#syscom

Explore tagged Tumblr posts

Text

Rockwell system integrator

Introduction:

In the dynamic landscape of industrial automation, Syscom Automation takes center stage as a distinguished Rockwell System Integrator. This overview explores the pivotal role of Syscom Automation in leveraging Rockwell Automation solutions to drive innovation, efficiency, and excellence in the United Arab Emirates (UAE).

1. Strategic Partnership with Rockwell Automation:

Syscom Automation has strategically aligned itself as a Rockwell System Integrator, fostering a strong partnership with Rockwell Automation, a global leader in industrial automation and information solutions. This alliance reflects a commitment to delivering cutting-edge solutions tailored to the unique needs of industries in the UAE.

2. Expertise in Rockwell Automation Products:

As a Rockwell System Integrator, Syscom Automation boasts expertise in deploying and optimizing a comprehensive range of Rockwell Automation products. This includes Programmable Logic Controllers (PLCs), Human-Machine Interfaces (HMIs), motion control systems, and other industrial automation solutions that Rockwell Automation is renowned for.

3. Seamless Integration of Rockwell Automation Platforms:

Syscom Automation excels in seamlessly integrating Rockwell Automation platforms within diverse industrial applications. Whether it's enhancing control processes with Allen-Bradley PLCs or implementing FactoryTalk software for real-time data visualization, the integration ensures a cohesive and efficient automation environment.

4. Specialized Knowledge in Connected Enterprise Solutions:

Syscom Automation's role as a Rockwell System Integrator extends to implementing Rockwell Automation's Connected Enterprise solutions. This approach emphasizes connectivity, data analytics, and smart manufacturing practices, empowering clients to achieve enhanced operational visibility and efficiency.

5. Tailored Solutions for Varied Industries:

Syscom Automation's collaborative approach as Rockwell System Integrators ensures the delivery of tailored solutions across varied industries. From manufacturing and utilities to energy and infrastructure, their expertise allows them to customize Rockwell Automation solutions to address the unique challenges of each sector.

6. Implementation of PlantPAx® DCS:

Syscom Automation excels in the implementation of Rockwell Automation's PlantPAx® Distributed Control System (DCS). This advanced system provides a scalable and integrated control solution, enabling clients to optimize their industrial processes while maintaining flexibility and agility in their operations.

7. Commitment to Industry 4.0 Principles:

The partnership between Syscom Automation and Rockwell Automation aligns with Industry 4.0 principles. By integrating smart technologies, connectivity, and data analytics, the collaboration delivers solutions that position clients at the forefront of the fourth industrial revolution, driving efficiency and innovation.

8. Ongoing Support and Innovation:

Syscom Automation's role as Rockwell System Integrators goes beyond initial implementation to provide ongoing support and innovation. Their collaborative efforts aim to offer continuous support, ensuring that businesses stay at the forefront of technological advancements and Rockwell Automation's product innovation.

Conclusion:

Syscom Automation's position as a Rockwell System Integrator in the UAE signifies a dedication to excellence, innovation, and efficiency in industrial automation. The alliance with Rockwell Automation empowers Syscom Automation to deliver sophisticated solutions, ensuring that businesses in the UAE are well-equipped to thrive in an era of rapid technological evolution.

0 notes

Text

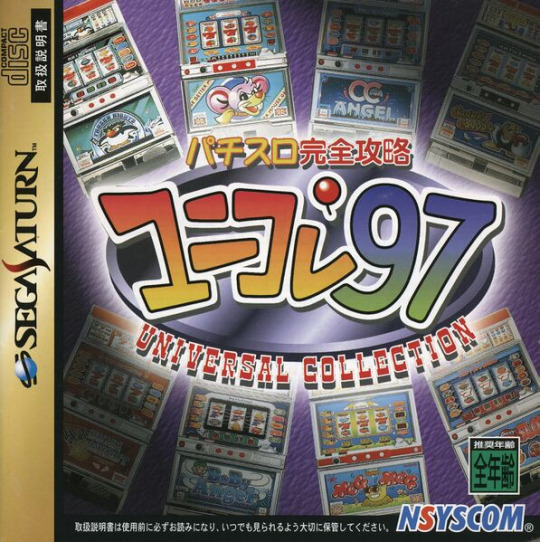

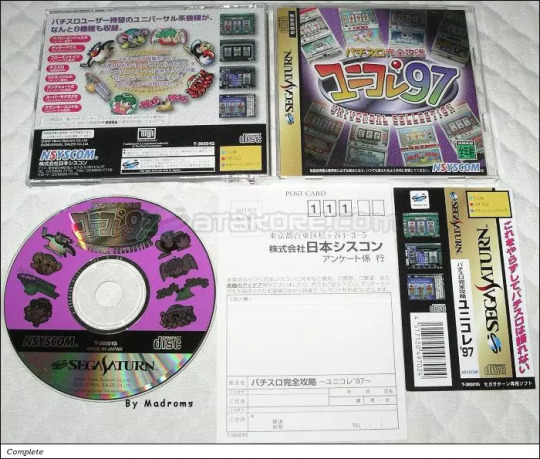

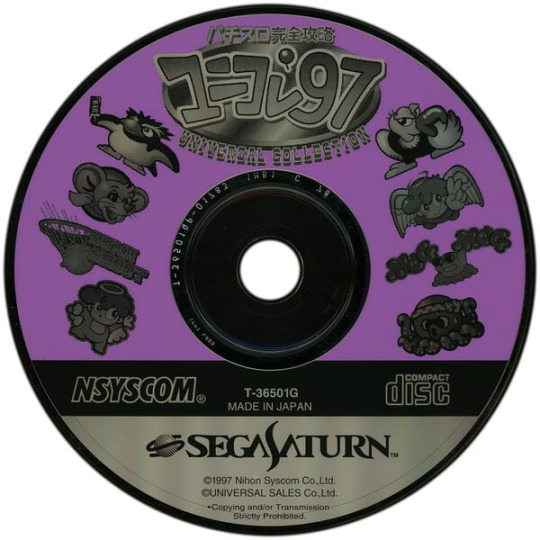

Sega Saturn - Pachi-Slot Kanzen Kouryaku Uni-Colle'97

Title: Pachi-Slot Kanzen Kouryaku Uni-Colle'97 / パチスロ完全攻略 ユニコレ’97

Developer/Publisher: SYSCOM Entertainment

Release date: 18 September 1997

Catalogue No.: T-36501G

Genre: Pachi-Slot

8 Slot machines from Universal for your playing pleasure, thanks to Nsyscom (Syscom Entertainment, the same guys that released GTA 1 for the PS1 in Japan).

youtube

2 notes

·

View notes

Video

youtube

Action Bass PS1 1999 2000

Action Bass or Akushon Basu is an arcade action fishing game developed by Japanese studio Vingt-et-un Systems Corporation and published by Syscom and Take Two Interactive for the PlayStation 1, and released in 1999 in Japan, and in 2000 in North American and Europe.

#youtube#gaming#90s games#fishing#angling#action bass#90s gaming#video games#games#gamer#1999#PS1#akushon basu#arcade#arcade fishing game#fishing game#sports fishing

2 notes

·

View notes

Text

syscommedia

At Syscom Media, we’re here to help you achieve your digital marketing goals. Whether you have a question, need assistance, or want to discuss your next project, we’re just a message away.

At Syscom Media, every project starts with a deep understanding of your vision. We take the time to connect with your brand’s unique essence, crafting designs that are more than just visuals—they’re reflections of your story. We believe in pushing the boundaries of creativity. By leveraging the latest trends and technologies, we develop innovative solutions that stand out, delivering designs that are not only modern and engaging but also strategically effective. Design for us is about making an impact. Our work is crafted with purpose, aiming to elevate your brand, increase engagement, and drive measurable results. We don’t just design; we create experiences that resonate and perform.

1 note

·

View note

Text

Littelfuse 250A 190-480Vac Motor Saver 3-Phase Syscom | PartsHnC

The Littelfuse 250A 190-480Vac Motor Saver is a guardian angel for three-phase motors found in HVAC equipment. It shields these motors by constantly monitoring the electrical current. If it ever detects an overload or a short circuit, the Motor Saver swiftly interrupts the circuit. This preventative measure stops motors from burning out, which can cripple your HVAC system and result in pricey repairs and downtime.

https://www.partshnc.com/250a-littelfuse-190-480vac-3ph-syscom-mtr-svr

0 notes

Text

Best Top 10 Servo Stabilizer Manufacturers in Faridabad

What is a Servo Stabilizer?

Servo Stabilizer Manufacturers – A servo stabilizer is a type of voltage regulator that is used to control and stabilize the voltage output of electrical appliances or systems. Its primary function is to ensure a consistent and stable electrical power supply, protecting equipment from voltage fluctuations and irregularities in the power grid.

Key components of a servo stabilizer typically include a control circuit, a voltage sensor, a servo motor, and an autotransformer. The control circuit monitors the input voltage, and the voltage sensor provides feedback to the servo motor, which, in turn, adjusts the voltage through the autotransformer.

Servo stabilizers are commonly used in industrial settings, data centers, medical facilities, and other environments where a stable power supply is crucial for the proper functioning of equipment. They help prevent damage to sensitive electronic devices, improve energy efficiency, and extend the lifespan of electrical appliances by ensuring they operate within a specified voltage range.

List of Top 10 Servo Stabilizer Manufacturers in India for 2024 full details?

1. Indian Servo Controls:- Indian Servo Controls is a leading manufacturer of power conditioning and power-saving equipment, including servo stabilizers.

2. Purevolt Products Pvt. Ltd:- Purevolt specializes in manufacturing voltage stabilizers, servo stabilizers, and various power conditioning products.

3. V-Guard Industries Ltd:- V-Guard is a well-known brand in India, offering a range of electronic and electrical products, including servo stabilizers.

4. Delta Power Solutions India Pvt. Ltd:- Delta is a global provider of power management solutions, and they offer servo stabilizers for industrial applications.

5. Luminous Power Technologies Pvt. Ltd:- Luminous is a popular brand for power backup and power solutions, and they manufacture servo stabilizers for different sectors.

6. Consul Neowatt Power Solutions Pvt. Ltd:- Consul Neowatt is known for its power conditioning and power backup solutions, including servo stabilizers.

7. Stabiline Systems Pvt. Ltd:- Stabiline specializes in the design and manufacture of power conditioning equipment, including servo stabilizers.

8. Statcon Energiaa Pvt. Ltd:- Statcon Energiaa focuses on power quality solutions, and their product range includes servo stabilizers for industrial use.

9. Everest Stabilizers Pvt. Ltd:- Everest is a reputed manufacturer of voltage stabilizers and servo stabilizers for various applications.

10. Syscom Corporation Ltd:- Syscom is involved in providing power solutions, and they offer servo stabilizers for diverse industrial and commercial needs.

Keep in mind that the market and industry landscape may change, so it’s advisable to check the latest reviews, customer feedback, and industry reports to determine the current top manufacturers in the servo stabilizer segment in India for 2024.

How to Search Servo Stabilizer Manufacturers in Faridabad

1. Online Business Directories:- Explore online business directories like IndiaMart, TradeIndia, or other industry-specific directories. Search for “Servo Stabilizer Manufacturers in Faridabad” to find potential companies.

2. Industry Associations:- Contact industry associations related to electrical and power equipment in Haryana or Faridabad. They might provide recommendations or a list of manufacturers.

3. Local Distributors or Suppliers:- Reach out to local distributors or suppliers of electrical equipment in Faridabad. They may have insights into reputable manufacturers.

4. Trade Shows and Exhibitions:- Attend industry-related trade shows or exhibitions in Faridabad. These events often bring together manufacturers showcasing their products.

5. Online Searches:- Conduct online searches using search engines. Look for companies specializing in servo stabilizers and operating in or around Faridabad.

The Best Servo Stabilizer in India is now in Faridabad

It’s great to hear that there is a high-quality servo stabilizer available in Faridabad, India. To choose the best servo stabilizer for your specific needs, consider factors such as the capacity (in kVA), input voltage range, output voltage stability, and any additional features that may be relevant to your application. Additionally, look for products from reputable manufacturers that adhere to relevant quality standards like Indian Servo Controls. Reading customer reviews and seeking recommendations can also help ensure you make an informed decision.

Discover the Key Features of our Faridabad-based Servo Stabilizers

However, here are some key features commonly associated with high-quality servo stabilizers:

1. Voltage Regulation:

Precise and stable output voltage, ensuring equipment operates within the desired voltage range.

2. Wide Input Voltage Range:

Ability to handle a wide range of input voltage fluctuations while providing a consistent output.

3. Fast Correction Speed:

Quick response to voltage changes to maintain stability and protect connected devices.

4. Digital/Analog Control:

Advanced digital or analog control mechanisms for accurate voltage regulation.

5. Overload Protection:

Built-in protection mechanisms to safeguard against overloads and ensure long-term reliability.

6. High Efficiency:

Efficient energy conversion to minimize power losses and reduce energy consumption.

7. Compact Design:

Space-saving design is suitable for various installation environments.

8. User-Friendly Interface:

Intuitive control panel or interface for ease of operation and monitoring.

9. Remote Monitoring (Optional):

Capability for remote monitoring and control for enhanced convenience.

10. Customization Options:

Ability to customize the stabilizer based on specific requirements and applications.

FAQs: Transformer

Q1. Which company is best for Servo Stabilizers?

Ans.

Indian Servo Controls:

A global leader in power management, offering a range of servo stabilizers.

V-Guard Industries:

A prominent Indian company known for its voltage stabilizers, including servo stabilizers.

Luminous Power Technologies:

Offers a variety of power solutions, including servo stabilizers for different applications.

Microtek International Pvt. Ltd.:

Known for its power backup and stabilization products, including servo stabilizers.

Servokon Systems Ltd.:

Specializes in manufacturing servo voltage stabilizers for various industries.

Delta Electronics India:

A global company offering power and thermal management solutions, including servo stabilizers.

Genus Power Infrastructures Limited:

Provides power solutions, including servo stabilizers, for diverse applications.

Q2. What is the price of a 750 KVA servo stabilizer?

Ans. 750 Kva 750KVA Digital Servo Voltage Stabilizer at Rs 925000/piece in New Delhi.

Q3. Who is the Manufacturer of Servo Stabilizers?

Ans. Indian Servo Controls has been the market leader in the manufacture and distribution of servo stabilizers in Faridabad, Delhi NCR, India Since 1995. We have a track record of offering the highest-quality and best-performing servo stabilizers to all our esteemed customers.

Q4. How do I choose a servo stabilizer and servo stabilizer manufacturers?

Ans. Choosing the right servo stabilizer and servo stabilizer manufacturers involves considering various factors to ensure it meets your specific requirements. Here’s a guide to help you make an informed decision:

Voltage Fluctuation Range:

Identify the range of voltage fluctuations in your area. Choose a servo stabilizer with an input voltage range that covers these fluctuations.

Load Capacity (kVA):

Determine the total power load (in kilovolt-amperes or kVA) you need to stabilize. Choose a servo stabilizer with a capacity that comfortably accommodates your load.

Type of Load:

Consider the type of equipment or machinery the stabilizer will support. Different applications may have specific requirements.

Response Time:

Evaluate the response time of the servo stabilizer. A faster response time ensures quick correction of voltage fluctuations.

Accuracy of Voltage Regulation:

Look for a stabilizer with high voltage regulation accuracy to maintain a stable output voltage.

Efficiency:

Consider the efficiency of the servo stabilizer. Higher efficiency means less energy loss during operation.

Build Quality and Durability:

Ensure the stabilizer is built with high-quality materials to withstand environmental conditions and provide long-term durability.

Digital or Analog Control:

Decide between digital and analog control based on your preference. Digital controls often offer more precision and additional features.

Overload Protection:

Check for overload protection features to safeguard the stabilizer and connected equipment from potential damage.

Brand Reputation:

Choose a reputable brand with a history of manufacturing reliable and high-performance servo stabilizers.

Certifications:

Verify that the servo stabilizer complies with relevant standards and certifications to ensure safety and quality.

Warranty and After-Sales Support:

Consider the warranty offered by the manufacturer and the availability of reliable after-sales support.

Customization Options:

If your application has specific requirements, check if the manufacturer offers customization options.

Customer Reviews:

Read customer reviews and testimonials to gain insights into the performance and satisfaction levels of users with similar needs.

By carefully assessing these factors, you can select a servo stabilizer that not only meets your current needs but also provides a reliable and efficient solution for the long term.

Q5. What is the difference between a stabilizer and a servo stabilizer?

Ans. The main difference between a stabilizer and a servo stabilizer lies in the mechanism they use to regulate and stabilize voltage. Here’s a brief comparison:

Stabilizer:-

Type of Regulation:

Stabilizers typically use relay-based or mechanical mechanisms to control voltage.

Voltage Correction Speed:

They have a slower response time compared to servo stabilizers.

Accuracy:

The voltage regulation accuracy may not be as precise as in servo stabilizers.

Applications:

Commonly used for basic voltage stabilization in household appliances and some commercial equipment.

Servo Stabilizer:-

Type of Regulation:

Servo stabilizers use a motor-driven variable transformer (autotransformer) to adjust the voltage.

Voltage Correction Speed:

They offer a faster response time compared to traditional stabilizers.

Accuracy:

Servo stabilizers provide more precise voltage regulation, maintaining a stable output.

Applications:

Widely used in applications requiring high precision and quick correction of voltage fluctuations, including industrial machinery, medical equipment, and sensitive electronic devices.

Common Features:

Both stabilizers and servo stabilizers aim to maintain a consistent voltage output despite fluctuations in the input voltage.

They help protect connected equipment from voltage-related issues.

Q6. What are the different types of servo stabilizers?

Ans. These come in 3 types:

Single Phase Servo Based Voltage Stabilizers.

Three Phase Balanced Type Servo Based Voltage Stabilizers.

Three Phase Unbalanced Type Servo Based Voltage Stabilizers.

Q7. Why servo stabilizer is used?

Ans. Servo stabilizers are essential for maintaining stable voltage levels in the face of fluctuations. Known for their precision and quick response, they protect equipment from potential damage, extend device lifespan, and prevent costly downtime in industrial and commercial settings. Their reliability is particularly valuable in applications involving sensitive electronics and precision machinery. Additionally, some models prioritize energy efficiency, minimizing power losses during voltage stabilization. Overall, servo stabilizers play a vital role in ensuring consistent and regulated power, contributing to the optimal performance of diverse electrical systems.

Q8. Servo stabilizer manufacturers in Faridabad contact number?

Ans. Have questions about this number and email?

Phone No:- +91 7503323739, +91 9643465114

Email Id:- [email protected]

Q9. What are the disadvantages of servo stabilizers?

Ans. There are a few disadvantages to using a servo voltage stabilizer. – Servo Voltage stabilizer can add noise to the servo system. – Another disadvantage is that the stabilizer may not work as well in high-vibration environments.

1 note

·

View note

Text

J'ai choisis le bâtiment BC qui est le bâtiment de la section syscom pour plusieurs raisons.

Esthétique. (La vue)

Au risque d'en effaroucher certains j'ai toujours aimé l'architecture moderne, je ne la trouve pas sans âme et je m'y sens bien. Les couleurs sont rassurantes et les matériaux métalliques grisonnant, inspirent confiance de part leur solidité apparente. Le tout est agrémenté de plein de petites tâches de couleurs qui font très start up nation, pas pour me déplaire. Finalement l'éclairage est naturel, l'entreprise qui pose les vitre dans ce bâtiment a du bien renflouer les caisses avec ce devis seulement. Cela contribue à cette ambiance très "open-space, start-up nation, macron est pas si mauvais que ca, on mange des graines de chia et on vient en vélo". Je prend un petit plaisir peut être malsain et m'y sentir different. Captation. (l'ou��e, l'odorat)

Le bâtiment est une sorte d'escargot géant ou le son résonne de manière assez inédite. Les parois interne de ce bâtiment sont des salles remplie d'ordinateurs ou des étudiants à l'hygiène discutable s'adonne à coeur joie à la programmation, très souvent en groupe. Nos oreilles sont donc constamment bercer par ce brouhaha ambiant auquel une fois de plus on est très content de ne pas participer.

C'est pour ces raisons, que j'ai choisis ce lieu.

0 notes

Text

PLC Commissioning | PLC Comissioning

What is PLC Commissioning?

PLC Commissioning is a series of careful examinations done in a PLC control system to ensure that the controller, program, input and output devices, and associated wiring conform to the specifications of the design. Before you start PLC commissioning, it is important that you eliminate the possible hazards in your workspace first.

This means that actuators, especially ones that produce powerful movements such as motors or valves must be disconnected from the programmable logic controller.

With that out of the way, here are the steps to get you started with PLC Commissioning.

OR

PLC Comissioning is a progression of cautious assessments done in a PLC control framework to guarantee that the regulator, program, information and result gadgets, and related wiring adjust to the determinations of the plan.

Before you start PLC appointing, you must first dispense with the potential risks in your work area.

This implies that actuators, particularly ones that produce strong developments, for example, engines or valves should be detached from the programmable rationale regulator.

Steps in PLC Commissioning

1. Cable connections must meet standards

All cable connections between the PLC, the input devices, the power supply, the output devices, and the programming device must be checked thoroughly as they are the media that the PLC uses to communicate between each of the devices.

All cables must meet the required specifications according to the standards, it should even meet the local standards set for the specific hardware.

2. Check the power supply

The power supply of the PLC must match the voltage setting of the PLC.

The voltage setting of the power supply must also conform to the voltage ratings of the input and output devices, otherwise, one of the two must be replaced by another device.

3. Check indicator lights of the PLC

The indicator lights on the PLC should determine if the PLC will work properly.

If the power is properly applied, the power indicator of the PLC should turn on. Fault indicators are usually installed on PLCs, so ensure that the fault light is not turned on at this point.

4. Put PLC in a test mode.

The PLC must be put in a mode that prevents it from sending an output voltage or current to the output devices.

This can either be called “Disable” or “Continuous test” mode depending on the PLC manufacturer.

In this mode of operation, the outputs will be de-energized, so you are assured of your safety when testing.

5. Check protective devices

In this step, you must ensure that the protective devices of the PLC are set to their proper trip settings.

6. Check emergency stop buttons

The emergency stop buttons, usually normally closed push buttons, must be checked thoroughly because these buttons are the ones that will stop ALL PLC operations in an emergency event.

7. Check connection points of input and output devices

In this step, the connection points of all input and output devices must be double-checked.

Make sure that each device is connected to the proper address according to the program present in the PLC memory.

If you fail to do this step, you may encounter issues such as the output being turned on at inappropriate times (usually because of the wrong sensor being activated).

So, pay extra attention to this step.

8. Test the software

After all of the previous steps have been performed, it is now time to load the program into the PLC and start testing the software.

Testing the software is relatively easy as most PLCs contain software-checking programs already.

Even though this step checks the program for incorrect device addresses, it is always important to do the preceding step (Checking connection) in order to save time.

The PLC provides a printout of the input and output points that were used, along with the counter presets, timer settings, with the errors that it has encountered.

If you already did a great job in the preceding steps, doing this only serves as a “proofread” for all the things that you have performed.

Conclusion

PLC Commissioning is a process that involves doing each and every detail of setting up a PLC system with a safety precaution in mind. Also, it is a good investment of your time because it lessens the possibility of failures in the future.

0 notes

Photo

Syscom Mart wishes Happy and prosperous Navratri to all. To join Syscom Mart and grow your business on ecommerce, visit - syscommart.com

0 notes

Text

IEC 62443

Introduction:

In an era where industrial processes are increasingly digitized, ensuring robust cybersecurity is paramount. Syscom Automation, a leader in providing advanced automation solutions, takes a proactive stance in safeguarding industrial systems. This overview explores Syscom Automation's commitment to cybersecurity, specifically in alignment with the International Electrotechnical Commission's (IEC) standard, IEC 62443.

1. Embracing Cybersecurity Standards:

Syscom Automation stands at the forefront of industrial cybersecurity by aligning its practices with the IEC 62443 standard. This internationally recognized standard outlines best practices for securing industrial control systems, ensuring a comprehensive and systematic approach to cybersecurity.

2. IEC 62443: A Framework for Industrial Cybersecurity:

IEC 62443 is a set of standards developed to address the unique cybersecurity challenges faced by industrial control systems. It provides a robust framework encompassing policies, procedures, and technical measures to safeguard critical infrastructure from cyber threats.

3. Comprehensive Cybersecurity Solutions:

Syscom Automation integrates IEC 62443 principles into its cybersecurity solutions. From risk assessment to system design and implementation, the company ensures that its cybersecurity offerings align with the standard, providing clients with comprehensive protection against cyber threats.

4. Risk Assessment and Mitigation:

Syscom Automation begins its cybersecurity journey with a thorough risk assessment, a key component of IEC 62443. By identifying and evaluating potential vulnerabilities and threats, the company develops targeted strategies for mitigating risks and enhancing the resilience of industrial control systems.

5. Secure System Design and Implementation:

IEC 62443 emphasizes the importance of secure system design and implementation, and Syscom Automation incorporates these principles into its solutions. The company ensures that industrial control systems are architected with cybersecurity in mind, incorporating measures to prevent, detect, and respond to cyber incidents.

6. Continuous Monitoring and Adaptation:

Cybersecurity is an ongoing process, and Syscom Automation adopts a continuous monitoring approach, as advocated by IEC 62443. By implementing monitoring mechanisms and regularly assessing cybersecurity measures, the company ensures that industrial systems remain resilient in the face of evolving cyber threats.

7. Compliance and Certification:

Syscom Automation's commitment to IEC 62443 extends to compliance and certification. The company works diligently to ensure that its cybersecurity solutions meet the stringent requirements of the standard, providing clients with the assurance that their systems adhere to international cybersecurity best practices.

8. Expert Guidance and Training:

Beyond implementing cybersecurity measures, Syscom Automation provides expert guidance and training to clients. This includes educating clients and their workforce on the principles of IEC 62443, fostering a culture of cybersecurity awareness and empowering them to actively contribute to the protection of industrial control systems.

Conclusion:

Syscom Automation's commitment to IEC 62443 underscores its dedication to providing robust and comprehensive industrial cybersecurity solutions. In a landscape where cyber threats are increasingly sophisticated, Syscom Automation's alignment with international standards ensures that industrial control systems in the UAE are fortified against evolving cybersecurity challenges.

0 notes

Text

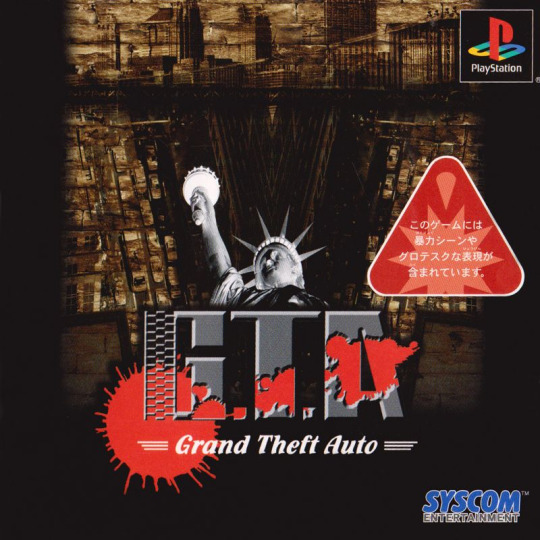

Sony PlayStation - G.T.A Grand Theft Auto

Title: G.T.A Grand Theft Auto / G.T.A グランド・セフト・オート

Developer: DMA Design (Rockstar Games North) / Visual Sciences Ltd.

Publisher: Take-Two Interactive / SYSCOM Entertainment

Release date: 17 January 2002 (Pokkiri 1400 Series)

Catalogue No.: SLPM 87007 (Pokkiri 1400 Series)

Genre: 2D Top-Down Action / Racing

GTA was controversial due to its criminal violence, blood, and profanity. It wasn't a best-seller, however (at least on consoles), until GTA 3 came to the PlayStation 2 in 2001 and since then gave the series its third dimension. Released by Syscom in Japan, the crude, flat graphics of this game are a far cry from the virtual 3D world of GTA3. The overhead perspective doesn't always give you a good angle since buildings and overpasses often block your view. The graphics aren't particularly good, with tiny people and pixelated scenery. The sound effects are amusing however, especially the "splat" of running over pedestrians. There's a car radio, but it doesn't play anything worth hearing. GTA's action is a mix of car driving and on-foot mayhem, and you receive mission instructions from pay phones across town. You'd be wise to carry out your dirty deeds without generating much commotion because once the cops swarm, they will drag your criminal-ass right out of your vehicle.

A handy yellow arrow always points to your next destination, and it's absolutely necessary, considering there's no map or radar display. As you can imagine, constantly following this arrow starts to feel tedious after a while. The missions are somewhat challenging, but that's mainly due to the controls. The directional pad controls your direction, but you need to hold down the buttons to run forward and backward, which is awkward, to say the least. The driving is even worse. Not only does it seem like you're always turning in the wrong direction, but your car constantly gets stuck. It also doesn't help that the layout of the city is so poor. I've never seen roads that zigzag through town (except that one in San Francisco), but in this game, they're quite common. In light of the frustrating gameplay, the blood and profanity seem more silly and gratuitous than offensive. GTA2 (the only GTA series entry to see a Sega console entry) was a slight improvement, but the series didn't grow teeth until its third installment.

youtube

2 notes

·

View notes

Text

Show Your Spine! spoilers without context

4 notes

·

View notes

Video

youtube

A compilation of Japanese PS1 commercials, featuring one for none other than Vigilante 8 (it’s at the 2:28 mark just in case)

I find it amusing how it’s basically the polar opposite of the US commercial, considering this time it’s the students that encourage the action. Also the massive disconnect between the very Japanese cars and an obviously US-style school bus (in fact I think it’s basically the same as how it appears on the cover)

6 notes

·

View notes

Photo

‘Vigilante 8′

[PS1] [JAPAN] [MAGAZINE, SPREAD] [1998]

It’s not a driving game.

It’s not even a combat game.

....Then what the hell is it?! ~Ad Blurb

Source: Weekly Famitsu, 12/11/1998 (#521) || personal collection

#gaming#advertising#vigilante 8#japan#syscom entertainment#activision#luxoflux#vehicular combat#ps1#playstation#spreads#video games#1998

38 notes

·

View notes