplastic market share#horticulture bioplastic market trends#horticulture bioplastic market demand#horticulture bioplastic market growth#horticulture bioplastic market scope

1 note

·

View note

Text

Biodegradable Plastics Market - Major Industry Growth Driving Factors

Biodegradable Plastics Market – Major Industry Growth Driving Factors

This report studies the Biodegradable Plastics Market with many aspects of the industry like the market size, market status, market trends and forecast, the report also provides brief information of the competitors and the specific growth opportunities with key market drivers. Find the complete Biodegradable Plastics Market analysis segmented by companies, region, type and applications in the…

View On WordPress

#Biodegradable Plastics#Biodegradable Plastics forecast#Biodegradable Plastics Industry#Biodegradable Plastics Market#Biodegradable Plastics price#Biodegradable Plastics report#Biodegradable Plastics research#Biodegradable Plastics share#Biodegradable Plastics trends#Covid-19 Impact Analysis

0 notes

Text

Researchers invent 100% biodegradable 'barley plastic'

A biofriendly new material made from barley starch blended with fiber from sugarbeet waste—a strong material that turns into compost should it end up in nature—has been created at the University of Copenhagen. In the long term, the researchers hope that their invention can help put the brakes on plastic pollution while reducing the climate footprint of plastic production.

Enormous islands of plastic float in our oceans and microscopic particles of it are in our bodies. The durability, malleability and low cost of plastics has made them ubiquitous, from packaging to clothing to aircraft parts. But plastics have a downside. Plastics contaminate nature, are tough to recycle and their production emits more CO2 than all air traffic combined.

Now, researchers at the University of Copenhagen's Department of Plant and Environmental Sciences have invented a new material made from modified starch that can completely decompose in nature—and do so within only two months. The material is made using natural plant material from crops and could be used for food packaging, among many other things.

Read more.

32 notes

·

View notes

Text

The Future of Plastics: Innovations and Alternatives - Technology Org

New Post has been published on https://thedigitalinsider.com/the-future-of-plastics-innovations-and-alternatives-technology-org/

The Future of Plastics: Innovations and Alternatives - Technology Org

Plastics have become an integral part of our daily lives, but their environmental impact cannot be ignored. From production to disposal, plastics contribute to pollution, waste, and the depletion of natural resources. The need for sustainable alternatives to traditional plastics has never been more urgent.

Reusable garbage bag – zero waste kitchen ideas. Image credit: Sasha Pestano via Unsplash, free license

Plastics are made from fossil fuels, such as oil and natural gas, which are non-renewable resources. The extraction and processing of these resources contribute to air and water pollution, as well as greenhouse gas emissions. Additionally, the production of plastics requires large amounts of energy and water, further straining our already limited resources.

Once plastics are discarded, they can take hundreds of years to decompose. As a result, they accumulate in landfills and oceans, posing a threat to wildlife and ecosystems. Marine animals often mistake plastic debris for food, leading to ingestion and entanglement. Furthermore, when plastics break down into smaller pieces, known as microplastics, they can enter the food chain and potentially harm human health.

The Rise of Bioplastics: A Sustainable Alternative

Bioplastics offer a promising solution to the environmental issues associated with traditional plastics. Unlike conventional plastics, which are derived from fossil fuels, bioplastics are made from renewable resources such as plants or microorganisms. They can be produced using agricultural by-products or dedicated crops that require less water and pesticides than traditional crops.

Bioplastics have similar properties to conventional plastics and can be used in a wide range of applications, including packaging, textiles, and automotive parts. They can be biodegradable or compostable, meaning they break down into natural elements under specific conditions. This reduces the amount of plastic waste that ends up in landfills or oceans.

However, bioplastics also have some drawbacks. The production of certain types of bioplastics can still have negative environmental impacts if not managed properly. Additionally, the infrastructure for collecting and processing bioplastics for recycling is still limited in many regions. Despite these challenges, the demand for bioplastics is growing, and innovations in production and recycling technologies are making them more viable.

Innovations in Plastic Recycling Technology

Plastic recycling is an essential part of reducing plastic waste and conserving resources. Currently, most plastic recycling involves mechanical processes, such as shredding and melting, to transform used plastics into new products. However, these methods have limitations, as they can only be applied to certain types of plastics and may result in a lower quality material.

New technologies and processes are being developed to overcome these limitations and improve the efficiency and effectiveness of plastic recycling. Chemical recycling, for example, involves breaking down plastics into their basic building blocks, which can then be used to produce new plastics or other chemicals. This method has the potential to recycle a wider range of plastics and produce higher quality materials.

Another innovation in plastic recycling is the development of advanced sorting technologies. These technologies use artificial intelligence and machine learning algorithms to identify and separate different types of plastics more accurately. This improves the quality of recycled materials and reduces contamination.

The ultimate goal is to create a closed-loop system for plastic production and consumption, where plastics are continuously recycled and reused without generating waste. This would significantly reduce the demand for virgin plastics and minimize their environmental impact.

The Role of Biodegradable Plastics in Reducing Waste

Biodegradable plastics are designed to break down naturally in the environment, either through biological or chemical processes. They can be made from renewable resources or fossil fuels, but their ability to decompose sets them apart from conventional plastics.

Biodegradable plastics offer several advantages over traditional plastics. They can reduce the amount of plastic waste that ends up in landfills or oceans, as they break down into harmless substances over time. This can help alleviate the pollution and harm caused by plastic debris to wildlife and ecosystems.

However, biodegradable plastics also have some disadvantages. The conditions required for biodegradation, such as temperature, humidity, and microbial activity, may not be present in all environments. This means that biodegradable plastics may not break down as quickly or completely as intended, leading to persistent waste.

Furthermore, the production of biodegradable plastics can still have negative environmental impacts if not managed properly. The cultivation of crops for bioplastics, for example, can contribute to deforestation and the use of pesticides. Therefore, it is important to consider the entire life cycle of biodegradable plastics and ensure that they are produced and disposed of in a sustainable manner.

The Potential of Plant-Based Plastics

Plant-based plastics, also known as bio-based plastics or bio-plastics, are derived from renewable resources such as plants or microorganisms. They can be made from agricultural by-products or dedicated crops that require less water and pesticides than traditional crops.

Plant-based plastics offer several advantages over conventional plastics. They have a lower carbon footprint, as they absorb carbon dioxide during their growth phase. They also reduce the dependence on fossil fuels and contribute to the development of a more sustainable and circular economy.

In terms of performance, plant-based plastics can have similar properties to traditional plastics and be used in a wide range of applications. They can be biodegradable or non-biodegradable, depending on their composition and intended use.

However, plant-based plastics also have some drawbacks. The infrastructure for collecting and processing plant-based plastics for recycling is still limited in many regions.

Despite these challenges, plant-based plastics are gaining traction in various industries, including packaging, automotive, and consumer goods. As technology advances and economies of scale are achieved, plant-based plastics have the potential to become a mainstream alternative to traditional plastics.

The Future of Packaging: Sustainable Materials and Designs

Packaging plays a significant role in the plastic waste problem, as it accounts for a large portion of plastic consumption and waste. However, there are innovative materials and designs that can help reduce the environmental impact of packaging.

One approach is to use sustainable materials for packaging, such as bioplastics, plant-based plastics, or recycled plastics. These materials can be used to create packaging that is biodegradable, compostable, or recyclable, reducing the amount of plastic waste that ends up in landfills or oceans.

Another approach is to design packaging that is more efficient and lightweight. This reduces the amount of material required and the energy consumed during production and transportation. Additionally, innovative designs can make packaging easier to recycle or reuse, promoting a circular economy for packaging materials.

Reusable and refillable packaging is another trend that is gaining momentum. By encouraging consumers to return packaging for refilling or reuse, this approach reduces the need for single-use packaging and minimizes waste. It also promotes a shift towards a more sustainable and circular model of consumption.

The Impact of Microplastics on the Environment and Human Health

Microplastics are small pieces of plastic less than 5 millimeters in size. They can come from a variety of sources, including the breakdown of larger plastic debris, microbeads in personal care products, and synthetic fibers from clothing.

Microplastics have become a major concern due to their widespread presence in the environment and their potential negative impact on ecosystems and human health. They can be ingested by marine animals, leading to physical harm and disruption of their digestive systems. Microplastics can also accumulate toxic chemicals from the surrounding environment, which can then be transferred to organisms higher up the food chain.

In addition to their impact on marine life, microplastics can also pose risks to human health. They have been found in drinking water, seafood, and even the air we breathe. While the long-term effects of microplastic exposure on human health are still being studied, there is growing evidence that they may have adverse effects on the immune system, hormonal balance, and organ function.

Efforts are underway to reduce microplastic pollution at its source. Some countries have banned the use of microbeads in personal care products, and there are ongoing initiatives to reduce the release of microfibers from clothing during washing. Additionally, improved wastewater treatment systems can help capture and remove microplastics before they enter water bodies.

The Role of Government and Industry in Promoting Sustainable Plastics

Government policies and regulations play a crucial role in promoting sustainable plastics. They can incentivize the use of bioplastics, plant-based plastics, or recycled plastics through tax breaks, subsidies, or procurement policies. They can also impose restrictions or bans on certain types of plastics or promote extended producer responsibility, where manufacturers are responsible for the entire life cycle of their products.

Industry initiatives and collaborations are also essential in reducing plastic waste. Many companies are setting ambitious targets to increase the use of sustainable plastics or reduce their plastic footprint. They are investing in research and development to improve the performance and cost-effectiveness of sustainable alternatives. Additionally, industry collaborations can help drive innovation and create a more circular economy for plastics.

However, more action and accountability are needed from both government and industry to address the plastic waste problem effectively. Governments should implement stronger regulations and enforce existing ones to ensure compliance. Industry should prioritize sustainability over short-term profits and invest in long-term solutions. Collaboration between government, industry, and other stakeholders is crucial to achieve a sustainable future for plastics.

The Circular Economy: A New Model for Plastic Production and Consumption

The circular economy is a new model for production and consumption that aims to minimize waste and maximize resource efficiency. It is based on three principles: designing out waste and pollution, keeping products and materials in use, and regenerating natural systems.

In the context of plastics, the circular economy involves designing products for durability, recyclability, and reuse. It also entails establishing efficient collection and recycling systems to ensure that plastics are kept in circulation for as long as possible. Finally, it requires transitioning to renewable resources and renewable energy sources to reduce the environmental impact of plastic production.

There are already examples of circular economy initiatives in the plastic industry. Some companies are exploring closed-loop systems where they collect and recycle their own products or packaging. Others are developing innovative business models, such as product-as-a-service or leasing, where consumers pay for the use of a product rather than owning it.

The circular economy offers a promising solution to the plastic waste problem by shifting from a linear model of production and consumption to a more sustainable and regenerative one. However, its implementation requires collaboration between government, industry, consumers, and other stakeholders.

The Importance of Consumer Education and Behavior Change

Consumers play a crucial role in reducing plastic waste. Their choices and behaviors can drive demand for sustainable alternatives and influence industry practices. However, consumer education and behavior change are essential to achieve meaningful impact.

Many consumers are unaware of the environmental impact of plastics or the availability of sustainable alternatives. Therefore, education and awareness campaigns are needed to inform consumers about the benefits of sustainable plastics and how they can make more environmentally friendly choices.

Consumers can reduce their plastic footprint by adopting simple habits such as using reusable bags, bottles, and containers; avoiding single-use plastics; and recycling properly. They can also support businesses that prioritize sustainability and advocate for stronger government regulations on plastic waste.

It is important to note that individual actions alone cannot solve the plastic waste problem. Systemic changes are needed at all levels, from government policies to industry practices. However, consumer education and behavior change can create a demand for sustainable plastics and drive the transition to a more sustainable and circular economy.

A Sustainable Future for Plastics

The negative environmental impact of plastics is undeniable, but there is hope for a more sustainable future. Bioplastics, plant-based plastics, and biodegradable plastics offer alternatives to traditional plastics that can reduce waste and conserve resources. Innovations in plastic recycling technology are making it more efficient and effective, paving the way for a closed-loop system for plastic production and consumption.

The role of government and industry is crucial in promoting sustainable plastics. Policies and regulations can incentivize the use of sustainable alternatives and impose restrictions on harmful plastics. Industry initiatives and collaborations can drive innovation and create a more circular economy for plastics.

Consumer education and behavior change are also essential in reducing plastic waste. By making more environmentally friendly choices and advocating for sustainable practices, consumers can contribute to a more sustainable future for plastics.

In conclusion, achieving a sustainable future for plastics requires collective action and collaboration from individuals, government, and industry. By prioritizing sustainable alternatives, investing in research and development, and promoting education and awareness, we can reduce plastic waste, protect the environment, and create a more sustainable world for future generations.

#Accounts#air#Algorithms#Animals#applications#approach#artificial#Artificial Intelligence#automotive#awareness#Behavior#biodegradable#Biodegradable plastics#biodegradation#bioplastic#Building#Business#Capture#carbon#Carbon dioxide#carbon footprint#change#chemical#chemicals#Chemistry & materials science news#circular economy#clothing#Collaboration#Collective#Companies

0 notes

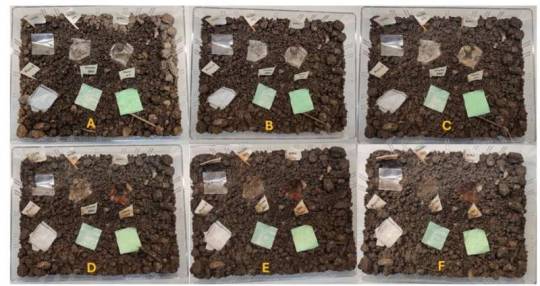

Photo

337 notes

·

View notes

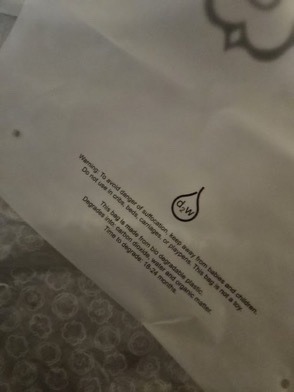

Text

🌿 The 28 Clothing packaging bags are made from biodegradable plastic that can decompose in 18-24 months (via theAFHFspain)

#nice#biodegradable plastic#I would reuse it until it was worn and torn before throwing it away too#enviromentally friendly#28 Official Programme#28 Clothing packaging#Louis Tomlinson#first collection#mine

55 notes

·

View notes