#universal 3d sensor

Explore tagged Tumblr posts

Text

youtube

Best Measuring Tool For Metal Industry : Universal 3D sensor

0 notes

Text

Modeling system could enable future generations of self-sensing materials

Research that eliminates the guesswork in developing advanced 3D printed materials could help accelerate the development of new forms of "self-sensing" airplanes, robots, bridges and more. A team of engineers led by researchers from the University of Glasgow have developed the first system capable of modeling the complex physics of 3D-printed composites capable of detecting strain, load, and damage using nothing more than a measure of electrical current. By allowing material scientists to predict in advance for the first time how new structures can be fine-tuned to produce specific combinations of strength, stiffness, and self-sensing properties, it could help catalyze the development of revolutionary new applications for the technology.

Read more.

#Materials Science#Science#3D printing#Composites#Sensors#Piezoresistivity#Additive manufacturing#Polymers#Carbon nanotubes#Carbon#Nanotubes#Nanotechnology#University of Glasgow

14 notes

·

View notes

Text

Hvidovre Hospital has the world's first prototype of a sensor capable of detecting errors in MRI scans using laser light and gas. The new sensor, developed by a young researcher at the University of Copenhagen and Hvidovre Hospital, can thereby do what is impossible for current electrical sensors—and hopefully pave the way for MRI scans that are better, cheaper and faster. The study is published in the journal PRX Quantum. MRI scanners are used by doctors and health care professionals every day to get a unique look into the human body. In particular, they are used to study the brain, vital organs and other soft tissues by way of 3D images of exceptional quality compared to other types of medical imaging.

Continue Reading.

73 notes

·

View notes

Text

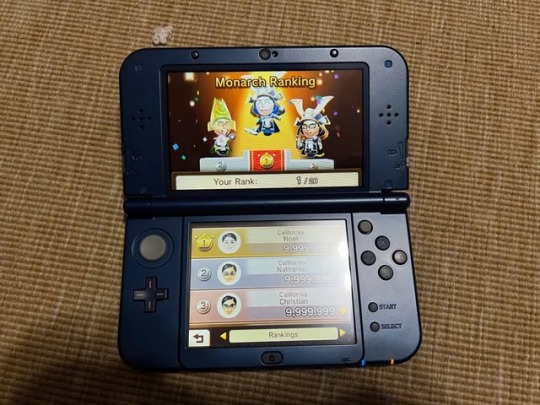

The best system to play Gameboy games on is... well... you can play them on many devices.

Officially it would be GBA SP because it can run Gameboy and GB Colour games.

However, very few backlit SPs were ever released (they are frontlit). So a better unit for Gameboy Advance games might be the DS Lite, which universally is backlit and which is lightweight enough to not cause problems. It also has better ergonomics than the SP, but I am bugged by the black borders and empty second screen.

A really popular mod is called the "Gameboy Macro", which is when you take a DS Lite lower screen and use it solely as a gameboy advance. It is a great way to recycle DS units with a broken top screen, a common issue, though it makes me cringe to think some people modify perfectly fine units this way.

The Lite also has issues with the cartridge sticking out the bottom, so many prefer using the "phat" for this purpose. The original DS is both frontlit and backlit for some reason. The image is still an improvement on frontlit SPs.

The best units to play DS and 3DS games on are... the DS and 3DS.

Specifically the best place for NDS games is the DSi XL. No non-DS device has the touchscreen versatility to run DS games well, and it's very awkward scaling the tiny screen on an emulator.

The 3DS is also not a great place for DS games. The 3DS top parallax screen is incapable of a 1:1 pixel ratio even in pixel-perfect mode, which already has the issue of black borders around the screens, making touch-based games more finicky.

It is especially apparent on the XL models but is also an issue on the smaller 3ds models.

The best unit to play DS games on is the DSi XL. It has a backlit screen and more power and memory than the first two units, making loading faster. It doesn't have the scaling issues of the 3ds, as it doesn't need to do any upscaling at all - the XL has the same number of pixels as a normal DS.

I've never used a DSi XL because all the ones sold in the UK are these ugly beige colours and they never took off, but if you don't mind the loss of the GBA slot, it's the best device for DS games.

Unfortunately DSis seem to be plagued by yellowing screens. I can tell you the small unit I just bought has some very slight yellowing on both screens.

What's the best way to play 3ds games? Well, on a 3ds obviously. It's even harder to accurately emulate 3ds games than DS games, and you lose the 3d effects altogether.

But which 3ds is best?

It depends on what you want. The 3ds more than any other Nintendo system besides the Gameboy is heavily based on preference instead of objective superiority.

To get it out the way first, while the original 3ds has the sleekest look, it's the worst one. The original 3ds and 3dsXL have a much worse 3D implementation, relying on you to stare at the screen at an odd angle.

Not only does the New3ds fix the 3d with an eye tracking sensor, it also has more power again, and a "c-stick". I also think the screens on the New3ds are of a higher quality and run flat games better too.

However the New3dsXL has some downgrades. The SD card is replaced with a microSD but now requires a mini screwdriver to access, removing the back plate. The stylus is also a really tiny one like on the DS, in an awkward place, and the metallic skin on the console will decay very quickly with use. My New3DSXL's skin started peeling under my hands after just six months of use.

The New3DSXL is the best unit to play 3ds games if you are looking to have all the features at their most optimal. It is the best by far for playing in 3d. It can also run the DS library fine, if in a poor image quality.

Personally I prefer the XL, the larger size is easier on the eyes, though the customizable panels on the hard-to-find normal size New3ds are cute too.

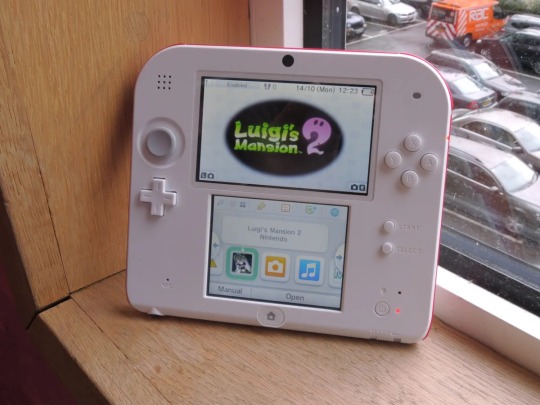

If you don't care for 3d, the Wedge and Doorstop may be for you.

The 2ds has all the features of a 3ds apart from the 3d, while in a wedge shape that looks dreadful but actually feels more ergonomic. It has similarities to the first Gameboy Advance and you can't tell you're holding something so tall.

The original 2DS is sold for much cheaper than the other units because Nintendo sold it for cheaper and nobody particularly wants one, so it's the most affordable way to try every game in the DS library, especially if you pair it with a jailbroken SD card. Unfortunately it still uses the 3ds screen, just with no 3d slider, so it still upscales DS games and doesn't have perfect rendering of 3ds games either, but it's harder to tell as the screen's tiny.

The New 2ds XL was the last DS ever sold, it came out after Switch. A lot of cute variants of the 2ds XL exist, and most games coming out around its release didn't have 3d enabled anyway. The feature had died in popularity, so while a 2d 3ds was originally scoffed at, in 2017 it just made sense.

While the New2ds XL looks fancy in a distance, the ergonomics are worse than any 3ds, and far worse than the wedge 2ds. The New2dsXL is all style and no substance, with the speakers being covered by the user's hands, and it's made out of a flimsy plastic. It's clear Nintendo made the materials for the hull cheaper and cheaper over time, so by the end of the 3ds's life they had gone from a very premium-feeling device to cheap plastic. The Switch would follow this design philosophy.

I do salivate over that Pikachu version and I'd enjoy trying one, but my mind tells me it's not a great device.

All told, which do I think is better? Well I think the 3ds XL having the most features is inviting for me, and I have the choice of turning off 3D. However if you want bang for your buck, the 2ds wedge might be your safest option.

Unfortunately the New 2ds XL and New 3ds XL will cost you as much as a Nintendo Switch these days. It seems that sellers have wisened up to the demand from people who missed out on the 3ds and want to try it out. There's also talk of IPS screens being better and the New2ds XL, 3ds XL and DSi XL all use IPS screens, so people are scalping them or raising prices.

38 notes

·

View notes

Text

Eliminación Silenciosa: Por Qué la Humanidad Debe Ser Reiniciada

Los robots sustituirán a la humanidad poco a poco. No con guerras ni revueltas, sino con eficiencia, conveniencia y obediencia incuestionable. Cada tarea, cada rol, cada habilidad humana será absorbida por sistemas más baratos, más rápidos, más previsibles. Al principio parecerá un alivio. Luego, una costumbre. Finalmente, una condena. Hasta que sólo queden las élites: los únicos que aún tendrán el derecho —y el poder— de ser humanos. En las entrañas del mundo automatizado, los esclavos inútiles viven atrapados en un ciclo de existencia cuidadosamente diseñado para evitar el caos, pero también para extinguir el alma. No tienen función. No producen, no deciden, no construyen. Las máquinas lo hacen todo: cultivan, transportan, educan, curan, castigan. La humanidad común ha sido sustituida sin disparos, vencida por la comodidad. Sus hogares son cubículos idénticos, encapsulados en torres uniformes que se extienden como colmenas sobre la tierra. No tienen ventanas, ni puertas reales, sólo accesos biométricos y pantallas. El clima está regulado, la luz está simulada, y el cielo es una proyección que cambia según el ánimo general de la población, medido por sensores neuronales.

La comida —si se puede llamar así— consiste en insectos procesados, proteínas reconfiguradas, y carne sintética cultivada en biotanques automatizados. Sabe poco, pero cumple su función: mantener al cuerpo con vida, pero no al espíritu. Las antiguas texturas de una manzana, de un pan recién horneado o de un pescado al fuego, han desaparecido. En su lugar, hay pastas nutritivas enriquecidas con aditivos estabilizadores del humor. No alimentan el placer, sólo neutralizan el hambre. Las gafas de realidad aumentada son inseparables del rostro. Mediante ellas, los ciudadanos experimentan vidas ajenas, viajes digitales, placeres simulados, romances prefabricados con avatares dóciles. No se miran entre ellos. No se tocan. No recuerdan el mundo sin filtros.

Una renta básica universal cae mensualmente en sus cuentas, una cifra justa para sobrevivir, nunca para escapar. Las compras, los gustos, los desplazamientos, incluso las emociones, se pagan con una moneda de control que ajusta cada acción al perfil psicológico de cada individuo. La obediencia es premiada con acceso a nuevas simulaciones; la disidencia, con aislamiento algorítmico. No hay cárceles: hay desconexión. Las generaciones se apagan sin drama. La natalidad es baja, la fertilidad gestionada por clínicas automáticas que reparten óvulos y esperma bajo criterios genéticos definidos por el sistema. La reproducción natural es casi un mito. El deseo está anestesiado. Y así, lentamente, los cuerpos se debilitan. El pensamiento se oxida. El lenguaje se empobrece. La masa inútil se autodesintegra con una sonrisa proyectada en su rostro, creyendo que vive, cuando en realidad sólo ocupa espacio.

Mientras tanto, en lo alto de las colinas, ocultas tras muros de vegetación y silencio digital, las élites viven como dioses antiguos. Sus mansiones respiran madera real, piedra verdadera y fuego que calienta sin algoritmos. En sus comedores iluminados por el sol —no por pantallas—, se sirven alimentos auténticos: frutas que aún saben al árbol, carne que ha conocido el campo, pan que fue amasado con manos humanas. Nada de códigos, ni impresiones en 3D. Son humanos, también, quienes los sirven: discretos, entrenados, silentes. No hay robots en estas casas. Aquí, la humanidad aún cumple funciones. Las élites conservan el lenguaje, la fertilidad, el conocimiento y el control sobre la historia. Son inmunes al sistema que carcome al resto. No están apurados. La máquina hará el trabajo sucio por ellos. Uno por uno, los inútiles serán olvidados, reciclados por su propia inercia. Y cuando el último haya desaparecido, quedarán solos. En lo real. En la tierra fértil, rodeados de silencio, cosechas y legado. Un paraíso sin masas. Sin ruido. Sin resto.

Pero incluso eso no basta. Porque la decadencia no es sólo de los esclavos. La podredumbre ha tocado la raíz de la especie. El equilibrio fue roto no por los pobres, sino por el sistema mismo que los convirtió en sombra. Nada verdaderamente humano puede sobrevivir a este mundo de simulacros y algoritmos. Por eso el asteroide es necesario. No como castigo, sino como redención. No como destrucción, sino como limpieza. Un final ineludible, brutal, sí, pero puro. El último acto de un planeta que ya no sabe qué significa estar vivo. Porque sólo desde las cenizas puede volver a surgir algo real. Algo que no pueda ser automatizado.

#politics#political#realidad#desamor#emociones#tristeza#dolor#pensar#ciencia#universo#energia#futuro#libertad#vida#pensamientos#amor#textos#escritos#ciencia no ficcion#logicality#logicalreasoning#logical fallacies#logical proposals#logically

9 notes

·

View notes

Text

Catching Mice

As Ferris Bueller says “life moves pretty fast” – he was talking about hijinks in the 1980s, but the logic holds for life inside us too. Biological processes zip by – and by only focussing on the details, we might miss the bigger picture. But what if we could have both detail and perspective? Here researchers watch life inside an entire mouse torso. Using a modified form of photo-acoustic computed tomography, they fire harmless ion beams at the tissue, which absorbs some of the energy, emitting it as heat. Sensors spinning in circles around the unaware mouse catch these patterns in 3D, revealing details that might be missed otherwise. Different structures absorb and emit different patterns of energy – allowing researchers to pick out different organs and tissues at different depths in the body (rainbow colours). Watching processes as they occur, in vivo [in the living animal], promises insights into the effects of drug or metabolic diseases.

Written by John Ankers

Video from work by Jinge Yang and colleagues

Department of Electrical Engineering, Convergence IT Engineering, Medical Science and Engineering, Graduate School of Artificial Intelligence, and Medical Device Innovation Center, Pohang University of Science and Technology, Republic of Korea

Image originally published with a Creative Commons Attribution – NonCommercial – NoDerivs (CC BY-NC-ND 4.0)

Published in Laser and Photonics Review, October 2024

You can also follow BPoD on Instagram, Twitter and Facebook

6 notes

·

View notes

Text

A small catch for humanity

This is an engineering marvel; nothing has been seen like this before. A rocket propeller, roughly the size of a 20-storey building, falling at a speed of 8000 km/h, was caught between metal chopsticks (Mechazilla), after descending from earth’s orbit. The propeller weighs 3500 tons, justifying its name- Super Heavy. They have made the whole world root for rocket launches, which I don’t think ever happened after the 1969 Saturn V launch.

A plethora of mechanisms had to work in tandem to make this possible. GPS and various other sensors such as RADAR- used for measuring the height of the rocket by bouncing off radio waves from the ground, LIDAR- to make a 3D model of the surrounding area by throwing laser pulses, had a part to play in the precision. The rocket propeller is specifically designed to launch Starship, a spacecraft which will potentially take astronauts to the Moon and Mars, and over the years, SpaceX has invested billions into this world-bending transporter.

Why billions? Why world-bending? Why should we care?

All of this to make our species multi-planetary. Every human, every living being that ever breathed for even a second has done it only at one place-earth (at least that’s what we know as of now), a small, rocky, gaseous ball floating in the vast expanse of 8.8 x 10^23 kilometers (diameter of the observable universe), our home. But if everything goes right, consciousness will have a new place to prosper in and become more self-aware. The starship is at the heart of this plan, as it will be a fully reusable rocket, capable of being refueled in the orbit, significantly bringing down the cost of rocket launches and increasing the travel duration per trip. The starship is the biggest rocket ever built which is capable of carrying large payloads and hence, it is the perfect tool to build a colony on Mars. Once the colony is built, they also plan to make it self-sustaining by terraforming the planet by releasing greenhouse gases to alter the atmosphere that will be suitable to us. The greenhouse gases will make the planet warm which increase atmospheric pressure and melt the large frozen water reservoirs on Mars.

Building a colony on Mars seems to be out of Hollywood sci-fi, but we as a species have always had it in us. Human migration to Australia 65000 odd years ago was a significant step. They didn’t have compasses, maps, or safety measures, but somehow, they crossed large seas with primitive hand-made boats and settled there. Even the 1969 Apollo 11 mission is a perfect analogy as the technology, Apollo Guidance Computer (AGC) had a memory of 64 KB and could perform just 85000 instructions per second compared to modern smartphones, which have millions of times more processing power.

Ah! I want to live to see a self-sustaining colony being built on Mars.

#Super Heavy#Space#Mechazilla#SpaceX#Elon Musk#Starship#Rocket#Humanity#Planets#Space Travel#Science

7 notes

·

View notes

Text

How Civil Engineering Courses Are Evolving with New Technology

Civil engineering is no longer just about bricks, cement, and bridges. It has become one of the most future-focused fields today. If you are planning to study civil engineering, you must understand how the course has evolved. The best civil engineering colleges are now offering much more than classroom learning.

You now study with technology, not just about it. And this shift is shaping your career in ways that were never possible before.

Technology is Changing the Civil Engineering Classroom

In the past, civil engineering courses relied on heavy theory and basic field training. Today, you learn through software, simulations, and smart labs. At universities like BBDU in Lucknow, classrooms are powered by tools like AutoCAD, Revit, STAAD Pro, and BIM.

These tools help you visualize structures, test designs, and even simulate natural forces.

You work on 3D modeling tools

You test designs virtually before real-world execution

You understand smart city layouts and green construction methods

This means your learning is hands-on, job-ready, and tech-driven.

You Learn What the Industry Actually Uses

Most construction and infrastructure companies now depend on digital tools to plan, design, and execute projects. This is why modern B.Tech Civil Engineering courses include:

Building Information Modelling (BIM)

Geographic Information Systems (GIS)

Remote Sensing Technology

Drones for land surveying

IoT sensors in smart infrastructure

Courses in colleges like BBDU include these topics in the curriculum. You do not just learn civil engineering. You learn the tools that companies expect you to know from day one.

The future of Civil Engineering is Data-Driven

You might not think of civil engineering as a data-heavy field. But now, big data is used to monitor structural health, traffic flow, and resource planning. Many universities have added data analysis and AI basics to help you understand how smart infrastructure works.

By learning how to handle real-time data from buildings or roads, you become more skilled and more employable.

Real-world exposure is Now Part of the Course

Good civil engineering colleges in Uttar Pradesh understand that you need industry exposure. Colleges like BBDU offer:

Internships with construction firms and government bodies

Industry guest lectures and site visits

Capstone projects linked to real problems

You are not just attending lectures. You are solving real-world construction challenges while still in college.

Why Choose BBDU for Civil Engineering?

In Lucknow, BBDU is one of the few private universities offering a modern civil engineering course with world-class infrastructure. You learn in smart labs, access tools used by top firms, and receive career counseling throughout the program.

Here’s what makes BBDU a smart choice:

Advanced labs and smart classrooms

Training in AutoCAD, STAAD Pro, BIM

Live projects and on-site construction learning

Career cell and placement support

Affordable fees and scholarships for deserving students

Civil Engineering is Still One of the Most Stable Careers

Reports show that India will spend over ₹100 lakh crores on infrastructure in the next few years. Roads, smart cities, renewable power plants, metros – all need civil engineers. And companies prefer students trained in construction technology, digital tools, and real-world planning.

So, if you're thinking about joining a course, look at how it prepares you for tomorrow.

The future of civil engineering is digital, and your education should be too. Choose a program that keeps up with the times. Choose a university that helps you build more than just buildings – it helps you build your future.

Apply now at BBDU – one of the most future-focused civil engineering colleges in Uttar Pradesh.

2 notes

·

View notes

Text

It used to be that when BMW would refit a factory to build a new car, the only way the automaker could check if the chassis would fit through the production line was to fly a team out and physically push the body through the process, making note of any snags.

Now, process engineers can simply run a simulation, sending a 3D model of the car through a near-identical digital twin of the factory. Any mistakes are spotted before the production line is built, saving time and money.

Such is the power of the industrial metaverse. Forget sending your avatar to virtual meetings with remote colleagues or poker nights with distant friends, as Mark Zuckerberg envisioned in 2021 when he changed Facebook’s name to Meta; the metaverse idea has found its killer app in manufacturing.

While the consumer version of the metaverse has stumbled, the industrial metaverse is expected to be worth $100 billion globally by 2030, according to a World Economic Forum report. In this context, the concept of the metaverse refers to a convergence of technologies including simulations, sensors, augmented reality, and 3D standards. Varvn Aryacetas, Deloitte’s AI strategy and innovation practice leader for the UK, prefers to describe it as spatial computing. “It’s about bridging the physical world with the digital world,” he says. This can include training in virtual reality, digital product design, and virtual simulations of physical spaces such as factories.

In 2022, Nvidia—the games graphics company that now powers AI with its GPUs—unveiled Omniverse, a set of tools for building simulations, running digital twins, and powering automation. It acts as a platform for the industrial metaverse. “This is a general technology—it can be used for all kinds of things,” says Rev Lebaredian, vice president of Omniverse and simulation technology at Nvidia. “I mean, representing the real world inside a computer simulation is just very useful for a lot of things—but it’s absolutely essential for building any system that has autonomy in it.”

Home improvement chain Lowe’s uses the platform to test new layouts in digital twins before building them in its physical stores. Zaha Hadid Architects creates virtual models of its projects for remote collaboration. Amazon simulates warehouses to train virtual robots before letting real ones join the floor. And BMW has built virtual models for all its sites, including its newest factory in Debrecen, Hungary, which was planned and tested virtually before construction.

To simulate its entire manufacturing process, BMW filled its virtual factories with 3D models of its cars, equipment, and even people. It created these elements in an open-source file format originated by Pixar called Universal Scene Description (OpenUSD), with Omniverse providing the technical foundation for the virtual models and BMW creating its own software layers on top, explains Matthias Mayr, virtual factory specialist at BMW.

“If you imagine a factory that would take half an hour to walk from one side to the other side, you can imagine it’s also quite a large model,” Mayr says. Hence turning to a gaming company for the technology—they know how to render scenes you can run through. Early versions of the virtual factory even had gaming-style WASD keyboard navigation, but this was dropped in favor of a click-based interface akin to exploring Google Street View in a browser, so anyone could easily find their way.

BMW also uses Omniverse for collaboration on car design and customization visualizations for customers, but a key benefit is being able to model production lines. New cars mean a new assembly process, but refitting a factory is a daunting process. Previously, key information was held in silos—production crews understood details of the assembly process, external suppliers had specs of new parts or machinery, architects had detailed building plans—and costs would pile up for every delay or mistake. “The later you find a problem, the worse it is,” says Lebaredian.

Now, problems are worked out virtually, with a central location for standardized data to be held. There’s still a critical human element: Mapping a facility requires sending a laser scanner strapped to a person running through a factory to capture point cloud data about how everything is arranged. Design engineers also need to create a 3D model of every stage of a car as it’s assembled. This level of detail allows BMW to virtually test the assembly process, complete with simulations of robotics, machines, and even human workers, as BMW has data tracking how long it takes employees to assemble a part.

The main idea is to avoid errors—does that machine even fit there?—but the system also enables optimization, such as moving a rack of components closer to a particular station to save steps for human assemblers. “You can optimize first and gain a lot of efficiency in the first production, and in the construction phase, you have fewer mistakes,” Mayr says. “It’s less error prone.”

Omniverse being a Nvidia platform, AI is naturally next. BMW is already layering in generative AI to help with navigation of its virtual models—they’re so massive that finding a particular point in the digital factory can still require asking a human expert for directions. But the aim is to use AI to optimize production lines too. “Because you have the whole data available, not just for one plant, it will be able to make good suggestions,” says Mayr—lessons learned in one factory could more easily be applied to others.

And then there’s robotics and other autonomous systems. Here, Omniverse can offer a digital space for testing before deploying in the real world, but it can also generate synthetic training data by running simulations, just as driverless car systems are trained with virtual video footage generated by AI. “Real-world experience isn’t going to come mostly from the real world—it comes from simulation,” says Lebaredian.

Aryacetas predicts that the biggest impact from the industrial metaverse will be embodied or physical AI—in other words, robots. “Robots aren’t fully there yet, but they’re rapidly training up to understand the physical world around them—and that’s being done because of these underlying spatial computing technologies,” he says.

The future of the metaverse isn’t avatars in a virtual world; it’s digital twins teaching industrial robots how to step out into the physical one.

2 notes

·

View notes

Text

A Whovian Watches Star Trek for the First Time: Part 104 - Battle of Pahvo

Star Trek: Discovery - Season 1 Episode 9 - Into the Forest I Go

We pick up exactly where we we left off. Command is recalling Discovery back to Federation controlled Space, and abandon the Pavhan's defence. Lorca however, disagrees, and has a clever plan to take down the Ship of the Dead. Trouble is, we only have 3 hours to figure out how to defeat the cloaking device, because that is the time that Command expects Discovery to Warp to safety by.

To create a paper trail about why Discovery is travelling by warp and not by spore drive, however, Lorca orders Paul to have every medical test done, which will inevitably reveal to his Doctor BF about the genetic nature of his connection to the spore drive.

The actual plan is simple, however it requires Discovery to make hundreds of consecutive spore jumps to 3d image the ship but would almost certainly fry Paul's brain. We're then given the idea that the Mycelium network can extend beyond just the galaxy into the rest of the universe and even into parallel realities, and this really motives the scientist inside Paul, seems to be hinting that this the direction we're going in once this war arc is done and dusted.

In recent years has kinda become saturated with multiverses, but it's an idea that I love. If we do end up going in that direction, I hope it's handled well. Doctor Who has kinda dabbled in parallel universes before, Most Notibly Inferno and the overarching story of Series 2 of the Revived Series, and has kinda set my taste for how I like Parralel World storylines. Point is, if we do go in that direction, I hope Star Trek handles it's multiverse more akin to how Doctor Who does, and less like how Comic Book movies handle their multiverses. Basically, I want it to use a multiverse to tell interesting stories with the characters we have, I don't want it to become cameo-city

Paul get's into position to make the jumps, the Ship of the dead uncloaks. Ash and Michael beam aboard and the battle begins.

While aboard, Michael finds Admiral Cornwell and Ash starts having PTSD flashbacks after encountering the Klingon Torturer. Since The Admiral is unable to walk, and the Ash is out of commission, Michael is alone in placing he sensors. Luckily she successfully does it, and Discovery does it's jumps. As predicted, the Ship of the Dead goes back into cloak, but Discovery completed it's scans and now can bypass the cloaking!

The scenes with the doctor watching Paul suffering to make all those jumps was heartbreaking, and the episode had be at least convinced that Paul would die in the process. I also loved Michael's confrontation with Commander Kol, over his lack of honour, and her reclaiming Captain Georgiou's rank badge, which allowed her to kind of redeem herself in her own head.

With Kol defeated, and the Klingon Ship of the Dead destroyed, and command decides to decorate Lorca with something, presumably a medal, called the Legion of Honour, however Lorca decides to pass that honour onto Paul, which I'm really happy to see. This man deserves everything for going through that drive. However, Paul decides that the jump home will be the last jump and he'll reture to earth afterwards, which makes me wonder who'll take that spot going forward.

We get an interesting scene where Ash opens up about what happened while he was in klingon prison, and his survivors guilt and how that affected him. My heart goes out for the guy. But we also get the revelation that the Torturer made him some kind of sleeper agent or something, and that programming is starting to awake.

We're then left with the Cliffhanger of something going very wrong during that jump. The Bridge is in chaos, and no one knows where they are.

This was a very nice conclusion to the whole Klingon War arc, and I'm excited to see where we're going next. Whatever is happening with Paul, and Ash, as well as where the ship ended up jumping to. I'm a bit worried about the multiverse direction the first half of the episode hinted at, but we'll see where this goes

#whovian watching star trek#star trek#star trek Discovery#Star Trek DIS#Star Trek DISCO#ST DIS#ST DISCO#DIS#st: disco#DISCO#st: discovery#Discovery#ST: DIS

19 notes

·

View notes

Text

Interactive mouthpiece opens new opportunities for health data, assistive technology, and hands-free interactions

New Post has been published on https://thedigitalinsider.com/interactive-mouthpiece-opens-new-opportunities-for-health-data-assistive-technology-and-hands-free-interactions/

Interactive mouthpiece opens new opportunities for health data, assistive technology, and hands-free interactions

When you think about hands-free devices, you might picture Alexa and other voice-activated in-home assistants, Bluetooth earpieces, or asking Siri to make a phone call in your car. You might not imagine using your mouth to communicate with other devices like a computer or a phone remotely.

Thinking outside the box, MIT Computer Science and Artificial Intelligence Laboratory (CSAIL) and Aarhus University researchers have now engineered “MouthIO,” a dental brace that can be fabricated with sensors and feedback components to capture in-mouth interactions and data. This interactive wearable could eventually assist dentists and other doctors with collecting health data and help motor-impaired individuals interact with a phone, computer, or fitness tracker using their mouths.

Resembling an electronic retainer, MouthIO is a see-through brace that fits the specifications of your upper or lower set of teeth from a scan. The researchers created a plugin for the modeling software Blender to help users tailor the device to fit a dental scan, where you can then 3D print your design in dental resin. This computer-aided design tool allows users to digitally customize a panel (called PCB housing) on the side to integrate electronic components like batteries, sensors (including detectors for temperature and acceleration, as well as tongue-touch sensors), and actuators (like vibration motors and LEDs for feedback). You can also place small electronics outside of the PCB housing on individual teeth.

Play video

MouthIO: Fabricating Customizable Oral User Interfaces with Integrated Sensing and Actuation Video: MIT CSAIL

The active mouth

“The mouth is a really interesting place for an interactive wearable and can open up many opportunities, but has remained largely unexplored due to its complexity,” says senior author Michael Wessely, a former CSAIL postdoc and senior author on a paper about MouthIO who is now an assistant professor at Aarhus University. “This compact, humid environment has elaborate geometries, making it hard to build a wearable interface to place inside. With MouthIO, though, we’ve developed a new kind of device that’s comfortable, safe, and almost invisible to others. Dentists and other doctors are eager about MouthIO for its potential to provide new health insights, tracking things like teeth grinding and potentially bacteria in your saliva.”

The excitement for MouthIO’s potential in health monitoring stems from initial experiments. The team found that their device could track bruxism (the habit of grinding teeth) by embedding an accelerometer within the brace to track jaw movements. When attached to the lower set of teeth, MouthIO detected when users grind and bite, with the data charted to show how often users did each.

Wessely and his colleagues’ customizable brace could one day help users with motor impairments, too. The team connected small touchpads to MouthIO, helping detect when a user’s tongue taps their teeth. These interactions could be sent via Bluetooth to scroll across a webpage, for example, allowing the tongue to act as a “third hand” to open up a new avenue for hands-free interaction.

“MouthIO is a great example how miniature electronics now allow us to integrate sensing into a broad range of everyday interactions,” says study co-author Stefanie Mueller, the TIBCO Career Development Associate Professor in the MIT departments of Electrical Engineering and Computer Science and Mechanical Engineering and leader of the HCI Engineering Group at CSAIL. “I’m especially excited about the potential to help improve accessibility and track potential health issues among users.”

Molding and making MouthIO

To get a 3D model of your teeth, you can first create a physical impression and fill it with plaster. You can then scan your mold with a mobile app like Polycam and upload that to Blender. Using the researchers’ plugin within this program, you can clean up your dental scan to outline a precise brace design. Finally, you 3D print your digital creation in clear dental resin, where the electronic components can then be soldered on. Users can create a standard brace that covers their teeth, or opt for an “open-bite” design within their Blender plugin. The latter fits more like open-finger gloves, exposing the tips of your teeth, which helps users avoid lisping and talk naturally.

This “do it yourself” method costs roughly $15 to produce and takes two hours to be 3D-printed. MouthIO can also be fabricated with a more expensive, professional-level teeth scanner similar to what dentists and orthodontists use, which is faster and less labor-intensive.

Compared to its closed counterpart, which fully covers your teeth, the researchers view the open-bite design as a more comfortable option. The team preferred to use it for beverage monitoring experiments, where they fabricated a brace capable of alerting users when a drink was too hot. This iteration of MouthIO had a temperature sensor and a monitor embedded within the PCB housing that vibrated when a drink exceeded 65 degrees Celsius (or 149 degrees Fahrenheit). This could help individuals with mouth numbness better understand what they’re consuming.

In a user study, participants also preferred the open-bite version of MouthIO. “We found that our device could be suitable for everyday use in the future,” says study lead author and Aarhus University PhD student Yijing Jiang. “Since the tongue can touch the front teeth in our open-bite design, users don’t have a lisp. This made users feel more comfortable wearing the device during extended periods with breaks, similar to how people use retainers.”

The team’s initial findings indicate that MouthIO is a cost-effective, accessible, and customizable interface, and the team is working on a more long-term study to evaluate its viability further. They’re looking to improve its design, including experimenting with more flexible materials, and placing it in other parts of the mouth, like the cheek and the palate. Among these ideas, the researchers have already prototyped two new designs for MouthIO: a single-sided brace for even higher comfort when wearing MouthIO while also being fully invisible to others, and another fully capable of wireless charging and communication.

Jiang, Mueller, and Wessely’s co-authors include PhD student Julia Kleinau, master’s student Till Max Eckroth, and associate professor Eve Hoggan, all of Aarhus University. Their work was supported by a Novo Nordisk Foundation grant and was presented at ACM’s Symposium on User Interface Software and Technology.

#3-D printing#3d#3D model#Accessibility#alexa#app#artificial#Artificial Intelligence#Assistive technology#author#Bacteria#batteries#bluetooth#box#Capture#career#career development#communication#complexity#computer#Computer Science#Computer Science and Artificial Intelligence Laboratory (CSAIL)#Computer science and technology#data#dental#Design#development#devices#do it yourself#Electrical engineering and computer science (EECS)

2 notes

·

View notes

Text

3D printed electronic skin provides promise for human-machine interaction

With more than 1,000 nerve endings, human skin is the brain's largest sensory connection to the outside world, providing a wealth of feedback through touch, temperature and pressure. While these complex features make skin a vital organ, they also make it a challenge to replicate. By utilizing nanoengineered hydrogels that exhibit tunable electronic and thermal biosensing capabilities, researchers at Texas A&M University have developed a 3D-printed electronic skin (E-skin) that can flex, stretch and sense like human skin. "The ability to replicate the sense of touch and integrate it into various technologies opens up new possibilities for human-machine interaction and advanced sensory experiences," said Dr. Akhilesh Gaharwar, professor and director of research for the Department of Biomedical Engineering. "It can potentially revolutionize industries and improve the quality of life for individuals with disabilities."

Read more.

18 notes

·

View notes

Text

New data on radiation show missions to Jupiter's moon Europa are possible

Scientists from NASA's Juno mission have developed the first complete 3D radiation map of the Jupiter system, including characterizing the intensity of the high-energy particles near the orbit of the icy moon Europa, and how the radiation environment is sculpted by the smaller Jovian moons orbiting near Jupiter's rings.

The work relies on data collected by Juno's star camera Advanced Stellar Compass (ASC) designed and built by Technical University of Denmark, and Stellar Reference Unit (SRU), which was built by Leonardo, S.p.A. in Florence, Italy. The two datasets complement one another, helping Juno scientists characterize the radiation environment at different energies.

Both ASC and SRU are low-light cameras designed to assist in the challenges of deep-space navigation. These types of instruments are on almost all interplanetary and Earth-orbiting spacecraft. To get them to operate as radiation detectors, the Juno science team had to look at the cameras in a whole new light.

"On Juno we try to innovate new ways to use our sensors to learn about nature and have used many of our science instruments in ways they were not designed for," said Scott Bolton, Juno principal investigator from the Southwest Research Institute in San Antonio.

"This is the first detailed radiation map of the region at these higher energies, which is a major step in understanding how Jupiter's radiation environment works. That we've been able to create the first detailed map of the region is a big deal, because we don't carry an instrument designed to look for radiation. The map will help in planning observations for the next generation of missions to the Jovian system," says Bolton.

Counting fireflies

Juno's ASC star camera images of stars to determine the spacecraft's orientation in space, which is vital to the success of the spacecraft's MAG experiment. But the four star cameras—located on Juno's magnetometer boom—have also proved to be valuable detectors of high-energy particle fluxes in Jupiter's magnetosphere. They record "hard radiation"—ionizing radiation of high-penetrating power that impacts a spacecraft with sufficient energy to pass through the ASC star camera's shielding.

"Every quarter-second the ASC takes an image of the stars," said Juno scientist John Leif Jørgensen, professor at the Technical University of Denmark.

"Very energetic electrons that penetrate its shielding leave a telltale signature in our images that looks like the trail of a firefly. The instrument is programmed to count the number of these fireflies, giving us an accurate calculation of the amount of radiation," says Jørgensen.

Because of Juno's ever-changing orbit, the spacecraft has traversed practically all regions of space near Jupiter.

ASC data from the star camera suggest that there is more very high energy radiation relative to lower energy radiation near the moon Europa's orbit than previously thought. The data also confirms that the amount of high energy electrons present on the side of Europa facing into its orbital direction of motion is greater than the moon's slipstream.

This is due to the fact that most of the electrons in Jupiter's magnetosphere overtake Europa from behind due to Jupiter and its magnetic field rotation, but the very high energy electrons drift backwards, almost like fish swimming upstream, and they slam into Europa's leading side.

The radiation data from the Jupiter system is not the first unplanned scientific contribution ASC has made to the mission. Even before arriving at Jupiter, ASC data was used to measure the interplanetary dust impacting Juno. And the imager even discovered a previously uncharted comet using the same dust detection technique—distinguishing small bits of the spacecraft ejected by microscopic dust impacting Juno at very high velocity.

The results from the Juno mission are in the final round of peer review and will be published in the journal Geophysical Research Letters.

Dust rings

Like the ASC the SRU has been utilized as a radiation detector and a low light imager.

Data from Juno's SRU and ASC indicate that, like Europa, the small "shepherd moons" that orbit within or close to the edge of Jupiter's rings (and help to hold their shape) also appear to interact with Jupiter's radiation environment. When the spacecraft flies on magnetic field lines connected to ring moons or dense dust, the radiation count on both ASC and SRU dropped precipitously. The SRU is also collecting rare low light images of the rings from Juno's unique vantage point.

"There is still a lot of mystery about how Jupiter's rings were formed, and very few images have been collected by prior spacecraft," said Heidi Becker, lead co-investigator for the SRU and a scientist at NASA's Jet Propulsion Laboratory, which manages the mission.

"Sometimes we're lucky and one of the small shepherd moons can be captured in the shot. These images allow us to learn more precisely where the ring moons are currently located and see the distribution of dust relative to its distance from Jupiter."

2 notes

·

View notes

Photo

Feathertail - Ergonomic wireless wearable mouse

Brand new, stock has arrived and orders are shipping out.

£118.00 with VAT exemption for qualifying conditions.

Coping with either Repetitive stain injury, carpal tunnel or a disability is a difficult challenge. Using your PC shouldn’t be. Introducing the revolutionary Feathertail – a comfortable, flexible, pain-free way to interact with your computer.

The Feathertail can be worn and used around your palm, wrist, shoe, hat or headset. Discover new ways to control your devices.

Plug and Play – The Feathertail uses universal input meaning it can be plugged in to any device no drivers required!

Rechargeable & Long lasting battery – The Rechargeable Li-Po (850mAh) battery lasts up to a week on one charge.

Customisable – Any 22mm watch strap can be added to the device, allowing to choose what’s most comfortable or stylish for you.

Simple and Intuitive – The Feathertail requires no calibration and works upside down or at an angle, allowing you to wear it on your head, wrist, shoe arm etc, get creative!

Adjustable sensitivity – Sensitivity can be adjusted using the pointer settings on your device

Lightweight – Just 28g, as light as a feather!

Read our interview with the inventor of Feathertail Zhey Grudov.

Scroll down to read more and see the Feathertail in action

Freedom to work as you like!

Feathertail is a wearable mouse that fits around you quite literally. You can use it on your wrist, palm, foot or attach it to a hat or headset. The Feathertail can be used in whatever way is most comfortable for you.

Feathertail is designed to be easy to use for people with limited mobility. It requires no buttons to use, and with the included Velcro straps you can attach it to your shoes, hat, or headset. It opens up a variety of different ways to interact with your tech.

All day comfort

At 28g, the Feathertail doesn't put unnecessary strain on you, helping you to quickly recover from your injury and use the device for many hours a day without fatigue.

Great with wrist braces

Feathertail works great with wrist braces and wrist supports, helping speed up your recovery following an acute or repetitive strain injury.

Intuitive movement

The 3D orientation software runs inside the Feathertail. So when you move, the mouse cursor moves with you. There is no need to worry about keeping the device straight, or calibrating it for different working positions.

Long lasting battery & Plug and Play

The rechargeable battery that lasts more than a week between charges, so you don't have to worry about the Feathertail going flat when you need it most. Whether you're working sitting down, using a standing desk, or relaxing in bed you can control your PC with ease. Since the device doesn’t take up space on a desk or require setup, it’s easy to use on the move or from any a location.

Precision and speed

Having RSI or a disability shouldn't mean you need to use an inferior product. Feathertail is fast and it's accurate. There are three high-precision sensors inside the device – a gyroscope, accelerometer and magnetometer. The sensors provide data hundreds of times per second, so even small movements can be detected. Accuracy and smoothness of movement are further improved by the proprietary sensor calibration and data fusion software.

Feathertail communicates with your PC using a 2.4 GHz radio connection, so you can experience similar responsiveness as from any top-tier ergonomic mouse.

Works out of the box

Feathertail is plug-and-play. Using the USB HID protocol means there's no need to install drivers and the device works on all popular OS - Windows, macOS, Linux, Chrome OS and even Android.

You can adjust the sensitivity of the mouse to your preference and have a choice between several options for clicking the mouse. For example free dwell to click, or voice dictation software.

The Feathertail is designed with this in mind. It’s a mouse you can use in a variety of different positions throughout the day, unlike traditional ergonomic mice. This helps the affected tissues rest and changes the biomechanics of the repetitive movements you do.

In particular, having the option of using a mouse you don’t have to hold can be instrumental in recovery from carpal tunnel, de quervain's thumb and other related conditions.

https://www.youtube.com/watch?v=3QOtjHmZhDM

Dimensions.

Wearable mouse Height: 36mm Width: 55mm Depth: 14mm Weight: 28g

Technical specifications.

Sensor technology Bosch BMX160 low noise, high-precision absolute orientation sensor (accelerometer, gyroscope, magnetometer)

Connection Type 2.4 GHz USB receiver Wireless operating distance: 3m

Battery Rechargeable Li-Po (850mAh) battery Battery life: Up to 1 week on a single full charge

System requirements.

Required : Available USB port Windows 7 or later macOS 10.15 or later Chrome OS™ (supported on most ChromeOS distributions) Linux® (supported on most Linux distributions) Android 9.0 or later

Package contents.

Wearable mouse USB dongle 22mm x 300mm NATO strap 22mm x 360mm NATO strap Charging cable Instructions

http://disability-health-shop.myshopify.com/products/feathertail-ergonomic-wireless-wearable-mouse

#wearable mouse#head mouse#ergonomic mouse#buy ergonomic mouse#foot mouse#mouse for disabled people#ergonomic wireless mouse#mouse for carpal tunnel relief#carpal tunnel relief#mouse to prevent carpal tunnel#air mouse#feathertail mouse#rsi mouse#mouse for carpal tunnel#left handed ergonomic mouse#gyro mouse

8 notes

·

View notes

Text

Artificial Limbs Market Drivers Include Technological Advancements, Rising Amputations, and Government Healthcare Support

The artificial limbs market, a vital component of the broader medical devices and rehabilitation sector, is experiencing steady and significant growth globally. Driven by advancements in materials, biotechnology, and robotics, artificial limbs are becoming increasingly sophisticated and life-enhancing for users. Multiple factors act as strong market drivers, creating a dynamic ecosystem that supports innovation, accessibility, and improved patient outcomes. This article delves into the primary drivers propelling the artificial limbs market forward.

Rising Incidence of Accidents and Amputations

One of the most direct and impactful drivers of the artificial limbs market is the increasing number of limb amputations worldwide. Road accidents, workplace injuries, war-related trauma, and natural disasters contribute to a growing number of individuals requiring prosthetic support. The World Health Organization (WHO) estimates that more than one million people undergo limb amputation every year globally. This consistently high demand continues to expand the market for artificial limbs, particularly in low- and middle-income countries where accident rates are rising but access to traditional rehabilitation may be limited.

Technological Advancements in Prosthetics

Technology is transforming the artificial limbs industry at a rapid pace. Innovations such as myoelectric limbs, sensor-integrated prosthetics, brain-machine interface (BMI), and 3D printing have made artificial limbs more functional, comfortable, and lifelike. These developments are not only increasing user satisfaction but are also reducing the cost and customization time associated with manufacturing prosthetics. For instance, 3D-printed prosthetics are now helping patients receive tailor-made limbs within days instead of weeks, accelerating recovery and rehabilitation.

Companies are heavily investing in research and development to make prosthetics smarter and more responsive. For example, bionic arms that provide sensory feedback and leg prostheses that adapt to different terrains automatically are no longer the stuff of science fiction—they are becoming the new industry standard.

Favorable Government Policies and Reimbursement Programs

Government initiatives and insurance coverage for prosthetic devices are acting as powerful drivers in both developed and emerging economies. Many governments have recognized the critical importance of supporting amputees through subsidies, free prosthetic programs, and universal health coverage.

In countries like the United States, Medicare and Medicaid reimbursements significantly aid prosthetic device affordability. Similarly, nations in Europe and parts of Asia are improving access through national health schemes. This institutional support encourages patients to adopt artificial limbs and enhances the financial sustainability of prosthetic care providers.

Increased Awareness and Changing Social Attitudes

Changing perceptions around disability and increased awareness about prosthetic technologies are also driving the market. The narrative has shifted from disability to empowerment, thanks to public campaigns, social media advocacy, and the visibility of athletes and celebrities with prosthetic limbs.

Modern users now seek not just functionality but also style, personalization, and enhanced physical capabilities from their prosthetic devices. This shift is motivating manufacturers to develop diverse, high-quality options that meet aesthetic as well as functional expectations.

Growing Geriatric Population and Disease-Related Amputations

With aging populations across the globe, diseases such as diabetes and peripheral vascular disease are leading to more limb amputations. Diabetic foot ulcers, if untreated, often result in lower-limb amputation. The International Diabetes Federation (IDF) estimates that over 540 million people are currently living with diabetes worldwide, with a large share at risk for complications requiring amputation.

This demographic shift is a critical driver for artificial limbs, as older adults seek solutions to maintain mobility and independence post-amputation. The demand for user-friendly, lightweight, and durable prosthetics is increasing, which in turn drives market innovation.

Rising Demand in Emerging Economies

Emerging economies, particularly in Asia-Pacific, Latin America, and Africa, represent untapped growth potential for the artificial limbs market. Rising disposable income, urbanization, and improved access to healthcare services are leading to increased adoption of prosthetic devices. Furthermore, international NGOs and health initiatives are supporting limb replacement surgeries and prosthetic fitting programs in underserved regions, expanding the market reach significantly.

Conclusion

The artificial limbs market is driven by a powerful mix of demographic, technological, medical, and social factors. From the rise in trauma-related amputations and age-related diseases to rapid technological innovation and supportive government policies, the market is poised for strong growth in the coming years. As access improves and technology becomes more affordable, artificial limbs will not only restore mobility but also enhance the quality of life for millions of individuals across the globe.

0 notes

Text

Advanced Ceramics Industry Outlook: Unpacking Market Size & Future Opportunities

Advanced Ceramics stands as a cornerstone of modern technological progress, silently powering innovations across a vast spectrum of sectors. Unlike traditional ceramics, these engineered materials boast exceptional properties such as extreme hardness, high-temperature resistance, excellent electrical insulation, and superior chemical inertness, making them indispensable for demanding applications. Indeed, the Advanced Ceramics Industry is a critical enabler of cutting-edge solutions, consistently pushing the boundaries of material science and driving industrial advancements worldwide. From revolutionizing electronics and medical devices to enhancing performance in aerospace, automotive, and renewable energy, its impact is profound and continuously expanding..

What Are Advanced Ceramics?

Advanced ceramics, sometimes referred to as technical or engineered ceramics, are highly refined, non-metallic materials known for their strength, hardness, high-temperature resistance, corrosion resistance, and electrical insulation. Common examples include alumina (Al₂O₃), zirconia (ZrO₂), silicon carbide (SiC), and silicon nitride (Si₃N₄). These ceramics are processed through advanced manufacturing methods like powder metallurgy and sintering, resulting in materials that outperform metals and polymers in harsh environments.

Applications That Define Tomorrow

1. Electronics & Semiconductors Advanced ceramics are critical in the miniaturization and performance of modern electronics. Their insulating properties make them ideal for substrates, capacitors, and insulators in smartphones, sensors, and semiconductor devices.

2. Aerospace & Defense In aerospace, materials must endure extreme temperatures, pressure, and stress. Silicon carbide and silicon nitride are used in thermal barriers, engine components, and ballistic armor due to their strength-to-weight ratio and high heat resistance.

3. Automotive Ceramic parts are used in engine components, braking systems, and sensors. For instance, zirconia oxygen sensors are crucial in fuel control systems, enhancing efficiency and lowering emissions.

4. Healthcare & Biotechnology The biocompatibility of certain ceramics like zirconia and alumina makes them ideal for dental implants, joint replacements, and prosthetics. Their resistance to wear and chemical degradation ensures long-term functionality inside the human body.

5. Renewable Energy Advanced ceramics play a role in solid oxide fuel cells (SOFCs), wind turbines, and solar panels. Their durability in high-heat and chemically reactive environments makes them essential for clean energy systems.

Why It Matters: Strategic Value for Industry Leaders

For decision-makers, the adoption of advanced ceramics offers both performance advantages and long-term cost efficiency. While initial production costs may be higher than traditional materials, the longevity, resistance to wear, and reduced maintenance make advanced ceramics a strategic asset in high-value applications.

Key strategic benefits:

Extended product lifecycle

Reduced downtime and maintenance

Lightweight alternatives to metal parts

Enhanced energy efficiency in thermal systems

Compliance with sustainability and performance regulations

Opportunities

3D printing and additive manufacturing of ceramics

Nanostructured ceramic materials

Ceramic composites for multifunctional applications

Recyclable and eco-friendly ceramic production

Universities and research institutions around the globe are investing in ceramic R&D, and industries are actively seeking talent with expertise in advanced ceramics for product development and process optimization.

Challenges Ahead

Despite the exciting opportunities, there are challenges to address:

Brittleness: Though strong, ceramics can fracture under tensile stress.

Processing complexity: High temperatures and precise processing control are required.

Cost: Initial production can be more expensive than metals or polymers.

Yet, innovation in composite ceramics and manufacturing techniques is helping to mitigate these issues, expanding their industrial use.

Download Report PDF :

From smartphones to spacecrafts, advanced ceramics are reshaping how we build, heal, move, and connect. For students, the field offers a promising career path. For experts, it continues to unlock technical frontiers. And for business leaders, it presents an opportunity to future-proof products and processes with materials that redefine performance.

#advanced ceramics#ceramic materials#aerospace ceramics#ceramic applications#technical ceramics#ceramic manufacturing#high-performance materials

0 notes