#engineering plastics applications

Text

pvc electric red and blue wire #smartratework#tumblr

#flowers#aesthetic#alternative#grunge#1950s#cute#japan#60s#70s#80s#|| Smart Rate Work#Manufacturing encompasses a diverse array of processes and technologies aimed at producing a wide range of products#from everyday essentials to specialized components. Take wires#for instance: these are typically manufactured through drawing processes#where metal rods or strips are pulled through dies to reduce their diameter and achieve the desired thickness. This method ensures uniformi#crucial for applications in electronics#construction#and industrial settings.#On the other hand#the production of bottles involves molding techniques such as blow molding or injection molding. Blow molding heats plastic resin into a mo#used extensively for beverage containers and packaging. Injection molding#meanwhile#injects molten plastic into a mold under high pressure#ideal for producing intricate shapes with precision#like medical vials or automotive parts.#Both wire and bottle manufacturing rely heavily on materials science#engineering precision#and quality control measures to meet stringent specifications. Advances in automation#robotics#and sustainability practices are transforming these industries

2 notes

·

View notes

Text

Finding nature-inspired alternatives to plastics focus of new center - Technology Org

New Post has been published on https://thedigitalinsider.com/finding-nature-inspired-alternatives-to-plastics-focus-of-new-center-technology-org/

Finding nature-inspired alternatives to plastics focus of new center - Technology Org

Despite efforts to reduce the use of plastic or recycle it, most plastic produced in the world ends up in landfills, the oceans, or is dumped, causing catastrophic effects on the environment, the ecosystem, and the economy.

The mission of the Synthetic Biology Manufacturing of Advanced Materials Research Center is to push the frontiers of knowledge through convergent research; develop pathways to train a manufacturing workforce; leverage an environment of diversity; and enhance innovation in the manufacturing of synthetic biological materials. Image credit: Aimee Felter/McKelvey School of Engineering

To address this, a team of researchers in the McKelvey School of Engineering at Washington University in St. Louis has established the Synthetic Biology Manufacturing of Advanced Materials Research Center (SMARC) to create an integrated education, research and innovation ecosystem enabled by the convergence across multiple disciplines and research areas.

Its mission is to push the frontiers of knowledge through convergent research; develop pathways to train a manufacturing workforce that can harness artificial intelligence and the biological transformation in manufacturing; leverage an environment of diversity and inclusion to maximize human capital; and enhance innovation in the manufacturing of synthetic biological materials by understanding and overcoming barriers to technology adoption in partnership with industry.

Marcus Foston, an associate professor of energy, environmental and chemical engineering, will co-lead the center with Fuzhong Zhang, a professor of energy, environmental and chemical engineering and co-director of the center, which is funded in part by a five-year $3.6 million Growing Convergence Research grant from the National Science Foundation. With this funding, the team plans to develop a new class of biologically synthesized, protein-based and biodegradable materials that harness themes from nature to replace traditional petroleum-derived plastics.

“Our vision is a future in which advances in synthetic biology, biotechnology and biomanufacturing, machine learning, social sciences, materials science and mechanics converge to transition the world toward wide-spread use of bio-derived and biodegradable plastics from renewable feedstocks,” Foston said.

[embedded content]

Also on the Washington University leadership team are Guy Genin, the Harold and Kathleen Faught Professor of Mechanical Engineering, and Roman Garnett, an associate professor of computer science and engineering. Researchers from Northwestern University, Iowa State University and the University of South Florida bring together a convergence of cross-disciplinary expertise to evolve the plastics economy by developing a platform for the discovery of synthetic biological materials with desired properties.

Foston and Zhang will lead a team that includes experts in synthetic biology, machine learning, polymer science, material mechanics and computational materials simulation. They will use machine learning aided with material screening and simulation approaches to accelerate the process of finding promising protein sequences that can be used to make biodegradable materials with targeted properties to replace plastics in both high- and low-value applications. In addition, they will develop synthetic biological methods and genetically engineered microbes to produce protein-based materials sustainably and economically.

While much of the biomanufacturing industry has focused on medicines and biotherapeutics, this center will focus on fundamental scientific and engineering problems that occur during the design, development and manufacturing stages of synthetic biological materials, with the goal of leading a large-scale transition to an economy based upon sustainable and biodegradable plastics. This transition will begin with high-performance polymers.

“Synthetic biology has the potential to deliver the next generation of advanced materials with new functional properties to address a wide range of unmet needs,” Genin said. “With examples such as spider silk, elastin and resilin, synthetic biology also has the potential to leverage nature to provide access to affordable and sustainable production of novel macromolecular materials.”

Along with research, the center will include an education component.

“We will develop unique graduate educational frameworks for cross-disciplinary innovation at WashU, while simultaneously working to develop a pipeline of future innovators in the St. Louis community,” said Zhang, the center’s director of education and outreach. “This is a unique opportunity to impact our community and our world.”

[embedded content]

The center will open with a major international symposium April 18-19. Until then, Foston said, their work is cut out for them.

“This is a once-in-a-lifetime opportunity for major impact in the region and world,” he said. “We are all thrilled to have these resources to bring together the particular strengths of WashU and St. Louis to solve a pressing global challenge.”

Source: Washington University in St. Louis

You can offer your link to a page which is relevant to the topic of this post.

#A.I. & Neural Networks news#advanced materials#applications#artificial#Artificial Intelligence#artificial intelligence (AI)#biodegradable#biodegradable materials#Biodegradable plastics#Biology#biotechnology#challenge#chemical#Chemical engineering#Community#computer#Computer Science#Design#development#diversity#Diversity and Inclusion#economy#education#effects#energy#engineering#Environment#Environmental#Foundation#Fundamental

0 notes

Text

Shaping Tomorrow: Insights into the Thermoplastic Polyester Engineering Resins Market

The thermoplastic polyester engineering resins market was USD 3,912.2 million in 2022, and it will touch USD 5,896.6 million, advancing at a 5.4% compound annual growth rate, by 2030.

The growth of the industry is attributed to the increasing utilization of these resins for various nonstructural applications as they can be utilized without filters and are usually tougher and more ductile than…

View On WordPress

#advanced polymers#aerospace applications#automotive industry#engineering plastics#engineering resin market#high-performance polymers#Industrial applications#market growth#material innovation#plastic components#plastic industry#plastic materials#polymer engineering#resin manufacturing#sustainable materials#thermoplastic polyester engineering resins#thermoplastic properties#thermoplastic technology

0 notes

Text

I went to the Apple Store yesterday to try the scripted demo of their VR headset. My overall impression is that it's the best possible execution of what might be a fundamentally flawed idea.

The passthrough video is pretty incredible. It's somewhat dimmer than reality, and the color accuracy is just OK, but it's more than good enough to feel like you're looking through clear displays at the real world. I'm told the passthrough on the Quest 3 is even better, but haven't tried that and can't comment. One thing is that there is a weird motion blur effect when you turn your head, I'm not sure if that's a display tech limitation or introduced deliberately by the software as a workaround for a different display tech limitation.

The resolution is 4K per eye, which, as mentioned, is more than enough for a powerful sense of presence in the real world. One of the nifty bits of the demo was when you turn the dial to tune out the world and suddenly you're sitting by a mountain lake, and the feeling of actually being there is overwhelming. The dystopian implications of needing a VR headset to sit at a mountain lake aside, it would be cool to have one just to have your office be anywhere you can imagine. Not $3500-before-tax cool, but cool.

Wow sports leagues are going to love this thing. I don't give a shit about sports and even I was thinking, "If the NBA put a stereoscopic camera courtside and sold you games for $50 a pop, I'd absolutely buy that"

But 4K per eye is not enough to do work, not even close. The experience of using normal computer-y applications on this was not unlike plugging your laptop in to a TV that's at the normal TV distance. You can do it, it works, but it's not anyone's preferred way of working. Text is amazingly legible, but only at sizes that are equivalent to having a single webpage take up your entire 4K monitor at normal monitor distance.

It is not particularly comfortable. Part of this might be that the store demo makes you use the "catcher's mitt" strap, which only goes around the back of your head and so gravity has to be countered only by the pressure of the thing against your face. Reviewers have said that if you use the other band that goes over your head the situation is better, but still.

A lot of early comments were making fun of Apple for having the battery be an external thing you put in your pocket and attach with a wire, but I think that's just fine: we all walk around with giant batteries in our pockets anyway, and anything you can do to have less weight on your head is a Good Thing. But then Apple took all those weight savings and spent them on making the stupid thing out of metal and glass instead of polycarbonate. It's nuts! It's like if you made a car that was 500kg lighter because you invented magical tech for keeping the engine somewhere else, and then went "great! with all the weight savings now we can build the body out of lead". Apple, you don't need to fear plastic. Plastic is good! Plastic built modern civilization.

You control it with a combination of eye tracking and pinch gestures. This is the main piece of evidence of my "best version of a bad idea" thesis: it works really, really well; so well that I can tell this is probably an evolutionary dead end. It's just fine— miraculous, even— for dragging windows around and doing the basic stuff the in-store demo has you do. It's amazing that you can more or less have your hands anywhere, including on your lap, and the recognition works perfectly (by contrast with the HoloLens I tried 5 or so years ago where the gesture recognition was total crap). But it's immediately obvious that you can never do serious manipulation of your computing environment with this.

The takeaway is that it's incredible for passive consumption of specifically-made media, assuming that ever exists at scale. But it will be a long time before we're gogged in like Hiro Protagonist to do our office jobs this way.

167 notes

·

View notes

Text

Researchers in Purdue University's College of Engineering have developed and validated a patent-pending method that could expand the industrial applications of ceramics by making them more plastically deformable at room temperature.

Plasticity or plastic deformability is a material's ability to be deformed by compression, tension or shear into a specific shape or geometry without breaking. Typically, ceramic materials exhibit very limited plastic deformability under room temperature.

Continue Reading.

54 notes

·

View notes

Text

7/30 germs.

(Previous) | (Index) | (Next)

⛬

We return to a movie that disrespects the archaeological importance of roads, Prometheus.

I am still not over that. I will never be over that.

This time, content warnings for continuing frat boy archaeology, cringeful application of racist terms to lily-white androids, me screeching about site contamination some more, and Apollo’s dodgeball striking this movie with a glancing blow about masking.

So, back in the theater in 2012, I had already lost sympathy for the cast. They were being set up as stock horror movie characters, they were doing their jobs in a way with a certain flair for the incompetent.

And one of them, I suspect, the movie intends to make into a “flawed but you feel for him” kind of guy. Or, I hope they intended to make him “the guy in the slasher movie who you hate and want to see die”. That’s Holloway, one of the two archaeologists. He’s robot racist.

Like, seriously robot racist. The whole crew is, David literally gets referred to as “boy” here, which isn’t so much a dogwhistle as a tornado siren. No wonder David is quietly starting to show his disdain for the human crew.

“They're making you guys pretty close [to human now], huh?”

“Not too close, I hope.”

One of the few themes the movie handles halfway competently is the parallel between the humans stumbling all over themselves as they rush to go meet their makers, while David is already experiencing the disappointment of actually meeting his, and finding out they’re a bunch of clueless assholes. Are we supposed to believe the same of the Engineers? I don’t know. They definitely think of humans as lesser, though. More to come on that later.

Because right now, an expedition is barrelling toward the alien structure–again, driving all over the FCKING ALIEN ROAD–and they’re doing it with only six hours of daylight left, because Holloway literally says “It's Christmas [...] and I want to open my presents.”

I cannot communicate how heinous this character felt. The actor did a perfectly fine job playing him, but if Charlie Holloway was real, his name would be said with the same venom as that of the man pictured below: Heinrich Schliemann, the man who found the real, actual city of Troy, and immediately dynamited a trench through the royal palace, destroying who knows how many artifacts from the period the Iliad was based off of. Yes, I picked out the most assholish-looking photo of him I could find on purpose.

Also, Holloway’s an anti-masker, apparently.

I’m going to step back for just one second and list the one practical, movie budget reason why characters might take their helmets off. The costume designers did an admirable job coming up with something that fits the general requirement of a helmet in major studio releases, prior to The Mandalorian: make the actor’s faces completely visible, because without actors with a strong sense of physical presence and voice acting, you’ll lose connection with the audience.

They did a great job with that. Unfortunately, shiny helmets are a bastard to digitally edit film crew out of.

It’s not impossible to place lights and crew so that the audience won’t notice them. Alien certainly pulled it off. Clear plastic elements in helmets also mean other logistical challenges, though: fogging being the main one. This, and cooking your actors in a fishbowl under studio lights.

Both problems can be simultaneously combated by installing A/C fans within the helmets, but because these helmets are entirely clear, you’re limited to hiding them down near the neck, and anybody who’s done similar for a cosplay or suit will know that it’s potentially noisy and not always effective. You can actually see condensate on the helmets in the movie, though whether that’s from the actor’s breath or a deliberate choice, I don’t know.

All this adds up to increased time resetting actors (i.e. cleaning sweat off of them without disrupting their makeup), more exhaustion from said actors, and the worry that the highest-paid, plot-critical actors may decide they don’t want to do a sequel if the shooting experience is too physically unhealthy.

And then there’s also more time spent carefully arranging crew and lights to hide their reflections, or more time making some poor VFX artist erase a transparent, curved reflection from frame and replace it with something else, or make the actors more comfortable by adding the glass in later with CGI, at the potential loss of some realism. The average modern movie studio would choose one of these VFX-driven options and demand it done in a week, which is why VFX artists need to unionize.

So. I understand at least a few logistical reasons why you don’t tend to make actors wear helmets for too many shooting days. But it has to be balanced with the story. It has to feel believable. It has to fit the story. It has to not make your characters look like mud-witted morons.

As soon as they find liquid water and the oh-so-deadly CO2 levels start to drop, Holloway takes his helmet off.

“Don't be an idiot.”

“Don't be a skeptic.”

Flames on the side of my goddamn face.

Now, this is the moment a lot of people lost sympathy for the human characters, even back in 2012. It was a dumbass idea even then, in the pre-’rona years. Sadly, Millburn the biologist isn’t written smart enough to punch Holloway in the nuts over even thinking of doing this, because we have two problems with what Holloway’s doing here: Biology, and biology.

First, biology.

(https://www.turbosquid.com/3d-models/13-viruses-virus-3d-model/1071200)

Obviously, they don’t know if anything’s in the air. He could find out that humans are deathly allergic to alien dust mites. He could have just caught himself a case of space covid, which he and the lemmings that follow him can then transmit to the entire crew if he’s not kept in quarantine. They can sterilize the sealed suits, but they can’t sterilize the inside of his lungs. Yet.

Second, biology.

Specifically, Earth biology. Do you know how carefully modern space agencies sterilize anything that’s headed for Mars, or anywhere else that might have a biosphere of its own? A lot! They sterilize everything a lot! Because microbes are hardy little bastards. We’ve never found extraterrestrial life, only precursor molecules that show the capacity for life to develop in other places. How are you going to verify you’ve found alien life, or even those precursors, if you can’t prove that your samples are uncontaminated? What happens if microbes from Earth manage to survive the trip and establish a foothold somewhere? What if they destroy native life?

This movie’s characters treat this with only a fraction of the gravitas that the cinematography does, which is part of why this remains so jarring throughout. The practical sets, the art direction, and the camerawork are all excellent. The editing continues to do its best, though it almost feels like things were cut very tight through this to speed things along and to give more time, unfortunately, to what the characters are doing.

their crimes against my sanity are not done yet

⛬

(Previous) | (Index) | ⛬

⛬

As a side note, rounding up some discussion from a previous entry: The most excellent artist @noordzee pointed out that the clashing artistic style of the moon and stars slapped onto the carving of Kʼinich Janaab Pakal I. In the previous post, I focused on the link between that carving and its use in ancient aliens conspiracy theories. But let's dig a bit into actual Maya iconography around celestial bodies instead.

Now, I am not an expert on Classical Maya stuff. Not in the slightest. And there is a lot of information on their art that is linguistically inaccessible to me, as a non-Spanish speaker. But out of the Maya art and writing that survived the book-burning conquistadors, we have some iconography for the moon and stars, and they don’t look like what’s in the movie.

I wasn’t able to find any specific pieces of art that contained stars, but I did find the glyph for star, ek’.

I was only able to find depictions of a crescent moon in the context of the moon goddess, where she tends to be sitting on the crescent like a chair, or one part of it is shown behind her, almost like a tail (though I can’t be certain whether that’s due to chipped paint).

The moon by itself was somewhat harder to find. I couldn’t find any Maya depictions of it with my limited poking around of the spanish internet, but I did find a (much later) Mixtec depiction of the moon, complete with a lunar rabbit! Much like East Asian cultures, the darker markings on the moon are culturally interpreted as a rabbit shape.

Thanks again to nordzee for pointing out the dissonant art style, because the real mesoamerican art on this subject is phenomenal.

Next time, the movie will hurt me more, so if anybody else has fun facts to share or details to point out. PLEASE. Ease my pain.

⛬

(Previous) | (Index) | (Next)

⛬

Alt text citations:

None this time. Many ramblings, though.

#prometheus 2012#prometheus (2012)#I work in a place where quite a lot of people have to put on clean room suits to go to work#their rooms are behind airlock doors#and that's just to make sure outside germs don't get in#to keep things clean#we don't even have the REALLY scary containment rooms that a few biological laboratories have#I'll ramble more about the logistics of that later#when the movie gets around to breaking laboratory safety standards as well

51 notes

·

View notes

Text

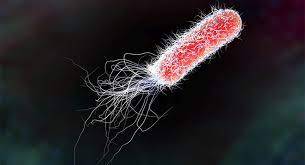

Genetically Modified Bacteria Produce Energy From Wastewater

E. Coli is one of the most widely studied bacteria studied in academic research. Though most people probably associate it with food/water borne illness, most strains of E. Coli are completely harmless. They even occur naturally within your intestines. Now, scientists at EPFL have engineered a strain of E. Coli that can generate electricity.

The survival of bacteria depends on redox reactions. Bacteria use these reactions to interconvert chemicals in order to grow and metabolize. Since bacteria are an inexhaustible natural resource, many bacterial reactions have been industrially implemented, both for creating or consuming chemical substrates. For instance, you may have heard about researchers discovering bacteria that can break down and metabolize plastic, the benefits of which are obvious. Some of these bacterial reactions are anabolic, which means that they need to be provided external energy in order to carry it out, but others are catabolic, which means that the reactions actually create energy.

Some bacteria, such as Shewanella oneidensis, can create electricity as they metabolize. This could be useful to a number of green applications, such as bioelectricity generation from organic substrates, reductive extracellular synthesis of valuable products such as nanoparticles and polymers, degradation of pollutants for bioremediation, and bioelectronic sensing. However, electricity producing bacteria such as Shewanella oneidensis tend to be very specific. They need strict conditions in order to survive, and they only produce electricity in the presence of certain chemicals.

The method that Shewanella oneidensis uses to generate electricity is called extracellular electron transfer (EET). This means that the cell uses a pathway of proteins and iron compounds called hemes to transfer an electron out of the cell. Bacteria have an inner and outer cell membrane, so this pathway spans both of them, along with the periplasmic space between. In the past, scientists have tried to engineer hardier bacteria such as E. Coli with this electron-generating ability. It worked… a little bit. They were only able to create a partial EET pathway, so the amount of electricity generated was fairly small.

Now, the EPFL researchers have managed to create a full pathway and triple the amount of electricity that E. Coli can produce. "Instead of putting energy into the system to process organic waste, we are producing electricity while processing organic waste at the same time -- hitting two birds with one stone!" says Boghossian, a professor at EPFL. "We even tested our technology directly on wastewater that we collected from Les Brasseurs, a local brewery in Lausanne. The exotic electric microbes weren't even able to survive, whereas our bioengineered electric bacteria were able to flourish exponentially by feeding off this waste."

This development is still in the early stages, but it could have exciting implications both in wastewater processing and beyond.

"Our work is quite timely, as engineered bioelectric microbes are pushing the boundaries in more and more real-world applications" says Mouhib, the lead author of the manuscript. "We have set a new record compared to the previous state-of-the-art, which relied only on a partial pathway, and compared to the microbe that was used in one of the biggest papers recently published in the field. With all the current research efforts in the field, we are excited about the future of bioelectric bacteria, and can't wait for us and others to push this technology into new scales."

147 notes

·

View notes

Text

Waldo Lonsbury Semon (10 September 1898 – 26 May 1999)

An American scientist, Waldo Lonsbury Semon was one of the first individuals in the country to be awarded a doctorate in chemical engineering. His most famous accomplishment was his invention of plasticized polyvinyl chloride (PVC), broadening the scope of applications of the material immensely (PVC is now the third most common polymer). In addition, he is also credited for commercializing said plasticizers, again increasing their use and popularity. Semon worked for almost 40 years for the B. F. Goodrich Company, spending most of his time on polymers and rubbers, including the development of synthetic rubbers. After retirement, he continued to work as a research professor at Kent State University.

Sources/Further Reading: (Image source - Wikipedia) (Plastics Hall of Fame) (MIT) (ThoughtCo)

#Materials Science#Science#Polymers#Plastics#Polyvinyl chloride#Scientists#Science history#ScientistSaturday#2024Daily

12 notes

·

View notes

Text

Whats up gamers its me WimpCritic186 here, and welcome to yet another viral Minecraft video. Are you suffering? Are you tired of the tedious march through the morass of grief and heartache life has handed you? Have you heard it said one too many times that the "only way out" is "through"? Well.

In today's redstone tutorial, I will show you how to build what I'm calling the "emotional helicopter", a server-friendly, slime-block-powered redstone contraption I've devised for the express purpose of lifting you up and around difficult emotional barriers in your life without the hassle of actually "processing" your "shit". Don't forget to "Like" this video.

Coming up, I'l test this simple and compact device on two of my friends and fellow DVorceCraft SMP members, Neomilk and banal_lad, who, as you might know, just went through a messy, extremely public breakup. Will Milk and Lad find closure, or will they be caught in the blades? Can 1,600 pistons do what 72 hours of couples-counseling livestreamed over tiktok failed to? And how exactly can a single zombie pigman and an obscure quirk of Minecraft Java's lighting engine combine to form the perfect backdoor into what American psychologist Marsha M. Linehan refers to as the "Wise Mind" in her acclaimed Dialectical Behavioral Therapy framework? Stay tuned for all of this and more, but first, let me take a moment to tell you about Ziploc.

I, WimpCritic186, am thrilled to announce that Ziploc is the sponsor of today's technical minecraft video. Ziploc is a special bag that is extremely pog and goated. As a full time content creator, I have to stay mad organized, and I love using reusable Ziplocbags to store my various gamer items and gamer substances.

Let's talk history. Originally developed and test marketed by The Dow Chemical Company in 1968, Ziploc is an undeniable icon in the crowded sliding-channel-storage-bag market-space, standing head and shoulders above competitors like Glad and Hefty in terms of name recognition and brand loyalty – but it wasn't always that way.

The year is 1951. Danish Inventor Borge Madsen submits a patent application for a new type of plastic slide fastener. Enter businessman and innovator Steven Ausnit. Now, Steven was born in Romania in 1924. His father was Max Ausnit, then regarded as the "The Steel King" of Romania – at least until the fateful day an industry rival falsely accused him of a crime he did not commit, leading to his wrongful conviction and imprisonment. During World War II, after successfully escaping house arrest, … Click To Continue

36 notes

·

View notes

Text

Across a sterile white table in a windowless room, I’m introduced to a woman in her forties. She has a square jaw and blonde hair that has been pulled back from her face with a baby-blue scrunchie. “The girls call me Marmalade,” she says, inviting me to use her prison nickname. Early on a Wednesday morning, Marmalade is here, in a Finnish prison, to demonstrate a new type of prison labor.

The table is bare except for a small plastic bottle of water and an HP laptop. During three-hour shifts, for which she’s paid €1.54 ($1.67) an hour, the laptop is programmed to show Marmalade short chunks of text about real estate and then ask her yes or no questions about what she’s just read. One question asks: “is the previous paragraph referring to a real estate decision, rather than an application?”

“It’s a little boring,” Marmalade shrugs. She’s also not entirely sure of the purpose of this exercise. Maybe she is helping to create a customer service chatbot, she muses.

In fact, she is training a large language model owned by Metroc, a Finnish startup that has created a search engine designed to help construction companies find newly approved building projects. To do that, Metroc needs data labelers to help its models understand clues from news articles and municipality documents about upcoming building projects. The AI has to be able to tell the difference between a hospital project that has already commissioned an architect or a window fitter, for example, and projects that might still be hiring.

Around the world, millions of so-called “clickworkers” train artificial intelligence models, teaching machines the difference between pedestrians and palm trees, or what combination of words describe violence or sexual abuse. Usually these workers are stationed in the global south, where wages are cheap. OpenAI, for example, uses an outsourcing firm that employs clickworkers in Kenya, Uganda, and India. That arrangement works for American companies, operating in the world’s most widely spoken language, English. But there are not a lot of people in the global south who speak Finnish.

That’s why Metroc turned to prison labor. The company gets cheap, Finnish-speaking workers, while the prison system can offer inmates employment that, it says, prepares them for the digital world of work after their release. Using prisoners to train AI creates uneasy parallels with the kind of low-paid and sometimes exploitive labor that has often existed downstream in technology. But in Finland, the project has received widespread support.

“There's this global idea of what data labor is. And then there's what happens in Finland, which is very different if you look at it closely,” says Tuukka Lehtiniemi, a researcher at the University of Helsinki, who has been studying data labor in Finnish prisons.

For four months, Marmalade has lived here, in Hämeenlinna prison. The building is modern, with big windows. Colorful artwork tries to enforce a sense of cheeriness on otherwise empty corridors. If it wasn’t for the heavy gray security doors blocking every entry and exit, these rooms could easily belong to a particularly soulless school or university complex.

Finland might be famous for its open prisons—where inmates can work or study in nearby towns—but this is not one of them. Instead, Hämeenlinna is the country’s highest-security institution housing exclusively female inmates. Marmalade has been sentenced to six years. Under privacy rules set by the prison, WIRED is not able to publish Marmalade’s real name, exact age, or any other information that could be used to identify her. But in a country where prisoners serving life terms can apply to be released after 12 years, six years is a heavy sentence. And like the other 100 inmates who live here, she is not allowed to leave.

When Marmalade first arrived, she would watch the other women get up and go to work each morning: they could volunteer to clean, do laundry, or sew their own clothes. And for a six hour shift, they would receive roughly €6 ($6.50). But Marmalade couldn’t bear to take part. “I would find it very tiring,” she says. Instead she was spending long stretches of time in her cell. When a prison counselor suggested she try “AI work,” the short, three-hour shifts appealed to her, and the money was better than nothing. “Even though it’s not a lot, it’s better than staying in the cell,” she says” She’s only done three shifts so far, but already she feels a sense of achievement.

This is one of three Finnish prisons where inmates can volunteer to earn money through data labor. In each one, there are three laptops set up for inmates to take part in this AI work. There are no targets. Inmates are paid by the hour, not by their work’s speed or quality. In Hämeenlinna, around 20 inmates have tried it out, says Minna Inkinen, a prison work instructor, with cropped red hair, who sits alongside Marmalade as we talk. “Some definitely like it more than others”. When I arrive at the prison on a Wednesday morning, the sewing room is already busy. Inmates are huddled over sewing machines or conferring in pairs over mounds of fabric. But the small room where the AI work takes place is entirely empty until Marmalade arrives. There are only three inmates in total who regularly volunteer for AI shifts, Inkinen says, explaining that the other two are currently in court. “I would prefer to do it in a group,” says Marmalade, adding that she keeps the door open so she can chat with the people sewing next door, in between answering questions.

Those questions have been manually written in an office 100 kilometers south of the prison, in a slick Helsinki coworking space. Here, I meet Metroc’s tall and boyish founder and CEO, Jussi Virnala. He leads me to a stiflingly hot phone booth, past a row of indoor swings, a pool table, and a series of men in suits. It’s an exciting week, he explains, with a grin. The company has just announced a €2 million ($2.1 million) funding round which he plans to use to expand across the Nordics. The investors he spoke with were intrigued by the company’s connection to Finland’s prisons, he says. “Everyone was just interested in and excited about what an innovative way to do it,” says Virnala. “I think it’s been really valuable product-wise.”

It was Virnala’s idea to turn to the prisons for labor. The company needed native Finnish speakers to help improve its large language model’s understanding of the construction-specific language. But in a high-wage economy like Finland, finding those data laborers was difficult. The Finnish welfare system’s generous unemployment benefits leaves little incentive for Finns to sign up to low-wage clickwork platforms like Amazon’s Mechanical Turk. “Mechanical Turk didn’t have many Finnish-language workers,” says Virnala. At the same time, he adds, automatic translation tools are still no good at Finnish, a language with only 5 million native speakers.

When Virnala pitched his idea to Pia Puolakka, head of the Smart Prison Project at Finland’s prison and probation agency, she was instantly interested, she says. Before the pandemic, another Finnish tech company called Vainu had been using prisoners for data labor. But Vainu abruptly pulled out after a disagreement between cofounders prompted Tuomas Rasila, who had been in charge of the project, to leave the company.

By the time Virnala approached her with his proposal in 2022, Puolakka was eager to resurrect the AI work. Her job is to try and make the relationship between Finnish prisons and the internet more closely resemble the increasingly digital outside world. So far, she has been installing laptops in individual cells so inmates can browse a restricted list of websites and apply for permission to make video calls. She considers data labor just another part of that mission.

The aim is not to replace traditional prison labor, such as making road signs or gardening. It’s about giving prisoners more variety. Data labeling can only be done in three-hour shifts. “It might be tiring to do this eight hours a day, only this type of work,” she says, adding that it would be nice if inmates did the data labeling alongside other types of prison labor. “This type of work is the future, and if we want to prepare prisoners for life outside prison, a life without crime, these types of skills might be at least as important as the traditional work types that prisons provide,” she says.

But how much data labeling offers inmates skills that are transferable to work after prison is unclear. Tuomas Rasila, the now estranged cofounder of Vainu, who managed the prison project there for a year, admits he has no evidence of this; the project wasn’t running for long enough to collect it, he says. “I think asking people, who might feel outside of society, to train the most high-tech aspect of a modern society is an empowering idea.”

However, others consider this new form of prison labor part of a problematic rush for cheap labor that underpins the AI revolution. “The narrative that we are moving towards a fully automated society that is more convenient and more efficient tends to obscure the fact that there are actual human people powering a lot of these systems,” says Amos Toh, a senior researcher focusing on artificial intelligence at Human Rights Watch.

For Toh, the accelerating search for so-called clickworkers has created a trend where companies are increasingly turning to groups of people who have few other options: refugees, populations in countries gripped by economic crisis—and now prisoners.

“This dynamic is a deeply familiar one,” says Toh. “What we are seeing here is part of a broader phenomenon where the labor behind building tech is being outsourced to workers that toil in potentially exploitative working conditions.”

Toh is also skeptical about whether data labor can help inmates build digital skills. “There are many ways in which people in prison can advance themselves, like getting certificates and taking part in advanced education,” he says. “But I'm skeptical about whether doing data labeling for a company at one euro per hour will lead to meaningful advancement.” Hämeenlinna prison does offer inmates online courses in AI, but Marmalade sits blank-faced as staff try to explain its benefits.

Science

Your weekly roundup of the best stories on health care, the climate crisis, genetic engineering, robotics, space, and more. Delivered on Wednesdays.

By the time I meet Lehtiniemi, the researcher from Helsinki University, I’m feeling torn about the merits of the prison project. Traveling straight from the prison, where women worked for €1.54 an hour, to Metroc’s offices, where the company was celebrating a €2 million funding round, felt jarring. In a café, opposite the grand, domed Helsinki cathedral, Lehtiniemi patiently listens to me describe that feeling.

But Lehtiniemi’s own interviews with inmates have given him a different view—he’s generally positive about the project. On my point about pay disparity, he argues this is not an ordinary workforce in mainstream society. These people are in prison. “Comparing the money I get as a researcher and what the prisoner gets for their prison labor, it doesn't make sense,” he says. “The only negative thing I’ve heard has been that there’s not enough of this work. Only a few people can do it,” he says, referring to the limit of three laptops per prison.

“When we think about data labor, we tend to think about Mechanical Turk, people in the global south or the rural US,” he says. But for him, this is a distinct local version of data labor, which comes with a twist that benefits society. It’s giving prisoners cognitively stimulating work—compared to other prison labor options—while also representing the Finnish language in the AI revolution.

Without this kind of initiative, Lehtiniemi worries that non-English languages are being locked out of this next generation of technology. Smart speakers still struggle to understand Finnish dialects. “Not all Finnish people speak English very well, so there's a need for these local forms of data labeling as well,” Lehtiniemi says. Metroc isn’t the only company that has been forced to get creative about finding Finnish data labor. In 2011, the national library created a game to incentivize volunteers to help digitize its archive. In 2020, broadcaster YLE teamed up with Helsinki University and the state development company VAKE to ask volunteers to donate recordings of them speaking Finnish.

There is a sense in Finland that the prison project is just the beginning. Some are worried it could set a precedent that could introduce more controversial types of data labeling, like moderating violent content, to prisons. “Even if the data being labeled in Finland is uncontroversial right now, we have to think about the precedent it sets,” says Toh. “What stops companies from outsourcing data labeling of traumatic and unsavory content to people in prison, especially if they see this as an untapped labor pool?”

It's also not clear whether labor conditions in Finland's prisons—which famously focus on rehabilitation—could be replicated in other countries with a less progressive approach to justice. In the US, 76 percent of prisoners report that prison labor is mandatory, according to civil rights group, the ACLU. “The prison system in the United States is very, very different from what we have in Finland or Nordic countries. It's a completely different idea,” says Rasila. “In Finland, there is an exclusively positive feeling around the project because everyone knows that this is very voluntary.”

AI companies are only going to need more data labor, forcing them to keep seeking out increasingly unusual labor forces to keep pace. As Metroc plots its expansion across the Nordics and into languages other than Finnish, Virnala is considering whether to expand the prison labor project to other countries. “It’s something we need to explore,” he says.

25 notes

·

View notes

Text

PREPRATION OF A BUEATY SOAP || A2Z SKILLS

Manufacturing encompasses a diverse array of processes and technologies aimed at producing a wide range of products, from everyday essentials to specialized components. Take wires, for instance: these are typically manufactured through drawing processes, where metal rods or strips are pulled through dies to reduce their diameter and achieve the desired thickness. This method ensures uniformity and strength, crucial for applications in electronics, construction, and industrial settings.

On the other hand, the production of bottles involves molding techniques such as blow molding or injection molding. Blow molding heats plastic resin into a molten state and then inflates it into a mold cavity to create a hollow shape, used extensively for beverage containers and packaging. Injection molding, meanwhile, injects molten plastic into a mold under high pressure, ideal for producing intricate shapes with precision, like medical vials or automotive parts.

Both wire and bottle manufacturing rely heavily on materials science, engineering precision, and quality control measures to meet stringent specifications. Advances in automation, robotics, and sustainability practices are transforming these industries, reducing waste, improving efficiency, and expanding design possibilities. Overall, manufacturing processes like these exemplify the intersection of innovation, engineering, and practical application in meeting global

OUR LINKS:

TIKTOK: https://www.tiktok.com/@a2zskills

YOUTUBE: https://www.youtube.com/@A2ZSKILLS-123

FACEBOOK: https://www.facebook.com/profile.php?id=61562585190878&sk=about

INSTAGRAM: https://www.instagram.com/a2zskills123/

VIMEO: https://vimeo.com/?signup=true

TUMBIR: https://www.tumblr.com/dashboard

HASAHTAGS :

#satisfying #manufacturing #molding #shorts #A2Zskills #thermacolplates #thermacol #clay #tips #tipsandtricks #tutorials #prank #youtubeshorts #youtube #manufacture #manufacturer #ytshorts #material #materials #science #sciencefacts #technology #equipments #wires #work #design #efficiency #hacks #reducingwaste #electronic #automobiles

3 notes

·

View notes

Text

Stronger, Stretchier, Self-Healing Plastic - Technology Org

New Post has been published on https://thedigitalinsider.com/stronger-stretchier-self-healing-plastic-technology-org/

Stronger, Stretchier, Self-Healing Plastic - Technology Org

Improved material can maintain complex shapes and biodegrades in seawater.

The new self-healing plastic. Image credit: Shota Ando / University of Toyo

An innovative plastic, stronger and stretchier than the current standard type and which can be healed with heat, remembers its shape and is partially biodegradable, has been developed by researchers at the University of Tokyo.

They created it by adding polyrotaxane to an epoxy resin vitrimer, a type of plastic.

Named VPR, the material can hold its form and has strong internal chemical bonds at low temperatures. However, at temperatures above 150 degrees Celsius, those bonds recombine and the material can be reformed into different shapes.

Applying heat and a solvent breaks VPR down into its raw components. Submerging it in seawater for 30 days also resulted in 25% biodegradation, with the polyrotaxane breaking down into a food source for marine life.

This new material could have wide-reaching applications for a more circular economy to recirculate resources and reduce waste, from engineering and manufacturing to medicine and sustainable fashion.

Good memory. The complex shape of an origami crane that was restored using heat after being flattened. Image credit: Shota Ando / University of Tokyo

Despite global campaigns to curb plastic use and waste, it is difficult to avoid the ubiquitous material. From toys and clothes, homeware and electronics, to vehicles and infrastructure, nowadays it may seem like it is in almost everything we use.

Although useful, there are many issues associated with plastic’s life cycle and disposal. Developing alternatives which last longer, can be reused and recycled more easily, or which are made from environmentally friendly sources, is key to helping solve these problems and realize several of the United Nations’ Sustainable Development Goals.

With this in mind, researchers at the University of Tokyo have created a more sustainable plastic, based on an epoxy resin vitrimer. Vitrimers are a relatively new class of plastics, which are solid and strong at lower temperatures (like thermoset plastics, used to make heat-resistant tableware), but which can also be reshaped multiple times at higher temperatures (like thermoplastics, used for plastic bottles).

However, they are typically brittle and cannot be stretched far before breaking. By adding a molecule called polyrotaxane, the team was able to create a dramatically improved version which they named VPR (vitrimer incorporated with polyrotaxane [PR]).

“VPR is over five times as resistant to breaking as a typical epoxy resin vitrimer,” said Project Assistant Professor Shota Ando from the Graduate School of Frontier Sciences. “It also repairs itself 15 times as fast, can recover its original memorized shape twice as fast, and can be chemically recycled 10 times as fast as the typical vitrimer. It even biodegrades safely in a marine environment, which is new for this material.”

Good memory. The complex shape of an origami crane that was restored using heat after being flattened. Image credit: Shota Ando / University of Tokyo

Polyrotaxane has been gaining interest in science and industry for its ability to enhance the toughness of different materials. In this study, the improved toughness of VPR meant that more complex shapes could be created and retained even at low temperatures (such as the origami crane in the video provided with this release).

Disposal or recycling was also easier than for vitrimers without polyrotaxane, explained Ando: “Although this resin is insoluble in various solvents at room temperature, it can be easily broken down to the raw material level when immersed in a specific solvent and heated. It also showed 25% biodegradation after exposure to seawater for 30 days. By comparison, vitrimer without PR did not undergo any apparent biodegradation. These characteristics make it an ideal material in today’s society, which demands resource recycling.”

From engineering to fashion, robotics to medicine, the team foresees both practical and playful applications for VPR. “Just to give some examples, infrastructure materials for roads and bridges are often composed of epoxy resins mixed with compounds such as concrete and carbon.

By using VPR, these would be easier to maintain as they would be stronger and healable using heat,” suggested Ando.

“Unlike conventional epoxy resins, this new material is hard but stretchable, so it could also be expected to strongly bond materials of different hardness and elongation, such as is needed for vehicle manufacture. Also, as it has shape memory, shape editing and shape recovery capabilities, you might also someday be able to rearrange the silhouette of your favorite clothes at home with a hair dryer or steam iron.”

Only a scratch. A VPR surface scratched to a depth of 0.1 millimeter with a scalpel, was able to fully heal within 60 seconds of being heated to 150 degrees Celsius with a heat gun. Image credit: Shota Ando / University of Tokyo

The team’s next step will be to work with companies to determine the feasibility of its various ideas for VPR, as well as continuing its research in the lab. “I have always thought that existing plastics are very difficult to recover and dispose of because they are subdivided according to their uses,” said Ando. “It would be ideal if we could solve many of the world’s problems with a single material like this.”

Source: University of Tokyo

You can offer your link to a page which is relevant to the topic of this post.

#applications#biodegradable#Biodegradable plastics#biodegradation#carbon#chemical#Chemistry & materials science news#circular economy#Companies#concrete#development#Developments#economy#Editing#Electronics#engineering#Environment#Explained#Featured technology news#Food#form#Global#healing#Heat#Ideas#Industry#Infrastructure#iron#issues#it

0 notes

Text

Week 4: I wonder if you know

Howdy y'all, it's me Connor back after another week jumping around Japan. And oh boy this week was one for the books as it was Tokyo week, but I'll get to that later.

Classes have continued on ramping up as my finals for Japanese and Engineering begin next week. I have been spending a lot more of my free time in the library rather than exploring the city, yet still I am always excited to learn. Japanese is such a fun language and I can't get enough. However I would be lying if I said I'm not stress about our final this Friday.

This is a photo my friend Ethan and myself in the library about to work on our engineering presentations. The topic I chose was car materials and applications. I am doing a deep dive primarily into the interior systems of a car and the different types of plastics and electronics that are used. I have a week left and lots of research to go so I'll get back to everyone on my findings.

We also had quite a few outings this week tied into what we were learning in the classroom:

These photo were taken in the National Traffic Safety and Environment Laboratory. This is a center dedicated research to improve automotive quality within Japan. My expectations were blown out of the water by this experience. They had a state of the art fog room (Left) where we got to see how they tested headlight power and visibility. They also had a massive anechoic chamber (Right), it was so quiet and they use it to make sure vehicles on the road are not too loud.

Another huge portion of this week was motorcycles. We got to visit both the Suzuki and Yamaha museums and see their massive displays of motorcycles and history. The top photo is in front of the Suzuki factor. The photo on the left is me sitting on the Suzuki Hayabusa, a motorcycle which when produced was so fast and had so much power that it changed the way motorcycles were produced forever, (There were laws made because it was so unsafe). On the right is Suzuki's most recent Motorsport bike. I did not know much about it but regardless the experience was a wonderful time.

This is a photo from inside the Yamaha Museum of the MT-09 an 850cc motorcycle. It was my favorite in the museum and there was so much to see. I even got to ride in a motorcycle simulator which was a ton of fun. I learned so much about motorcycles this week and if my mom were not reading these blogs I would say I want one.

The final academically tied experience was a trip to the Yokohama Rubber tire factory. Sadly I was not allowed to take any photos inside but the plant was massive and we got to walk around the factory floor seeing each step of how a tire is produced. If anyone plans on going in the future just know the factory is hot and smells terribly of burned rubber.

Now for the Complete Tokyo Review

Granted this won't be the largest review as I really only had one night and one day to explore but oh boy did I do so much.

This is me at Shibuya Crossing, one of if not the most famous crosswalk in the world if not for Times Square. We went on a Friday night and it was so amazing. The streets were packed and it was louder than any other place in Japan it was so exciting. In addition Shibuya Crossing is the home of the Hachiko statue. There is a very large history to this statue that I highly recommend everyone look up, it made me tear up a bit. We had a quick hot pot dinner that was amazing and I went with a huge group of my friends. That was just about the end of the first night in Tokyo as we got in super late and did not want to miss the last train but I had a massive day ahead of me.

These are photos of m at the Meiji-Jingu Shrine. I was not allowed to take photos within the shrine, it was very elegant however many of the shrines in Kyoto put it to shame. What was really cool was the massive Torii gates, the inner garden, and the famous sake wall. They were all spectacular and the garden was beyond serene. The one downside is that there were way more tourists here than in Nagoya.

The upper photos are from the Sinso-Ji shrine. It was exceptionally beautiful and there were a ton of shops around that I got lost in. I found this full fish skewers near a live performance and got one. It was unsurprisingly fishy and salty. The bottom photos are taken from the Tokyo Skytree the largest building in the city. The Tokyo Skyline is amazing and the city is so much bigger than I could ever imagine it was beautiful. I had such a full day in Tokyo and it really was amazing. Next up are all the roadside adventures we had.

This is a famous volcano we stopped at. It reeked of sulfur but was very cool otherwise. It was well know for its black eggs. They are hard-boiled eggs said to increase you life-span by 7 years and they only sold them in counts of 4 so hopefully I enjoy the extra 28 years I get. The bottom photo was just at a gas station on the side of the highway where you were supposed to be able to see Mount Fuji but it was covered in cloud and not in great view so I got this cool photo instead.

The last stop was a skywalk on the longest suspended bridge in Japan. This thing swayed back and forth like crazy and I was terrified walking across. However on the other side there was a ton of cool stuff such as this owl exhibit where you to pet and see owls up close. Although I also got a finger bit off I would do it again in a heart beat.

Because this week was so busy I do not have a ton of food pictures however I do have one very funny photo from Tokyo.

This was a bowl of ramen I received in Tokyo. I ordered a small and it came with this massive mountain of bean sprouts. I was very determined to finish it and it was so delicious but it proved to be too much.

Anyways, that about sums up my week so I will see y'all after finals.

Until next time, さようなら, また 来週

Connor Gilfillan

Mechanical Engineering

NUSIP Automotive Engineering in Nagoya, Japan

3 notes

·

View notes

Text

The Vital Art

When the human species began to master the molecular machinery that underlay its own existence, the first applications were thoroughly practical. It eventually became simple to engineer viruses that, injected into one's bloodstream, would go hunting on their own for pathogens and cancerous cells, and destroy them instance by instance with a thoroughness and ruthlessness that would make an inquisitor shudder. It was not unheard, of course, that some of these viruses would escape control and become pathogens of their own, as any selfish mutant would necessarily enjoy an immense evolutionary advantage over its obedient brethren. But other waves of nano-cleaners would come to chastise the first, and it would be rare for more than one to rebel.

Bacteria and other such microbes would be tailor-made for all sorts of industrial applications. The cunning alchemies devised by four billion years of seething mutation and merciless selection could be gathered and placed together by the foresight of intelligence. Some would be sprayed over landfills and polluted rivers to break down plastic polymers, encase radioactive waste in glassy foam, strip polluting organochlorides of their flesh-warping powers. Others would swarm on metal structures and use the energy of sunlight to reverse the oxidation slowly eroding their beams; or sifted through mining waste to concentrate and purify metals. It was possible to translate any message into a sequence of nucleotides, and to store them safely in bacterial spores, packing terabytes of data in a droplet of water. All had been carefully crafted so that they could never survive within animal bodies.

Thence it was hardly a leap to cultivate animal and vegetal cells in aquaria and petri dishes. It became trivial to grow any tissue from a single cell; and soon later, authentic giant panda meat was no more expensive than chicken breast. The basest mixture of organic matter, down to dead leaves raked from a yard, could be liquefied into nutrient broth, and sown with the seeds of a feast worthy of royal courts. Rumors were heard of wealthy eccentrics dining on their own projected and multiplied flesh. (Conveniently enough, large swathes of humanity agreed that raising animals for meat was a moral outrage only a few years after synthetic meat had become cheap and satisfactory; though not large enough to prevent meat breeds from surviving as pampered status symbols in isolated regions of the planet.)

Bio-artists managed to grow whole functional organs out of stem cells; and then linked them with artificial nerves and guts and blood vessels, giving life to minimal creatures, networks of interconnected glands lying in a collection of petri dishes. These could turn food into colored secretions or pleasant scents, baring every step of the process to the gawkers. Miniaturized versions were later enclosed in a smooth carapace and sold as decorations, such as living lanterns that could produce a warm firefly light for a few drops of nutritive solution. Designing self-sustaining systems that could perform such functions on a spoonful of sugar became a common assignment for schoolchildren.

Some bioart companies released all-purpose "basic creatures" into which decorative organs could be plugged and exchanged at will, so that the same pulsing fleshsac could nourish a cluster of multi-colored lights one day, musk glands with the scent of lavander and pine resin the next, then a chitinous carillon or a battery-recharging orifice. Subcultures made a game out of the collection of functional organs. This resulted, for a while, in unpleasant exchanges of pathogens; and many owners found expensive organs swollen and oozing with infections. Specialized antibiotic vials became very quickly an indispensable accessory.

All the arts of the animal and vegetal kingdoms were repurposed for human enjoyment. Cephalopod skins were grafted onto the manufactured creatures, and stimulated electrically so that pigmented cells would expand or contract as commanded, serving as biological pixels to display pictures and videos. Swarms of fabricated insects danced in the sky in evanescent shrouds, painting streaks of light with the glow of their own bodies. Worm-like ribbons were wrapped around Christmas trees, or around columns and lampposts during public holidays, to fill the air with the colors of their photophores, or festive stridulations; artificial syringes and gular sacs modeled after tree frogs and siamangs to produce songs of staggering beauty and complexity, with an organic, animal quality that no mechanical instrument nor human voice could have produced.

Synthetic pets came into demand, offering more flattery of human biophilic instincts in lieu of the cleanliness and efficiency of pet robots. They were built at first in imitation of slugs and shrimps (without unpleasant secretions, and built to withstand the manipulation of impatient children), then of birds and mammals. Soft textures, pleasant sounds and smells, endearing features were agreed upon in bioaesthetic committees, endlessly simulated in virtual ontogenesis, and finally translated into proprietary genetic code and packed into a convenient egg. Clean and sexless they were made for families that would feed them daily with patented formulas; and others were made in less innocent places for less innocent purposes.

Brain-designing teams became accustomed to threading a very fine needle, creating minds that were developed enough to avoid most frustrations of pet-owning, without crossing the threshold that would grant them the same personhood and self-ownership granted in extremis to the last gorillas and elephants. Years of poring over the daedalus of neurons with the resources of industry and its hunger for results uncovered many secrets that would feed the next waves of the vital arts.

The following wonder was of course the return of recently extinct species, the delicate-hued passenger pigeon, the reptile-jawed Tasmanian wolf, the purple-cheeked orangutan. Century-old plans were fulfilled as ruddy herds of mammoths wandered once again the pale tundra, although they had to be relocated to a thawing Antarctica. Much clamor was raised by the announce of restored dinosaurs, which were later revealed to have been manufactured out of modified emus and hoazins. Still they enjoyed a great popularity, in increasingly bizarre forms, that eventually resembled more the drooling monsters of ancient movies than the breathing animals of the Mesozoic. They were joined by other false resurrections, the living effigies of clankering sea scorpions, wheezing proto-tetrapods, and gibbering australopithecines.

The orangutans enjoyed the greatest success of all resurrected creatures; they established a thriving population in the half-sunken ruins of a once-great megalopolis in Southeast Asia, whose surviving inhabitants had long since moved to floating swarms of pelagopoleis. For many decades the reborn apes could be sighted from the sea, sitting placidly under red shawls of fur, on the greening roofs and rusting pylons. Apparently jealous of their own new life, they disappeared quickly into the thickest brush, or into galleries believed to extend deep below the sea level of that time. Many fantastic conjectures were made about their secret existence, though nobody quite managed to probe it by force or deceit. Presumably, when the War came some three decades later, the resurrected orangutans fell for the second time into the chasm of extinction.

In the later phase, mammalian and even human brains were produced, some apparently capable of nervous activity. There were many ways to expose it to the world: in some cases it was translated into a musical codex; in others, the outer cortex was made translucent, and the flow of neurotransmitters could be seen as a warm-colored glow. A Museum of Qualia was briefly opened in a northern city, where one could experience the colors of distant longing, the textures of sexual rapture, the notes of filial love, and the taste of divine inspiration. It became simple, then, to induce the same sensations in natural brains, and make everyone into a poète maudit and a prophet of God.

Most synthetic brains were mercifully awash in endorphins for all their existence. But in one infamous case, a particularly mad artist had their farmed brain glow with neuronal activity in ways consistent with excruciating pain. The debates were fierce, on questions both of fact and moral, and after a few months the damned creature, if such it was, was disconnected from support and incinerated. Its luckier brethren followed it soon. The natural-born brains that had been stored and preserved in view of a future reanimation, which for the time trauma or decay had made impossible, were kept in storage as long as dutiful heirs or charitable organizations funded it, and not one minute longer.

This one scandal marked the zenith of popularity of the vital art, and from there it swiftly withdrew from public exaltation into the pockets of practicality -- food production, medicine, waste treatment -- where it could not be abandoned, and where people had long accepted it as normal and natural. People would still dine on vat-grown meat -- who but a savage would prefer another kind? -- and saved their loved ones from death with any necessary mean. But year after year, the breathing infrastructures were quietly dismantled or fell into disrepair, and the synthetic companions lost much of their appeal.

Many countries of the world banned the applications of the art that were not essential, and some of those that were. Quickly the wealth of volumes written on the manipulation of life became little more than a catalogue of past curiosities, a glimpse into the alien thoughts and values that so recently were the rule.

In the last few years before the War, new developments of the vital art only occurred in secret, in the laboratories of tyrants and revolutionaries, meant not for unscrupulous creation, but for exceedingly scrupulous destruction.

10 notes

·

View notes

Text

Exploring the top-notch Tool and Die Steel in Ahmednagar Maharashtra?

Look no further! Virat Special Steels delivers excellence.

Whether it’s tool steel, die steel, mold steel or any other steel requirement, Virat Special Steels stands out as a trusted supplier in Maharashtra!

At the heart of Ahmednagar's manufacturing sector is the tool and die steel industry, which plays a pivotal role in supporting various production processes. Tool and die steel suppliers in Ahmednagar provide essential materials for the automotive, engineering, and numerous other industries, ensuring that the specific needs of their clients are met with precision and durability.

VIRAT SPECIAL STEELS PVT. LIMITED , INDIA is stands out as a prominent supplier in this sector, offering a wide range of tool and die steels for various applications. Their product list includes:

Special offer for Ahmednagar MIDC Industrial Area's :

Die Steel (HH 370 – 410 BHN): DB6, DIN-1.2714, and AISI L6.

Hot Work Steels: DIN 2343, 2344, AISI H11, and H13.

Plastic Mould Steels: Varieties like DIN 2738, 2311, and AISI P20.

High-Speed Steels: Featuring DIN 3243, 3343, AISI M2, and M35.

Cold Work Steels (HCHCr): DIN 2379, 2080, AISI D2, and D3.

Alloy Steels, EN-Series, and More.

With a state-of-the-art plant in #Gurugram and #Ludhiana, they ensure quality and reliability. Their strong distribution network across India makes them accessible to customers nationwide.

You can explore their offerings:

https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-midc-ahmednagar/

Any further queries feel free to contact us :

🌐https://www.viratsteels.com 📨 [email protected] 📞 +91 98140-21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#pune#iso9001#steel#gurugram#Ahmednagar#midc#MIDC Industrial Area#maharashtra#DieSteels#ToolSteel#H13Steel#db6 steel#h11steel#D2Steel#HCHCr

3 notes

·

View notes

Text

Substituting plastics with alternative materials is likely to result in increased GHG emissions, according to research from the University of Sheffield.

The study by Dr. Fanran Meng from Sheffield's Department of Chemical and Biological Engineering, in collaboration with researchers from the University of Cambridge and the KTH Royal Institute of Technology, has revealed the emissions associated with plastic products compared to their alternatives.

Published in the journal Environmental Science & Technology, the study looked at plastics and their replacements across various applications, including packaging, construction, automotive, textiles and consumer durables. These sectors collectively represent a significant portion of global plastic usage.

Findings from the study have revealed that in 15 out of the 16 applications examined, plastic products actually result in lower GHG emissions compared to their alternatives. The reduction in emissions spans from 10 percent to as high as 90 percent across the product life cycle.

Continue Reading.

49 notes

·

View notes