#hex screws

Text

Explore the Different Types of Hex Head Screws

Hex Head Screws are a staple in the world of construction, manufacturing, and DIY projects. Recognizable by their six-sided heads, these screws are prized for their strength and versatility. Let's delve into the various types of hex head screws and their unique applications.

1. Hex Cap Screws Hex cap screws are the most common type of hex head screws. They feature a flat washer face under the head and a chamfered point. Used extensively in machinery, construction, and automotive industries, hex cap screws are ideal for situations where high strength and durability are paramount.

2. Hex Bolts Similar to hex cap screws, hex bolts have a six-sided head but are typically used in pre-tapped holes or with a corresponding nut. They come in a range of sizes and materials, making them suitable for both heavy-duty industrial applications and lighter tasks such as securing wooden structures.

3. Flange Bolts Flange bolts are a variation of hex bolts that include an integrated washer, which distributes the load over a larger area. This design reduces the risk of damage to the bolted materials and provides a secure fit. Flange bolts are frequently used in automotive frames and other applications requiring a tight seal.

4. Socket Head Cap Screws These screws feature a hexagonal recess in the head, allowing them to be driven with an Allen wrench. The socket head design provides a clean and streamlined appearance, making these screws ideal for applications where aesthetics are important, such as in furniture assembly and certain electronic devices.

5. Self-Drilling Screws Equipped with a drill point, self-drilling hex head screws eliminate the need for pre-drilling. They are perfect for quickly fastening materials like metal sheets and wood. These screws save time and labor, making them a favorite in roofing and other large-scale construction projects.

6. Tap Bolts Tap bolts are fully threaded hex bolts, suitable for applications requiring full engagement with the material. They are often used in construction and repair jobs where a strong, consistent thread connection is essential.

7. Structural Bolts Designed for heavy-duty applications, structural bolts are used in steel construction and large-scale projects. These bolts are known for their high tensile strength and ability to withstand significant loads, ensuring the integrity of the structure.

In conclusion, hex head screws come in a variety of types, each tailored for specific applications. Understanding these differences can help you choose the right screw for your project, ensuring a secure and lasting result. Whether you're building a deck, assembling machinery, or working on a DIY project, there's a hex head screw designed to meet your needs.

More Info Contact Us:

Contact: 61 3 9336 0155

Timings: Mon-Fri: 9am to 5pm

Visit Us: https://www.ebolts.com.au/

0 notes

Video

youtube

❤️FIXDEX produce hardware such as wedge anchorthrough bolt, threaded rod...

#youtube#Photovoltaic Bracket#Angle Brackets#Stainless Steel Bracket#Bracket Clamp#Clamp Bracket#Hex Bolt#Hex Head Bolt#Hex Screws#Din 933 Bolt#U Bolt#L Bolt#J Bolt#Drop In Anchor Strength#Xylan Coated Threaded Rods Stud Bolt#Double Ended Threaded Bar#Threaded Bar And Nuts#Threaded Bar Anchors#Option 7 Wedge Anchor#Tb 7 Wedge Anchor#Option 7 Through Bolt#Tb 7 Through Bolt#Eta Approved Through Bolt#Eta Approved Wedge Anchor#Through (Thru) Bolts

0 notes

Photo

Some doodles of FPP and the Kaycee card/player character hanging out, and some additional drawings of the two. I think they’d vibe together.

#Inscryption#The Hex#the hex ???#the hex fpp#inscryption fanart#should I tag Kaycee? eh screw it#kaycee hobbes#traditional art#my art#Inscryption kaycee#I really like Kaycee's card#inscryption challenger

62 notes

·

View notes

Text

Jinx is the Tony Stark of Piltover cause she was able to build hextech weapons in a CAVE! WITH A BOX OF SCRAPS!

#seriously#jinx figured out how to harness hextech#and build weapons using it#a few days after she got it#while chasing her sister around and building other things#jace can go screw himself#jinx is girlboss#arcane#arcane league of legends#jinx#tony stark#memes#marvel#hex tech

25 notes

·

View notes

Text

did not get any helpful results with this search if you can believe it

#i bought a home tool kit last week (finally) inspired by my getting tired of manually screwing together a coffee table#the table is now put together but now i have a tool kit (WITH a power driver!)#instead of my usual home tools which include an old phillips head with the rubber handle disintegrating#and a handful of random hex keys and tiny screws left over from previous amazon furniture builds#so now that i dont have any more amazon furniture on the way#what should i do to break in the new tool set???

4 notes

·

View notes

Text

You know, if Deidara wasn't groomed into being a killing machine, been possibly expected to be the next Tsuchikage, didn't have his values ridiculed and lived in a more supportive environment,

He'd have been a pretty good person.

#deidara#akatsuki#naruto shippuden#naruto#rock lee and his ninja pals#that was a spin-off but#he was an ally there#it was mostly pure comedy and he got screwed up in there#and yet#he was still good.#nice. even#He could have been remembered had he not been like that...#it can be said for many#why the hex ninja world#making nine year olds do killings

10 notes

·

View notes

Text

The temptation to write a vent fic about the disaster that was how set strike was run is very strong

#isabel.vent#the whiplash of yay we did a show! to get your stuff out of the green room right the f*** now or I'll kill you was... something#and then some IDIOT used hex screws on the set and i couldn't find the right size bit#so i spent most of set strike hiding in a stairwell crying! i love having a brain that doesn't work quite right!#turns out other people thought it was unreasonable too at least#honestly i feel like doing the strike the next day would've made a huge difference#because then we wouldn't have been frantically trying to finish after a two show day y'know#was this reasonable/normal? or am i just too thin skinned?#vote now on your phones!

5 notes

·

View notes

Text

Pssssst @random-meme-bot

I'd click the Keep reading if I were you. >:]

Hah! Elly and Dan jumpscare!

I finally got time to draw them properly!! >:D

#my art#digital art#digital drawing#digital artwork#digital illustration#my artwork#artists on tumblr#mutuals oc#mutuals ocs#mutuals oc's#elly#dan#elizabeth roberts#hexes on the shelves#I REALLY hope I did their designs justice-#I know that I screwed up Elly's shirt a bit since the heart isn't visible but I realized that after I finished it-#I'll remember to add it next time-#Elly's hair was a lot of fun to draw!!#I know I said it before but I really like their color palletes!! Shading this was a charm :'>#Also Dan my beloved I made it my mission to give him a cute expression-#Also analysing your art of them made me realize that Dan is slightly transparent on Elly's head which is an interesting detail!!#Also I figured out that it's exactly 80% transparency#Also that Elly's eyes are actually dark purple which would explain the color choice for her ghost form even more!#Anyway I hope ya like it! 💜💚#others ocs

7 notes

·

View notes

Text

#types of fasteners#socket screws#machine screws#tapping screws#hex bolts#blind rivets#Semi-Tubular Rivets

0 notes

Text

1 note

·

View note

Video

youtube

FIXDEX have own Industrial wastewater Treatment Process

#youtube#Industrial wastewater#Industrial wastewater Treatment#Process environment#fixdexwedge anchor#threaded rods#chemical anchor#drop in anchor#foundation bolt#self drilling screw#drywall screw#hex bolt#hex nut#flat washer#Photovoltaic Bracket#Bracket Clamp#Clamp Bracket#hex screws#hexagon head bolt#din975#ETA APPROVED wedge anchor#option 7 wedge anchor#Wedge anchor bolts#stainless steel wedge anchors#stainless steel chemical anchor

1 note

·

View note

Text

need bnha town to change the criteria of the hero billboard chart so it doesn't feel like a popularity contest

#idk how to word it but you know how in the entrance exams deku got rescue points#how to word rhe thoughts ive been feeling for a while#years#ever since the bb chart csme out probably#cuz rhen we get endeavor types#which#i could go into that i wont but it's better to focus less on 1 person at the top and go into the groupvteam work kinda thing#which is ofc what the series has mentioned many times but#putting that ahead of like wHoS thE MoSt POopulAr#which ik top 10 are very strong but#im rambling stoppppp i need to eat my blue takis and doodle my head hurts so bad#my ps4 was havung a disc eject error and i was struggling tocfind a fckng screw driver that fit cuz mine is broken but i got a hex key#when icremoved rhe glossy part to get to the hard drive i was a little too agfressive and a 2mm pirce of plastic broke rippp#it was smth near the power button#this thing is so old like 10 years#i think it's the og ones#my sister Needed to watch a barbie movie which is how i found iut the eject thing was fucked up#anyways all good now :)#this has nothing to do w anything im just a yapper#scarlett.txt#brain fog hitting me hard rn fok

0 notes

Text

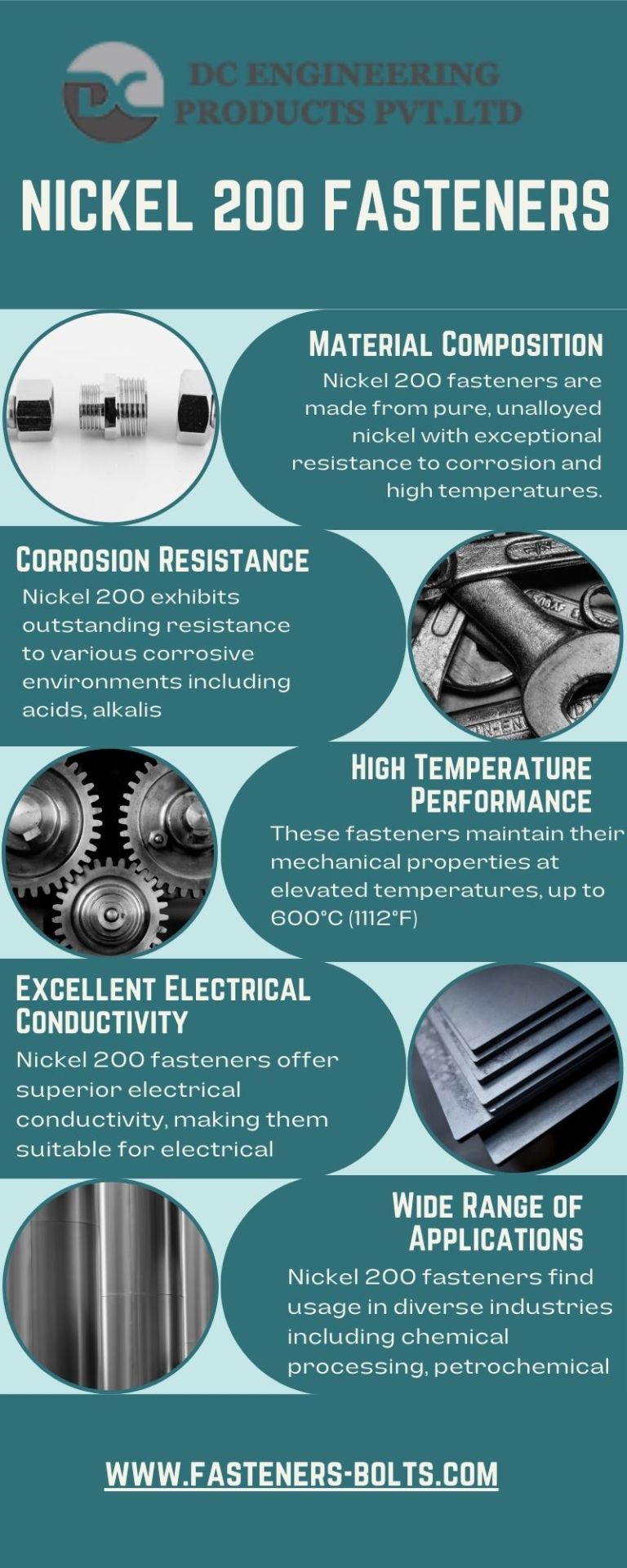

DC Engineering is leading Manufacture and Exporter of High quality of Nickel 200 Fasteners, UNS N02200 Fasteners, Alloy 200 Fasteners

#Nickel 200 Fasteners#High Nickel Alloy 200 Fastener Manufacturer#Nickel Alloy 200 Heavy Hex Nuts#Nickel 200 Hex Head Bolt#UNS N02200 Fastener#DIN 2.4066 Fasteners Supplier#Nickel 200 Spring Washer#Alloy 200 Socket Cap Screws#Nickel Alloy 200 U-bolts#Nickel Alloy 200 Hex Cap Screws#200 Nickel Alloy Hex Bolts

0 notes

Text

If you’re looking for a trustworthy source for prime hex bolts in India, go no further than Fastener World India. We guarantee that every hex bolt meets the highest industry standards by using cutting-edge manufacturing facilities and technology.

0 notes

Text

Hastelloy is a nickel-based alloy known for its exceptional resistance to corrosion, particularly in harsh environments such as chemical processing, aerospace, and marine applications. Hastelloy fasteners, including bolts, nuts, screws, and washers, are specifically manufactured using this alloy to provide superior corrosion resistance and strength in challenging environments where traditional materials may fail.

Here are some key features and benefits of Hastelloy fasteners:

Corrosion Resistance: Hastelloy alloys offer outstanding resistance to a wide range of corrosive chemicals, acids, and environments, including sulfuric acid, hydrochloric acid, nitric acid, and seawater. This makes Hastelloy fasteners suitable for use in chemical processing plants, oil and gas refineries, and marine applications.

High Temperature Performance: Hastelloy fasteners retain their mechanical properties and corrosion resistance at elevated temperatures, making them suitable for high-temperature applications such as aerospace, power generation, and industrial furnaces.

Strength and Durability: Hastelloy alloys exhibit high strength and toughness, providing reliable fastening solutions in demanding applications where mechanical stress and vibration are prevalent.

Versatility: Hastelloy fasteners are available in various grades and configurations to meet specific application requirements, including Hastelloy C276, Hastelloy C22, Hastelloy B2, and others. This versatility allows engineers and designers to choose the most appropriate Hastelloy grade based on factors such as chemical compatibility, temperature, and mechanical properties.

Longevity: Due to their excellent corrosion resistance and durability, Hastelloy fasteners have a long service life, reducing the need for frequent replacement and maintenance, which can result in cost savings over time.

Specialized Applications: Hastelloy fasteners are commonly used in critical applications where corrosion resistance, reliability, and safety are paramount, such as chemical processing equipment, gas turbines, valves, pumps, and reactors.

Overall, Hastelloy fasteners offer exceptional performance in corrosive and high-temperature environments, making them a preferred choice for industries requiring reliable fastening solutions in challenging operating conditions. However, it's essential to consult with materials engineers or specialists to ensure proper selection and application of Hastelloy fasteners based on specific project requirements and environmental conditions.

#hastelloy c276 gasteners#hastelloy c276 bolts#hastelloy c22 washers#hastelloy c276 nuts#hastelloy screws manufacturer#hastelloy hex bolts manufacturer

1 note

·

View note

Text

Stainless Steel Hex Bolts

#Din#Astm#Bs Bolts#Stainless Steel Hex Bolts#Duplex & Super Duplex Steel Heavy Hex Bolt#Alloy Steel Hex Cap Screw#Bolts Manufacturer & Stockist.

0 notes